Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

E05 Weikmann Automated Visual Inspection

Caricato da

Florin Pătrulescu0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

149 visualizzazioni12 paginet hgrtcerctg

Titolo originale

E05 Weikmann Automated Visual Inspection (1)

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentot hgrtcerctg

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

149 visualizzazioni12 pagineE05 Weikmann Automated Visual Inspection

Caricato da

Florin Pătrulescut hgrtcerctg

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 12

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

1

Automated Visual Inspection of

Pre-filled Syringes

Wolfgang Weikmann

Director Pharmaceutical Production / Engineering Director Pharmaceutical Production / Engineering

Vetter Pharma-Fertigung GmbH & Co. KG

24-25 February 2010, Tampa

Content

1. Manual Visual Inspection (MVI)

Basic requirements

2 Automated Visual Inspection (AVI) Machine 2. Automated Visual Inspection (AVI) Machine

overview

3. Qualification Approach

1. PQ: Pre-tests / Considerations

2. PQ 1: Knapp test (Test kit)

3 PQ 2: Knapp test (3 batches)

2

3. PQ 2: Knapp test (3 batches)

4. Operational Approach

5. Conclusion

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

2

1. MVI Basic requirements

Enclosed dedicated room

Incandescent Lamp

(light intensity: 2000-3750 LUX)

Black & white background

Reject bin / Eject bin for measurements

Defect evaluation list (SOP)

Temperature monitoring of room

One product per room at a given time!

Inspection speed

Obvious separation and placement of

3

Obvious separation and placement of

uncontrolled units, rejects and good pieces!

Scheduled Eye Breaks

2. AVI - Machine Overview

Glass Barrel Remover

(De-Trayer)

Inspection Machine

Glass Barrel Inserter

(Re-Trayer)

4

Ejection of syringes

Good Pieces

Product for inspection

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

3

2. AVI Machine Overview

Unit 2 (TV 2a/3a & 2b/3b)

Glass Barrel

Under- and Overfilling

Empty syringe

Dirt/Abrasion

Damage/Deviation

Unit 3 (TV 4/5)

Closure Part

Missing closure part

Bent Needle Shield

Fit of closure part/Total

length

Unit 4 (TV 6/7)

Stopper

Foreign particles

Solution in rib

Dirt/abrasion

Damage/deviation

Unit 5 (TV 8/9)

& 7 (TV 12/13)

Solution

Foreign particles

Damage/Deviation

Scratches/Cracks zone 1

Airline over total length

Closure Part

Dirt/Abrasion

Damage/ deviation

Broken bridge

Pierced Needle Shield

length Damage/deviation

Stopper position

Upside-down (180)

Crooked stopper

Double stopper

Unit 6 (TV 10/11)

Solution

Glass splinters

Unit 11 (HV)

INFEED

OUTFEED

0

1

2

5

Unit 1 (TV 1)

Glass Barrel

Damaged finger rest

Broken

Stopper

Missing stopper

Unit 9 (CA) and 10 (OD)

Solution

Discoloration, Turbidity

Unit 8 (TV 14/15)

Glass Barrel

Scratches/Cracks zone 2

Unit 11 (HV)

Solution

Leaking system

3

4

2. AVI Machine overview

Eject 0

Glass Barrel

Damaged finger rest

B k

Eject 1

Solution

Discoloration, Turbidity

Eject 3

Solution

Glass splinter

Under and overfilling

Eject 2

Solution

Foreign particle

INFEED

OUTFEED

0

1

2

Broken

Stopper

Missing stopper

Under- and overfilling

Empty syringe

Leaked system

Stopper

Upside-down (180)

Glass Barrel

Dirt/Abrasion

Damage/Deviation

Scratches/Cracks area 1

Scratches/Cracks area 2

Airline over total length

Closure Part

Dirt/Abrasion

Damage/Deviation

Stopper

Foreign particle

Solution in rib

Dirt/ abrasion

Damage/ deviation

Stopper position

Crooked stopper

Double Stopper

6

3

4

Broken bridge

Pierced Needle Shield

Missing closure part

Bent Needle Shield

Fit of the closure part/Total

length

Other defects

Wrong primary packaging

component

Eject 4

After a machine failure or

power break down, all

remaining syringes in the

machine are ejected here.

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

4

3. Qualification / Validation Approach

Design Qualification (DQ)

Installation Qualification (IQ) Installation Qualification (IQ)

Operational Qualification (OQ)

Performance Qualification (PQ)

PQ 1: Knapp test with Test kit

PQ 2: Knapp test with 3 commercial lots

7

PQ 2: Knapp test with 3 commercial lots

in this presentation, focus on PQ

3.1 PQ: Pre-tests / Considerations

Definition of Spinning speed

Definition of Inspection area / windows Definition of Inspection area / windows

Air bubbles

Evaluation of different turbidity levels

Evaluation of different colors of the

product solution

8

p

Detection level of foreign matter

depending on different filling levels

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

5

3.1 PQ: Pre-tests / Considerations

Light intensity

Regular checks

Definition of the max. holding time

Measures to be taken in case of

decrease of light intensity special

maintenance / definition of acceptance

criteria

9

Handling of exchange of lighting

Burn-in time of LED spare parts to reach

acceptable stability

3.1 PQ: Pre-tests / Considerations

Heat-up of syringes during machine

stop Definition of max. break time

without removal of syringes

Definition of Defect categories

(Assignment of minor, Major and Critical

Creation of Batch Report)

Assignment of defects to Eject bins

10

Assignment of defects to Eject bins

Strategy for Manual Classification

(Re-inspection) of Ejects

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

6

3.1 PQ: Pre-tests / Considerations

Handling / Risk assessment in case of

glass breakage at different locations

within the machine

Implementation of effective Line Cleaning

and Line Clearance

11

3.2 PQ 1: Knapp test (Test kit)

Creation of a product specific Test

kit (Rejects + Good pieces)

500 pieces in total comprising approx. 160

Rejects

Rejects selected from routine batches as

far as possible

Optional: Usage of standardized particles

12

Optional: Usage of standardized particles

for better reproducibility in case of

replacement due to destruction

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

7

3.2 PQ 1: Knapp test (Test kit)

Performance of the Knapp test

MVI: 20 Visual Inspectors inspect each the

test kit (500 pieces) / routine inspection

conditions

AVI: Test kit (approx. 160 Rejects) are run

21 times in the production mode of the

AVI machine Aim: simulation of real

13

AVI machine Aim: simulation of real

production conditions as listed in the

following:

3.2 PQ 1: Knapp test (Test kit)

AVI Efficiency Test

1. Reject Rate (RR) Rejects

1. Aim: Test of each Inspection unit per defect

(10 runs per defect)

2. AC: for each of the single defect categories:

RR AVI RR MVI

2. False Reject Rate (FRR) Good pieces

1 Aim: Test of each Inspection unit with 500

14

1. Aim: Test of each Inspection unit with 500

good pieces

2. AC: tbd. for each inspection unit

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

8

3.2 PQ 1: Knapp test (Test kit)

AVI Laboratory Test Run

1. Reject Rate Rejects

1. Testing each single Inspection unit

1. Aim: Test of each Inspection unit with

all related defects (10 runs per defect)

2. AC: RR AVI RR MVI

2 Testing all Inspection units

15

2. Testing all Inspection units

1. Aim: Test of all Inspection units with all

defects (1 run with all defects)

2. AC: RR AVI RR MVI

3.2 PQ 1: Knapp test (Test kit)

3. False Reject Rate Good pieces

1. Aim: Test of all Inspection units with 2000

good pieces (1 run) good pieces (1 run)

2. AC: tbd. for the whole machine

AVI Performance Run (Good pieces; at

least Placebo)

Aim: Determination of the repeatability

16

Aim: Determination of the repeatability

of detection within 3 technical runs of the

same lot ( 10.000 syringes recommended)

AC: tbd. dependent on Process Capability

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

9

3.3 PQ 2: Knapp test (3 batches)

17

Evaluation

M2.1 + M3.1 = RR AVI

M3.1 + M4.1 = RR MVI

Comparison

RR MVI vs. RR AVI

3.3 PQ 2: Knapp test (3 batches)

Acceptance criteria:

Different approaches are possible, e.g.: pp p , g

#1: RR AVI RR MVI for all defect categories,

not dependent on criticality of the defect

#2: Split into minor, Major and Critical:

Number of defects with (RR AVI RR MVI) (RR

AVI < RR MVI) per Criticality Class

18

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

10

4. Operational Approach

19

4. Operational Approach

2. Manual Visual

Classification

AQL V l di t MVI (ISO 2859)

Eject 0

Rejects

3. AQL

(Good Pieces of Eject 0-4)

AQL-Values according to MVI (ISO 2859)

Lot size = Sum of syringes of Ejects 0-4

Sampling randomized of the Good Pieces

(FRR) from Ejects 0-4:

n = 125 (Lot size less than 3.200)

200 (L t i b t 3 201 d 10 000)

Eject 0

Eject 1

Eject 2

Good Pieces (FRR)

Rejects

Good Pieces (FRR)

Rejects

Good Pieces (FRR)

Rejects

Critical, Major, minor

20

n = 200 (Lot size between 3.201 and 10.000)

n = 315 (Lot size between 10.001 and 35.000)

Eject 3

Eject 4 Good Pieces (FRR)

j

Good Pieces (FRR)

Rejects

Good Pieces (FRR)

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

11

4. Operational Approach

Eject 0

Rejects

2. Manual Visual

Classification

4. Batch Evaluation

3. AQL

(Good Pieces of

Ejects 0-4)

j

Eject 1

Eject 2

Good Pieces (FRR)

Rejects

Good Pieces (FRR)

Rejects

Good Pieces (FRR)

Rejects

Evaluation according to AVI

Evaluation matrix

Critical: X limit Batch Release

X > limit Deviation/Measures

Major: X limit Batch Release

X > limit Deviation/Measures

minor: X limit Batch Release

X > limit Deviation/Measures

21

Eject 3

Eject 4

Rejects

Good Pieces (FRR)

Rejects

Good Pieces (FRR)

Rejects (total)

5. Conclusion

Main topics to be considered upfront:

Product characteristics

Evaluation strategy / Assignment of

defects to Eject bins

Creation of the Test kit

Acceptable False Reject Rate

Re-Classification of Ejects

22

Performance of lighting

Preventive maintenance

Re-Qualification concept

ISPE Tampa Conference

22-25 February 2010

Tampa, Florida USA

12

Thank You!

Wolfgang Weikmann

Director Pharmaceutical Production / Engineering / g g

Vetter Pharma-Fertigung GmbH & Co. KG

Schuetzenstrasse 87

D - 88212 Ravensburg, Germany

+49-(0)751-3700-2401

Wolfgang.Weikmann@vetter-pharma.com

Potrebbero piacerti anche

- Knapp TestDocumento12 pagineKnapp Testsilvinas29203867% (3)

- PDAJChallenge KitDocumento15 paginePDAJChallenge KitElango Minnoor100% (1)

- Software Validation A Complete Guide - 2020 EditionDa EverandSoftware Validation A Complete Guide - 2020 EditionNessuna valutazione finora

- Qualification of A Manual Inspection Process For A New Fill Finish Facility PDFDocumento30 pagineQualification of A Manual Inspection Process For A New Fill Finish Facility PDFschumon50% (2)

- Sei de NaderDocumento47 pagineSei de Naderpamy26250Nessuna valutazione finora

- Techniques for Downstream process for Biologic Drugs and VaccinesDa EverandTechniques for Downstream process for Biologic Drugs and VaccinesNessuna valutazione finora

- Visual Inspector Qualification PDFDocumento7 pagineVisual Inspector Qualification PDFrobin hasanNessuna valutazione finora

- Biocontamination Control for Pharmaceuticals and HealthcareDa EverandBiocontamination Control for Pharmaceuticals and HealthcareValutazione: 5 su 5 stelle5/5 (1)

- Pharmaceutical Quality by Design: A Practical ApproachDa EverandPharmaceutical Quality by Design: A Practical ApproachWalkiria S. SchlindweinNessuna valutazione finora

- ICH Quality Guidelines: An Implementation GuideDa EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNessuna valutazione finora

- Current Good Manufacturing Practices (cGMP) for Pharmaceutical ProductsDa EverandCurrent Good Manufacturing Practices (cGMP) for Pharmaceutical ProductsNessuna valutazione finora

- Downstream Industrial Biotechnology: Recovery and PurificationDa EverandDownstream Industrial Biotechnology: Recovery and PurificationNessuna valutazione finora

- Validation Master Plan A Complete Guide - 2021 EditionDa EverandValidation Master Plan A Complete Guide - 2021 EditionNessuna valutazione finora

- Acceptance Quality Limits and Visual InspectionDocumento32 pagineAcceptance Quality Limits and Visual InspectionschumonNessuna valutazione finora

- ISO 13485 Quality Management System A Complete Guide - 2020 EditionDa EverandISO 13485 Quality Management System A Complete Guide - 2020 EditionNessuna valutazione finora

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesDa EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumNessuna valutazione finora

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersDa EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNessuna valutazione finora

- Biotechnology Risk Assessment: Issues and Methods for Environmental IntroductionsDa EverandBiotechnology Risk Assessment: Issues and Methods for Environmental IntroductionsNessuna valutazione finora

- Nonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsDa EverandNonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsWilliam J. BrockNessuna valutazione finora

- Verification And Validation A Complete Guide - 2021 EditionDa EverandVerification And Validation A Complete Guide - 2021 EditionNessuna valutazione finora

- Understanding CleanroomDocumento10 pagineUnderstanding CleanroommarkNessuna valutazione finora

- Advances in Cancer Nanotheranostics for Experimental and Personalized MedicineDa EverandAdvances in Cancer Nanotheranostics for Experimental and Personalized MedicineNessuna valutazione finora

- Environmental Monitoring and Control A Complete GuideDa EverandEnvironmental Monitoring and Control A Complete GuideNessuna valutazione finora

- A Comprehensive Text Book on Self-emulsifying Drug Delivery SystemsDa EverandA Comprehensive Text Book on Self-emulsifying Drug Delivery SystemsNessuna valutazione finora

- Genzyme Allston 483 11-20-09 PurgedDocumento23 pagineGenzyme Allston 483 11-20-09 PurgedMohamedRefaatMohamedNessuna valutazione finora

- Toxicological Risk Assessment and Multi-System Health Impacts from ExposureDa EverandToxicological Risk Assessment and Multi-System Health Impacts from ExposureAristidis M. TsatsakisNessuna valutazione finora

- Software Verification And Validation A Complete Guide - 2020 EditionDa EverandSoftware Verification And Validation A Complete Guide - 2020 EditionNessuna valutazione finora

- Leachables and Extractables Handbook: Safety Evaluation, Qualification, and Best Practices Applied to Inhalation Drug ProductsDa EverandLeachables and Extractables Handbook: Safety Evaluation, Qualification, and Best Practices Applied to Inhalation Drug ProductsDouglas J. BallNessuna valutazione finora

- USFDA - Pre-Approval InspectionDocumento53 pagineUSFDA - Pre-Approval Inspectionvg_vvgNessuna valutazione finora

- Disposable Technologies For Aseptic FillingDocumento33 pagineDisposable Technologies For Aseptic Fillingابُوالبَتُول ڈاکٹر صفدر علی قادری رضویNessuna valutazione finora

- Cold Chain Validate Temperature - IsTADocumento32 pagineCold Chain Validate Temperature - IsTAAlex GilNessuna valutazione finora

- SOP Pass Through PDFDocumento4 pagineSOP Pass Through PDFsami2210Nessuna valutazione finora

- Sutton The Sterility TestsDocumento26 pagineSutton The Sterility TestsSilke IgemannNessuna valutazione finora

- Lilly 483 IndianaDocumento14 pagineLilly 483 IndianaDan StantonNessuna valutazione finora

- A Final Floor Show For Bugs (Sandle)Documento4 pagineA Final Floor Show For Bugs (Sandle)Tim Sandle100% (1)

- An Audit Approach To Address Microbial C PDFDocumento39 pagineAn Audit Approach To Address Microbial C PDFOmar Faruq100% (1)

- Yves MayeresseDocumento66 pagineYves MayeressesumankatteboinaNessuna valutazione finora

- A Review Article On Visual Inspection Program For Sterile Injectable Product 2018Documento38 pagineA Review Article On Visual Inspection Program For Sterile Injectable Product 2018Marcelo Sousa SilvaNessuna valutazione finora

- Microbial Contamination-A Regulatory Perspective.Documento8 pagineMicrobial Contamination-A Regulatory Perspective.Sameer PanditNessuna valutazione finora

- Complexities of Medical Device TestingDocumento2 pagineComplexities of Medical Device TestingKeri Gobin SamarooNessuna valutazione finora

- CETA-Compounding-Isolator-Testing Guide PDFDocumento20 pagineCETA-Compounding-Isolator-Testing Guide PDFsantanu paulNessuna valutazione finora

- Cytopro Clinical Study ProtocolDocumento19 pagineCytopro Clinical Study ProtocolbeequesadaNessuna valutazione finora

- ICH Guidance For PSURDocumento24 pagineICH Guidance For PSURAwais KhanNessuna valutazione finora

- 4 White Paper BSC Comparison Between NSF49 and EN12469 05 Jan 2012Documento4 pagine4 White Paper BSC Comparison Between NSF49 and EN12469 05 Jan 2012ThisIs MyCatNessuna valutazione finora

- Quality Risk Management in Pharmaceutical Dispensing Center: M. Chitmetha, S. Prombanpong, and T. SomboonwiwatDocumento8 pagineQuality Risk Management in Pharmaceutical Dispensing Center: M. Chitmetha, S. Prombanpong, and T. SomboonwiwatmmmmmNessuna valutazione finora

- Containment EnclosuresDocumento1 paginaContainment EnclosuresAsif KhanNessuna valutazione finora

- Moist Heat Sterilization MythsDocumento10 pagineMoist Heat Sterilization MythsmmyNessuna valutazione finora

- Contamination Control in Healthcare Product Manufacturing Volume 5 - ContenidoDocumento11 pagineContamination Control in Healthcare Product Manufacturing Volume 5 - Contenidocargscrib100% (1)

- Eto Sterilization Process PDFDocumento2 pagineEto Sterilization Process PDFCraigNessuna valutazione finora

- Validation of Sterilization Equipments: Aseptic Area ValidationsDocumento51 pagineValidation of Sterilization Equipments: Aseptic Area ValidationsSweekar BorkarNessuna valutazione finora

- Hydrogen Peroxide ValidationDocumento18 pagineHydrogen Peroxide Validationdeepanmb007Nessuna valutazione finora

- Biologicals: Johannes Reich, Pierre Lang, Holger Grallert, Hubert MotschmannDocumento6 pagineBiologicals: Johannes Reich, Pierre Lang, Holger Grallert, Hubert MotschmannFlorin PătrulescuNessuna valutazione finora

- 8536 Dbi Sala Uni 8 Oh BCR enDocumento12 pagine8536 Dbi Sala Uni 8 Oh BCR enFlorin PătrulescuNessuna valutazione finora

- Atmel-9187-Rfid-Ata5577c - Datasheet Atmel Muy Bacano DiseñoDocumento47 pagineAtmel-9187-Rfid-Ata5577c - Datasheet Atmel Muy Bacano Diseñogabrielg_03@hotmail.comNessuna valutazione finora

- Ds Micro Xpe 26 56 enDocumento2 pagineDs Micro Xpe 26 56 enFlorin PătrulescuNessuna valutazione finora

- Zenitel - IP or Master - 1008015000Documento5 pagineZenitel - IP or Master - 1008015000Florin PătrulescuNessuna valutazione finora

- VeriCube Manual enDocumento76 pagineVeriCube Manual enFlorin PătrulescuNessuna valutazione finora

- VeriCube Manual enDocumento76 pagineVeriCube Manual enFlorin PătrulescuNessuna valutazione finora

- Variables in Bottle Cap Torque Testing 20140408Documento11 pagineVariables in Bottle Cap Torque Testing 20140408Florin PătrulescuNessuna valutazione finora

- Confined Space EntryDocumento42 pagineConfined Space EntryFlorin PătrulescuNessuna valutazione finora

- Magazine-23.02 Materials Rare Earths FOLLOW WIRED Twitter Facebook RSS If We Want To Keep The Gadgets Coming, Let's Mine GreenlandDocumento3 pagineMagazine-23.02 Materials Rare Earths FOLLOW WIRED Twitter Facebook RSS If We Want To Keep The Gadgets Coming, Let's Mine GreenlandFlorin PătrulescuNessuna valutazione finora

- Knapp TestDocumento2 pagineKnapp TestGeorge Litu67% (3)

- Ghs Pictogram PosterDocumento1 paginaGhs Pictogram PosterFlorin PătrulescuNessuna valutazione finora

- Pharmaceutical Isolator TechnologyDocumento34 paginePharmaceutical Isolator TechnologyFlorin Pătrulescu100% (3)

- Confined Space EntryDocumento42 pagineConfined Space EntryFlorin PătrulescuNessuna valutazione finora

- T8/T5 Dimmable LED Tubes - 3 in 1 Dimming FunctionDocumento2 pagineT8/T5 Dimmable LED Tubes - 3 in 1 Dimming FunctionFlorin PătrulescuNessuna valutazione finora

- Chlorine Free DPDDocumento8 pagineChlorine Free DPDEndang SupriyatnaNessuna valutazione finora

- Pi Acryleze Ent Coat StabDocumento2 paginePi Acryleze Ent Coat StabFlorin PătrulescuNessuna valutazione finora

- Oxygen Regulatory Limits IDocumento18 pagineOxygen Regulatory Limits IFlorin PătrulescuNessuna valutazione finora

- Headspace Oxygen Measurement in Vials and AmpoulesDocumento4 pagineHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNessuna valutazione finora

- InTech-Biotechnology of Agricultural Wastes Recycling Through Controlled Cultivation of MushroomsDocumento21 pagineInTech-Biotechnology of Agricultural Wastes Recycling Through Controlled Cultivation of MushroomsFlorin PătrulescuNessuna valutazione finora

- Double Platform Large Orbital: ShakersDocumento1 paginaDouble Platform Large Orbital: ShakersFlorin PătrulescuNessuna valutazione finora

- Headspace Oxygen Measurement in Vials and AmpoulesDocumento4 pagineHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNessuna valutazione finora

- 1 Seminar Taiwan-1Documento63 pagine1 Seminar Taiwan-1Florin PătrulescuNessuna valutazione finora

- Brochures Isoflex enDocumento8 pagineBrochures Isoflex enFlorin PătrulescuNessuna valutazione finora

- Adresa SisDocumento1 paginaAdresa SisFlorin PătrulescuNessuna valutazione finora

- E UK Flexible BrochureDocumento8 pagineE UK Flexible BrochureFlorin PătrulescuNessuna valutazione finora

- Monobloc EngineDocumento5 pagineMonobloc EngineFlorin PătrulescuNessuna valutazione finora

- 9CH0 03 Que 20201020Documento32 pagine9CH0 03 Que 20201020Jovian AlvinoNessuna valutazione finora

- Bond Work IndexDocumento7 pagineBond Work IndexJaime Alberto Sanchez CardonaNessuna valutazione finora

- IECEE-CTL EQL 62067 - Ed2 - 201404Documento10 pagineIECEE-CTL EQL 62067 - Ed2 - 201404raghavendran raghuNessuna valutazione finora

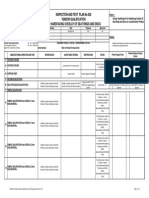

- Inspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsDocumento3 pagineInspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsGohilakrishnan ThiagarajanNessuna valutazione finora

- Protein MaterialDocumento61 pagineProtein MaterialAlyssa NesianandaNessuna valutazione finora

- AND From AND: FOR Rhodium, For Their GravimetricDocumento13 pagineAND From AND: FOR Rhodium, For Their GravimetricshahinNessuna valutazione finora

- HNDBK For Calculation of Nuclear Reaction DataDocumento166 pagineHNDBK For Calculation of Nuclear Reaction DatadelhiprashantNessuna valutazione finora

- The Electronic Spectra of Coordination CompoundsDocumento52 pagineThe Electronic Spectra of Coordination CompoundsAyuditNessuna valutazione finora

- Unit 4Documento76 pagineUnit 4raghuram67Nessuna valutazione finora

- EES Lecture 3 and 4 AssignmentDocumento2 pagineEES Lecture 3 and 4 AssignmentMarcelo GuerraNessuna valutazione finora

- Astm f136 Rev ADocumento4 pagineAstm f136 Rev AAhmad BrianNessuna valutazione finora

- Uniform Mechanical Code - 2009 Chapter 5Documento34 pagineUniform Mechanical Code - 2009 Chapter 5memosplumbingNessuna valutazione finora

- Check Valve (Swagelok) MS-01-176 PDFDocumento16 pagineCheck Valve (Swagelok) MS-01-176 PDFIsmailIbrahimNessuna valutazione finora

- Candy Cg434Documento26 pagineCandy Cg434Saša MihajlovNessuna valutazione finora

- Wl2000it Brochure ENGDocumento2 pagineWl2000it Brochure ENGSantos RodriguezNessuna valutazione finora

- Lir - Cv.truba Jaya EngDocumento7 pagineLir - Cv.truba Jaya EngbegateamNessuna valutazione finora

- 7es Lesson PlanDocumento6 pagine7es Lesson PlanMark Pecho91% (11)

- Synthesis of UiO 66 OH Zirconium Metal Organic FrameworkDocumento7 pagineSynthesis of UiO 66 OH Zirconium Metal Organic FrameworkFilozofijaPaleNessuna valutazione finora

- TelusDocumento3 pagineTelusGembonz Crew Gon'z SpeedNessuna valutazione finora

- Drew Marine - Bulk Carrier Guide For Cargo Hold CleaningDocumento2 pagineDrew Marine - Bulk Carrier Guide For Cargo Hold CleaningGauravNessuna valutazione finora

- H.Flyer - SN Housings - Fno3036 - SN - eDocumento4 pagineH.Flyer - SN Housings - Fno3036 - SN - epcesar777Nessuna valutazione finora

- Thermal Expansion Settings in GleebleDocumento4 pagineThermal Expansion Settings in GleeblePranav TripathiNessuna valutazione finora

- Market Survey On Copper PDFDocumento210 pagineMarket Survey On Copper PDFmujib uddin siddiquiNessuna valutazione finora

- Sand To Silicon 22nm VersionDocumento18 pagineSand To Silicon 22nm VersionDavid Rubio SaezNessuna valutazione finora

- ChemistryResearchandApplicationsColeLynwood Polystyrene - SynthesisCharacteristicsandApplications NovaSciencePubInc2014 PDFDocumento320 pagineChemistryResearchandApplicationsColeLynwood Polystyrene - SynthesisCharacteristicsandApplications NovaSciencePubInc2014 PDFMestviaNessuna valutazione finora

- Transcript of MarksDocumento2 pagineTranscript of MarksKiranPadman50% (2)

- Element Fe O: Find The Empirical Formula For A Compound Containing 40.6% Carbon, 5.1% Hydrogen, and 54.2% OxygenDocumento8 pagineElement Fe O: Find The Empirical Formula For A Compound Containing 40.6% Carbon, 5.1% Hydrogen, and 54.2% OxygenLEENA HingNessuna valutazione finora

- DPP No.B1 To B14 FacultyDocumento43 pagineDPP No.B1 To B14 Facultysharmagargi2626Nessuna valutazione finora

- TFP330 10 2013Documento4 pagineTFP330 10 2013Mihai CatalinNessuna valutazione finora

- BS Chemical EngineeringDocumento110 pagineBS Chemical EngineeringhorasiusNessuna valutazione finora