Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Luanda Oil Service Base Quay Wall Construction Method Statement

Caricato da

alec63636Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Luanda Oil Service Base Quay Wall Construction Method Statement

Caricato da

alec63636Copyright:

Formati disponibili

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

%reliminary #et$od Statement for

Quay Wall between Heavy Lift oc! and TCT "rea

& ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

Table of Contents

& *eneral++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ (

1.1 Site Location........................................................................................................... 3

1.2 Scope of Work........................................................................................................ 4

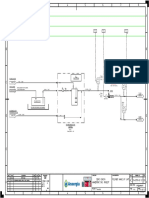

1.3 General Construction Flowchart.............................................................................5

, Temporary -acilities+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ .

( Construction+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ .

3.1 Dredin................................................................................................................. !

3.2 "u##le $eddin for Foundation %rench................................................................1&

3.3 'recast Counterfort units...................................................................................... 15

3.4 (nstallation of Counterfort )nits............................................................................1*

3.5 $ackfillin Sand and +i#ro,co-paction................................................................23

3.. De-olition Works................................................................................................. 24

3./ Cast (n,situ Cappin $ea-...................................................................................25

3.! Drainae Cul0ert.................................................................................................. 2!

3.* Construction of 1pron includin %rench................................................................2!

3.1& (nstallation of 1u2iliar3 Facilities...........................................................................32

3.11 'lace-ent of 1nti,scour 'rotection.......................................................................33

3.12 Fender "eplace-ent and Concrete "epairs........................................................35

, ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

& *eneral

(t is intended to construct a new 4ua3 wall at the 'ort of Luanda5 1nola5 currentl3

known as the Luanda 6il Ser0ice Centre. %he pro7ect co-prises the construction of

442.*- lon 4ua3 wall identified on the drawins referred to in the 8-plo3er9s

"e4uire-ents5 with cope at 3.35 - CD5 ha0in a desin depth of ,12.5- CD

includin foundation works and anti,scour protection #elow ,12.5- CD le0el5 t3in,

in with the e2istin 4ua3 walls and co-plete with na0iation5 #erthin and -oorin

e4uip-ent and pro0ision of spare #erthin e4uip-ent.

&+& Site Location

%he 'ro7ect Site is located at the 'ort of Luanda5 1nola5 currentl3 known as the

Luanda 6il Ser0ice Centre5 as indicated in the followin fiures:

( ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

Site Location

&+, Scope of Wor!

%he scope of the work re4uired includes the followin:

1. Construction of a new 4ua3 wall e2tension co-prisin:

1 new 442.*- lon 4ua3 wall identified on the drawins referred to in the

8-plo3er9s "e4uire-ents5 with cope at 3.35 - CD5 ha0in a desin depth of

,12.5- CD includin foundation works and anti,scour protection #elow ,12.5-

CD le0el5 t3in,in with the e2istin 4ua3 walls and co-plete with na0iation5

#erthin and -oorin e4uip-ent and pro0ision of spare #erthin e4uip-ent.

Dredin to lower the sea#ed in front of the 4ua3 wall to ;12.5- CD and

disposal of spoil to a location to #e areed with the 8-plo3er within Luanda $a3.

"e-o0al of an e2istin pipe spoolin 7ett35 piles alon shoreline5 s-all craft

4ua3 and disposal of -aterials off site.

Such te-porar3 works as -a3 #e re4uired to -aintain the interit3 of the

e2istin 4ua3 walls5 ede of %C% container 3ard5 outfall channels and an3 other

structures earthworks durin construction for the new 4ua3 wall.

$ackfillin #ehind the 4ua3 wall usin dreded sand -aterial pro0ided #3 the

Contractor. %he Contractor shall #e responsi#le to deter-ine where sand

-aterial can #e o#tained for the #ackfillin and shall o#tain the necessar3

appro0als fro- the rele0ant authorities for the re-o0al of sand. $ackfillin shall

follow the re-o0al of slope protection -aterial includin piles and concrete

#locks alon the shoreline close to the Contractor<s construction 3ard. %he slope

/ ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

protection rock -aterial -a3 #e used in the works if suita#le or elsewhere at a

price areed with Sonils. %his will #e deducted fro- the Contractors pa3-ent

clai-s.

1 pa0ed 4ua3 apron 3& - wide #ehind the new 4ua3 wall and the ends of the

e2istin walls.

'ipe trenches in the 4ua3 wall and apron.

Surface water drainae installations includin e2tensions of 3no. e2istin outfall

cul0erts and incorporation of 2no. into the new 4ua3 wall e2tension.

$. Suppl3 and installation of replace-ent fenders and repair of concrete alon the

e2istin 4ua3 wall.

&+( *eneral Construction -lowc$art

%o ensure the achie0e-ent of schedule of the pro7ect5 the construction of each

phase=section should #e started as earl3 as possi#le. 1s the dredin of foundation

trench ets started5 the construction of precast concrete counterforts should #e

initiall3 perfor-ed5 so as to proceed the followin construction as soon as possi#le.

%he eneral construction flowchart of the 'ro7ect is shown as follows:

0 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

Construction -lowc$art

) ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

, Temporary -acilities

"eferrin to the followin fiure5 the e2istin te-porar3 facilities5 includin the

li0in ca-p5 precast 3ard5 #atchin plant5 etc.5 will #e reused after decoration

and repairs. Site office -a3 #e esta#lished within the li0in ca-p or #3 precast

3ard site whose area to #e pro0ided #3 the 8-plo3er.

*eneral Layout of Temporary -acilities

( Construction

1fter the contract has #een awarded5 the -anpower -o#ili>ation will #e started

i--ediatel3. ?ost of the -anpower will #e -o#ili>ed5 so that the 'ro7ect can #e

started as soon as possi#le. @or-all35 the senior staffs will #e initiall3 -o#ili>ed

to the site within four week to start the preparation works. 'art of skilled workers

will #e -o#ili>ed initiall3 to start the construction of te-porar3 facilities within

three -onth. 6ther skilled la#ors and se-i la#ors will #e -o#ili>ed su#se4uentl3

#asin on the construction schedule. 'art of skilled workers5 se-i la#ors and

unskilled la#ors will #e recruited locall3 in Luanda5 1nola.

. ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

%he -o#ili>ation of the 84uip-ent5 such as ra# dreder5 flat top #are5 floatin

crane5 etc.5 will also #e co--enced earl3. 1fter o#tainin the construction

per-ission and consents5 the dredin construction will #e e2ecuted

i--ediatel3.

(+& red1in1

(+&+& *eneral

%he works co-prises the e2ecution of dredin works re4uired for foundation

trench and le0elin of the #erth pocket in front of the new 4ua3 wall to ,12.5 -

CD as indicated on the drawins in 8-plo3er9s "e4uire-ents.

(+&+, red1in1 #et$od

For this ter-inal5 the ra# dreder will #e allocated to the dredin works with

the assistance of the split hopper #are. 1ll dredin work will #e carried out

0erticall3 in la3ers and hori>ontall3 #a3s. %he sketch of dredin construction #3

ra# dreder is shown as #elow:

Gra#

Dreder

Aopper

$are

Gra# Dreder

Water Le0el

6riinal le0el

Desin le0el

Section of Dredin

'lan of Dredin

%he Sketch of Dredin

2 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

red1in1 by *rab red1er

%he procedure for dredin construction is shown as #elow:

%he dreder will #e positioned #3 G'S s3ste-. Durin the dredin5 the le0el of

dredin will #e -easured #3 lead. 6ne h3droraphic -easurin station will #e

also set on the e2istin 4ua3.

%he dredin sa-ple will #e checked and co-pared with #orehole data in ti-e

when it is carried out to each la3er. %he width and depth of the dredin area will

#e controlled in a tolerance of 8-plo3er9s "e4uire-ent. (f the sa-ple is different

with the desin5 it should #e reported to the 8-plo3er to -ake further decision.

Sinificant data and infor-ation of the dredin will #e recorded.

%he dredin works will #e -onitored #3 reular h3droraphic proress sur0e3 in

order to 0erif3 that works are #ein e2ecuted in accordance with the scope of

desin. %he sur0e3 will #e carried #3 echo sounder and G'S positionin de0ice.

%he post,dredin sur0e3 -ust #e carried out i--ediatel3 after the dredin of

the #a3 is finished.

(+&+( Construction Se3uence and Sc$edule

%he dredin se4uence will #e e2ecuted fro- dredin of foundation trench to

dredin of #erth pocket in front of 4ua3 wall. Considerin the site condition5

disposal distance and 0essels9 -aintenance5 a#out 152&&-

3

-aterials per da3

will #e e2ecuted #3 ra# dreder.

(+&+/ isposal of red1in1 #aterials

%he disposal areas are not 3et identified e2actl3 #ut it is assu-ed that dreded

-aterials will #e du-ped offshore to a location to #e areed with the 8-plo3er

within Luanda $a3.

4 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

(+&+0 red1in1 E3uipment

?a7or intended e4uip-ent resources for dredin are listed as #elow:

S=@ Description Bt3. "e-ark

1 Gra# Dreder5 13-

3

1

2 Split Aopper $are5 5&&-

3

2

3 %u $oat5 1&&&Ap 1

4 %raffic $oat 1

5 G'S 'ositionin De0ice 1

. 8cho Sounder 1

(+, 5ubble Beddin1 for -oundation Trenc$

(+,+& 5oc!fillin1

%he sketch of rockfillin for foundation trench is shown as follows and the

rockfillin 4uantit3 is a#out 555&&&-C .%he stone will #e supplied fro- the land

and transported to the te-porar3 4ua3. %he e2ca0ator will #e used to load the

stone onto the 15-

3

hoppers. When hoppers are full3 loaded5 the3 will #e

transported to the specified position for rockfillin. For accurate positionin for

hoppers5 flat top #are will #e used for positionin #3 G'S. %he -ethod of

plu-#in will #e adopted to control the rockfillin heiht accuratel3.

CD -12.5

'ositionin

$are

Split Aopper

$are

S!etc$ of 5oc!fillin1 for -oundation Trenc$

&6 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

$efore the rockfillin starts5 the foundation trench5 which has #een accepted #ut

is not 3et co0ered with rockfillin5 shall #e sur0e3ed aain. (f the thickness of

#ack siltin is a#o0e specified profile5 it shall #e reported to the site 8nineer5

and the work for clearance of silt shall #e orani>ed.

%rial rockfillin shall #e perfor-ed prior to deter-ine the location of the hopper

and thickness of stone du-ped at a ti-e. %hrouh different trial rockfillin with

different loads of stone5 the load for a certain rockfillin thickness can #e

deter-ined. %here#35 proper -ethods for loadin and positionin can also #e

ac4uired.

First5 the hopper will #e used for the coarse,rockfillin5 and then the flat top

#are loaded with stone will #e accuratel3 positioned for supple-entar3

rockfillin. Durin the rockfillin process5 fre4uent plu-#in and -ark ai-in will

#e perfor-ed to a0oid under,rockfillin or o0er,rockfillin.

Settle-ent shall #e taken into consideration for the rockfillin of foundation #ed.

%he preser0ed a-ount of settle-ent shall #e deter-ined #3 desin re4uire-ent.

(+,+, 5ammin1

6ne crawler crane /&t will #e fi2ed on the flat top #are for foundation trench

co-paction. %he foundation trench shall #e co-pacted #3 ra--in in la3ers

accordin to thicknessD and the thickness of the la3er is not ad0isa#le to #e

reater than 3- after co-paction. 1d7acent ra--in rounds with half o0erlapped

with each other lonitudinall3 and trans0ersel3 will #e adopted for co-paction.

%he ra--er will #e planned to use 5 t in weiht with 1.&- dia-eter circular

#otto-. When the #uo3ant force and resistance is not taken into account5 the

i-pact ener3 of each ra--in is not ad0isa#le to #e less than 12&EF=-

2

. %he

co-pact ener3 can #e o#tained when lifted heiht is up to 2.5-. %he ra--er

shall #e lifted up to 3 - to achie0e co-pact ener3 of 13&kF=-

2

for each

ra--in.

%he ra--in for rockfillin #ed shall proceed fro- one point to another5 with

ad7acent ra--in circles half o0erlapped with each other lonitudinall3 and

trans0ersel3 as shown in the sketch5 and will #e carried out in two rounds5 with

the initial ra--in followed #3 the recurrence5 four ti-es ra--in at each point

for each round5 and ! ti-es ra--in in total for each point.

&& ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

Transverse

direction

Direction in which the ship moves

Longitudinal direction

The layout of rammer's falling points

S!etc$ of Layout of 5ammer7s -allin1 %oints

1nchor

/&t Crawler Crane

S!etc$ of 5ammin1 for Trenc$

%he foundation trench shall #e di0ided into 2 sections5 with 2 - o0erlapped

lenth5 and 3- in thickness for each la3er.

%he plane of each rockfillin la3er shall #e checked #efore startin the ra--in5

and le0elin shall #e e2ecuted if heiht difference #etween ad7acent locations is

-ore than &.3-.

%3pical area5 with 1- e2ceedin each side of counterfort and lenth of 1&-5

shall #e chose as the trial section.

&, ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

%he initial ra--in and recurrence will #e e2ecuted #3 the sa-e -eans of

ad7acent ra--in rounds half o0erlapped with each other lonitudinall3 and

trans0ersel3 to pre0ent local hea0e of foundation #ed or flaw of ra--in. 1 -

e2ceedin front=#ack side line of the counterfort will #e taken for ra--ed width.

%he reser0ed settle-ent 0alue will #e ad7usted accordin to the trial ra--in

properl3.

(+,+( Levelin1

%he area of foundation trench to #e le0eled is a#out ./&&-G. When the rockfillin

for foundation trench is co-pleted and accepted5 the work of le0elin will #e

co--enced at once.

%he sur0e3 rod will #e controlled #3 the total station for rails place-ent of the

le0elin work5 while the sur0e3 rod will #e controlled #3 the water le0el to o#tain

the ele0ations. For the place-ent of rails5 the control points shall #e set on the

te-porar3 sur0e3 station.

'lease refer to the followin sketch for le0elin of foundation trech:

"ail

CD. -12.5

Concrete $lock

6#ser0ation #3 Le0elin (nstru-ent

Flat %op $are

Sur0e3 "od

&( ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

Scraper

Di0er

Flat %op $are

Slot Steel "ail

Suppl3 Stone with

Wo0en $a

S!etc$ of -oundation Trenc$ Levelin1

6ne le0elin #are and so-e di0ers will #e in0ol0ed for foundation le0elin. %he

a-ount of ru##le stone and crushed stone shall #e esti-ated #eforehand

accordin to the as,#uilt section of the rockfillin works5 and the stone needed

shall #e prepared.

Flat top #are will #e ser0ed for le0elin5 which can #e loaded with the stone for

le0elin. Crushed stone will #e used at the last step for fine le0elin. +ia the

wo0en #a which will #e raised and put down #3 -anpower5 the crushed stone

will #e transited to the location controlled #3 the di0er for le0elin.

Di0ers will #e e-plo3ed to la3 the steel rails underwater5 and a le0eler will #e

e4uipped on the rails to le0el the crushed stone within reach. Sur0e3ors shall

erect the total station at the sur0e3 station and direct the di0ers to place the steel

rails #3 o#ser0in the instru-ents. %he di0ers shall place concrete #locks

underwater to support the steel rails. 8le0ation of the rails shall #e controlled #3

the water le0el and sur0e3 rod. When the steel rails are read35 two tea-s of

di0ers shall di0e into water at the sa-e ti-e5 and push the le0eler forward alon

the steel rails.

Durin the process for fine le0elin5 ru##le stone shall #e used to fill the une0en

position a-on rock #locks5 while crushed stone shall #e used to fill the une0en

position a-on ru##le stone. %he crushed stone is allowed to for- a la3er with

thickness less than 5c-. 6nl3 those crushed stone of 2H4c- shall #e used. +ia

the #a-#oo #asket which will #e raised and put down #3 -anpower5 the crushed

stone will #e transferred to the position re4uired throuh underwater wire

telephone co--unication #etween the di0er and sur0e3or. %he di0ers shall push

the le0eler Isuch straiht hard -aterial as channel steelJ alon the rails to le0el

&/ ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

the stone. 1nd the co-pletion of le0elin for a section of foundation #ed shall #e

followed #3 the operation for the ne2t section.

8le0ation and position of rails shall #e rechecked at the ti-e after the fine

le0elin. (f an3 de0iation #e3ond allowa#le is found5 the rails shall #e ad7usted.

Life #uo3s connected with concrete #lock throuh n3lon rope shall #e placed for

each corner of the le0eled section of foundation #ed. 1nd those area co-pletel3

le0eled shall #e kept awa3 fro- anchorin of 0essels.

(+( %recast Counterfort units

(+(+& *eneral

%here are 53 units of counterfort ICFJ to #e precast in this pro7ect5 with 51 units

of standard and 2 special. 1ll of the CFs will #e prefa#ricated at the precast 3ard5

with *13&-3 concrete in0ol0ed. %he precast se4uence will in accordance with

the re4uire-ent of site installation.

(+(+, Existin1 Temporary Wor!s

%he e2istin te-porar3 works5 includin precast 3ard5 #atchin plant5 etc.5 will

#e used after decoration and repairs. %he sketch la3out of te-porar3 works is

shown as followins:

&0 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

110

8

100

'ond

"ail

Sedi-ent 'ond

$atchin 'lant

Fence

%e-porar3 Bua3

1reate Stackin Kard

Sand st akin Kard

'recast Line 1

Counterfort

Seaside

'recast Line 2

Counterfort

'recast Li ne 3

Sla#5 et c.

Warehouse

S!etc$ of *eneral Layout of Temporary Wor!s

(+(+( Construction #et$od

1. General arrane-ent

%wo precast lines will #e arraned for CF prefa#rication. ! CF units will #e

co-pleted e0er3 -onth. $allonet -ethod will #e used for transportin the

precast unit.

$. $otto- For-work 'reparation

For the con0enience of #allonet loadin out5 5 roups of (,Steels I32LJ and one

roup channel steel shall #e placed trans0ersall3 on the floor to for- 5

interspaces5 at the ends of the interspaces5 #uilt,up t3pe steel for-work shall #e

placed trans0ersall3 to connect with the lonitudinal (,#ars. %hus the outline of

&) ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

the #otto- for-work can #e for-ed. Sand shall then #e filled into the 5

interspaces5 which shall later #e watered and co-pacted until the surface of

sand is the sa-e le0el as that of the (,#ars and channel steel. 1fterwards5 2&--

thick wooden #oard and paper shall #e placed onto the sand for- the #otto-

for-work. %o transport the co-ponents5 re-o0e the trans0ersal steel for-work

at the ends of the (,#ars5 clear awa3 the sand in the interspaces5 then insert the

#allonets into the interspaces5 when the co-ponent is lifted #3 the #allonets filled

with air5 the (,#ars shall then #e re-o0ed5 and the co-ponent can #e loaded out

to the te-porar3 4ua3 #3 re0ol0in the #allonets in shift.

1s there 2 special counterfort in this pro7ect5 one set of the for-works should #e

chaned correspondinl3. %hese special will #e planed to #e produced finall35 so

that the for-work will not ha0e to #e chaned for tow ti-es.

C. 'rocessin and 8rectin of "e#ar

1fter processin in the shed5 the re#ar shall #e transported to the site #3 trucks

and then #e erected on the #otto- for-work. 1u2iliar3 steel fra-e for re#ar

erection #etween ri# sla# and the upriht sla# shall consist of / la3ers5 each

la3er 2.&- in heiht.

%he au2iliar3 fra-ework -entioned shall #e welded into an inteer #3 profile

steel and fi2ed with the #otto- for-work. %he erectin of re#ar shall #e kept

sta#le and fasten. (n order to han the 0ertical re#ar of upriht sla# and ri# sla#5

-o0a#le profile steel and hori>ontal haner rod shall #e set up on top of the steel

fra-ework. +ertical re#ar shall #e haned onto the hori>ontal haner ro#

accordin to the desin space5 a certain nu-#ers of hori>ontal re#ar shall #e

fastened on the top5 -iddle and #otto- of the 0ertical re#ar to for- a fra-e

structure5 afterwards5 fro- the upper to the down. %he inner re#ar shall #e

erected first5 then the outer hori>ontal re#ar5 and finall3 the re#ar for #otto- sla#.

When the #ar erection work is co-pleted5 concrete co0er spacer shall #e placed

on the surface of the re#ar cae5 outer for-work can #e installed then.

Supported #3 the outer for-work5 the re#ar of the counterfort shall keep sta#le5

afterwards5 the fra-e for #ar erection will #e hoisted out5 and the workin

procedure for fi2in and erection of re#ar has #een full3 finished.

D. Side For-work

CA8C has rich e2perience in precastin the sa-e counterfort in the Bua3 Wall

and G"@ pro7ect. %he antr3 crane 2&t will #e used for for-work installation=

&. ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

re-o0al5 while the inner for-work shall #e installed la3er #3 la3er5 concrete

castin shall #e perfor-ed continuousl3 until it is co-pleted5 so that the

concretin can o on s-oothl35 and the 4ualit3 of the counterfort units can #e

well ensured.

For-work for one side of #otto- sla# shall #e installed as a whole accordin to

the settin,out location. Lare for-work with a weiht of 15t will #e used as outer

for-work. 6utside the steel plate surface5 hori>ontal trusses shall #e erected at

the heiht of 1.2-. %he ad7acent trusses at #oth ends of the upriht wall of

counterfort will #e connected into a whole to for- a #earin rid. $olts that can

#e fastened at #oth ends will #e e4uipped in each ri# of the hori>ontal trusses of

the upriht wall. %herefore5 a #earin structure of -ulti,span continuous #ea- is

for-ed. %he #olts that can #e fastened at #oth ends shall then #e connected with

the fra-e of inner for-work.

$oth the counterfort ri# sla#s and the inner for-work of the upriht wall consist

of / la3ers with 2- la3er heiht. 'osition for erectin of for-work shall #e set out

on the #otto- for-work5 and the -arks shall #e -ade at the place where

supportin concrete #lock need to place. 'lace concrete colu-n #lock at the

riht place5 where steel for-work for #otto- sla# shall #e installed. %he inner

for-work for each la3er shall #e haned to the correspondin steel truss. 1nd

re-o0a#le for-work cha-fered for the con0enience of for-work re-o0al shall

#e installed at the corner. $olts shall #e installed #etween inner for-work and

outer for-work. %he support colu-n for inner for-work of each la3er shall #e

connected #3 #olts end to end. 1nd sealin strip shall #e used for 7oints #etween

for-work. 1 platfor- with #e0el will #e erected with the inner for-work to

facilitate the concrete castin. %he weiht for each section of inner for-work and

the support fra-e is a#out 1&t5 and it will #e hoisted and installed #3 antr3

crane.

1s there are 2 special counterfort is this pro7ect5 one set of the for-works should

#e chaned correspondinl3. %hese special ones will #e produced last5 so that

the for-work won9t ha0e to #e chaned two ti-es.

8. Concrete Castin

With reference to the desin of for-work5 the outer for-work installation shall #e

co-pleted at the #einnin for concrete castin. %he inner for-work #etween

two ri#s shall #e di0ided into / la3ers. %he3 shall #e asse-#led section after

section5 and then #e installed la3er #3 la3er alon with the concrete castin

&2 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

process.

When the installation of for-work is co-pleted and concretin has #een

appro0ed #3 the 8nineer5 the concrete castin -a3 #e co--enced at once.

%he antr3 crane with the concrete #ucket or concrete pu-p truck will #e used

for the castin operation. Concrete will #e supplied #3 the #atchin plant on site5

and #e deli0ered to site #3 concrete truck. Later5 the concrete will #e released

into the concrete #ucket5 hoisted to the for-work #3 the antr3 crane or directl3

cast #3 pu-p truck. La#ors shall then #e e-plo3ed to release the concrete into

the for-work and co-pact it #3 the internal 0i#rator.

%he #otto- sla# and the first la3er of 2- hih wall and ri# shall #e cast first5 and

then the inner for-work for each la3er shall #e installed alon with the increasin

concrete. 8ach la3er for concrete castin shall #e 2- in heiht. 1#out 2 hours

Iless ti-e for the s-aller upper sectionJ will #e taken for the castin of each

la3er. 1#out 1 hour for for-work installation of one la3er. So 3 hours will #e taken

on a0erae for co-pletion of one la3er. %aken other factors into consideration5

the / la3ers includin the #otto- sla#5 can #e co-pleted within 21 hours.

?eanwhile retarder shall #e added into the concrete to ensure the initial settin

ti-e proloned to 4.5,5 hours.

(n the case of hea03 rain durin castin concrete5 the castin can -ake a pause

te-porar35 and #e #etter to co0er the concrete with plastic sheet for a while. (f

the castin cannot #e stopped or resu-ed after pausin5 the -i2 of the concrete

should #e ad7usted appropriatel3.

F. Curin

When the re4uired strenth of the concrete is o#tained and appro0ed #3 the

8nineer5 side for-work can #e re-o0ed. %he concrete shall then #e -arked

and #e cured continuousl3 with fresh water. %he water for concrete curin shall

co-pl3 with the desin re4uire-ent. %he unit shall #e cured with water for /

da3s.

When the co-ponent reaches the 1&&M of the desin strenth5 it can #e -o0ed

to the te-porar3 4ua3 #3 #allonets5 and then #e hoisted to the #are for

installation #3 #are crane.

&4 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

(+/ 8nstallation of Counterfort 9nits

(+/+& *eneral

%here are 53 pieces counterfort ICFJ units weih a#out 432t for each. %he3 will

#e transported fro- the precast area to the te-porar3 4ua3 #3 #allonets5 loaded

on flat top #are 1&&&t and installed #3 floatin crane with -a2i-al hoistin

capa#ilit3 of !&&t.

(+/+, Construction #et$od

$allonet will #e used to transport the CF fro- precast area to te-porar3 4ua3 for

installation. Structure of #allonet is shown as follows:

1 #allonet consists of its #od35 head and no>>le5 etc. (ts au2iliar3 parts include

safet3 0al0e5 pressure -eter and pipe 7oints5 referrin to the followin sketch:

&.!-

1&..-

*-

1 1 2

&.!-

3 4

1

C

1

NN,

2

N

N

1,Aead 2,$od3 3,@o>>le 4,+al0e

Structure drawin of #allonet

S!etc$ of Ballonet Structure

%he #allonet to #e used in this pro7ect is -ade up of . la3ers. %he allowa#le

workin pressure is &.2?'aD and the e2tre-e pressure is &.5?'a. 6ne piece of

O1&&&--P*- #allonet weihs a#out 25&kD and enerall3 the -ass of the air

,6 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

chared can #e o-itted.

(n order to ensure hori>ontal load for the CF at the #einnin of liftin up the unit5

the #allonets shall #e set reularl3 alon the -o0in direction of the CF. 1s per

the le0el load principle:

2

5

Fiure for $allonet under Co-pressin

23!& 23.& 23.& 23.&

Counterfort

C- Transported by Ballonet

Le0elin for foundation trench rockfill -ust #e inspected and accepted #efore

installation. %he CF units will #e hoisted and loaded on #are in se4uence after

the concrete co-pressi0e strenth of the units reach the desined strenth. %he

,& ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

CF units will #e hoisted a#out 5&c- a#o0e the round at first5 and it will #e lifted

up aain when the floatin crane #eco-es stead3. %he #ar3center lines of the

CF unit and 2&&&t #are -ust #e -atched toether when loadin the unit on the

#are in order to a0oid inclination of the #are caused #3 i-#alanced load. %he

plan for CF units loadin on #are is shown as #elow:

Control

Room Longitudinal

Barycenter Line

CF CF

15t Flat Top Barge

Transverse

Barycenter Line

S!etc$ of C- units Loadin1

%he floatin crane and flat top #are will #e -o0ed to the Bua3 site with the help

of tu #oat. %he #ow direction of floatin crane shall #e nor-al to the cope line of

the 4ua35 and two front anchors will #e connected with round anchors #uried

onshore or #ollard.

Sur0e3 stations shall #e prepared #efore installation. %he sur0e3 stations should

#e ensured o#ser0ation without o#struction durin installation5 lonitudinal

sur0e3 station and G'S shall #e prepared separatel3 for controllin the

positionin.

%he installation se4uence will co--ence fro- the Aea03 Lift Dock to e2istin

G"@ Bua3. %i-#er will #e prepared to control 7oints width in ad0ance.

%he positionin for floatin crane and sur0e3 controllin are shown in the

sketches.

,, ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

800t Floating Crane

CF

-12.65 -12.5

S!etc$ of C- units 8nstallation

%he CF unit can #e put on the foundation trench when the positionin is

satisfied5 and di0ers will check width of 7oint and staerin #etween neih#orin

units separatel3. %he shackles can #e released and re-o0ed when the checked

ite-s are 4ualified.

6#ser0ation points for settle-ent and displace-ent can #e set after the

installation5 and the3 will #e sur0e3ed reularl3 or irreularl3 accordin to the

re4uire-ent.

,( ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

(+0 Bac!fillin1 Sand and :ibro;compaction

(+0+& Bac!fillin1 Sand

$ackfillin sand will #e e2ecuted after the co-pletion of eote2tile filter la3er.

Dreded sand will #e used as #ackfill -aterial. %he 4uantit3 of the #ackfillin

sand #ehind the 4ua3 wall is a#out 5*&5&&&-

3

.

%o pre0ent the foundation #ein silted5 the sand will #e #ackfilled when 3& CF

units Ia#out 255-J are installed. 1nd the -ethod of #ackfillin is h3draulic

#ackfillin. %he #ath3-etric sur0e3 should #e carried out #3 G'S echo sounder

or hand,lead sur0e3 #efore #ackfillin5 and then toporaphic -ap will #e -ade to

calculate the 4uantit3 for h3draulic #ackfillin. A3draulic #ackfillin shall #e

e2ecuted #3 recla-ation dreder and #e assisted to fill #3 #ulldo>er5 du-pers

and e2ca0ator. ?eanwhile the settle-ent and displace-ent of CF units will #e

-onitored #3 sur0e3or durin #ackfillin. %he di0er will check the eote2tile filter

la3er to ensure its sta#ilit3 durin construction. $ackfillin will #e e2ecuted with

the se4uence of CF installation.

%he outlet of the h3draulic #ackfillin pipe will #e laid in the location which is

a#out 4&- fro- the cop3 line. Dreded sand will #e used as the -aterial5 and

#ackfilled sand will #e transported5 loaded and le0eled #3 e2ca0ator and

#ulldo>er to the front5 ?anpower will #e used for partiall3 tri--in.

%he Le0el of the 4ua3 apron after #ackfillin #etween 3 and 3&- fro- the cope

line is a#out Q3.&-5 so the le0el after 0i#roflotation is a#out Q2.&-5 which is

a#o0e water le0el and is con0enient for the su#se4uence construction. 1nd the

le0el of the re-ainder is a#out Q3.5- which should co-pl3 with the 8-plo3er

re4uire-ent.

(+0+, :ibro;compaction

%he #ackfilled sand will #e treated I0i#ro,co-pactedJ which is #etween 3- and

3&- fro- the cope line.

+i#ro,flotation lifted #3 crawler crane will #e allocated to carr3 out this

construction5 referrin to the followin sketch:

,/ ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

!C"55 vi#roflot

crawler crane

steel pipe

switch #o$

water pipe

Compaction by :ibro;flotation

(+) emolition Wor!s

%he e2istin pipe spoolin 7ett35 piles alon shoreline5 slope protection -aterial

and e-erenc3 s-all craft 4ua3 shall #e de-olished and re-o0ed fro- site5

specified in 8-plo3er9s "e4uire-ents.

%he h3draulic #reaker and e2ca0ator will #e -ainl3 used for the de-olition

works. (f areed with the 8nineer5 the piles -a3 #e cut off at sea #ed le0el5

pro0ided the3 do not interfere with the 4ua3 wall works.

1cceptance of de-olition works will #e ranted followin the acceptance of the

surface #3 the 8nineer and receipt of all re4uired docu-entation.

%he disposal areas are not 3et identified e2actl3 #ut it is assu-ed that de-olition

-aterials will #e du-ped offsite at a distance5 in a leal -anner and with the

appro0al of local 1uthorities.

,0 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

emolition by Hydraulic Brea!er

(+. Cast 8n;situ Cappin1 Beam

%here is 442.*- cast,in,situ cappin #ea- for the 4ua3 wall5 which is di0ided

into 2. se-ents. %he desin co-pressi0e strenth of the concrete is 4& ?'a5

and the 4uantit3 of concrete in0ol0ed is a#out 2!.1-C. %he standard section of

4ua3 wall is shown as #elow:

Typical Section of Quay

,) ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

%ake the entire se-ent di0ided in accordance with the desin as a construction

unit I1/- as a se-entJ5 concrete will #e cast in place e0er3 other se-ent fro-

Aea03 Lift Dock to G"@ Bua35 and concrete castin for each se-ent shall #e

finished at a ti-e. %he flow chart of cast in,situ process is as follows:

-low C$art of Cast in;situ %rocess

%rianle #racket will #e installed at firstD and then 1&&P1&&-- ti-#er and

pl3wood for #otto- for-work. Side for-work structure shall #e !-- thick steel

plate interated with enclosin purlins. For-work includes outside part5 inner

part5 and end,sealin part. Side for-work will #e installed after the re#ar erection

is inspected and accepted #3 the 8nineer.

,. ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

S!etc$ of Trian1le Brac!et for Bottom -ormwor!

Side for-work will #e installed #3 crawler crane5 and the shape5 straihtness5

and di-ension of the for-work shall confor- to stipulations set forth in rele0ant

codes. %he e-#edded #olts such as the ru##er fender9s5 #ollard9s and ladder9s

should #e fi2ed accuratel3 and fir-l3 at the sa-e ti-e.

%he concrete will #e produced #3 #atchin plant on siteD it will #e transported to

the 4ua3 wall site #3 -i2er truck and will #e cast #3 concrete pu-p.

(nternal 0i#rator will #e used for co-pactin concrete. +i#ration 4ualit3 shall #e

ensured durin castin5 defects as hone3co-# on concrete surface and air 0oids

should #e a0oided.

Finishin shall #e perfor-ed with trowel when top ele0ation reaches5 and screed

#3 -anpower shall #e used for le0elin #efore initial settin of concrete.

When concrete co-pressi0e strenth reaches 1&@=--25 side for-work can #e

re-o0ed accordin to $S !11& part 1. Side for-work will #e re-o0ed #3 la#ors

with the help of crane. 1ttentions to safet3 and interalit3 of for-work should #e

paid durin the re-o0al of for-work5 don not pri>e and ha--er here and there

so as to a0oid defor-ation of for-work. $otto- for-work will #e re-o0ed at last

when co-pressi0e strenth confor-s to rele0ant stipulation. %he structure shall

#e co0ered i--ediatel3 and cured with fresh water or #3 appl3in curin aent5

and -oist curin period shall not #e less than / da3s.

,2 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

(+2 raina1e Culvert

Surface water drainae installations5 includin e2tensions of 3 no. e2istin outfall

cul0erts and incorporation of 2 no. into the new 4ua3 wall e2tension5 will #e cast

on site. %he concrete will #e pro0ided #3 the #atchin plant.

(+4 Construction of "pron includin1 Trenc$

(+4+& *eneral

%he 4ua3 has an apron of 3&- wide. %he section co0ers cappin #ea- and

concrete pa0e-ent Iser0ice trenchJ. 1s for the 25.1- wide pa0e-ent5 it consists

of a 2&&-- thick raded crushed rock su#,#ase5 a 25& thick lean concrete C15

#ase course and a 43&-- thick reinforced concrete C4& surface course. %he

total thickness is !!&--5 and the section of apron is as follows:

(+4+, Service Trenc$

Ser0ice trenches are situated lonitudinall3 and trans0ersel3 in the 4ua3. %he

di-ension of the trench situated trans0ersel3 is 1.!/- in heiht and 2.2- in

width5 it is a sinle #o2 with two cells. %he di-ension of the lonitudinal trench is

1..5H1.!/- in heiht and 1.*- in width5 which is a sinle #o2 with one cell.

Co0er sla#s will #e precast and installed for the trenches. %he co-pressi0e

strenth of the concrete for the trench is 4&?'a. %here is a#out 1.!4-

3

concrete in0ol0ed in ser0ice trenches.

,4 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

%he co0er sla# prefa#rication is prior to the principle part of trench construction.

%he trench construction procedure is as follows:

Foundation e2ca0ation R raded crushed rock su#,#ase R C15 lean

concrete #ase course R re#ar asse-#lin R side for-work installin R

concretin R curin R co0er sla# installin

Steel side for-work will #e used for ser0ice trench5 which will #e installed and

re-o0ed with the help of the crawler crane.

Concrete placin shall #e di0ided into three ti-es. Firstl35 concrete of #otto-

sla# and side walls is to #e castD secondl35 the pedestal for co0er sla#s is to #e

cast to ensure its straihtnessD the central partition Ionl3 trans0erse trenchJ is to

#e cast finall3. %he castin se4uence is shown as #elow:

to #e cast firstly

to #e cast thirdly

%&etch for %e'uence of Trench Concreting

to #e cast secondly

S!etc$ of Se3uence of Trenc$ Concretin1

1fter side for-work re-o0al5 concrete shall #e cured ti-el3 in accordance with

rele0ant re4uire-ents5 and it shall #e kept da-p not less than / da3s.

Bualified Co0er sla# will #e installed #3 .5t auto crane after the pa0e-ent is

finished.

(+4+( Sub;base

2&&-- thick raded crushed rock which lies on #ackfilled sand su#,rade after

co-paction will ser0e as un#ound su#,#ase for pa0e-entD and 3&!4-

3

raded

crushed rock will #e in0ol0ed in su#,#ase.

(6 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

Construction for su#,#ase will #e e2ecuted for- west to east in section and in

one la3er. 1nd the procedure is as follows:

'repare raded crushed rock spreadin co-pactin

When the co-pactness of su#,rade has #een accepted5 settin out for raded

crushed rock su#,#ase can #e e2ecuted5 whilst raded crushed rock can #e

stored and tested in accordance with desin re4uire-ent or rele0ant codes.

%3pe SD23 #ulldo>er will #e used for spreadin for crushed rockD and partial

tri--in and le0elin shall #e e2ecuted #3 -anpower to ensure thickness and

le0el of the su#,#ase.

Co-paction should #e carried out as soon as possi#le after crushed rock has

#een spread accordin to the re4uire-ents and rele0ant codes.

%3pe LSS21!$ 0i#rator3 roller with static linear load 415@=c- will #e used for

co-paction. $asin on the desin thickness of the su#,#ase is 2&&--5 / passes

will #e e2ecuted for co-paction in accordance with re4uire-ent.

Special care should #e taken to o#tain full co-paction in the 0icinit3 of #oth

lonitudinal and trans0erse 7oints.

1 -ini-u- width of 2- of properl3 co-pacted su#,#ase #e3ond the ede of the

lean concrete should #e prepared #efore actuall3 placin the lean concrete.

(+4+/ Base Course

25&-- thick lean concrete C15 which lies on the su#,#ase will ser0e as #ase

course for pa0e-entD and the 4uantit3 of lean concrete is a#out 3!55-

3

.

%he construction se4uence for lean concrete is stated as #elow:

Site prepare R for-work installation R concretin R curin

Settin out for lean concrete #ase can #e e2ecuted after su#,#ase has #een

accepted. Lean concrete will #e constructed lonitudinall3 in a#out 5- strips.

%he staered distance #etween lonitudinal 7oints of lean concrete #ase and

upper la3er pa0e-ent sla# shall #e -ore than 3&&--D whilst the staered

distance #etween trans0erse 7oints of lean concrete #ase and upper la3er

pa0e-ent sla# shall #e -ore than 1-.

Concrete for #ase will #e produced #3 our #atchin plant. 1nd the slu-p

constant of lean concrete shall #e -et with the desin re4uire-ent. Lean

(& ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

concrete will #e transported #3 -i2er truck. (t shall #e constructed in one la3er

and in strip alon lonitudinal direction of 4ua3 wall. Aand uided -ethod shall

#e adopted for concretin in a continuous process. (nternal 0i#rator will #e used

for co-paction.

%he side for-work shall #e re-o0ed #3 la#ors. Curin li4uid or fresh water shall

#e in0ol0ed in curin. Lean concrete shall #e cured in accordance with rele0ant

re4uire-ents.

(+4+0 Surface Course

43&-- thick reinforced concrete C4& which lies on the #ase course will ser0e as

surface course for pa0e-ent5 with the 4uantit3 of a#out ..31-

3

.

Construction for reinforced concrete will #e e2ecuted trans0ersel3 se-ent #3

se-entD and e0er3 se-ent of the reinforced concrete sla#5 which is in accord

with the desin plan5 will #e cast in one la3er. (ts procedure is as follows:

'repare R re#ar prepare and erection R for-work installation R

concretin curin

When the lean concrete #ase has #een accepted5 settin out for reinforced

concrete sla# can #e e2ecuted5 whilst reinforce-ent caes can #e prepared.

Steel side for-work with reser0ed holes for dowel #ars will #e used for

reinforced sla#. For-work will #e installed when reinforce-ent caes for

pa0e-ent sla# ha0e #een finished. Dowel #ars shall #e installed after for-work

has #een installed.

%he concrete shall #e produced #3 the #atchin plant in precast 3ardD it will #e

transported to the 4ua3 site #3 -i2er truck and will #e cast #3 concrete pu-p.

(nternal 0i#rator will #e used for co-pactin concrete. +i#ration 4ualit3 shall #e

ensured durin castin5 defects as hone3co-# and #i air 0oids should #e

a0oided. Finishin shall #e perfor-ed when top ele0ation reaches5 and concrete

finishin -achine will #e in0ol0ed in le0elin concrete surface. Screed #3

-anpower shall #e used for le0elin #efore initial settin of concrete.

Curin li4uid will #e spra3ed when the concrete sets finall35 and eote2tile will #e

co0ered su#se4uentl3. %he da-p curin will #e applied at least / da3s. %he side

for-work will #e re-o0ed #3 la#ors when concrete co-pressi0e strenth

reaches 1&@=--2. %hen the contraction 7oint will #e cut i--ediatel3 after the

re-o0al of side for-work.

(, ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

(+&6 8nstallation of "uxiliary -acilities

1u2iliar3 facilities5 includin #ollard5 fender5 ladder5 etc. will #e installed after the

co-pletion of cappin #ea- and apron.

-ender and Bollard 8nstallation

(+&& %lacement of "nti;scour %rotection

"eno -attress5 LPWPAS3&&&P2&&&P5&&--5 is desined for anti,scour protection

in front of 4ua3 wall. %he construction se4uence is as follows:

Site preparation ?attress asse-#lin R Foundation preparation R

?attress installation.

1. Site 'reparation

?attresses5 stone for -attresses and liftin fra-e should #e prepared #efore

construction. %he si>e of liftin fra-e is ..&- in lenth and 2.&- in width the

sketch is shown as follows:

B B

A-A A

A

B-B

fl3in rins

fl3in rins

fl3in rins

fl3in rins

Si>e of liftin fra-e

%he sketch of Liftin Fra-e

(( ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

$. 1sse-#l3 and Fillin

%he folded units shall #e taken out fro- the #undle and placed on a flat round.

?attresses should #e opened5 unfolded and pressed out to their oriinal shape.

Front5 #ack and end panels shall #e lifted to a 0ertical position to for- an open

#o2 shape. 8nd flaps shall #e folded and o0erlapped5 as appropriate. 1ll edes

of the diaphra-s and panels shall #e tied or fastened to front and #ack of the

-attress. %he -attresses should #e asse-#led indi0iduall35 #3 erectin the

sides5 ends and diaphra-s5 ensurin that all creases are in the correct position

and the tops of all sides are le0el. %hen5 the edes of the -attress will #e

connected #3 usin lacin wire. When usin lacin wire5 cut a sufficient lenth of

wire and first loop and twist the lacin wire to the wire -esh. 'roceed with t3in

alternate dou#le and sinle loops throuh e0er3 -esh openin appro2i-atel3

e0er3 1&& --5 and pull each loop tiht and finall3 securin the end of the lacin

wire to the wire -esh #3 loopin or twistin. %he lacin wire should #e supplied

with the -attresses.

1fter #ein asse-#led5 the -attresses shall #e filled with rocks. "ocks for

-attresses shall #e hard5 anular to round5 dura#le and of such 4ualit3 that the3

shall not disinterate on e2posure to water or weatherin durin the life of the

structure. Care shall #e taken when placin the stone to a0oid da-ain the wire

coatin. 1fter a la3er of rock has #een placed in the cell5 sufficient hand

-anipulation of the rock shall #e perfor-ed to -ini-i>e 0oids and achie0e a

-a2i-u- densit3 of the rock in the units.

%o allow for settle-ent5 fill -ore and le0el it off a#o0e the tip of the -esh. %hen

la3 the lid down and pull the edes of the panels to #e connected. %he lids shall

#e tihtl3 laced alon all edes5 ends and diaphra-s in the sa-e -anner as

descri#ed for asse-#lin.

C. Foundation preparation

%he foundation on which the -attresses are to #e placed shall #e le0el to the

ele0ations as shown on the pro7ect construction drawins and surface

irreularities5 loose -aterial and 0eetation in accordance with the pro7ect

specifications.

D. (nstallation

Finall35 the -attresses shall #e placed in their proper location and securel3

attached to the ad7acent ones. (n principle5 the -attresses will #e installed #3 the

(/ ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

autocrane on the 4ua35 and pro#a#l3 a few #3 crane on the #are.

Control for installation: When installin the -attresses5 direction of the installin

-attress should #e controlled #3 the followin steps. First5 #efore the -attress

liftin underwater #3 crane with liftin fra-e5 the location should #e ad7usted #3

pullin ropes and -o0in the crane hook a#o0e the water. %hen5 di0er shall di0e

under water to ad7ust the location of the -attress #3 directin the crane until the

location is riht. Finall35 take off the hooks and -ake a -ark on the cappin

#ea- to record the installation location.

'lace-ent of "eno ?attress

(+&, -ender 5eplacement and Concrete 5epairs

%he scope of this contract includes the installation of a fenderin solution for the

followin 4ua3 walls:

@ew 4ua3 to #e constructedD

82istin 4ua3 wall of caisson construction I*&-J D

82istin 4ua3 wall constructed #3 ?urra3 and "o#erts I4&1-JD

82istin 4ua3 walls constructed #3 CA8C I/!2 Q 3&5-J

82istin dock 4ua3 walls constructed #3 CA8C either side of the hea03 lift

dock I42 Q 42-J

@o fender repairs are re4uired to the e2istin G"@ 4ua3 or in the hea03 lift dock.

%he old concrete will #e de-olished #3 h3draulic #reaker and re-o0ed fro- site.

Concrete will then #e placed durin inter0al. 1ll these works will #e carried out in

(0 ' ()

Luanda Oil Service Base Expansion Contract for Tender Submission

Quay Wall between Heavy Lift oc! and TCT "rea #et$od Statement

accordance with the prora--e and in such a wa3 as to -ini-i>e interference

with the nor-al #usiness of the 'ort and the Luanda 6il Ser0ice Centre.

() ' ()

Potrebbero piacerti anche

- Method Statement ConbextraGPDocumento7 pagineMethod Statement ConbextraGPsinambeladavidNessuna valutazione finora

- 11 - Method of Statement For Stub Angle InstallationDocumento10 pagine11 - Method of Statement For Stub Angle InstallationiloveumakkahNessuna valutazione finora

- Midal Cables Method StatementDocumento13 pagineMidal Cables Method StatementRICHARD FUNUENessuna valutazione finora

- J213-AHC-EMD-MS-C-04-R0 MS For Substructure Waterprooing Bitumen CoatDocumento7 pagineJ213-AHC-EMD-MS-C-04-R0 MS For Substructure Waterprooing Bitumen CoatKafeel AbbasNessuna valutazione finora

- Method Statement Cathodic ProtectionDocumento10 pagineMethod Statement Cathodic Protectiontrungtinh1506100% (1)

- Dewatering Method Statement for Abu Dhabi International Airport ExpansionDocumento6 pagineDewatering Method Statement for Abu Dhabi International Airport ExpansionDomie Neil Bucag SalasNessuna valutazione finora

- Method Statement Pressure TestDocumento5 pagineMethod Statement Pressure TestAnand NarayananNessuna valutazione finora

- FP - Method of Statement - Al PheniqDocumento9 pagineFP - Method of Statement - Al PheniqelbaraniNessuna valutazione finora

- Repair Precast Sea Wall Panels Minor CorrosionDocumento3 pagineRepair Precast Sea Wall Panels Minor CorrosionPankaj PaulNessuna valutazione finora

- TEC-036400 - MET-DoR-003a (Method Statement For Concrete Crack Repairing by Concresive 2200&concresive - 1Documento8 pagineTEC-036400 - MET-DoR-003a (Method Statement For Concrete Crack Repairing by Concresive 2200&concresive - 1Micheal B HaizenNessuna valutazione finora

- Method StatementDocumento2 pagineMethod StatementKason YiNessuna valutazione finora

- IR Sub Grade ConstructionDocumento2 pagineIR Sub Grade ConstructionWr Ar100% (2)

- Method StatementDocumento4 pagineMethod StatementDebraj RoyNessuna valutazione finora

- 006-Sample Method Statement Structure New WorksDocumento4 pagine006-Sample Method Statement Structure New WorksS.C.Satish ChanderNessuna valutazione finora

- As-Built Draughting Method StatementDocumento6 pagineAs-Built Draughting Method StatementMichaelChiwuezeNessuna valutazione finora

- DTTN Dt1 PC Rfi ST 0100Documento1 paginaDTTN Dt1 PC Rfi ST 0100Tariq Ali SialNessuna valutazione finora

- Initial PID - 19-0379 A01 01Documento39 pagineInitial PID - 19-0379 A01 01rajap2737Nessuna valutazione finora

- Method Statement IFIDocumento17 pagineMethod Statement IFIHaitham M A Bechara0% (1)

- Lean Concrete MOSDocumento9 pagineLean Concrete MOSebrahimlinda25619Nessuna valutazione finora

- Method Statement For Taxiway Edge Lights & ManholesDocumento7 pagineMethod Statement For Taxiway Edge Lights & ManholesRomeoAryan100% (1)

- METHOD STATEMENT - CHB LAYINGdocDocumento12 pagineMETHOD STATEMENT - CHB LAYINGdocJMNessuna valutazione finora

- Essential waterproofing methods for flat roofsDocumento39 pagineEssential waterproofing methods for flat roofsJaime A. NavarijoNessuna valutazione finora

- Multiplex Vertical Structures Method StatementDocumento7 pagineMultiplex Vertical Structures Method StatementAdel SaqqaNessuna valutazione finora

- Method Statement For Retaining Wall: 1.1 List of Proposed Manpower and MachineriesDocumento2 pagineMethod Statement For Retaining Wall: 1.1 List of Proposed Manpower and MachineriesSerkam PEDNessuna valutazione finora

- TEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Documento8 pagineTEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Tomi Wiryandi SaputraNessuna valutazione finora

- Ae W-PQ 9601.1 en 4.0Documento60 pagineAe W-PQ 9601.1 en 4.0Farrukh Javed100% (1)

- HSE PLAN Generic RAaaaaaaaaaaDocumento7 pagineHSE PLAN Generic RAaaaaaaaaaaテレブリコ ジェファーソンNessuna valutazione finora

- Greater Yangon Water Supply Improvement Project (Phase II) Final Report 4 Feb 2017Documento108 pagineGreater Yangon Water Supply Improvement Project (Phase II) Final Report 4 Feb 2017lwin_oo2435Nessuna valutazione finora

- Epoxy Grouting Application Work ProcedureDocumento14 pagineEpoxy Grouting Application Work Proceduremanoj thakkarNessuna valutazione finora

- MS - Raft PouringDocumento14 pagineMS - Raft PouringAby ThykkodathuNessuna valutazione finora

- Method Statement Log-CivilDocumento1 paginaMethod Statement Log-CivilDia AjjouriNessuna valutazione finora

- Garmony Environmental Statement Rev B App BDocumento15 pagineGarmony Environmental Statement Rev B App BTAHER AMMARNessuna valutazione finora

- P4586-CPC-WEC-PJ-MS-0004 Method Statement For Installation of HDPE Work Apron ABCDocumento19 pagineP4586-CPC-WEC-PJ-MS-0004 Method Statement For Installation of HDPE Work Apron ABCLahiru IndrajithNessuna valutazione finora

- Maintaining Flood Mitigation WorksDocumento42 pagineMaintaining Flood Mitigation WorksKuang Ngang ENessuna valutazione finora

- 1.3minute Meeting For Qms ReviewDocumento1 pagina1.3minute Meeting For Qms ReviewStephen David GozunNessuna valutazione finora

- Karnaphuli Water Supply Project Phase 2: Product Data On Chlorine Booster PumpDocumento16 pagineKarnaphuli Water Supply Project Phase 2: Product Data On Chlorine Booster PumpJahangir AlamNessuna valutazione finora

- Internal Plumbing Installation MethodDocumento4 pagineInternal Plumbing Installation MethodAmigowzz HoodNessuna valutazione finora

- Method Statement TRIO MPMDocumento8 pagineMethod Statement TRIO MPMtarekNessuna valutazione finora

- Rev 00 - Method Statement - Roof& Ceiling VentilatorDocumento11 pagineRev 00 - Method Statement - Roof& Ceiling VentilatorJuwe PkdoNessuna valutazione finora

- Ms Common WorkDocumento25 pagineMs Common WorkSahabzada AamirNessuna valutazione finora

- Checklist For Pre-PourDocumento1 paginaChecklist For Pre-PourMin Min SoeNessuna valutazione finora

- Method Statement-Ext Pipe FittingsDocumento13 pagineMethod Statement-Ext Pipe FittingsSam JoseNessuna valutazione finora

- Site Investigation Land Survey Installation of BenchmarkDocumento17 pagineSite Investigation Land Survey Installation of BenchmarkAnonymous ze9ag1Nessuna valutazione finora

- Concrete Casting Preparation For PourDocumento4 pagineConcrete Casting Preparation For PourJedNessuna valutazione finora

- Structured Method Statement For Concrete Repair - 2Documento10 pagineStructured Method Statement For Concrete Repair - 2m.umarNessuna valutazione finora

- Work Method StatementDocumento10 pagineWork Method StatementMdNasruddin shaikhNessuna valutazione finora

- Technical Proposal: Submitted ToDocumento37 pagineTechnical Proposal: Submitted ToLevofloxacinCoccusNessuna valutazione finora

- Ed 000 CST WMS 0021Documento9 pagineEd 000 CST WMS 0021Fitriansyah Adi Putra IrwanNessuna valutazione finora

- Method Statement Anti Termite r2 MRTDocumento10 pagineMethod Statement Anti Termite r2 MRTKeristiyantoNessuna valutazione finora

- Method of Statement PartDocumento3 pagineMethod of Statement PartAl Manar PetroleumNessuna valutazione finora

- Preliminary Quality Assurance/Quality Control Plan: Mohawk Solar ProjectDocumento4 paginePreliminary Quality Assurance/Quality Control Plan: Mohawk Solar Project无时差Nessuna valutazione finora

- Internal Painting Method StatementDocumento8 pagineInternal Painting Method StatementMonali VarpeNessuna valutazione finora

- Earthwork Excavation-Method StatementDocumento4 pagineEarthwork Excavation-Method StatementKhaled AbdelbakiNessuna valutazione finora

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionDocumento33 pagineEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇Nessuna valutazione finora

- 16 0105 Construction Method StatementDocumento3 pagine16 0105 Construction Method StatementChun KedNessuna valutazione finora

- Checklist For PCCDocumento4 pagineChecklist For PCCSR BuildersNessuna valutazione finora

- PCW Installation MethodologyDocumento42 paginePCW Installation MethodologyEZEKIEL VALENCIANessuna valutazione finora

- As Built ReportDocumento1 paginaAs Built ReportWakil AhmadNessuna valutazione finora

- Method Statement Striking FormworkDocumento3 pagineMethod Statement Striking FormworkSurya HeriwijayaNessuna valutazione finora

- Workover Operations PDFDocumento13 pagineWorkover Operations PDFterusunduhNessuna valutazione finora

- Gorkha Eco Panel PDFDocumento61 pagineGorkha Eco Panel PDFSaurav ShresthaNessuna valutazione finora

- Evolutionary Architectures Day 1 81621Documento10 pagineEvolutionary Architectures Day 1 81621Raghunandan GuptaNessuna valutazione finora

- Freight Summit Delegate ListDocumento19 pagineFreight Summit Delegate ListMichael MaquinianaNessuna valutazione finora

- ICFE 2014 - Business Model InnovationsDocumento22 pagineICFE 2014 - Business Model InnovationsYorman Arley Piraneque CojoNessuna valutazione finora

- Construction Method Statement FOR RCC Boundry Wall With Precast Panel & ColumnDocumento8 pagineConstruction Method Statement FOR RCC Boundry Wall With Precast Panel & Columnkhurshidoman123Nessuna valutazione finora

- Castable RefractoryDocumento4 pagineCastable RefractorySarbajitMannaNessuna valutazione finora

- Types of Ties For and Placement of Reinforcing SteelDocumento8 pagineTypes of Ties For and Placement of Reinforcing Steelइंजि कौस्तुभ पवारNessuna valutazione finora

- Longitudinal Induction Voltage Measurement On Communication Cables Running Parallel To Overhead Lines or Power CablesDocumento4 pagineLongitudinal Induction Voltage Measurement On Communication Cables Running Parallel To Overhead Lines or Power CablesmojoNessuna valutazione finora

- Interpretation of The Mandatory Requirements For UMS ShipsDocumento7 pagineInterpretation of The Mandatory Requirements For UMS ShipsCvitaCvitićNessuna valutazione finora

- Electrical Systems Design GuideDocumento19 pagineElectrical Systems Design GuideDhivya N100% (5)

- AP M.Tech College ListDocumento93 pagineAP M.Tech College ListVikram Reddy100% (1)

- CSL PDFDocumento6 pagineCSL PDFanumnedNessuna valutazione finora

- 2-STOREY RESIDENTIAL BUILDING SPECIFICATIONSDocumento11 pagine2-STOREY RESIDENTIAL BUILDING SPECIFICATIONSTrisha Casiño88% (16)

- Introduction To CNC ProgrammingDocumento28 pagineIntroduction To CNC ProgrammingDIPAK VINAYAK SHIRBHATENessuna valutazione finora

- Pavement and Materials Design Manual 1999 - CHAPTER 8Documento12 paginePavement and Materials Design Manual 1999 - CHAPTER 8Kisali Sarakikya100% (2)

- BCE M2 Ktunotes - inDocumento17 pagineBCE M2 Ktunotes - intahaNessuna valutazione finora

- Glf-whp02-Epcic4 Exhibit H App h1Documento7 pagineGlf-whp02-Epcic4 Exhibit H App h1Pete RueangchimNessuna valutazione finora

- Steel Reference GuideDocumento36 pagineSteel Reference GuideCésar VenegasNessuna valutazione finora

- Maven Silicon VLSI RNDocumento4 pagineMaven Silicon VLSI RNPeter Gata AyubaNessuna valutazione finora

- MC DC Bin DPR Con 0009Documento10 pagineMC DC Bin DPR Con 0009khalidusman1984Nessuna valutazione finora

- Satish Resume 2017Documento3 pagineSatish Resume 2017Satish KumarNessuna valutazione finora

- Abbrivation List 10001246905Documento7 pagineAbbrivation List 10001246905hemant_durgawaleNessuna valutazione finora

- AISC-327-05 Seismic Design ManualDocumento386 pagineAISC-327-05 Seismic Design ManualDavid Tovar GarcíaNessuna valutazione finora

- Summer Training Project Report - PLCDocumento28 pagineSummer Training Project Report - PLCNitish Bhardwaj84% (19)

- IEng and CEng Applications WorkshopDocumento2 pagineIEng and CEng Applications WorkshopmachinemanNessuna valutazione finora

- Eurocodes 7 Geotechnical Design Course Outline 2016 Sihle PDFDocumento8 pagineEurocodes 7 Geotechnical Design Course Outline 2016 Sihle PDFernestnsabimana74Nessuna valutazione finora

- Structural Design PDFDocumento100 pagineStructural Design PDFDennoh Mbuthia100% (1)

- DetailedSchedule ICONCT09Documento13 pagineDetailedSchedule ICONCT09surendiranNessuna valutazione finora

- Model-Based Design For Automotive Control UnitDocumento78 pagineModel-Based Design For Automotive Control UnitMohammed UvaisNessuna valutazione finora