Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Intertek Poster A1 (HazLoc - Guide) - 0

Caricato da

Antonio FilipeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Intertek Poster A1 (HazLoc - Guide) - 0

Caricato da

Antonio FilipeCopyright:

Formati disponibili

Europe United Kingdom

+44 1244 882590

hazloc@intertek.com

Americas Cortland

+1 607 753 6711

icenter@intertek.com

Europe Italy

+39 0432 653411

info.etls-italy@intertek.com

Published: July 2013

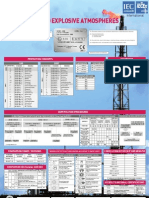

ATEX Categories v Zones of Use

Equipment Category

ATEX 94/9/EC

Zone of Use

Gas, Vapours, & Mist Dust

Cat 1 Zone 0, 1 & 2 Zone 20, 21 & 22

Cat 2 Zone 1 & 2 Zone 21 & 22

Cat 3 Zone 2 Zone 22

Note: Unless the explosion protection risk assessment states otherwise.

Groups [ATEX and IECEx]

Group Environment Location Typical Substance

I

Gases, Vapours

and Coal Dust

Coal Mining Methane (Fire damp)

IIA

Gases, Vapours

and Mists

Surface and other

locations

Methane, Propane etc.

IIB Ethylene

IIC Hydrogen, Acetylene etc.

IIIA

Combustible

Dusts

Surface and other

locations

Combustible flyings

IIIB Non-conductive

IIIC Conductive

International Protection IEC 60529

First Figure Protection against Solids Second Figure Protection against Liquids

IP Test Comment IP Test Comment

0 No Protection 0 No Protection

1 50

Protected against solid

bodies greater than

50mm diameter (e.g.

accidental contact with

the hand)

1

Protected against

vertically falling drops

of water (condensation)

2 12.5

Protected against solid

bodies greater than

12.5mm diameter (e.g.

finger)

2

15

Protected against drops

of water falling up to

15 from the vertical

3

2.5

Protected against solid

bodies greater than

2.5mm diameter (e.g.

tools, wires)

3

30

Protected against water

sprayed up to 60 from

the vertical

4

1.0

Protected against solid

bodies greater than

1.0mm diameter (e.g.

thin tools and fine wire)

4

Protected against

splashing water from

all directions

5

Protected against dust

(no harmful deposit) -

Dust Proof

5

Protected against

jets of water from all

directions

6

Completely protected

against dusts - Dust

Tight

6

Protected against

powerful jets of water

from all directions

IEC (International Electrotechnical Commission)

Publication 60529: Classification of Degrees of

Protection Provided by Enclosures provides a system

for specifying the enclosures of equipment on

the basis of the degree of protection provided by

the enclosure. IEC 60529 does not specify degrees

of mechanical damage of equipment, risk of

explosions, or conditions such as moisture (produced

for example by condensation), corrosive vapours,

fungus, or vermin.

7

1M

150mm Protected against the

effects of temporary

immersion in water

8

m

Protected against the

continuous effects of

immersion in water

having regard to

specific conditions

Zoning Definitions

Equipment Categories &

Protection Levels

Gas

IEC 60079-10-1

Dust

IEC 60079-10-2

Definitions

ATEX

Category

Equipment

Protection

Levels

Typical Zone Suitability

0

A place in which an explosive atmosphere

is continually present

1 G Ga Equip. suitable for Zones 0,1,2

20 1 D Da Equip. suitable for Zones 20,21,22

1 A place in which an explosive atmosphere

is likely to occur in normal operation

occasionally

2 G Gb Equip. suitable for Zones 1,2

21 2 D Db Equip. suitable for Zones 21,22

2 A place in which an explosive atmosphere

is not likely to occur in normal operation,

but if it does only occurs for short periods

3 G Gc Equip. suitable for Zone 2

22 3 D Dc Equip. suitable for Zone 22

Protection Concepts [North America]

Type of Protection

USA Canada

Basic Concept of

Protection

NEC

500 NEC

505 Existing New

Area Classification Code Area Classification Code

Increased Safety

Non-Incendive

NA

Division 2

Zone 1, 2

Zone 2

AEx e

AEx n

NA

Division 2

Zone 1, 2

Zone 2

Ex e

Ex n

No arcs, sparks, or

hot surfaces

Flameproof

Explosionproof

Powder Filled

NA

Division 1,2

NA

Zone 1, 2

NA

Zone 1, 2

AEx d

NA

AEx q

NA

Division 1,2

NA

Zone 1, 2

NA

Zone 1, 2

Ex d

NA

Ex q

Contain the

explosion, prevent

flame propagation

Intrinsic Safety

Division 1,2

NA

Zone 0,1,2

Zone 1, 2

AEx ia

AEx ib

Division 1,2

NA

Zone 0,1,2

Zone 1, 2

Ex ia

Ex ib

Limit the spark

energy and

temperatures

Pressurized (Purged)

Encapsulation

Oil Immersion

Division 1,2

NA

Division 2

Zone 1, 2

Zone 1, 2

Zone 1, 2

AEx p

AEx m

AEx o

Division 1,2

NA

Division 2

Zone 1, 2

Zone 1, 2

Zone 1, 2

Ex p

Ex m

Ex o

Exclude gas from

ignition sources

Note: NEC Article 501.1 permits the use of zone-rated equipment in Class I Division 2 locations.

Equipment Group [ATEX and IECEx]

Equipment Group

Equipment

Category

EPL Atmosphere

Protection

Level

Required Protection

Performance & Operation

I (Mines with

firedamp)

M1 Ma Methane & Dust Very High

Two Faults, Remain

energised and functioning

I (Mines with

firedamp)

M2 Mb Methane & Dust High

Severe normal operation,

De-energise in exp. atm.

II (all other areas) 1 a Gas, Vapour, Mist, Dust Very High Two Faults

II (all other areas) 2 b Gas, Vapour, Mist, Dust High One Fault

II (all other areas) 3 c Gas, Vapour, Mist, Dust Low Normal operation

Typical NEC

Marking

NEC

500 NEC

505

Class I, Zone 0, AEx ia IIC T4

Hazard

Class

Protection

Concept

Code

Area

Classification

Approved to

US Standards

Class I, Division 1, Groups A&B T4

Temperature

Class

Gas Group

Hazard

Class

Area

Classification

Temperature

Class

Gas

Group

Typical ATEX and IECEx Marking [*ATEX only]

II 2 GD Ex d IIC T4 Gb

0359

*Complies

with

European

Directive Equipment

Protection

Level

Type of

Protection

Explosion

Protection

*Environment

*Equipment

Category

Temperature

Class (T1-T6)

(and/or T135C)

Group

*Specific

Marking for

Explosion

Protection

*Equipment

Group

*Notified

Body Number

Gas Groups [North America]

Substance:

Hazard

Class:

NEC 500: NEC 505:

Lower

Exposure Limit:

Upper

Exposure Limit:

Any Gas

Class I

Acetylene Group A IIC 2.3 % 100 %

Hydrogen Group B IIC 4 % 77 %

Ethylene Group C IIB 2.3 % 36 %

Propane Group D IIA 1.7 % 11 %

Methane (mining) Group D 4.4 % 17 %

Combustible Metal Dusts

Class II

Group E

Combustible Carbonaceous Dusts Group F

Combustible Dusts not in Group E or F

(Flour, Grain, Wood, Plastics, Chemicals)

Group G

Combustible Fibres and Flyings Class III

Temperature Classification

Max. Surface

Temperature

NEC

500 CEC

NEC

505 IEC - Group II

450 C (842F) T1 T1 T1

300 C (572F) T2 T2 T2

280 C (536F) T2A

260 C (500F) T2B

230 C (446F) T2C

215 C (419F) T2D

200 C (392F) T3 T3 T3

180 C (356F) T3A

165 C (329F) T3B

160 C (320F) T3C

135 C (275F) T4 T4 T4

120 C (248F) T4A

100 C (212F) T5 T5 T5

85 C (185F) T6 T6 T6

Note: For Group I (CENELEC/IEC) applications, electrical apparatus has fixed temperature limits i.e., 150 C and 450C.

Protection Concepts [ATEX and IECEx]

Type of Protection Symbol

Typical

IEC EPL

Typical

Zone(s)

IEC Standard Basic concept of protection

Electrical equipment for gases, vapours and mists (G)

General requirements 0,1,2 IEC 60079-0

Optical Radiation

Op pr

Op sh

Op is

Gb

Ga

Ga

1,2

0,1,2

0,1,2

IEC 60079-28

IEC 60079-28

IEC 60079-28

Inherently safe protected by

shutdown

Increased safety

Type n (non-sparking)

e

nA

Gb

Gc

1,2

2

IEC 60079-7

IEC 60079-15

No arcs, sparks or hot surfaces.

Enclosure IP54 or better

Flameproof

Type n (enclosed break)

d

nC

Gb

Gc

1,2

2

IEC 60079-1

IEC 60079-15

Contain the explosion, quench

the flame

Quartz/sand filled q Gb 1,2 IEC 60079-5 Quench the flame

Intrinsic safety

Intrinsic safety

Intrinsic safety

ia

ib

ic

Ga

Gb

Gc

0,1,2

1,2

2

IEC 60079-11

IEC 60079-11

IEC 60079-11

Limit the energy of sparks and

surface temperatures

Pressurised

Pressurised

Pressurised

px

py

pz

Gb

Gb

Gc

1,2

1,2

2

IEC 60079-2

IEC 60079-2

IEC 60079-2

Keep the flammable gas out

Type n (sealing &hermetic sealing)

Type n (restricted breathing)

nC

nR

Gc

Gc

2

2

IEC 60079-15

IEC 60079-15

Keep the flammable gas out

Encapsulation

Encapsulation

Encapsulation

ma

mb

mc

Ga

Gb

Gc

0,1,2

1,2

2

IEC 60079-18

IEC 60079-18

IEC 60079-18

Keep the flammable gas out

Oil immersion o Gb 1,2 IEC 60079-6 Keep the flammable gas out

Electrical equipment for combustible dusts (D)

Enclosure

ta

tb

tc

Da

Db

Dc

20,21,22 IEC 60079-31

Standard protection for dusts,

rugged tight enclosure

Intrinsic safety

ia

ib

ic

Da

Db

Dc

20,21,22 IEC 60079-11

Similar to t, but with some

relaxations if circuit inside is

intrinsically safe

Encapsulation

ma

mb

mc

Da

Db

Dc

20,21,22 EC 60079-18

Protection by encapsulation of

incendive parts

Pressurised pD

Db 21,22

IEC 61241-4

Protection by pressurisation of

enclosure

Dc 22

Non-Electrical equipment

General - -

0,1,2

20,21,22

EN 13463-1 Low potential energy

Flow restricted enclosure

flameproof enclosure

fr

d

-

-

2,22

1,2,21,22

EN 13463-2

EN 13463-3

Relies on tight seals, closely

matched joints and tough

enclosures to restrict the

breathing of the enclosure

Constructional safety c -

0,1,2,

20,21,22

EN 13463-5

Ignition hazards eliminated by

good engineering methods

Control of ignition sources b -

0,1,2,

20,21,22

EN 13463-6

Control equipment fitted to

detect malfunctions

Pressurisation p -

1,2

21,22

EN 60079-2

EN 61241-4

Enclosure is purged and

pressurised to prevent ignition

sources from arising

Liquid immersion k -

0,1,2,

20,21,22

EN 13463-8

Enclosure uses liquid to

prevent contact with explosive

atmosphere

Useful Standards

Topic IEC Standard

Area Classification - Gases, Vapours and Mists IEC 60079-10-1

Area Classification - Combustible Dusts IEC 60079-10-2

Electrical Equipment Installation IEC 60079-14

Electrical Equipment Inspection and maintenance IEC 60079-17

Electrical Equipment Repair and Overhaul IEC 60079-19

Material Characteristics for gas and vapour classification IEC 60079-20-1

Cable Gland Selection Chart

Start

is area zoned?

is

equipment EX d

concept?

The electrical concepts will be

one of the following types:

For Gases and Vapours

Increased safety (Ex e)

Purge and Pressurisation (Ex p)

Type n (Ex n)

For Combustible Dusts

Potection by enclosure (Ex t)

Glands must meet

the requirements

of IEC 60079-0

Use non-certified

compression cable

glands

To EX d cable

selector chart

No

Yes

No Yes

Notes:

All cable glands should maintain the

protection concept of the enclosure, e.g.

Ex d enclosures should use Ex d glands

Ex e enclosures should use Ex e glands

Ex nR enclosures use Ex e glands

Ex nA, nC enclosures use Ex e glands

Ex t enclosures use Ex e glands

Ex p enclosures the gland can be certified

or non-certified. Ingress Protection to be

maintained.

lnternationaI (ingress) protection can be

maintained by the correct use of barrier

glands, sealing washers or thread sealant

Yes

No

Glands to comply with the

requiremerjs of Clause 9

of IEC 60079-14 and in

accordance with

manufacturers equipment

documentation

Ex e and Ex n Ex p

Flow chart in accordance

with IEC 60079-14 Ed 4.0

EX d Selection Chart

Note 1: Cables used for fixed wiring in hazardous

areas shall be appropriate for the ambient

conditions in service. Cables shall be:

A) Sheathed with thermoplastic, thermo-setting

or elastomeric material. They shall be circular,

compact, have extruded bedding and fillers, if

any shall be non-hygroscopic

B) Mineral insulated metal sheathed e.g. pyros

C) Special e.g. flat cable with appropriate cable

glands

Ensure cable type is in

accordance with the

requirements of IEC

60079-14. Refer to note 1

Use a suitable

flameproof cable

gland with a

sealing ring

(e.g. compression

glands)

Fromcable gland

selector chart

No Yes

Does this

enclosure

contain an internal

source of ignition?

See note 2

No Yes

Does the

hazardous

gas require IIC

apparatus?

No Yes Is the area

of installation of

zone 1?

No Yes

Is the free

volume of the

enclosure greater

than 2 dm3?

Use a barrier

gland

Note 2: Internal sources of ignition include sparks

or equipment temperatures occurring in normal

operation which can cause ignition. An enclosure

containing terminals only or an indirect entry

enclosure is not regarded as an internal source

of ignition

Flow chart in accordance

with IEC 60079-14:2008

Operatives

(Technicians)

Electrical / Instrumentation Mechanical

Explosive Atmospheres Training Courses

Persons working in

hazardous areas have

to be competent

1

Technical

Person? Foundation

Course Ex F

No No

DSEAR/ATEX

Awareness course

for operators

(Bespoke)

Yes

e.g. Operators e.g. Management

Yes

Application Designers

course Ex12

Practioners course

Ex01-Ex04 Gases and

Vapours

Ex01R-Ex04R Gases and

Vapours Refresher

Ex05 & Ex06

Combustible Dusts

Ex07and Ex08 Fuel

Filling Station

(Grangemouth only)

Outside of UK ask

about our CompEx

mobile rig

Practitioners

course Ex11

Mechanical

No

No

Yes

and/or

Designers

Project Engineer /

Maintenance

Engineer

Underpinning

Competency2&3

Electrical / Instrumentation Mechanical

Underpinning

Competency

achieved

Candidate Pre-

learning and self

assessment

2&3

Candidate Pre-

learning and self

assessment

5

Underpinning

Competency

achieved

Yes Yes

Yes

Notes

1 The latest editions of IEC 60079-14 and IEC 60079-17 identify the

skill sets required for Electro-Technical persons who may carry out

work in explosive atmospheres as:

a) Responsible Persons

b) Designers (Refer to flow chart)

c) Operatives (Refer to flow chart)

2 If the candidate is unsure whether they possess sufficient technical

knowledge to undertake the CompEx assessments they will be

offered the option of undertaking the pre-learning and self-

assessment route. Successful completion of this material would

indicate that the candidate is suitable to attend the CompEx

course. The pre-learning and self-assessment route is unique to

lntertek. This does not cover any practical skills.

3 A candidate could prior to attending Ex01-Ex06 complete an Ex F

course as an introduction to the basics of explosive atmospheres.

4 Courses can be undertaken at either our Chester or Grangemouth

training centres, or on the clients site - this is subject to certain

conditions, please request additional information.

5 Pre-learning material currently in progress.

Conformity Assessment Procedures

Equipment of Groups I & II

Categories M2 and 2

No Yes

Internal

combustion

engine or electrical

equipment

Equipment of Groups I & II

Categories M1 and 1 and

Autonomous Protective Systems

EC type Examination

Annex III

and

Production

QA Annex IV

Product

Verification

Annex V

or

EC type Examination

Annex III

and

Conformity to

type Annex VI

Product QA

Annex VII

or

Internal control of

production Annex

VIII

and

Communicate

a technical

documentation to a

Notified Body

Equipment of Group II

Category 3

Internal control of

production Annex

VIII

Equipment of Groups I & II

and Autonomous Protective

Systems

Unit verification

Annex IX

OR

Potrebbero piacerti anche

- ExtronicsWallchart 160708Documento1 paginaExtronicsWallchart 160708Shyam VarunNessuna valutazione finora

- Poster Explosive CEDocumento1 paginaPoster Explosive CENico ArdeleanNessuna valutazione finora

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDocumento1 paginaHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (4)

- IECDocumento1 paginaIECJay Jay100% (1)

- Hazardous Area ClassificationsDocumento1 paginaHazardous Area ClassificationsAndrew Bull100% (2)

- Zone Classification ChartDocumento1 paginaZone Classification ChartMaahiNessuna valutazione finora

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDocumento1 paginaiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNessuna valutazione finora

- Bartec Hazardous Class PosterDocumento1 paginaBartec Hazardous Class PosterDen Andri Nchu100% (2)

- Haz Area ChatDocumento1 paginaHaz Area Chatmaniking1Nessuna valutazione finora

- Ex Poster SVDocumento1 paginaEx Poster SVsaiyedasadNessuna valutazione finora

- Explosion Protection Wall Chart BASEEFADocumento1 paginaExplosion Protection Wall Chart BASEEFAweby98Nessuna valutazione finora

- Hazardous Area ClassificationDocumento63 pagineHazardous Area Classificationhtetwin100% (3)

- List of Standards - InstrumentationDocumento3 pagineList of Standards - InstrumentationHardik Acharya100% (1)

- AtexDocumento8 pagineAtexBao Quoc Mai100% (1)

- Control Valve Specification Sheet: Customer Application End User Tag No End DestinationDocumento3 pagineControl Valve Specification Sheet: Customer Application End User Tag No End DestinationAnonymous oVRvsdWzfBNessuna valutazione finora

- Area Classification IEC NECDocumento18 pagineArea Classification IEC NECin107247100% (1)

- Hazardous Area Classification BasicsDocumento20 pagineHazardous Area Classification Basicssohelazam89% (9)

- Selection of Explosion Protected Equipment For Hazardous LoctionsDocumento32 pagineSelection of Explosion Protected Equipment For Hazardous Loctionsasex4uNessuna valutazione finora

- New Atex Directive: Lars EkströmDocumento23 pagineNew Atex Directive: Lars EkströmvalimironescuNessuna valutazione finora

- D2P2 IECExConf2014 Thurnherr PDFDocumento88 pagineD2P2 IECExConf2014 Thurnherr PDFMakiberNessuna valutazione finora

- Hazardous Area Classification PDFDocumento23 pagineHazardous Area Classification PDFlagm54100% (1)

- Hazardous Area ClassificationDocumento23 pagineHazardous Area ClassificationDattatray Nikam100% (11)

- iPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBDocumento1 paginaiPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBmlutfimaNessuna valutazione finora

- Atex GuideDocumento44 pagineAtex Guideminah22100% (4)

- AtexDocumento60 pagineAtexWendi Junaedi100% (1)

- Atex ClassificationDocumento1 paginaAtex ClassificationDANE80Nessuna valutazione finora

- Po Ex en 170413 WebDocumento1 paginaPo Ex en 170413 Webswordleee swordNessuna valutazione finora

- Hazardous Area SH CourseDocumento22 pagineHazardous Area SH CourseafnakshNessuna valutazione finora

- Pressure Gauge: Max Norm Min UnitsDocumento1 paginaPressure Gauge: Max Norm Min Unitssairam2234Nessuna valutazione finora

- JTL Assessment Practice PaperDocumento20 pagineJTL Assessment Practice PaperKeystoneworks4me100% (1)

- Cable Glands in Hazardous Areas CCG PresentationDocumento59 pagineCable Glands in Hazardous Areas CCG PresentationAwotiku Abimbola100% (2)

- ATEX Wall Chart Reduced PDFDocumento1 paginaATEX Wall Chart Reduced PDFVassoula Dar100% (1)

- Expert Guide To Hazardous LocationsDocumento1 paginaExpert Guide To Hazardous Locationsyuthonline0% (1)

- Sop GSSDocumento3 pagineSop GSSArun MurugaiyanNessuna valutazione finora

- DCS Grounding - LinkedInDocumento8 pagineDCS Grounding - LinkedInmaryamNessuna valutazione finora

- Intrinsic SafetyDocumento85 pagineIntrinsic Safetycaigithe852456100% (2)

- At ExDocumento2 pagineAt ExMoustafa Ibrahim YehyaNessuna valutazione finora

- Ingress SafetyDocumento1 paginaIngress Safetyjohn_tigerNessuna valutazione finora

- Equipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonDocumento1 paginaEquipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonBalan PalaniappanNessuna valutazione finora

- CSA Group WallchartDocumento1 paginaCSA Group WallchartMohd Lutfi MahaliNessuna valutazione finora

- Your Safety - Our Reality: Electrical EquipmentDocumento1 paginaYour Safety - Our Reality: Electrical EquipmentHimanshu ChichraNessuna valutazione finora

- 207-x Marking UkDocumento4 pagine207-x Marking UkgueridiNessuna valutazione finora

- Safety. Everywhere.: Electrical Equipment Non-Electrical EquipmentDocumento1 paginaSafety. Everywhere.: Electrical Equipment Non-Electrical EquipmentNavin KeralaNessuna valutazione finora

- Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6Documento1 paginaYour Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6And WebNessuna valutazione finora

- ATEX-affisch MaluxDocumento1 paginaATEX-affisch MaluxHomer SilvaNessuna valutazione finora

- Classification of Hazardous AreasDocumento1 paginaClassification of Hazardous Areasadhi2001Nessuna valutazione finora

- Data AtexDocumento4 pagineData AtexdursosonoNessuna valutazione finora

- 986 07 1006 031 - ManDocumento8 pagine986 07 1006 031 - ManFernando Ledesma RamirezNessuna valutazione finora

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocumento1 paginaWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishJohnNessuna valutazione finora

- Hazardous AREA ClassificationDocumento10 pagineHazardous AREA Classificationfarzam100% (1)

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocumento1 paginaWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDave CNessuna valutazione finora

- EX Plakat GBDocumento1 paginaEX Plakat GBBohumil NáplavaNessuna valutazione finora

- DS51 Non Electrical Wallchart Iss5 0813Documento1 paginaDS51 Non Electrical Wallchart Iss5 0813perumal1312Nessuna valutazione finora

- North America: Hazardous Areas, Explosive Atmospheres and Equipment GroupDocumento1 paginaNorth America: Hazardous Areas, Explosive Atmospheres and Equipment GroupkazdanoNessuna valutazione finora

- Atex eDocumento1 paginaAtex egtomyNessuna valutazione finora

- GBDocumento11 pagineGBdungtran77Nessuna valutazione finora

- Lcie Bureau Veritas Atex Poster PDFDocumento1 paginaLcie Bureau Veritas Atex Poster PDFAncaOniscuNessuna valutazione finora

- D199-00-601-IS Issue 2 STExC1 MANUALDocumento9 pagineD199-00-601-IS Issue 2 STExC1 MANUALRoberto Martin NavarroNessuna valutazione finora

- Instruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust AtmospheresDocumento4 pagineInstruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust Atmospheresgelustan2006Nessuna valutazione finora

- MTL Flamable FactsDocumento1 paginaMTL Flamable FactsAdeDCNessuna valutazione finora

- NaziZombieArmy PDFDocumento36 pagineNaziZombieArmy PDFCristian Reyes100% (1)

- NTSB Preliminary Report On Northwest Dallas Gas LeaksDocumento5 pagineNTSB Preliminary Report On Northwest Dallas Gas LeaksKERANewsNessuna valutazione finora

- Projecting Bomb, by Titus de Bobula, 1934/1936Documento9 pagineProjecting Bomb, by Titus de Bobula, 1934/1936Vincze Miklós / 24.huNessuna valutazione finora

- Nitrogen TriiodideDocumento8 pagineNitrogen Triiodidesharklaser009Nessuna valutazione finora

- PLN ASM 308 Emergency Preparedness Disaster Management Plan V 4.0Documento180 paginePLN ASM 308 Emergency Preparedness Disaster Management Plan V 4.0Domie Neil Bucag Salas100% (1)

- 7000 English WordlistDocumento42 pagine7000 English WordlisthanweicNessuna valutazione finora

- Catalogo Generale Marston PDFDocumento40 pagineCatalogo Generale Marston PDFANessuna valutazione finora

- Carfil Catalog 2016Documento34 pagineCarfil Catalog 2016Gabitsa GabrielaNessuna valutazione finora

- Lithium-Ion Battery Safety HazardsDocumento3 pagineLithium-Ion Battery Safety HazardsAnas SakrNessuna valutazione finora

- If Steam Drum Under Vacuum Then What Will HappenDocumento2 pagineIf Steam Drum Under Vacuum Then What Will HappenyogacruiseNessuna valutazione finora

- R. Bhattacharya Atomic Energy Regulatory BoardDocumento23 pagineR. Bhattacharya Atomic Energy Regulatory BoardAnonymous YYsE1BxrNessuna valutazione finora

- Cammish DecisionDocumento9 pagineCammish DecisionChris BusbyNessuna valutazione finora

- Advanced Space Hulk v1.0Documento92 pagineAdvanced Space Hulk v1.0adlard_matthew100% (2)

- Explosion e Implosion CalderasDocumento2 pagineExplosion e Implosion CalderasAntonio RamonNessuna valutazione finora

- German Bonfire Tests 40 MMDocumento19 pagineGerman Bonfire Tests 40 MMAmiVolat100% (1)

- Linking Words ExercisesDocumento1 paginaLinking Words ExercisesmidobaseNessuna valutazione finora

- Performance of Emulsion ExplosivesDocumento7 paginePerformance of Emulsion ExplosivesOscar PamosNessuna valutazione finora

- Worlds of HeroesDocumento121 pagineWorlds of HeroesMitchNessuna valutazione finora

- LabuddeDocumento84 pagineLabuddeAli MuzzammilNessuna valutazione finora

- EN 14373-2005 Explosion Suppression Systems PDFDocumento46 pagineEN 14373-2005 Explosion Suppression Systems PDFMurray PeartNessuna valutazione finora

- 7 E's Lesson Plan DRRM VolcanoDocumento4 pagine7 E's Lesson Plan DRRM VolcanoMiljun LacbayoNessuna valutazione finora

- Fire Safety Model-A Restaurant Kitchen FireDocumento9 pagineFire Safety Model-A Restaurant Kitchen FireSean BuckNessuna valutazione finora

- United States Bomb Data Center (Usbdc) Explosives Incident Report (Eir)Documento23 pagineUnited States Bomb Data Center (Usbdc) Explosives Incident Report (Eir)Junarey VerranoNessuna valutazione finora

- Tenerife DisasterDocumento12 pagineTenerife DisasterMuhsin Azhar ShahNessuna valutazione finora

- Colima, Mexico EarthquakeDocumento22 pagineColima, Mexico EarthquakeGerardo GonzálezNessuna valutazione finora

- Dalhousie University - Importance of Perforation Process & Its TechniquesDocumento100 pagineDalhousie University - Importance of Perforation Process & Its TechniquesFernandoEnriqueCalveteGonzálezNessuna valutazione finora

- Fluidized Bed Jet MillDocumento5 pagineFluidized Bed Jet Milln73686861Nessuna valutazione finora

- Rock Breakage ExplosivesDocumento12 pagineRock Breakage ExplosivesRONELNessuna valutazione finora

- Article 4 Methodology - Task 2 - Assessment Human Health PDFDocumento61 pagineArticle 4 Methodology - Task 2 - Assessment Human Health PDFtavo0688100% (1)

- HAZIDDocumento2 pagineHAZIDAnonymous zwSP5gvNessuna valutazione finora