Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Preventive Maintenance Cost Effective Technique To Preserve Indian Highways

Caricato da

Devela Avinash0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

62 visualizzazioni31 paginel

Titolo originale

Preventive Maintenance Cost Effective Technique to Preserve Indian Highways

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentol

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

62 visualizzazioni31 paginePreventive Maintenance Cost Effective Technique To Preserve Indian Highways

Caricato da

Devela Avinashl

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 31

PREVENTIVE MAINTENANCE : COST-EFFECTIVE

TECHNIQUE TO PRESERVE INDIAN HIGHWAYS

Maj. Shailendra Singh

Former M.Tech Student

Transportation Engineering Division

Department of Civil Engineering

Indian Institute of Technology Madras

Chennai

Prof. A. Veeraragavan

Professor of Civil Engineering

Indian Institute of Technology Madras

Chennai.

ABSTRACT

For the development of economy of any nation, road networks in good condition play an

important role. It has been felt that new highway construction is as important as preserving the

existing highway system in a good condition. By adopting preventive maintenance strategies into

the maintenance programs, the quality of the road network can be enhanced with reduced

expenditures and improved road user satisfaction. . There is a need to quantify the benefits due

to various preventive maintenance strategies to decide the choice and timing of application of

appropriate preventive maintenance treatment duly considering the traffic level and the

condition of the pavement.

In the present study, the benefits due to different preventive maintenance strategies have

been quantified over the service life of the pavement and the best timing for the application of

appropriate treatment has been presented. The pavement performance data collected for an

existing state highway and a national highway sections are considered in the present study.

Based on the projected traffic and the present structural condition of the pavement, appropriate

first stage strengthening by overlays has been suggested. The performance of the overlaid

pavement in terms of deflection, roughness, cracking and ravelling are predicted for do-nothing

strategy and after the application of different preventive maintenance strategies.

The cost effectiveness is computed during the service life of the pavement considering

various performance indicators. The best timing for the application of the preventive

maintenance strategy and the effect of varying the threshold values of the performance indicator

are also analyzed for the different preventive maintenance strategies. The strategy giving

maximum road user cost benefit and cost effectiveness are considered as the most cost- effective

preventive maintenance strategy. The suggested approach may be adopted for the

upgraded/newly constructed National and State Highway sections in the country. The application

of appropriate preventive maintenance treatment is likely to significantly reduce the future

maintenance cost of these highways and thereby preserving the road assets in the country.

1.0 INTRODUCTION

1.1 Asset Management

An efficient road transport system is seen by most countries as an essential precondition for

economic development, and considerable resources are devoted to road construction and

improvements. The resultant road network usually has an asset value that represents a significant

proportion of the national wealth, and the road sub sector should make an important contribution

to gross national product (GNP). It is therefore, important and appropriate that this asset is

managed in a business like manner.

As we proceed into the 21

st

century, highway agencies are undergoing a significant transition

from the original focus on new highway construction to the preservation of the existing highway

system. These agencies are facing a tremendous challenge in preserving and improving their

highway infrastructure because of aging highway networks, budget constraints, and the

continuous increase of traffic demand. As a result, highway agencies have started to adopt

Preventive Maintenance (PM) strategies into their maintenance programs. The demand to do

more with less has become an operating slogan for many highway agencies.

1.2 The Challenge of Maintenance

Maintaining Indias present highway network to full maintenance standards will require annual

funding of about Rs.70 billion, three times the current level of expenditure. The economic road

user costs are 23 percent higher on roads in poor condition than on good roads and 55 percent

higher, if the roads are in very poor condition. Goods are the building blocks of economy of a

country. Better road systems will bring significant economic and social benefits and increased

employment opportunities. The quantifiable benefits accruing from the improvements and better

maintenance of road consists of savings in vehicle operating costs and travel time, which will

reduce overall transport costs. Though, the direct beneficiaries are road users and transport

operators, the benefits of transport cost savings will be passed on to end-users. For every rupee

spent on maintaining the road network, there are net benefits (NPV) in excess of Rs.7/-.

Indian road network at nearly 3.2 million km falls under one of the worlds largest road

networks. Out of this length, less than 1% of the roads are being developed under various

schemes and projects by central and state governments. Considerable amount of manpower,

technology and expertise are being used for these roads at various levels from inception to

completion. The remaining 99% of the roads are being maintained by mere routine and periodic

maintenance by the respective road agencies. According to World Bank the loss in vehicle

operation costs on account of poor road maintenance in India is estimated to be about Rs. 20,000

crores per annum.

1.3 Importance of Timely Maintenance

1

Often pavement maintenance decisions are based on skimpy rules and rules of thumb. The road

maintenance is generally based on routine maintenance and periodic maintenance, which are

generally carried out on a fixed time frame. The functional condition parameters of the roads

(viz. roughness, cracking and ravelling) are generally not considered while deciding timing and

choice of the maintenance treatment. The timing of maintenance intervention and standards of

the maintenance governs the service life of a pavement. The rate of pavement deterioration

depends on the timing, type and quality of the maintenance treatment. If the maintenance is not

carried out with due consideration to the structural and functional condition parameters of the

pavement section (viz. roughness, cracking and ravelling), it may not be possible for the

pavement to serve its intended function at the desired level of performance during its service life.

1.4 Penalties Due To Deferred Maintenance

If the maintenance of the pavement is deferred by 2-3 years, the condition of the pavement will

further deteriorate causing discomfort to users and loss in terms of monetary value. There will be

substantial increase in agency cost due to pavement deterioration during the deferred period due

to the requirement of additional overlay for strengthening to have the desired level of

serviceability. It is seen that construction of thicker overlays more than what is required based on

the structural requirements will result in lower economic benefits.

1.5 Benefits Of Timely Maintenance

If the pavements are maintained in time, significant benefits viz. savings in vehicle operating

costs, comfort, savings in travel time can be achieved. Preventive maintenance is a systematic

process of applying a series of preventive maintenance treatments over the life of the pavement

to maintain a good condition, extend pavement life and minimize life cycle costs without

substantially increasing the structural aspects. It is believed to result in lowering the agency cost,

improved pavement condition and increased road user satisfaction. Preventive maintenance is

applying the right treatment to the right pavement at the right time. The experience with

pavement preventive maintenance demonstrates that each rupee spent now is estimated to save

up to six rupees in future. But the barriers or potential pitfalls to the development of a pavement

preventive maintenance technique are public/user perception, management perception, research

needs, training, dedicated funding and data management which can be overcome by explaining

the added advantage of the treatment as a whole.

1.6 Need for Pavement Preservation

Pavement preservation is aimed at preserving the investment in our highway system, extending

pavement life and meeting the road users needs. It is the timely application of carefully selected

surface treatments to maintain or extend a pavements effective service life. Pavement

preservation does not include any activity that significantly increases the structural capacity of

the existing pavement.

An effective pavement preservation program encompasses a full range of preventive maintenance

techniques and strategies, such as crack sealing, fog seals, slurry seals, surface dressing, thin

overlays etc. A traditional rehabilitative approach allows the original pavement section to

deteriorate to a fair to poor condition in terms of both ride quality and structural conditions. At

this stage, structural damage occurrs, and the objective of the rehabilitation treatment is to repair

that damage and restore the pavement. Thus the traditional approach is reactive and can be costly

and time consuming process, when compared to preventive maintenance which is a pro-active

and cheaper approach.

2.0 OBJECTIVES AND SCOPE OF THE PRESENT STUDY

2.1 Objectives of the Present Study

The main objectives of the present study are to-

i. Quantify the benefits due to application of various preventive maintenance

treatments

2

ii. Evaluate the short term and long term effectiveness of the preventive maintenance

treatments

iii. Quantify the effect of variation in threshold values on the benefits due to different

preventive maintenance treatments

2.2 Scope of the Present Study

The present study is aimed to quantify the benefits of timely preventive maintenance. The data

on road geometrics, traffic, pavement condition viz.,, roughness, deflection, cracking, raveling

etc are collected for a typical state highway section in Karnataka and a National highway section

in Kerala. The structural and functional condition needs of the sections are evaluated. The short

term and long term cost effectiveness are calculated for various preventive maintenance

strategies. The best timing for the application of preventive maintenance treatment and the

effects of benefit cutoff values for various preventive maintenance strategies are computed.

3.0 LITERATURE REVIEW

3.1 Pavement Performance Models

The flexible pavement deteriorates gradually over a period of time, as a function of material

properties, structural design details, traffic loading and environmental factors. The pavement

evaluation has two distinctly different components. The first one relates to evaluation of

pavement performance from the point of view of road users requirement, such as riding quality

in terms of pavement surface undulations and road safety in terms of skid resistance of the

pavement surface. The second one relates to evaluation of the pavement structure in terms of

deflection or stresses or strains in pavement layers due to load related factors and the structural

deterioration that has occurred to a pavement layer system.

Arunachalam (1971) carried out an analysis of data from extensive field investigations for

evaluating the strengthening requirements of flexible pavements both by California Bearing

Ratio and Benkelman Beam deflection methods. The analysis shows that the deflection method

gives realistic results in consonance with pavement performance and is more reliable than CBR

method. A design relationship for working out the overlay thickness of the flexible pavement is

evolved.

Ralph Haas (1994) has emphasized that pavement evaluation is generally directed towards

selection of projects and treatment strategies at the network level and identification of specific

maintenance requirements at the project level. This requires the use of a Pavement Condition

Index (PCI) considering two or more distress parameters and assigning suitable weighing factor

for each pavement distress parameter based on its severity and magnitude.

Sharma et al (1996) developed deterioration models for Indian conditions. The various factors

considered in the prediction models are pavement type, traffic, climate, condition of the road, age

and type of maintenance treatment. Periodic pavement performance observations were made for

a period of 3-5 years. Models are developed to predict initiation of distress, progression of

distress and roughness progression. The models are developed to predict the deterioration of

pavement sections resurfaced with Premix Carpet (PMC), Semi Dense Bituminous Concrete

(SDBC) and Bituminous Concrete (BC). The various parameters considered are cracking,

ravelling, pothole and roughness.

3.2 Effectiveness and Timing of Preventive Maintenance

3

Theeffectiveness of a particular preventive maintenance application can be assessed in terms of

both benefit it provides and cost required to obtain that benefit. Here, benefit is defined as the

quantitative influence on pavement performance as measured by one or more condition

indicators. The benefits due to preventive maintenance can be compared in terms of the benefits

per unit cost of applying the treatment over the life of pavement as compared to do-nothing

scenario. Costs that may be included in the analysis include the treatment costs, road user costs

and additional routine maintenance costs.

The effectiveness of a preventive maintenance treatment is directly related to the condition of the

pavement .Delays in preventive maintenance increases the quantity and severity of pavement

defects and results in higher maintenance costs during pavement life. Routine and reactive

approach is expected to considerably increase the life cycle costs of the pavement. Accepting a

preventive maintenance philosophy is the most important factor in an agencys maintenance

management programme.

Baker (2005) attempted to explain various maintenance processes and their choice and timing

for the maintenance intervention under diminishing funds and increased traffic load repetitions.

The author has suggested the various type of preventive maintenance treatments viz., fog seal,

slurry seal, and microsurfacing etc., that may be used for different problems viz.,crack, rut,

corrugation, depression etc.. Four different strategies for pavement evaluation were selected

based on the value of the lowest possible Present Serviceability Index (PSI) level. It was

demonstrated that the economic discount rate assumed for analysis make a substantial impact on

the final outcome of results.

Samuel Labi et al (2003) developed an approach for cost-effectiveness evaluation of various

levels of preventive maintenance activities over pavement life-cycle. Pavements were grouped by

surface type, traffic, and functional class. For each pavement family, alternative preventive

maintenance strategies were formulated, and the cost and benefit (effectiveness) associated with

each strategy was determined. The cost of each strategy was measured in terms of agency and

user costs associated with the various constituent treatments .The costs and benefits of each

strategy were estimated and non linear statistical cost-effectiveness models were developed to

reflect the relationship between preventive maintenance effort and cost effectiveness of such

efforts over pavement life cycle. The modeling results show that increasing preventive

maintenance is generally associated with increasing cost-effectiveness but only up to certain time

period during the design life.

4

Transportation engineers are accustomed to selecting worst first highway sections as

candidates for rehabilitation and reconstruction. However, using this criterion for preventive

maintenance can lead to disastrous results. Although it is understood that periodic inexpensive

treatments are more economical than infrequent high cost treatments, engineers must recognize

the causes of pavement deterioration and timing of application of appropriate treatments at

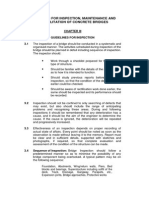

appropriate times during the pavement life. This is best illustrated by Figure 1 and Figure 2. Both

figures display a diagonal line on the graph, representing normal pavement distress accumulating

over time. A distress value between zero and 50 points indicates a pavement in satisfactory

condition. Distress value more than 50 points, measures a pavement in unsatisfactory condition.

Figure 1 shows the result when preventive maintenance is applied to a pavement in

unsatisfactory condition. Figure 2 shows the results when a preventive maintenance treatment is

applied early, to a pavement in a satisfactory condition. The shaded area represents the

improvement to the pavement condition over the treatment life. If the shaded areas from both

graphs are compared it can be observed that the treatments applied to severely distressed

pavements received little benefit. However, treatments applied to pavements with light to

moderate distress provide substantial benefits by extending the pavement life. The long term

effectiveness can increase in service life of the pavement due to application of preventive

maintenance. The effectiveness in short term can be described as performance jump and

reduction in deterioration level.

C u r r e n t C o n d i t i o n

D

i

s

t

r

e

s

s

P

o

i

n

t

F i x L i f e

T i m e

R

e

p

a

i

r

D

o

N

o

t

h

i

n

g

0

0

5 0

Figure 1: Application of Preventive Maintenance to a Pavement in an Unsatisfactory

Condition (Larry Galehouse, 1999)

L i f e E x t e n d e d

D e s i g n L i f e

P

r

e

v

e

n

t

i

v

e

M

a

i

n

t

e

n

a

n

c

e

D

o

N

o

t

h

i

n

g

C u r r e n t

C o n d i t i o n

D

i

s

t

r

e

s

s

P

o

i

n

t

5 0

0

0

T i m e

Figure 2: Application of Preventive Maintenance to a Pavement in a Satisfactory Condition

(Larry Galehouse, 1999)

Maintenance effectiveness or deterioration reduction, may be viewed as the increase in

positive service attributes of an infrastructure system in response to the treatment .Such

effectiveness may be in the form of an improved surface conditions [such as Present

Serviceability Index (PSI) and pavement quality index] or decreased surface roughness

[roughness number (RN), International Roughness Index (IRI), etc.] .There are three measures of

deterioration reduction i.e. deterioration reduction level (DRL), performance jump (PJ ) and

deterioration rate reduction (DRR).

5

i. Deterioration Reduction Level (DRL) It is defined as the improvement in

infrastructure condition due to maintenance application, calculated on the basis of

deterioration measurements taken between two consecutive, spaced out points in time

period, which is typically one year. It can be expressed as absolute change or a simple

difference between two measurements in time relative to the first of the two

measurements (such as change in PSI).

ii. Performance Jump (PJ) - Performance jump may simply be considered as the vertical

or instantaneous elevation in the performance or condition of a pavement due to

maintenance. This is computed using values of deterioration taken just before and just

after maintenance.

iii. Deterioration Rate Reduction (DRR) The DRR concept involves the slowing

down of pavement deterioration with respect to time or cumulative loading , due to the

application of maintenance. DRR is calculated as the difference in the slope of the

deterioration curve before maintenance and after maintenance.

Mamlouk et al (1998) stressed that the level of funding by various highway agencies is

inadequate to keep road networks in a good condition. Through preventive maintenance program,

pavements can be maintained in a cost effective manner. Pavement preventive maintenance has

been found to be successful for low as well as high volume of roads. He emphasized that the

selection of preventive maintenance treatment should be based on the condition of the existing

pavement, traffic volume and environmental conditions.

Larry Galehouse (1999) proposed that accepting preventive maintenance philosophy in an

agencys pavement maintenance program affords to the manager the capability to achieve

maximum benefits from available funds. A strategy that incorporates preventive maintenance can

significantly alter the distribution of the pavements remaining life. By targeting large

concentration of pavements with similar remaining lives, preventive maintenance treatment can

be used to equalize project work loads before problem develops and will ensure manageable

work loads for available revenues.

Wael et al (2005) analyzed the effects of implementing preventive preservation programme in

Ministry of Transportation of Ontario (MTO). In this programme a practical Preventive

Maintenance (PM) model is developed through a set of dedicated decision trees. It determines the

feasible maintenance activities for each pavement section based on a number of factors including

existing pavement surface layer, condition, age and traffic. The impact of preventive

Maintenance activities has shown an increase in PCI value and slower rate of deterioration.

Samuel Labi et al (2005) investigated the cost effectiveness of preventive maintenance for three

Asphaltic pavement functional class families. The field data for validation was used from in

service state highway pavements in Indiana. The strategy formulated in the present study consists

of various treatment types, timings and vary by the level of the preventive maintenance effort.

The effectiveness is defined as the increase in service life relative to a base case (the do nothing

strategy). The study suggests that preventive maintenance cost effectiveness generally increases

with increase in preventive maintenanceeffort up to a certain maximum, after which it declines

with increasing effort.

3.3 Cost Considerations

The inclusion of cost may be those cost that have an impact on the application of preventive

maintenance activities. The various costs that may be considered are preventive maintenance

treatment cost (agency cost), vehicle operating costs, work zone related user delay costs and

other routine maintenance costs.

6

Reddy et al (2003) made an effort to develop Road User Cost Models by conducting intense

research through experimentation as well as road user surveys. They updated the existing Road

User Cost models by including many more vehicle types. It is observed that significant increase

in levels of congestion on Indian roads is affecting the road user costs.

3.4 Discussions

For specific climate conditions and traffic levels, the performance of the restored pavement will

depend not only on the types of maintenance treatment, but also on the existing pavement

condition. The need for various type of deterioration models are felt for different surface, climate

and traffic levels. Deterioration models are needed to predict post-treatment scenario for different

types of preventive maintenance treatments.

For decision making, the road user cost model is effective as benefits can be evaluated in rupee

value that is easily understandable to the politicians and top management levels. For comparison

of strategies, cost-effectiveness can be used, as it is a simple ratio of effectiveness divided by

cost. This ratio has no physical or economic meaning but is valuable in carrying out priority

programming.

4.0 PREVENTIVE MAINTENANCE

4.1 General

AASHTO (Foundation for Pavement Preservation, 2001) defines preventive maintenance as:

the planned strategy of cost-effective treatments to an existing roadway system and its

appurtenances that preserves the system, retards future deterioration , and maintains or

improves the functional condition of the system(without substantially increasing structural

capacity) . Pavement preventive maintenance narrows the focus to the application of one or more

treatments, generally to a surface of a structurally sound roadway. AASHTOs Lead State Team

on pavement preservation summed things up quite nicely by defining pavement preventive

maintenance as,

Applying The Right Treatment To

The Right Pavement At The Right Time.

The cost of a typical preventive maintenance like surface dressing forroads in good condition is

66 percent lower than resurfacing or strengthening for roads in fair condition and only 25 percent

of the reconstruction cost. Traditionally, the highway agencies have allowed the ride quality and

structural condition of a pavement to deteriorate to fair to poor condition before taking steps to

rehabilitate the pavement. The aim of rehabilitation is to repair structural damage and restore

measurable pavement conditions such as ride, rutting and cracking. This is costly and time

consuming activity. The service lives of the pavements can be extended by applying a series of

low cost preventive treatments. This translates into a better investment, better ride quality,

increased customer satisfaction and support. The application of pavement preventive

maintenance demonstrates that each rupee spent now has been estimated to save up to six

rupees in the future.

7

Pavement preventive treatments are surface rehabilitation and operations applied to improve or

extend the functional life of a pavement. It is a strategy intended to arrest deterioration, retard

progressive failures, and reduce the frequent need for the routine maintenance and service

activities. It preserves the structural capacity of the pavement structure. Preventive maintenance

treatments are limited to pavements in sound structural condition. The pavement treatments can

be used for preventive, corrective or emergency maintenance. The difference between all these is

the condition of the pavement when the treatment is applied rather than the type of the treatment.

4.2 Benefits of Pavement Preventive Maintenance

The various benefits of pavement preventive maintenance are-

i. Higher road user satisfaction

ii. Better informed decisions

iii. Improved strategies and techniques

iv. Improved pavement condition

v. Cost savings

vi. Increased safety

4.3 Preventive Maintenance Treatment

Preventive maintenance treatments that are suitable for use by a given agency can be identified

by considering the following factors or treatment attributes-

i. Purpose of the treatment

ii. Applicability- Traffic, environment, pavement condition

iii. Construction considerations

iv. Expected performance and cost

v. Customer satisfaction

Several types of treatments can be adopted for preventive maintenance. It includes conventional

treatments such as crack treatment, fog seal, slurry seal, surface dressing, micro-surfacing, Stone

Matrix Asphalt (SMA) and thin hot mix overlay.

4.3.1 Crack Filling and Crack Sealing

These treatments are intended to prevent the intrusion of moisture through existing cracks.

Crack sealing refers to a sealant operation that addresses working cracks i.e. those that open and

close with changes with temperature. Crack filling is for cracks that undergo little movement.

Sealants used are typically thermoplastic bituminous materials. The conditions addressed are

longitudinal cracking, minor block cracking and transverse cracking. The expected life of

treatment is 2-6 years.

4.3.2 Fog Seals

Fog seals are placed primarily to seal the pavement, inhibit ravelling and enrich the

hardened/oxidized bitumen. Fog seals are very light applications of a diluted bituminous

emulsion placed directly on the pavement surface with no aggregates. The conditions addressed

are longitudinal cracking, minor block cracking, transverse cracking, ravelling, bitumen aging,

oxidation, hardening and moisture infiltration. The expected life of treatment is 1-2 years when

placed in a preventive maintenance mode.

4.3.3 Slurry Seals

8

Slurry seal is a mixture of well graded aggregates, sand, mineral filler and bituminous emulsion

that is spread over the entire pavement surface. It is effective in sealing low severity surface

cracks, waterproofing the pavement surface and improving the skid resistance. The conditions

addressed are longitudinal cracking, minor block cracking, transverse cracking, ravelling,

bitumen aging, oxidation, hardening, moisture infiltration and friction loss. The expected life of

treatment is 3-5 years when placed in a preventive maintenance mode.

4.3.4 Microsurfacing

Microsurfacing consists of a mixture of polymer modified emulsified bitumen, mineral

aggregate, mineral filler, water and additives applied in a process similar to slurry seals. The

conditions addressed are longitudinal cracking, transverse cracking, ravelling, weathering,

bleeding, roughness, friction loss and moisture infiltration. The expected life of the treatment is

4-7 years when placed in a preventive maintenance mode. Maximum thickness of the treatment

may be 40 mm.

4.3.5 Surface Dressing

Bitumen is applied directly to the pavement surface followed by the application of aggregate

chips, which are then immediately rolled to imbed chips. Application rates depend upon

aggregate gradation, traffic level and type of surface. The conditions addressed are longitudinal

cracking, transverse cracking, block cracking, ravelling, weathering, bleeding, roughness, friction

loss and moisture infiltration. The expected life of treatment is 4-7 years when placed in a

preventive maintenance mode. Maximum thickness of the treatment may be 25 mm.

4.3.6 Thin Hot-Mix Bituminous Overlays

Plant mixed combinations of bitumen and aggregates applied to the pavement in thickness

between about 25 and 40 mm are considered as thin overlays. Dense- graded, open graded and

stone matrix mixes are used. The conditions addressed are longitudinal cracking, transverse

cracking, block cracking, ravelling, weathering, bleeding, roughness and friction loss. The

expected life of treatment is 7-10 years when placed in a preventive maintenance mode.

Maximum thickness of the treatment may be 40 mm.

An effective pavement preventive maintenance program must include the periodic application of

the preventive maintenance treatments. A program can be a mixture of various preventive

maintenance treatments. For example fog seal may be used 3 and 6 years after construction and

from 7 to 9 years after the construction of the pavement surface dressing or slurry seal.

4.4 Treatment Selection and Timing

The selection of preventive maintenance treatments for evaluation in the project should be based

on the specific goals of the agencys preventive maintenance program. The selected treatment

should match the agencys preventive maintenance objective. For example, if the agencys

objective is to reduce the crack area, then treatment that reduce crack area should be used in the

maintenance program. The Table 1 summarizes some of the primary benefits provided by the

different preventive maintenance treatments. This will help in selecting treatments to support

specific preventive maintenance objectives.

Table 1: The Primary Benefits of Different Preventive Maintenance Treatment (Peshkin et

al, 2004)

9

Treatment Roughness Crack Ravelling Friction Moisture reduction Life extension

Crack seal

Fog seal

Slurry seal

Surface dressing

Thin overlay

Micro-surfacing

For computing the pavement preventive maintenance treatment timing, two critical issues are

important for consideration. First determining when the first treatment should be applied and

determining how often subsequent treatments should be applied. The timing of cycles is

influenced by traffic, climate and construction quality. The suggested treatment timing cycles are

given as in Table 2.

Table 2: Suggested Treatment Timing Cycles (Peshkin et al, 2004)

Treatment Recommended year of initial treatment Treatment timing cycle

Crack seal 1 to 3 Annually

Fog seal 0 to 3 Annually

Slurry seal 2 to 6 Annually

Surface dressing 2 to 5 Annually/2 years

Thin overlay 2 to 6 Annually

Microsurfacing 3 to 7 2 years

4.5 Quantification of Benefits

The quantification of benefits of preventive maintenance treatments can be carried out by two

methods-

i. Cost- effectiveness method

ii. Road user cost method

4.5.1 Cost Effectiveness Method

Effectiveness of a maintenance strategy is the net area above the deterioration curve ( for

increasing condition indicator like roughness index) multiplied by length of the section and

volume of the traffic duly considering the axle load spectrum and the transverse distribution of

traffic. The calculation of the cost effectiveness would be a simple ratio of effectiveness divided

by the cost of the treatment. This ratio has no physical or economic meaning but is valuable in

the relative comparison of various alternatives. The important benefit related areas are those

below condition indicator curves that decreases over time like skid resistance and above the

condition indicator curves that increases over time like the roghness. The benefit areas associated

with do-nothing strategy for increasing condition indicator is shown in Figure 3. The benefit

areas associated with preventive maintenance strategy for increasing condition indicator is shown

in Figure 4. The computation of benefit areas is done by subtraction of do-nothing condition

curve areas from areas associated with the post treatment case.

Effectiveness =(area under the deterioration curve) volume of the traffic over the service life

in msa (million standard axles) length of the section (in kilometre)

Cost - effectiveness =effectiveness/discounted agency cost

10

U B C - U p p e r b e n e f i t c u t o f f v a l u e

L B C - L o w e r b e n e f i t c u t o f f v a l u e

X ( 0 ) X ( 1 ) X ( 2 )

A g e ( Y e a rs )

C

o

n

d

i

t

i

o

n

I

n

d

i

c

a

t

o

r

D o n o t h i n g

P e rf o rm a n ce

c u r v e

A R E A ( D o n o t h i n g )

Fig 3: Determination of benefit areas associated with increasing individual condition

indicator for do-nothing strategy (Peshkin et al, 2004)

A g e ( Y e a r s )

X ( 2 ) X ( 1 ) X ( 0 )

I

n

c

r

e

a

s

i

n

g

C

o

n

d

i

t

i

o

n

I

n

d

i

c

a

t

o

r

X ( 3 ) X ( 4 )

A R E A ( P o s t T r e a t m e n t )

U B C - U p p e r b e n e f i t c u t o f f v a l u e

L B C - L o w e r b e n e f i t c u t o f f v a l u e

T r e a t m e n t

P e r f o r m a n c e

c u r v e

D o n o t h i n g

P e r f o r m a n c e

c u r v e

Fig

4: Determination of benefit areas associated with increasing individual condition indicator

with preventive maintenance strategy (Peshkin et al, 2004)

4.5.2 Road User Cost Method

Only preventive maintenance cost (agency cost) and road user cost are considered in the study

for calculation of benefits. The vehicle operating cost equations developed by Reddy et al (2003)

for different classes of vehicles are used in the computation of vehicle operation cost per km. The

cost associated with each treatment at different time periods during the design life is converted to

present worth at discount rate of 6%. The costs of various bituminous treatments are based on

prevailing standard schedule of rates. The difference in vehicle operating costs for do-nothing

strategy and post treatment strategy is considered as the benefit. The treatment with the

maximum benefit per unit agency cost is considered as the best preventive maintenance strategy.

5.0 Deterioration Models

5.1 Deflection Criteria

11

The performance in case of deflection for the set of alternatives in each section is evaluated by

using deflection progression models (Reddy, 1996). The deflection progression models are

function of initial deflection (iDEF), age and cumulated standard axles (N).The set of deflection

progression models are shown in Table 3.

Table 3: Deflection Progression Models (Reddy, 1996)

iDef Range(mm) Model Form n R

2

S.E

.44<iDEF<0.61 D

t

=iDEF+0.07884[(N

t

*Age)

iDEF

] 28 0.92 0.11

.66<iDEF<0. 80 D

t

=iDEF+0.0027exp[(iDEF*N

t

)

iDEF

]+.0859(Age) 47 069 0.29

.84<iDEF<1.05 D

t

=iDEF+0.04513(expN

t

)

0.45

+0.0924(exp Age)

log

iDEF

45 0.82 0.82

1.10<iDEF<1.25 D

t

=iDEF+0.03658[exp(iDEF*N

t

]

0.5

+0.19864(Age)

0

.26

29 0.82 0.02

Where, iDEF : Stabilised Initial deflection (mm) after the construction

D

t

: Corrected characteristic rebound deflection (mm) at any time t

N

t

: Cumulative standard axles (millions) at time, t

Age : Age of pavement at t (years)

5.2 Roughness Index Criteria (For MDR and State Highway)

The performance of the pavement section is predicted by using roughness progression models

(Reddy, 1996). The critical values are taken for various types of bituminous surfacing as per

IRC: SP: 16-2004. Roughness progression model is a function of Initial Roughness, age,

deflection and Cumulative standard axle load repetitions (CSA)

UI

t

=UI

0

[1+0.065187(N

t

)

1.22

+0.18426(DEF

0

)

0.61Age

]

[n=62, R

2

=0.62, S.E=0.233]

Where, UI

t

: Roughness Index (mm/km) at any time t

UI

0

: Initial Roughness Index (mm/km) at time t=0

N

t

: Cumulative standard axles (millions) at time, t

Age : Age of pavement at t (years)

DEF

0

: Deflection (mm) at the time t=0

5.3 Roughness Index Criteria (For National Highway)

The road section performance is predicted by using roughness progression models (Reddy,

1996). The critical values for roughness are considered from IRC: SP: 16:2004 for the different

types of surfacings. Roughness progression model is a function of initial roughness, age,

deflection and CSA.

UI

t

=iUI [1+0.3012(N

t

DEF

0

)

0.08 Age

(N=64, R

2

=0.7, S.E=0.2067)

5.4 Cracking Criteria

The crack in the bituminous surfacing occurs due to combined action of traffic loading and the

environment. The cracking initiation model by Sood et al, 1996 is as follows:

For AC Surfacing: AGECRIN=4.00EXP [-1.09

2

MSN

CSALYR

]

[n=20, R

2

=0.45, SE=0.43]

12

Cracking progression model is given by-

i

t

t

CR

=4.26[

MSN

CSALYR

]

0.65

*SCR

i

[n=124, R

2

=.25, SE=1.14]

Where, AGECRIN : Age of pavement at the time of cracking initiation (years)

CSALYR : Cumulative standard axles per year (millions)

MSN : Modified structural number

Where, MSN=3.28(DEF

0

)

-0.23

CR

t

: Percentage change in Crack area over time (t) in

years (%)

SCR

i

: Initial crack area (%)

t

i

: Time interval (years)

For the analysis purpose, the initial crack area is assumed as 2% of the whole area.

5.5 Ravelling Criteria

Ravelling occurs either due to loss of fines/stone particles from the surfacing and/or due to loss

of adhesion /bonding between binder and aggregates. The general form of ravelling initiation

model by Sood et al, 1996 is as follows:

AGERVIN=3.18 AXLEYR

-0.138

* (CQ+1)

-0.38

[n=26,R

2

=0.43, SE=0.38]

The model for ravelling progression is:

i

t

t

RV

=3.94 AXLEYR

0.32

*SRV

i

0.46

[n=82, R

2

=0.28, SE=1.02]

Where , AGERVIN : Age of the pavement at the time of ravelling initiation

AXLEYR : No. of vehicle axle per year (million)

CQ : Construction quality (For NH=0, For SH=1)

RV

t

: Ravelling at time t (%)

SRV

i

: Initial ravelling (%)

t

i

: Time interval (years)

For the analysis purpose the initial ravelling is assumed as 1% of the whole area.

5.6 Pavement Condition Index

Pavement Condition Index (PCI) is a numerical indicator of present pavement condition that is

directly related to the pavement surface operational condition. The PCI is a function of the type

of distress, severity of distress and the density of the distress.

The distress parameters for the present study were selected as roughness, cracking and ravelling.

The weighted factors assigned to the roughness, cracking and ravelling are 60%, 30%, and 10%

respectively. The Pavement Condition Index (PCI) for each section of road stretch is calculated

as-

PCI=100-CDV

13

Where, CDV=Corrected or Normalized Deduct Value (Not exceeding 100)

The PCI value ranges from 0 to 100 with a score of 100 representing a pavement in perfect

condition. The classes of PCI and appropriate maintenance intervention to be adopted are

presented in the Table 4.

Table 4: Ranges of PCI and suggested maintenance interventions

PCI Rating Type of maintenance

80-100 Very good Preventive / resurfacing

60-80 Good Thin overlay (<50 mm)

5.7 Cost considerations

Only agency cost and vehicle operation costs are included in the present study. The vehicle

operation costs differ between different classes of vehicles for the same roadway conditions. The

total vehicles operation costs is the total operating costs of all vehicles plying on the road. The

vehicles operation cost for the same class of vehicles depends upon the width of the road,

roughness and rise and fall of the road stretch. Reddy et al (2003) gave different equation for

different classes of vehicles for calculating the vehicle operation cost per km including the tax.

The vehicle classifications covered are new technology cars, old technology cars, two wheelers,

buses, light commercial vehicles (LCV), two axle heavy commercial vehicles (HCV) and multi

axle heavy commercial vehicles (MAV).The rise and fall value is considered as 7.5m/km.The

width of the road for MDR and SH is considered as 3.75 m and for NH is taken as 7.00 m. The

cost associated with each treatment is converted to present worth at discount rate of 6%.The

equations used in the present study are as shown in Table 5.

Table 5: Equations for Calculating Vehicle Operating Cost (Rs/km/vehicle) for Different

Classes of Vehicles (Reddy et al, 2003)

Vehicle type VOC equations

New technology cars Log

e

VOCNBC=1.381-0.115*W+0.00008300*RG+0.01302*RF

Old technology cars Log

e

VOCOBC=1.666-0.134*W+.00008789*RG+0.01145*RF

LCV Log

e

VOCLCV=2.143-0.039*W+0.00002668*RG+0.01323*RF

Buses Log

e

VOCBUS=2.135-0.070*W+0.00004553*RG+0.01208*RF

Two-Wheelers Log

e

VOCTW =0.452-0.13*W+0.000111*RG+0.01473*RF

HCV 2-axle Log

e

VOCHCV=2.472-0.065*W+0.00004121*RG+0.00992*RF

HCV Multiaxle Log

e

VOCMAV=2.926-0.050*W+0.00002969*RG+0.01443*RF

Where, W : Road width (m)

RG : Roughness (mm/km)

RF : Rise and fall (m/km)

14

6.0 Case Study of Preventive Maintenance Options for an Upgraded MDR and a State

Highway

Three road stretches, a Major District Road of 25.6 km, a State Highway of 70.3 km in Karnataka

and a National Highway of 46.7 km in Kerala are considered in the present study. The existing

MDR and SH is single lane with two way traffic and NH is two lanes with two way traffic.

6.1 Prediction of Cumulative Standard Axle Load Repetitions

In the entire stretch of MDR and SH, there were four traffic count stations. The traffic was

projected upto year 2020. The projected traffic is given in Table 6.

Table 6: Predicted Traffic Load Repetitions (per year)

Year Count station1

(in msa)

Count station 2

(in msa)

Count station 3

(in msa)

Count station 4

(in msa)

2003 0.52 0.38 0.36 0.25

2004 0.56 0.42 0.39 0.27

2005 0.62 0.45 0.43 0.30

2006 0.67 0.49 0.47 0.33

2007 0.73 0.54 0.51 0.36

2008 0.80 0.58 0.56 0.39

2009 0.87 0.64 0.60 0.42

2010 0.95 0.69 0.66 0.46

2011 1.04 0.75 0.71 0.50

2012 1.13 0.82 0.77 0.54

2013 1.23 0.89 0.84 0.59

2014 1.35 0.97 0.91 0.64

2015 1.47 1.05 0.99 0.69

2016 1.60 1.14 1.08 0.75

2017 1.75 1.25 1.17 0.82

2018 1.91 1.36 1.28 0.89

2019 2.09 1.48 1.39 0.97

2020 2.29 1.61 1.51 1.05

The road was opened for traffic in the year 2003. The traffic in commercial vehicles per day at

count station 1, 2, 3 and 4 were 531,457,405,275 respectively.

15

6.2 Upgradation Details

The data for the project road in terms of PCI values, characteristic Benkelman beam rebound

deflection values and roughness index for different homogenous sections are shown as in Table

7. The existing pavement was strengthened for the projected traffic for the design life of 20

years. Based on the procedure given in IRC: 81-1997 the overlay thickness values were

calculated for all the sections. The strengthening requirements for each section are summarized

in Table 7.

Table 7: List of Homogenous Sections and their Recommended Strengthening

Deflection (mm) Homogenous

Section

Count

Station

Max. Min.

PCI Recommended

Treatment

1 1.55 1.23 20-40 Thick Overlay

2 1.68 .94 20-40 Thick Overlay

3 1.2 .97 20-40 Thick Overlay

4 1.45 .99 20-40 Thick Overlay

5

CS-4

1.14 .91 20-40 Thick Overlay

6 1.57 1.01 40-60 Thin overlay

7

CS-3

1.41 1.02 40-60 Thin overlay

8 1.61 1.2 40-60 Thin overlay

9

CS-2

.99 .65 80-100 Resurfacing

10 .81 .36 80-100 Resurfacing

11 1.12 .56 40-60 Thin overlay

12

CS-1

1.19 .74 20-40 Thick Overlay

6.3 Calculation of initial deflection

16

By strengthening the existing pavement with the suitable overlay, the deflection will reduce to its

minimum value. The percentage reduction in the deflection is computed by using the deflection

reduction chart (Arunachalam, 1971) shown in Fig.5.

0 5 1 0 1 5 2 0 2 5 3 0

0

1 0

2 0

3 0

4 0

5 0

6 0

7 0

8 0

P

e

r

c

e

n

t

r

e

d

u

c

t

i

o

n

i

n

B

e

n

k

e

l

m

a

n

D

e

f

l

e

c

t

i

o

n

O v e r l a y th i c k n e s s i n te r m s o f g r a n u l a r m a te r i a l ( c m )

Fig. 5 Design Chart for Strengthening the Flexible Highway Pavements (Arunachalam,

1971)

6.4 Detailed calculations and results for a road section on State Highway

The proposed approach considers that pavement with inadequate structural capacity will be

strengthened initially and the effectiveness of the preventive maintenance treatment will be

quantified for the subsequent period only. For a typical road section on State Highway, the

suggested strengthening requirement was DBM (Dense bituminous macadam) of 115 mm and

BC (Bitumen Concrete) of 40 mm. The reduction in the deflection value due to suggested

overlay was 66%. The initial deflection after the overlay construction was estimated to be 0.29

mm The roughness, cracking and ravelling progression were computed for do-nothing strategy

are shown in Table 8.

Table 8: Progression Of Functional Parameters For Do-Nothing Strategy

Year Roughness(mm/km) Cracking (%) Ravelling (%) PCI

Initial

Values

1500 0 0 100

2003 1691 0 0 95

2004 1916 0 0 90

2005 2182 0 2 82

2006 2498 2 3 72

2007 2874 4 4 59

2008 3326 7 6 45

2009 3871 10 7 27

6.5 Benefit cut-off values

The benefit cut-off values are defined as the condition indicators (viz. roughness, cracking and

ravelling) which are the boundary conditions for the performance curves that define the upper

and lower limits for the calculation of the benefit area. The specific definitions of the upper and

lower benefit cutoff values are as follows-

17

i. Upper benefit cut-off values- The Upper benefit cut-off value is the upper limit to the

benefit area computations. (i.e., no area above the upper benefit cutoff level is included

in the benefit computation) as shown in Figure 6.

ii. Lower benefit cut-off values- The lower benefit cut-off value is the lower limit to the

benefit area computations. (i.e., no area below benefit cut-off level is included in the

benefit computation).

iii. The upper and lower benefit cutoff values for different condition indicators are shown in

Table 9.

Age (Years)

UBC- Upper benefit cutoff value

LBC- Lower benefit cutoff value C

o

n

d

i

t

i

o

n

I

n

d

i

c

a

t

o

r

Area limited by benefit cutoff values

Fig 6: Illustration of the upper and lower benefit cut-off values for increasing condition

indicator

Table 9: Upper and Lower benefit cut-off values for different condition indicators

Benefit cut-off values/

condition indicator

Roughness (mm/km) Cracking (%) Ravelling (%)

Upper Benefit cut-off

values

4000 30 10

Lower Benefit cut-off

values

1500 0 0

The trigger point for roughness condition indicator for different preventive maintenance

treatments are shown in Table 10. When the following trigger point is reached, the preventive

maintenance treatment is applied.

Table 10: Trigger point for different condition indicators

Condition indicator/

Preventive maintenance

strategies

Roughness(mm/km)

(Before treatment)

Roughness(mm/km)

(After treatment)

Microsurfacing 2500 1500

Thin overlay 2800 1500

Surface-dressing 2700 2500

Slurry-seal 2500 2000

18

6.6 Quantification of Benefits Due to Preventive Maintenance

The service life for the do-nothing scenario for the strengthened pavement section was

found to be six years viz., upto 2009 considering threshold value of roughness as shown in Table

9. . The deterioration progression of the strengthened pavement in terms of different performance

condition indicators viz. roughness, cracking and ravelling was computed for four different

preventive maintenance strategies viz. microsurfacing, thin overlay, surface dressing and slurry

seal. The vehicle operation costs (VOC) for the do-nothing scenario and the vehicle operating

costs after the preventive maintenance strategy were compared. The strategy that gave maximum

benefit per unit agency cost was considered as the most cost effective strategy. Both agency cost

and VOC were discounted to the present value at the discount rate of 6%. The roughness,

cracking and ravelling progression was computed for microsurfacing strategy as shown in Table

11 and benefit per unit agency cost is shown as in Table 12.

Table 11 Progression of Functional parameters for Micro-surfacing strategy

Year Roughness(cm/km) Cracking (%) Ravelling (%) PCI Remarks

2003 1691 0 0 95

2004 1916 0 0 90

2005 2182 0 2 82

2006 2498 2 3 72

2007 1500 0 0 100

Micro-surfacing

provided

2008 1736 3 2 91

2009 2021 5 3 80

2010 2368 8 5 68

2011 2794 10 6 53

2012 3322 14 8 36

2013 3980 17 9 15

Table 12 Benefit per unit agency per km cost for microsurfacing strategy

Vehicle Operation Costs (VOC) for do-nothing strategy Rs. 363.97 lakhs

Vehicle Operation Costs (VOC) after the application of micro-

surfacing treatment

Rs. 330.69 lakhs

Benefit Rs. 33.28 lakhs

Discounted Agency cost Rs. 1.82 lakhs

Benefit per unit agency cost/ lane km ( for service life of pavement) Rs. 18.28 lakhs

6.7 Cost Effectiveness

6.7.1 Computation of Benefit Area

19

The cost-effectiveness was computed by considering the area under the curve. The benefit area

for roughness, cracking and ravelling for do-nothing strategy is shown below as in Fig. 7, Fig. 8,

and Fig. 9 respectively. The benefit areas for roughness, cracking and ravelling for micro-

surfacing strategy are shown in Fig. 10, Fig. 11 and Fig. 12 respectively.

2 0 0 2 2 0 0 3 2 0 0 4 2 0 0 5 2 0 0 6 2 0 0 7 2 0 0 8 2 0 0 9

1 5 0 0

2 0 0 0

2 5 0 0

3 0 0 0

3 5 0 0

4 0 0 0

4 5 0 0

5 0 0 0

L o w e r b e n e f i t c u t - o f f v a l u e

U p p e r b e n e f i t c u t - o f f v a l u e

+ v e b e n e f i t a r e a

R

o

u

g

h

n

e

s

s

(

m

m

/

k

m

)

A g e ( Y e a r s )

Fig 7 Roughness Growth Area for do-nothing strategy

2 0 0 2 2 0 0 3 2 0 0 4 2 0 0 5 2 0 0 6 2 0 0 7 2 0 0 8 2 0 0 9

- 2

0

2

4

6

8

1 0

1 2

1 4

1 6

1 8

2 0

2 2

2 4

2 6

2 8

3 0

3 2

L o w e r b e n e f i t c u t - o f f v a l u e

U p p e r b e n e f i t c u t - o f f v a l u e

+ v e b e n e f i t a r e a

C

r

a

c

k

i

n

g

(

%

)

A g e ( Y e a r s )

Fig 8 Crack growth area for do-nothing strategy

2 0 0 2 2 0 0 3 2 0 0 4 2 0 0 5 2 0 0 6 2 0 0 7 2 0 0 8 2 0 0 9

- 2

0

2

4

6

8

1 0

1 2

L o w e r b e n e f i t c u t - o f f v a l u e

U p p e r b e n e f i t c u t - o f f v a l u e

+ v e b e n e f i t a r e a

R

a

v

e

l

l

i

n

g

(

%

)

A g e ( Y e a r s )

Fig 9 Ravelling growth area for do-nothing strategy

20

2 0 0 2 2 0 0 4 2 0 0 6 2 0 0 8 2 0 1 0 2 0 1 2 2 0 1 4

1 0 0 0

1 5 0 0

2 0 0 0

2 5 0 0

3 0 0 0

3 5 0 0

4 0 0 0

4 5 0 0

L o w e r b e n e f i t c u t - o f f v a l u e

U p p e r b e n e f i t c u t - o f f v a l u e

+ v e b e n e f i t a r e a

R

o

u

g

h

n

e

s

s

(

m

m

/

k

m

)

A g e ( Y e a r s )

Fig 10 Roughness growth area after Micro-surfacing strategy

2 0 0 2 2 0 0 4 2 0 0 6 2 0 0 8 2 0 1 0 2 0 1 2 2 0 1 4

- 4

- 2

0

2

4

6

8

1 0

1 2

1 4

1 6

1 8

2 0

2 2

2 4

2 6

2 8

3 0

3 2

L o w e r b e n e f i t c u t - o f f v a l u e

U p p e r b e n e f i t c u t - o f f v a l u e

+ v e b e n e f i t a r e a

C

r

a

c

k

i

n

g

(

%

)

A g e ( Y e a r s )

Fi

g 11 Crack growth area after Micro-surfacing strategy

2 0 0 2 2 0 0 4 2 0 0 6 2 0 0 8 2 0 1 0 2 0 1 2 2 0 1 4

- 2

0

2

4

6

8

1 0

1 2

L o w e r b e n e f i t c u t - o f f v a l u e

U p p e r b e n e f i t c u t - o f f v a l u e

+ v e b e n e f i t a r e a

R

a

v

e

l

l

i

n

g

(

%

)

A g e ( Y e a r s )

Fig 12 Ravelling growth area after Micro-surfacing strategy

The benefit due to micro-surfacing was computed by subtracting do-nothing benefit area from

micro-surfacing benefit area. After the calculation of benefit areas due to micro-surfacing

strategy, the weighted factors were applied to arrive at weighted benefit area and further cost

effectiveness was computed as shown in Table 13.

21

6.5.2 Sample Calculation of Benefit Areas

The sample computation for benefit areas and cost-effectiveness is given below in detail.

Benefit area for roughness=Area under the curve for micro surfacing strategy- Area under the

curve for do- nothing =16141 8423 =7718

Weighted benefit area for roughness =Area under the curve for roughness weightage factor =

7718 0.6 =4631

Benefit area for crack area= Area under the curve for micro surfacing strategy - Area under the

curve for do- nothing =250.6 - 162.9 =87.7

Weighted benefit area for crack area =Area under the curve for crack weightage factor =87.7

0.3 = 26.3

Benefit area for ravelling= Area under the curve for micro surfacing strategy - Benefit area for

do- nothing =69.57 - 44.3 =25.27

Weighted benefit area for ravelling =Area under the curve for ravelling weightage factor =

25.27 0.1 =2.53.

Total benefit area after providing micro surfacing strategy=4631+26.3+2.53=4660

Table 13: Computation of benefit areas for micro-surfacing strategy

Strategy Do-nothing Micro-surfacing

Condition

Indicator

Area Weighted area Area Weighted

area

Total benefit

Roughness 8423 5054 16141 9684

Cracking 163 49 251 75

Ravelling 44 4.4 70 7

4660

Effectiveness =(area under the deterioration curve) volume of the traffic over the service life

in msa (million standard axles) length of the section (in km)

Effectiveness =4660 9.12 msa 1km=42500

Cost Effectiveness=Effectiveness/discounted cost of treatment (in lakhs)

Cost-Effectiveness=

82 . 1

1 12 . 9 4660

= 23351

6.5.3 Cost Effectiveness of Different Preventive Maintenance Strategies

The benefit per unit agency cost per km per year and cost effectiveness for surface dressing, thin

overlay, surface dressing and slurry seal for the project level road are shown in Table 14 and

Table 15 respectively.

22

Table 14 Benefit Per Unit Agency Cost Per Km For Different Preventive Maintenance

Treatment

Strategy Traffic

(msa)

Life Life

extension

Application

year

VOC

(Rs. in

lakhs)

Do-

nothing

VOC (Rs.

in lakhs)

With

treatment

Benefit/agen

cy cost per

km per year

(Rs. in

lakhs)

Do- nothing 2009 - - - - -

Micro-

surfacing

2013 4 years 2007 363.97 330.69 18.28

Thin overlay 2013 4 years 2007 363.97 330.69 12.15

Surface

dressing

2012 3 years 2007,2008,

2009

315.98 299.3 3.82

Slurry-seal

21.58

2013 4 years 2007, 2009 363.97 332.06 11.99

Table 15 Cost Effectiveness For Different Preventive Maintenance Treatment

Strategy Life Life

extension

Application year Benefit area Cost effectiveness

(CE)

Do- nothing 2009 - - 5156 -

Micro-surfacing 2013 4 years 2007 9767 23106

Thin overlay 2013 4 years 2007 9767 15347

Surface dressing 2012 3 years 2007,2008,

2009

7296 3862

Slurry-seal 2013 4 years 2007, 2009 9145 13676

6.5.4 Effect of Threshold Level on the Benefits

It is understood that applying preventive maintenance to a particular pavement too early or too

late does not yield better results. So to study the effect of the different benefit cut-off values for a

typical preventive maintenance strategy, viz., micro-surfacing for three different benefit cut-off

values for roughness (viz. 2000mm/km, 2500mm/km and 3000mm/km) are considered in the

analysis. The variation in roughness, cracking and ravelling for different benefit cut-off values of

2000mm/km, 2500mm/km and 3000mm/km of study section are shown in Table 16. It can be

observed from the analysis of data that benefit per unit agency cost is maximum when a

threshold level of 2500mm/km is considered. It is not beneficial to apply the maintenance

treatment earlier than this level.

6.5.3 Deterioration progression of different condition indicators (viz. roughness, cracking

and ravelling) for different preventive maintenance strategies

23

The deterioration progression of different condition indicators (viz. roughness, cracking and

ravelling) for different preventive maintenance strategies (viz. thin overlay, surface dressing and

slurry seal) and benefit associated with them is shown in Table 17.

Table16: Computation of benefit for different benefit cut-off values for micro-surfacing treatment

Benefit Cut Off Value 2000 mm/Km Benefit Cut Off Value 2500 mm/Km Benefit Cut Off Value 3000 mm/Km

Year Roughness

(mm/km)

Crack

(%)

Ravelling

(%)

PCI Remarks Roughness

(mm/km)

Crack

(%)

Ravelling

(%)

PCI Remarks Roughness

(mm/km)

Crack

(%)

Ravelling

(%)

PCI Remarks

2003 1691 0 0 95 1691 0 0 95 1691 0 0 95

2004 1916 0 0 90 1916 0 0 90 1916 0 0 90

2005 1500 0 0 100 Microsurfacing 2182 0 1 82 2182 0 2 82

2006 1717 2 2 92 2498 2 2 72 2498 2 3 72

2007 1975 4 3 82 1500 0 0 100 Micro

surfacing

2874 4 4 59

2008 1500 0 0 100 Microsurfacing 1736 2 1 91 1500 0 0 82 Microsurfacing

2009 1746 3 2 91 2021 5 3 80 2328 3 2 77

2010 2046 5 3 79 2368 7 4 68 2728 5 3 63

2011 2414 8 5 66 2794 10 6 53 3219 8 5 47

2012 2870 11 6 51 3322 13 7 36 3827 11 6 28

2013 3439 14 8 32 3980 16 9 15

2014 4161 18 10 13

Year of application 2005,2008 Year of application 2007 Year of application 2008

Extended service life 5 years Extended service life 4 years Extended service life 3 years

5

6

Benefit per agency cost Rs.14.17 lakhs Benefit per agency cost Benefit per agency cost Rs. 10.94 lakhs Rs.18.28 lakhs

24

Table17: Progression of functional parameters for different preventive maintenance strategies

Micro-surfacing Surface Dressing Slurry seal

Year Roughness Crack Ravelling PCI Remarks Roughness Crack Ravelling PCI Remarks Roughness Crack Ravelling PCI Remarks

(mm/km) (%) (%) (mm/km) (%) (%) (mm/km) (%) (%)

2003 1691 0 0 95 1691 0 0 95 1691 0 0 95

2004 1916 0 0 90 1916 0 0 90 1916 0 0 90

2005 2182 0 1.2 82 2182 0 1.2 82 2182 0 1.2 82

2006 2498 1.9 2.4 72 2498 2 2.4 72 2498 2 2.4 72

2007 1500 0 0 100 2500 0 0 76 2000 0 0 88 Micro-surfacing Surface dressing Slurry seal

2008 1736 2.15 1.2 91 2893/2500 2.2 / 0 1.3 / 0 76 /

63

2315 2.2 1.3 77 Surface dressing

2009 2021 4.53 2.6 80 2910 / 2500 2.3 / 0 1.4 / 0 76 /

62

2000 0 0 88 Surface dressing Slurry seal

2010 2368 7.17 4.1 68 2929 2.4 1.4 62 2343 2.4 1.4 76

2011 2794 10 5.6 53 3457 5.1 2.8 45 2766 5.1 2.8 62

2012 3322 13.2 7.1 36 4109 7.9 4.3 28 3288 7.9 4.3 45

2013 3980 16.6 8.8 15 3940 11.1 5.9 24

2014

Vehicle Operation Costs (VOC) for do-

nothing strategy

Rs.363.97 lakhs Rs.315.98 lakhs Rs.363.97 lakhs

Vehicle Operation Costs (VOC) for thin

overlay strategy

Rs.330.69 lakhs Rs.299.3 lakhs Rs.332.06 lakhs

Benefit Rs.33.28 lakhs Rs.16.68 lakhs Rs.31.91 lakhs

Agency cost Rs.2.74 lakhs Rs.4.37 lakhs Rs.2.66 lakhs

Benefit per unit agency cost ( for service life

of pavement)

Rs.12.15 lakhs Rs.3.82 lakhs Rs.11.91lakhs

Note: For comparison, the preventive treatments are considered upto the do-nothing design life viz., 2009

25

6.5.5 Summary

The results obtained from road user cost method are easily understandable as the benefits due

to preventive maintenance treatment are in rupee term and they can be effectively used in

prioritization of preventive maintenance treatment for the road projects. The results obtained

from cost-effectiveness method are not quantified in rupee terms. It can be used in selection

of most cost-effective treatment. The most cost effective treatment for different sections of

the project level road and their benefit per unit agency cost per km are shown as in Table 18.

By applying preventive maintenance treatments the benefit per unit agency cost per km for

the different sections of the project level road is 158.55 lakhs during the design life.

Table 18 Cost effective treatment for different sections of the project level road

Section

No.

Count Treatment Benefit per unit agency cost

stations (Rs. in lakhs)

1 Thin overlay 7.15

2 Thin overlay 6.74

3 Micro-surfacing 13.8

4 Thin overlay 5.97

CS-4

5 Micro-surfacing 13.8

6 Thin overlay 13.55 CS-3

7 Thin overlay 12.71

8 Thin overlay 17.22 CS-2

9 Micro-surfacing 17.41

10 Thin overlay 14.18

11 Micro-surfacing 18.28

CS-1

12 Micro-surfacing 17.34

6.5.6 Discussion

From the analysis of the sections of the project level road for quantification of benefits due to

the preventive maintenance treatment following points are observed-

i. For the sections having the same range of deflection values (0.50 mm to 0.55 mm),

the benefits per unit agency cost per km are Rs.6.36 lakhs and Rs. 13.13 lakhs for

traffic intensity of 275 cvpd and 405cvpd respectively.

ii. Micro-surfacing is the most cost-effective option for road sections with traffic

intensity in the range between 500 cvpd to 600 cvpd.

iii. The ranking of treatment obtained from road user cost method and cost-effectiveness

method (viz.by calculating area under the curve) are nearly same with few

exceptions.

iv. The benefits per unit agency cost for surface dressing is low because of its high

initial condition indicator values for functional parameter (viz. the roughness value

decreases to 2500mm/km when surface dressing is laid when the roughness is 2700

mm/km).

7.0 Effectiveness of Preventive Maintenance for National Highway Sections

7.1 Cost Effectiveness of Different Preventive Maintenance Strategies

The benefit per unit agency cost per km and cost effectiveness for microsurfacing, thin

overlay, surface dressing and slurry seal for a pavement in a National Highway having an

initial deflection of 0.4 mm and carrying low traffic are shown in Table 19 and Table 20

26

respectively. It can be seen that the cost effectiveness of the thin overlay strategy is

maximum when compared to micro surfacing, surface dressing and slurry seal.The thin

overlay is found to be the most cost effective treatment for road sections of National

Highways carrying heavy traffic.

Table 19:Benefit per unit agency cost per km for different preventive maintenance

treatment

Strategy Traffic Life Life Application

year

VOC

(Rs. in

lakhs)

Do-

nothing

VOC (Rs. in

lakhs) With

treatment

Benefit/agency

cost per km per

year

(msa) extension

(Rs. in lakhs)

Do-

nothing

2009 - - - - -

Micro-

surfacing

2012 3 years 2007 2130.10 2076.10 29.67

Thin

overlay

2014 5 years 2009 2637.4 2526.10 45.61

87.84

Surface

dressing

2012 3 years 2008 2130.10 2093.70 25.27

Slurry-

seal

2013 4 years 2007,2008, 2377.80 2298.20 20.10

2009

Table 20: Cost effectiveness for different preventive maintenance treatment

Strategy Life Life Application year Benefit area Cost

effectiveness extension

(CE)

Do- nothing 2009 - - 5361

Micro-surfacing 2012 3 years 2007 8711 1,11,935

Thin overlay 2014 5 years 2009 10085 1,50,943

Surface dressing 2012 3 years 2008 7718 99,529

Slurry-seal 2013 4 years 2007,2008, 9368 70,105

2009

7.2 Summary

The results obtained from road user cost method are easily understandable as the benefits due

to preventive maintenance treatment are in rupee term and they can be effectively considered

in prioritization of preventive maintenance treatments for the road projects. The cost-

effectiveness method can be used in the selection of appropriate cost-effective treatment.

The analysis was performed for pavements with different structural adequacies

expressed in terms of initial deflection values of 0.4 mm, 0.5 mm, 0.6 mm and for low,

medium and high traffic for the test sections. After the application of the preventive

27

maintenance treatments, the benefit per unit agency cost per km for a typical road section is

shown in Table 8.16

Table 8.16 Cost effective treatment for road section

S.No Traffic Initial Treatment Benefit per unit agency cost

growth Deflection

(mm)

(Rs. in lakhs)

1 0.4 Thin overlay 45.61

2 0.5 Thin overlay 42.52 Low

(7.7%) 3 0.6 Microsurfacing 33.2

4 0.4 Thin overlay 46.1

5 0.5 Thin overlay 43.4 Medium

(9.3%) 6 0.6 Thin overlay 30.14

7 0.4 Thin overlay 47.22

8 0.5 Thin overlay 44.57 High

(10%) 9 0.6 Thin overlay 35.14

7.3 Discussions

From the analysis of the National Highway section to quantify the benefits due to the various

preventive maintenance treatment following points are observed-

i. For pavement sections with higher initial deflection values (0.6 mm) the rate of

deterioration of the functional parameters (viz. roughness, cracking and ravelling) are

high when compared to low initial deflection values (0.4mm).

ii. The benefits per unit agency cost per km is more by 37% for pavement sections with

low initial deflection values (0.4 mm) for constant traffic growth rate as compared to

high initial deflection values ( 0.6 mm).

iii. For high trafficked road sections (5000cvpd-6000cvpd), thin overlay is the most cost

effective preventive maintenance treatment.

8.0 Conclusions

i. The life of the pavement can be significantly extended by the application of

appropriate preventive maintenance treatments.

ii. The best timing for the application of preventive maintenance treatment varies

with the type of treatment and the volume of traffic.

iii. The benefit cut off factor has major impact on the cost effectiveness of the

treatment. It can be seen from the analysis that maintaining the pavement too

early or too late is not beneficial. From the analysis the benefit cut-off value for

roughness of 2500 mm/km is found to have the maximum benefit.

iv. As the initial deflection value increases from 0.4 mm to 0.6 mm, the do- nothing

service life of the pavement decreases from 6 years to 5 years for national

highway sections under high traffic levels.

v. Thin overlay preventive maintaince strategy is the most cost effective for

highways carrying traffic from 5000 cvpd to 6000 cvpd.

28

vi. The benefits per unit agency cost for different preventive maintenance treatment

depends on the trigger point of the functional parameters and the cost of the

treatment.

vii. The ranking of treatment obtained from road user cost method and cost-

effectiveness method (viz.by calculating area under the curve) are nearly the

same.

8.1 Scope of future research

i. For Indian conditions there is need to have good data base for different types of

pavement construction and deterioration models for functional parameters for pre-

treatment and post treatment scenario for tracking appropriate measures of

performance for different treatments.

ii. The most cost effective methodology can be evaluated from performance of test

sections overlaid with different preventive maintenance treatments and the

methodology can be enhanced.

REFERENCES

ARUNACHALAM, K. (1961). Evaluating Strengthening Requirements of Flexible

Pavement by Deflection Method., Indian Road Congress, Vol. 1, pp111-129.

FPP. (2001). Pavement Preventive Maintenance Guidelines. Foundation for

Pavement Preservation, USA.

HAAS, R., HUDSON W.R., and ZANEWSKI.J . (1994). Modern Pavement

Management. Krieger Publishing Company, Malabar, Florida.

IRC: 37-2001, Guidelines for the design of flexible pavements, Indian Road

Congress, New Delhi.

IRC: 64-1990, Guidelines for capacity of roads in rural areas, Indian Road Congress,

New Delhi.

IRC: 73-1980, Geometric design standards for rural highways, Indian Road Congress,

New Delhi.

IRC: 81-1997, Guidelines for strengthening of flexible road pavements using

Benkelman Beam deflection technique, Indian Road Congress, New Delhi.

IRC: SP-16-2004, Guidelines for surface evenness of highway pavements, Indian

Road Congress, New Delhi.

IRC: SP-30-1984, Manual on economic evaluation of highway projects in India,

Indian Road Congress, New Delhi.

LARRY GALEHOUSE. (1999). A Pavement Preventive Maintenance Program.

APWA Satellite Video Conference Moving Roadway Maintenance into the 21

st

century.

MAMLOUK, M.S., and ZANIEWSKI, J .P. (1998). Pavement Preventive

Maintenance: Description, Effectiveness, and Treatments. Flexible Pavement

29

Rehabilitation and Maintenance, ASTM STP 1348, P.S. Kanghal and M.Stroup, Eds.,

American Society for Testing and Materials.

PESHKIN., HOERNER., ZIMMERMAN. (2004). Optimal Timing of Pavement

Preventive Maintenance Treatment Applications. NCHRP Report 523,

Transportation Research Board.

REDDY.B.B. (1996). Development of Failure Criteria for Flexible Pavements. PhD

Thesis, Bangalore University, Bangalore.

REDDY., VELMURUGAN., MADHU., and RAMALINGAIAH. (2003). Updation

of Road User Cost and Revised Software for Evaluation of Highway Projects. Indian

Road Congress, Volume 64-3, pp 207-267.

RONALD BAKER. (2005) Routine Maintenance Work Saves Pavements and