Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design of Pier Frame 172

Caricato da

mvap2856Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design of Pier Frame 172

Caricato da

mvap2856Copyright:

Formati disponibili

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 1 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Contract No.: T/MONORAIL/WJ WC/2008

Project Title: MUMBAI MONORAIL

Document Title:

Design Calculation for Pier Structures of Pier

1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop)

(Definitive Design Review)

Revision History

A1 21/6/2010 Initial Submission

MARK DATE DESCRIPTION SYSTEMS CIVIL

APPROVED BY (LTSE)

Project Director

M I S Saini

J oint Project Director

Suhaimi Yaacob

SCOMI ENGINEERING BERHAD LARSEN & TOUBRO LIMITED

Checked By (QA/QC Manager)

Checked By (QA/QC

Manager)

Checked By (Civil Head)

Checked By (Design &

Engineering Manager)

Checked By (Project Manager)

Checked By (Contracts

Manager)

Prepared By Prepared By

DATE DATE

CONTRACTORS

DOCUMENT No.:

DOCUMENT No.:

MM001-D-DR-VSB-LTSE-303182

REVISION

A1

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 2 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

PRELIMINARY NOTE

This document is the exclusive property of PJ SI Consultants Sdn. Bhd. (PJ SI).

It is confidential and may not be used, reproduced or communicated either in

whole or in part, in any form or manner without the prior written agreement of

PJ SI.

This document shall not be distributed to third parties except under the terms of

the contract.

REVISION STATUS

A1 21/6/2010 Initial Submission LEEKL YAPKS AKI

Rev. Date Revision Note Designed by Checked by Approval by

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 3 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

TABLE OF CONTENTS

TITLE

1. Summary

2. Design Criteria

3. Computer Model

4. Pier Type 12

a. Pier Stem

b. Pier Head

c. Pier Cap

PAGE

4

5

5

8

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 4 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

1.0 SUMMARY

This report presents the design calculations for Pier 1A10a and 2G1 (Type 12) of frame 4 and

frame 172 with the following parameters. A pair of buffer stops are mounted on the end span

beam adjacent to pier 1A10a and 2G1 to absorb train impact load upon train overshot.

(a) Horizontal alignment of the guideway structure in plan

The alignment is straight or very gently curved with a horizontal radius of greater

than 1000m.

(b) Soil condition

The pier base is founded on shallow foundation where the rock level is shallower

than 5m from the ground level (or about 3m from the pile cut-off level). The base of

the pier is modeled as fixed in this case.

(c) Span configuration of the guideway frame structure

-The spans are not to exceed 27m and each frame has not more than 4 spans hence

limiting the overall length between expansion joints not more than 108m. (Frame 4)

- There is single span which is not exceeds 27m with a bearing end. (Frame 172)

(d) Pier height

-Top surface of the guideway beam is about 15m from the top of pilecap.

(Frame 4 and Frame 172)

Generally, the design of the pier in buffer stop consists of three sections; pier stem, pier head

and pier cap (see Figure 3.1). the pier is of the typical Y pier (1700mm x 1200mm),

The dimensions and reinforcement bars for the piers are summarized as below:

(i) Pier Type 12 (for Pier 1A10a and 2GT) : (Refer drawings MB-GS-D-0557/0558)

- Pier Stem :

o Size : 1700mm x 1200mm (Rectangular shape)

o Main Bars : 48T32 (about 1.89% of A

c

)

o Links : T16-150 (Outer) + 8T12-150 (Ties)

- Pier Head :

o Main Bars : 16T20 + 36T32

o Links : T16-150 (Outer) + 15T12-150 (Ties)

- Pier Cap :

o Main Bars : 12T20 + 34T25 (about 0.90% of A

c

)

o Links : 2T16-175 (Outer) + T16-100/150 (Ties)

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 5 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

2.0 DESIGN CRITERIA

Refer to design criteria for guide way structure (Definitive Design Review) (MM002-D-DR-

VSP-LTSE-303001) for details design criteria. Apart from the loads as applied in typical

analysis models, these frames are subject to an additional impact load of 400kN, one at a

time, at the end of the frames adjacent to pier 1A10a & 2G1. This impact load of 400kN,

derived from the accidental impact force caused by train overshot, is supplied by Scomi vide

its Letter LT-Gen-MM-L-220378. As it is a type of collision load, it is thus applied under

additional ULS5 load combinations.

Besides, as it is anticipated that these frames are to be connected with future monorail line at

pier 1A10a and 2G1, these piers have thus been duly designed to take the loading from an

isolated single span frame, which is to be supported by bearing on these piers. The vertical

and lateral loads being considered are dead load, superimposed dead load, train live load,

hunting force, and longitudinal traction & braking force, which are applied as point loads on

top of the piers.

3.0 COMPUTER MODEL

Fig 3.1 shows the finite element model of the structure. Elastic springs are included in the

model to simulate the soil-structure interaction in both longitudinal and transverse direction.

The elements local axis and sign conventions of internal forces used in the computer model

are as shown in Fig. 3.2 and Fig. 3.3, respectively.

1A10a

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 6 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Fig. 3.1: Frame 4 and Frame 172 models

Fig. 3.2: Local axis of pier elements (right hand rule).

2G1

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 7 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Fig. 3.3: Sign convention of internal forces in the element's local coordinate system

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 8 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

PIER TYPE 12

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 9 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4.0 PIER TYPE 12

4.1 PIER STEM TYPE 12

This section documented all results and designs for Pier Stem of TYPE 12.

4.1.1 SUMMARY OF PIER STEM FORCES

The summary of the maximum element forces due to various load combinations are

tabulated as below. The results are separated into two tables; first table presents the

summary solely due to service load combinations 1&5 for crackwidth check, and second

table is of all ultimate load combinations for ultimate design. There are 12 summary cases in

each table, in which:

Case 1 - Maximum & Minimum Axial Force + Corresponding Results

Case 2 - Maximum & Minimum My + Corresponding Results

Case 3 - Maximum & Minimum Mz + Corresponding Results

Case 4 - Maximum & Minimum Vy + Corresponding Results

Case 5 - Maximum & Minimum Vz + Corresponding Results

Case 6 - Maximum & Minimum Torsion + Corresponding Results

Negative sign in axial force indicates compression and vice versa. As the global analysis

model does not include secondary effects on slender column, additional moment induced

due to slenderness of column shall be added to the initial moment extracted from the

analysis model. If it is short column, additional moment produced in considering a nominal

allowance for eccentricity due to construction tolerance (20mm) shall be added to the initial

moment from the analysis model. The calculation is as shown below:

Notation :

N = Axial force (kN)

My_ct = Bending moment about local axis-y for construction tolerance (kNm)

My_s = Bending moment about local axis-y due to column slenderness (kNm)

Mz_ct = Bending moment about local axis-z for construction tolerance (kNm)

Mz_s = Bending moment about local axis-z due to column slenderness (kNm)

(i) Column bending about local-y

- Shape of deflection:

z

N

lo = 15000mm

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 10 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

- Column dimension: (shown with local axis)

- Check slenderness:

l

ey

= 1.5 l

o

= 22.50m

l

ey

/h

z

= 22.50m / 1.20m = 18.75 > 12 Slender column

- Additional moment due to construction tolerance (20mm), My_ct :

My_ct = 0.02N

- Additional moment due to column slenderness, My_s :

My_s = N [(h

z

/1750) (l

ey

/ h

z

)

2

(1-0.0035 l

ey

/ h

z

)]

= 0.225N

(ii) Column bending about local-z

- Shape of deflection:

15000mm

X

Z

Top face of pilecap

N

y

lo = 15000mm

1700

z

y

1200

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 11 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

- Column dimension: (shown with local axis)

- Check slenderness:

l

ez

= 2.3 l

o

= 34.50m

l

ez

/h

y

= 34.50m / 1.7m = 20.29 > 12 slender column

- Additional moment due to construction tolerance (20mm),Mz_ct :

Mz_ct = 0.02N

- Additional moment due to column slenderness,Mz_s :

Mz_s = N [(h

y

/1750) (l

ez

/ h

y

)

2

(1-0.0035 l

ez

/ h

y

)]

= 0.372N

These additional moments due to the effects of construction tolerance or pier slenderness

(whichever is greater) are then added to the Midas analysis output for final design forces.

15000mm

X

Y

Top face of pilecap

1700

z

y

1200

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 12 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Pier Stem Results

Table 4.1: Service Load Combinations 1&5 (S1&S5)

CASE Elem Load Part Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 1010 S1-64(max) I[1011] -2288 12 -3 7 -94 41

1 (min) 3010 S1-11 J[3012] -4507 -1251 -436 45 256 113

2 (max) 1010 S1-57(max) J[1012] -3197 1539 -972 19 -127 115

2 (min) 3010 S5.1-3 J[3012] -4276 -2834 -196 67 440 268

3 (max) 1010 S1-24(max) J[1012] -3442 919 2027 -28 -7 138

3 (min) 3010 S1-13 J[3012] -3754 -607 -1489 91 132 13

4 (max) 3010 S1-13 I[3011] -3357 602 -649 91 132 13

4 (min) 1010 S1-28(max) I[1011] -2828 837 624 -84 106 70

5 (max) 3010 S5.1-2 I[3011] -3878 1223 -384 -15 440 -252

5 (min) 1010 S1-57(min) I[1011] -2876 -697 -800 19 -243 115

6 (max) 1010 SLS5-2(max) I[1011] -3025 454 1354 -33 15 277

6 (min) 3010 S5.1-2 I[3011] -3878 1223 -384 -15 440 -252

Table 4.2: Ultimate Load Combinations 1 - 5 (U1-U5)

CASE Elem Load Part Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 1010 U4.1-256 I[1011] -2801 -1675 -1044 10 -577 65

1 (min) 3010 U3b_3.1-11 J[3012] -6381 -3501 -3629 20 -13 -120

2 (max) 1010 U4.1-129 J[1012] -4892 6370 -2384 54 -751 19

2 (min) 1010 U4.1-92 J[1012] -4613 -4831 3938 -134 635 111

3 (max) 1010 U2b.1-20 J[1012] -5143 -1408 7244 -224 132 214

3 (min) 1010 U3b_4.1-59 J[1012] -4753 1735 -5324 -35 -160 -189

4 (max) 3010 U2b.1-10 I[3011] -5157 2818 -2210 316 374 -93

4 (min) 1010 U2b.1-28 I[1011] -3890 1846 3875 -303 153 313

5 (max) 3010 U5.1-1 J[3012] -3738 -3938 -1451 5 1300 -50

5 (min) 1010 U4.1-129 I[1011] -4329 -2608 -1679 54 -751 19

6 (max) 1010 U2b.1-25 I[1011] -4190 1145 3118 -168 -59 591

6 (min) 1010 U3b_4.1-4 I[1011] -4235 -1023 -2064 -13 -180 -419

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 13 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4.1.2 PIER STEM ULTIMATE LIMIT STATE DESIGN

The ultimate limit state sectional analysis is carried out by AdSEC software, whereas

ultimate shear and torsion design is done by using spreadsheet.

4.1.2.1 Pier Stem Axial and Bending Design to IRS CBC - 1997

The table 4.3 shows the envelope of pier forces for ultimate axial and bending design. The

ultimate limit state analysis is done by using AdSEC software. Figure 4.1 shows the

arrangement of bars in the pier stem. 7 cases are studied, which are:

Case 1 - Max & Min Axial Force + Corresponding Results

Case 2 - Max & Min My + Corresponding Results

Case 3 - Max & Min Mz + Corresponding Results

Case 6 - Absolute Max Torsion + Corresponding Results

Table 4.3: Ultimate Load Combinations 1 - 5 (U1-U5) Maximum Final Design Forces for

Axial and Bending Design

CASE Elem Load Part Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 1010 U4.1-256 I[1011] -2801 -1675 -1044 10 -577 65

1 (min) 3010 U3b_3.1-11 J[3012] -6381 -3501 -3629 20 -13 -120

2 (max) 1010 U4.1-129 J[1012] -4892 6370 -2384 54 -751 19

2 (min) 1010 U4.1-92 J[1012] -4613 -4831 3938 -134 635 111

3 (max) 1010 U2b.1-20 J[1012] -5143 -1408 7244 -224 132 214

3 (min) 1010 U3b_4.1-59 J[1012] -4753 1735 -5324 -35 -160 -189

6 (max) 1010 U2b.1-25 I[1011] -4190 1145 3118 -168 -59 591

Fig. 4.1: Pier Stem bar arrangement

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 14 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Definition

Name Pier Stem 12

Type Concrete

Material C45

Section Area 2.039E+6mm

Reinforcement Area 38600.mm

Reinforcement 1.894%

Properties

Area 2.039E+6mm

Geometric Centroid y 0.0mm

z 0.0mm

Second Moments of Area Iyy 244.4E+9mm4

Izz 490.4E+9mm4

Iyz -10760.mm4

Principal Second Moments of Area Iuu 490.4E+9mm4

Izz 244.4E+9mm4

Angle 90.00

Shear Area Factor ky 0

kz 0

Torsion Constant 0.0mm4

Section Modulus Zy 407.3E+6mm

Zz 577.0E+6mm

Plastic Modulus Zpy 611.3E+6mm

Zpz 865.9E+6mm

Radius of Gyration Ry 346.2mm

Rz 490.5mm

Maximum compressive force Nmax 53990.kN

Strain at Nmax 0

Moment at ref. pt. for Nmax Myy 0.0kNm

Mzz 0.0kNm

Note: Nmax is the maximum compressive force which can be carried by the section.

This is calculated by applying a constant strain across the entire section, using

ultimate material properties.

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 15 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Section Material Properties

Type Concrete

Name C45

Weight Normal Weight

Density 2.300t/m

Cube Strength fcu 45Mpa

Tensile Strength fct 3.22Mpa

Elastic Modulus (short term) E 32500MPa

Poisson's Ratio v 0.2

Coeff. Thermal Expansion 12.00E-6/C

Partial Safety Factor

mc

,ULS 1.5

mc

,SLS 1

Maximum Strain 0.0035

ULS Compression Curve Recto-parabolic

ULS Tension Curve No-tension

SLS Compression Curve Linear

SLS Tension Curve No-tension

Aggregate Size 20.00mm

Reinforcement Properties

Loading

Reference Point

All loading acts through the Reference Point.

All strain planes are defined relative to the Reference Point.

Definition Geometric Centroid

Reference Point Coordinates y 0.0mm

z 0.0mm

Total ULS Loads

Analysis N Myy Mzz M

Case [kN] [kNm] [kNm] [kNm] []

1 2801 -1675 -1044 1974 148.1

2 6381 -3501 -3629 5042 134

3 4892 6370 -2384 6801 20.52

4 4613 -4831 3938 6233 -140.8

5 5143 -1408 7244 7380 -101

Name Fe500

fy 500MPa

Modulus 200000MPa

Partial Safety Factor

mc

,ULS 1.15

mc

,SLS 1

Maximum Strain 0.05

Stress/Strain Curve Fig 2

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 16 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

6 4753 1735 -5324 5600 71.95

7 4190 1145 3118 3322 -69.84

Strength Analysis Summary

Governing conditions are defined as:

A - reinforcing steel tension strain limit

B - concrete compression strain limit

Effective centroid is reported relative to the reference point.

Analysis Eff. Eff. N Nmax N/Nmax M Mu M/Mu Governing Neutral Neutral

Case Centroid Centroid Condition Axis Axis

(y) (z) Angle Depth

(

NA

)

[mm] [mm] [kN] [kN] [kNm] [kNm] [] [mm]

1 0.00 0.00 2801 53990 0.0519 1974.0 9965 0.1981 B: Node 7 160.5 559.6

2 0.00 0.00 6381 53990 0.1182 5042.0 11150 0.4521 B: Node 7 148.7 748.9

3 0.00 0.00 4892 53990 0.0906 6801.0 10400 0.6543 B: Node 2 13.33 517.6

4 0.00 0.00 4613 53990 0.0854 6233.0 10590 0.5883 B: Node 6 -154.3 665.8

5 0.00 0.00 5143 53990 0.0953 7380.0 13230 0.5580 B: Node 5 -111.7 691.1

6 0.00 0.00 4753 53990 0.0880 5600.0 12490 0.4483 B: Node 1 58.38 737.3

7 0.00 0.00 4190 53990 0.0776 3322 12160 0.2731 B: Node 4 -55.92 732.9

M/Mu < 1.0 OK!

4.1.2.2 Pier Stem Shear and Torsion Design to IRS CBC - 1997

The table 4.4 shows the most critical cases for shear and torsion design.

Table 4.4: Ultimate Load Combinations 1 - 5 (U1-U5) Maximum Final Design Forces for

Shear and Torsion Design

CASE Elem Load Part Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

4 (max) 3010 U2b.1-10 I[3011] -5157 2818 -2210 316 374 -93

4 (min) 1010 U2b.1-28 I[1011] -3890 1846 3875 -303 153 313

5 (max) 3010 U5.1-1 J[3012] -3738 -3938 -1451 5 1300 -50

5 (min) 1010 U4.1-129 I[1011] -4329 -2608 -1679 54 -751 19

6 (max) 1010 U2b.1-25 I[1011] -4190 1145 3118 -168 -59 591

6 (min) 1010 U3b_4.1-4 I[1011] -4235 -1023 -2064 -13 -180 -419

The design calculations for ultimate shear and torsion are shown in the spreadsheet next

pages. 3 cases are studied, which are:

i) Absolute Maximum Vy + Corresponding Vz & Torsion

ii) Absolute Maximum Vz + Corresponding Vy & Torsion

iii) Absolute Maximum Torsion + Corresponding Vz & Vy

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 17 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

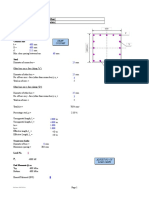

PIER SHEAR & TORSION DESIGN

to IRS CBC - 1997

Reference : Pier Stem for Buffer Stop

Case : Maximum Vy + corresponding Vz & Torsion

Input Data : Z

h

y

= 1700 mm Cover = 50 mm Y

b

z

= 1200 mm Tension Reinf. F = 32 mm

fcu = 45 N/mm

2

As provided,(z-dir) = 8040 mm

2

fy = 415 N/mm

2

As provided,(y-dir) = 14472 mm

2

1200

fyv = 415 N/mm

2

Shear Link, (z-dir) = 12 mm

Shear Link, (y-dir) = 12 mm 1700

Torsion Link = 16 mm

Analysis Results :

Shear (z-dir) = 374 kN

Shear (y-dir) = 316 kN

N = 5157 kN

Torsion = 93 kNm

SHEAR DESIGN (Cl. 15.6.6 IRS CBC - 1997)

a) Shear in z- direction:

V = 374.0 kN

b = 1700.0 mm

d = 1118.0 mm

v

z

= 0.20

N/mm

2

OK!

100As/bd = 0.76

vc = 0.67 N/mm

2

depth factor, s= 0.82

1+0.05N/Ac = 1.13

Asv/sv = 1.88 mm

2

/mm

b) Shear in y- direction:

V = 316.0 kN

b = 1200.0 mm

d = 1618.0 mm

v

y

= 0.16

N/mm

2

OK!

100As/bd = 0.41

vc = 0.55 N/mm

2

depth factor, s= 0.70

1+0.05N/Ac = 1.13

Asv/sv = 1.33 mm

2

/mm

c) Shear resistance of pier:

Vcz = 1181 kN [concrete capacity)

Vsz = 2604 kN [link capacity = 0.87fy(As)d/(sv) ]

Vcy = 843 kN [concrete capacity]

Vsy= 2887 kN [link capacity = 0.87fy(As)d/(sv)]

Vz / Vuz + Vy / Vuy < 1

0.10 + 0.08 = 0.18 OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 18 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

TORSION DESIGN (Cl. 15.4.4 IRS CBC - 1997)

a) Torsional Shear Stress, v

t

v

t

= 2T / [h

2

min

(h

max

- h

min

/3)] = 0.10

N/mm

2

h

min

= 1200 mm

h

max

= 1700 mm

c) Minimum Ultimate Torsional Shear Stress, v

tmin

v

tmin = 0.067 (f

cu )

0.5

= 0.42

N/mm

2

No Torsional Reinf Required

d) Ultimate Torsional Shear Stress, v

tu

v

tu = 0.75 (f

cu)

0.5

= 4.74

N/mm

2

x

1

= 1068 mm

y

1 = 1568 mm

In z-dir : v

z

+ v

t = 0.30

N/mm

2

(OK)

In y-dir: v

y

+ v

t = 0.26

N/mm

2

(OK)

e) Torsional link, A

st

/s

v

A

st

/s

v = T / [0.8 x

1

y

1

(0.87f

yv )] = 0.19

mm

2

/mm

COMBINED SHEAR AND TORSION DESIGN

a) Shear Links

Torsion Required 2 T 16 Links @ 2091

alone Provide 2 T 16 Links @ 150 (Asv/sv = 2.68 mm

2

/mm )

(OK)

Torsion In z-dir: Total torsion + shear link required = 2.08 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 5 T 12 Links @ 150 (inner legs) (Asv/sv = 6.45 mm

2

/mm )

(OK)

Torsion In y-dir: Total torsion + shear link required = 1.52 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 3 T 12 Links @ 150 (inner legs) (Asv/sv = 4.94 mm

2

/mm )

(OK)

b) Longitudinal Reinforcement, A

sL

/s

L

A

sL

/s

L

= A

st

/s

v

(f

yv

/f

y

) = 0.10

mm

2

/mm

A

sL

= 253 mm

2

Required 1 T 32 EF (As = 804 mm

2

)

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 19 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

PIER SHEAR & TORSION DESIGN

to IRS CBC - 1997

Reference : Pier Stem for Buffer Stop

Case : Maximum Vz + corresponding Vy & Torsion

Input Data : Z

hy = 1700 mm Cover = 50 mm Y

bz = 1200 mm Tension Reinf. F = 32 mm

fcu = 45 N/mm

2

As provided,(z-dir) = 8040 mm

2

fy = 415 N/mm

2

As provided,(y-dir) = 14472 mm

2

1200

fyv = 415 N/mm

2

Shear Link, (z-dir) = 12 mm

Shear Link, (y-dir) = 12 mm 1700

Torsion Link = 16 mm

Analysis Results :

Shear (z-dir) = 1300 kN

Shear (y-dir) = 5 kN

N = -3738 kN

Torsion = 50 kNm

SHEAR DESIGN (Cl. 15.6.6 IRS CBC - 1997)

a) Shear in z- direction:

V = 1300.0 kN

b = 1700.0 mm

d = 1118.0 mm

vz = 0.68

N/mm

2

OK!

100As/bd = 0.76

vc = 0.67 N/mm

2

depth factor, s= 0.82

1+0.05N/Ac = 0.91

Asv/sv = 2.74 mm

2

/mm

b) Shear in y- direction:

V = 5.0 kN

b = 1200.0 mm

d = 1618.0 mm

vy = 0.00

N/mm

2

OK!

100As/bd = 0.41

vc = 0.55 N/mm

2

depth factor, s= 0.70

1+0.05N/Ac = 0.91

Asv/sv = 1.33 mm

2

/mm

c) Shear resistance of pier:

Vcz = 952 kN [concrete capacity)

Vsz = 2604 kN [link capacity = 0.87fy(As)d/(sv) ]

Vcy = 680 kN [concrete capacity]

Vsy= 2887 kN [link capacity = 0.87fy(As)d/(sv)]

Vz / Vuz + Vy / Vuy < 1

0.37 + 0.00 = 0.37 OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 20 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

TORSION DESIGN (Cl. 15.4.4 IRS CBC - 1997)

a) Torsional Shear Stress, v

t

v

t

= 2T / [h

2

min

(h

max

- h

min

/3)] = 0.05

N/mm

2

h

min

= 1200 mm

h

max

= 1700 mm

c) Minimum Ultimate Torsional Shear Stress, v

tmin

v

tmin = 0.067 (f

cu)

0.5

= 0.42

N/mm

2

No Torsional Reinf Required

d) Ultimate Torsional Shear Stress, v

tu

v

tu = 0.75 (f

cu )

0.5

= 4.74

N/mm

2

x

1

= 1068 mm

y

1 = 1568 mm

In z-dir : v

z

+ v

t = 0.74

N/mm

2

(OK)

In y-dir: v

y

+ v

t = 0.06

N/mm

2

(OK)

e) Torsional link, A

st

/s

v

A

st

/s

v = T / [0.8 x

1

y

1

(0.87f

yv )] = 0.10

mm

2

/mm

COMBINED SHEAR AND TORSION DESIGN

a) Shear Links

Torsion Required 2 T 16 Links @ 3890

alone Provide 2 T 16 Links @ 150 (Asv/sv = 2.68 mm

2

/mm )

(OK)

Torsion In z-dir: Total torsion + shear link required = 2.85 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 5 T 12 Links @ 150 (inner legs) (Asv/sv = 6.45 mm

2

/mm )

(OK)

Torsion In y-dir: Total torsion + shear link required = 1.43 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 3 T 12 Links @ 150 (inner legs) (Asv/sv = 4.94 mm

2

/mm )

(OK)

b) Longitudinal Reinforcement, A

sL

/s

L

A

sL

/s

L

= A

st

/s

v

(f

yv

/f

y

) = 0.05

mm

2

/mm

A

sL

= 136 mm

2

Required 1 T 32 EF (As = 804 mm

2

)

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 21 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

PIER SHEAR & TORSION DESIGN

to IRS CBC - 1997

Reference : Pier Stem for Buffer Stop

Case : Maximum Torsion + corresponding Vy & Vz

Input Data : Z

h

y

= 1700 mm Cover = 50 mm Y

b

z

= 1200 mm Tension Reinf. F = 32 mm

fcu = 45 N/mm

2

As provided,(z-dir) = 8040 mm

2

fy = 415 N/mm

2

As provided,(y-dir) = 14472 mm

2

1200

fyv = 415 N/mm

2

Shear Link, (z-dir) = 12 mm

Shear Link, (y-dir) = 12 mm 1700

Torsion Link = 16 mm

Analysis Results :

Shear (z-dir) = 59 kN

Shear (y-dir) = 168 kN

N = 4190 kN

Torsion = 591 kNm

SHEAR DESIGN (Cl. 15.6.6 IRS CBC - 1997)

a) Shear in z- direction:

V = 59.0 kN

b = 1700.0 mm

d = 1118.0 mm

v

z

= 0.03

N/mm

2

OK!

100As/bd = 0.76

vc = 0.67 N/mm

2

depth factor, s= 0.82

1+0.05N/Ac = 1.10

Asv/sv = 1.88 mm

2

/mm

b) Shear in y- direction:

V = 168.0 kN

b = 1200.0 mm

d = 1618.0 mm

v

y

= 0.09

N/mm

2

OK!

100As/bd = 0.41

vc = 0.55 N/mm

2

depth factor, s= 0.70

1+0.05N/Ac = 1.10

Asv/sv = 1.33 mm

2

/mm

c) Shear resistance of pier:

Vcz = 1156 kN [concrete capacity)

Vsz = 2604 kN [link capacity = 0.87fy(As)d/(sv) ]

Vcy = 825 kN [concrete capacity]

Vsy= 2887 kN [link capacity = 0.87fy(As)d/(sv)]

Vz / Vuz + Vy / Vuy < 1

0.02 + 0.05 = 0.06 OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 22 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

TORSION DESIGN (Cl. 15.4.4 IRS CBC - 1997)

a) Torsional Shear Stress, v

t

v

t

= 2T / [h

2

min

(h

max

- h

min

/3)] = 0.63

N/mm

2

h

min

= 1200 mm

h

max

= 1700 mm

c) Minimum Ultimate Torsional Shear Stress, v

tmin

v

tmin = 0.067 (f

cu)

0.5

= 0.42

N/mm

2

Torsional Reinf Required

d) Ultimate Torsional Shear Stress, v

tu

v

tu = 0.75 (f

cu )

0.5

= 4.74

N/mm

2

x

1

= 1068 mm

y

1 = 1568 mm

In z-dir : v

z

+ v

t = 0.66

N/mm

2

(OK)

In y-dir: v

y

+ v

t = 0.72

N/mm

2

(OK)

e) Torsional link, A

st

/s

v

A

st

/s

v = T / [0.8 x

1

y

1

(0.87f

yv )] = 1.22

mm

2

/mm

COMBINED SHEAR AND TORSION DESIGN

a) Shear Links

Torsion Required 2 T 16 Links @ 329

alone Provide 2 T 16 Links @ 150 (Asv/sv = 2.68 mm

2

/mm )

(OK)

Torsion In z-dir: Total torsion + shear link required = 3.11 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 5 T 12 Links @ 150 (inner legs) (Asv/sv = 6.45 mm

2

/mm )

(OK)

Torsion In y-dir: Total torsion + shear link required = 2.55 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 3 T 12 Links @ 150 (inner legs) (Asv/sv = 4.94 mm

2

/mm )

(OK)

b) Longitudinal Reinforcement, A

sL

/s

L

A

sL

/s

L

= A

st

/s

v

(f

yv

/f

y

) = 0.61

mm

2

/mm

A

sL

= 1610 mm

2

Required 3 T 32 EF (As = 2413 mm

2

)

Maximum torsion induced in pier stem required 3T32 each face or total 6T32, which is about

0.1071 of total perimeter bar provided. The ultimate moment utilized 0.2731 corresponding

to absolute maximum torsion, giving a total utilization ratio of 0.3802 < 1. Hence, it deemed

satisfactory.

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 23 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4.1.3 PIER STEM SERVICEABILITY LIMIT STATE CHECK

The crack width of the pier is checked against service load combinations 1&5, by using

AdSEC software. Table below shows the envelope of pier forces for serviceability check. The

arrangement of bars in the pier stem is shown in ultimate limit check. 6 cases are checked,

which are:

Case 1 - Max & Min Axial Force + Corresponding Results

Case 2 - Max & Min My + Corresponding Results

Case 3 - Max & Min Mz + Corresponding Results

Table 4.5: Serviceability Load Combinations 1&5 (S1 and S5) Maximum Final Forces for

Combined Axial and Bending SLS check

CASE Elem Load Part Axial My Mz

(kN) (kNm) (kNm)

1 (max) 1010 S1-64(max) I[1011] -2288 12 -3

1 (min) 3010 S1-11 J[3012] -4507 -1251 -436

2 (max) 1010 S1-57(max) J[1012] -3197 1539 -972

2 (min) 3010 S5.1-3 J[3012] -4276 -2834 -196

3 (max) 1010 S1-24(max) J[1012] -3442 919 2027

3 (min) 3010 S1-13 J[3012] -3754 -607 -1489

Loading

Reference Point

All loading acts through the Reference Point.

All strain planes are defined relative to the Reference Point.

Definition Geometric Centroid

Reference Point Coordinates y 0.0mm

z 0.0mm

Applied loads

Load N Myy Mzz

Case [kN] [kNm] [kNm]

1 2288 12 -3

2 4507 -1251 -436

3 3197 1539 -972

4 4276 -2834 -196

5 3442 919 2027

6 3754 -607 -1489

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 24 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

SLS Cases Analysed

Name Loading Pre-stress Creep Mq/Mg Cnom Crack Eqn.

Long Interm. Short Factor Coeff.

Term Term Term A [mm]

1 L1 - - 0 2 1 50 Eqn. 24

2 L2 - - 0 2 1 50 Eqn. 24

3 L3 - - 0 2 1 50 Eqn. 24

4 L4 - - 0 2 1 50 Eqn. 24

5 L5 - - 0 2 1 50 Eqn. 24

6 L6 - - 0 2 1 50 Eqn. 24

Total SLS Loads

Analysis N Myy Mzz M

Case [kN] [kNm] [kNm] [kNm] []

1 2288 12 -3 12.37 14.04

2 4507 -1251 -436 1325 160.8

3 3197 1539 -972 1820 32.28

4 4276 -2834 -196 2841 176

5 3442 919 2027 2226 -65.61

6 3754 -607 -1489 1608 112.2

SLS Loads Analysis - Summary

Analysis Secant Neutral Neutral k at M

0

Case EI Axis Axis

Angle Depth

(

NA

)

[kNm] [] [mm] [/m]

1 4.34E+06 7.492 28070 1.94E-12

2 4.35E+06 169 1241 1.23E-12

3 3.89E+06 19.81 1015 2.07E-12

4 3.25E+06 177.7 714.1 1.78E-12

5 5.35E+06 -49.51 1230 1.74E-12

6 6.30E+06 127.8 1499 1.61E-12

Moment summary for SLS axial loads

Effective centroid is reported relative to the reference points

Case Eff. Centroid N Nmax N/Nmax M Mu M/Mu Mcr

y z

[mm] [mm] [kN] [kN] [kNm] [kNm] [kNm]

1 0.00 0.00 2288 53990 0.04 12 9526 0.00 433

2 0.00 0.00 4507 53990 0.08 1325 10280 0.13 827

3 0.00 0.00 3197 53990 0.06 1820 10080 0.18 565

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 25 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4 0.00 0.00 4276 53990 0.08 2841 10260 0.28 881

5 0.00 0.00 3442 53990 0.06 2226 11650 0.19 702

6 0.00 0.00 3754 53990 0.07 1608 11890 0.14 783

Crack Widths at SLS Loads

Crack widths calculated at 20mm intervals

Analysis Face Point y z Strain Strain bt Control Acr Cmin Cmin h x Crack

Case Em E1 Bar From Width

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

2 2 79 684.7 588 -64.90E-06 -64.90E-06 732.3 17 66 62 Face 2 1492 1241 0.0114

3 86 795.3 588 -71.32E-06 -71.32E-06 732.3 1 55.44 62 Face 2 1492 1241 0.0114

4 90 834 549.3 -61.99E-06 -61.99E-06 732.3 1 55.44 62 Face 2 1492 1241 0.0099

3 4 140 834 -450.7 -250.40E-06 -250.40E-06 878.9 8 81.19 62 Face 6 1688 1015 0.0558

5 149 795.3 -588 -304.70E-06 -304.70E-06 878.9 8 55.44 62 Face 6 1688 1015 0.0499

6 161 575.3 -588 -269.90E-06 -269.90E-06 878.9 27 73.64 62 Face 6 1688 1015 0.0557

7 231 -7.95E+02 -588 -52.70E-06 -52.70E-06 878.9 16 55.44 62 Face 6 1688 1015 0.0086

8 235 -8.34E+02 -549.3 -29.57E-06 -29.57E-06 878.9 16 55.44 62 Face 6 1688 1015 0.0048

4 1 4 -795.3 588.0 -414.20E-06 -414.20E-06 1701 9 55.44 62 Face 2 1264 714.1 0.0676

2 73 564.7 588.0 -460.90E-06 -460.90E-06 1701 18 80.2 62 Face 2 1264 714.1 0.0999

3 86 795.3 588.0 -468.90E-06 -468.90E-06 1701 1 55.44 62 Face 2 1264 714.1 0.0765

4 95 834 449.3 -349.20E-06 -349.20E-06 1701 1 82.16 62 Face 2 1264 714.1 0.0771

8 285 -834 450.7 -293.00E-06 -293.00E-06 1701 9 81.19 62 Face 2 1264 714.1 0.0641

5 1 1 -834 5.49E+02 -27.90E-06 -27.90E-06 655.6 9 55.44 62 Face 2 2040 1230 0.0046

2 5 -795.3 588 -5.24E-06 -5.24E-06 655.6 9 55.44 62 Face 2 2040 1230 0.0009

6 218 -564.7 -588 -249.70E-06 -249.70E-06 655.6 35 80.2 62 Face 6 2040 1230 0.0559

7 234 -8.34E+02 -549.3 -324.40E-06 -324.40E-06 655.6 16 55.44 62 Face 6 2040 1230 0.0532

8 240 -834 -449.3 -297.40E-06 -297.40E-06 655.6 16 82.16 62 Face 6 2040 1230 0.0679

6 2 85 7.95E+02 588 -131.20E-06 -131.20E-06 486.7 1 55.44 62 Face 2 2048 1499 0.0214

3 89 834 549.3 -133.00E-06 -133.00E-06 486.7 1 55.44 62 Face 2 2048 1499 0.0217

4 95 834 449.3 -117.30E-06 -117.30E-06 486.7 1 82.16 62 Face 2 2048 1499 0.0259

Max. Crack width = 0.0999 < 0.2mm OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 26 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4.2 PIER HEAD TYPE 12

The methodology adopted for the computation of the forces acting on the solid pier-head is

as described below. The corresponding member forces (for the same relevant load

case/combination) in each of the two pier legs from the computer model are resolved and

statically combined to act at the centroid of the solid pier-head. The envelope of the resultant

forces for all the relevant load cases and combinations are then used for section analysis

using the AdSec software to check for crack-width and ultimate strength capacity.

1. Find the member forces for each of the two pier legs corresponding to the relevant

load case/combination.

2. Resolve the member forces to the line of cut taking into consideration of the geometry

and inclination of the pier legs. Two horizontal cuts are made (See Fig 4.2): CUT-1 at

the top of the pier-head and just below the pier-cap, and CUT-2 at the mid-height of

the pier-head i.e. mid-point between the pier-cap and the top of the pier stem.

3. The resolved member forces are statically combined to obtain the force resultant

acting at the centroid of the solid pier-head.

4. The envelope of the force resultants from various relevant load combinations are then

used for section analyses to check for crack-width and ultimate strength capacity by

means of the AdSec software.

Fig. 4.2: Figure Showing CUT-1 And CUT-2 Across The PierHead

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 27 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4.2.1 SUMMARY OF RESULTANT FORCES FOR TYPE 12 PIER-HEADS

The summary of the envelope of maximum resultant forces in the pier-heads TYPE 12 due to

various load combinations are tabulated below. The results are separated into two tables.

Tables 4.6 and 4.8 present the force summaries at CUT-1 (just below the pier-cap, see Fig4.2)

and CUT-2 (at pier-head mid height) due to service load combination 1 for the purpose of

crack-width check. Tables 4.7 and 4.9 are of all ultimate load combinations for the purpose of

ultimate limit state design. There are 12 summary cases in each table, namely:

Case 1 Maximum & minimum Axial Force + corresponding results

Case 2 Maximum & minimum Axial Force + corresponding results

Case 3 Maximum & minimum My + corresponding results

Case 4 Maximum & minimum My + corresponding results

Case 5 Maximum & minimum Mz + corresponding results

Case 6 Maximum & minimum Mz + corresponding results

Negative sign in axial force indicates compression and vice versa.

Envelope Of Type 12 Pier-Head Resultant Forces

Table 4.6: Service Load Combinations 1&5 (SLS1 and SLS5) Along CUT-1

CASE

Leg 1

Elem

Leg 2

Elem Load Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 1008 1009 S1-32(max) -2328 -1000 62 -53 -60 189

1 (min) 3008 3009 S5.1-3 -3648 -629 -2589 440 67 268

2 (max) 1008 1009 S1-57(max) -2516 741 957 -185 19 105

2 (min) 1008 1009 S1-24(max) -2761 -1683 106 -66 -28 129

3 (max) 1008 1009 S1-57(max) -2516 741 957 -185 19 105

3 (min) 3008 3009 S5.1-2 -3648 431 -2602 440 -15 -252

4 (max) 3008 3009 S5.1-3 -3648 -629 -2589 440 67 268

4 (min) 1008 1009 S1-57(max) -2516 741 957 -185 19 105

5 (max) 3008 3009 S5.1-3 -3648 -629 -2589 440 67 268

5 (min) 1008 1009 S1-32(max) -2328 -1000 62 -53 -60 189

6 (max) 3008 3009 S5.1-3 -3648 -629 -2589 440 67 268

6 (min) 3008 3009 S5.1-2 -3648 431 -2602 440 -15 -252

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 28 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Table 4.7: Ultimate Load Combinations 1 - 5 (U1-U5) Along CUT-1

CASE

Leg 1

Elem

Leg 2

Elem Load Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 3008 3009 U3a_2.1-1 -2885 1 -87 6 5 -150

1 (min) 3008 3009 U2b.1-11 -5463 -760 -3008 407 86 351

2 (max) 3008 3009 U3b_3.1-15 -4843 1362 -1884 181 26 216

2 (min) 1008 1009 U2b.1-22 -3869 -3312 -440 22 -130 384

3 (max) 1008 1009 U4.1-129 -4041 -99 3987 -751 54 19

3 (min) 3008 3009 U5.1-3 -4909 -1052 -3536 520 136 286

4 (max) 1008 1009 U4.1-94 -3339 -1543 -3095 525 -95 279

4 (min) 1008 1009 U4.1-129 -4041 -99 3987 -751 54 19

5 (max) 3008 3009 U5.1-3 -4909 -1052 -3536 520 136 286

5 (min) 3008 3009 U2b.1-8 -4154 -1158 -2547 326 -217 254

6 (max) 1008 1009 U4.1-153 -3741 -384 2565 -541 -77 433

6 (min) 1008 1009 U4.1-132 -3741 -291 2558 -540 -2 -304

Table 4.8: Service Load Combinations 1&5 (SLS1 and SLS5) Along CUT-2

CASE

Leg 1

Elem

Leg 2

Elem Load Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 1008 1009 S1-32(max) -2443 -1095 -21 -53 -60 189

1 (min) 3008 3009 S5.1-3 -3764 -524 -1899 440 67 268

2 (max) 1008 1009 S1-57(max) -2631 770 667 -185 19 105

2 (min) 1008 1009 S1-24(max) -2877 -1727 3 -66 -28 129

3 (max) 1008 1009 S1-57(max) -2631 770 667 -185 19 105

3 (min) 3008 3009 S5.1-2 -3763 408 -1912 440 -15 -252

4 (max) 3008 3009 S5.1-3 -3764 -524 -1899 440 67 268

4 (min) 1008 1009 S1-57(max) -2631 770 667 -185 19 105

5 (max) 3008 3009 S5.1-3 -3764 -524 -1899 440 67 268

5 (min) 1008 1009 S1-32(max) -2443 -1095 -21 -53 -60 189

6 (max) 3008 3009 S5.1-3 -3764 -524 -1899 440 67 268

6 (min) 3008 3009 S5.1-2 -3763 408 -1912 440 -15 -252

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 29 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Table 4.9: Ultimate Load Combinations 1 - 5 (U1-U5) Along CUT-2

CASE

Leg 1

Elem

Leg 2

Elem Load Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 3008 3009 U3a_2.1-1 -3029 9 -87 6 5 -191

1 (min) 3008 3009 U2b.1-11 -5608 -625 -2371 407 86 351

2 (max) 3008 3009 U3b_3.1-15 -4987 1403 -1598 181 26 226

2 (min) 1008 1009 U2b.1-22 -4013 -3516 -406 22 -130 384

3 (max) 1008 1009 U4.1-129 -4185 -14 2810 -751 54 19

3 (min) 3008 3009 U5.1-3 -5053 -839 -2721 520 136 286

4 (max) 1008 1009 U4.1-94 -3483 -1693 -2272 525 -95 279

4 (min) 1008 1009 U4.1-129 -4185 -14 2810 -751 54 19

5 (max) 3008 3009 U5.1-3 -5053 -839 -2721 520 136 286

5 (min) 3008 3009 U2b.1-8 -4298 -1498 -2036 326 -217 254

6 (max) 1008 1009 U4.1-153 -3885 -505 1717 -541 -77 433

6 (min) 1008 1009 U4.1-132 -3886 -294 1712 -540 -2 -304

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 30 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4.2.2 TYPE 12 PIER-HEADS Of PIER: ULTIMATE LIMIT STATE DESIGN

The ultimate limit state sectional analysis is carried out by AdSec software, whereas shear

and torsion design is done by using spreadsheet.

4.2.2.1 Type 12 Pier-Heads Of Pier: Axial and Bending Design to IRS CBC 1997 Along

CUT-1

Table below shows the envelope of pier-head resultant forces along CUT-1 for ultimate axial

and bending design. The ultimate limit state analyses are done by using AdSec software.

Figure shows the arrangement of bars in the pier-head. 6 cases are studied, which are:

Case 1 Maximum & minimum Axial Force + corresponding results

Case 2 Maximum & minimum My + corresponding results

Case 3 Maximum & minimum Mz + corresponding results

Table 4.10: Ultimate Load Combinations 1 - 5 (U1-U5) Maximum And Minimum Resultant

Forces Of Pier-Head Type 12 At CUT-1 for Combined Axial and Bending Ultimate Design

CASE

Leg 1

Elem

Leg 2

Elem Load Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 3008 3009 U3a_2.1-1 -2885 1 -87 6 5 -150

1 (min) 3008 3009 U2b.1-11 -5463 -760 -3008 407 86 351

2 (max) 3008 3009 U3b_3.1-15 -4843 1362 -1884 181 26 216

2 (min) 1008 1009 U2b.1-22 -3869 -3312 -440 22 -130 384

3 (max) 1008 1009 U4.1-129 -4041 -99 3987 -751 54 19

3 (min) 3008 3009 U5.1-3 -4909 -1052 -3536 520 136 286

Fig. 4.3: Pier HEAD bar arrangement

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 31 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Definition

Name Pier HEAD 12

Type Concrete

Material C45

Section Area 5.693E+6mm

Reinforcement Area 33980.mm

Reinforcement 0.5969%

Properties

Area 5.693E+6mm

Geometric Centroid y 0.0mm

z 0.0mm

Second Moments of Area Iyy 682.8E+9mm4

Izz 10.68E+12mm4

Iyz -436800.mm4

Principal Second Moments of Area Iuu 10.68E+12mm4

Izz 682.8E+9mm4

Angle 90.00

Shear Area Factor ky 0

kz 0

Torsion Constant 0.0mm4

Section Modulus Zy 1.138E+9mm

Zz 4.500E+9mm

Plastic Modulus Zpy 1.707E+9mm

Zpz 6.752E+9mm

Radius of Gyration Ry 346.3mm

Rz 1369mm

Maximum compressive force Nmax 125900.kN

Strain at Nmax 0

Moment at ref. pt. for Nmax Myy 0.0kNm

Mzz 0.0kNm

Note: Nmax is the maximum compressive force which can be carried by the section.

This is calculated by applying a constant strain across the entire section, using

ultimate material properties.

Section Material Properties

Type Concrete

Name C45

Weight Normal Weight

Density 2.300t/m

Cube Strength fcu 45Mpa

Tensile Strength fct 3.22Mpa

Elastic Modulus (short term) E 32500MPa

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 32 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Poisson's Ratio v 0.2

Coeff. Thermal Expansion 12.00E-6/C

Partial Safety Factor

mc

,ULS 1.5

mc

,SLS 1

Maximum Strain 0.0035

ULS Compression Curve Recto-parabolic

ULS Tension Curve No-tension

SLS Compression Curve Linear

SLS Tension Curve No-tension

Aggregate Size 20.00mm

Reinforcement Properties

Loading

Reference Point

All loading acts through the Reference Point.

All strain planes are defined relative to the Reference Point.

Definition Geometric Centroid

Reference Point Coordinates y 0.0mm

z 0.0mm

Total ULS Loads

Analysis N Myy Mzz M

Case [kN] [kNm] [kNm] [kNm] []

1 2885 1 -87 87.01 89.34

2 5463 -760 -3008 3103 104.2

3 4843 1362 -1884 2325 54.14

4 3869 -3312 -440 3341 172.4

5 4041 -99 3987 3988 -91.42

6 4909 -1052 -3536 3689 106.6

Name Fe500

fy 500MPa

Modulus 200000MPa

Partial Safety Factor

mc

,ULS 1.15

mc

,SLS 1

Maximum Strain 0.05

Stress/Strain Curve Fig 2

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 33 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Strength Analysis Summary

Governing conditions are defined as:

A - reinforcing steel tension strain limit

B - concrete compression strain limit

Effective centroid is reported relative to the reference point.

Analysis Eff. Eff. N Nmax N/Nmax M Mu M/Mu Governing Neutral Neutral

Case Centroid Centroid Condition Axis Axis

(y) (z) Angle Depth

(

NA

)

[mm] [mm] [kN] [kN] [kNm] [kNm] [] [mm]

1 0.00 0.00 2885 125900 0.0229 87.0 37880 0.0023 B: Node 1 84.22 572.5

2 0.00 0.00 5463 125900 0.0434 3103.0 33030 0.0939 B: Node 7 165.7 624.6

3 0.00 0.00 4843 125900 0.0385 2325.0 17080 0.1361 B: Node 2 3.018 280

4 0.00 0.00 3869 125900 0.0307 3341.0 10010 0.3339 B: Node 7 179.8 136

5 0.00 0.00 4041 125900 0.0321 3988.0 39950 0.0998 B: Node 5 -102.8 681.3

6 0.00 0.00 4909 125900 0.0390 3689.0 29920 0.1233 B: Node 7 169.1 539.1

M/Mu < 1.0 OK!

4.2.2.2 Type 12 Pier-Heads Of Pier: Axial and Bending Design to IRS CBC 1997 Along

CUT-2

Table below shows the envelope of pier-head resultant forces along CUT-2 for ultimate axial

and bending design. The ultimate limit state analyses are done by using AdSec software.

Figure shows the arrangement of bars in the pier-head. 6 cases are studied, which are:

Case 1 Maximum & minimum Axial Force + corresponding results

Case 2 Maximum & minimum My + corresponding results

Case 3 Maximum & minimum Mz + corresponding results

Table 4.11: Ultimate Load Combinations 1 - 5 (U1-U5) Maximum And Minimum Resultant

Forces Of Pier-Head Type 12 At CUT-2 for Combined Axial and Bending Ultimate Design

CASE

Leg 1

Elem

Leg 2

Elem Load Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

1 (max) 3008 3009 U3a_2.1-1 -3029 9 -87 6 5 -191

1 (min) 3008 3009 U2b.1-11 -5608 -625 -2371 407 86 351

2 (max) 3008 3009 U3b_3.1-15 -4987 1403 -1598 181 26 226

2 (min) 1008 1009 U2b.1-22 -4013 -3516 -406 22 -130 384

3 (max) 1008 1009 U4.1-129 -4185 -14 2810 -751 54 19

3 (min) 3008 3009 U5.1-3 -5053 -839 -2721 520 136 286

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 34 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Fig. 4.4: Pier HEAD Cut 2 bar arrangement

Definition

Name Pier HEAD 12

Type Concrete

Material C45

Section Area 2.892E+6mm

Reinforcement Area 28950.mm

Reinforcement 1.001%

Properties

Area 2.892E+6mm

Geometric Centroid y 0.0mm

z 0.0mm

Second Moments of Area Iyy 346.7E+9mm4

Izz 1.400E+12mm4

Iyz -46030.mm4

Principal Second Moments of Area Iuu 1.400E+12mm4

Izz 346.7E+9mm4

Angle 90.00

Shear Area Factor ky 0

kz 0

Torsion Constant 0.0mm4

Section Modulus Zy 577.6E+6mm

Zz 1.161E+9mm

Plastic Modulus Zpy 867.2E+9mm

Zpz 1.742E+9mm

Radius of Gyration Ry 346.3mm

Rz 695.7mm

Maximum compressive force Nmax 67890.kN

Strain at Nmax 0

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 35 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Moment at ref. pt. for Nmax Myy 8.078E-6kNm

Mzz 0.0kNm

Note: Nmax is the maximum compressive force which can be carried by the section.

This is calculated by applying a constant strain across the entire section, using

ultimate material properties.

Section Material Properties

Type Concrete

Name C45

Weight Normal Weight

Density 2.300t/m

Cube Strength fcu 45Mpa

Tensile Strength fct 3.22Mpa

Elastic Modulus (short term) E 32500MPa

Poisson's Ratio v 0.2

Coeff. Thermal Expansion 12.00E-6/C

Partial Safety Factor

mc

,ULS 1.5

mc

,SLS 1

Maximum Strain 0.0035

ULS Compression Curve Recto-parabolic

ULS Tension Curve No-tension

SLS Compression Curve Linear

SLS Tension Curve No-tension

Aggregate Size 20.00mm

Reinforcement Properties

Loading

Reference Point

All loading acts through the Reference Point.

All strain planes are defined relative to the Reference Point.

Definition Geometric Centroid

Reference Point Coordinates y 0.0mm

z 0.0mm

Name Fe500

fy 500MPa

Modulus 200000MPa

Partial Safety Factor

mc

,ULS 1.15

mc

,SLS 1

Maximum Strain 0.05

Stress/Strain Curve Fig 2

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 36 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

Total ULS Loads

Analysis N Myy Mzz M

Case [kN] [kNm] [kNm] [kNm] []

1 3029 9 -87 87.46 84.09

2 5608 -625 -2371 2452 104.8

3 4987 1403 -1598 2127 48.72

4 4013 -3516 -406 3539 173.4

5 4185 -14 2810 2810 -90.29

6 5053 -839 -2721 2847 107.1

Strength Analysis Summary

Governing conditions are defined as:

A - reinforcing steel tension strain limit

B - concrete compression strain limit

Effective centroid is reported relative to the reference point.

Analysis Eff. Eff. N Nmax N/Nmax M Mu M/Mu Governing Neutral Neutral

Case Centroid Centroid Condition Axis Axis

(y) (z) Angle Depth

(

NA

)

[mm] [mm] [kN] [kN] [kNm] [kNm] [] [mm]

1 0.00 0.00 3029 67890 0.0446 87.5 15790 0.0055 B: Node 1 70.99 601.3

2 0.00 0.00 5608 67890 0.0826 2452.0 16200 0.1514 B: Node 8 133.5 796.8

3 0.00 0.00 4987 67890 0.0735 2127.0 11440 0.1860 B: Node 2 14.7 545.5

4 0.00 0.00 4013 67890 0.0591 3539.0 8476 0.4176 B: Node 7 178.5 235.9

5 0.00 0.00 4185 67890 0.0617 2810.0 17070 0.1646 B: Node 5 -90.99 469.2

6 0.00 0.00 5053 67890 0.0744 2847.0 15450 0.1843 B: Node 7 138 778.8

M/Mu < 1.0 OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 37 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4.2.2.2 Type 12 Pier-Heads Of Pier: Shear And Torsion Design to IRS CBC 1997 Along

CUT-1

The table 4.12 shows the most critical cases for shear and torsion design.

Table 4.12: Ultimate Load Combinations 1 - 5 (U1-U5) Maximum Final Design Forces for

Shear and Torsion Design

CASE

Leg 1

Elem

Leg 2

Elem Load Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

4 (max) 1008 1009 U4.1-94 -3339 -1543 -3095 525 -95 279

4 (min) 1008 1009 U4.1-129 -4041 -99 3987 -751 54 19

5 (max) 3008 3009 U5.1-3 -4909 -1052 -3536 520 136 286

5 (min) 3008 3009 U2b.1-8 -4154 -1158 -2547 326 -217 254

6 (max) 1008 1009 U4.1-153 -3741 -384 2565 -541 -77 433

6 (min) 1008 1009 U4.1-132 -3741 -291 2558 -540 -2 -304

The design calculations for ultimate shear and torsion are shown in the spreadsheet next

pages. 3 cases are studied, which are:

i) Absolute Maximum Vy + Corresponding Vz & Torsion

ii) Absolute Maximum Vz + Corresponding Vy & Torsion

iii) Absolute Maximum Torsion + Corresponding Vz & Vy

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 38 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

PIER SHEAR & TORSION DESIGN

to IRS CBC - 1997

Reference : Pier Head for Buffer Stop (CUT 1)

Case : Maximum Vy + corresponding Vz & Torsion

Input Data : Z

h

y

= 4745 mm Cover = 50 mm Y

b

z

= 1200 mm Tension Reinf. F = 32 mm

fcu = 45 N/mm

2

As provided,(z-dir) = 6432 mm

2

fy = 415 N/mm

2

As provided,(y-dir) = 12160 mm

2

1200

fyv = 415 N/mm

2

Shear Link, (z-dir) = 12 mm

Shear Link, (y-dir) = 12 mm 4745

Torsion Link = 16 mm

Analysis Results :

Shear (z-dir) = 54 kN

Shear (y-dir) = 751 kN

N = 4041 kN

Torsion = 19 kNm

SHEAR DESIGN (Cl. 15.6.6 IRS CBC - 1997)

a) Shear in z- direction:

V = 54.0 kN

b = 4745.0 mm

d = 1118.0 mm

v

z

= 0.01

N/mm

2

OK!

100As/bd = 0.23

vc = 0.45 N/mm

2

depth factor, s= 0.82

1+0.05N/Ac = 1.04

Asv/sv = 5.26 mm

2

/mm

b) Shear in y- direction:

V = 751.0 kN

b = 1200.0 mm

d = 4663.0 mm

v

y

= 0.13

N/mm

2

OK!

100As/bd = 0.11

vc = 0.36 N/mm

2

depth factor, s= 1.00

1+0.05N/Ac = 1.04

Asv/sv = 1.33 mm

2

/mm

c) Shear resistance of pier:

Vcz = 2031 kN [concrete capacity)

Vsz = 4734 kN [link capacity = 0.87fy(As)d/(sv) ]

Vcy = 2081 kN [concrete capacity]

Vsy= 8322 kN [link capacity = 0.87fy(As)d/(sv)]

Vz / Vuz + Vy / Vuy < 1

0.01 + 0.07 = 0.08 OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 39 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

TORSION DESIGN (Cl. 15.4.4 IRS CBC - 1997)

a) Torsional Shear Stress, v

t

v

t

= 2T / [h

2

min

(h

max

- h

min

/3)] = 0.01

N/mm

2

h

min

= 1200 mm

h

max

= 4745 mm

c) Minimum Ultimate Torsional Shear Stress, v

tmin

v

tmin = 0.067 (f

cu)

0.5

= 0.42

N/mm

2

No Torsional Reinf Required

d) Ultimate Torsional Shear Stress, v

tu

v

tu = 0.75 (f

cu )

0.5

= 4.74

N/mm

2

x

1

= 1068 mm

y

1 = 4613 mm

In z-dir : v

z

+ v

t = 0.02

N/mm

2

(OK)

In y-dir: v

y

+ v

t = 0.14

N/mm

2

(OK)

e) Torsional link, A

st

/s

v

A

st

/s

v = T / [0.8 x

1

y

1

(0.87f

yv )] = 0.01

mm

2

/mm

COMBINED SHEAR AND TORSION DESIGN

a) Shear Links

Torsion Required 2 T 16 Links @ 30117

alone Provide 2 T 16 Links @ 150 (Asv/sv = 2.68 mm

2

/mm )

(OK)

Torsion In z-dir: Total torsion + shear link required = 5.27 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 12 T 12 Links @ 150 (inner legs) (Asv/sv = 11.73 mm

2

/mm )

(OK)

Torsion In y-dir: Total torsion + shear link required = 1.34 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 3 T 12 Links @ 150 (inner legs) (Asv/sv = 4.94 mm

2

/mm )

(OK)

b) Longitudinal Reinforcement, A

sL

/s

L

A

sL

/s

L

= A

st

/s

v

(f

yv

/f

y

) = 0.01

mm

2

/mm

A

sL

= 38 mm

2

Required 1 T 32 EF (As = 804 mm

2

)

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 40 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

PIER SHEAR & TORSION DESIGN

to IRS CBC - 1997

Reference : Pier Head for Buffer Stop (CUT 1)

Case : Maximum Vz + corresponding Vy & Torsion

Input Data : Z

h

y

= 4745 mm Cover = 50 mm Y

b

z

= 1200 mm Tension Reinf. F = 32 mm

fcu = 45 N/mm

2

As provided,(z-dir) = 6432 mm

2

fy = 415 N/mm

2

As provided,(y-dir) = 12160 mm

2

1200

fyv = 415 N/mm

2

Shear Link, (z-dir) = 12 mm

Shear Link, (y-dir) = 12 mm 4745

Torsion Link = 16 mm

Analysis Results :

Shear (z-dir) = 217 kN

Shear (y-dir) = 326 kN

N = 4154 kN

Torsion = 254 kNm

SHEAR DESIGN (Cl. 15.6.6 IRS CBC - 1997)

a) Shear in z- direction:

V = 217.0 kN

b = 4745.0 mm

d = 1118.0 mm

v

z

= 0.04

N/mm

2

OK!

100As/bd = 0.23

vc = 0.45 N/mm

2

depth factor, s= 0.82

1+0.05N/Ac = 1.04

Asv/sv = 5.26 mm

2

/mm

b) Shear in y- direction:

V = 326.0 kN

b = 1200.0 mm

d = 4663.0 mm

v

y

= 0.06

N/mm

2

OK!

100As/bd = 0.11

vc = 0.36 N/mm

2

depth factor, s= 1.00

1+0.05N/Ac = 1.04

Asv/sv = 1.33 mm

2

/mm

c) Shear resistance of pier:

Vcz = 2033 kN [concrete capacity)

Vsz = 4734 kN [link capacity = 0.87fy(As)d/(sv) ]

Vcy = 2083 kN [concrete capacity]

Vsy= 8322 kN [link capacity = 0.87fy(As)d/(sv)]

Vz / Vuz + Vy / Vuy < 1

0.03 + 0.03 = 0.06 OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 41 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

TORSION DESIGN (Cl. 15.4.4 IRS CBC - 1997)

a) Torsional Shear Stress, v

t

v

t

= 2T / [h

2

min

(h

max

- h

min

/3)] = 0.08

N/mm

2

h

min

= 1200 mm

h

max

= 4745 mm

c) Minimum Ultimate Torsional Shear Stress, v

tmin

v

tmin = 0.067 (f

cu)

0.5

= 0.42

N/mm

2

No Torsional Reinf Required

d) Ultimate Torsional Shear Stress, v

tu

v

tu = 0.75 (f

cu )

0.5

= 4.74

N/mm

2

x

1

= 1068 mm

y

1 = 4613 mm

In z-dir : v

z

+ v

t = 0.12

N/mm

2

(OK)

In y-dir: v

y

+ v

t = 0.14

N/mm

2

(OK)

e) Torsional link, A

st

/s

v

A

st

/s

v = T / [0.8 x

1

y

1

(0.87f

yv )] = 0.18

mm

2

/mm

COMBINED SHEAR AND TORSION DESIGN

a) Shear Links

Torsion Required 2 T 16 Links @ 2253

alone Provide 2 T 16 Links @ 150 (Asv/sv = 2.68 mm

2

/mm )

(OK)

Torsion In z-dir: Total torsion + shear link required = 5.44 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 12 T 12 Links @ 150 (inner legs) (Asv/sv = 11.73 mm

2

/mm )

(OK)

Torsion In y-dir: Total torsion + shear link required = 1.51 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 3 T 12 Links @ 150 (inner legs) (Asv/sv = 4.94 mm

2

/mm )

(OK)

b) Longitudinal Reinforcement, A

sL

/s

L

A

sL

/s

L

= A

st

/s

v

(f

yv

/f

y

) = 0.09

mm

2

/mm

A

sL

= 507 mm

2

Required 1 T 32 EF (As = 804 mm

2

)

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 42 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

PIER SHEAR & TORSION DESIGN

to IRS CBC - 1997

Reference : Pier Head for Buffer Stop (CUT 1)

Case : Maximum Torsion + corresponding Vy & Vz

Input Data : Z

h

y

= 4745 mm Cover = 50 mm Y

b

z

= 1200 mm Tension Reinf. F = 32 mm

fcu = 45 N/mm

2

As provided,(z-dir) = 6432 mm

2

fy = 415 N/mm

2

As provided,(y-dir) = 12160 mm

2

1200

fyv = 415 N/mm

2

Shear Link, (z-dir) = 12 mm

Shear Link, (y-dir) = 12 mm 4745

Torsion Link = 16 mm

Analysis Results :

Shear (z-dir) = 77 kN

Shear (y-dir) = 541 kN

N = 3741 kN

Torsion = 433 kNm

SHEAR DESIGN (Cl. 15.6.6 IRS CBC - 1997)

a) Shear in z- direction:

V = 77.0 kN

b = 4745.0 mm

d = 1118.0 mm

v

z

= 0.01

N/mm

2

OK!

100As/bd = 0.23

vc = 0.45 N/mm

2

depth factor, s= 0.82

1+0.05N/Ac = 1.03

Asv/sv = 5.26 mm

2

/mm

b) Shear in y- direction:

V = 541.0 kN

b = 1200.0 mm

d = 4663.0 mm

v

y

= 0.10

N/mm

2

OK!

100As/bd = 0.11

vc = 0.36 N/mm

2

depth factor, s= 1.00

1+0.05N/Ac = 1.03

Asv/sv = 1.33 mm

2

/mm

c) Shear resistance of pier:

Vcz = 2026 kN [concrete capacity)

Vsz = 4734 kN [link capacity = 0.87fy(As)d/(sv) ]

Vcy = 2076 kN [concrete capacity]

Vsy= 8322 kN [link capacity = 0.87fy(As)d/(sv)]

Vz / Vuz + Vy / Vuy < 1

0.01 + 0.05 = 0.06 OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 43 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

TORSION DESIGN (Cl. 15.4.4 IRS CBC - 1997)

a) Torsional Shear Stress, v

t

v

t

= 2T / [h

2

min

(h

max

- h

min

/3)] = 0.14

N/mm

2

h

min

= 1200 mm

h

max

= 4745 mm

c) Minimum Ultimate Torsional Shear Stress, v

tmin

v

tmin = 0.067 (f

cu)

0.5

= 0.42

N/mm

2

No Torsional Reinf Required

d) Ultimate Torsional Shear Stress, v

tu

v

tu = 0.75 (f

cu )

0.5

= 4.74

N/mm

2

x

1

= 1068 mm

y

1 = 4613 mm

In z-dir : v

z

+ v

t = 0.15

N/mm

2

(OK)

In y-dir: v

y

+ v

t = 0.24

N/mm

2

(OK)

e) Torsional link, A

st

/s

v

A

st

/s

v = T / [0.8 x

1

y

1

(0.87f

yv )] = 0.30

mm

2

/mm

COMBINED SHEAR AND TORSION DESIGN

a) Shear Links

Torsion Required 2 T 16 Links @ 1322

alone Provide 2 T 16 Links @ 150 (Asv/sv = 2.68 mm

2

/mm )

(OK)

Torsion In z-dir: Total torsion + shear link required = 5.56 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 12 T 12 Links @ 150 (inner legs) (Asv/sv = 11.73 mm

2

/mm )

(OK)

Torsion In y-dir: Total torsion + shear link required = 1.63 mm

2

/mm

+ Provide 2 T 16 Links @ 150 + (outer legs)

Shear 3 T 12 Links @ 150 (inner legs) (Asv/sv = 4.94 mm

2

/mm )

(OK)

b) Longitudinal Reinforcement, A

sL

/s

L

A

sL

/s

L

= A

st

/s

v

(f

yv

/f

y

) = 0.15

mm

2

/mm

A

sL

= 864 mm

2

Required 2 T 32 EF (As = 1608 mm

2

)

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 44 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

4.2.2.3 Type 12 Pier-Heads Of Pier: Shear And Torsion Design to IRS CBC 1997 Along

CUT-2

The table 4.13 shows the most critical cases for shear and torsion design.

Table 4.13: Ultimate Load Combinations 1 - 5 (U1-U5) Maximum Final Design Forces for

Shear and Torsion Design

CASE

Leg 1

Elem

Leg 2

Elem Load Axial My Mz Vy Vz T

(kN) (kNm) (kNm) (kN) (kN) (kNm)

4 (max) 1008 1009 U4.1-94 -3483 -1693 -2272 525 -95 279

4 (min) 1008 1009 U4.1-129 -4185 -14 2810 -751 54 19

5 (max) 3008 3009 U5.1-3 -5053 -839 -2721 520 136 286

5 (min) 3008 3009 U2b.1-8 -4298 -1498 -2036 326 -217 254

6 (max) 1008 1009 U4.1-153 -3885 -505 1717 -541 -77 433

6 (min) 1008 1009 U4.1-132 -3886 -294 1712 -540 -2 -304

The design calculations for ultimate shear and torsion are shown in the spreadsheet next

pages. 3 cases are studied, which are:

i) Absolute Maximum Vy + Corresponding Vz & Torsion

ii) Absolute Maximum Vz + Corresponding Vy & Torsion

iii) Absolute Maximum Torsion + Corresponding Vz & Vy

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 45 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

PIER SHEAR & TORSION DESIGN

to IRS CBC - 1997

Reference : Pier Stem for Buffer Stop (Cut 2)

Case : Maximum Vy + corresponding Vz & Torsion

Input Data : Z

h

y

= 2411 mm Cover = 50 mm Y

b

z

= 1200 mm Tension Reinf. F = 32 mm

fcu = 45 N/mm

2

As provided,(z-dir) = 6432 mm

2

fy = 415 N/mm

2

As provided,(y-dir) = 9648 mm

2

1200

fyv = 415 N/mm

2

Shear Link, (z-dir) = 12 mm

Shear Link, (y-dir) = 12 mm 2411

Torsion Link = 16 mm

Analysis Results :

Shear (z-dir) = 54 kN

Shear (y-dir) = 751 kN

N = 4185 kN

Torsion = 19 kNm

SHEAR DESIGN (Cl. 15.6.6 IRS CBC - 1997)

a) Shear in z- direction:

V = 54.0 kN

b = 2411.0 mm

d = 1118.0 mm

v

z

= 0.02

N/mm

2

OK!

100As/bd = 0.36

vc = 0.52 N/mm

2

depth factor, s= 0.82

1+0.05N/Ac = 1.07

Asv/sv = 2.67 mm

2

/mm

b) Shear in y- direction:

V = 751.0 kN

b = 1200.0 mm

d = 2329.0 mm

v

y

= 0.27

N/mm

2

OK!

100As/bd = 0.23

vc = 0.45 N/mm

2

depth factor, s= 1.00

1+0.05N/Ac = 1.07

Asv/sv = 1.33 mm

2

/mm

c) Shear resistance of pier:

Vcz = 1240 kN [concrete capacity)

Vsz = 2908 kN [link capacity = 0.87fy(As)d/(sv) ]

Vcy = 1357 kN [concrete capacity]

Vsy= 4156 kN [link capacity = 0.87fy(As)d/(sv)]

Vz / Vuz + Vy / Vuy < 1

0.01 + 0.14 = 0.15 OK!

MUMBAI MONORAIL PROJECT

Definiti ve Design Review Design Calculation for Pier

Structures of Pier 1A10a (Frame 4) & Pier 2G1 (Frame 172)

(Buffer Stop) Rev.A1

MM001-D-DR-VSB-LTSE-303182

21-Jun-10

Page 46 / 72

LARSEN & TOUBRO LI MI TED - SCOMI ENGG. BHD. CONSORTI UM

TORSION DESIGN (Cl. 15.4.4 IRS CBC - 1997)

a) Torsional Shear Stress, v

t

v

t

= 2T / [h

2

min

(h

max

- h

min

/3)] = 0.01

N/mm

2

h

min

= 1200 mm

h

max

= 2411 mm

c) Minimum Ultimate Torsional Shear Stress, v

tmin

v

tmin = 0.067 (f

cu)

0.5

= 0.42

N/mm

2

No Torsional Reinf Required