Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Earthing Design Case Study

Caricato da

JayadevDamodaranCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Earthing Design Case Study

Caricato da

JayadevDamodaranCopyright:

Formati disponibili

I nternational J ournal of Advanced Computer Research (I SSN (print): 2249-7277 I SSN (online): 2277-7970)

Volume-2 Number-4 I ssue-6 December-2012

237

Design of Earthing System for a Substation : A Case Study

O.P. Rahi

1

, Abhas Kumar Singh

2

, Shashi Kant Gupta

3

, Shilpa Goyal

4

Electrical Engineering Department, National Institute of Technology, Hamirpur, India

1,2,3,4

oprahi2k@gmail.com

1

, abhasnith@gmail.com

2

, skgsrmscet@gmail.com

3

, shilpa.nith@gmail.com

4

Abstract

This paper presents the design of earthing system for 132

KV substation and simulation for calculation of required

parameters. This paper is to provide information pertinent

to safe earthing practices in ac substation design and to

establish the safe limits of potential difference under

normal and fault conditions. The grounding grid system of

a practical 220 kV substation is calculated by MATLAB

program. The supporting data has been obtained from

actual field tested at the substation. Standard equations

are used in the design of earthing system to get desired

parameters such as touch and step voltage criteria for

safety, earth resistance, grid resistance, maximum grid

current, minimum conductor size and electrode size,

maximum fault current level and resistivity of soil. By

selection the proper horizontal conductor size, vertical

electrode size and soil resistivity, the best choice of the

project for safety is performed. This paper mentions the

calculation of the desired parameters which are simulated

by MATLAB program. Some simulated results are

evaluated.

Keywords

component; Safe earthing system, Grounding, resistivity , AC

substation, MATLAB program, Flowchart

1. Introduction

In substation earthing system is essential not only to provide

the protection of people working in the vicinity of earthed

facilities and equipments against danger of electric shock but

to maintain proper function of electrical system. Reliability

and security are to be taken in considerations as well as

adherence to statutory obligations (IEEE and Indian

standards on electrical safety [1-2] and environmental

aspects). Earthing system thus design must be easily

maintained and future expansion must be taken into account

while designing the dimensions of earth mat.

This paper is concerned with earthing practices and design

for outdoor AC substation for power frequency in the range

of 50 Hz. DC substation GIS and lightening effects are not

covered in this paper. With proper caution, the method

described here is also applicable to indoor portion of such

substation. By using proper conductor and electrode size,

earthing system may be able to overcome lightening effects.

2. Earthing system for a substation

A. Components of earthing system

An effective substation earthing system typically consists

of earth rods, connecting cables from buried earthing grid to

metallic parts of structures and equipments, connections to

earthed system neutrals, and the earth surface insulating

covering material briefly discussed in [1,3]. Current flowing

into the earthing grid from lightening arrester operation

impulse or switching surge flashover of insulators and line to

ground fault current from the bus or connected transmission

lines all cause potential differences between earthed points in

the substation. Without a properly designed earthing system,

large potential differences can exist between different points

within the substation itself. Under normal circumstances, it is

the current constitutes the main threat to personal.

B. Data needed for design of earthing

Substation grid area

Soil resistivity at the site

Fault clearing time

Maximum grid current

Resistivity of soil at surface

C. Factors on which design of earthmat depends

Materials used for earth electrodes and

conductors must be chosen carefully taking into

account physical, chemical and economical

constraints. Ground conductor must be adequate

for fault current (considering corrosion). Basic

requirements are thoroughly studied in paper

[4].

Conductor sizing depends on fault current and

conductivity as well as mechanical strength of

material used.

Resistivity of soil and surface layer determines

the STEP and TOUCH potentials, which

I nternational J ournal of Advanced Computer Research (I SSN (print): 2249-7277 I SSN (online): 2277-7970)

Volume-2 Number-4 I ssue-6 December-2012

238

determine safe values of operation as described

in reference [1, 5-9]. Also the multilayer

resistivity has been a subject of continuous

attention by the researchers [10-13].

A good grounding system provides a low

resistance in order to minimize GPR (ground

potential rise)[14].

Grid geometry is a major factor in determining

the step, touch and mesh potential contours and

current distribution in grid. The limitations on

the physical parameters of a ground grid are

based on economics and the physical limitations

of the installation of the grid.

D. Fault Clearing Time

The faults clearing time is governed by system stability

consideration and depend on protection and switchgear

equipment. Generally a value of 0.5 seconds is assumed.

The size of the conductor is based on a time of 1 second.

E. Determination of Maximum Grid Current

A single line to ground fault is more common and causes

more fault current as compared to a double line to ground

fault. Therefore , the design is based on single line to

ground fault current. For calculation of this current grid

resistance and fault resistance are assumed to be zero. Then

I

g

=S

f

I

f

Where

I

g

= symmetrical grid current , Amp

I

f

= rms value of symmetrical ground fault current,

Amp

S

f

= current division factor relating the magnitude of

fault current to that of its portion flowing in the earthing

grid.

Only a part of the total fault current flows through

the grid. The remaining current flows through the overhead

ground wires and other ground return paths. The factor S

f

gives this current division and can be calculated, if the

system data is known, from the value of I

g

the design value

of grid current is found as

I=G

f

D

f

I

g

Where

I= maximum grid current

G

f

= A factor to account for increase in fault current

due to system growth during life span of grid.

D

f

= Decrement factor to account for asymmetry of

the fault current wave.

Typical values of G

f

assumed in design, lie in the range

of 1.2 to 1.5 depending on the rate of growth of the system.

F. Selection of Electrode material

The material for grounding grid should have good

conductivity, be mechanically rugged and resist fusing and

deterioration of joints.

Copper was very commonly used in the past. It has high

conductivity and is resistant to underground corrosion.

However, a grid of copper forms a galvanic cell with other

buried structure and pipes and is likely to hasten the

corrosion of the latter. Aluminium is not used because of

corrosion problem.

3. Mathematical Description

G. Safe limits and values of potentials

The safety of a person depends on preventing the critical

amount of shock energy from being absorbed. The

maximum driving voltage of any accidental circuit should

not exceed the limits defined as follows.

The tolerable step voltage criteria is

The tolerable touch voltage criteria is

Where

C

s

= 1 for no protective surface layer

s

= the resistivity of the surface material in A-m

t

s

= duration of shock circuit in seconds

The minimum conductor size formula is mentioned below-

3)

Where

K

o

= 1/

o

or 1/

o

- T

r

t

c

= time of current flow in sec

TCAP = thermal capacity factor

For grounding resistance, the following formula is used

Where

= soil resistivity

L

t

= total length of grid conductor

A = total area enclosed by earth grid

h = depth of earth grid conductor

For calculation of grid current, equation (5) is used

I nternational J ournal of Advanced Computer Research (I SSN (print): 2249-7277 I SSN (online): 2277-7970)

Volume-2 Number-4 I ssue-6 December-2012

239

Where

I

g

= maximum grid current

3I

o

= symmetrical fault current in substation for Conductor

sizing in A

S

f

= current diversity factor

Equation (6) is expressed for grid potential rise (GPR)

Maximum attainable step and touch voltages are given by:

Formula for c-alculation of mesh and step voltage are

Where

= soil resistivity, ohms-m

E

m

= mesh voltage at the center of corner mesh

E

s

= step voltage between point

K

m

= spacing factor for mesh voltage

K

s

= spacing factor of step voltage

K

i

= correct factor for grid geometry

Where

D = spacing between conductor of the grid

d = diameter of grid conductor

K

m

= spacing factor for mesh voltage

K

ii

= 1 for grids with rods along perimeter

K

h

= Corrective weighting factor for grid depth

Where

D = spacing between conductor of the grid

h = depth of burial grid conductor

n = number of parallel conductor in one direction

The length required to keep mesh voltage within safe limits,

can be calculated by

(11)

If the length of conductor in the Preliminary design is less

than that given eqn. (11) a revision in design is necessary.

H. Design procedure

Values of maximum attainable touch voltages are calculated.

If the GPR of the preliminary design is below the tolerable

touch voltage, no further analysis is necessary. Only

additional conductor required to provide access to equipment

grounds is necessary.

If the computed mesh voltage is below the tolerable touch

voltage, the design may be complete. If the computed mesh

voltage is greater than the tolerable touch voltage, the

preliminary design should be revised. If both the computed

touch and step voltages are below the tolerable voltages, the

design needs only the refinements required to provide access

to equipment grounds. If not, the preliminary design must be

revised.

Further for the safe design we need to compare the length of

the electrode in the preliminary design to the length of the

electrode required to keep mesh voltage within safe limits

If either the step or touch tolerable limits are exceeded,

revision of the grid design is required. These revisions may

include smaller conductor spacing, additional ground rods,

and use of closer spacing of conductor. In case the length

given by eqn. (11) is too small to allow for connections to all

equipments, more conductor may be required even though it

is not necessary for safety ,etc as discussed in reference [1].

If the length of the conductor in the preliminary design is

less than the length required to keep mesh voltage within

safe limits. ,

then the design needs to be revised by entering

more number of electrodes or by decreasing spacing

between the conductors, otherwise the design is accurate.

Further, if the Ground Potential Rise (R*Ig) is less than the

tolerable value of touch potential then the design of the

electrical grid is considered to be safe otherwise we need to

guard personnel and other communication equipment

against transferred potential.

Checking of step Potential:-

The tolerable step potential and actual step potential can be

calculated from eqn (1) and eqn (8). If actual step potential

is more than tolerable, a revision in design is necessary. The

final step in design includes provision of closer meshes in

the area frequently visited by operating personnel, additional

ground rods for surge arrester leads, etc., and provision of

risers for connection to equipments.

Impulse behaviour of earthing system:

The degree of protection provided by an earthing system

under lightning discharge conditions depends on its impulse

impedance (i.e.,impedance under impulse conditions) and

not the power frequency resistance. The impulse impedance

is different from the power frequency resistance due to

effect of 1

st

soil ionization 2

nd

electrode inductance.

I nternational J ournal of Advanced Computer Research (I SSN (print): 2249-7277 I SSN (online): 2277-7970)

Volume-2 Number-4 I ssue-6 December-2012

240

When the magnitude of impulse current is high, the soil in

the vicinity of electrode may break-down causing a decrease

in resistance. When the length of electrode is large, its

inductance may cause only a part of the earthing system to

be effective in dissipating current and, thus result in an

increase in impedance.

The relative contributions of these two factors depend on the

type of earthing system. The effect of soil ionization is very

predominant in driven rods so that the impulse resistance of

a driven rod is always less than its power frequency

resistance.

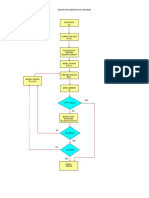

The whole procedure can be shown by this flowchart:

Input Net work t opology

, A

Comput e of Net work Conduct or

3Io , tc , d

Comput e of Touch and St ep Volt age

Etouch , Estep

Init ial design

D, n, L, h

Grid Resist ance

Rg, Lc, Lr

Grid current

IG, tf

Fig 1. Design procedure

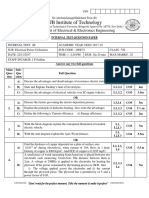

. Table I

Constant values for design calculations

Quantity Symbol Value

Ambient temperature T

a

40

Maximum allowable

temperature

T

m

620

Fault duration time t

s

1s

Thermal coefficient of

resistivity

r

0.0042

Resistivity of conductors

r

15

Resistivity of substation

soil

220

Resistivity of surface

material

s

3300

Thermal capacity factor TCAP 3.7490

Depth of burial conductor

h 0.6m

Diameter of grid

conductor

d 25mm

Length of one earth rod L

r

3m

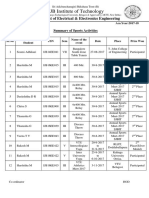

Table II

Output results for grid construction design

Quantity Symbol Value

Earth conductor size A

c

376.257

3

Maximum grid current I

G

15750

Ground resistance R

g

0.9646

Ground potential rise GPR 1512

Spacing factor for mesh

voltages

K

m

0.2244

Spacing factor for step

voltages

K

s

0.4338

Touch voltage criteria E

touch

689.97

Step voltage criteria E

step

2267.72

Maximum attainable step

voltage

E

s

1453.93

Maximum attainable

mesh voltage

E

m

581.61

4. Result

These results are obtained by a MATLAB program.

Comput e of Real Net work volt ages

Em, Es, Km, Ks, Ki, Kii, Kh

Invest igat e of Design and it s Det ails

St udies

IG.Rg <Etouch

Em<ETouch

Em <EStep

Modify design

D,n, Lc,h

YES

NO

NO

I nternational J ournal of Advanced Computer Research (I SSN (print): 2249-7277 I SSN (online): 2277-7970)

Volume-2 Number-4 I ssue-6 December-2012

241

Fig. 2 Mesh Voltage with Different Values of Spacing

Between Conductors.

Fig. 3 Grid Potential Rise with Different Values of

Resistivity of Soil

5. Significance and Touch Voltage

The step and touch voltages are dangerous for human body.

Human body may get electric shocks from step and touch

voltages. From the safety point of view it is necessary to

calculate step and touch voltage. When high voltage

substations are designed step and touch voltages should be

calculated and must be in specified standard. The expected

shock current caused by touch voltage can be effectively

limited by applying inexpensive insulating layers on the

earths surface .The limits of step and touch potentials varies

in different seasons because the resistivity of the soil layer is

affected by different seasons .The step and touch voltage

calculations are very significant while designing substation.

6. Conclusion

This paper has a focus on designing of an AC

substation.The results for earthing system design are

obtained by MATLAB program for earthing conductor and

vertical earth electrode mild steel is used.

ACKNOWLEDGEMENT

The author wish to thank Er. O. P. Rahi for his guidance and

moral support provided during this research effort, and Dr.

M.G.Sharma for helping with substation data.

References

[1] N.M. Tabatabaei, S.R. Mortezaeei; Design of Grounding

System in

Substation by ETAP Intelligent Softwere,IJTPE Journal,

March 2010, Page(s):45-49

[2] Chae-Kyun Jung; Jong-kee choi; Ji-won Kang, A study on

effect of grounding system on transient voltage in 154kV

Substation, IEEE Conference Publications, 2009, Page(s): 1-

6

[3] Ladanyi, J. Survey of the equivalent Substation earth current

and earth impedance for transformer Station, IEEE

Conference Publications, 2011, Page(s): 1-5

[4] Lee, C.H; Lin, S. D., Safety assesment of AC earthing

system in a DC traction-supply Substation, IEEE Journals,

2005, Page(s): 885-893

[5] IEEE Std. 80-2000, IEEE Guide for Safety in AC Substation

Grounding, IEEE: Institute of Electrical and Electronic

Engineers, Inc., New York, 2000, Page(s) 1- 192

[6] F. Gatta, S. Lauria, G. Parise, Common grounding system in

urban areas (in italian), Conference on Safety in complex

system-Bari (Italy) 16-17 October 2003.

[7] K. M. Bhatia and B. K. Jain, Standardization in the Field of

Electrical Safety.

[8] IEEE Std. 142-2007, IEEE Recommended Practice for

Grounding of Industrial and Commercial Power System,

IEEE: Institute of Electrical and Electronic Engineers, Inc.,

New York, 2007. Page(s): 1-215

[9] Brian Allport, Practical considerations (substation earthing),

VA TECH Reyrolle Transmission.

[10] H.B. Dwight, "Calculations of Resistances to Ground", AIEE

Transactions, December 1936, pp.1319-1328.

[11] J. Nohman and S. Skuletich, "Irregularity Correction Factors

for Mesh and Step Voltages of Grounding Grids", IEEE

Transactions on Power Apparatus and Systems, vol. PAS-99,

No. 1, 1980,pp 174-180.

[12] Thapar, B., Gerez, V., Balakrishnan, A., and Blank, D.,

Simplified equations for mesh and step voltages in an AC

substation, IEEE Trans. Power Delivery, 6, 601607, 1991

[13] R. J. Heppe, Computation of potential at surface above an

energized grid or other electrode, allowing for nonuniform

current distribution, IEEE Trans. on PAS, vol. 98, no. 6, pp.

19781989, Nov.Dec. 1979.

[14] Marlar Thein oo, Ei Ei Cho,Design of earthing system for

new substation project , Myanmar.

I nternational J ournal of Advanced Computer Research (I SSN (print): 2249-7277 I SSN (online): 2277-7970)

Volume-2 Number-4 I ssue-6 December-2012

242

[15] S. J. Schwartz, "Analytical Expression for Resistance of

Grounding Systems", AIEE Transactions, vol. 73, Part 111-B,

1954, pp. 1011-1016.

[16] F. P. Dawalibi and D. Mukhedkar, Optimum design of

substation grounding in two-layer earth structurePart I,

Analytical study, IEEE Trans. on PAS, vol. 94, no. 2, pp.

252261, Mar.Apr. 1975.

[17] Xun Long; Ming Dung; Wilsun Xu ; Yun Weili, Omline

Monitoring of Substation Grounding Grid Conditions Using

Touch and Step Voltage Sensors, IEEE Journals, 2012,

Page(s):761-769

[18] Hernandez Martinez.G.; Venegas Rehollar, V., Design and

Simulation of a grounding grid for GIS Substation IEEE

Journals, 2008, Page(s): 137-143

[19] Dwarka Prasad, H.C. Sharma; Significance of Step and

Touch voltages, (IJSCE) Volume-1, Issue-5, November

2011

Om Prakash Rahi was born in Kullu (H.P.),

India. He received the B.Tech. degree from REC

Hamirpur (HP), India, in 1992, and the M.E.

degree in Electrical Power Systems from Punjab

Engineering College, Chandigarh, in 1997. He

joined Government Polytechnic, Sundernagar

(HP) as Lecturer in 1997. Since 2000, he has

been working as Lecturer in the Electrical

Engineering Department, National Institute of Technology,

Hamirpur, H.P., and India. He has published a number of research

papers. His research interests are in the area of Condition

Monitoring of Power Transformers, Deregulation of Power and

Hydro Power Development.

Abhas Kumar Singh was born in Ambikapur

(Surguja) C.G., India. He received the 3 year

Diploma in Electrical Engg. from Govt.

Polytechnic College Ambikapur India, in 2007

and the B.Tech. degree in Electrical and

Electronics Engineering from Shri

Shankaracharya College of Engg. & Tech.

Bhilai, India, in 2010.He is currently pursuing

the M.Tech. degree in Power System from National Institute of

Technology, Hamirpur.

Shashi Kant Gupta was born in Obra (Uttar

Pradesh), India. He received the B.Tech. degree

in Electrical and Electronics Engineering from

S.R.M.S.C.E.T. Bareilly (UP), India, in 2010.

He is currently pursuing the M.Tech. degree in

Power System from National Institute of

Technology, Hamirpur.

Shilpa goyal was born in Chandigarh . She

received the B.Tech. degree in Electrical and

Electronics Engineering from NIT Hamirpur in

2010. She is currently working in Infosys.

Authors Photo

Authors Photo

Authors Photo

Authors Photo

Potrebbero piacerti anche

- Improved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationDocumento9 pagineImproved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Substation Grounding Training ManualDocumento22 pagineSubstation Grounding Training ManualWilheim Janssen GoNessuna valutazione finora

- Grounding EarthingDocumento5 pagineGrounding EarthingNuri BerishaNessuna valutazione finora

- Earthing CalculationDocumento250 pagineEarthing CalculationJeremy HensleyNessuna valutazione finora

- IEEE Design and Optimize Subs Grounding Grid MatlabDocumento7 pagineIEEE Design and Optimize Subs Grounding Grid MatlabKesavanNessuna valutazione finora

- Modern Approach To Earthing System Design and Its AnalysisDocumento7 pagineModern Approach To Earthing System Design and Its AnalysisDoly DamanikNessuna valutazione finora

- 66kv Earthing System R-1 (For Print Out)Documento8 pagine66kv Earthing System R-1 (For Print Out)g_nraja100% (1)

- Quick Guide On CDEGS CRDocumento28 pagineQuick Guide On CDEGS CRrian0201100% (1)

- Grounding System For High Resistivity Limited Area Substations in Hilly Region of Himachal PradeshDocumento7 pagineGrounding System For High Resistivity Limited Area Substations in Hilly Region of Himachal Pradeshostojic007Nessuna valutazione finora

- Earthing Ieee80-Pmu GambangDocumento10 pagineEarthing Ieee80-Pmu GambangMohamad HishamNessuna valutazione finora

- Earthmat Calculations For WTG HT YardDocumento3 pagineEarthmat Calculations For WTG HT YardSanthosh KumarNessuna valutazione finora

- SS Earthing Mat Design 22 8 12Documento7 pagineSS Earthing Mat Design 22 8 12Vishal ThakurNessuna valutazione finora

- Substation Earthing by JGNDocumento49 pagineSubstation Earthing by JGNrupamNessuna valutazione finora

- Effect of High Resistive Barrier On Earthing System: Abstract: Substation Earthing Provides A LowDocumento4 pagineEffect of High Resistive Barrier On Earthing System: Abstract: Substation Earthing Provides A Lowalcie_scribdNessuna valutazione finora

- 1 Earth Testing 2010Documento68 pagine1 Earth Testing 2010Ramy DiabNessuna valutazione finora

- Earthing DesignDocumento40 pagineEarthing DesignSanjeev Kumar100% (1)

- EARTHING DESIGN CALCULATIONDocumento10 pagineEARTHING DESIGN CALCULATIONarafinNessuna valutazione finora

- Measurement of Earth ResistanceDocumento34 pagineMeasurement of Earth ResistanceYousefHassanNessuna valutazione finora

- Grounding Bonding For Substation CommunicationsDocumento54 pagineGrounding Bonding For Substation CommunicationsAlbieNessuna valutazione finora

- Power Systems Study Specifications XXXDocumento8 paginePower Systems Study Specifications XXXharmlesdragonNessuna valutazione finora

- BSF Earthing System Calculation 1Documento29 pagineBSF Earthing System Calculation 1Veerasamy KarikalvalavanNessuna valutazione finora

- Earthing Calculation - Grid (Exm)Documento33 pagineEarthing Calculation - Grid (Exm)balaeee123Nessuna valutazione finora

- Assessment of Soil Resistivity On Grounding of Electrical Systems: A Case Study of North-East Zone, NigeriaDocumento10 pagineAssessment of Soil Resistivity On Grounding of Electrical Systems: A Case Study of North-East Zone, NigeriaJornal of Academic and Applied StudiesNessuna valutazione finora

- To Check The Reliability of Different Power Sources and Bus Bar Schemes Using EtapDocumento83 pagineTo Check The Reliability of Different Power Sources and Bus Bar Schemes Using EtapMuhammad MudassarNessuna valutazione finora

- Substation GroundingDocumento19 pagineSubstation GroundingDev SwainNessuna valutazione finora

- Design procedure block diagram earth calculationDocumento10 pagineDesign procedure block diagram earth calculationWaleed BASALAMANessuna valutazione finora

- 02 Earthing SystemsDocumento113 pagine02 Earthing Systemsagent42505100% (1)

- IEEE 1850 GroundGridCalcsDocumento11 pagineIEEE 1850 GroundGridCalcsaabts1413Nessuna valutazione finora

- System Neutral EarthingDocumento70 pagineSystem Neutral Earthingsorry2qazNessuna valutazione finora

- Chapter 17 - NT PWC SDM Substation Layouts and Facilities - Outdoor Section Rev 2 - 17-1-2012Documento12 pagineChapter 17 - NT PWC SDM Substation Layouts and Facilities - Outdoor Section Rev 2 - 17-1-2012Punit RatnaniNessuna valutazione finora

- Determining Cross Section Area of The Protective ConductorDocumento4 pagineDetermining Cross Section Area of The Protective ConductorS Amila C RajapaksaNessuna valutazione finora

- Lightning Protection in SubstationsDocumento31 pagineLightning Protection in Substationsvikasrajput198971% (7)

- System earthing methods comparisonDocumento14 pagineSystem earthing methods comparisonsubhranil157Nessuna valutazione finora

- Presentation On Insulation CoordinationDocumento17 paginePresentation On Insulation CoordinationBhavik PrajapatiNessuna valutazione finora

- Is 2309 1989Documento72 pagineIs 2309 1989Jagdish PalariyaNessuna valutazione finora

- Selecting Arrester MCOV-UcDocumento9 pagineSelecting Arrester MCOV-Ucjose GonzalezNessuna valutazione finora

- Quick Guide On Cdegs CRDocumento28 pagineQuick Guide On Cdegs CRGilberto MejíaNessuna valutazione finora

- Building Arrangement Iec61936-2002Documento5 pagineBuilding Arrangement Iec61936-2002Cinar InalNessuna valutazione finora

- Grounding electrical systems safetyDocumento3 pagineGrounding electrical systems safetyMiko Quijano100% (1)

- Underground Duct Banks and Raceways - Electrical Design GuideDocumento2 pagineUnderground Duct Banks and Raceways - Electrical Design GuideDaniel BolivarNessuna valutazione finora

- Ect129 Uninterruptible Static Power Supplies and The Protection of PersonsDocumento44 pagineEct129 Uninterruptible Static Power Supplies and The Protection of PersonsMarko VujicaNessuna valutazione finora

- Direct Stroke Lightning Protection Calculation For 110Kv Switchyard by Lighting Mast ReferenceDocumento11 pagineDirect Stroke Lightning Protection Calculation For 110Kv Switchyard by Lighting Mast ReferenceneerajNessuna valutazione finora

- Earthing SystemDocumento22 pagineEarthing Systemashokparikh100% (2)

- Knowledge is "Real Power": Introduction to Power QualityDa EverandKnowledge is "Real Power": Introduction to Power QualityNessuna valutazione finora

- Design of Earthing System For A Substation: A Case StudyDocumento6 pagineDesign of Earthing System For A Substation: A Case StudyHimanshu RanjanNessuna valutazione finora

- EE161027 (Assignment#02)Documento10 pagineEE161027 (Assignment#02)candylandkefantyNessuna valutazione finora

- Grounding - Earthing - Grounding Grid Study GuideDocumento11 pagineGrounding - Earthing - Grounding Grid Study GuideSridharan Priyadharsen100% (1)

- ## Etap Earth Sample PDFDocumento5 pagine## Etap Earth Sample PDFdcf67myNessuna valutazione finora

- Design of Earthing System For HVDocumento22 pagineDesign of Earthing System For HVAshwani Dogra100% (1)

- Earth MatDocumento6 pagineEarth MatSmitha PatelNessuna valutazione finora

- Grounding Design Using Optimization MethodDocumento12 pagineGrounding Design Using Optimization MethodharyhaysNessuna valutazione finora

- Substation Earthing Design: Akshay PatilDocumento6 pagineSubstation Earthing Design: Akshay PatilSunil SinghNessuna valutazione finora

- E1 PDFDocumento14 pagineE1 PDFSunilNessuna valutazione finora

- Design of Earthing SystemDocumento5 pagineDesign of Earthing SystemNishant SinhaNessuna valutazione finora

- CYMGRD Optimal Design of Substation Grounding GridsDocumento5 pagineCYMGRD Optimal Design of Substation Grounding Gridsjaneth lozanoNessuna valutazione finora

- Keywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDocumento6 pagineKeywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDebasish RahaNessuna valutazione finora

- Vol4no2 2 PDFDocumento8 pagineVol4no2 2 PDFyasser awwadNessuna valutazione finora

- Cyme GridDocumento6 pagineCyme Gridprabhakaran_hdec100% (1)

- Grounding: Egbodor Peter UwhubetineDocumento18 pagineGrounding: Egbodor Peter UwhubetineEgbodor Peter100% (1)

- Solution Manual for 100 Genesys Design Examples: Second EditionDa EverandSolution Manual for 100 Genesys Design Examples: Second EditionNessuna valutazione finora

- New Microsoft Word DocumentDocumento2 pagineNew Microsoft Word DocumentjpsridharNessuna valutazione finora

- SubjectsAnalog CircuitsDocumento4 pagineSubjectsAnalog CircuitsjpsridharNessuna valutazione finora

- SJB Institute of Technology: Department of Electrical & Electronics EngineeringDocumento1 paginaSJB Institute of Technology: Department of Electrical & Electronics EngineeringjpsridharNessuna valutazione finora

- Contents PDFDocumento9 pagineContents PDFjayashreeNessuna valutazione finora

- SJB Institute of Technology: Department of Electrical & Electronics EngineeringDocumento1 paginaSJB Institute of Technology: Department of Electrical & Electronics EngineeringjpsridharNessuna valutazione finora

- Ch-3 ElectrolysisDocumento6 pagineCh-3 ElectrolysisjpsridharNessuna valutazione finora

- SJB Institute of Technology: Department of Electrical & Electronics EngineeringDocumento1 paginaSJB Institute of Technology: Department of Electrical & Electronics EngineeringjpsridharNessuna valutazione finora

- DC MACHINES TESTDocumento1 paginaDC MACHINES TESTjpsridharNessuna valutazione finora

- SJB Institute of Technology: Department of Electrical & Electronics EngineeringDocumento1 paginaSJB Institute of Technology: Department of Electrical & Electronics EngineeringjpsridharNessuna valutazione finora

- Res Test III 15ee563Documento1 paginaRes Test III 15ee563jpsridharNessuna valutazione finora

- Updated Sports Actvities 2017-18Documento5 pagineUpdated Sports Actvities 2017-18jpsridharNessuna valutazione finora

- Res Test III 15ee563Documento1 paginaRes Test III 15ee563jpsridharNessuna valutazione finora

- Ch-3 ElectrolysisDocumento6 pagineCh-3 ElectrolysisjpsridharNessuna valutazione finora

- Ch-3 ElectrolysisDocumento6 pagineCh-3 ElectrolysisjpsridharNessuna valutazione finora

- P.HD Course Work SyllabusDocumento2 pagineP.HD Course Work SyllabusjpsridharNessuna valutazione finora

- Upqc Block DiagramDocumento3 pagineUpqc Block DiagramjpsridharNessuna valutazione finora

- Basic Electrical Engineering10ELE25Documento78 pagineBasic Electrical Engineering10ELE25jpsridharNessuna valutazione finora

- Title of The Paper (24 Font) : Name of The Author, Name of The Author, Name of The Author (12 Font)Documento1 paginaTitle of The Paper (24 Font) : Name of The Author, Name of The Author, Name of The Author (12 Font)jpsridharNessuna valutazione finora

- Power QualityDocumento218 paginePower QualityjpsridharNessuna valutazione finora

- Viva QuestionsDocumento16 pagineViva Questionsjpsridhar100% (1)

- Ies 2013Documento4 pagineIes 2013jpsridharNessuna valutazione finora

- Paper On IMDocumento5 paginePaper On IMjpsridharNessuna valutazione finora

- Certificate VtuDocumento1 paginaCertificate VtujpsridharNessuna valutazione finora

- Rules and RegulationsDocumento2 pagineRules and RegulationsjpsridharNessuna valutazione finora

- IES ESE 2012 Solution Ee Paper2Documento2 pagineIES ESE 2012 Solution Ee Paper2jpsridharNessuna valutazione finora

- Substation EarthingDocumento6 pagineSubstation Earthingjpsridhar100% (1)

- Conv Elect I PDFDocumento12 pagineConv Elect I PDFsuperkan619Nessuna valutazione finora

- Mini ProjectDocumento2 pagineMini ProjectjpsridharNessuna valutazione finora

- Applications of DSPDocumento6 pagineApplications of DSPjpsridharNessuna valutazione finora

- Workshop Shedule Foe CommunicationDocumento1 paginaWorkshop Shedule Foe CommunicationjpsridharNessuna valutazione finora