Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Compaction Test

Caricato da

Arjun MulluCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Compaction Test

Caricato da

Arjun MulluCopyright:

Formati disponibili

Page | 1

FACULTY OF ENGINEERING AND BUILT ENVIRONMENT

EXPERIMENT: COMPACTION TEST

MEHREEN ZEENAT HEERAH SCM-019211

MOHAMMAD ARSHAD HOSSANY SCM-020570

NIHAAD LAULLOO SCM-014963

GROUP NO. : GROUP 2

SUBJECT NAME : SOIL MECHANICS 2

COURSE CODE : ECG 4313

LECTURERS NAME : MISS JAMILAH BINTI JAADIL

DATE OF EXPERIMENT : 08. 07. 2014

DATE OF SUBMISSION : 16. 07. 2014

Page | 2

Table of Contents

Purpose ............................................................................................................................................ 3

Introduction ..................................................................................................................................... 3

Standard Reference ......................................................................................................................... 3

Significance..................................................................................................................................... 3

Equipment ....................................................................................................................................... 4

Procedures ....................................................................................................................................... 4

Calculations..................................................................................................................................... 5

Results and Calculations ................................................................................................................. 6

Graph............................................................................................................................................... 7

Discussion ....................................................................................................................................... 7

Conclusion ...................................................................................................................................... 8

References ....................................................................................................................................... 9

Appendix ......................................................................................................................................... 9

Page | 3

Purpose

This experiment was performed to determine the relationship between the moisture content and

the dry density of a sample of soil for a specified compactive effort.

Introduction

This experiment is also known as the Proctor test. The Proctor compaction test is a laboratory

method of experimentally determining the optimal moisture content at which a given soil type

will become most dense and achieve its maximum dry density. There are different ways to

compact the soil on site. For example kneading compactors, tamping, vibration plates and static

load compaction. But in this experiment we use the tamping or impact compaction. Compaction

is a dense state which is achieved through the reduction of the air voids in the soil with little or

no reduction in the water content. Compaction of the soil is very important before starting the

construction as it decreases the risk of future settlement, it increases the shear strength of the soil

and decrease the permeability also.

Standard Reference

ASTM D 698 Standard Test Methods for Laboratory Compaction

Characteristics of Soil Using Standard Effort (12, 400 ft-lbs/ft (600 KN-m/m)

ASTM D 1557- Standard Test Methods for Laboratory Compaction Characteristics of

Soil Using Modified Effort (56, 000 ft-lbs/ ft (2700 KN-m/m)

Significance

Mechanical compaction is considered to be the most common and cheapest way of stabilizing the

soil. One of the most important things for a geotechnical engineer is to check that performance

and analysis of the compacted soil are meeting the performance of the design specifications. The

required density and water content are usually stated in the design specifications. Usually, when

increasing the soil density, the other engineering properties, like strength, stiffness, resistance to

shrinkage and imperviousness of the soil will also improve. The optimum water is the water

content that results in the greatest density for a specified compactive effort.

Page | 4

Equipment

1. Moulds

2. Manual rammer

3. Balance

4. Drying oven

5. Mixing pan

6. Trowel

7. Moisture cans

8. Graduated cylinder

9. Straight edge

10. Ruler

11. Sieve

Procedures

1. The weight of the mould (mould + base + side screw) was measured by using the

electronic balance.

2. The internal diameter and height was measured by using a ruler.

3. Afterwards grease was applied on the sides of the mould and on the collar.

4. 5 mixing pans and 10 moisture cans were prepared (2 containers per sample).

5. The weight of each moisture cans together with lid was measured with the help of

electronic balance.

6. The soil was sieved.

7. 3kg of loose soil was then measured.

8. The required amount of distilled water was measured according to the assumed water

content.

9. The soil was mixed thoroughly with the water by using both hands.

10. After having mixed it completely, the soil was divided into 3 sections.

11. The first section of the soil was put up to

2

of the mould.

12. With the help of the rammer, the soil was compacted by 25 blows.

13. The second layer of soil is added and rammered 25 more times

Page | 5

14. Then the collar was assembled and the screws were tightened.

15. The last layer of soil was added and was rammered for 25 times again.

16. Then the collar was removed and the soil was levered using a straight edge.

17. The mould containing the compacted soil together with the base and side screws were

weighed.

18. Then a small portion of soil at the top was taken and placed in the moisture can.

19. Afterwards the mould is turned upside down and a small portion of soil was taken at the

bottom also and placed in another moisture can.

20. Steps 5 to 19 were repeated for each assumed water content.

21. The moisture cans were weighed.

22. Then these moisture cans were placed in the oven to dry.

23. After 24hr the moisture cans were removed from the oven and was allowed to cool for 10

minutes.

24. Then the weight of the moisture cans was noted.

Calculations

Page | 6

Results and Calculations

Water Content Determination:

Water content 9% 12% 15% 18% 21%

Compacted Soil Top Bottom Top Bottom Top Bottom Top Bottom Top Bottom

M

C

= Mass of

empty can+lid (g)

33.0 32.9 33.3 33.0 33.2 32.0 32.6 32.4 32.6 33.0

M

CMS

= Mass of

can, lid and moist

soil (g)

45.2 41.5 50.6 47.2 49.9 46.2 43.3 43.1 62.7 67.1

M

CDS

= Mass of

can, lid and dry

soil (g)

44.3 40.8 48.7 45.8 47.8 44.4 41.8 41.5 57.2 61.2

M

S

= Mass of soil

solids (g)

11.3 7.9 15.4 12.8 14.6 12.4 9.2 9.1 23.6 28.2

M

W

= Mass of

pure water (g)

0.9 0.7 1.9 1.4 2.1 1.8 1.5 1.6 5.5 5.9

W = Water

content (w%)

7.96 8.86 12.34 10.94 14.38 14.52 16.30 17.39 23.31 20.92

Average water

content (w%)

8.41 11.64 14.45 16.85 22.12

Density Determination:

Compacted Soil Sample no. 1 2 3 4 5

w = Assumed water content, w% 9 12 15 18 21

Actual average water content, w% 8.41 11.64 14.45 16.85 22.12

Mass of compacted soil and mold (g) 5800 6850 5850 5950 6200

Mass of mold (g) 4400 5050 4450 4400 4450

Wet mass of soil in mold (g) 1400 1800 1400 1550 1750

Diameter of mold (cm) 10.2 10.4 10.1 10.2 10.1

Height of mold (cm) 11.6 11.5 11.7 11.6 11.7

Volume of mold (cm

3

) 947.9 976.9 937.4 947.9 937.4

Wet density, 1.477 1.843 1.493 1.635 1.867

Dry density,

d

1.362 1.650 1.304 1.399 1.529

Page | 7

Graph

Graph of dry density against water content

Discussion

The Proctor test is carried out to determine the relationship between the moisture content and the

dry density of a soil sample. From the graph plotted above, we can see that the maximum dry

density, 1.65 g/cm

3

, occurred when the water content is 11.64%. One can also see that the

assumed water content is almost the same the theoretical one. This slight difference has occurred

due to some small errors. For example, due to the presence of fans or because when pouring the

water, some of it was splashed.

Furthermore, we can conclude from the shape of the graph that experiment for the 15% and 21%

are not correct. The actual result should be like the red graph below.

1.2

1.25

1.3

1.35

1.4

1.45

1.5

1.55

1.6

1.65

1.7

1.75

1.8

8 10 12 14 16 18 20 22 24

D

r

y

d

e

n

s

i

t

y

(

g

/

c

m

)

Water content (w%)

Dry density vs Water content

Page | 8

Some errors that might have occurred during the experiment:

1. Parallax error when taking the measurement of the mould or when reading the measuring

cylinder.

2. The presence of fan which can make the soil become dry more quickly.

3. The water and the soil were not mixed properly and uniformly.

4. Loss of water due to splashing of water.

5. The soil was not rammered uniformly which can result for some areas not being well

compacted.

6. The mould was not completely filled due to presence of air voids. So, the volume of soil

will not be correct.

Conclusion

The proctor test is very important in the construction field. It helps to lower the permeability of

the soil and to increase its shear stress. From the results obtained above we can conclude that the

dry density of soil is dependent of its water content. But the relationship is not a linear one. We

can also conclude that the optimum water content is found at the maximum dry density of the

soil.

1

1.05

1.1

1.15

1.2

1.25

1.3

1.35

1.4

1.45

1.5

1.55

1.6

1.65

1.7

1.75

1.8

8 10 12 14 16 18 20 22 24

D

r

y

d

e

n

s

i

t

y

(

g

/

c

m

)

Water content (%)

Experimental results

Theoretical results

Page | 9

References

http://www.uic.edu/classes/cemm/cemmlab/Experiment%209-Compaction.pdf

Appendix

Figure 1. Sample soil Figure 2. Weighing moisture can

Figure 3. Rammering the soil Figure 4. Levelling the soil

Potrebbero piacerti anche

- Proctor Standard Soil CompactionDocumento11 pagineProctor Standard Soil Compactionikhwan100% (2)

- Soil-Compaction Lab 1Documento9 pagineSoil-Compaction Lab 1Abdulrahman Alnagar100% (1)

- Compaction ReportDocumento6 pagineCompaction ReportharinderNessuna valutazione finora

- Determination of Field Density of Soils by The Core Cutter Method PDFDocumento4 pagineDetermination of Field Density of Soils by The Core Cutter Method PDFShafiq Kadir100% (3)

- Lab 7 - Triaxial (Uu)Documento12 pagineLab 7 - Triaxial (Uu)NurulAdilahNessuna valutazione finora

- Lab Sheet - Atterberg LimitsDocumento6 pagineLab Sheet - Atterberg LimitsLuqman YusofNessuna valutazione finora

- Material LaboratoryDocumento14 pagineMaterial LaboratoryAnonymous tLXKwTNessuna valutazione finora

- Atterberg LimitsDocumento6 pagineAtterberg LimitsMuhammadZAmjadNessuna valutazione finora

- Field Density Test by Sand Replacement MethodDocumento4 pagineField Density Test by Sand Replacement Methodibrih wazirNessuna valutazione finora

- C2-Consistency Cement PasteDocumento4 pagineC2-Consistency Cement PasteMuhamad FarhanNessuna valutazione finora

- 3.0 Determination of Liquid Limit Using The Cone PenetrometerDocumento10 pagine3.0 Determination of Liquid Limit Using The Cone PenetrometerasNessuna valutazione finora

- CompactionDocumento15 pagineCompactionpp hsu100% (6)

- Hydraulics JumpDocumento10 pagineHydraulics JumpIkhwan Z.100% (2)

- Permiability Test Aim of The ExperimentDocumento7 paginePermiability Test Aim of The ExperimentArif AzizanNessuna valutazione finora

- Physics ProjectDocumento12 paginePhysics ProjectsandsphilipNessuna valutazione finora

- Exp 4 Unconfined TestDocumento6 pagineExp 4 Unconfined TestumarNessuna valutazione finora

- Softing PointDocumento12 pagineSofting PointMUHAMMAD AKRAMNessuna valutazione finora

- Experiment No. 7 Bulking of SandDocumento1 paginaExperiment No. 7 Bulking of SandShubham GautamNessuna valutazione finora

- Lab Report Atterberg LimitDocumento8 pagineLab Report Atterberg LimitMohamad HazimNessuna valutazione finora

- Standard Proctor Compaction TestDocumento7 pagineStandard Proctor Compaction TestGnabBang75% (4)

- Lab 3: Atterberg Limits CE 340Documento8 pagineLab 3: Atterberg Limits CE 340satyam agarwal100% (1)

- Unconfined Compression TestDocumento11 pagineUnconfined Compression TestAmiruddin JSNessuna valutazione finora

- Lab Sheet - Infiltration TestDocumento8 pagineLab Sheet - Infiltration TestDINAMARIANASAMUJI0% (1)

- Lab Soil-Hydrometer TestDocumento6 pagineLab Soil-Hydrometer TestSyed Zulfaizzuan AljufriNessuna valutazione finora

- Consolidation TestDocumento4 pagineConsolidation TestrbhavishNessuna valutazione finora

- Proctor Standard Soil Compaction Test ReportDocumento7 pagineProctor Standard Soil Compaction Test ReportMohamad Haris Fadhilah Bin Mohamad RazaliNessuna valutazione finora

- Lab ReportDocumento39 pagineLab ReporthaftamuTekleNessuna valutazione finora

- Lab7 ReportDocumento4 pagineLab7 ReporthelensongyNessuna valutazione finora

- Soil Mechanics Lab RecordDocumento55 pagineSoil Mechanics Lab RecordshubhamNessuna valutazione finora

- LL & PLDocumento6 pagineLL & PLSougata DasNessuna valutazione finora

- Discussin and Conclusion Geotechnical Falling HeadDocumento2 pagineDiscussin and Conclusion Geotechnical Falling HeadAzizi YahyaNessuna valutazione finora

- Consolidation TestDocumento9 pagineConsolidation Testdatonizam0% (1)

- Soil Classification Test: Determination of Liquid Limit and Plastic LimitDocumento11 pagineSoil Classification Test: Determination of Liquid Limit and Plastic LimitEver SimNessuna valutazione finora

- Lab 4 - Hydrometer Testnvxjkcvbcxckvbckjvjkvknvck.Documento6 pagineLab 4 - Hydrometer Testnvxjkcvbcxckvbckjvjkvknvck.Amirah ShafeeraNessuna valutazione finora

- Use of Non-Biodegradable Plastics in Flexible Pavement ConstructionDocumento74 pagineUse of Non-Biodegradable Plastics in Flexible Pavement ConstructionWaleed Bin YousufNessuna valutazione finora

- Consolidation TestDocumento8 pagineConsolidation TestCasper da MagnificientNessuna valutazione finora

- Falling Head Permeability Lab TestDocumento6 pagineFalling Head Permeability Lab TestHamierul MohamadNessuna valutazione finora

- Determination of Aggregate Crushing ValueDocumento10 pagineDetermination of Aggregate Crushing ValueArivalagan Revichandran100% (1)

- What Is The Difference Between Standard Proctor Test and Modified Proctor Test.Documento7 pagineWhat Is The Difference Between Standard Proctor Test and Modified Proctor Test.Asif RajaNessuna valutazione finora

- In-Situ Density Determination by Sand Replacement MethodDocumento11 pagineIn-Situ Density Determination by Sand Replacement MethodkillerhAPPyNessuna valutazione finora

- Direct Shear TestDocumento19 pagineDirect Shear Testshahrolhazrien75% (4)

- Falling Head PermeabilityDocumento13 pagineFalling Head PermeabilitySitiNessuna valutazione finora

- Falling Heat Permeability TestDocumento10 pagineFalling Heat Permeability TestAiryn UyienNessuna valutazione finora

- Geotech Lab Report 1 FinalDocumento11 pagineGeotech Lab Report 1 FinalkennethcyinNessuna valutazione finora

- Lab 6: Specific Gravity of Sand and SoilDocumento16 pagineLab 6: Specific Gravity of Sand and Soiljads docallosNessuna valutazione finora

- Consolidation TestDocumento10 pagineConsolidation TestMostafa NouhNessuna valutazione finora

- Liquid and Plastic LimitDocumento13 pagineLiquid and Plastic LimitDariusAngelitoNessuna valutazione finora

- Professor V, Agricultural Machinery Division, Institute of Agricultural Engineering, College of Engineering and Agro-Industrial Technology, UPLBDocumento15 pagineProfessor V, Agricultural Machinery Division, Institute of Agricultural Engineering, College of Engineering and Agro-Industrial Technology, UPLBKelvin Michael A. CrystalNessuna valutazione finora

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Da EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Nessuna valutazione finora

- Standard Protactor TestDocumento8 pagineStandard Protactor TestNur ZakariaNessuna valutazione finora

- Soil Cmpaction DDDocumento18 pagineSoil Cmpaction DDZhwa 18Nessuna valutazione finora

- A Technical Report On Soil Compaction TestDocumento13 pagineA Technical Report On Soil Compaction TestBrown LatteNessuna valutazione finora

- Standard Proctor TestDocumento6 pagineStandard Proctor TestJulius BaniquedNessuna valutazione finora

- Compaction LabDocumento10 pagineCompaction LabKarl Todd100% (5)

- Proctor Test-: Kabul University Engineering Faculty Civil DepartmentDocumento4 pagineProctor Test-: Kabul University Engineering Faculty Civil DepartmentAssad YaqubiNessuna valutazione finora

- معمل سويل CompactionDocumento8 pagineمعمل سويل CompactionHamida MahmoudNessuna valutazione finora

- Geoechnical Engineering Third YearDocumento59 pagineGeoechnical Engineering Third Yearrozita kadirNessuna valutazione finora

- Report Standard Compaction TestDocumento14 pagineReport Standard Compaction TestLuqman Yusof100% (1)

- Atterberg Limits TestDocumento11 pagineAtterberg Limits TestUTKARSH MEENA 16110171Nessuna valutazione finora

- CompactionDocumento3 pagineCompactionスルタンリスクNessuna valutazione finora

- Cost of DeportationDocumento1 paginaCost of DeportationArjun MulluNessuna valutazione finora

- NSW Abalone Assessment 2017Documento18 pagineNSW Abalone Assessment 2017Arjun MulluNessuna valutazione finora

- News Gulf NewspaperDocumento2 pagineNews Gulf NewspaperArjun MulluNessuna valutazione finora

- Dragline Dictionary Apr14Documento578 pagineDragline Dictionary Apr14dhowardj100% (1)

- ConversionDocumento1 paginaConversionCosmin CinciNessuna valutazione finora

- SALE of Vehicle FormDocumento1 paginaSALE of Vehicle FormArjun MulluNessuna valutazione finora

- ConversionDocumento1 paginaConversionCosmin CinciNessuna valutazione finora

- Mount AgungDocumento3 pagineMount AgungArjun MulluNessuna valutazione finora

- Manchester City Vs BarcelonaDocumento4 pagineManchester City Vs BarcelonaArjun MulluNessuna valutazione finora

- Joints in Concrete SlabsDocumento2 pagineJoints in Concrete SlabsmutyokaNessuna valutazione finora

- Masterseal 550Documento4 pagineMasterseal 550Arjun MulluNessuna valutazione finora

- Self Supporting TowerDocumento3 pagineSelf Supporting TowerArjun MulluNessuna valutazione finora

- Standard BoQ (UAE - DoT) - CESMM4 PDFDocumento554 pagineStandard BoQ (UAE - DoT) - CESMM4 PDFNektarios Matheou86% (44)

- RC RepairDocumento20 pagineRC Repairer_zaheerNessuna valutazione finora

- Flash and False SetDocumento2 pagineFlash and False Setpxt90100% (3)

- Mix DesignDocumento1 paginaMix DesignArjun MulluNessuna valutazione finora

- Cambridge Scientists Consider Fake News 'Vaccine': BBC NavigationDocumento3 pagineCambridge Scientists Consider Fake News 'Vaccine': BBC NavigationArjun MulluNessuna valutazione finora

- Americans Go To The Polls On 8 November To Elect The 45th US PresidentDocumento8 pagineAmericans Go To The Polls On 8 November To Elect The 45th US PresidentArjun MulluNessuna valutazione finora

- Truss TableDocumento1 paginaTruss TableArjun MulluNessuna valutazione finora

- Preliminary Treatment Process of Waste WaDocumento9 paginePreliminary Treatment Process of Waste WaArjun MulluNessuna valutazione finora

- Fifa 'Rejects England & Scotland Request To Wear Poppies On Armbands'Documento3 pagineFifa 'Rejects England & Scotland Request To Wear Poppies On Armbands'Arjun MulluNessuna valutazione finora

- Cinema Voucher PDFDocumento1 paginaCinema Voucher PDFArjun MulluNessuna valutazione finora

- Exercise LOSDocumento1 paginaExercise LOSArjun MulluNessuna valutazione finora

- FitnessCenterProposal 1-12Documento21 pagineFitnessCenterProposal 1-12Arjun MulluNessuna valutazione finora

- Rein F Detail Footing ColDocumento25 pagineRein F Detail Footing Colsom_bs79Nessuna valutazione finora

- TGV Cinemas 2 TGV Tickets +1 Large Popcorn + 2 Small Soft DrinksDocumento1 paginaTGV Cinemas 2 TGV Tickets +1 Large Popcorn + 2 Small Soft DrinksArjun MulluNessuna valutazione finora

- Ice Factory - Perspective ViewDocumento1 paginaIce Factory - Perspective ViewArjun MulluNessuna valutazione finora

- BNBC Part 6 - Chapter 3 - 170612geotecniaDocumento75 pagineBNBC Part 6 - Chapter 3 - 170612geotecniaPaslapola Pas Lapola100% (5)

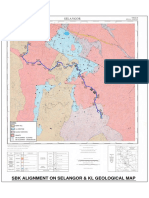

- Geological Map Selangor PDFDocumento1 paginaGeological Map Selangor PDFArjun Mullu100% (1)

- Bar Bending Schedule Format (BBS)Documento4 pagineBar Bending Schedule Format (BBS)Joshua YaoNessuna valutazione finora

- Tripura University (A Central University) : Material Science & Engineering M. Tech 2 Semester Session-2020-2021Documento16 pagineTripura University (A Central University) : Material Science & Engineering M. Tech 2 Semester Session-2020-2021Abhijit RoyNessuna valutazione finora

- Design BasisDocumento55 pagineDesign BasisAnonymous fLgaidVBhz100% (1)

- Flexible Cables BrochureDocumento16 pagineFlexible Cables Brochuresunil_v50% (1)

- High Performance Concrete With Partial Replacement of Cement by ALCCOFINE & Fly AshDocumento6 pagineHigh Performance Concrete With Partial Replacement of Cement by ALCCOFINE & Fly AshvitusstructuresNessuna valutazione finora

- NUST Journal of Engineering Science (NJES) PDFDocumento97 pagineNUST Journal of Engineering Science (NJES) PDFjasim aliNessuna valutazione finora

- Surface Energy TestingDocumento4 pagineSurface Energy TestingvalentinarichitaNessuna valutazione finora

- Goodfellow SRMs AlloyDocumento306 pagineGoodfellow SRMs AlloytqthienNessuna valutazione finora

- Lot - 1 Weekly Progress ReportDocumento14 pagineLot - 1 Weekly Progress ReportMesfin DerbewNessuna valutazione finora

- Metal & Fabric Expansion JointsDocumento8 pagineMetal & Fabric Expansion JointsliNessuna valutazione finora

- Environmental Laws and RegulationsDocumento50 pagineEnvironmental Laws and RegulationsPaul Santos NonatNessuna valutazione finora

- Types and Design of The Towers TraysDocumento12 pagineTypes and Design of The Towers TraysoluninjaaNessuna valutazione finora

- Panasonic 206 ManualDocumento40 paginePanasonic 206 ManualNikos Georgopoulos100% (1)

- F1079Documento2 pagineF1079Gustavo Suarez100% (1)

- Ingles Proyecto 3 Semana3Documento2 pagineIngles Proyecto 3 Semana3DavidLYT LáinezNessuna valutazione finora

- Masonry: Construction Method and Project ManagementDocumento43 pagineMasonry: Construction Method and Project ManagementJQNessuna valutazione finora

- IILFDocumento10 pagineIILFAMARNATH KNessuna valutazione finora

- SMP For Supply Water PumpDocumento13 pagineSMP For Supply Water PumpSonratNessuna valutazione finora

- CASE 7 71427 PreviewDocumento51 pagineCASE 7 71427 PreviewOneplayerNessuna valutazione finora

- Recycling Market Study ReportDocumento132 pagineRecycling Market Study ReportMelih AltıntaşNessuna valutazione finora

- L-05 Critical Activities Anp-2Documento11 pagineL-05 Critical Activities Anp-2SamNessuna valutazione finora

- Upuuteg Aug2012Documento80 pagineUpuuteg Aug2012josipNessuna valutazione finora

- Strainoptic Stress ManualDocumento9 pagineStrainoptic Stress Manualjsrplc7952Nessuna valutazione finora

- University of Nottingham Department of Architecture and Built EnvironmentDocumento43 pagineUniversity of Nottingham Department of Architecture and Built EnvironmentDaniahNessuna valutazione finora

- Helix Installation Manual Rev 002Documento112 pagineHelix Installation Manual Rev 002Edgar Mendoza100% (2)

- Elective Course (2) - Composite Materials MET 443Documento16 pagineElective Course (2) - Composite Materials MET 443يوسف عادل حسانينNessuna valutazione finora

- Productattachments Files R o Rotronic Catalogue en 2020-v2 PDFDocumento161 pagineProductattachments Files R o Rotronic Catalogue en 2020-v2 PDFMiguel Angel Pacahuala CristobalNessuna valutazione finora

- Ibrahiiiiim Rep. Conradson Carbon ResidueDocumento7 pagineIbrahiiiiim Rep. Conradson Carbon ResidueIbrahim Dewali100% (2)

- Science 5 Q1 WK7Documento12 pagineScience 5 Q1 WK7ivy loraine enriquezNessuna valutazione finora

- 01 Integrity Management of CRA Pipelines - 20 December 2015 PDFDocumento24 pagine01 Integrity Management of CRA Pipelines - 20 December 2015 PDFIndunil Prasanna Bandara WarnasooriyaNessuna valutazione finora

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Documento2 pagineWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200kashyap_structuralNessuna valutazione finora