Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pelton Wheel

Caricato da

Ryan MahoneyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pelton Wheel

Caricato da

Ryan MahoneyCopyright:

Formati disponibili

FLUID MECHANICS D203

SAE SOLUTIONS TUTORIAL 8A TURBINES

SELF ASSESSMENT EXERCISE No. 1

1. The buckets of a Pelton wheel revolve on a mean diameter of 1.5 m at 1500 rev/min. The jet

velocity is 1.8 times the bucket velocity. Calculate the water flow rate required to produce a power

output of 2MW. The mechanical efficiency is 80% and the blade friction coefficient is 0.97. The

deflection angle is 165

o

.

D =1.5 m N =1500 rev/min v =1.8 u =80% k =0.97 =165

o

Diagram Power =2MW/0.8 =2.5 MW

u =ND/60 =117.8 m/s

v =1.8 x 117.8 =212 m/s

DP =m u (v-u) (1- kcos) =2.5 x 10

6

m x 117.8 (94.24)(1- 0.97cos 165) =2.5 x 10

6

m =2.5 x 10

6

/21503 =116.26 kg/s

2. Calculate the diagram power for a Pelton Wheel 2m mean diameter revolving at 3000 rev/min

with a deflection angle of 170

o

under the action of two nozzles , each supplying 10 kg/s of water

with a velocity twice the bucket velocity. The blade friction coefficient is 0.98.

If the coefficient of velocity is 0.97, calculate the pressure behind the nozzles.

(Ans 209.8 MPa)

D =2m N =3000 rev/min =170

o

v =2u k = 0.98 c

v

=0.97 m =2 x 10 =20 kg/s

u =ND/60 =314.16 m/s

DP =m u (v-u) (1- kcos) = 20 x 314.16 x 314.16(1- 0.98 cos170

o

) =3.879 MW

v =c

v

2p/

p =(314.16 x 2/0.97)

2

x 1000/2 =209.8 MPa

3. A Pelton Wheel is 1.7 m mean diameter and runs at maximum power. It is supplied from two

nozzles. The gauge pressure head behind each nozzle is 180 metres of water. Other data for the

wheel is :

Coefficient of Discharge C

d

=0.99

Coefficient of velocity C

v

=0.995

Deflection angle =165

o

.

Blade friction coefficient =0.98

Mechanical efficiency =87%

Nozzle diameters =30 mm

Calculate the following.

i. The jet velocity (59.13 m/s)

ii. The mass flow rate (41.586 kg/s)

iii The water power ( 73.432 kW)

iv. The diagram power ( 70.759 kW)

v. The diagram efficiency (96.36%)

vi. The overall efficiency (83.8%)

vii. The wheel speed in rev/min (332 rev/min)

D =1.7 m H =180 m c

d

=0.99 c

v

=0.995 c

c

=c

d

/c

v

=0.995 =1000 kg/m

3

Power is maximum so v =2u 2 nozzles

v =c

v

2g H =0.995 (2g x 180) =59.13 m/s

m =c

c

A v =0.995 x 1000 ( x 0.03

2

/4) x 59.13 =41.587 kg/s per nozzle

Water Power =mg H =41.587 x 9.81 x 180 =73.43 kW per nozzle.

u =v/2 =29.565 m/s

Diagram Power =m u (v-u) (1- kcos)

DP =41.587 x 29.565 (29.565)(1 0.98cos165) =70.76 kW per nozzle

d

=70.76/73.43 =83.8%

Mechanical Power =70.76 x 87% =61.56 kW per nozzle.

oa

=61.56/73.43 =83.8%

N =60u/D =29.565 x 60/( x 1.7) =332.1 rev/min

4. Explain the significance and use of 'specific speed

5/4 1/2

1/2

(gH)

NP

Ns=

Calculate the specific speed of a Pelton Wheel given the following.

d =nozzle diameter. D =Wheel diameter.

u =optimum blade speed =0.46 v

1

v

1

=jet speed.

=88% C

v

=coefficient of velocity =0.98

1/2

v j

4.34H 2gH 0.98 2gH c v = = = u =0.46 v

j

=ND/60

D

H

38.128

D

60 x 4.34H x 0.46

D

60 x v 0.46

N

1/2 1/2

j

= = =

Q =A

j

v

j

=(d

2

/4) x 4.34 H

=3.41 H

d

2

P = m g H = x g Q H =0.88 x 1000 x 9.81 x 3.41 x H

d

2

=29438 H

d

2

H

( )

D

d

11.9

H D

d H H

x

81 . 9 1000

28438 x 38.128

(gH)

d H 28438

x

D

H

38.128 Ns

5/4

3/4 1/2

4 / 5 2 / 1

1/2

5/4 1/2

1/2

2 3/2 1/2

= = =

5. A turbine is to run at 150 rev/min under a head difference of 22 m and an expected flow rate of

85 m

3

/s.

A scale model is made and tested with a flow rate of 0.1 m

3

/s and a head difference of 5 m.

Determine the scale and speed of the model in order to obtain valid results.

When tested at the speed calculated, the power was 4.5 kW. Predict the power and efficiency of the

full size turbine.

N

1

=150 rev/min Q

1

=85 m

3

/s H

1

=22 m

Q

2

=0.1 m

3

/s H

2

=55 m

For similarity of Head Coefficient we have

2

2

2

2

2

2

1

2

1

1

D N

H

D N

H

=

2

2

2

2

2

2

1

2

2

N

5114

22N

5x150

D

D

= =

2

2

2 1

2

N

71.51

N

5114

D

D

= =

For similarity of Flow Coefficient we have

3

2 2

2

3

1 1

1

D N

Q

D N

Q

=

2 2

3

1

3

2

N

0.176

85N

0.1x150

D

D

= =

1/2

2

3

2 1

2

N

0.560

N

71.51

D

D

= =

Equate

1/2

2 2 1

2

N

0.560

N

71.51

D

D

= =

0.56

71.51

N

2/3

2

= N

2

=1443 rev/min

0496 . 0

D

D

1

2

=

Note if we use

3/4

2

1/2

2

3/4

1

1/2

1

H

Q N

H

Q N

2 1

= we get the same result.

Power Coefficient

5

2

3

2

2

5

1

3

1

1

D N

P

D N

P

=

( )

16.2MW

1443

0.05

1

x 150 x 4.5

D N

D N P

D N

D N P

P

3

5

3

5

2

3

2

5

1

3

1 2

5

2

3

2

5

1

3

1 2

1

=

= = =

Water Power =mgH =(85 x 1000) x 9.81 x 22 =18.3 MW

=16.2/18.3 =88%

SELF ASSESSMENT EXERCISE No.2

1. The following data is for a Francis Wheel

Radial velocity is constant

No whirl at exit.

Flow rate=0.4 m

3

/s D

1

=0.4 m D

2

=0.15 m k =0.95

1

=90

o

N=1000 rev/min

Head at inlet =56 m head at entry to rotor =26 m head at exit =0 m

Entry is shock less.

Calculate i. the inlet velocity v

1

(24.26 m/s)

ii. the guide vane angle (30.3

o

)

iii. the vane height at inlet and outlet (27.3 mm, 72.9 mm)

iv. the diagram power (175.4 MW)

v. the hydraulic efficiency (80%)

v

1

=(2gh)

={2 x 9.81 x (56 26)}

=24.26 m/s

u

1

=ND/60 = x 1000 x 0.4/60 =20.94 m/s

1

=cos

-1

(20.94/24.26) =30.3

o

1

=v

r1

=12.25 m/s

Q =0.4 = D t k v

r

t

1

=0.4/( x 0.4 x 0.95 x 12.25) =0.0273 m

t

2

=0.4/( x 0.15 x 0.95 x 12.25) =0.0729 m

v

w1

=20.94 v

w2

=0

P =mu

1

v

w1

=400 x 20.94 x 20.94 =174.4 kW

Water Power =m g H =400 x 9.81 x 56 =219.7 kW

=174.4/219.7 =80%

2. A radial flow turbine has a rotor 400 mm diameter and runs at 600 rev/min. The vanes are 30

mm high at the outer edge. The vanes are inclined at 42

o

to the tangent to the inner edge. The flow

rate is 0.5 m

3

/s and leaves the rotor radially. Determine

i. the inlet velocity as it leaves the guide vanes. (19.81 m/s)

ii. the inlet vane angle. (80.8

o

)

iii. the power developed. (92.5 kW)

u

1

Radial Flow Turbine Inlet is the outer edge.

=ND/60 = x 600 x 0.4/60 =12.57 m/s

v

r1

=Q/Dt =0.5/( x 0.4 x 0.03) =13.26 m/s

13.26/v

w1

=tan 42

o

v

w1

=14.72 m/s

v

1

=(13.26

2

+14.72

2

)

=19.81 m/s

13.26/(14.72 12.57) =tan

1

1

=80.8

o

v

w2

=0

DP =mu =v

w1

DP =500 x 12.57 x 14.72 =92.5 kW

3. The runner (rotor) of a Francis turbine has a blade configuration as shown. The outer diameter

is 0.45 m and the inner diameter is 0.3 m. The vanes are 62.5 mm high at inlet and 100 mm at

outlet. The supply head is 18 m and the losses in the guide vanes and runner are equivalent to 0.36

m. The water exhausts from the middle at atmospheric pressure. Entry is shock less and there is no

whirl at exit. Neglecting the blade thickness, determine :

i. The speed of rotation.

ii. The flow rate.

iii. The output power given a mechanical efficiency of 90%.

iv. The overall efficiency.

v. The outlet vane angle.

INLET

Useful head is 18 0.36 =17.64 m

m u

1

v

w1

=m u

2

v

w2

u

1

v

w1

=u

2

v

w2

(u

1

v

w1

/g) =H =17.64

sine rule (v

1

/sin 60) =(u

1

/sin 100)

v

1

=0.879 u

1

(v

r1

/ v

1

) =sin 20 v

1

=2.923 v

r1

Equate 0.879 u

1

=2.923 v

r1

v

r1

=0.3 u

1

v

w1

=v

r1

/tan 20 =0.824 u

1

17.64 =u

1

x 0.824 u

1

/g u

1

2

= 210 u

1

= 14.5 m/s

v

r1

=0.3 u

1

=4.35 m/s

EXIT

u = N D N =u

1

/ D

1

=u

2

/ D

2

u

2

=u

1

D

1

/ D

2

=14.4 x 300/450 =9.67 m/s

N =u

1

/ D

1

=14.5 x 60/( x 0.45) =615 rev/min

v

r

=Q/Dh

v

r1

=4.35 =Q/D

1

h

1

=Q/( x 0.45 x 0.0625)

Q = 0.384 m

3

/s

v

r2

=Q/D

2

h

2

=Q/( x 0.3 x 0.1) =10.61 Q =4.08 m/s

4.08/9.67 =tan

2

2

=22.8

o

P =m g H =384 x 9.81 x 17.64 =66.45 kW

Output Power =66.45 x 90% =59.8 kW

Overall efficiency = 59800/(m g H) =58805/(384 x 9.81 x 18) =88.2 %

Potrebbero piacerti anche

- Assignment-6 Solutions - FinalDocumento8 pagineAssignment-6 Solutions - FinalmaheshNessuna valutazione finora

- Mka-03 Pelton and Francis TurbinesDocumento11 pagineMka-03 Pelton and Francis TurbineshasshosNessuna valutazione finora

- Hydraulics and Hydraulic Machinery 2009 JNTUK QUESTION PAPERDocumento8 pagineHydraulics and Hydraulic Machinery 2009 JNTUK QUESTION PAPERhimabindugvsd71Nessuna valutazione finora

- Tutorial 5Documento1 paginaTutorial 5AJAY MEENANessuna valutazione finora

- DESIGNOFHIGHEFFICIENCYPELTONTURBINEFORMICRO HYDROPOWERplant PDFDocumento13 pagineDESIGNOFHIGHEFFICIENCYPELTONTURBINEFORMICRO HYDROPOWERplant PDFSadrakhNessuna valutazione finora

- Francis Turbine Test RigDocumento4 pagineFrancis Turbine Test RigAditya SinghNessuna valutazione finora

- CFD Analysis of Pelton TurbineDocumento4 pagineCFD Analysis of Pelton TurbineSanam ManutdNessuna valutazione finora

- Levelling Alignment: Levelling, Alignment and Centering of Suspended Type Vertical MachineDocumento6 pagineLevelling Alignment: Levelling, Alignment and Centering of Suspended Type Vertical MachineSajid AkhterNessuna valutazione finora

- Tutorial Load C-C PDFDocumento3 pagineTutorial Load C-C PDFEyad A. FeilatNessuna valutazione finora

- Solar Irrigation SystemDocumento18 pagineSolar Irrigation SystemHarishwar ReddyNessuna valutazione finora

- Solar Powered Water Pumping Systems: AbstractDocumento4 pagineSolar Powered Water Pumping Systems: AbstractbalaNessuna valutazione finora

- 007 Kaplan 10 PaginasDocumento11 pagine007 Kaplan 10 PaginasricardoNessuna valutazione finora

- 110kv Sagtension Calculation 1 PDF FreeDocumento13 pagine110kv Sagtension Calculation 1 PDF FreeAnonymous 5XvUbWynnNessuna valutazione finora

- M.g.say ch01Documento5 pagineM.g.say ch01prabhjot singh150% (2)

- 908design of High Efficiency Cross-Flow TurbineDocumento4 pagine908design of High Efficiency Cross-Flow TurbineAdi Setiadi100% (1)

- Image Analysis Method For Quantifying Snow Losses On PV SystemsDocumento7 pagineImage Analysis Method For Quantifying Snow Losses On PV SystemsJennifer BraidNessuna valutazione finora

- Laboratory Manual MEC-325 Thermo Fluid Engineering LaboratoryDocumento36 pagineLaboratory Manual MEC-325 Thermo Fluid Engineering LaboratoryArpit Kumar Jain100% (1)

- Civil Engineering Hydraulics & Geotechnical Engineering Set ADocumento3 pagineCivil Engineering Hydraulics & Geotechnical Engineering Set Acielo_cetd3670Nessuna valutazione finora

- Promlem 1: A) The Discharge Through The Penstock. B) The Mean Annual Energy ProductionDocumento4 paginePromlem 1: A) The Discharge Through The Penstock. B) The Mean Annual Energy ProductionbkkbrazilNessuna valutazione finora

- Power Transmitting ElementsDocumento10 paginePower Transmitting ElementsLAMPASA JOSE ROGER JR.Nessuna valutazione finora

- Fluid Mechanics and Machinery Hydraulic TurbinesDocumento17 pagineFluid Mechanics and Machinery Hydraulic Turbineszakaria masud sonyNessuna valutazione finora

- Assignment 1Documento3 pagineAssignment 1Engr Hafiz Umar100% (1)

- Journal BearingDocumento8 pagineJournal Bearingدنيا قيس كاظم100% (1)

- Renewable Energy Systems Assignment 1Documento7 pagineRenewable Energy Systems Assignment 1Choudary SonuNessuna valutazione finora

- Conceptual Design Optimization of Francis TurbinesDocumento11 pagineConceptual Design Optimization of Francis TurbinesJun GWan ParkNessuna valutazione finora

- 909design of High Efficiency Pelton Turbine For Micro-HydropowerDocumento13 pagine909design of High Efficiency Pelton Turbine For Micro-HydropowerrachidtuNessuna valutazione finora

- Hydraulic Machines LaboratoryDocumento27 pagineHydraulic Machines LaboratoryAnonymous f1UCK4Nessuna valutazione finora

- 7 Segment Data SheetDocumento9 pagine7 Segment Data SheetMus LihNessuna valutazione finora

- Piping Systems Srac 1994Documento6 paginePiping Systems Srac 1994maheshNessuna valutazione finora

- Mbeya Institute of Science and Technology: Power Plant Lecture Seven Hydropower PlantsDocumento125 pagineMbeya Institute of Science and Technology: Power Plant Lecture Seven Hydropower PlantsNyandaMadili MalashiNessuna valutazione finora

- PV Based Grid Connected, Standalone and Pumping SystemDocumento48 paginePV Based Grid Connected, Standalone and Pumping SystemparthichristoNessuna valutazione finora

- Hydraulic Design - ScanDocumento36 pagineHydraulic Design - ScancjayamangalaNessuna valutazione finora

- Assignment (Electric Power Utilization EE16105)Documento4 pagineAssignment (Electric Power Utilization EE16105)Prasenjit DeyNessuna valutazione finora

- Renovation Modernization and Uprating of Hydro Power StationsDocumento5 pagineRenovation Modernization and Uprating of Hydro Power StationsAbhijeet SinghNessuna valutazione finora

- HW3 SolutionsDocumento2 pagineHW3 SolutionsmojoNessuna valutazione finora

- Tutorium Compressor SolutionDocumento12 pagineTutorium Compressor SolutionNadia Balqis0% (1)

- 9A01308 Fluid Mechanics and Hydraulic MachineryDocumento4 pagine9A01308 Fluid Mechanics and Hydraulic MachinerysivabharathamurthyNessuna valutazione finora

- Experiment 8 Transformer Equivalent CircuitDocumento9 pagineExperiment 8 Transformer Equivalent CircuitBrett GallNessuna valutazione finora

- C4ce22 Hydro Power Engineering Set1Documento9 pagineC4ce22 Hydro Power Engineering Set1bhkedarNessuna valutazione finora

- Cycle Engine PDFDocumento6 pagineCycle Engine PDFk marcusNessuna valutazione finora

- Kaplan and Pelton QuestionsDocumento13 pagineKaplan and Pelton Questionstixy2013Nessuna valutazione finora

- Polyphase RectifierDocumento4 paginePolyphase RectifierGlenda Grageda100% (1)

- Gecolea, ME143-2 Sample QuestionsDocumento25 pagineGecolea, ME143-2 Sample QuestionsJazztine Andrei GecoleaNessuna valutazione finora

- Vortex Bladeless Wind TurbineDocumento17 pagineVortex Bladeless Wind TurbineFahad AhamedNessuna valutazione finora

- Shaft Bearings: Plain and Tilting Pad BearingsDocumento3 pagineShaft Bearings: Plain and Tilting Pad Bearingsbadppl100% (1)

- Module 7 Exercises Problem No. 1Documento3 pagineModule 7 Exercises Problem No. 1Ariel Gamboa100% (1)

- DC Machine DesignDocumento25 pagineDC Machine DesignJatin PradhanNessuna valutazione finora

- Hydro Electric Power PlantsDocumento99 pagineHydro Electric Power Plantsncaliao_1Nessuna valutazione finora

- Design of The Rotor Blades of A Mini Hydraulic Bulb-TurbineDocumento9 pagineDesign of The Rotor Blades of A Mini Hydraulic Bulb-TurbineuroskNessuna valutazione finora

- Sample of Residential Load Computation For Power System AnalysisDocumento4 pagineSample of Residential Load Computation For Power System AnalysisMarvin GagarinNessuna valutazione finora

- Introduction Synopsis Hydro Power PlantDocumento7 pagineIntroduction Synopsis Hydro Power PlantSuresh KumarNessuna valutazione finora

- Study of Performance Characteristics of Francis TurbineDocumento6 pagineStudy of Performance Characteristics of Francis TurbineBandam Nitish kumarNessuna valutazione finora

- Question Bank PS1Documento3 pagineQuestion Bank PS1goyal.167009Nessuna valutazione finora

- Speed Measuring InstrumentsDocumento7 pagineSpeed Measuring InstrumentsJoshua GarciaNessuna valutazione finora

- Solve Problem of Hydroelectric Power PlantDocumento17 pagineSolve Problem of Hydroelectric Power PlantAnonymous 1VhXp189% (28)

- A Pump Delivers 10 Dm3Documento8 pagineA Pump Delivers 10 Dm3Deesee JeyNessuna valutazione finora

- Reaction Turbine Problems PDFDocumento18 pagineReaction Turbine Problems PDFDeva Raj86% (29)

- Saet 8 BDocumento3 pagineSaet 8 BnaefmubarakNessuna valutazione finora

- Turbine SeatworkDocumento14 pagineTurbine SeatworkChoie kun100% (3)

- Fluid Mechanics d203 ReseniDocumento90 pagineFluid Mechanics d203 ReseniDennys Fabricio Ramirez100% (1)

- Fatigue Life Prediction of A Wind Turbine NacelleDocumento1 paginaFatigue Life Prediction of A Wind Turbine NacelleRyan MahoneyNessuna valutazione finora

- MEC 3111 - Finite Element AnalysisDocumento3 pagineMEC 3111 - Finite Element AnalysisRyan MahoneyNessuna valutazione finora

- Year 4 MechDocumento2 pagineYear 4 MechRyan MahoneyNessuna valutazione finora

- AbcDocumento1 paginaAbcRyan MahoneyNessuna valutazione finora

- Water Flowing (Discharging) From A Tank Calculation and EquationsDocumento2 pagineWater Flowing (Discharging) From A Tank Calculation and EquationsmartinNessuna valutazione finora

- European Catalog Asia Pacific Express Asco en 5041722Documento70 pagineEuropean Catalog Asia Pacific Express Asco en 5041722treborNessuna valutazione finora

- Tugas II Mekanika FluidaDocumento14 pagineTugas II Mekanika FluidaHengki JuntakNessuna valutazione finora

- HAMMER Modeling Reference - Air Valves - Haestad - Hydraulics and Hydrology Wiki - Haestad - Hydraulics and Hydrology - Bentley CommunitiesDocumento18 pagineHAMMER Modeling Reference - Air Valves - Haestad - Hydraulics and Hydrology Wiki - Haestad - Hydraulics and Hydrology - Bentley CommunitiesSalaheddine OURNessuna valutazione finora

- Advances in Drilling Hydraulics and Drilling Fluid Rheology-KelessidisDocumento11 pagineAdvances in Drilling Hydraulics and Drilling Fluid Rheology-KelessidisVassilios KelessidisNessuna valutazione finora

- Dimensionless Group of Heat TransferDocumento1 paginaDimensionless Group of Heat TransferSalwanNessuna valutazione finora

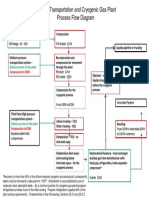

- Generic Transportation and Cryogenic Gas Plant Process Flow DiagramDocumento1 paginaGeneric Transportation and Cryogenic Gas Plant Process Flow DiagramSyahmi AbdullahNessuna valutazione finora

- Exam On Pumps and Pipe NetworksDocumento10 pagineExam On Pumps and Pipe Networksm_abdelgawadNessuna valutazione finora

- Wettability and ProductionDocumento13 pagineWettability and ProductionYamal E Askoul T0% (1)

- The Long Term Calibration Stability of Critical Flow Nozzles and Laminar FlowmetersDocumento20 pagineThe Long Term Calibration Stability of Critical Flow Nozzles and Laminar FlowmetersSatit hunsaNessuna valutazione finora

- NGWA 2004mcellhiney PDFDocumento44 pagineNGWA 2004mcellhiney PDFJordi EscorciaNessuna valutazione finora

- Groundwater HydrologyDocumento83 pagineGroundwater Hydrologydixn__100% (1)

- DamsDocumento9 pagineDamsRichard TagleNessuna valutazione finora

- Cat FiltersDocumento168 pagineCat Filterskiko100% (1)

- B.E. / B.Tech Degree Examinations April / May 2021 Mechatronics EngineeringDocumento2 pagineB.E. / B.Tech Degree Examinations April / May 2021 Mechatronics EngineeringAravinthNessuna valutazione finora

- Argus Biofuels (2023!08!08)Documento11 pagineArgus Biofuels (2023!08!08)Pitipat LeeNessuna valutazione finora

- 3 (B) Groundwater Flow - Darcy's LawDocumento10 pagine3 (B) Groundwater Flow - Darcy's LawKaran GuptaNessuna valutazione finora

- Guidelines On Compressor Sizing and SelectionDocumento35 pagineGuidelines On Compressor Sizing and SelectionIan LuyaoNessuna valutazione finora

- Aerodynamics Imp QuesDocumento5 pagineAerodynamics Imp Quesranjeet_daheNessuna valutazione finora

- Radial - Flow: (Centrifugal Pump)Documento17 pagineRadial - Flow: (Centrifugal Pump)John A. CenizaNessuna valutazione finora

- 6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsDocumento9 pagine6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsdgkmurtiNessuna valutazione finora

- Wind Turbines: Drag or Lift Driven Horizontal or Vertical Axis (HAWT / VAWT) Small or LargeDocumento4 pagineWind Turbines: Drag or Lift Driven Horizontal or Vertical Axis (HAWT / VAWT) Small or LargeDanial KhanNessuna valutazione finora

- Selection of Taper Roller BearingsDocumento5 pagineSelection of Taper Roller BearingsJai SharmaNessuna valutazione finora

- Bapetco Final #2 Model AnswerDocumento10 pagineBapetco Final #2 Model AnswerKhaled AdelNessuna valutazione finora

- Storm Water Drainage SystemDocumento32 pagineStorm Water Drainage SystemshashidharsagarNessuna valutazione finora

- Back Pressure Calculation 1 PDFDocumento2 pagineBack Pressure Calculation 1 PDFRanu Januar100% (6)

- C410 963 A RA-635784 001 D: LegendsDocumento1 paginaC410 963 A RA-635784 001 D: LegendsmuthuvelaaNessuna valutazione finora

- Predicting Bottom-Hole Pressure For Gas and GasDocumento2 paginePredicting Bottom-Hole Pressure For Gas and GasLibya TripoliNessuna valutazione finora

- Petrophysics AND Reservoir Properties LaboratoryDocumento79 paginePetrophysics AND Reservoir Properties LaboratoryAmeer Bakry ZulkiffliNessuna valutazione finora

- Part 1 - Some FundamentalsDocumento10 paginePart 1 - Some FundamentalsMatsobane LekalaksNessuna valutazione finora