Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Twenty Five Ton Padeye - Spreadsheet

Caricato da

oluomo1Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Twenty Five Ton Padeye - Spreadsheet

Caricato da

oluomo1Copyright:

Formati disponibili

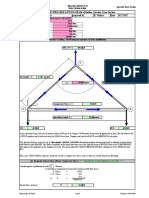

17 TON PADEYE

Page 1 of 4

1.0 Inputs

1.1 Padeye characteristics

R_eye = 26.5 mm eye radius

R_main = 95 mm main plate radius

R_cheek = 70 mm cheek plates radius

th_main = 30 mm main plate thickness

th_cheek = 15 mm cheek plate thickness

a_weld = 7 mm welding dimension between main & cheek plates

H_stiff1 = 95 mm stiffner 1 height

H_stiff2 = 95 mm stiffner 2 height

th_stiff1 = 15 mm stiffner 1 thickness

th_stff2 = 15 mm stiffner 2 thickness

H_eye = 98 mm height of eye

V = 395 mm distance between center of stiffners

V_s1 = 325 mm distance eye-center to stiffner 1

Lenth = 420 mm total length of padeye (stiffners included)

Width1 = 0 mm width of stiffner 1 at feet

Width2 = 0 mm width of stiffner 2 at feet

1.2 Applied loads

F = 331 kN Nominal applied load

a = 60 deg. angle between applied load & Y-Z plane

b = 31 deg. additional sling deviation

S = 2.00 safety coefficient applied to get design load

1.3a Shackle characteristics

d_pin = 41.4 mm pin diameter

in_length = 146 mm Inside length

shackle_safe_load = 17 MT Safe working load

Ash = 60.5 mm Shackle inside width

1 3b N d f t li l t d i lifti THIS CHECK IS NOT PART OF STRENGTH CHECK CALCULATIONS 1.3b Need for centralizer plates during lifting : THIS CHECK IS NOT PART OF STRENGTH CHECK CALCULATIONS

Tt = 60.00 mm Total padeye thickness (both main & cheek plates)

Ash - Tt = 0.50 mm provide centralizer plates with total thickness of -9.5 mm

1.4 Material characteristics

Fy = 235.00 Mpa yield strength

E = 20000.00 Kn/sqc Young elastic modulus

2.0 Design load

together with an inclination angle of 60 deg. to Y-Z plane, and 31 deg. additional sling deviation

Applying a safely factor of 2 gives a design load of:

FD =F*S = 662.00 kN

This results in the following padeye loading

Design load applied in the plane of padeye

FDy =FD*cosa*cosb = 283.72 kN

FDx =FD*sina = 573.31 kN

Design load applied perpendicular to padeye plane

FDz = FD*cosa*sinb+0.05*FD = 203.58 kN as per API-RP-2A recommendations

The lifting eye is checked for a maximum static sling load of 331 kN

x

a

Cheek

Main

Hole

y

1

1

F

Stiffner 1

Stiffner 2

H

H

_

e

y

e

h

t

17 TON PADEYE

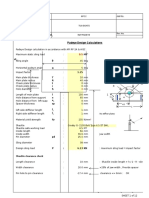

Page 2 of 4

3.0 Check stresses at eye location

3.1 Check shear stress: fy = FD/As

As =2*(th_main*(R_main -

R_eye)+(2*th_cheek)*(R_cheek - R_eye)) = 6720.00 mm^2

fv =FD*10^3/As = 98.51 Mpa

fallowable_v =0.4*Fy = 94.00 Mpa

Stress ratio:

Rv = fv / fallowable_v = 1.05 >1 Not ok

3.2 Check bearing shear stress or radial pressure: fp = FD/Ax

r_axe =d_pin/2 20.70 mm

Ax =2*r_axe*(th_main +2*th_cheek) = 2484.00 mm^2

fx =FD*10^3/Ax = 266.51 MPa

fallowabe_x =0.9*Fy = 211.50 MPa

Stress ratio:

Rx = fx / fallowable_x = 1.26 >1 Not ok

3.3 Check Hertz pressure: fm

Checking in line with the Hertz Formula (Roark -Table 33-2c)

Kb=2*R_eye*d_pin/(2*R_eye-d_pin) = 189.16 mm

fm=0.591*sqrt(F*E/(2*th_cheek+th_main)) = 2018.58 Mpa

fallowable_m =2.5*Fy = 587.50 Mpa

Stress ratio:

Rm = fm / fallowable_m

= 3.44 >1 Not ok

3 4 Check welding between cheek plates & main plate: fvs = FJ/Avs

1 - 1

th_cheek

th main

z

z

3.4 Check welding between cheek plates & main plate: fvs FJ/Avs

Welding characteristics

d_weld =a_weld/sqrt(2) = 4.95 mm

Avs =2*pi*r_cheek*d_weld = 2177.01 mm^2

Load applied per cheek plate

Fj =FD*th_cheek/(2*th_cheek+th_main) = 165.50 kN

fvs =Fj*10^3/Avs = 76.02 Mpa

fallowable_vs =0.4*Fy = 94.00 MPa

Stress ratio:

Rm = fm/fallowable_m = 0.81 <1 ok

tw =Fj/sqrt(2) 117.03 kN

Nw =Fj/sqrt(2) 117.03 kN

Stresses:

fwa =Nw/Avs 53.76 MPa

fwv =Tw/(Avs*2/3) 80.63 MPa

fwVM =sqrt(fwa^2+3fwv^2) 149.65 MPa

Stress ratio:

Rwa = fwa/(0.6*Fy) = 0.38 <1 ok

Rwv = fwv/(0.4*Fy) = 0.86 <1 ok

RwVM = fwVM/(0.66*Fy) = 0.96 <1 ok

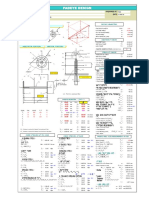

17 TON PADEYE

Page 3 of 4

4.0 Check Shear between Main Plate and Flanges:

F1 =Mz/H - Fx/2 = 215.36007 kN Shear force b/w stiffner 1 and Main plate

F2 =Mz/H +Fx/2 = 357.94875 kN Shear force b/w stiffner 2 and Main plate

fva=Max(F1,F2)/(h*th_main)<=0.4*FY = 125.59605 N/mm2Shear stress in Main plate

fvb=Max(F1,F2)/(h*th_main)<=0.4*FY 125.59605 N/mm2

Stress ratio:

Rva = fva/(0.4*Fy) = 1.34 >1 Not ok

Rvb = fvb/(0.4*Fy) = 1.34 >1 Not ok

5.0 Check Shear in the Chord at Chord / Main Plate Connection

T =Fdy = 283.72 kN

t (Chord thickness) = 31.75 mm

Tv =T/(2*H*t)<=0.4*FY = 11.456587

Stress ratio:

RTV = Tv/(0.4*FY)

= 0.12 <1 ok

6.0 Checking of I-shaped section based on AISC formulae

6.1. Applied load parameters toward the checked section:

I = 98.00 mm Length between the applied load

section and the section checked

along x-axis

d = 0.00 mm Length between the applied load

point and the section checked

COG along y-axis

6.2. Checked section geometrical parameters :

H = 390.00 mm length of the section along y-axis

ew = 30 00 mm thickness of the section parallel to y axis ew = 30.00 mm thickness of the section parallel to y-axis

B = 30.00 mm length of the section along z-axis

ef = 15.00 mm thickness of the section parallel to z-axis

dg = 325.00 mm distance between z-axis and gusset plate axis

6.3. Miscellaneous points definition :

Vy (cm) Vz (cm)

point1 1.50 19.50

point2 1.50 33.25

point3 1.50 31.75

point4 1.50 33.25

CoA 0.00 0.00

6.4. Checked section geometrical parameters :

Areas Ay = 11700.00 mm^2

Az = 900.00 mm^2

Ax = 12600.00 mm^2

Inertias Iy = 94.50 cm^4

Iz = 19584.56 cm^4

Inertia modulus Ny1 =Iy/Vy1 = 63.00 cm^3

Ny2=Iy/Vy2 = 63.00 cm^3

Ny3=Iy/Vy3 = 63.00 cm^3

Ny4=Iy/Vy4 = 63.00 cm^3

Nz1 =Iz/Vz1 = 1004.34 cm^3

Nz2=Iz/Vz2 = 589.01 cm^3

Nz3=Iz/Vz3 = 616.84 cm^3

Nz4=Iz/Vz4 = 589.01 cm^3

17 TON PADEYE

Page 4 of 4

Static moment MsyCoA = 716.63 cm^3

Msy3 = -795.47 cm^3

Msy4 = -1087.97 cm^3

Msz3 = 6.75 cm^3

Msz4 = 6.75 cm^3

6.5. Loading :

N =FD = 662.00 kN

My =-FDz*I = 19950.61 kN.mm

Mz =-FDy*I - FDx*d = 27804.79 kN.mm

Ty =FDy = 283.72 kN

Tz =FDz = 203.58 kN

6.6. Resulting stresses :

Normal stress fa: = 52.54 N/mm^ Ra = 0.37 <1 O.K.

Bending stresses fby1= = 316.68 N/mm^2

fby2= = 316.68 N/mm^2

fby3= = 316.68 N/mm^2

fby4= = 316.68 N/mm^ Rby = 2.04 >1 NOT O

fbz1= = 27.68 N/mm^2

fbz2= = 47.21 N/mm^2

fbz3= = 45.08 N/mm^2

fbz4= = 47.21 N/mm^ Rbz = 0.30 <1 O.K.

Shear stresses fvyCoA= = 34.61

fvy3=Ty*msy3/Iz*t = -38.41 N/mm^2

fvy4=Ty*msy4/Iz*t = -52.54 N/mm^2

fvz3=Tz*msz3/Iy*t = 48.47 N/mm^2

fvz4=Tz*msz4/Iy*t = 48.47 N/mm^2

fv3= = 61.85 N/mm^2

fv4= = 71.48 N/mm^ Rv = 0.76 <1 O.K.

7. AISC streess interaction ratio & Von-Mises stress ratio :

R = fai/0.6 x Fy +(fbyi +fbzi)/0.66 x Fy

(AISC stress interaction ratio)

dVM = [(fai +fbyi +fbzi)^2 +3 x fvi^2]^1/2

(Von - Mises stress ratio)

Point 1 Axial stress + bending y + bending z

R

= 2.59 R = 2.59 >1 NOT O.K.

Point 2 Axial stress + bending y + bending z

R

= 2.72 R = 2.72 >1 NOT O.K.

Point 3 Axial stress + bending y + bending z

R

dVM = 2.71 R = 2.71 >1 NOT O.K.

= 427.92 N/mm^ Rvm = 2.76 >1 NOT O.K.

Point 4 Axial stress + bending y + bending z

R

dVM = 2.72 R = 2.72 >1 NOT O.K.

= 434.44 N/mm^ Rvm = 2.80 >1 NOT O.K.

CoA Axial stress + bending y + bending z

R

dVM = 0.37 R = 0.37 <1 O.K.

= 79.71 N/mm^ Rvm = 0.51 <1 O.K.

Rvm = dVM/0.66 x Fy

Potrebbero piacerti anche

- Bolt Design For Steel Connections As Per AISCDocumento24 pagineBolt Design For Steel Connections As Per AISCJayachandra PelluruNessuna valutazione finora

- Lifting AnalysisDocumento7 pagineLifting AnalysissaharuiNessuna valutazione finora

- Lifting Lug DesignDocumento27 pagineLifting Lug Designmramico100% (1)

- Microsoft Excel ExercisesDocumento14 pagineMicrosoft Excel ExercisesJumaryse Marabut100% (2)

- 1st Stage Lifting & Transportation AX 010915Documento95 pagine1st Stage Lifting & Transportation AX 010915Fauzan Rusmayadi ReharderNessuna valutazione finora

- Pad Eye New ReleaseDocumento10 paginePad Eye New ReleaseEnrique BarajasNessuna valutazione finora

- Lifting Lug Calc-Single CPI - RFDocumento7 pagineLifting Lug Calc-Single CPI - RFRustam RiyadiNessuna valutazione finora

- Design of Cargo Handling Baskets Step ChangeDocumento27 pagineDesign of Cargo Handling Baskets Step ChangeSteve MorrisonNessuna valutazione finora

- Padeye DolphinDocumento38 paginePadeye DolphinMuhammad FadelNessuna valutazione finora

- Padeye - 01Documento9 paginePadeye - 01ramNessuna valutazione finora

- Mathcad - X 320016 30 22 PDFDocumento1 paginaMathcad - X 320016 30 22 PDFUmair LiaqatNessuna valutazione finora

- Multi Lift Point CalcsDocumento4 pagineMulti Lift Point CalcsPalani KarthiNessuna valutazione finora

- Ice-Cream ProductionDocumento65 pagineIce-Cream ProductionMujtaba HaseebNessuna valutazione finora

- Lifting Analysis Report - Mahadi KurniawanDocumento31 pagineLifting Analysis Report - Mahadi KurniawanDian SasNessuna valutazione finora

- Lifting Lug Design-MrDocumento5 pagineLifting Lug Design-MrMiguelRagasNessuna valutazione finora

- Padeye Calculation For Lifting AnalysisDocumento3 paginePadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- Padeye Design GuidelinesDocumento4 paginePadeye Design GuidelineskazdanoNessuna valutazione finora

- Selecting Spreader Beam Check Beam For ES/EEC 1 Compression StressDocumento2 pagineSelecting Spreader Beam Check Beam For ES/EEC 1 Compression StressSudar MyshaNessuna valutazione finora

- Padeye CalculationDocumento6 paginePadeye CalculationKarun DasNessuna valutazione finora

- Spreader Beam Design for 10 Ton LiftingDocumento25 pagineSpreader Beam Design for 10 Ton LiftingWalterNessuna valutazione finora

- Padeye Calculation Calculations To Determine The Pad Eye Thickness Is Based On DNV 2Documento1 paginaPadeye Calculation Calculations To Determine The Pad Eye Thickness Is Based On DNV 2Zulham Chandra100% (1)

- Multi Lift Point CalcsDocumento3 pagineMulti Lift Point CalcsLarry DeemNessuna valutazione finora

- Horizontal Lifting LugDocumento1 paginaHorizontal Lifting LugTushar MangratiNessuna valutazione finora

- Lifting BEAMSDocumento90 pagineLifting BEAMSGogyNessuna valutazione finora

- Ce 1353 - Construction Planning and Scheduling: Noorul Islam College of EngineeringDocumento67 pagineCe 1353 - Construction Planning and Scheduling: Noorul Islam College of EngineeringMarimuthu Kannimuthu100% (1)

- Calculation Lifting LugDocumento4 pagineCalculation Lifting Lugelang purbayaNessuna valutazione finora

- ARMARE GRINDA ''T'' (IN CAMPDocumento39 pagineARMARE GRINDA ''T'' (IN CAMPAndreea Nan100% (2)

- Level 1 Deck Lifting - Lifting LugDocumento20 pagineLevel 1 Deck Lifting - Lifting LugNag RajNessuna valutazione finora

- Marine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102Documento22 pagineMarine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102leelarama100% (1)

- Properties of Skeletal MuscleDocumento72 pagineProperties of Skeletal MuscleAakash GohilNessuna valutazione finora

- False CeilingDocumento70 pagineFalse CeilingBharti Sikri93% (15)

- Strength Calculation For PlatformDocumento2 pagineStrength Calculation For PlatformRaghNessuna valutazione finora

- Sendai Project Lifting Lug DesignDocumento6 pagineSendai Project Lifting Lug DesignkalpanaadhiNessuna valutazione finora

- Axion DatabaseDocumento25 pagineAxion Databasemacy williamsNessuna valutazione finora

- Calculation Sheet: Design of PadeyeDocumento7 pagineCalculation Sheet: Design of PadeyeIkade SuartanaNessuna valutazione finora

- Skid Lifitng Lug CalculationsDocumento9 pagineSkid Lifitng Lug CalculationsMohamed ImthiyasNessuna valutazione finora

- Section Properties: Design of Padeye As Per Aisc 360-2005Documento5 pagineSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNessuna valutazione finora

- Table Calculation LiftingsetDocumento8 pagineTable Calculation LiftingsetSupriyadiNessuna valutazione finora

- Spreader Bar3 - L.9 M-CertificationDocumento10 pagineSpreader Bar3 - L.9 M-CertificationsiagiandobahNessuna valutazione finora

- EC3 - Offshore Padeye DesignDocumento4 pagineEC3 - Offshore Padeye Designscaricatutto100% (1)

- 17 TON PADEYE STRENGTH CHECKDocumento12 pagine17 TON PADEYE STRENGTH CHECKoluomo1Nessuna valutazione finora

- Weld Design - Inplace and Accidental Conditions: InputDocumento2 pagineWeld Design - Inplace and Accidental Conditions: InputinnovativekarthiNessuna valutazione finora

- TQ-0305-R00 - Calculo Estrutura PDFDocumento4 pagineTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroNessuna valutazione finora

- Padeye .5MT CHKDocumento12 paginePadeye .5MT CHKDhanraj VasanthNessuna valutazione finora

- Spreader Beam SampleDocumento10 pagineSpreader Beam SampleAdi SutardiNessuna valutazione finora

- Calculation For Lifting Lug DesignDocumento6 pagineCalculation For Lifting Lug DesignErin JohnsonNessuna valutazione finora

- Beam-Column Hunch-End Plate Moment Conn PDFDocumento11 pagineBeam-Column Hunch-End Plate Moment Conn PDFnagiA ahmedNessuna valutazione finora

- Individual tone frequencies have hidden qualitiesDocumento7 pagineIndividual tone frequencies have hidden qualitiesArnauNessuna valutazione finora

- Pile Foundation Concrete Column DesignDocumento27 paginePile Foundation Concrete Column DesignMachez PenyNessuna valutazione finora

- SEA FASTENING CALCULATIONS FOR EVAPORATOR MODULEDocumento11 pagineSEA FASTENING CALCULATIONS FOR EVAPORATOR MODULEPradeep ChitluriNessuna valutazione finora

- Padeye CALCULATIONDocumento9 paginePadeye CALCULATIONramana_96392699Nessuna valutazione finora

- Flutter Layout Cheat SheetDocumento11 pagineFlutter Layout Cheat SheetJarrett Yew0% (1)

- SWI PadeyeDocumento11 pagineSWI PadeyeFian ArdiyanaNessuna valutazione finora

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Documento7 pagineLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonNessuna valutazione finora

- CO2 AbsorberDocumento11 pagineCO2 AbsorberDhrumil Gandhi100% (2)

- Numerical Reasoning Formulas PDFDocumento7 pagineNumerical Reasoning Formulas PDFandreea_zgrNessuna valutazione finora

- 8 Padeye - Spreadsheet Check1Documento4 pagine8 Padeye - Spreadsheet Check1oluomo1Nessuna valutazione finora

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocumento1 pagina2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNessuna valutazione finora

- EN 12079-1:2006 (E) Forklift Pocket DimensionsDocumento3 pagineEN 12079-1:2006 (E) Forklift Pocket Dimensionsdsn_sarmaNessuna valutazione finora

- ASME SpreaderBar DWGDocumento1 paginaASME SpreaderBar DWGInspetor SoldagemNessuna valutazione finora

- Structural Analysis of 67m3 Above Ground Storage TankDocumento16 pagineStructural Analysis of 67m3 Above Ground Storage TankTech DesignNessuna valutazione finora

- Transmission Line Design and Steel Pole StructuresDocumento27 pagineTransmission Line Design and Steel Pole StructuresDanNessuna valutazione finora

- Mathcad - Grout Connection HSE RulesDocumento3 pagineMathcad - Grout Connection HSE RulesRayodcNessuna valutazione finora

- Securing Straps & RatchetsDocumento2 pagineSecuring Straps & RatchetsKhurram S. MuzammilNessuna valutazione finora

- Out of Roundnesscalculations:: Max MinDocumento6 pagineOut of Roundnesscalculations:: Max MinAdekimi EmmanuelNessuna valutazione finora

- 6a Padeye Aisc 360 2005Documento6 pagine6a Padeye Aisc 360 2005mjlazoNessuna valutazione finora

- Torsion Validation ShayanDocumento10 pagineTorsion Validation ShayanGicuNessuna valutazione finora

- NDECKDocumento12 pagineNDECKNhân Lê TrọngNessuna valutazione finora

- 2 ProracunDocumento6 pagine2 ProracunStjepan RadosavljevicNessuna valutazione finora

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationDa EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNessuna valutazione finora

- Statement of Purpose GuidelinesDocumento2 pagineStatement of Purpose Guidelinesparin advaniNessuna valutazione finora

- 3293 14043 1 PBDocumento18 pagine3293 14043 1 PBoluomo1Nessuna valutazione finora

- MosesDocumento34 pagineMosesoluomo1Nessuna valutazione finora

- EiDocumento21 pagineEioluomo1Nessuna valutazione finora

- Safety Nets: Fall Protection For The Construction Industry: National Safety Council Data Sheet 608 Rev. February 2006Documento14 pagineSafety Nets: Fall Protection For The Construction Industry: National Safety Council Data Sheet 608 Rev. February 2006oluomo1Nessuna valutazione finora

- Tool For Ssuccess PDFDocumento1 paginaTool For Ssuccess PDFoluomo1Nessuna valutazione finora

- Welds Connection PDFDocumento27 pagineWelds Connection PDFoluomo1Nessuna valutazione finora

- Usfos HydrodynamicsDocumento95 pagineUsfos Hydrodynamicsabhinavka123Nessuna valutazione finora

- CARFAX Vehicle History Report OnDocumento4 pagineCARFAX Vehicle History Report Onoluomo1Nessuna valutazione finora

- Fiber Glass SystemDocumento36 pagineFiber Glass SystemLe Ngoc AnhNessuna valutazione finora

- Field2 MaginalDocumento1 paginaField2 Maginaloluomo1Nessuna valutazione finora

- Pin Connections// Top and Bottom Flange Crop Parallel To Plane of ConnectionDocumento3 paginePin Connections// Top and Bottom Flange Crop Parallel To Plane of Connectionoluomo1Nessuna valutazione finora

- Bill Gates - The Skills You Need To SucceedDocumento3 pagineBill Gates - The Skills You Need To SucceedCedric NiamkéNessuna valutazione finora

- SFM NotesDocumento11 pagineSFM NotesHanuma GonellaNessuna valutazione finora

- MFM PrayersDocumento1 paginaMFM Prayersoluomo1Nessuna valutazione finora

- Position Details - Construction AdvisorDocumento2 paginePosition Details - Construction Advisoroluomo1Nessuna valutazione finora

- Statement of Purpose GuidelinesDocumento2 pagineStatement of Purpose Guidelinesparin advaniNessuna valutazione finora

- Position Detials - Project Manager Non-ITDocumento1 paginaPosition Detials - Project Manager Non-IToluomo1Nessuna valutazione finora

- Maginal FieldDocumento1 paginaMaginal Fieldoluomo1Nessuna valutazione finora

- Position Details - Construction AdvisorDocumento2 paginePosition Details - Construction Advisoroluomo1Nessuna valutazione finora

- Catalog - ISO 1161 Steel Container Corner Castings - Cargo Container PartsDocumento2 pagineCatalog - ISO 1161 Steel Container Corner Castings - Cargo Container Partsoluomo1100% (1)

- OGUNDocumento1 paginaOGUNoluomo1Nessuna valutazione finora

- Sheduling TOOLDocumento1 paginaSheduling TOOLoluomo1Nessuna valutazione finora

- Sheduling TOOLDocumento1 paginaSheduling TOOLoluomo1Nessuna valutazione finora

- Scheduling STDDocumento1 paginaScheduling STDoluomo1Nessuna valutazione finora

- Scheduling STD PDFDocumento1 paginaScheduling STD PDFoluomo1Nessuna valutazione finora

- Knight LeaderDocumento1 paginaKnight Leaderoluomo1Nessuna valutazione finora

- Sick GM31Documento54 pagineSick GM31Magdy SalehNessuna valutazione finora

- Six Sigma MotorolaDocumento3 pagineSix Sigma MotorolarafaNessuna valutazione finora

- Elon Musk: AI Is A Fundamental Risk To The Existence of Human CivilizationDocumento19 pagineElon Musk: AI Is A Fundamental Risk To The Existence of Human CivilizationBDApp StarNessuna valutazione finora

- 3D Printing Seminar REPORT-srijanDocumento26 pagine3D Printing Seminar REPORT-srijanSrijan UpadhyayNessuna valutazione finora

- OAF Hello Word Page PDFDocumento20 pagineOAF Hello Word Page PDFNaveen KumarNessuna valutazione finora

- Drilling RisersDocumento13 pagineDrilling Risersadvantage025Nessuna valutazione finora

- Sany - SCC8300 Crawler CraneDocumento52 pagineSany - SCC8300 Crawler CraneNunoNessuna valutazione finora

- Perfect Secrecy: Chester Rebeiro IIT MadrasDocumento50 paginePerfect Secrecy: Chester Rebeiro IIT MadrasDr. Jayanthi V.S.Nessuna valutazione finora

- Earthquake Faults and Tectonic Plate Boundaries ExplainedDocumento21 pagineEarthquake Faults and Tectonic Plate Boundaries ExplainedAngelo RemeticadoNessuna valutazione finora

- AS-9100-Rev-D Internal-Audit-Checklist SampleDocumento4 pagineAS-9100-Rev-D Internal-Audit-Checklist Samplesaifulramli69Nessuna valutazione finora

- ĐỀ CƯƠNG ÔN TẬP HỌC KÌ 1-LỚP 12Documento15 pagineĐỀ CƯƠNG ÔN TẬP HỌC KÌ 1-LỚP 12Anh Duc VuNessuna valutazione finora

- Baumann Forklift Dx50!14!40 S N 5361 Spare Parts CatalogueDocumento22 pagineBaumann Forklift Dx50!14!40 S N 5361 Spare Parts Catalogueanneclark120297mgz100% (108)

- EGGAR - Final ReportDocumento8 pagineEGGAR - Final ReportAndrew LeeNessuna valutazione finora

- Practical Project Planning and Tracking Using Microsoft Project v2.7Documento47 paginePractical Project Planning and Tracking Using Microsoft Project v2.7Nelson Aguirre BravoNessuna valutazione finora

- DLookup Function - Access - Microsoft OfficeDocumento2 pagineDLookup Function - Access - Microsoft OfficevinahackNessuna valutazione finora

- Meinrad 2018 All Symbols With NumbersDocumento4 pagineMeinrad 2018 All Symbols With NumbersXer N. AcostaNessuna valutazione finora

- RDSCM HowTo GuideDocumento17 pagineRDSCM HowTo GuideEric LandryNessuna valutazione finora

- Keurig Gourmet Single Cup Home Brewing System: Section 1Documento11 pagineKeurig Gourmet Single Cup Home Brewing System: Section 1Tijuan MuhammadNessuna valutazione finora

- This Study Resource Was: Practice Questions and Answers Inventory Management: EOQ ModelDocumento7 pagineThis Study Resource Was: Practice Questions and Answers Inventory Management: EOQ Modelwasif ahmedNessuna valutazione finora

- Worksheet Chapter 50 Introduction To Ecology The Scope of EcologyDocumento2 pagineWorksheet Chapter 50 Introduction To Ecology The Scope of EcologyFernando CastilloNessuna valutazione finora

- Leadership EthiqueDocumento16 pagineLeadership EthiqueNOURDINE EZZALMADINessuna valutazione finora

- Emp Unit-1 Communication SkillsDocumento14 pagineEmp Unit-1 Communication SkillsSaraswathi GopalNessuna valutazione finora

- 5.2 Flanged Bolt CouplingDocumento11 pagine5.2 Flanged Bolt CouplingShayneBumatay0% (1)