Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Paper - 2 - SetA - 090410 - Key PDF

Caricato da

Nataraj Singh SardarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Paper - 2 - SetA - 090410 - Key PDF

Caricato da

Nataraj Singh SardarCopyright:

Formati disponibili

Paper 2 Set A Solutions

1

_______________________

Bureau of Energy Efficiency

Regn No: _________________

Name: ___________________

(To be written by the candidate)

10

th

NATIONAL CERTIFICATION EXAMINATION July, 2010

FOR

ENERGY MANAGERS & ENERGY AUDITORS

PAPER 2: Energy Efficiency in Thermal Utilities

Date: 17.7.2010 Timings: 1400-1700 HRS Duration: 3 HRS Max. Marks: 150

General instructions:

o Please check that this question paper contains 12 printed pages

o Please check that this question paper contains 64 questions

o The question paper is divided into three sections

o All questions in all three sections are compulsory

o All parts of a question should be answered at one place

Section - I: OBJECTIVE TYPE Marks: 50 x 1 = 50

(i) Answer all 50 questions

(ii) Each question carries one mark

(iii) Please hatch the appropriate oval in the OMR answer sheet with Black Pen or HB

pencil, as per instructions

1. Which of the following fuels needs minimum stoichiometric air for combustion?

a) coal b) natural gas c) LPG d) fuel oil

2. Which parameter influences flame profile most?

a) fixed carbon b) volatile matter c) carbon/hydrogen ratio d) none of the above

3. Natural draft in a combustion system is produced by

a) fuel firing rate b) stack temperature c) stack height d) stack temperature and height

4. The efficiency of a boiler was improved from 70% to 80%. The % fuel savings achieved are

a) 12.5% b) 18% c) 25% d) none of the above

5. Which of the following is the best way to assess boiler losses?

a) benchmarking evaporation ratio b) indirect efficiency evaluation

c) direct efficiency evaluation d) none of the above

6. What is the appropriate fuel size in a coal fired FBC boiler?

Paper 2 Set A Solutions

2

_______________________

Bureau of Energy Efficiency

a) 25-50 mm b) 50-75 mm c) 6-10 mm d) less than 5 mm

7. Waste heat recovery systems with a high LMTD results in

a) higher heat transfer area b) lower heat transfer area c) higher u-factor d) none of the above

8. A steam trap helps to

a) block steam and allow condensate b) block condensate and allow steam

c) block condensate and allow air and steam d) recover flash steam

9. Which property is most important for a fire brick?

a) high porosity b) thermal stability at high temperature

c) low bulk density d) chemical resistance

10. NO

X

formation chances are least in

a) FBC boilers b) pulverised fuel fired boilers c) furnace oil fired boilers d) stoker fired boilers

11. Flash steam quantity per kg of condensate depends upon

a) condensate pressure only b) condensate pressure and flow

c) condensate pressure and flash steam pressure d) none of the above

12. Which of the following waste heat recovery systems is of thermal storage type?

a) ceramic recuperator b) metallic recuperator c) regenerative burner d) waste heat boiler

13. A boiler trial indicated 2% O

2

at boiler exit and 7% O

2

at stack. The in-leak air quantity between

these two measurement is

a) 25% b) 40% c) 50% d) 5%

14. Spontaneous combustion is a loss area in

a) fuel oil storage b) natural gas storage c) furnace hearth d) coal storage

15. Which of the following fuel requires the largest amount of excess air for complete combustion?

a) furnace oil b) LDO c) coal d) natural gas

16. Which of the following is one of the components of LPG?

a) methane b) iso-octane c) hexane d) propane

17. Enthalpy of evaporation of steam will be higher at

a) 2 kg/cm

2

b) 8 kg/cm

2

c) 12 kg/cm

2

d) 20 kg/cm

2

18. The element that does not contribute to heating value during combustion process is

a) nitrogen b) sulphur c) hydrogen d) carbon

19. Which of the following is not one of the 3 Ts of combustion?

a) time b) temperature c) turbulence d) tertiary

20. Which of the following is not required in the boiler efficiency evaluation by direct method?

a) steam flow b) fuel flow c) feed water temperature d) oxygen % in the flue gas

21. The concentration of solids in a boiler is controlled by

Paper 2 Set A Solutions

3

_______________________

Bureau of Energy Efficiency

a) steam venting b) blow down c) air venting d) deaeration

22. Soot on boiler tubes is formed by

a) poor water treatment b) low steam pressure c) high excess air d) incomplete combustion

23. Which of the following will be ideal heating medium for heat transfer in a heat exchanger?

a) superheated steam b) saturated steam

c) high pressure condensate d) condensate at atmospheric pressure

24. Insulating material made by blending and melting of alumina and silica is known as

a) ceramic fibre b) high alumina brick c) fire brick d) insulating brick

25. Which of the following cannot be fired in a gas turbine?

a) natural gas b) LPG c) naptha d) coal

26. The waste heat boiler application is not suitable for which of the following?

a) gas turbine b) diesel engine c) furnaces d) dryers

27. A thermal insulator has

a) low thermal conductivity b) high thermal conductivity

c) high convection coefficient d) low convection coefficient

28. The dry saturated steam when throttled to a lower pressure will

a) become wet b) become superheated c) remain dry saturated d) become condensate

29. Which type of steam trap operates on the principal of difference in temperature of steam and

condensate?

a) thermodynamic trap b) inverted bucket c) thermostatic trap d) none of the above

30. Furnace wall heat loss does not depend on

a) temperature of external surface b) temperature of air around the furnace

c) emissivity of external wall surface d) stock to be heated

31. Emissivity is a measure of materials ability to

a) only absorb heat b) only radiate heat c) absorb and radiate heat d) none of the above

32. Removal of dissolved gases from the boiler feed water is called

a) descaling b) deaeration c) deoxidation d) none of the above

33. Which of the following boiler type has the lowest permissible boiler drum TDS concentration?

a) low pressure water tube boiler b) fire tube boiler c) Lancashire boiler d) all of the above

34. Velocity of steam in a pipe does strongly depend on

a) number of bends and valves in the pipe b) specific volume of steam

c) length of the pipe d) none of the above

35. Regenerators are widely used in

a) glass melting furnace b) reheating furnace c) baking ovens d) heat treatment furnace

Paper 2 Set A Solutions

4

_______________________

Bureau of Energy Efficiency

36. In a CFBC boiler, the capture and recycling of bed materials is accomplished by

a) bag filters b) settling chamber c) cyclone d) scrubber system

37. The coefficient of thermal expansion of refractory materials should be

a) low b) medium c) high d) very high

38. The purpose of venting air from steam system is because air is

a) an insulator b) a good conductor c) an inert substance d) incompressible

39. The working fluid of a steam thermo-compressor is

a) high pressure air b) low pressure steam c) high pressure steam d) high pressure condensate

40. Scale losses of stock in reheating furnace will

a) increase with increase of CO

2

in combustion gases b) increase with increase in excess air

c) decrease with increase in excess air d) have no relation with excess air

41. Latent heat of steam at the critical point is

a) 540 kCal/kg b) zero c) infinite d) equal to sensible heat

42. For combustion, controlled wetting of coal (during the coal preparation) would result in

a) reduction in flue gas exit temperatures b) decrease in the percentage of unburnt carbon

c) coal fines carryover d) increase in the coal fines

43. Fluidized bed combustion results in _________ SO

x

and NO

x

emissions

a) increased b) decreased c) no effect on d) elimination of

44. The limit to reduction of stack temperature in an oil fired boiler is influenced by

a) oil temperature b) air temperature c) % carbon in oil d) % sulphur in oil

45. Which type of turbine has high heat-to-power ratio?

a) gas turbine b) back pressure turbine c) extraction condensing turbine d) reciprocating engine

46. The highest percentage of sulphur is present in

a) FO b) LDO c) LSHS d) kerosene

47. Furnace oil contains 84% carbon by weight. How many kg of CO

2

does complete combustion of 1

kg of furnace oil generate?

a) 2.4 b) 4.0 c) 3.6 d) 3.1

48. The furnace bed temperature of a fluidized bed boiler is about

a) 850C b) 1100C c) 700C d) 1000C

49. Which data is not required to calculate the efficiency of boiler by indirect method

a) blow down rate b) ambient temperature c) calorific value of fuel d) flue gas temperature

50. For transporting steam to long distance, the best quality of steam is

a) slightly superheated steam b) dry saturated steam

c) slightly wet steam d) very high pressure steam

Paper 2 Set A Solutions

5

_______________________

Bureau of Energy Efficiency

. End of Section I .

Section II: SHORT DESCRIPTIVE QUESTIONS Marks: 8 x 5 = 40

(i) Answer all Eight questions

(ii) Each question carries Five marks

S-1 What is draft and briefly explain its importance in boilers and furnaces?

Ans: Draft is the difference of pressure producing air flow through a boiler furnace, flue and

chimney.

2 Marks

The function of draft in a combustion system is to exhaust the products of combustion

into the atmosphere overcoming the pressure drop across the boiler tubes, baffles,

economizer, flue duct bends, air pollution control system etc. if draft is not properly

maintained it affects the combustion system and results in high energy consumption.

3 Marks

S-2 What is meant by air venting in a steam system and what is its purpose?

Ans: When steam is first admitted to a pipe/equipment after a period of shut down, the

pipe/equipment is full of air. Further amounts of air and other non condensable gases

will enter with the steam, although the proportions of these gases are normally very

small compared with the steam. When the steam condenses, these gases will

accumulate in pipes and heat exchangers. Precautions should be taken to discharge

them.

The consequence of not removing air increases heatup time and reduces plant efficiency

and process performance. The presence of air affects heat transfer.

5 Marks

S-3 In a heat exchanger, steam is used to heat 3 kl/hr of furnace oil from 30

o

C to 100

o

C. The

specific heat of furnace oil is 0.22 kCal/ kg/

o

C and the density of furnace oil is 0.95.

How much steam per hour is needed if steam at 4 kg/cm

2

with latent heat of 510 kCal/

kg is used.

If steam cost is Rs. 4.0/kg and electrical energy cost is Rs.6.0/kWh, which type of

heating would be more economical in this particular case? (assume no losses in

electrical and steam heating process)

Ans: Total heat required = m Cp T

= (3 x 1000 x 0.95) x 0.22 x (100-30)

= 43890 kcal/hr

1 Mark

a) Amount of steam required = 43890/510

Paper 2 Set A Solutions

6

_______________________

Bureau of Energy Efficiency

= 86 kg/hr

Steam cost = 86 x Rs.4

= Rs. 344/hr

2 Marks

b) Amount of electricity required = 43890/860

= 51 kWh

= 51 x Rs. 6

= Rs.306/ hr

Electrical heating will be more economical

2 Marks

S-4 Write short notes on economic insulation thickness for energy efficiency.

Ans: Insulation of any system means capital expenditure. Hence an important factor in any

insulation system is to analyse the thermal insulation with respect to cost. The

effectiveness of insulation follows the law of decreasing returns. Hence, there is a

definite economic limit to the insulation thickness, which is justified. Excess thickness is

uneconomical and cannot be recovered through heat savings. Each industry has

different cost of heat loss due to variation in fuel cost and boiler efficiency. These values

can be used for calculating economic thickness of insulation, where thickness for a given

set of circumstances, which results in the lowest overall cost of insulation and heat loss

combined economic insulation thickness.

Note : figure is optional

5 Marks

S-5 For a 8 TPH capacity boiler, estimate the rise in temperature of water in an economizer.

The flue gas temperature decreases from 315 C to 210 C in the economiser. Air to fuel

ratio and evaporation ratio of the boiler are 20 kg of air/kg of fuel and 12 respectively.

Assume condensate recovery and boiler blow down is nil. Specific heat of flue gas: 0.23

kCal/kg

o

C

Ans: For 1 kg of fuel steam generated is = 12 kg

For 1 kg of fuel makeup water is = 12 kg

For 1 kg of fuel required combustion air is = 20 kg

For 1 kg of fuel flue gas generated is = 20 +1= 21 kg

In economizer heat given by flue gas = heat received by makeup water

2 Marks

Paper 2 Set A Solutions

7

_______________________

Bureau of Energy Efficiency

21 x 0.23 x (315-210) = 12 x 1 x T

T = 42.26 C

3 Marks

S-6 The evaporation ratio of a coal fired boiler is 5.1. Estimate boiler efficiency if steam

enthalpy is 650 kCal/kg; feed water temperature is 80

0

C and calorific value of coal is

4500 kcal/kg.

Boiler efficiency = output/input x 100

Boiler efficiency = 100 x Q (H-h) / (q x GCV)

2 Marks

= 5.1 x (650-80) x 100

----------------------- = 64.6%

1 x 4500

3 Marks

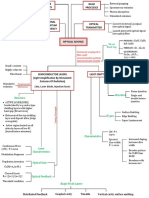

S-7 Sketch the schematic diagram of Back Pressure Turbine and Extraction Condensing

Turbine Cogeneration systems (Note: no explanation required).

S-8 A 5 MW DG Set is operating at 80 % load. A waste heat recovery boiler is installed to

recover heat from exhaust gas to generate steam at 10 kg/cm

2

. Find out the quantity of

steam generated annually after installing the waste heat recovery boiler

Given Data:

Flue gas exit temperature = 450

o

C

Flue gas temperature after Waste heat recovery boiler = 230

o

C

Specific heat of flue gases = 0.25 kCal/kg/

o

C

Specific gravity of diesel oil = 0.85

Air to fuel ratio = 28 kg/kg

Specific fuel consumption = 4.2 kWh/liter

Enthalpy of steam at 10 kg/cm

2

= 660 kCal/kg

Feed water temperature = 60

o

C

Operating hours per year = 7500 hrs

Paper 2 Set A Solutions

8

_______________________

Bureau of Energy Efficiency

Solution:

Average load of DG set = 5 x 0.8 = 4.0 MW or 4000 kW

1 Mark

Diesel consumption = 4000 x 0.85 /4.2 = 809.52 kg/hr

1 Mark

Heat available for WHR boiler = [809.52 + (809.52 x 28)] x 0.25 (450 230) = 1291184

kCal/hr

1 Mark

Steam generation at 10 kg/cm

2

= 1291184 / (660 60) = 2152 kg/hr or 2.152 tons/hr

Annual steam generation = 2.152 X 7500 = 16,140 tons /year.

2 Marks

2.5 Marks for each figure

------- End of Section - II ---------

Section III: LONG DESCRIPTIVE QUESTIONS Marks: 6 x 10 = 60

(i) Answer all Six questions

(ii) Each question carries Ten marks

L-1 A furnace is used to heat the stock. The stock is charged through a door, which is

always kept open. The door size is 800 mm x 800 mm. The furnace wall thickness is 400

mm. The furnace operating temperature is 1260 C.

Calculate the hourly direct radiation heat loss through openings? Convert the heat loss

in terms of oil equivalent loss if GCV of oil is 10250 kCal/kg.

Other data are as under:

Blackbody radiation corresponding to 1260 C = 30 kCal/cm

2

/hr

Emissivity = 0.82

Factor of radiation = 0.7

Ans: Area of opening = 80 cm x 80 cm

= 6400 cm

2

2 Marks

The factor of radiation = 0.7

Emissivity = 0.82

Total heat loss through opening

= Black body radiation x Area of opening x factor of radiation x Emissivity

= 30 x 6400 x 0.7 x 0.82

= 1,10,208 kCal/hr

6 Marks

Equivalent oil loss = 110208/10250

Paper 2 Set A Solutions

9

_______________________

Bureau of Energy Efficiency

= 10.75 kg/hr

2 Marks

L-2 In a steam system, mention three types of classification of steam traps and give their

principle of operation. Give one example for each type.

Ans: Mechanical trap

Principle of operation is difference in density between steam and condensate

The different mechanical traps are

Open bucket (or)

Inverted bucket (or)

Float type

3 Marks

Thermodynamic trap

Principle of operation is difference in thermodynamic properties between steam and

condensate

The different thermodynamic traps are

Disc type

4 Marks

Thermostatic trap

Principle of operation is difference in temperature between steam and condensate.

The different thermostatic traps are

Bimetallic type

3 Marks

L-3 An oil fired reheating furnace has an operating temperature of around 1200 C. The

average fuel oil (FO) consumption is 420 litres/hour. The flue gas exit temperature after

the air preheater is 320C. Find out the percentage sensible heat loss in exhaust gases.

Other data are as under:

Specific gravity of oil = 0.92

Calorific value of oil = 9300 kCal/kg

Average O

2

percentage in flue gas = 13%

Theoretical air required = 14 kg of air to burn 1 kg of oil

Ambient temperature = 40

o

C

Specific heat of flue gas = 0.25 kCal/kgC

Ans: Energy input = 420 lph

= 420 x 0.92 = 386.4 kg/hr

= 386.4 x 9300

= 3593520 kCal/hr

2 Marks

Sensible heat loss in flue gas

Corresponding excess air = (%O

2

/ (21-O

2

)) x 100

= (13/ (21-13)) x 100

= 162 %

2 Marks

Theoretical air required = 14 kg of air to burn 1 kg of oil

Paper 2 Set A Solutions

10

_______________________

Bureau of Energy Efficiency

Actual air required = 14 x (1+1.62) kg/kg of oil

= 36.68 kg/kg of oil

2 Marks

Sensible heat loss in flue gas = m x C

p

x T

m = mass of flue gas

= 36.68 + 1

= 37.68 kg/kg of oil

Cp = Specific heat of flue gas

= 0.25

T = Temperature of flue gas ambient temperature

= 320C - 40C

= 280C

Heat loss = 37.68 x 0.25 x (320 -40)

= 37.68 x 0.25 x 280

= 2637.6 kCal/kg of oil

= 2637.6 x 386.4

= 1019168 kCal/hr

2 Marks

Sensible heat loss in flue gas

as % heat loss to input energy = (1019168 x 100)/(3593520)

= 28.36%

2 Marks

L-4 What is the need for boiler blow down? Explain intermittent and continuous blow down.

Ans: Water contains certain percentage of dissolved solids. The percentage of dissolved

solids found in boiler water depend on the untreated feed water quality, the treatment

process and the boiler operating procedures, as the feed water evaporate in to steam,

dissolved solids concentrate in the boiler either in dissolved or suspended state. Above

certain level of concentration, these solids encourage foaming and cause carry over of

water in to the steam. This leads to scale formation inside the boiler, resulting in

localized overheating and ending finally in tube failure.

If in therefore necessary to control the level of concentration of the solids and this is

achieved by the process of blowing down, where a certain volume of water in blown off

and is automatically replaced by feed water thus maintaining the optimum level of total

dissolved solids (TDS)in the water .

4 Marks

The intermittent blow down in given by manually operating a valve fitted to discharge

pipe at the lowest point of boiler shell to reduce parameters with in prescribed limits so

that steam quality is not likely to be affected.

3 Marks

The continuous blow down is a steady and constant dispatch of small stream of

concentrated boiler water and replacement by steady and constant inflow of feed water.

This ensures constant TDS and steam purity at a given steam load .once blow down

valve is set for a given conditions there is no need for regular operator intervention.

Paper 2 Set A Solutions

11

_______________________

Bureau of Energy Efficiency

3 Marks

L-5 List ten of energy conservation opportunities in an oil fired reheating furnace?

Ans:

1. Complete combustion with minimum excess air

2. Correct heat distribution.

3. Operating at the desired temperature

4. Reducing heat losses from furnace opening

5. Maintaining correct amount of furnace draught

6. Optimum capacity utilization

7. Waste heat recovery from the flue gas

8. Minimum refractory losses

9. Use of ceramic coating

10. Maintaining proper cycle time

1 Mark for each point

Note: Any other relevant point may also be given marks

L-6 A boiler utilizes bio-mass as fuel and the ultimate analysis (by weight %) of the fuel is

given below:

Component %

Carbon 40

Hydrogen 7

Nitrogen 0.5

Oxygen 50.5

Sulphur 0.5

Ash 1.5

Using the basic combustion equations estimate the theoretical air requirement for 100 kg

of dry fuel fired:

Ans: Basic equations:

C + O

2

= CO

2

2H

2

+ O

2

= 2H

2

O

S + O

2

= SO

2

2 Marks

Theoretical amount of air for combustion

12 kg carbon requires 32 kg of oxygen forming 44 kg of CO

2

.

1 kg carbon requires 32/12=2.67 kg O

2

.

(40)C + (2.67x40) O

2

= (146.67) CO

2

2 Marks

4 kg of Hydrogen requires 32 kg of oxygen.1 kg of Hydrogen requires 8 kg of oxygen.

(7) H

2

+ (7x8) O

2

= (63) H

2

O

Paper 2 Set A Solutions

12

_______________________

Bureau of Energy Efficiency

2 Marks

32 kg Sulfur requires 32 kg oxygen to form 64 kg of SO

2

. 1 kg Sulfur requires 1 kg

Oxygen.

(0.5) S + (0.5) O

2

= (1) SO

2

2 Marks

Total oxygen required = (106.67+56+0.5) = 163.17 kg

Oxygen present in fuel = 50.5 kg

Oxygen to be supplied = 163.17-50.5 = 112.6 kg

Amount of air to be supplied =112.6 x100/23

= 490 kg

2 Marks

-------- End of Section - III ---------

Potrebbero piacerti anche

- Paper 2 SetB 090410 KeyDocumento12 paginePaper 2 SetB 090410 KeyNataraj Singh SardarNessuna valutazione finora

- EAs 2 BDocumento13 pagineEAs 2 BNeeraj Singh GautamNessuna valutazione finora

- Paper 2 - Set A With Solutions: (To Be Written by The Candidate)Documento17 paginePaper 2 - Set A With Solutions: (To Be Written by The Candidate)Erin WardNessuna valutazione finora

- Paper 2 Key - 12th National Certification Exam for Energy ManagersDocumento22 paginePaper 2 Key - 12th National Certification Exam for Energy ManagersRichard RegidorNessuna valutazione finora

- Regular Paper 2 - Set BDocumento16 pagineRegular Paper 2 - Set Bcynaidu100% (1)

- 2004 Paper 2 Set BDocumento6 pagine2004 Paper 2 Set BNataraj Singh SardarNessuna valutazione finora

- 17th Exam P2 PDFDocumento16 pagine17th Exam P2 PDFLuthfansyah MohammadNessuna valutazione finora

- Supplimentary Paper 2 - Set BDocumento15 pagineSupplimentary Paper 2 - Set BcynaiduNessuna valutazione finora

- 2a-Model SolutionDocumento14 pagine2a-Model SolutionIsrael GarciaNessuna valutazione finora

- Paper 2 - Set B With Solutions: (To Be Written by The Candidate)Documento16 paginePaper 2 - Set B With Solutions: (To Be Written by The Candidate)Shahedabanu Aghadi0% (1)

- 2 BDocumento13 pagine2 BSonali PriyadarshiniNessuna valutazione finora

- Paper 2 - Set A Solution: General InstructionsDocumento16 paginePaper 2 - Set A Solution: General InstructionsMukesh KumarNessuna valutazione finora

- National Certification Exam Paper EA2 - Energy AuditorDocumento7 pagineNational Certification Exam Paper EA2 - Energy AuditorMayukh DebdasNessuna valutazione finora

- 16th Exam Paper 2 Sup - Set - BDocumento23 pagine16th Exam Paper 2 Sup - Set - BSaurabh RautNessuna valutazione finora

- Section - I: Objective Type: Marks: 50 X 1 50Documento21 pagineSection - I: Objective Type: Marks: 50 X 1 50YogaAnandNessuna valutazione finora

- Paper 2 Set B 24nov2009 KeyDocumento14 paginePaper 2 Set B 24nov2009 KeySHAMSIK2002Nessuna valutazione finora

- 16th Exam Paper2 Reg SetA PDFDocumento21 pagine16th Exam Paper2 Reg SetA PDFSaurabh RautNessuna valutazione finora

- Paper - 2 - SetB - QADocumento14 paginePaper - 2 - SetB - QANataraj Singh SardarNessuna valutazione finora

- Paper 2 - Set B Solutions: General InstructionsDocumento12 paginePaper 2 - Set B Solutions: General InstructionsRichard RegidorNessuna valutazione finora

- Bureau of Energy EfficiencyDocumento10 pagineBureau of Energy EfficiencyVishwa MurthyNessuna valutazione finora

- Objective Type: Each Question Carries MarkDocumento44 pagineObjective Type: Each Question Carries MarkAshutosh KumarNessuna valutazione finora

- Paper 2 - Set B Solution: General InstructionsDocumento16 paginePaper 2 - Set B Solution: General InstructionsMukesh KumarNessuna valutazione finora

- Regular Paper 2 - Set BDocumento15 pagineRegular Paper 2 - Set BPalashNessuna valutazione finora

- MCQs - EAM - Unit 4Documento11 pagineMCQs - EAM - Unit 4Sayee DeshpandeNessuna valutazione finora

- National Certification Examination, 2004: Paper EM2 - Energy Manager - Set B SolutionsDocumento11 pagineNational Certification Examination, 2004: Paper EM2 - Energy Manager - Set B Solutionsraghavan1984Nessuna valutazione finora

- Paper-2 Set-A KeyDocumento14 paginePaper-2 Set-A Keydkhatri01Nessuna valutazione finora

- 2a KeyDocumento16 pagine2a KeyHimanshu RanjanNessuna valutazione finora

- Energy Efficiency in Thermal Utilities Paper 2Documento7 pagineEnergy Efficiency in Thermal Utilities Paper 2Pushpendra YadavNessuna valutazione finora

- 8 National Certification Examination - MAY, 2009 FOR Energy Managers & Energy AuditorsDocumento14 pagine8 National Certification Examination - MAY, 2009 FOR Energy Managers & Energy AuditorsErin WardNessuna valutazione finora

- Energy Efficiency in Thermal Utilities Model Question PaperDocumento12 pagineEnergy Efficiency in Thermal Utilities Model Question PaperSampat PrajapatiNessuna valutazione finora

- Paper 2 - Set A Solutions: General InstructionsDocumento18 paginePaper 2 - Set A Solutions: General Instructionsjp nayakNessuna valutazione finora

- 8 National Certification Examination - May, 2009 FOR Energy Managers & Energy AuditorsDocumento14 pagine8 National Certification Examination - May, 2009 FOR Energy Managers & Energy AuditorsEmperorNessuna valutazione finora

- 142 BDocumento15 pagine142 BarunachalamNessuna valutazione finora

- 20th Exam P2 B PDFDocumento13 pagine20th Exam P2 B PDFAlbert SekarNessuna valutazione finora

- 2 National Certification Examination 2005 FOR: Energy Managers and Energy Auditors Model Test Series - 1Documento8 pagine2 National Certification Examination 2005 FOR: Energy Managers and Energy Auditors Model Test Series - 1Shahedabanu AghadiNessuna valutazione finora

- Key to Paper 2 – Set BDocumento14 pagineKey to Paper 2 – Set Bchkk.ramakumarNessuna valutazione finora

- 2 National Certification Examination - 2005 FOR: Energy Managers and Energy Auditors Model Test Series-1Documento18 pagine2 National Certification Examination - 2005 FOR: Energy Managers and Energy Auditors Model Test Series-1Rupesh ParadeNessuna valutazione finora

- Bee 1Documento13 pagineBee 1thathurvelNessuna valutazione finora

- Final Paper 2 Sup Set B 20.04.2017Documento21 pagineFinal Paper 2 Sup Set B 20.04.2017Er Rohit SoniNessuna valutazione finora

- Model Question Paper - 2006 National Certification Examination for Energy Auditors and Energy ManagersDocumento12 pagineModel Question Paper - 2006 National Certification Examination for Energy Auditors and Energy ManagersSampat PrajapatiNessuna valutazione finora

- NATIONAL CERTIFICATION EXAM GUIDE FOR ENERGY MANAGERSDocumento18 pagineNATIONAL CERTIFICATION EXAM GUIDE FOR ENERGY MANAGERSzoom2Nessuna valutazione finora

- Pe MCQ UpdatedDocumento42 paginePe MCQ UpdatedĀditya SonāvanéNessuna valutazione finora

- Khaire Sir Classes: All Imp Question of Unit 2 Sub: EtmDocumento6 pagineKhaire Sir Classes: All Imp Question of Unit 2 Sub: EtmAkshay KhangreNessuna valutazione finora

- MCQS Group B (Section-II) PDFDocumento10 pagineMCQS Group B (Section-II) PDFCenter of KnowledgeNessuna valutazione finora

- (Questions Only) ME 366 ONLINE REGULAR QUIZ 5 2022 - 2023Documento10 pagine(Questions Only) ME 366 ONLINE REGULAR QUIZ 5 2022 - 2023Don CarlosNessuna valutazione finora

- HMT Unit 4 MCQDocumento13 pagineHMT Unit 4 MCQSatish kumar patleNessuna valutazione finora

- FFRDocumento5 pagineFFRpappuNessuna valutazione finora

- Power Engineering MCQDocumento22 paginePower Engineering MCQĀditya SonāvanéNessuna valutazione finora

- Model Question Paper - 2006Documento13 pagineModel Question Paper - 2006Faiq HasnainNessuna valutazione finora

- Please (X) Mark in The Answer Sheet For Marking The Correct AnswerDocumento6 paginePlease (X) Mark in The Answer Sheet For Marking The Correct Answerbikas_sahaNessuna valutazione finora

- Generation of Electric Power McqsDocumento10 pagineGeneration of Electric Power McqskeerthikaNessuna valutazione finora

- MCQ Question Bank - PE-ME 801B - Part IDocumento8 pagineMCQ Question Bank - PE-ME 801B - Part IBibekNessuna valutazione finora

- Unit No I MCQ Energy EngineeringDocumento13 pagineUnit No I MCQ Energy EngineeringDevesh DhumalNessuna valutazione finora

- 15 CalculationsDocumento9 pagine15 CalculationsJohn P. BandoquilloNessuna valutazione finora

- SUP1SetB PDFDocumento13 pagineSUP1SetB PDFcynaiduNessuna valutazione finora

- l6ll2l20L8: Fifth 2018Documento16 paginel6ll2l20L8: Fifth 2018dileepNessuna valutazione finora

- FPFF Questions - 1Documento15 pagineFPFF Questions - 1AryanNessuna valutazione finora

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Da EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Nessuna valutazione finora

- Process Intensification for Sustainable Energy ConversionDa EverandProcess Intensification for Sustainable Energy ConversionNessuna valutazione finora

- Materials Science and Laser Physics BooksDocumento6 pagineMaterials Science and Laser Physics BooksAbubakar Mughal0% (1)

- LectureNotes SolidStateTheory KehreinDocumento106 pagineLectureNotes SolidStateTheory KehreinNataraj Singh SardarNessuna valutazione finora

- JD Manager Energy Services July'14 PDFDocumento1 paginaJD Manager Energy Services July'14 PDFNataraj Singh SardarNessuna valutazione finora

- Outcome 4Documento20 pagineOutcome 4Nataraj Singh SardarNessuna valutazione finora

- Bang La Word HelpDocumento7 pagineBang La Word HelpSwarnendu Biswas100% (3)

- 3d Nature Wallpaper Landscape PDFDocumento1 pagina3d Nature Wallpaper Landscape PDFNataraj Singh SardarNessuna valutazione finora

- Purchase of Library BookDocumento26 paginePurchase of Library BookNataraj Singh SardarNessuna valutazione finora

- Impact of Energy Conservation Activities in The State of BiharDocumento1 paginaImpact of Energy Conservation Activities in The State of BiharNataraj Singh SardarNessuna valutazione finora

- Paper - 2 - SetB - QADocumento14 paginePaper - 2 - SetB - QANataraj Singh SardarNessuna valutazione finora

- How to Calculate Coal Calorific ValuesDocumento2 pagineHow to Calculate Coal Calorific ValuesKhloud MadihNessuna valutazione finora

- 2004 Paper 2 Set BDocumento6 pagine2004 Paper 2 Set BNataraj Singh SardarNessuna valutazione finora

- How To Calculate Duty and Surface Area of Heat Ex ChangersDocumento7 pagineHow To Calculate Duty and Surface Area of Heat Ex ChangersJohn Obidi100% (2)

- 2004 Paper 2 Set BDocumento6 pagine2004 Paper 2 Set BNataraj Singh SardarNessuna valutazione finora

- EOI Details For PMU PDFDocumento7 pagineEOI Details For PMU PDFNataraj Singh SardarNessuna valutazione finora

- 18th Electric Power Survey of IndiaDocumento7 pagine18th Electric Power Survey of Indiasaifmuiz136950% (2)

- BOI BGP Electrical Audit 2012-2013Documento6 pagineBOI BGP Electrical Audit 2012-2013Nataraj Singh SardarNessuna valutazione finora

- 1302 2012-05-12 1336813401Documento8 pagine1302 2012-05-12 1336813401Nataraj Singh SardarNessuna valutazione finora

- Ea Hal Nit Asd-008 19-06-12Documento6 pagineEa Hal Nit Asd-008 19-06-12Nataraj Singh SardarNessuna valutazione finora

- EA BoI VadodaraDocumento6 pagineEA BoI VadodaraNataraj Singh SardarNessuna valutazione finora

- ToR PDFDocumento3 pagineToR PDFNataraj Singh SardarNessuna valutazione finora

- EA BoI HazaribagDocumento8 pagineEA BoI HazaribagNataraj Singh SardarNessuna valutazione finora

- EA BoI HazaribagDocumento8 pagineEA BoI HazaribagNataraj Singh SardarNessuna valutazione finora

- 1 PB PDFDocumento4 pagine1 PB PDFNataraj Singh SardarNessuna valutazione finora

- Eac GedaDocumento10 pagineEac GedaNataraj Singh SardarNessuna valutazione finora

- EA Balmer Lawrie KolkataDocumento6 pagineEA Balmer Lawrie KolkataNataraj Singh SardarNessuna valutazione finora

- WRPLVGMTS201213004 File2of2-UntochedDocumento12 pagineWRPLVGMTS201213004 File2of2-UntochedNataraj Singh SardarNessuna valutazione finora

- 3 Buildings PunjabDocumento29 pagine3 Buildings PunjabNataraj Singh SardarNessuna valutazione finora

- 1302 2012-05-12 1336813401Documento8 pagine1302 2012-05-12 1336813401Nataraj Singh SardarNessuna valutazione finora

- TG Jiu-EuDocumento7 pagineTG Jiu-EuRamonik RbelaNessuna valutazione finora

- Jacketed Weld Strength CheckDocumento10 pagineJacketed Weld Strength CheckKshitiz SikkaNessuna valutazione finora

- Calculation of Pseudo-components Specific GravitiesDocumento3 pagineCalculation of Pseudo-components Specific GravitiesJean Carlo PizarroNessuna valutazione finora

- Viscoelastic Creep and Stress-Strain BehaviorDocumento11 pagineViscoelastic Creep and Stress-Strain BehaviorHARIMETLYNessuna valutazione finora

- An Overview of Traditional Fish Smoking in Africa PDFDocumento20 pagineAn Overview of Traditional Fish Smoking in Africa PDFBzmania SlimnzieNessuna valutazione finora

- Transom cw03Documento2 pagineTransom cw03Pamps MangampoNessuna valutazione finora

- Tank Cleaning Vacuum Residue AsphaltDocumento2 pagineTank Cleaning Vacuum Residue AsphaltSushilNessuna valutazione finora

- Leon Scope-62225-TC-7081-1679956348Documento8 pagineLeon Scope-62225-TC-7081-1679956348raghavan_gopinathNessuna valutazione finora

- Suitable dimensions, performance requirements, and processes for optical transmittersDocumento1 paginaSuitable dimensions, performance requirements, and processes for optical transmittersshruti soniNessuna valutazione finora

- Encyclopedia of Surface and Colloid Science: January 2014Documento15 pagineEncyclopedia of Surface and Colloid Science: January 2014Khurelbaatar GanboldNessuna valutazione finora

- Adaptive Teaching Guide SampleDocumento2 pagineAdaptive Teaching Guide SampleMai SasaNessuna valutazione finora

- Hazard AnalysisDocumento39 pagineHazard AnalysisvishnuNessuna valutazione finora

- Udel PSU Design Guide - EN v5.0 - 0 - 0 PDFDocumento84 pagineUdel PSU Design Guide - EN v5.0 - 0 - 0 PDFReza Pencinta AL HadadNessuna valutazione finora

- Evaporation: Heat Transfer Coefficients and Single Effect EvaporatorsDocumento26 pagineEvaporation: Heat Transfer Coefficients and Single Effect EvaporatorsIram TahiraNessuna valutazione finora

- Pyrocrete 241Documento2 paginePyrocrete 241Carboline2013Nessuna valutazione finora

- Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionDocumento11 pagineHydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionSebastian Chaverra100% (1)

- Flat RollingDocumento39 pagineFlat Rollinglamia97Nessuna valutazione finora

- P K Nag SolutionDocumento5 pagineP K Nag SolutionMuthu Ezhilan80% (5)

- CBSE Class 11 and 12 Chemistry Notes The P-Block ElementsDocumento45 pagineCBSE Class 11 and 12 Chemistry Notes The P-Block ElementsPrabhuPalanichamy50% (2)

- Proposal Defense PresentationDocumento52 pagineProposal Defense PresentationJanine TacaisanNessuna valutazione finora

- Protocols Cleaning Disinfection SterilizationDocumento23 pagineProtocols Cleaning Disinfection SterilizationGeneSegoviaNessuna valutazione finora

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Documento11 pagine(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifNessuna valutazione finora

- Parker SizeTempratureApplicationMediaPressureDocumento40 pagineParker SizeTempratureApplicationMediaPressuretrilemmaNessuna valutazione finora

- Chapter 11 - Chemical Reactions PDFDocumento17 pagineChapter 11 - Chemical Reactions PDFapi-239855791Nessuna valutazione finora

- Ix All Subj Guess PapersDocumento27 pagineIx All Subj Guess PapersAsim AbbasNessuna valutazione finora

- Dielectric Constants Chart: How To Use This GuideDocumento10 pagineDielectric Constants Chart: How To Use This GuideDewet VirmondNessuna valutazione finora

- Chemistry Practical Class XDocumento11 pagineChemistry Practical Class XAditya PandeyNessuna valutazione finora

- IGS-M-CH-38 (1) Oct IGS. Iranian Gas Standards $ - &' (! ! Odorant To Be Used For Odorization of Natural Gas-1Documento12 pagineIGS-M-CH-38 (1) Oct IGS. Iranian Gas Standards $ - &' (! ! Odorant To Be Used For Odorization of Natural Gas-1KHALED KHALEDNessuna valutazione finora

- Aspen Exchanger Design and Rating Plate V10: Cold Side DatabankDocumento12 pagineAspen Exchanger Design and Rating Plate V10: Cold Side DatabankCHELSEE VALENTINA SANCHEZ MUÑOZNessuna valutazione finora

- Triazine DyesDocumento30 pagineTriazine DyesRoxanaNessuna valutazione finora