Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PMI Procedure Tracebilty Matrial

Caricato da

Iksan Adityo MulyoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PMI Procedure Tracebilty Matrial

Caricato da

Iksan Adityo MulyoCopyright:

Formati disponibili

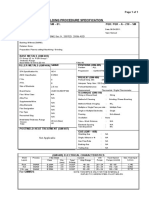

JOB No. DOC. No. Rev.

0-5151-20 S-900-1540-201 0

DATE 5 - Jan - 2012 SHEET 1 OF 11

PREPD S. Kuritsubo

CHKD T. Kiyama

APP'D Y. Kawase

REV. Date Page DESCRIPTION PRED CHKD APPD

0 05 Jan 2012 All Issued for Information S. Kuritsubo T. Kiyama Y. Kawase

REQUIREMENTS OF MATERIAL CERTIFICATION &

TRACEABILITY AND POSITIVE MATERIAL IDENTIFICATION

FOR CONSTRUCTION WORK

DONGGI SENORO LNG PROJECT

FOR INFORMATION

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 2 OF 11

Contents

1 GENERAL..................................................................................................................................... 3

1.1 Scope............................................................................................................................................. 3

1.2 Purpose.......................................................................................................................................... 3

1.3 Objective ........................................................................................................................................ 3

2 ABBREVIATION AND DEFINITION............................................................................................. 3

3 REFERENCES.............................................................................................................................. 4

4 MATRIAL CERTIFICATION, MARKING AND TRACEABILITY................................................. 4

4.1 General Requirement for Certification of Materials........................................................................... 4

4.2 Type of Certificates......................................................................................................................... 4

4.3 Contents of Certificate..................................................................................................................... 4

4.4 Certification Selection ..................................................................................................................... 5

5 MATERIAL TRACEBILITY........................................................................................................... 6

5.1 Tagged Items.................................................................................................................................. 6

5.2 Piping Bulk Materials....................................................................................................................... 6

5.3 Identification ................................................................................................................................... 7

6 POSITIVE MATERIAL IDNETIFICATION (PMI) .......................................................................... 7

6.1 Extent of PMI testing....................................................................................................................... 7

6.2 Exemption of PMI............................................................................................................................ 7

6.3 Test Procedure ............................................................................................................................... 8

6.4 Acceptable PMI Equipment ............................................................................................................. 8

6.5 Elements to be Verified................................................................................................................... 9

6.6 Qualification of PMI Operators ........................................................................................................ 9

6.7 Acceptance Criteria......................................................................................................................... 9

6.8 Retest and Nonconformity of PMI.................................................................................................... 9

6.9 Marking and Identification of PMI .................................................................................................. 10

6.10 Record.......................................................................................................................................... 10

Attachment-1 : Scope and Extent of PMI in Construction Phase..................................................... 11

Attachment-2 : Identification Elements of PMI.................................................................................. 11

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 3 OF 11

1 GENERAL

1.1 Scope

This specification describes

Requirements for certification, marking and material traceability for equipment and

piping components in process or pressure containing duty to be applied for field

fabrication and installation and

Requirements of Positive Material Identification (PMI) for construction work. PMI

is applicable to metallic alloy material components except carbon steel used in

Donggi-Senoro LNG (DSLNG) Project.

1.2 Purpose

The purpose of this procedure is:

To define the requirement of scope, extent and procedure of certification, marking ,

material traceability and PMI

To handle tested materials and documentation requirements for PMI.

1.3 Objective

The objective of this procedure is to ensure that

PMI will be done by Subcontractor certainly and collect material are used for

construction work at job site.

To maintain the appropriate material installation as per the applicable standard and

drawing by Subcontractor

2 ABBREVIATION AND DEFINITION

Owner: PT. Donggi Senoro LNG

Contractor: PT.JGC Indonesia and JGC Corporation Consortium (JIND/JGC)

Subcontractor: The person, firm or corporation to whom the Order is issued

FQCM: Field QC Manager

PMI Positive Material Identification

Tagged Items Equipment allocated a unique tag number or spool

number i.e., tanks, vessels, rotating equipment,

packaged units, fabricated pipe spools, control valves,

relief valves, and any other items listed in equipment

list or instrument schedule

Bulk Items Piping materials purchased in bulk by the Contractor

where individual items are not allocated a unique tag

number.

e.g.) plate, pipe, tube, valves, fittings, traps and

strainers, other castings and forgings

In-Line

Instrument

Instruments and components mounted in pressure

piping or equipment. Typical examples are control

valves, turbine meters, orifice plates and flanges,

thermowells

(Note : safety valve and level gauge are classified as

piping material)

Off-Line

Instrument

Instruments and components connected to pressure

piping or equipment via small block valves. Typical

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 4 OF 11

examples are transmitters, pressure gauges, analyzer

sampling systems

ITP: Inspection and Test Plan

NDE Non-Destructive Examination

NCR: Nonconformity Report

3 REFERENCES

S-900-1540-002 Project Quality Control Procedure for Construction Work

(Construction Phase)

S-900-1540-101 Quality Control Requirements to Subcontractor

S-900-1540-102 Nonconformity Control Procedure

EN10204 : Metallic Products-Types of Inspection Documents

4 MATRIAL CERTIFICATION, MARKING AND TRACEABILITY

4.1 General Requirement for Certification of Materials

(1) The language used within material certificates should be English. Certificates in

other languages are acceptable provided that they are accompanied by English

translation of the contents

.

(2) Certificates shall be complete, unambiguous and legible over the full contents and

care should be taken so that copies present a full and clear reproduction.

(3) Certificates shall be dated and signed by an authorized person, whose name and

position shall be indicated on the document.

(4) For Tagged Items, the certificates shall cover all components used in the

manufacture of Tagged Item.

4.2 Type of Certificates

4.2.1 Type A (Certificate of Compliance)

This is a certificate issued by the manufacturing or processing works and signed by a

person responsible for quality, stating that the material supplied complies with that

specified in the purchase order requirements

4.2.2 Type B (Material Test Certificate)

This is a certificate issued by the manufacturers or process works quality department

confirming that the product supplied corresponds with the specified requirements.

Certification shall be based on tests carried out on the material of the product itself or

on test samples of the material in accordance with the material specification and the

purchase order requirement. Testing must have been carried out by a testing center

which is independent of the production section of the manufacturing works

4.3 Contents of Certificate

Type A and B certificates shall contain the following information:

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 5 OF 11

(1) Name of material manufacturer identification number of certificate and its date of

issue

(2) Material specification (including class, grade and heat treatment condition, where

applicable

(3) Dimensions and quantity covered

(4) Name, job title and signature of person authorizing the certificate

(5) Such supplementary or additional information as may be required by the purchase

order

Additionally, Type B certificates shall contain the following information:

(1) Purchase order number

(2) Material manufacturers work order number

(3) Material charge number, batch number, heat/lot number or other references

required to demonstrate that the testing and inspection has been performed on

the required number of test units

(4) Test and inspection results

4.4 Certification Selection

The required type of certificate listed below for equipment and piping shall be the

minimum requirement. When local regulation, the other applicable Project ,

Specification data sheet, and/or requisition specify more stringent or specific

requirement, it shall prevail

4.4.1 Tank

Type B certificate shall be required for bottom/shell plates and shell openings for API

650 tanks, and bottom/shell/roof plates and shell/roof openings for API 620 tanks. In

addition, any 9% nickel materials including non-pressure parts for LNG storage tank

shall be Type B.

For piping bulk materials and instruments procured by LNG Tank subcontractor, the

material certification requirements as specified in Subsections 4.4.2 and 4.4.3 shall

apply.

4.4.2 Piping Bulk Materials Procured by Subcontractor

(1) Pipe, Fitting, Flange and Bolting

Type B certificate shall be required for pipe/fit-tings/flange and stud bolting for

pressure retaining parts

(2) Valves

Type B certificate shall be required for body/bonnet/cover and Type A certificate

shall be required for closure member (gate/wedge, disc, ball, and plug), stem,

seat and bolting

(3) Piping Specialties

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 6 OF 11

Type B certificate for pressure parts and Type A certificate for internal parts and

bolting shall be required

4.4.3 Instruments Procures by Subcontractor

(1) For In-Line Instruments, the same certification requirements as for piping shall be

required as follows

Instrument Valves

Type B certificate for body/bonnet/cover and Type A certificate for closure

member, stem, seat and bolting.

Other In-Line Instruments

Type B certificate for pressure retaining envelope and Type A certificate for

bolting.

Example: Level switch, displacer, thermowell, turbine meter, orifice flange and

plate, ventury tube, rota meter, annuber, pitot tube, etc

.

(2) For Off-Line Instruments and their connections to pressure piping system, no

material certification is required provided facilities are foreseen to block these

instruments and connections of the piping system

Example: Analyzer sampling system, controller, pressure and differential

pressure transmitter, pressure gauge, pressure switch, etc.

For instrument bulk material to be used for Off-Line Instrument connections such

as instrument tubing, etc., and conduit pipe, junction box, etc., material certificate

is not required except that special high alloy tubing other than 300 series S/S,

such as Monel etc., (if applied) shall require Type A certificate

5 MATERIAL TRACEBILITY

When a Type B certificate is specified for Tagged Items or Bulk Items, materials shall

be traceable to the material certificate after assembly, at the time of final inspection at

Subcontractors shop before shipping

5.1 Tagged Items

Each completed Tagged Item at Subcontractors shop shall be identifiable and

traceable by tag number and accompanied Subcontractors Manufacturing Reports.

For field assembled tanks, the following traceability requirements shall apply:

(1) API 620/650 Tanks

Shell, shell opening and annular bottom plate materials shall be traceable back to

the material certificate after assembly with as-built sketch

(2) API 620 App. LNG Tanks:

All primary components shall be traceable back to the material certificate after

assembly with as-built sketch. Shell and annular bottom plate materials for outer

tank to be also traceable back to the material certificate with as-built sketch.

5.2 Piping Bulk Materials

Prefabricated piping or assembled piping and bolting shall be traceable to the material

specification, grade, size and schedule/ rating after assembly, at the time of final

inspection at Subcontractors shop.

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 7 OF 11

(1) At the time of receiving stage of piping bulk material at site

All piping materials shall be identifiable by marking and/or color coding and shall

be traceable to its material certificate. Receiving inspection by visual check of

marking/ color coding/ overage/ shortage/ damage and confirmation of Inspection

Release Notice for the received materials shall be carried out. Only accepted

materials shall be issued for prefabrication and installation

(2) During and after prefabrication or installation of piping before piping system

pressure test, all piping materials shall be controlled/identified by color coding (or

piping spool ID number) and piping code number (or piping material spec. & size

marking, such as TP316L, 2, sch.40). When cutting pipes, piping code number

and/or equivalent marking shall be transferred and be identified (color code shall

still remain) so that each pressure retaining piping material shall have the

traceability to the material specification, grade, size and schedule/rating after

assembly.

5.3 Identification

The Subcontractor shall maintain an identification procedure of all materials, parts and

components, including partially fabricated assemblies.

The location and method of the identification shall not affect the function or quality of

the item being identified.

The procedure shall require that verification of correct identification of materials, parts

and components be made and documented prior to release for fabrication, assembly,

shipping or installation

6 POSITIVE MATERIAL IDNETIFICATION (PMI)

6.1 Extent of PMI testing

(1) PMI shall be performed on pressure containing alloy materials and all associated

welds in accordance with Attachment-1 : Extent of PMI Field Fabrication and

Attachment-2 : Elements of common alloys subject to PMI

.

(2) PMI shall also be performed on completed equipment or assembled part of

equipment by the Subcontractor, at such a time as to ensure that only verified

materials have been used in fabrication and final assembly of items.

(3) Components not accessible after assembly shall have PMI undertaken prior to

assembly

6.2 Exemption of PMI

The following items / materials are exempted from PMI:

Aluminum and aluminum alloy

Non-pressure containing parts of pressure vessels/heat exchanger internals

Internal parts of valves, instruments and piping specialties

Off-Line Instruments

Instrument pneumatic tubing and fittings

Tubing and fittings

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 8 OF 11

Air/drain traps, metallic flexible hoses, hose couplings

B7, L7, B7M, L7M bolting

All copper or copper alloy components exclusive to water service

Austenitic stainless steel components for water/air/nitrogen/chemical/lube oil/seal oil

service

Gaskets

6.3 Test Procedure

(1) PMI shall be performed in accordance with written Subcontractors PMI

procedure approved by Contractor prior to the start of implementation. And testing

shall also be performed according to the alloy analyzer Manufacturer's

procedures. Any modification of such procedures shall be approved by Contractor

(2) PMI procedure shall ensure that tests are performed in accordance with this

specification. Contractors inspector will confirm that Subcontractors

implementation and conducting of the PMI program is in accordance with this

procedure.

(3) Subcontractors PMI procedure shall contain, as a minimum, the following

information;

Name and Manufacturer of PMI equipment to be used.

Description of equipment operating principle.

Calibration procedure and frequency

Qualification and training procedure of PMI operator

PMI Marking method for typical components

Acceptance criteria of PMI

Procedure steps in detail.

- Timing of PMI

- PMI Elements of each material

Segregation procedures for tested material

Procedure to follow when identification results are inconclusive (alloy type is

unknown).

Radiation Safety Operating and Emergency Procedures, if applicable.

Statement of operator competency for PMI techniques.

Sample of PMI record or PMI record form

6.4 Acceptable PMI Equipment

(1) Portable X-ray fluorescence spectrometers with direct reading of alloy grade or

composition in the applicable range are generally acceptable. TN Technologies

(former Texas Nuclear) Model 9266 or 9277 and Metrex X-MET instruments are

acceptable.

(2) Portable arc-emission spectrometers with direct reading of alloy grade or

composition (former Texas Nuclear) Model 9266 or 9277 and Metrex X-MET

instruments are acceptable (former Texas Nuclear) Model 9266 or 9277 and

Metrex X-MET instruments are acceptable.

Spectrotest instruments are acceptable.

(3) Portable arc-emission spectroscopes with output in the form of visible light spectra

(e.g. Metascope) are generally acceptable, provided the competence of the PMI

operator is demonstrated and accepted by Contractor.

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 9 OF 11

(4) All materials shall be made good after examination e.g. by dressing out arc

strikes.

6.5 Elements to be Verified

(1) Elements of alloy materials and welds joining them shall be analyzed in

accordance with Attachment-2 : Elements of common alloys subject to PMI.

(2) Where material type is not specified in Attchment-2, alloy elements to be verified by

PMI testing shall be stipulated in the Subcontractors PMI testing procedure and be

subject to approval of Contractor and Owner.

6.6 Qualification of PMI Operators

Subcontractors PMI operator shall be trained, qualified, and experienced to perform

PMI activities. Operator training, qualification and experience record shall be

submitted for Contractors approval.

The PMI operator shall demonstrate their capabilities to the satisfaction of Contractor.

6.7 Acceptance Criteria

(1) Alloys elements verified in accordance with Attachment-2 shall be ranged

between minimum and maximum (+/-) 12.5% of the amounts of alloying elements

specified in each material Code/specification for quantitative analysis.

(2) For qualitative analysis (such as Metascope) existence of alloy elements shall be

verified.

(3) The acceptance criteria for weld metals are based on the requirements of ASME SEC.

II, Part C except for the those used for dissimilar welding

6.8 Retest and Nonconformity of PMI

6.8.1 Retest of PMI

If the PMI test results fall outside the acceptable range, using the standard

instruments described in this Practice, Subcontractor may obtain a quantitative

check analysis performed by an independent testing laboratory. If no method is

referenced in the applicable materials standard, an appropriate method of chemical

analysis, as specified in this Practice, shall be used. Results of this analysis shall

govern

When the Nonconforming item is sampled from a lot, Subcontractor may conduct

100% examination for the remaining items of the lot to verify the acceptability of the

remaining items

In any case, the next 2 lots from the same Supplier shall be examined on 100%

basis.

If the 2 lots contain an unsuccessful item /items, the examination on 100% basis

shall be repeated for the next 2 lots.

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 10 OF 11

6.8.2 Nonconforming Item of PMI

If the PMI test results fall outside of the acceptable ranges, such item shall be

rejected and will be regarded as Nonconforming item. Nonconforming items shall be

dealt with in accordance with Nonconformity Control Procedure (S-900-1540-102)

(1) Whenever materials are identified as incorrect, a rejection note shall be issued

indicating unacceptable materials have been supplied.

(2) Subcontractor shall be responsible for replacing the material with the correct

specified material and for performing PMI on all replacement materials.

(3) Material rejected by PMI shall be marked to designate rejection using indelible ink

or paint.

The rejected items shall be held in a designated area to prohibit their re-use.

6.9 Marking and Identification of PMI

(1) "PMI shall be marked by the PMI operator with a suitable marker on base metal

near the weld when the weld and both sides of base metal are PMI tested and

accepted or onto the component for non-welded part.

(2) Any markers used for identification shall not contain any substances detrimental

to the corrosion resistant materials on site

(3) If the material or item is too light, too small, or cannot otherwise be marked, color

coding shall be applied in conjunction with Subcontractors standard with

Contractors approval.

6.10 Record

All PMI test records shall be the following;

have all required information including unique report number (Refer to Attachment-3)

reviewed by Contractor and Owner with their signature

encoded into QC data control system such as CMS and TOMAS in timely manner

compiled by Subcontractor with traceability

Submitted to Owner through Contractors review as final documentation

DSLNG Project Job No. : 0-5151-20

Requirements of Material Certification & Traceability and

Positive Material Identification for Construction Work

Doc. No. : S-900-1540-201<Rev.0>

SHEET 11 OF 11

Attachment-1 : Scope and Extent of PMI in Construction Phase

Items Extent Notes

LNG

Storage

Tank

Pressure Parts

& Weld

100%

- Pressure containing alloy components and all

associated weld after assembly.

- 100% PMI of welds is defined as 1 location check of

finished weld per each continuous weld.

- For horizontal seam, 1 determination per every

10m length.

Fired

Heater

Pressure Parts

and Weld

100%

- When field assembly is required for furnace tube or

boiler.

- Pressure containing alloy components and all

associated welds after assembly. (Tube skin

thermocouple and refractory anchor welds are

exempted)

- 100% PMI of welds is defined as 1 location check of

finished weld per each continuous weld.

Piping

Material

Bulk Valve

(Non tagged

Valve)

5 % (before

installation)

- PMI of valves shall be applied to the body, bonnet,

cover of alloy valves.

- an Inspection lot is a group of the same valve type,

size and rating.

Bolting

material

5 % (before

installation)

- an Inspection lot is a group of the same alloy type

and size

Piping

Specialties

(Tagged Item)

N/A - To be performed by Vendor/Manufacturer

Pre-fabricated

and Field installed

ping, welds (pipe,

fitting, flange, etc)

100%

(after

installation)

- Pressure containing alloy components and all

associated welds.

- 100% PMI of welds is defined as 1 location check of

finished weld per each continuous weld.

Attachment-2 : Identification Elements of PMI

Alloy Cr Ni Mo Cb Ti Cu Al Remarks

304 / 304L / 304H / 308 /

309 / 310 Stainless Steel

x x

316 / 316L

Stainless Steel

x x x

9% Ni x

Potrebbero piacerti anche

- Engineering Spec For Positive Material IdentificationDocumento8 pagineEngineering Spec For Positive Material Identificationcancerian86100% (1)

- PMI Test ProcedureDocumento5 paginePMI Test Procedureazimr157100% (2)

- PMI Test ProcedureDocumento13 paginePMI Test Proceduredarkchess76100% (1)

- Jpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Documento9 pagineJpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Anoop N Kutty100% (1)

- NDT ProcedureDocumento17 pagineNDT ProcedureFerdie WakeUp FromAdversity100% (1)

- j34 A Doc Ve 678138 Pmi ProcedureDocumento20 paginej34 A Doc Ve 678138 Pmi Proceduremohdbaquer_024100% (1)

- PMI Just in Case: Measurement of Ferrite Content in Austenitic & Duplex SteelDocumento7 paginePMI Just in Case: Measurement of Ferrite Content in Austenitic & Duplex Steelmahi1437100% (1)

- Dye Penetrant ProcedureDocumento7 pagineDye Penetrant Procedurezaki fadl100% (1)

- Post Weld Heat Treatment ProcedureDocumento22 paginePost Weld Heat Treatment ProcedureFerdie OSNessuna valutazione finora

- Sahid PWHT ProcedureDocumento16 pagineSahid PWHT ProcedurebaNessuna valutazione finora

- Marine Facilities Work Egyptian LNG Project-Idku Work Instruction FOR Handling of Consuamable MaterialsDocumento6 pagineMarine Facilities Work Egyptian LNG Project-Idku Work Instruction FOR Handling of Consuamable Materialszaki fadlNessuna valutazione finora

- Welding Procedure Specification: Page 1 of 1Documento2 pagineWelding Procedure Specification: Page 1 of 1Anderson Perez MartinezNessuna valutazione finora

- Procedure For Post Weld Heat Treatment (PWHT PROCEDURE)Documento10 pagineProcedure For Post Weld Heat Treatment (PWHT PROCEDURE)Senthil Kumaran100% (2)

- Inspection Report: CPP-RM-PO-0180Documento4 pagineInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- 4215107-01 Flash Inspection ReportDocumento2 pagine4215107-01 Flash Inspection Reportyat_alaydrusNessuna valutazione finora

- Welding Procedures and Welding Qualiy Control For PipingDocumento18 pagineWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNessuna valutazione finora

- Heat Treatment Procedure GuideDocumento4 pagineHeat Treatment Procedure GuideDemir Alp IlıkobaNessuna valutazione finora

- Madina Group W.L.L. Procedure Qualification Record 152Documento38 pagineMadina Group W.L.L. Procedure Qualification Record 152MAT-LIONNessuna valutazione finora

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocumento3 pagineIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNessuna valutazione finora

- PT NDT ProcedureDocumento5 paginePT NDT ProcedureMohamed AbubackerNessuna valutazione finora

- Example of Positive Material Identification Procedure-PlanDocumento17 pagineExample of Positive Material Identification Procedure-Planglazetm100% (4)

- PMI Procedure Rev.00Documento13 paginePMI Procedure Rev.00Abdul Khaliq40% (5)

- Liquid Penetrant Testing Report SummaryDocumento1 paginaLiquid Penetrant Testing Report SummaryAbdul NaveedNessuna valutazione finora

- Differences between Welding Procedure Specification and Welder Performance QualificationDocumento1 paginaDifferences between Welding Procedure Specification and Welder Performance QualificationFazeel Rick MohammedNessuna valutazione finora

- PT BM 183 DC 00007 PWHT ProcedureDocumento7 paginePT BM 183 DC 00007 PWHT Procedureeldobie3100% (1)

- PWHT Procedure for Boiler OverhaulDocumento10 paginePWHT Procedure for Boiler OverhaulDedy Trianda100% (1)

- Dye Penetrant Inspection ProcedureDocumento14 pagineDye Penetrant Inspection Proceduretankimsin100% (1)

- Vacuum Box TestingDocumento8 pagineVacuum Box TestingMajid Dawood Khan100% (2)

- Calibration Control ProcedureDocumento13 pagineCalibration Control ProcedureHưng Hoàng DuyNessuna valutazione finora

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocumento7 pagineA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNessuna valutazione finora

- DPT ProcedureDocumento4 pagineDPT ProcedureRohit Attri100% (1)

- 8 Material ControlDocumento8 pagine8 Material ControlPrakash RajNessuna valutazione finora

- POSITIVE RECALL PROCEDUREDocumento6 paginePOSITIVE RECALL PROCEDURESiva RamNessuna valutazione finora

- 10 Procedure For PWHT PDFDocumento5 pagine10 Procedure For PWHT PDFeghashangzadeh100% (1)

- Quality Control Plan For Ducting: Project Name: TokushimaDocumento4 pagineQuality Control Plan For Ducting: Project Name: TokushimaNguyen Anh TuanNessuna valutazione finora

- RT ReportDocumento4 pagineRT ReportWeldcast Ndt100% (1)

- UT ProcedureDocumento14 pagineUT Procedurepoodook100% (3)

- Non-Destructive Testing Procedure SummaryDocumento17 pagineNon-Destructive Testing Procedure SummaryFerdie WakeUp FromAdversity100% (2)

- Post Weld Heat Treatment ProcedureDocumento15 paginePost Weld Heat Treatment ProcedureSamer Bayati100% (1)

- Vacuum Box TestingDocumento8 pagineVacuum Box Testingergyap100% (4)

- Welding Inspector Job and ResponsilbilitiesDocumento5 pagineWelding Inspector Job and ResponsilbilitiesFelix GomintongNessuna valutazione finora

- Procedure For The Dye Penetrant Testing of Steel Forgings To BS EN 10228-2:2016Documento4 pagineProcedure For The Dye Penetrant Testing of Steel Forgings To BS EN 10228-2:2016Mark BrailsfordNessuna valutazione finora

- Ultrasonic Thickness Inspection SOPDocumento2 pagineUltrasonic Thickness Inspection SOPJaya Di60% (5)

- PWHT ProcedureDocumento10 paginePWHT ProcedureSang Nguyen QuangNessuna valutazione finora

- A106 Pipe Spec SheetDocumento7 pagineA106 Pipe Spec SheetyanurarzaqaNessuna valutazione finora

- Magnetic Particle Examination Procedure PorDocumento7 pagineMagnetic Particle Examination Procedure PorFasil ParuvanathNessuna valutazione finora

- MAGNETIC PARTICLE TESTING PROCEDUREDocumento24 pagineMAGNETIC PARTICLE TESTING PROCEDURETrung Tinh Ho100% (1)

- Welder IdentificationDocumento9 pagineWelder Identificationdandiar1Nessuna valutazione finora

- Process Piping Guide R2Documento12 pagineProcess Piping Guide R2Edson Araga100% (1)

- Amigos Technical PWHT ProcedureDocumento12 pagineAmigos Technical PWHT Procedurevsnaiduqc50% (2)

- Welding InspectionDocumento7 pagineWelding Inspectionzahid_497100% (1)

- PAUT ProcedureDocumento50 paginePAUT ProcedureAvijit Debnath100% (1)

- Enbridge Pipeline Repair Workplan WeldingDocumento23 pagineEnbridge Pipeline Repair Workplan WeldingJesus MaestreNessuna valutazione finora

- MPT Report FormatDocumento1 paginaMPT Report FormatRoshan ThomasNessuna valutazione finora

- 013 NDT-UT TSE API 1104 - Rev 00-2-21Documento21 pagine013 NDT-UT TSE API 1104 - Rev 00-2-21zainalNessuna valutazione finora

- Industrial radiography A Complete Guide - 2019 EditionDa EverandIndustrial radiography A Complete Guide - 2019 EditionNessuna valutazione finora

- C075 Aq SPC 0006 - 3Documento12 pagineC075 Aq SPC 0006 - 3Mingyu SongNessuna valutazione finora

- Donggi Senoro LNG Project ITP for Pipe Internal BlastingDocumento17 pagineDonggi Senoro LNG Project ITP for Pipe Internal BlastingIksan Adityo MulyoNessuna valutazione finora

- Itp HeDocumento15 pagineItp HeAldeline SungahidNessuna valutazione finora

- ASME Section III Quality Manual I3 R1 03JA2011Documento150 pagineASME Section III Quality Manual I3 R1 03JA2011Juan Enric ElricNessuna valutazione finora

- Signature MT B313Documento1 paginaSignature MT B313Iksan Adityo MulyoNessuna valutazione finora

- Signature Written PracticeDocumento1 paginaSignature Written PracticeIksan Adityo MulyoNessuna valutazione finora

- Indikator Kunci Kinerja k3lDocumento1 paginaIndikator Kunci Kinerja k3lIksan Adityo MulyoNessuna valutazione finora

- Standar ApdDocumento1 paginaStandar ApdIksan Adityo MulyoNessuna valutazione finora

- TA1179-D-5212-100X-3 - P&ID (Marked-Up)Documento40 pagineTA1179-D-5212-100X-3 - P&ID (Marked-Up)Iksan Adityo Mulyo100% (1)

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocumento4 pagineSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiNessuna valutazione finora

- List Kekurangan Isometric DrawingDocumento8 pagineList Kekurangan Isometric DrawingIksan Adityo MulyoNessuna valutazione finora

- P&IDDocumento18 pagineP&IDhectornicolauNessuna valutazione finora

- Risk MatrixDocumento2 pagineRisk MatrixIksan Adityo Mulyo100% (1)

- Hse CommitteeDocumento1 paginaHse CommitteeIksan Adityo MulyoNessuna valutazione finora

- ASME Section IX Welding Code GuideDocumento5 pagineASME Section IX Welding Code GuideIksan Adityo MulyoNessuna valutazione finora

- P CSLTD 028 Pnuematic TestDocumento9 pagineP CSLTD 028 Pnuematic TestIksan Adityo MulyoNessuna valutazione finora

- Medevac & Tim TKTDDocumento6 pagineMedevac & Tim TKTDIksan Adityo Mulyo100% (1)

- Standard Specification for Underground Piping InstallationDocumento22 pagineStandard Specification for Underground Piping Installationt_solanki2001100% (1)

- Manufacture and Designation of SteelsDocumento11 pagineManufacture and Designation of SteelsIksan Adityo MulyoNessuna valutazione finora

- Handout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Documento96 pagineHandout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Iksan Adityo Mulyo100% (1)

- QP - 02 Magnetic Particle Test, Rev 01Documento13 pagineQP - 02 Magnetic Particle Test, Rev 01Iksan Adityo MulyoNessuna valutazione finora

- P CSLTD 028 Hydro TestDocumento9 pagineP CSLTD 028 Hydro TestIksan Adityo MulyoNessuna valutazione finora

- 23 - PT Q&a 1-3 - PDFDocumento49 pagine23 - PT Q&a 1-3 - PDFbassamNessuna valutazione finora

- F.sq-Wi.013.2 Work Instruction For Performing Test at Switch GearDocumento3 pagineF.sq-Wi.013.2 Work Instruction For Performing Test at Switch GearIksan Adityo MulyoNessuna valutazione finora

- QP - 01 Penetrant Test, Rev. 02Documento13 pagineQP - 01 Penetrant Test, Rev. 02Iksan Adityo Mulyo100% (1)

- F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselDocumento7 pagineF.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselIksan Adityo MulyoNessuna valutazione finora

- F.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearDocumento3 pagineF.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearIksan Adityo MulyoNessuna valutazione finora

- Section 01 - Typical Duties of Welding InspectorsDocumento12 pagineSection 01 - Typical Duties of Welding InspectorsIksan Adityo MulyoNessuna valutazione finora

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocumento6 pagineF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoNessuna valutazione finora

- F.sq-wI.008 Procedure For Inspection of Existing Storage TankDocumento17 pagineF.sq-wI.008 Procedure For Inspection of Existing Storage TankIksan Adityo MulyoNessuna valutazione finora

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentDocumento13 pagineF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- Indra: For ConstructionDocumento13 pagineIndra: For ConstructionIksan Adityo MulyoNessuna valutazione finora

- Const/Pip/QC Report June 2012Documento17 pagineConst/Pip/QC Report June 2012Iksan Adityo MulyoNessuna valutazione finora

- Iom DSM100-36Documento27 pagineIom DSM100-36rogueatdoorNessuna valutazione finora

- NATEF Engine Performance Job SheetsDocumento13 pagineNATEF Engine Performance Job SheetsAdriRojasNessuna valutazione finora

- Fire Pump Performance Test Results TemplateDocumento2 pagineFire Pump Performance Test Results TemplateATAIYERO ADEKUNLENessuna valutazione finora

- L. G. Transfer Valve L. G. Transfer Valve: Flaps Fully DownDocumento4 pagineL. G. Transfer Valve L. G. Transfer Valve: Flaps Fully DownArthur NetoNessuna valutazione finora

- ASME 2017 SEC II Part A - Impact TempDocumento1 paginaASME 2017 SEC II Part A - Impact TempVIVEKNessuna valutazione finora

- Control ValvesDocumento32 pagineControl ValvesParmeshwar Nath Tripathi100% (1)

- Pipe Thread Types and DesignationsDocumento2 paginePipe Thread Types and DesignationsJenner Volnney Quispe ChataNessuna valutazione finora

- Worksheet on Work, Power and Energy CalculationsDocumento3 pagineWorksheet on Work, Power and Energy CalculationsMahad Asim100% (2)

- Tutorial Completo Stepper SKCDocumento52 pagineTutorial Completo Stepper SKCricwerNessuna valutazione finora

- Cat Deo Pehj0021-08Documento2 pagineCat Deo Pehj0021-08Edison Mauricio Villamarin MiñoNessuna valutazione finora

- Measuring Distances Using TapeDocumento6 pagineMeasuring Distances Using TapeRogie100% (1)

- Hydraulic Mining Excavator CAT 6040: Matthias Aust - 2013Documento11 pagineHydraulic Mining Excavator CAT 6040: Matthias Aust - 2013----Nessuna valutazione finora

- Switched Reluctance MotorDocumento12 pagineSwitched Reluctance MotorSUMAN CNessuna valutazione finora

- DTC 51Documento4 pagineDTC 51victorNessuna valutazione finora

- Coupled Harmonic Oscillators Made Easy: Articles You May Be Interested inDocumento4 pagineCoupled Harmonic Oscillators Made Easy: Articles You May Be Interested in饒英仿Nessuna valutazione finora

- hx10m 2008 540Documento6 paginehx10m 2008 540Хелфор УкраинаNessuna valutazione finora

- COMPACT RIG HK80CK SOLUTIONDocumento2 pagineCOMPACT RIG HK80CK SOLUTIONuri0% (1)

- Spelter SocketDocumento1 paginaSpelter SocketarslanahmedkhawajaNessuna valutazione finora

- MANUAL PARTES Y SERVICIO SD100sDocumento58 pagineMANUAL PARTES Y SERVICIO SD100sAlberto LimónNessuna valutazione finora

- EME Unit 2 Turbines PPT by Kalyan ChakravarthyDocumento64 pagineEME Unit 2 Turbines PPT by Kalyan ChakravarthyvenkatNessuna valutazione finora

- English Manual PDFDocumento16 pagineEnglish Manual PDFARISNessuna valutazione finora

- Especificaciones 2011-12Documento64 pagineEspecificaciones 2011-12Jose FontenlaNessuna valutazione finora

- Direct Quantification of Rapid and Efficient Single-Stroke Actuationby A Martensitic Transition in A Thermosalient CrystalDocumento5 pagineDirect Quantification of Rapid and Efficient Single-Stroke Actuationby A Martensitic Transition in A Thermosalient CrystalAbdullah KhalilNessuna valutazione finora

- Generator Construction, Opn N Cooling SystemDocumento187 pagineGenerator Construction, Opn N Cooling SystemHelal RahmanNessuna valutazione finora

- fp50 fp100 fp200Documento10 paginefp50 fp100 fp200ducmanh83Nessuna valutazione finora

- Rigging Engineering PDFDocumento18 pagineRigging Engineering PDFHelen Kate Saccuan50% (2)

- Trane Screw Wiring Diagram CHHB070-100 REVaDocumento1 paginaTrane Screw Wiring Diagram CHHB070-100 REVaDarrell MaffeiNessuna valutazione finora

- Design and Evaluate Finned Tube BundlesDocumento6 pagineDesign and Evaluate Finned Tube BundlesGee FungNessuna valutazione finora

- Introduction To Fluid Mechanics Prof. Suman Chakraborty Department of Mechanical Engineering Indian Institute of Technology, Kharagpur Lecture - 39 Application of Bernoulli's Equation - Part - IIDocumento8 pagineIntroduction To Fluid Mechanics Prof. Suman Chakraborty Department of Mechanical Engineering Indian Institute of Technology, Kharagpur Lecture - 39 Application of Bernoulli's Equation - Part - IIdjadja nakamayaNessuna valutazione finora

- SEISMIC ISOLATORSDocumento16 pagineSEISMIC ISOLATORSWillygan PmNessuna valutazione finora