Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hydrostatic and Settlement Tests Procedure

Caricato da

ツ ツCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hydrostatic and Settlement Tests Procedure

Caricato da

ツ ツCopyright:

Formati disponibili

HYDROSTATIC AND

SETTLEMENT TESTS

PROCEDURE

Bina Consulting Stone & Webster

RnPineera T.imited

BCE Job no: LAJ950133

SWL Job no: 123065

OLEFIN PLANT

Ilam Petrochemical Complex

Hydrostatic and Settlement Tests

Procedure

&

A

National Petrochemical Co.

DOC. no. :I 0-VD-PCJ-QC-351144

Rev. no. : 2

Sheet no. : 1 1 11+1

Hydrostatic And

Settlement

Tests

Procedure

CLIENT : ILAM Petrochemical Company

Prj. Doc. NO.

: 10-VD-PCJ -QC-351144

ILAM ETHYLENE PLANT-ILAM OLEFIN COMPLEX

02 1.Mar.09 For Approval

R.N

Tech.

Dep.

A.S

01 28.Dec.08 For Approval R.N

Tech.

Dep.

A.S

MFS DOC.NO: MFS PR-HT(I L)-86-06-441 (02) Rev. Date Description Prepare. Chk. App.

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 2 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

CONTENT

1.0 Scope 3

2.0 Applicable Codes and Standards 3

3.0 Test Stages 3

4.0 Sequence of Work 4

5.0 Water 5

6.0 Method 5

7.0 Assessment and Report 10

8.0 Cleaning 10

Level Reference Table 11

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 3 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

This procedure briefly describes the general methods to be performed for Hydrostatic and

Settlement testing after completing welding operation and performing required N.D.T.

Test for Storage Tanks.

Before hydrostatic test, reports of all inspection and test as per relevant QCP such as joint

history N.D.T map, punch list, test certificate, general drawing etc. approval by the

owners representative shall be provided.

1.0. Scope

The purpose of performing following test is to controlling and measuring any changes to

body and foundation level and also to prove integrity of Storage Tanks body.

This document applies to Nine Storage Tanks of OLEFIN PLANT ILAM

PETROCHEMICAL COMPLEX.

After completing erection and performing required Tests, Visual Inspection, Vacuum

Box Testing, Pneumatic Test, Hydrostatic operation and settlement test will be

performed. Accoding Applicable codes and standards as defined in item 20.

2.0. Applicable codes and standards

API 650 Welded Steel Storage Tanks.

API 653 Tank Inspection, Repair, Alternation and Reconstruction.(Appendix B.)

Client Documents and specification No: 10-00-spc-ME-1003 Rev.c

3.0. Test Stages

This test will divide to following mentioned stages:

Test preliminaries such as visual inspection.

Inspection of Tank Bottom Welds (Vacuum Box Testing)

Inspection of Reinforcement-Plate Welds (Pneumatic Testing)

Testing of the Shell (Hydrostatic Testing)

It must be mentioned all of the mentioned test must perform after controlling all of the

N.D.T. test reports.

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 4 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

4.0. Sequence of Work

Water Filling

Holding Stage

Cleaning and Drying

Settlement

Monitoring

N.D.T Test records

Holding Stage

Water Discharge

Holding Stage

Emptying Stage

Settlement

Monitoring

Leak test

Hydrostatic Test

Holding Stage

Holding Stage at 1/2 Ht

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 5 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

5.0. Water

For accomplishment of hydrostatic test, storage tanks must filled with plant water and

prior to filling the Storage Tank with water.

TEST METHODS IN ACCORDANCE WITH API 650

6.0. Method

Describing inspection and test methods for following fixed & floating roof storage tanks,

which were fabricated and tested in accordance with API 650:

C5+Feed Tank (TK-031) Floating Roof

Pyrolysis Gasoline Tank (TK-903 A/B) Floating Roof

Benzene Stripper Feed Tank (TK-985)

Chemical Waste Neutralisation Tank (TK-984)

Caustic Tank (TK-981)

Spent Caustic Holding Tank (TK-941)

Fuel Oil Storage Tank (TK-904)

Sulphuric Acid Storage Tank (TK-982)

6.1. Test Preliminary

6.1.1. Visual Examination

All of the weld seams of bottom plates must be visually inspected. This inspecting shall

meet the following requirements:

6.1.1.1. The surface of weld lines must free from cavities and construction derbries using

trains of pigs fitted with brushes.

6.1.1.2. There must not be any pronounced lumps or cavities, which have been caused by

starting or finishing a weld bead.

6.1.1.3. Welds must free from under cutting. The height and spacing or ripples must be

uniform. For welds that attach nozzles, manholes and cleanout openings.

6.1.1.4. The profile of fillet welds must be uniform and surface of the weld must slightly

convex and free from over lap at the toes of weld lines.

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 6 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

If any problems meet in visual inspection, following corrective action must be performed

before starting next stage of the test:

Removing all of the defects by using mechanical means or thermal gouging processes.

Repairing arc strikes which have been discovered in or adjacent to weld lines by

grinding and re-welding as required.

The repaired weld shall be visually examined for defects.

6.2. Inspection of Tank Bottom Welds by performing Vacuum Box Test:

After termination of visual inspection and cleaning above-mentioned surfaces, or

performing corrective action, vacuum box testing will be executed by using following

methods:

6.2.1. Vacuum testing is conveniently performed by using a testing Box with about15 cm

wide and 75 cm long with a glass window in the top and sealing the open bottom

with using a sponge-rubber gasket and suitable connections. Suitable connection

valves and gauges shall be provided on it.

6.2.2. Approximately 75 cm of the seam under test, must brushed with a soap solution or

linseed oil. In freezing weather, a non-freezing solution may be necessary. The

vacuum box will place over the coated section of the seam, and vacuum will apply

to the box. Bubbles will indicate the presence of porosity in the seams or foam,

which was produced by air sucked through the welded seam.

6.2.3. A vacuum can be drawn on the box by any convenient method, such as connection

to a gasoline- or diesel motor intake manifold or to an air ejector or special

vacuum pump.

6.2.4. As an alternate to vacuum box testing, a suitable tracer gas and compatible

detector can be used to test the integrity of welded bottom joints for their entire

length provided that an appropriate tracer gas testing procedure has been reviewed

an approved by the purchaser.

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 7 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

6.3. Inspection of Reinforcement-Plate Weld

After completing fabrication and prior to filling the tanks with water for performance of

hydrostatic test, all of the reinforcements shall be tested by pneumatic method.

Applying up to 100 Kpa Pressure between the tanks shell and openings reinforce pads,

with using contrived telltale holes on pads, and covering all of the attachments and

welding around the reinforce pads by suitable material such as a soap film or linseed oil.

If weld joints contained any defect, bubbles will appeared on the covered material.

Suitable convenient method shall be applied for repairing all of the existent defects.

6.4. Testing of the Shell by using Hydrostatic Test Method

After the entire tank is completed but before any permanent external piping is connected

to the tank, the shell shall be tested by Hydrostatic Testing. This Test must be performed

after completing tank fabrication and finishing all of the welding operation and

Radiographic Test, prior to painting and / or insulation.

Hydrostatic testing methods consist of filling a Tank System with (Water) containing a

max of 25 ppm chloride up to high liquid level or over flow nozzle, until a certain

pressure is reached, and observing. A loss of liquid pressure can be attributed to a leak, a

decrease in liquid temperature, distortion due to the pressure, or trapped vapor.

During test operation, inspector should check for conformity with design drawings and

specification, accessibility of valves, controls and gages and proper installation of water

pumps. All equipment should be checked for correct identification and operating

instructions.

Water supply pipe work should be flushed thoroughly at the maximum practicable rate of

flow, before connection is made to system piping, in order to remove foreign materials

which may have interred during installation or which may have accumulated in the mains

system at lower rates of flow. The minimum rate of flow for flushing should be not less

than the water demand rate of the system.

Filling operation and method will be according to clause 6.4.3 of this procedure.

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 8 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

6.4.1. Hydrostatic Test provision

6.4.1.1. Interior of the tanks shall be free from greases, weld spatter, scale, slag, rust and

any other foreign matter and broom swept.

6.4.1.2. Roof manhole (as vent) shall be open during of filling and emptying operation

(very important).

6.4.1.3. All appurtenances inside of the tanks such as coils or pipe supports shall have

been installed.

6.4.1.4. Settlement monitoring devices shall be provided prior to filling water.

6.4.1.5. Permanent or temporary tank level gauges shall be provided to monitor the water

level.

6.4.1.6. Cleaning Surfaces (Internal / External) completely and pips and fittings should

be carefully cleaned before assembly and any loose jointing material should be

removed.

6.4.1.7. Installing of valves and fittings.

6.4.1.8. Installing pressure gauges.

6.4.1.9. Temporary water piping and pumps for filling and discharging shall be installed

from the tank to water supply point and disposal point.

6.4.1.10. Hydrostatic test shall be commenced and finished during day lights hours.

6.4.1.11. Hydrostatic test chart(time &levels)shall be provided.

6.4.2. Type of settlement :

Type of settlement will be according to API653 Appendix B, clause B2 and should be

recorded upon related formats.

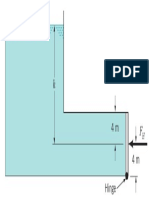

6.4.3. Settlement Monitoring:

To restrain and monitoring foundation settlement, according to following mentioned

method, filling will be done under controlled condition, which was measured with

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 9 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

concerning speculation upon soil settlement and soil bearing capacity which have been

concluded from ground research.

Considering and marking 12 points (0, 30, 60, 90, 120, 150, 180, 210, 240, 270,

300, 330) around storage tank base ring as leveling references and measuring the

elevation with 1mm accuracy with dial gauge. Before filling tanks with water the level at

each mentioned reference point will be registered. Permanent reference level will be

established in unaffected location of tanks (Bench Mark). Gauge contact surfaces should

be provided with glued glass plates or similar for a smooth contact.

6.4.4. Filling

6.4.4.1. Filling operation

The test water shall be filled slowly until the water level reaches minimum 300 mm

height. The water-filling rate shall not exceed 900 mm depth per hour, and then inlet

nozzle shall be gradually opened and continuing filling operation. Water will be filled in

to the tanks by approximately filling rate about 900mm /hr, until water level reach

to1/3Ht, at such a head, filling will stop for 6 hours and level at the reference points will

be recorded.

Continuing filling operation with 900mm/hr water flow rate up to water level reached to

2/3Ht of required hydro test level at such a head, filling will stop for 12 hours and levels

will be measured and checked and comparing with registered measure before start of

filling (while tanks were empty) to ensure that uneven settlement have not occur. In this

situation, filling will proceed by the same rate up to water leveled reached to required

height. Each day levels at reference points will register and recorded. (Refer to page 12

for filling diagram).

The filled tanks will be maintained for 24 hours and provided levels remain

consistent, the tank can be off loaded prior to calibration for service.

As filling of tanks, according to the mentioned method, will be done gradually and in

steps, it prevents non-uniform settlement.

During hydro test and after finishing of each one of filling steps or emptying stages,

checking will be made on followings:

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 10 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

Settlement Monitoring

All shell welding joints lower than liquid level

Corner joints including the fillet weld between shell and bottom, which shall visually

check for water tightness.

Shell roundness

Note: For repair of any leakage ad weld, water level shall be drained 330 mm below the

failure point and after repair, hydrostatic test shall re-started from actual level.

It must be mentioned prior to the roof installation, fixed roof column supports shall be

inspected for plumbness and tank shells shall be inspected for distortion or ovalization.

Roof support columns which are out-of-plumb by more than 15mm in every 3m and/or

more than 60mm for the total length shall be realigned.

7.0. Assessment and Report

Gauge measurements and visual inspection shall be assessed and reported together with

measurement records, including gauge plots relative to water levels.

The measurement records shall be issued to the engineering manager and company and

the engineering manager shall review and interpret measurement records if anomalies are

happened, the engineering manager shall instruct the site immediately to stop the water

filling, and shall discuss with Company.

8.0. Cleaning

The tanks shall be completely drained and thoroughly dried immediately after hydrostatic

Test. If necessary during discharging the test water, put the inflatable boat on the test

water and brushing the wall by using the boat as water level goes down.

After the tanks were emptied, surfaces of the bottom plates shall be cleaned with fresh

water. Water, which will be used for cleaning, shall be same quality as test water. All

sand, sludge and rubbish shall be removed from the tanks bottom.

After final draining and drying, brushing, broom or vacuum cleaner shall clean surface of

the tanks bottoms.

Masnouat Felezi Sangin

OLEFIN PLANT

Ilam Petrochemical

Complex

National Petrochemical Co.

Doc. No. : 10-VD-PCJ-QC-351144

Hydrostatic And

Settlement Test Procedure

Rev. No. : 02

Sheet no. : 11 / 11

\\Server\Users New\monshi\Monshi\SAYER MON 1 Projects\Olefin Petroshimi Ilam\procedure\ITP-02.doc

Level Refrence Table

Reference Point Height of Level Indicator Date Time

0

30

60

90

120

150

180

210

240

270

300

330

Potrebbero piacerti anche

- Water Fill Up Testing Procedure-R3 07.07.2011sohar 2Documento7 pagineWater Fill Up Testing Procedure-R3 07.07.2011sohar 2AjeetKumarNessuna valutazione finora

- Tank Field Inspection and Test ProcedureDocumento29 pagineTank Field Inspection and Test Proceduresbmmla91% (22)

- Hydrotest Procedure For PipingDocumento4 pagineHydrotest Procedure For Pipingsuria qaqcNessuna valutazione finora

- Pressure Testing of API TanksDocumento7 paginePressure Testing of API TanksRakesh Ranjan50% (2)

- Inspection and Test Plan For Storage TankDocumento7 pagineInspection and Test Plan For Storage Tankgst ajahNessuna valutazione finora

- Vessel Cleaning ProcedureDocumento6 pagineVessel Cleaning ProcedureZool HilmiNessuna valutazione finora

- Itp - Tanks - 01Documento10 pagineItp - Tanks - 01ravigurajapuNessuna valutazione finora

- Welding Report For PipingDocumento1 paginaWelding Report For PipingRifki HasyaNessuna valutazione finora

- SCTPL Q SP 002 A1 Vaccum Box Testing ProcedureDocumento6 pagineSCTPL Q SP 002 A1 Vaccum Box Testing ProcedureKandula Raju100% (1)

- Shop Fabrication Procedure (Supply of Tank Option#3) PDFDocumento7 pagineShop Fabrication Procedure (Supply of Tank Option#3) PDFGATOTNessuna valutazione finora

- 5 - Tank Itp - Inspection & Test Plan For TanksDocumento10 pagine5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- ONS-09-0-PR-5254 - R3 ITP For Atmospheric Tank Work - AFCDocumento34 pagineONS-09-0-PR-5254 - R3 ITP For Atmospheric Tank Work - AFCshankarmech04@gmail.comNessuna valutazione finora

- Itp For Storage TanksDocumento7 pagineItp For Storage TanksHamid MansouriNessuna valutazione finora

- ITP Heat ExchangerDocumento3 pagineITP Heat ExchangerĐỗ Thị Huyền100% (3)

- Itp Internal CoatingDocumento4 pagineItp Internal CoatingkamlNessuna valutazione finora

- ID-PRC 21 - Anti-Corrosion Wrapping UG Steel PipingDocumento10 pagineID-PRC 21 - Anti-Corrosion Wrapping UG Steel Pipingcloud23Nessuna valutazione finora

- 10) Itp - Tank Fabrication PDFDocumento6 pagine10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- 16 JRTP 02 ITP - Rev01Documento13 pagine16 JRTP 02 ITP - Rev01khsaeed100% (1)

- Itp For Tank Fabrication & Installation Work1 - Rev02Documento22 pagineItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- Inspection Test Plan For Pipeline JobsDocumento6 pagineInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNessuna valutazione finora

- 24.tank Oil Chalk TestDocumento3 pagine24.tank Oil Chalk TestShubham ShuklaNessuna valutazione finora

- Tank Erection ProcedureDocumento29 pagineTank Erection ProcedureVisas Siva100% (3)

- Itp-Fbe Pipe CoatingDocumento4 pagineItp-Fbe Pipe CoatingpertmasterNessuna valutazione finora

- Hydrostatic Test ProcedureDocumento9 pagineHydrostatic Test ProcedureMohammed Kamal83% (12)

- Holiday Testing ProcedureDocumento1 paginaHoliday Testing ProcedureSyed Zakiuddin100% (2)

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocumento19 pagineHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNessuna valutazione finora

- Inspection and Test Plan For Storage TankDocumento6 pagineInspection and Test Plan For Storage Tankpluton1954Nessuna valutazione finora

- Tank Erection Procedure: Note: This Is The Sample Document For The Related Job OnlyDocumento5 pagineTank Erection Procedure: Note: This Is The Sample Document For The Related Job Onlygeorge israelNessuna valutazione finora

- 5 - Tank Itp - Inspection & Test Plan For TanksDocumento9 pagine5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- Chemical Resistance (LLDPE) PDFDocumento24 pagineChemical Resistance (LLDPE) PDFrubyshreeNessuna valutazione finora

- Sample Work Activities For Process Tank FabricationDocumento4 pagineSample Work Activities For Process Tank FabricationMuhammad ZubairNessuna valutazione finora

- Construction Leak Test ProcedureDocumento9 pagineConstruction Leak Test Procedurezack zeeartNessuna valutazione finora

- Hydrotest ProcedureDocumento12 pagineHydrotest Procedurealex_feryando42100% (1)

- Api 653 Report-Hydrolic Test PDFDocumento12 pagineApi 653 Report-Hydrolic Test PDFnaoufel1706Nessuna valutazione finora

- MS For Fabrication of Above-Ground Storage TankDocumento8 pagineMS For Fabrication of Above-Ground Storage Tankdadz mingiNessuna valutazione finora

- Inspection and Test Plan For Pipe Rack and Piping Painting WorksDocumento2 pagineInspection and Test Plan For Pipe Rack and Piping Painting WorksRanjan KumarNessuna valutazione finora

- Vacuum Box TestingDocumento8 pagineVacuum Box Testingergyap100% (4)

- Pttep Painitng of Offshore FacilitiesDocumento66 paginePttep Painitng of Offshore FacilitiesSufianNessuna valutazione finora

- Procedure For Fab, Erec & Testing of Undergroud PipingDocumento12 pagineProcedure For Fab, Erec & Testing of Undergroud Pipingvpsimbu86Nessuna valutazione finora

- Procedure For Holiday Testing PDFDocumento2 pagineProcedure For Holiday Testing PDFSaptarshi MandalNessuna valutazione finora

- Tank Inspection ReportDocumento2 pagineTank Inspection ReportRavi Kumar VatturiNessuna valutazione finora

- ITP (Test Procedure) PDFDocumento2 pagineITP (Test Procedure) PDFkrishnit100% (1)

- Pressure Test Certificate PDFDocumento1 paginaPressure Test Certificate PDFMarkLouiseSumugatOlandresNessuna valutazione finora

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocumento3 pagineBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNessuna valutazione finora

- SETTLEMENT Test ProcedureDocumento9 pagineSETTLEMENT Test Procedurehrdsby100% (1)

- Holiday Tester Voltage Setting CalculationDocumento4 pagineHoliday Tester Voltage Setting Calculationjojeecares100% (1)

- Hydrostatic Test ProcedureDocumento3 pagineHydrostatic Test Proceduregstketut100% (6)

- SOP Tank ConstructionDocumento24 pagineSOP Tank ConstructionSuci YatiningtiyasNessuna valutazione finora

- Diesel Leak TestDocumento3 pagineDiesel Leak Testsbmmla67% (3)

- Sigmacover™ 620: Product Data SheetDocumento5 pagineSigmacover™ 620: Product Data SheetMahmoud TahaNessuna valutazione finora

- Job Methodology For DRT Tank Procedure - 0618-R1Documento15 pagineJob Methodology For DRT Tank Procedure - 0618-R1purshottam GHNessuna valutazione finora

- Painting Procedure NG SystemsDocumento6 paginePainting Procedure NG SystemsTanveer Rajput EngrNessuna valutazione finora

- Summary of NDT Requirements For Storage TankDocumento1 paginaSummary of NDT Requirements For Storage TankAbdul Hamid DjaelaniNessuna valutazione finora

- Api 653 Report-Hydrolic Test PDFDocumento12 pagineApi 653 Report-Hydrolic Test PDFnaoufel1706Nessuna valutazione finora

- Pozo SikuDocumento2 paginePozo SikuDjoko WidodoNessuna valutazione finora

- QCP-12 Valve Leak Test Procedure PDFDocumento21 pagineQCP-12 Valve Leak Test Procedure PDFIbrahim100% (3)

- Approved Tank Hydrostatic Test Procedure - Rev.FDocumento28 pagineApproved Tank Hydrostatic Test Procedure - Rev.Fimran0% (1)

- ATTL - METHOD OF STATEMENT FOR TANK HYDROTESTINGdocxDocumento8 pagineATTL - METHOD OF STATEMENT FOR TANK HYDROTESTINGdocxMohammed Mostafa El Haddad100% (1)

- Job Procedure For Hydrotest/Water Fillup Test: 1. ScopeDocumento3 pagineJob Procedure For Hydrotest/Water Fillup Test: 1. ScopeRebecca SchultzNessuna valutazione finora

- Welding HandbookDocumento48 pagineWelding HandbookMohan Prasad.M93% (27)

- Welding Handbook ESABDocumento529 pagineWelding Handbook ESABErdinc_Bal_1026100% (8)

- Welding EducatorDocumento30 pagineWelding Educatorツ ツNessuna valutazione finora

- Triangle SolverDocumento3 pagineTriangle Solverツ ツNessuna valutazione finora

- SLOFEC TankScanningDocumento7 pagineSLOFEC TankScanningツ ツNessuna valutazione finora

- Hydra TightDocumento29 pagineHydra Tightツ ツNessuna valutazione finora

- RoundnessDocumento35 pagineRoundnesssrinivasansscNessuna valutazione finora

- RoundnessDocumento35 pagineRoundnesssrinivasansscNessuna valutazione finora

- Calculation of Working Pressure of CylinderDocumento6 pagineCalculation of Working Pressure of Cylindervilaschinke123Nessuna valutazione finora

- ASME Code Case PautDocumento10 pagineASME Code Case PautAnonymous kIrNuhNessuna valutazione finora

- 2000 Spring Leveling by Excel 1Documento3 pagine2000 Spring Leveling by Excel 1ツ ツNessuna valutazione finora

- 650 150Documento10 pagine650 150ツ ツNessuna valutazione finora

- HTTP Biosystems - OkstateDocumento11 pagineHTTP Biosystems - Okstateツ ツNessuna valutazione finora

- LevelMe-DataSheet ENG 130702Documento2 pagineLevelMe-DataSheet ENG 130702ツ ツNessuna valutazione finora

- SLOFEC TankScanningDocumento7 pagineSLOFEC TankScanningツ ツNessuna valutazione finora

- LevelMe-DataSheet ENG 130702Documento2 pagineLevelMe-DataSheet ENG 130702ツ ツNessuna valutazione finora

- HTTP Biosystems - OkstateDocumento11 pagineHTTP Biosystems - Okstateツ ツNessuna valutazione finora

- 650 150Documento10 pagine650 150ツ ツNessuna valutazione finora

- 2000 Spring Leveling by Excel 1Documento3 pagine2000 Spring Leveling by Excel 1ツ ツNessuna valutazione finora

- Ust Operator Study GuideDocumento82 pagineUst Operator Study Guideツ ツNessuna valutazione finora

- Commercial Pipe Size and Wall ThicknessesDocumento2 pagineCommercial Pipe Size and Wall Thicknessesvk2111Nessuna valutazione finora

- MT 200 User ManualDocumento48 pagineMT 200 User Manualツ ツNessuna valutazione finora

- Flaw Manufacturing TechnologyDocumento31 pagineFlaw Manufacturing Technologyツ ツNessuna valutazione finora

- Ind Radiography GuideDocumento25 pagineInd Radiography Guideツ ツNessuna valutazione finora

- API-653 Tank Inspection Sample ReportDocumento19 pagineAPI-653 Tank Inspection Sample Reportツ ツ93% (15)

- Basic ExcelDocumento3 pagineBasic Excelツ ツNessuna valutazione finora

- 8332-5 6eDocumento12 pagine8332-5 6eツ ツNessuna valutazione finora

- Screwed Flat Plate 45amp SwitchesDocumento2 pagineScrewed Flat Plate 45amp Switchesツ ツNessuna valutazione finora

- General Guidance For Installing New Above Ground Storage TanksDocumento1 paginaGeneral Guidance For Installing New Above Ground Storage Tanksツ ツNessuna valutazione finora

- Sample Question PaperDocumento4 pagineSample Question PaperRajat ShrirameNessuna valutazione finora

- HJT MBB Half-Cut Bifacial Dual-Glass Module Ska611HdgdcDocumento2 pagineHJT MBB Half-Cut Bifacial Dual-Glass Module Ska611HdgdcMarko Maky ZivkovicNessuna valutazione finora

- 6 Types of EngineersDocumento5 pagine6 Types of EngineersAsad NawazNessuna valutazione finora

- UUSITALODocumento9 pagineUUSITALOMarcosNessuna valutazione finora

- Laporan Soil Investigation Pertamina PanjangDocumento60 pagineLaporan Soil Investigation Pertamina PanjangAlex SudrajatNessuna valutazione finora

- Fluid Statics: F I G U R E P2.69Documento1 paginaFluid Statics: F I G U R E P2.69andres bernalNessuna valutazione finora

- Unit 43 Heat Pumps1Documento92 pagineUnit 43 Heat Pumps1hvactrg1Nessuna valutazione finora

- Contact Pressure-Overclosure Relationships in AbaqusDocumento8 pagineContact Pressure-Overclosure Relationships in AbaqusOliver GiraldoNessuna valutazione finora

- Example Problem Solutions - Chapter 8Documento18 pagineExample Problem Solutions - Chapter 8Nguyen Tien DungNessuna valutazione finora

- Induction BendingDocumento20 pagineInduction BendingAnoop N Kutty100% (4)

- Bauchau Benchmark 16Documento20 pagineBauchau Benchmark 16Victor Hugo Garcia de CamposNessuna valutazione finora

- Chapter 4. Heat Treatment by InductionDocumento1 paginaChapter 4. Heat Treatment by InductionKamil IbraNessuna valutazione finora

- Generator Foundation MountingsDocumento2 pagineGenerator Foundation MountingsSuresh Gunasekara100% (1)

- Hydraulic & Pneumatic SystemDocumento69 pagineHydraulic & Pneumatic SystemSandeep Singh100% (1)

- FEA 16 Mark QBDocumento12 pagineFEA 16 Mark QBMr. N. Aravindkumar Asst Prof MECHNessuna valutazione finora

- RS - Final 2023Documento3 pagineRS - Final 2023Yousif Taha Al-badranNessuna valutazione finora

- Automatic Transmission 42REDocumento121 pagineAutomatic Transmission 42REmtaylor030% (7)

- Euler-Bernoulli Beam Theory - Simple English Wikipedia, The Free EncyclopediaDocumento2 pagineEuler-Bernoulli Beam Theory - Simple English Wikipedia, The Free EncyclopediaCordy Jourvel Itoua-TseleNessuna valutazione finora

- Lecture-05 Reservoir Pressure&TemperatureDocumento20 pagineLecture-05 Reservoir Pressure&TemperatureShuvro Aakash100% (1)

- Fluid MechanicsDocumento2 pagineFluid MechanicsSandip KadoliNessuna valutazione finora

- Lec16 PDFDocumento13 pagineLec16 PDFRohan sharmaNessuna valutazione finora

- IRC 58 ExcelDocumento21 pagineIRC 58 ExcelMadhavpokale100% (4)

- Observation On Design and Drawing of Widening Box Culverts (Straight & Skew) and Miscellaneous Drawings Reg LTR DT - 31-07-2020Documento14 pagineObservation On Design and Drawing of Widening Box Culverts (Straight & Skew) and Miscellaneous Drawings Reg LTR DT - 31-07-2020Vikas SharmaNessuna valutazione finora

- Affinity Laws For Fan & PumpDocumento12 pagineAffinity Laws For Fan & PumpHari Krishna.MNessuna valutazione finora

- Computational Fluid Dynamics Fundamentals Course: Fluid Mechanics 101 Dr. Aidan WimshurstDocumento51 pagineComputational Fluid Dynamics Fundamentals Course: Fluid Mechanics 101 Dr. Aidan WimshurstRaquel VelascoNessuna valutazione finora

- Physics Answer SchemeDocumento4 paginePhysics Answer SchemeBENNY LAU XUE ZHENG MoeNessuna valutazione finora

- ME 308 Machine Elements Ii: Spring Design - 2Documento50 pagineME 308 Machine Elements Ii: Spring Design - 2xxxNessuna valutazione finora

- Utilizare VAS 6096Documento6 pagineUtilizare VAS 6096georgescuriosNessuna valutazione finora

- Optimization of Labyrinth Seal For Screw Compressor Ht2007-32275Documento7 pagineOptimization of Labyrinth Seal For Screw Compressor Ht2007-32275api-3842143Nessuna valutazione finora

- EnergySRP Forms MatchingDocumento2 pagineEnergySRP Forms Matchingeiad-mahmoudNessuna valutazione finora