Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

EEM 402 Lect 3 Air Pollution Control Methods Summer 2014

Caricato da

Altaf Ur Rehman0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

20 visualizzazioni36 pagine12

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento12

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

20 visualizzazioni36 pagineEEM 402 Lect 3 Air Pollution Control Methods Summer 2014

Caricato da

Altaf Ur Rehman12

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 36

Air Pollution Prevention

Management and Control

Strategies

Dr. Shahid Amjad

Institute of Business Management

(IoBM)

Air Pollution Effects

Adversely affects human health

Damages crops and forests

Highly corrosive

Industrial Emission

Emission from an industry may pass into the air

environment through the stack/chimney (stack emission).

It can also be fugitive in nature (fugitive emission), that is, it

can come out from various leakage points or from an open

system and not from any dedicated duct.

While the impact of stack emission can be felt at long

distances, the fugitive emissions are confined to the work

environment and the areas of close vicinity of the plant.

Good house keeping, maintenance of joints, hoods, etc.

and small measures of trapping emissions at the sources of

generation (like water spraying at transfer points of coal

handling) can greatly reduce fugitive emissions.

Since fugitive emissions are difficult to measure, regulatory

agencies often tend to ignore such emissions in their

authorizations, consents, etc. Nevertheless, control of

fugitive emissions is very important, at least for protection

of workers' health.

Episodic emissions always draw public attention.

These emissions occur in upset conditions, often

resulting in release of toxic gases and thus causing

loss to life and property.

The Bhopal gas tragedy is probably the worst

incident of episodic emissions experienced so far.

Preventive maintenance, close monitoring, etc. are

some of the measures the management should

take to prevent episodic emissions.

Once such an emission occurs, immediate

mitigative measures are required for which

contingent action plans must be ready.

On-site and off-site disaster management plans are

requirements under the law for major hazardous

installations.

Gaseous Pollutant Control Techniques

Two techniques are generally followed for the

control of gaseous pollutants. They are

(i) Sorption of the pollutant (absorption in a

liquid or adsorption on a solid surface

(ii) Chemical Alterations (the pollutant is

converted to innocuous substances).

Absorption by a liquid The pollutant is brought

into contact with an appropriate liquid or solution

by counter current methods whereby the gaseous

impurity is transferred from the gaseous phase to

the liquid phase.

The gas absorption devices are similar to the wet

collection devices for particulate control

(scrubbers, spray towers, Venturi scrubber, etc.)

with minor modifications wherever necessary.

The different absorbent liquids or solutions used

for various pollutant gases are shown in Table

Adsorption on solid surface. In this method, the polluted

air is passed through a column of absorbent solid, usually

activated carbon, activated alumina, silica gel and organic

polymeric compound (molecular sieve), etc. whereby the

pollutant in the air stream is held on the solid surface. This

method, though not very common, is useful for odour

removal.

The following lists some adsorbents and their common use.

Activated carbon : Used for odour removal, purification of

industrial gases, hydrocarbons, pesticides etc.

Silica gel : Used for dehydration of gases

Activated alumina : Used for dehydration of gases and for

removal of HF in aluminum smelter

Molecular sieves : Wide application, selective adsorption of

gases like NH

3

, SO

2

, etc.

Air Pollution Control Strategies

Air pollution control methods can, in general, be

grouped into the following categories:

(i) Pollution control at source,

(ii) Installation of control devices and equipments

(End-of-the pipe cleaning),

(iii) Plantation of trees and creation of green belt,

(iv) Construction of high stacks and chimneys.

All these methods, however, propose good

maintenance and house keeping in the factory.

POLLUTION CONTROL AT SOURCE

The ideal approach to pollution control is to

prevent or minimize the formation of

pollutants at the source itself, i.e., in the

manufacturing process.

This should be done at an early stage of

process design and development. Any

modifications at the later stage may become

costly.

Source correction methods include: raw

material changes, process changes and

equipment modification or replacement.

Raw Material and Process Changes

Pollutants have their origin in the raw materials. They are

either present in the raw materials as such or are byproducts

of those materials. Thus use of purer grade raw materials

may be beneficial in producing less pollutants.

Use of low-sulphur fuels instead of high-sulphur ones in

power generation produces less oxides of sulphur as

pollutant. Desulphurization of the fuel is an option available

for cleaner production, but economics of this often prevents

this option.

Nevertheless there is no escape from this if a power plant is

to be established using high-sulphur coal in an area.

Ore handling operations in steel plants causes dust pollution.

Much of this nuisance can be removed by using dust

suppressors or by replacing ordinary ores with pelleted

sintered ones.

Equipment Modification or Replacement

Loss of hydrocarbons by evaporation in the

storage tanks of refineries can be controlled,

to a very large extent, by designing the tanks

with floating roof covers or by pressurizing the

tanks.

CONTROL DEVICES AND EQUIPMENTS (END-OF-THE

PIPE CLEANING)

The strategy for this method is to remove the

particulate and gaseous pollutants after they are

formed. The earlier methods, described, aim at

reducing the pollutants. If, however, pollutants cannot

be adequately removed or reduced by source control,

it becomes necessary to install control equipments

along the main gas stream.

Normally it will be economical and more convenient to

install these equipments close to source where the

volume of the gas is less and the concentration of the

pollutant is high. But in many cases, there are space

constraints to install such equipments near the source.

The cleaning devices can be broadly classified into 2

groups (i) Particulate Control and (ii) Gaseous Pollutant

Control.

Particulate Control

Particulate Matters (PMs) are common pollutants present

in the emission of an industry. They are formed in wide

range of sizes, diameter varying from 0.0002 to 500 micron

(1 micron = 10

-6

m).

Their life-time in the atmosphere depends on the settling

range. Larger size particles settle faster than the smaller

ones. Different devices are available for the collection of

particulate matters from the gaseous stream.

These can be broadly divided into 3 categories, viz., Internal

Separators, Wet Collection Devices and Electrostatic

Precipitators.

Internal separators. Three types of devices are commonly

in use as internal separators. They are (i) Gravitational

settling chambers, (ii) Cyclone separators and (iii) Bag filters

or fabric filters. and wet scrubbers.

Gravitational settling chambers are generally

used to collect larger particles of size greater

than 50 micron. A stream of dust-laden gas is

passed into the settling chamber where the

velocity of the gas is suddenly reduced.

As a result, the dust particles settle down and

collected through a hopper at the bottom.

There are various types of settling chambers.

Figure 5.1 shows a horizontal flow type

settling chamber.

The collection efficiency can be increased by

installing a series of settling chambers in

parallel.

Cyclone separator utilizes centrifugal force to separate the

particulate matters from the carrier gas. The particle laden gas

receives a rotating motion as it enters the cyclone cylinder. A

centrifugal force is developed due to the vortex formed which throws

the particles towards the wall. These particles get collected at the

conical bottom of the cyclone cylinder.

The spinning gas stream spirals downward to the bottom of the cone.

At this point the flow reverses to form an inner vortex and finally

leaves the cylinder through the outlet pipe situated at the top (Figure

5.2).

High efficient cyclones are designed. A series of cyclones, called the

multiclone, are used in many industries to increase the efficiency of

collection.

The settling efficiency of cyclone separator is higher than that of

gravity separator because the centrifugal force is added to the

gravitational force to settle the particles.

An ordinary conventional cyclone can have an efficiency of 95-99%

collection for particles greater than 40 micron diameter. At the other

end, for particles of size greater than 5 micron, the collection

efficiency can be 50-80% with cyclones of very high efficiency

Bag filters are devices by which gas is purified through

various filtering cloths (cotton, wool, chemical filters, fibre

glass, etc.) or fabric filters (filters made of granular materials

like ceramics, porous plastics, etc).

A typical bag house consists of a tubular bag or an envelope

mounted in such a manner that the particle laden gas

passing through the filter bags get deposited on the

inside/outside surface of the bags which are dusted of by

shaking in intervals.

The dusts are collected in a hopper at the bottom. The

collection of the dust particles on the surface of the filters

take place

Bag filters have high efficiency but the filters are required to

be cleaned and changed in regular intervals. Many filters

made of clothes, plastics, etc. cannot work at high

temperatures. Figure 5.3 shows the arrangement of a typical

bag house.

However though bag filters are highly efficient, these are

more expensive and require frequent maintenance.

Wet collection devices.

In the wet collection methods, various types of

scrubbers are used by which the particulate matters

are brought into contact with the scrubbing liquid,

usually water, and the wetted particles settle down.

This is similar to the natural process of cleaning of the

atmosphere by the water cycle Wet collections have

the advantage of collecting.

not only particulates but also gaseous impurities by

suitable choice of the scrubbing liquid (which can

absorb the gases). But wet scrubbers have the

problems of corrosion.

The scrubbed water (slurry) is required to be treated

before disposal. In this system, air pollution problem is

passed on to the water environment.

The collection efficiency of spray towers can

be increased by the use of centrifugal

scrubbers in which the water spraying nozzles

are fitted inside a conventional dry cyclone.

The water spray acts on the particles in the

outer vortex and the particulate matters are

collected at the bottom as in dry cyclones but

in the form of slurry

Packed beds and plate columns

are well-known absorbers in chemical

industries. These can also be used as wet

scrubbers. These are distinguished by their

simple design and operation, stability in

service, low hydraulic resistance and low

energy consumption.

In a simple packed bed scrubber, the polluted

air stream moving upwards comes in contact

with the scrubbing liquid stream moving

downward over the packing (Figure 5.5).

Venturi scrubber

followed by cyclone separator, the venturi

scrubber offers a high performance collection of

fine particles (2-3 micron). The polluted gas

stream is accelerated by the passage through a

narrow throttle (velocity of the order of 60-120

m/sec).

Scrubbing liquid is injected at this throttle

through low pressure nozzles. The gas-liquid

mixture then goes to the cyclone separator.

The separated slurry is removed from the bottom

(Figure 5.6). Venturi scrubbers are particularly

suitable for sticky and flammable particles.

Electrostatic precipitation. The gaseous stream is

passed through a strong electric field where the

particulate matters get electrically charged and are

attracted towards the electrode of opposite charge. In

a typical Electrostatic Precipitator (ESP), the positive

electrode (grounded) is the collecting electrode and

the negative electrode is suspended at the top.

A high voltage DC current through the electrodes

produces a corona. The gas close to the negative

electrode is ionized. The electrons produced in the

ionization process move towards the positively charged

grounded surface.

During this passage, the particulate matters also get

negatively charged by the electrons and get collected

on the positive surface (Figure 5.7).

ESPs are considered as highly efficient particulate

collecting systems and are widely used in industries.

PLANTATION OF TREES AND CREATION OF GREEN BELT

Adequate greenery in industrial establishment helps in creating

better environment in many ways.

It provides a sylvan surrounding to improve the aesthetical

conditions which, in turn, improve the working condition of the

workers.

Tall trees attract birds to roost and also provide shelter to other

small creatures like squirrel, and other reptiles, etc. Thus

biodiversity is restored.

properly designed green belt of adequate width acts as a filter of air

pollutants for outside. Fugitive emissions are mainly controlled by

the green belt. Plantation of pollution indicating species at strategic

locations can indicate the air pollution status of the area. These are

plant species which are sensitive to specific air pollutants. Such

species serve as 'bioindicators'.

Green belt acts as a noise barrier for outside.

Treated wastewater of an industry is always recommended for

maximum utilization within the premises. If the wastewater is

utilized for irrigation of the green

.

belt and other plantations within,

the objective is partially achieved.

CONSTRUCTION OF HIGH STACKS/CHIMNEYS

With all the control devices, it may not be always possible to

effectively remove the pollutants from the emission. Sometimes

the available technology for complete pollutant removal may be

cost-prohibitive.

The next best approach for control of pollution is to allow the

pollutant to be diluted to the maximum and dispersed to minimize

its adverse effect. This can be done by releasing the emissions at a

high altitude with long stacks. The height and the diameter of the

stack should be designed to keep the ground level concentration

within the permissible limits.

The concentration of the pollutant at the ground level decreases

exponentially with the height of the stack and is found to be

maximum at a distance of about 5 to 10 times the stack height at

normal meteorological condition.

The coal used in thermal power plants contains sulphur, weak acid

rain can be except in small pockets.

Installation of desulphurization unit requires heavy capital

investment. The sulphur dioxide control thermal power plants is

mostly done by maintaining long stack heights

Exercise

Before the installation of an Electrostatic

Precipitator (ESP) the stack of a power plant

contained 6.0 gms particulates per m

3

of gas. The

Gas flow rate is 300 m

3

/minute. The new

Precipitator can remove 2591 kg particulates/day.

What is the emission rate of particulates before

and after pollution control in Kg/day?

What is the efficiency (%)of the ESP.?

Will the new system meet the emission

particulate standards of 500g/m

3

Solution: Data

a) w=6gms/m

3

; flow rate Q=300m

3

; m=2591 kg/day.

300x6=1800gms/min or 1800x10

-3

kg/min.

1800x10

-3

x24x60 = 2592kg/day (Before).

New ESP 2591 kg/day

2592-2591=1 kg/day

b) n=Quantity of dust collection x100

Quantity of dust in flowing gas

2591 x100 =99.96%

2592

c) Total particulates at source=6gms

ESP efficiency= 99.96%

Particulates removed 6x0.9996 = 5.9976gms.

Particulates remain 6.0 5.9976 = 0.0024gms/m(2400g)

So the new ESP system cannot meet emission standard of 500g/m

3

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Adc Invoice 400Documento2 pagineAdc Invoice 400Altaf Ur RehmanNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- File IndexDocumento113 pagineFile IndexAltaf Ur RehmanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Enquiry ListDocumento12 pagineEnquiry ListAltaf Ur RehmanNessuna valutazione finora

- Weboc 1Documento30 pagineWeboc 1Altaf Ur RehmanNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Documentation Description: For Import & Export GoodsDocumento8 pagineDocumentation Description: For Import & Export GoodsAltaf Ur RehmanNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Bill of Entry Bill of Export Baggage Declaration Transshipment PermitDocumento2 pagineBill of Entry Bill of Export Baggage Declaration Transshipment PermitAltaf Ur RehmanNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 1) Sales Contract 1) Sales Contract Importer or Buyer Importer or BuyerDocumento5 pagine1) Sales Contract 1) Sales Contract Importer or Buyer Importer or BuyerAltaf Ur RehmanNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- CondolenceDocumento23 pagineCondolenceAltaf Ur RehmanNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- CSS Everyday Science Notes PDFDocumento50 pagineCSS Everyday Science Notes PDFWaqas Gul100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Sami Pharmaceuticals (PVT) LTD Costing / Comparison: Butylated Hydroxy AnisolDocumento5 pagineSami Pharmaceuticals (PVT) LTD Costing / Comparison: Butylated Hydroxy AnisolAltaf Ur RehmanNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Clarification LetterDocumento1 paginaClarification LetterAltaf Ur RehmanNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Experiment NoDocumento5 pagineExperiment NoAbdullah UsmaniNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Papercrete4 PDFDocumento9 paginePapercrete4 PDFPrasad TekadeNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Paint Master Bonding Liquid - SDSDocumento3 paginePaint Master Bonding Liquid - SDSMichael JoudalNessuna valutazione finora

- 3 Effects of Electric Current Physics ProjectDocumento20 pagine3 Effects of Electric Current Physics ProjectAkshatNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- D525Documento6 pagineD525Erika DanielaNessuna valutazione finora

- Basics of Paint TechnologyDocumento9 pagineBasics of Paint TechnologySantosh Raj100% (1)

- Avogadro ActivityDocumento4 pagineAvogadro ActivityShazmie Mohammad NadziriNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Effect of Polycarboxylate Ethers As Deflocculants in CastablesDocumento4 pagineThe Effect of Polycarboxylate Ethers As Deflocculants in CastablesAmi Sa100% (1)

- (Solutions Chapter) Introduction To Plasma Physics and Controlled Fusion Plasma Physics - Francis F. ChenDocumento47 pagine(Solutions Chapter) Introduction To Plasma Physics and Controlled Fusion Plasma Physics - Francis F. ChenLu Young80% (5)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

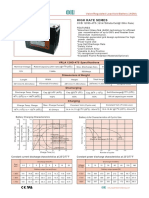

- High Rate Series: CCB 12HD-475Documento1 paginaHigh Rate Series: CCB 12HD-475orunmila123Nessuna valutazione finora

- Assignment 1 - Mass and Energy Balance March 2020Documento2 pagineAssignment 1 - Mass and Energy Balance March 2020Porkkodi SugumaranNessuna valutazione finora

- Acamprosate CalciumDocumento2 pagineAcamprosate Calciumjafranco.tfsNessuna valutazione finora

- Chloride MohrDocumento2 pagineChloride MohrVaibhav KrNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- FiberDocumento7 pagineFiberHue Trang Nguyen ThiNessuna valutazione finora

- Trepanning Positioning Welding ManualDocumento14 pagineTrepanning Positioning Welding ManualGovindan PerumalNessuna valutazione finora

- Plastics PDFDocumento18 paginePlastics PDFV Phanindra BoguNessuna valutazione finora

- HVAC Water TreatmentDocumento6 pagineHVAC Water TreatmentAbdullah.N FAAliNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Solar Stills For Desalination of Water in Rural Households: Amitava BhattacharyyaDocumento10 pagineSolar Stills For Desalination of Water in Rural Households: Amitava BhattacharyyaTrimo Wahyu Bimantoro100% (1)

- Nuclear Technology and EnergyDocumento4 pagineNuclear Technology and EnergyJessica Anna LuchkaNessuna valutazione finora

- Mission S and W Dims and Curve Chart PDFDocumento28 pagineMission S and W Dims and Curve Chart PDFcaballero_tigreNessuna valutazione finora

- ACS Sustainable Chemistry & Engineering - 2020Documento9 pagineACS Sustainable Chemistry & Engineering - 2020Eugene YiNessuna valutazione finora

- Pacing Guide: Inspire ChemistryDocumento6 paginePacing Guide: Inspire Chemistryjsencion977Nessuna valutazione finora

- Advanced Nonlinear Materials: Section 4Documento116 pagineAdvanced Nonlinear Materials: Section 4hakan demirNessuna valutazione finora

- Agar Desalter Control Sys3 Appl 3Documento2 pagineAgar Desalter Control Sys3 Appl 3JADNessuna valutazione finora

- Ne335 Macro Lab1Documento17 pagineNe335 Macro Lab1Moeen Khan RisaldarNessuna valutazione finora

- Introductions To Water and Wastewater Treatment Basics of Water Supply Networks Forecasting Methods On Site and Centralized Treatment SystemsDocumento397 pagineIntroductions To Water and Wastewater Treatment Basics of Water Supply Networks Forecasting Methods On Site and Centralized Treatment SystemsSrivvass ReddyNessuna valutazione finora

- Heat Exchanger Selection GuideDocumento2 pagineHeat Exchanger Selection GuiderodrigoperezsimoneNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Ge 2009Documento3 pagineGe 2009RICHARD MACIENTE SILVINO DA SILVANessuna valutazione finora

- Mitsubishi CBN PCDDocumento70 pagineMitsubishi CBN PCDtoms4Nessuna valutazione finora

- Double Majors TYBSc Biochemistry-Zoology - 2019-2020Documento58 pagineDouble Majors TYBSc Biochemistry-Zoology - 2019-2020Meir SabooNessuna valutazione finora