Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

7 Drilling Brake

Caricato da

Hany AhmedCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

7 Drilling Brake

Caricato da

Hany AhmedCopyright:

Formati disponibili

Davorin Matanovi

Drilling

BRAKE

Mechanical brake

Mechanical brake is the essential part of the

derrick.

Its purpose is to slow down and stop the downwards

movement of the drill string.

It also serves to control the load on the bit.

The frictional brake consists basically of flexible

steel bands that fit around the drum flanges, each

having one end anchored and the other free..

When the free end is pulled (by means of a brake lever,

the whole band tightens around the drum flange and

slows or stops it by friction.

Band frictional

brake

Construction

Drum flanges have wear

resistant rims bolted to them.

They are gripped by the brake

bands as they tighten.

The brake bands have a lining

of brake blocks.

The blocks are composed of

asbestos fiber compounded

with a bonding agent

interwoven with cooper wire.

The blocks are bolted to the

brake bands with brass bolts

countersunk on the inside of

the band circle.

One end (the dead end) of

each brake band is anchored;

and the other end (the live

end) is attached to the manual

brake lever by means of a

camshaft.

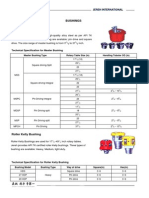

Blocks bolting

API standard defines friction blocks

with four or six bores

Blocks with six

bores

Blocks with four

bores

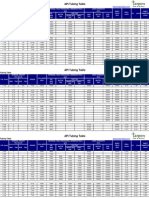

API

No.

A (mm) B (mm) C (mm)

1 152,4 31,8 88,9

2 177,8 38,1 101,6

3 203,2 44,5 114,3

4 228,6 50,8 127

5 254 57,2 139,7

6 279,4 63,5 152,4

7 304,8 69,9 165,1

The thickness of the

block is not defined, but

it is possible to use

several block thickness:

t

*

(mm)

15,9 19 22,2 25,4 28,6 31,8

(inch) 5/8 3/4 7/8 1

1

1/8

1 1/4

API

No.

D (mm) E (mm) F (mm)

10 152,4 31,8 88,9

11 177,8 38,1 101,6

12 203,2 38,1 127

13 228,6 38,1 152,4

14 254 38,1 177,8

t

*

(mm) 15,9 19 22,2 25,4

(inch) 5/8 3/4 7/8 1

Screw diameter

for block

fastening is 9,525

mm (3/8") with

the flat -

countersunk head

with angle of 120

and thread;16

UNC-2A.

o

120

Several factors affect breaking capacity:

The first is the ratio between the diameter of

the brake flange and the diameter of the drum

spool.

Another is a band width. That is according to

friction area.

Third one is the angle of wrap, that means the

distance that the brake band wraps around

the flange.

It can be from 270 to 330.

330 wrapping

270 wrapping

Equalizer

At the front of the hoist, the brake bands are

fastened with heavy-duty pins or bolts to a dead

anchor firmly fastened to the draw works frame at

the center of the drum.

This dead anchor is in the form of a yoke and acts as

an equalizer to ensure that each brake band will

receive an equal amount of tension.

The equalizer also switches the full load to one band if

the other fails.

The brakes must be adjusted properly to make sure the

long lasting work. Some draw works have automatic

equalizing devices.

Cooling

The brakes are cooled with clean fresh water

circulated through the drum shaft to the brake

flanges.

Cooling is necessary to help dissipate the heat that is

generated by the friction of brake lining on flanges.

It is important for water to be fresh to prevent mineral

deposition that would affect the cooling system.

The water is pumped by the system that has

independent power.

The great amount of generated heat must be

removed quickly to prevent poor braking action

and excessive wear on blocks and flanges.

Frictional brake acts

as it is shown on

picture.

The force on the

lever that driller

must apply is

defined as:

( ) ( )

N

e l R

b M

l e

b Q

l

b t

F

o o

k kv

k br

k

k br

k

p

k

490

1 1

2

2

. .

=

=

=

Where:

F

k

the force the driller must apply on the lever, N

t

p

force in the free end of band, N

b

k

length of the short lever, m

l

k

length of the long lever, m

Q

br.

braking force on the flange, N

e natural logarithm base (2,718)

- coefficient of friction (0,5)

o

wrap angle (from 270 to 330)

R

kv

brake flange radius, m

M

br.

breaking moment that must be achieved,

Nm

r

kon

final drum diameter, m

b

drum efficiency (0,95)

K

br.

factor due the dynamic forces (from 1,2 to

2,5)

D

kv

braking flange diameter, m (1,8 to 2,8)D

b

D

b

drum diameter, m

F force in the wire rope, N

kv

br

br

R

M

Q

=

2

.

.

. . br b kon br

K r F M =

( )

2

8 , 2 8 , 1

2

b kv

kv

D to D

R

= =

Auxiliary brakes

Auxiliary brakes are used in the hoisting

system to slow the rate of descent of the

traveling block with a heavy load.

They ensure that a heavy load comes down slowly

and smoothly.

Care must be taken, to prevent the blocks from

falling faster than they could be stopped by the

friction brake alone.

Auxiliary brake should be hydrodynamic

brake or electrodynamic brake.

Hydrodynamic brake

Hydrodynamic brake

is often called as the

water-brake,

because it works by

the action of fluid;

normally water.

The fluid is circulated by a moving rotor,

and mechanical energy is converted into

heat within the fluid itself.

The amount of mechanical energy that can

be absorbed depends upon the quantity

and velocity of the fluid in the working

chamber.

It will be increased with revolving speed of

the rotor.

To control the operating level, driller simply

opens or closes the valve that controls the

level of the water in the brake.

So the main control should be in the

circulating system.

Maximum allowable brake outlet

temperature must never exceed 77 C (180

F).

Electrodynamic

brake

An electrodynamic brake

consists basically of a large

steel armature drum that

rotates in a magnetic field

produced by electromagnets

around the drum.

The combination of drum motion

(rotation) and magnetic fields

causes electric currents (eddy

currents) to flow in the drum.

They react with the stationary

magnetic fields to resist the drum

motion and produce a retarding

or breaking action.

The amount of breaking action is

controlled by adjusting the

strength of magnetic fields, by

the amount of direct current.

ROTOR

WATER

INLET

WATER OUTLET

ELECTRO

MAGNETS

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Thermal Rehabilitation (Azuma House)Documento47 pagineThermal Rehabilitation (Azuma House)Haseeb Uz Zaman67% (6)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- GrantPrideco Drill Pipe Data TablesDocumento24 pagineGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezNessuna valutazione finora

- Dams: Parts, PakistanDocumento22 pagineDams: Parts, PakistanEnigmatic Yousafzai100% (1)

- Modeling Transient Liquid Phase Bonding Process in The Ni (Final)Documento20 pagineModeling Transient Liquid Phase Bonding Process in The Ni (Final)Debopriyo RoyNessuna valutazione finora

- Safety Alert: Stabbing Board Related IncidentsDocumento1 paginaSafety Alert: Stabbing Board Related IncidentsHany AhmedNessuna valutazione finora

- Stabbing Board Accident Panel Report 2006-002Documento48 pagineStabbing Board Accident Panel Report 2006-002Hany AhmedNessuna valutazione finora

- Critical AreaDocumento2 pagineCritical AreaHany AhmedNessuna valutazione finora

- S WeatherfDocumento3 pagineS WeatherfHany AhmedNessuna valutazione finora

- Critical Area Drawings: Document Number 50000805-MAN-001 Revision A 64 of 66Documento2 pagineCritical Area Drawings: Document Number 50000805-MAN-001 Revision A 64 of 66Hany AhmedNessuna valutazione finora

- Guidance For RcaDocumento12 pagineGuidance For RcaHany AhmedNessuna valutazione finora

- Fishbone RevisedDocumento3 pagineFishbone RevisedHany AhmedNessuna valutazione finora

- Радиус-Сервис - Products - JarsDocumento4 pagineРадиус-Сервис - Products - JarsHany AhmedNessuna valutazione finora

- API Tubing TableDocumento6 pagineAPI Tubing TableDavid KusumaNessuna valutazione finora

- Oilfield JetlubeDocumento24 pagineOilfield JetlubeHany AhmedNessuna valutazione finora

- Радиус-Сервис - Products - Shock ToolsDocumento2 pagineРадиус-Сервис - Products - Shock ToolsHany AhmedNessuna valutazione finora

- Bushings Master BushingDocumento2 pagineBushings Master BushingHany AhmedNessuna valutazione finora

- Jereh ElevatorDocumento4 pagineJereh ElevatorHany AhmedNessuna valutazione finora

- Stabbing BoardsDocumento2 pagineStabbing BoardsHany AhmedNessuna valutazione finora

- High Output Hydraulic - Mechanical Drilling Jar - (HO-HMJ) - Downhole Drilling ToolsDocumento4 pagineHigh Output Hydraulic - Mechanical Drilling Jar - (HO-HMJ) - Downhole Drilling ToolsHany AhmedNessuna valutazione finora

- Spider Varco 375Documento1 paginaSpider Varco 375Hany AhmedNessuna valutazione finora

- Hydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsDocumento4 pagineHydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsHany AhmedNessuna valutazione finora

- Jet Lube Jet Lok IIDocumento2 pagineJet Lube Jet Lok IIHany Ahmed0% (1)

- Shock Tool - Downhole Drilling ToolsDocumento4 pagineShock Tool - Downhole Drilling ToolsHany AhmedNessuna valutazione finora

- 758 42000e Testork Revd LoresDocumento4 pagine758 42000e Testork Revd LoresHany AhmedNessuna valutazione finora

- Hydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsDocumento4 pagineHydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsHany AhmedNessuna valutazione finora

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf4Documento3 pagineTianhe Oil Group Huifeng Petroleum Equipment Co - pdf4Hany AhmedNessuna valutazione finora

- Challenger Bumper Jar - Downhole Drilling ToolsDocumento3 pagineChallenger Bumper Jar - Downhole Drilling ToolsHany AhmedNessuna valutazione finora

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf1Documento3 pagineTianhe Oil Group Huifeng Petroleum Equipment Co - pdf1Hany AhmedNessuna valutazione finora

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf2Documento3 pagineTianhe Oil Group Huifeng Petroleum Equipment Co - pdf2Hany AhmedNessuna valutazione finora

- Jar Pro Drillstring Jarring Analysis SoftwareDocumento5 pagineJar Pro Drillstring Jarring Analysis SoftwareHany AhmedNessuna valutazione finora

- Tianhe Oil Group Huifeng Petroleum Equipment CoDocumento3 pagineTianhe Oil Group Huifeng Petroleum Equipment CoHany AhmedNessuna valutazione finora

- Drill String DesignDocumento12 pagineDrill String DesignAsaadgz100% (1)

- Pumps Motors AssDocumento57 paginePumps Motors AssHany AhmedNessuna valutazione finora

- EC ElectromagneticsDocumento51 pagineEC ElectromagneticsNilamani Umashankar JenaNessuna valutazione finora

- Seal of BushingDocumento6 pagineSeal of BushingB.k. BirtiaNessuna valutazione finora

- Bloodbank EquipmentDocumento28 pagineBloodbank EquipmentDavid PinningtonNessuna valutazione finora

- Electricoutboard: Ep-50 Electric Outboard Features and BenefitsDocumento1 paginaElectricoutboard: Ep-50 Electric Outboard Features and Benefitsjuniono raharjoNessuna valutazione finora

- Advances in Magnetic Pipeline InspectionDocumento5 pagineAdvances in Magnetic Pipeline InspectionJohnny Walker100% (3)

- 12 Physics Exemplar Chapter 14Documento11 pagine12 Physics Exemplar Chapter 14Haarish KrishnamurthyNessuna valutazione finora

- BY127, BY133, EM513, EM516: General Purpose Plastic Rectifier Reverse Voltage - Forward CurrentDocumento3 pagineBY127, BY133, EM513, EM516: General Purpose Plastic Rectifier Reverse Voltage - Forward CurrentJose Fernandez LopezNessuna valutazione finora

- Spare Parts List STORM 15 20180000 XDocumento4 pagineSpare Parts List STORM 15 20180000 XFati ZoraNessuna valutazione finora

- 2012 A6 Self Study Program Part 1Documento44 pagine2012 A6 Self Study Program Part 1Soriteu Sorin100% (2)

- Radiography Procedure RNDTDocumento27 pagineRadiography Procedure RNDTrashmibetuNessuna valutazione finora

- Ash Handling PlantDocumento6 pagineAsh Handling Plantapumoni123Nessuna valutazione finora

- 14.03 - General Design - Design of Steel Bridges BD 13-90Documento27 pagine14.03 - General Design - Design of Steel Bridges BD 13-90Oscar MendozaNessuna valutazione finora

- 24" (61 CM) Electric Single and Double Built-In Oven: Product Model Series Overall DimensionsDocumento1 pagina24" (61 CM) Electric Single and Double Built-In Oven: Product Model Series Overall DimensionsHewa PCNessuna valutazione finora

- Omnicomm LLS 4 Fuel Level Sensors: User Manual 18.12.2018Documento20 pagineOmnicomm LLS 4 Fuel Level Sensors: User Manual 18.12.2018Giovanni QuinteroNessuna valutazione finora

- CH 8 Class 12 Chem PDFDocumento12 pagineCH 8 Class 12 Chem PDFDhanushNessuna valutazione finora

- My M.SC Thesis ..Documento33 pagineMy M.SC Thesis ..Mallika P. Shivam100% (1)

- Reservoir Engineering Manager - OxyDocumento1 paginaReservoir Engineering Manager - OxyEd ChambersNessuna valutazione finora

- Assignment 1 Reservoir EngineeringDocumento4 pagineAssignment 1 Reservoir EngineeringMarlisa SalamatNessuna valutazione finora

- CAT4-2 Complete ENDocumento264 pagineCAT4-2 Complete ENalltheloveintheworldNessuna valutazione finora

- 02 Water Supply Engineering-Lecture 2-Quantity of Water 2019-2020 PDFDocumento14 pagine02 Water Supply Engineering-Lecture 2-Quantity of Water 2019-2020 PDFSeashells Do ImpossibleNessuna valutazione finora

- Atoms, Electron Structure and Periodicity HWDocumento14 pagineAtoms, Electron Structure and Periodicity HWLuke WilliamsonNessuna valutazione finora

- 844K 4WD Loader PIN 1DW844K D642008 Replacement Parts GuideDocumento3 pagine844K 4WD Loader PIN 1DW844K D642008 Replacement Parts GuideNelson Andrade VelasquezNessuna valutazione finora

- SD 33Documento8 pagineSD 33Neddy Bdo Veras Estevez100% (2)

- Catálogo VPADocumento2 pagineCatálogo VPARafael LimaNessuna valutazione finora

- Spray Pump: Technical ManualDocumento15 pagineSpray Pump: Technical ManualNal AlmeidaNessuna valutazione finora

- MGG155N2: Gaseous Generator Parts ManualDocumento94 pagineMGG155N2: Gaseous Generator Parts ManualYAKOVNessuna valutazione finora

- Lecture Notes 08Documento25 pagineLecture Notes 08Abdul Hakeem Semar KamaluddinNessuna valutazione finora