Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aquaciat 2 - NA14590A PDF

Caricato da

duiechDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aquaciat 2 - NA14590A PDF

Caricato da

duiechCopyright:

Formati disponibili

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

1 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

Hydraulic

module

USE

AQUACIAT2 LD-LDC-LDH and ILD-ILDC-ILDH series

packaged water chillers or heaters with air cooled condenser

are medium-capacity units specifically designed for heating

and air conditioning applications in Offices, Healthcare,

Administrations, Shopping Centres and the Residential sector.

These packaged units are designed for outdoor installation

and require no special protection against adverse weather

conditions.

An optional XTRAFAN version enables installation with

ductable fan(s), if required, if there is a risk of air recycling, or

for sound insulation on site.

To operate in HEATING or COOLING mode, they use the

outdoor air as the only external source; this allows heat to be

evacuated in summer and thermal energy to be supplied for

heating in winter.

Connected to an underfloor heating or cooling system, fan coil

units or an air handling unit, the reversible AQUACIAT2 ILD-

ILDC-ILDH series is an extremely easy way to heat and air

condition buildings.

Each unit is delivered fully assembled, wired (control and

power), charged with refrigerant and factory tested.

Simply make the necessary electrical and hydraulic

connections, and your unit is ready to operate.

RANGE

AQUACIAT2 LD series

Cooling only versions without hydraulic system

AQUACIAT2 LDC-LDH series

Cooling only versions with hydraulic system (circulation pump

only or pump and buffer tank).

AQUACIAT2 ILD series

Reversible Air/Water versions without hydraulic system

AQUACIAT2 ILDC-ILDH series

Reversible Air/Water versions with hydraulic system (circulation

pump only or pump and buffer tank).

Cooling capacity: 20 to 170 kW

Heating capacity: 20 to 180 kW

High energy efficiency with

R410A

Compact and quiet

Scroll compressors

Brazed plate heat exchangers

Self-adjusting

electronic control

Heat

recovery

Cooling or

heating

Cooling

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

AQUACIAT2

EVOLUTION

2

Water chillers

Heat pumps

DESCRIPTION

AQUACIAT2 LD-LDC-LDH cooling only or ILD-ILDC-ILDH reversible series models are supplied with the following

components as standard:

- air-cooled condenser with axial fan motor assembly,

- chilled-water evaporator (or hot water condenser on reversible models),

- chilled water or hot water capacity control,

- control, automatic operation and startup box:

. Power supply: 3~50Hz 400V (+10%/-10%) +earth

. 1~50Hz 230V control circuit (transformers fitted as standard on the machine),

- casing for outdoor installation.

n Complies with European CE directives

- Machinery 2006/42/EC

- EMC directive (2004/108 EC)

- Pressure equipment PED 97/23 EC:

category 2 for LD - LDC - LDH 80V to 700V

category 2 for ILD - ILDC - ILDH 80V to 700V

- Low voltage (2006/95/EC)

n Complies with standards

- EN 60-204, EN 378-2 (NFC 15-100, France)

DESCRIPTION

ILD > Reversible version H > hydraulic with pump and buffer tank

LD > cooling only version 540 > unit size

C > hydraulic with pump only V > R410A refrigerant

80 to 300

MAIN COMPONENTS

n Casing

- Removable galvanised metal panels,

- RAL 7024 and RAL 7035 lacquer coating

n Hermetic SCROLL compressors

- Built-in electric motor cooled by suction gases

- Motor protected by internal winding thermostat

- Placed on anti-vibration mounts

n Evaporator

- Brazed plate exchanger(s)

- End and inside plates in AISI 316 stainless steel

- High-performance, optimised plate patterns

- Thermal insulation

n Condenser

- High efficiency air-cooled exchanger, aluminium fins with

optimised profiles and grooved copper tubes

- Condenser or evaporator mode heat exchanger on ILD-ILDC-

ILDH reversible heat pump versions

- Axial fan(s) with aluminium airfoil blades

- 2-speed motors - IP 54, class F

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

3 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

n Control functions and safety devices

- Water flow control

- Thermostatic expansion valve(s)

- Refrigerant HIGH and LOW-pressure safety devices,

- Safety valves on refrigeration circuit

- Temperature and pressure sensors

- Water flow controller, evaporator fitted

- Unit start-up sequence

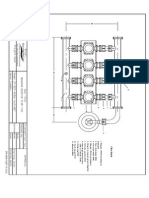

fans

air-cooled condenser

buffer tank

hydraulic pump

versions C and H

electrics box

compressor compartment

n Electrics box

The fully wired electrics box which houses all the electrical

components and the electronic CPU board, controls the

entire unit, monitors its operation, adjusts water setpoints and

interfaces with an external control system.

It comprises:

- Control and power circuits,

- Wire numbering,

- Main safety switch with handle on front,

- Control circuit transformer,

- Circuit breakers on the power and control circuits,

- Compressor and motor switches,

- Main earth connection,

- Microprocessor-controlled electronic control unit,

- Alarm or information signals on free terminals.

n Main options

- Additional voltage-free contact boards,

- Remote control unit,

- Phase controller =rotation direction, missing phases, over-

and undervoltage (factory fitted on 350 to 700 versions)

- Soft start system (factory fitted on 350 to 700 versions)

- Frost protection,

- Fan speed regulator (factory fitted on 350 to 700 versions)

- 800-micron water filter supplied as standard on LDC-LDH

or ILDC-ILDH versions, and as an option on LD-ILD versions,

- Evaporator and condenser flexible couplings,

- Hydraulic control kit including manifold pressure gauges,

control valve and shut-off valve,

- Dual pump for 180 to 700 versions (factory fitted on 350 to

700 versions),

- 15 kW extra heater kit (ILD, ILDC, ILDH 80 to 150).

- 15-30-45-60 kW extra heater MODULE kit (ILD, ILDC, ILDH

180 to 300).

- MULTICONNECT management of up to 8 units.

- Management of 4 auxiliary heating devices.

- LONWORKS protocol (gateway)

- Container handling kit (350 to 700)

ELECTRONIC CONTROL MODULE

CIAT electronic control module with microprocessor and

CPU, with central automatic operation and access to internal

operation states.

n Features:

- Start, stop, reset or remote control,

- COOLING or HEATING mode selector,

- Outputs. RS485 output for CMS link (ModBus-J Bus),

. board adapter for additional voltage-free contacts,

. remote control adapter (optional)

- Multilingual analogue LCD and LEDs.

n Functions:

- operation information displayed via:

. multilingual clear-text messages

. direct temperature and pressure readings

- complete management of compressors with start-up

sequence, timer and runtime balancing

- Self-adjusting and proactive functions with adjustment of

settings drift control

- Series stage capacity-reduction system on multi-compressors

according to cooling and heating demands based on water

temperatures

- Monitoring of internal operation parameters

- Pump standby based on demand

- Second setpoint management

- Direct display of water temperature and pressure

- Diagnosis of operation and fault states:

HP/LP, water flow rate, compressor motor(s), frost protection

- Short-cycle protection

- Remote management and remote monitoring

- Master Slave Management allows two machines to be

controlled on a single water loop, by alternating the Master

and Slave according to the running time.

- Setpoint adjustable by 4-20 mA signal

- Weekly programming

OPTIONS (KIT FOR INSTALLATION ON SITE)

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

AQUACIAT2

EVOLUTION

4

Water chillers

Heat pumps

Simple to use

The "Variable Speed Pump" is fully integrated and protected on

the CIAT machine and, as it is installed outdoors, there is no

need for work to be carried out in the machine room.

The assembly is factory-fitted and pre-set on the unit by CIAT;

it is therefore quick to install and reduces the cost of work, in

particular because there is no water flow control valve on the

outlet of the unit.

The ability to adjust the water flow to your requirements means

that the pump pressure can be adapted precisely to the actual

pressure drop on the system when it is started up on-site.

SOFT START

A SOFT START function prevents any current peaks when

the pump is started up to protect the electrical system, thereby

limiting the building's electricity use at peak times and ensuring

the smooth operation of the pipework.

STANDBY function

A "Standby" function controls the electricity consumed by the

pump; this works by reducing the pump's speed when the

compressors are ordered to stop by the control, using a specific

algorithm on the regulator.

Lowering the speed to the minimum frequency when the

compressors are on standby reduces the water flow to ensure the

water loop is perfectly homogenised and the control temperature

sensors are well irrigated.

This reduces electricity consumption by around 70% during

standby periods, which represents a significant proportion of the

machine's normal operating time, in particular for air conditioning

applications.

VARIABLE SPEED PUMP

Description

The "Variable Speed Pump" option on the primary circuit saves

you energy by adjusting the electrical consumption of one

pump to the actual requirements of a hydraulic system (P2

pressure), in particular for oversized installations.

A regulator enables one pump (pump A in the example below) to be

adapted, by lowering its pressure P1 to the requirements of system

P2, to obtain the optimal water flow setpoint.

Electricity bills relating to the pump's consumption are reduced

proportionately, by around 25% per year on average; this

means you will see a return on investment (ROI) in only a few

years, compared with the same fixed speed pump equipped

with a simple flow control valve.

Operating principle

This relies on precise adjustment of the water flow required

for an installation when the unit is started up; this must

subsequently be maintained within a minimum/maximum range

by constantly measuring the differential pressure on the pump

terminals.

The speed regulator is then triggered based on the events

occurring in the hydraulic system, such as valves opening or

closing, re-establishing the water flow setpoint.

Any deviation in the pressure recorded on the unit's terminals

is immediately handled by the pump's variable speed control

which is automatically adjusted based on the variations

generated by the hydraulic system.

The machine independently controls adjustments in the water

flow between two (minimum and maximum) setpoints, without

any external intervention.

Pa

S

S

S

mWC

mWC

P2

P2

P

P1

Rated flow

Rated flow

Pressure drop

m

3

/h

m

3

/h

Hz

Time

System pressure drop

Water flow rate

setpoint

Regulator frequency

m

3

/h

max.

min.

P

u

m

p

A

P

u

m

p

B

V

a

r

ia

b

le

s

p

e

e

d

p

u

m

p

"

A

"

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

7 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

Aquaciat LD - LDC - LDH 80V 90V 100V 120V 150V 180V 200V 240V 300V

Net cooling capacity (1) kW 20,50 23,37 27,28 30,43 38,24 46,18 53,20 60,10 75,73

Net absorbed power kW 6,73 7,73 8,74 10,10 13,88 14,77 17,74 20,44 28,07

Net energy efficiency rating (EER) (2) 3,04 3,02 3,12 3,01 2,75 3,12 2,99 2,93 2,69

Net seasonal energy efficiency rating (ESEER) LN 3,68 3,66 3,78 3,63 3,18 4,26 4,28 4,10 4,01

Net seasonal energy efficiency rating (ESEER) HP 3,62 3,63 3,81 3,69 3,29 4,36 4,31 4,01 4,01

Lw / Lp (3) (high performance version - HP) dB(A) 75/43 77/45 78/46 79/47 84/52 87/55

Lw / Lp (3) (Low Noise version - LN) dB(A) 71/39 73/41 75/43 77/45 76/44 80/48 81/49

Compressor Hermetic SCROLL (2900 rpm)

Start-up mode Direct in line in series

Quantity 1 2

Power control % 100-0 100-50-0

Refrigerant oil type Polyol ester POE 3MAF (32 cst)

Oil capacity l 2,50 3,25 3,25 3,25 4,14 6,50 6,50 6,50 8,30

No. of refrigerating circuits 1

Refrigerant (GWP) R410A (GWP = 2088)

Refrigerant charge kg 3,7 3,9 5,5 5,5 5,2 10,0 10,5 10,2 11,0

Tonne CO

2

Equivalent TCO

2

Eq 7,72 8,14 11,48 11,48 10,85 20,88 21,92 21,29 22,96

Power supply ph/Hz/V 3~50Hz 400V (+10%/-10%) + Earth

Machine protection rating IP 44

Control circuit voltage ph/Hz/V 1~50Hz 230V (+10%/-10%) -transformer fitted

Evaporator Brazed plate exchanger(s)

Water content l 1,78 1,78 2,22 2,22 3,11 3,55 4,22 4,77 7,71

Chilled water outlet temp. (min./max.) C -12 / +18

Minimum water flow rate m

3

/h 2,4 2,7 3,1 3,5 4,4 5,4 6,1 6,9 8,8

Maximum water flow rate m

3

/h 7,2 8,3 9,6 10,8 13,4 16,2 18,7 21,3 26,3

Water connections Male G 1"1/4 Male G 1"1/2 Male G 2"

Max. pressure, water end bar 10 bar (LOD)/4 bar (LDC-LDH)

Air-cooled condenser Finned heat exchanger

Fan mm 800

No. x Motor output, high-performance (HP) version no. x kW 1x0.8 1x0.8 1x0.8 1x0.8 1x0.8 1x0.8 1x0.8 1x1.6 1x1.6

Qty x Motor output Low noise version - LN no. x kW 1x0.5 1x0.5 1x0.5 1x0.5 1x0.5 1x0.5 1x0.5 1x1.1 1x1.1

Air flow, High Performance - HP m

3

/h 15500 15500 16100 16100 16100 16200 16200 21700 21700

Air flow, Low Noise - LN m

3

/h 12300 12300 13100 13100 13100 13200 13200 17600 17600

Min water volume (ILD - ILDC) l 114 130 155 173 229 131 149 173 209

Tank volume, model H l 100 150 200

Expansion vessel, C & H l 6 18

Standard pump no. 44 44 44 44 45 40 40 40 41

Height (excluding mounts) mm 1170 1393 1743

Length (standard version) mm 1995 1995 1995

Length (version C) mm 1995 1995 1995

Length (version H) mm 1995 1995 2676

Depth mm 1055 1055 1055

Weight (empty, standard version) kg 347 350 365 367 449 569 575 581 711

Weight (empty, version C) kg 365 368 383 385 467 616 619 625 756

Weight (empty, version H) kg 390 393 407 409 492 813 816 822 953

Storage temperature C + 50C

(1) Capacities on HIGH PERFORMANCE version based on: Net conditions, COOLING: +12C/+7C and condenser air inlet temperature +35C

EN14511-2013 EUROVENT conditions

(2) Net value EER (excluding pump)

(3) Lw: Overall sound power level as per standard ISO3744

Lp: Overall pressure level measured at 10m in a free field, calculated using the formula Lp=Lw- 10 log S

(4) Based on selection

TECHNICAL CHARACTERISTICS - COOLING ONLY

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

AQUACIAT2

EVOLUTION

8

Water chillers

Heat pumps

Aquaciat LD - LDC - LDH 350V 400V 500V 540V 600V 700V

Net cooling capacity (1) kW 91,95 100,81 125,65 141,08 154,23 170,45

Net absorbed power kW 30,23 35,02 43,17 46,31 53,73 62,95

Net energy efficiency rating (EER) (2) 3,04 2,87 2,91 3,04 2,87 2,70

Seasonal energy efficiency rating (ESEER) Net LN 4,10 4,12 3,43 4,08 3,85 3,78

Seasonal energy efficiency rating (ESEER) Net HP 4,08 4,05 3,48 4,04 3,89 3,86

Lw/ Lp (3) (High Performance version - HP) dB(A) 87/55 88/56 88/56 88/56 89/57 89/57

Lw / Lp (3) (Low Noise version - LN) dB(A) 81/49 81/49 83/51 83/51 83/51 83/51

Compressor Hermetic SCROLL (2900 rpm)

Start-up mode Direct in line in series

Quantity 2 2 2 4 4 4

Power control % 100-57-43-0 100-63-37-0 100-50-0

100-78-72-55-50-

45-28-22-0

100-75-50-25-0

100-78-71-57-50-

43-28-21-0

Refrigerant oil type Polyol ester POE 3MAF (32 cst)

Oil capacity l 8,8 9,8 11,2 14,8 16,6 17,6

No. of refrigerating circuits 1 2

Refrigerant (GWP) R410A (GWP = 2088)

Refrigerant charge kg 22 22 12 +12,6 15,3 + 15,6 15,2 + 15,7 17 + 17,4

Tonne CO

2

Equivalent TCO

2

Eq 45,93 45,93 51,36 64,51 64,51 71,82

Power supply ph/Hz/V 3~50Hz 400V (+10%/-10%) + Earth

Machine protection rating IP 44

Control circuit voltage ph/Hz/V 1~50Hz 230V (+10%/-10%) - transformer fitted

Evaporator Brazed plate exchanger(s)

Water content l 6,4 7,5 9,3 9,3 10,6 11,8

Chilled water outlet temp. (min./max.) C -12 / +18

Minimum water flow rate m

3

/h 10,7 11,8 17,3 18,1 20,8 20,8

Maximum water flow rate m

3

/h 32,5 35,3 43,6 48,7 53,0 59,0

Water connections DN 80 flange DN80 flange

Max. pressure, water end bar 10 bar (LOD)/4 bar (LDC-LDH)

Air-cooled condenser Finned heat exchanger

Fan mm 800

Number x Motor output

High-performance (HP version)

no. x kW 2x1.7 2x1.7 2x1.7 2x1.6 2x1.6 2x1.6

Qty x Motor output

Low noise version - LN - XLN

no. x kW 2x1.1 2x1.1 2x1.1 2x1.1 2x1.1 2x1.1

High performance air flow- HP m

3

/h 37 600 37 600 40 000 41 500 41 500 41 500

Air flow, Low Noise - LN - XLN m

3

/h 29 000 29 000 31 000 33 200 33 200 33 200

Min water volume (ILD - ILDC) l 220 213 357 164 207 203

Tank volume, model H l 250

Expansion vessel, C & H l 18

Standard pump no. (4)

Height (excluding mounts) mm 2117 2117

Length (standard version) mm 2190 2740

Length (version C) mm 2190 2740

Length (version H) mm 2190 2740

Depth mm 2129 2129

Weight (empty, standard version) kg 1064 1163 1245 1530 1666 1732

Weight (empty, version C) kg 1162 1268 1315 1725 1845 1911

Weight (empty, version H) kg 1233 1332 1380 1790 1908 1974

Storage temperature C + 50C

(1) Capacities on HIGH PERFORMANCE version based on: Net conditions, COOLING: +12C/+7C and condenser air inlet temperature +35C

EN14511-2013 EUROVENT conditions

(2) Net value EER (excluding pump)

(3) Lw: Overall sound power level as per standard ISO3744

Lp: Overall pressure level measured at 10m in a free field, calculated using the formula Lp=Lw- 10 log S

(4) Based on selection

CHARACTERISTICS - COOLING ONLY

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

9 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

Aquaciat ILD - ILDC - ILDH 80V 90V 100V 120V 150V 180V 200V 240V 300V

Net cooling capacity (1) kW 20,06 22,72 27,21 30,26 40,22 46,77 53,16 61,50 75,29

Net absorbed power kW 7,03 8,17 9,29 10,83 13,27 15,52 18,64 21,09 27,90

Net energy efficiency rating (EER) (2) 2,85 2,77 2,92 2,79 3,02 3,01 2,85 2,91 2,69

Seasonal energy efficiency rating (ESEER) Net LN 3,16 3,03 3,17 2,95 3,11 4,09 3,93 3,83 3,66

Seasonal energy efficiency rating (ESEER) Net HP 3,20 3,10 3,30 3,13 3,38 4,07 4,05 3,75 3,70

Lw / Lp (3) (High Performance version - HP) dB(A) 75/43 77/45 78/46 79/47 84/52 87/55

Lw / Lp (3) (Low Noise version - LN) dB(A) 71/39 73/41 75/43 77/45 76/44 80/48 81/49

Net heating capacity (1) kW 20,84 23,38 28,30 31,85 41,69 48,74 55,25 64,12 81,75

Net absorbed power kW 7,14 8,08 9,80 10,95 13,89 15,74 18,25 21,32 26,65

COP/net COP performance 2,91 2,89 2,88 2,90 3,00 3,09 3,02 3,00 3,06

Compressor Hermetic SCROLL (2900 rpm)

Start-up mode Direct in line in series

Quantity 1 2

Power control % 100-0 100-50-0

Refrigerant oil type Polyol ester POE 3MAF (32 cst)

Oil capacity l 2,50 3,25 3,25 3,25 4,14 6,50 6,50 6,50 8,30

No. of refrigerating circuits 1

Refrigerant (GWP) R410A (GWP = 2088)

Refrigerant charge kg 5,2 5,2 6,4 7,1 9,7 12,5 12,7 13,1 13,1

Tonne CO

2

Equivalent TCO

2

Eq 10,85 10,85 13,36 14,82 20,25 26,1 26,51 27,35 27,35

Power supply ph/Hz/V 3~50Hz 400V (+10%/-10%) + Earth

Machine protection rating IP 44

Control circuit voltage ph/Hz/V 1~50Hz 230V (+10%/-10%) -transformer fitted

Evaporator Brazed plate exchanger(s)

Water content l 1,78 1,78 2,22 2,22 3,11 3,55 4,22 4,77 7,71

Chilled water outlet temp. (min./max.) C -10 / +18

Hot water outlet temp. (min./max.) C +30 / +50

Minimum water flow rate m

3

/h 2,9 2,9 3,6 3,6 5,1 5,8 6,9 7,8 10,4

Maximum water flow rate m

3

/h 6,7 7,4 9,0 10 13,1 15,4 17,6 20,4 24,5

Water connections Male G 1"1/4 Male G 1"1/2 Male G 2"

Max. pressure, water end bar 10 bar (ILD)/4 bar (ILDC-ILDH)

Air-cooled condenser Finned heat exchanger

Fan mm 800

Number x Motor output

High-performance (HP version)

no. x kW 1x0.5 1x0.5 1x0.9 1x0.9 1x0.9 1x0.9 1x0.9 1x1.7 1x1.7

Qty x Motor output Low noise version - LN no. x kW 1x0.35 1x0.35 1x0.46 1x0.46 1x0.46 1x0.46 1x0.46 1x1.2 1x1.2

Air flow, High Performance - HP m

3

/h 10800 10800 16700 16700 15500 16100 16100 24000 24000

Air flow, Low Noise - LN m

3

/h 8700 8700 10800 10800 9700 10800 10800 18000 18000

Min water volume (ILD - ILDC) l 114 130 155 173 229 131 149 173 209

Tank volume, model H l 100 150 200

Expansion vessel, C & H l 6 18

Standard pump no. 44 44 44 45 40 40 40 41

Height (excluding mounts) mm 1170 1393 1743

Length (standard version) mm 1995 1995 1995

Length (version C) mm 1995 1995 1995

Length (version H) mm 1995 1995 2676

Depth mm 1055 1055 1055

Weight (empty, standard version) kg 328 331 366 368 452 611 614 620 756

Weight (empty, version C) kg 346 349 384 386 470 648 651 656 789

Weight (empty, version H) kg 371 374 409 411 495 845 848 853 986

Storage temperature C + 50C

(1) HIGH PERFORMANCE version capacities based on: Net conditions,

a/ COOLING: +12C/+7C and condenser air inlet temperature +35C - EN14511-2013 EUROVENT conditions

b/ HEATING: hot water outlet +45C and outdoor air +7C DB 86%RH

(2) EER or COP in net values (excluding pump)

(3) Lw: Overall sound power level as per standard ISO3744

Lp: Overall pressure level measured at 10m in a free field, calculated using the formula Lp=Lw- 10 log S

TECHNICAL CHARACTERISTICS - REVERSIBLE HEAT PUMPS

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

AQUACIAT2

EVOLUTION

10

Water chillers

Heat pumps

Aquaciat ILD - ILDC - ILDH 350V 400V 500V 540V 600V 700V

Net cooling capacity (1) kW 92,41 104,77 127,51 139,23 154,68 162,42

Net absorbed power kW 31,78 35,61 44,98 46,76 53,11 60,21

Net energy efficiency rating (EER) (2) 2,90 2,94 2,83 2,97 2,91 2,69

Seasonal energy efficiency rating (ESEER) Net LN 3,71 3,77 3,15 3,99 3,91 3,69

Seasonal energy efficiency rating (ESEER) Net HP 3,56 3,70 3,16 3,83 3,81 3,50

Lw/ Lp (3) (High Performance version - HP) dB(A) 87/55 88/56 88/56 88/56 89/57 89/57

Lw / Lp (3) (Low Noise version - LN) dB(A) 81/49 81/49 83/51 83/51 83/51 83/51

Net heating capacity (1) kW 95,40 109,25 133,22 147,83 164,68 182,37

Net absorbed power kW 31,80 36,45 43,72 48,43 53,68 58,89

COP/net COP performance 2,99 2,99 3,04 3,05 3,06 3,15

Compressor Hermetic SCROLL (2900 rpm)

Start-up mode Direct in line in series

Quantity 2 2 2 4 4 4

Power control % 100-57-43-0 100-63-37-0 100-50-0

100-78-72-55-

50-45-28-22-0

100-75-50-25-0 100-78-50-22-0

Refrigerant oil type Polyol ester POE 3MAF (32 cst)

Oil capacity l 8,8 9,8 11,2 14,8 16,6 17,6

No. of refrigerating circuits 1 2

Refrigerant (GWP) R410A (GWP = 2088)

Refrigerant charge kg 21 24

14,0

+14.0

18,0

+18.0

18,2

+19.2

19,5

+19.5

Tonne CO

2

Equivalent TCO

2

Eq 43,84 50,11 58,46 75,16 78,09 81,43

Power supply ph/Hz/V 3~50Hz 400V (+10%/-10%) + Earth

Machine protection rating IP 44

Control circuit voltage ph/Hz/V 1~50Hz 230V (+10%/-10%) - transformer fitted

Evaporator Brazed plate exchanger(s)

Water content l 8,68 9,88 10,66 12,48 15,42 15,42

Chilled water outlet temp. (min./max.) C -10 / +18

Hot water outlet temp. (min./max.) C +30 / +50

Minimum water flow rate m

3

/h 11,7 13,3 17,3 18,1 20,8 20,8

Maximum water flow rate m

3

/h 30,7 34,6 41,9 45,9 50,7 50,7

Water connections DN 80 flange DN80 flange

Max. pressure, water end bar 10 bar (ILD)/4 bar (ILDC-ILDH)

Air-cooled condenser Finned heat exchanger

Fan mm 800

Number x Motor output

High-performance (HP version)

no. x kW 2x1.7 2x1.7 2x1.8 2x1.7 2x1.7 2x1.7

Qty x Motor output

Low noise version - LN

no. x kW 2x1.2 2x1.2 2x1.2 2x1.1 2x1.1 2x1.1

Air flow, High Performance - HP m

3

/h 44000 42000 41000 44000 44000 44000

Air flow, Low Noise - LN - XLN m

3

/h 32000 29000 30500 35000 35000 35000

Min water volume (ILD - ILDC) l 220 213 357 164 207 203

Tank volume, model H l 250

Expansion vessel, C & H l 18

Standard pump no. (4)

Height (excluding mounts) mm 2117 2117

Length (standard version) mm 2190 2740

Length (version C) mm 2190 2740

Length (version H) mm 2190 2740

Depth mm 2129 2129

Weight (empty, standard version) kg 1096 1195 1283 1570 1706 1878

Weight (empty, version C) kg 1194 1292 1355 1675 1804 1976

Weight (empty, version H) kg 1257 1356 1418 1748 1868 2040

Storage temperature C + 50C

(1) HIGH PERFORMANCE version capacities based on: Net conditions:

a/ COOLING: +12C/+7C and condenser air inlet temperature +35C

b/ HEATING: hot water outlet +45C and outdoor air +7C DB 86%RH

EN14511-2013 EUROVENT conditions

(2) EER or COP in net values (excluding pump)

(3) Lw: Overall sound power level as per standard ISO3744

Lp: Overall pressure level measured at 10m in a free field, calculated using the

formula Lp=Lw- 10 log S

(4) Based on selection

TECHNICAL CHARACTERISTICS - REVERSIBLE HEAT PUMPS

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

11 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

ELECTRICAL CHARACTERISTICS

n Basic unit (excluding pump)

80V 90V 100V 120V 150V 180V 200V 240V 300V 350V

Power supply ph/Hz/V 3~50Hz 400V (+10%/-10%) + Earth

Monitor circuit voltage ph/Hz/V 1~50Hz 230V (+10%/-10%) -transformer fitted

Starting current (excluding pump) A 95 111 118 137 174 129 139 160 205 256

Starting current, SOFT START option A 50 53 55 70 60 70 76 93 91 168

Breaking capacity (TN-TT neutral system) kA 15 10 15 10

Max. wire cross-section mm

2

10 35 70 95

MAX nominal current (1) A 19,8 22,3 25,8 27,8 35,7 40,0 47,0 52,0 68,0 83,1

400V 500V 540V 600V 700V

Power supply ph/Hz/V 3~50Hz 400V (+10%/-10%) + Earth

Monitor circuit voltage ph/Hz/V 1~50Hz 230V (+10%/-10%) -transformer fitted

Starting current (excluding pump) A 303 317 251 267 323

Starting current, SOFT START option A 195 208 137 153 235

Breaking capacity (TN-TT neutral system) kA 10 35 10

Max. wire cross-section mm

2

95

MAX nominal current (1) A 91,3 105,0 123,6 139,4 150,4

(1) pump current not included

n Hydraulic pumps (versions C and H)

SINGLE PUMP NO. 44 45 40 41 42 43 140 138 139 117 102 103 118 105 107 119

DUAL PUMP NO. - - 2 x

40

2 x

41

2 x

42

2 x 43 240 238 239 217 202 203 218 205 207 219

Max. curr. at

50Hz (A)

400V 1,7 1,91 1,91 2,36 3,15 5,2 3,2 3,2 4,6 4,4 5,8 7,7 7,7 10,2 13,7 13,7

Motor output 400V/

50Hz

66.4% 77.4% 79.0% 80.5% 82.0% 84.0% 81.3% 81.3% 83.2% 83.2% 84.6% 85.8% 85.8% 87.0% 88.1% 88.1%

Max. working P

(kW)

0,55 0,75 0,75 1,1 1,5 2,2 1,5 1,5 2,2 2,2 3 4 4 5,5 7,5 7,5

Max. abs. P (kW) 0,83 0,97 0,95 1,37 1,83 2,62 1,85 1,85 2,64 2,64 3,55 4,66 4,66 6,32 8,51 8,51

Min fow rate m

3

/h 1,0 1,9 5,0 6,0 7,0 8,0 4,2 4,0 6,1 15,0 20,0 20,0 15,0 20,0 20,0 15,0

MAX. pressure mWC 20,6 20,9 17,5 21,5 22,0 24,5 14,2 18,5 22,3 15,5 14,5 18,0 26,0 26,0 33,0 39,0

MAX. fow rate m

3

/h 8,0 13,0 19,0 22,5 30,0 30,0 30,0 28,0 32,0 55,0 80,0 86,0 60,0 80,0 80,0 60,0

MIN. pressure mWC 7,3 9,7 8,5 8,0 10,0 14,0 12,1 12,5 13,7 10,0 8,0 10,0 21,0 19,5 27,0 31,0

Protection

rating

IP55

Power supply V 3ph-50Hz 400V (+10%/-10%) + Earth

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

AQUACIAT2

EVOLUTION

54

Water chillers

Heat pumps

DIMENSIONS

AQUACIAT2 size 80 - 90

4 removable

lifting lugs

holes x 20.5

Wooden

handling blocks to be

removed when

installing

Outdoor air discharge

Outdoor air intake

5: G 1/2" M hot water inlet

6: G 1/2" M hot water outlet

1: G 1"1/4 M chilled water inlet

2: G 1"1/4 M chilled water outlet

E: Power supply x 80

Aquaciat 2

Position of mounts

Anti-vibration

mounts

Weight (kg)

A B C D empty in operation

LD

80

250 1284 250 P25 50 x 100

347 352

90 350 355

LDC

80 365 370

90 368 373

LDH

80

140 1114 490 P25 50 x 120

390 495

90 393 498

ILD

80

250 1284 250 P25 50 x 100

328 333

90 331 336

ILDC

80 346 351

90 349 354

ILDH

80

140 1114 490 P25 50 x 120

371 476

90 374 479

Leave a space of 1 metre around the unit for

maintenance

974 x 957 (int) connection sleeve (option)

Connection frame (option)

XTRAFAN OPTION

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

55 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

DIMENSIONS

AQUACIAT2 size 100 to 150

Outdoor air discharge

Outdoor air intake

5: G 1/2" M hot water inlet

6: G 1/2" M hot water outlet

1: G 1"1/2 M chilled water inlet

2: G 1"1/2 M chilled water outlet

E: Power supply x 80

4 removable

lifting lugs

holes x 20.5

Wooden handling

blocks to be removed

when installing

Leave a space of 1 metre around the unit for

maintenance

Aquaciat 2

Position of mounts

Anti-vibration

mounts

Weight (kg)

A B C D empty in operation

LD

100

250 1284 250 P25 50 x 100

365 370

120 367 372

150 240 1264 240 P25 50 x 120 449 454

LDC

100

250 1284 250 P25 50 x 100

383 388

120 385 390

150 240 1264 240 P25 50 x 120 467 472

LDH

100

125 1084 475 P25 50 x 150

407 562

120 409 564

150 492 647

ILD

100

250 1284 250 P25 50 x 100

366 371

120 368 373

150 240 1264 240 P25 50 x 120 452 457

ILDC

100

250 1284 250 P25 50 x 100

384 389

120 386 391

150 240 1264 240 P25 50 x 120 470 475

ILDH

100

125 1084 475 P25 50 x 150

409 564

120 411 566

150 495 650

974 x 957 (int) connection sleeve (option)

Connection frame (option)

XTRAFAN OPTION

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

AQUACIAT2

EVOLUTION

56

Water chillers

Heat pumps

DIMENSIONS

AQUACIAT 2 LD - LDC - ILD - ILDC size 180 to 300

Aquaciat 2

Position of mounts Anti-vibration mounts Weight (kg)

A B C D E empty in operation

LD

180

100

1260 328 P25 50 x 150

P25 50 x 150

569 575

200 575 579

240 581 585

300 1138

400 P25 50 x 200

711 717

LDC

180

1168 P25 50 x 120

616 621

200 619 623

240 625 629

300 1088 P25 50 x 200 756 760

ILD

180

150 1218 300

P25 50 x 200

P25 50 x 120

611 615

200 614 618

240 620 624

300

100

1088 400 P25 50 x 200 756 760

ILDC

180

1188 350 P25 50 x 150

648 652

200 651 655

240 656 660

300 1088 400 P25 50 x 200 789 793

Outdoor air discharge

Outdoor air intake

5: G1" M hot water inlet

6: G1" M hot water outlet

1: G 2" M chilled water inlet

2: G 2" M chilled water outlet

E: Power supply x 80

4 removable

lifting lugs

holes x 20.5

Wooden handling

blocks to be removed

when installing

Leave a space of 1 metre around

the unit for maintenance

974 x 957 (int) connection sleeve (option)

Connection frame (option)

XTRAFAN OPTION

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

57 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

DIMENSIONS

AQUACIAT 2 LDH - ILDH size 180 to 300

Aquaciat 2

Position of mounts Anti-vibration mounts Weight (kg)

A B C D E F G empty in operation

LDH 180

196 600 1156 196 P25 50 x 200 P25 50 x 200 P25 50 x 120

813 1017

ILDH 180 845 1049

LDH 200 816 1020

ILDH 200 848 1052

LDH 240 822 1026

ILDH 240 853 1057

LDH 300

196 600 1076 196 P25 50 x 200 P25 50 x 200 P25 50 x 200

953 1157

ILDH 300 986 1190

Outdoor air discharge

Outdoor air intake

4 removable

lifting lugs

holes x 20.5 Wooden handling

blocks to be removed

when installing

5: G1" M hot water inlet

6: G1" M hot water outlet

1: G 2" M chilled water inlet

2: G 2" M chilled water outlet

E: Power supply x 80

Leave a space of 1 metre around

the unit for maintenance

HM

HM =Hydraulic module supplied separately.

974 x 957 (int) connection sleeve (option)

Connection frame (option)

XTRAFAN OPTION

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

AQUACIAT2

EVOLUTION

58

Water chillers

Heat pumps

DIMENSIONS

AQUACIAT 2 size 350 to 500

385

330 330

663

500

350 - 400

1b

1b

9

0

3

2

7

8

Outdoor air discharge

Outdoor air intake

4 removable

lifting lugs

holes x 20.5

Wooden handling blocks to

be removed when installing

5: G1"1/2 M hot water inlet

6: G1"1/2 M hot water outlet

E: Power supply x 60

Leave a space of 1 metre around the

unit for maintenance

Aquaciat 2

Position of mounts Anti-vibration mounts Weight (kg)

A B C D Qty F G H empty in operation

LD 350

150 422,5 P25 50 x700 4 311

411

1064 1084

ILD 350 1096 1116

LD 400 1163 1183

ILD 400 1195 1215

LD 500 1245 1265

ILD 500 1283 1303

LDC 350 1162 1182

ILDC 350 1194 1224

LDC 400 1268 1298

ILDC 400 1292 1322

LDC 500 1315 1336

ILDC 500 1355 1385

LDH 350

150 422,5 742,25 P25 50 x700 6 549

1233 1503

ILDH 350 1257 1527

LDH 400 1332 1602

ILDH 400 1356 1626

LDH 500 1380 1650

ILDH 500 1418 1688

1a-1b: DN 80 chilled water inlet

2a -2b: DN 80 chilled water outlet

XTRAFAN OPTION

with connection sleeve

Position of hydraulic connections

Size K Pump Chilled water inlet Chilled water outlet

LD - ILD 1a 2a

LDC - ILDC 330

No.140-240-138-238-139-239

1b 2a

No.117-217-118-218-119-219

LDH - ILDH 330

No.140-240-138-238-139-239

1b 2b

No.117-217-118-218-119-219

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

59 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

DIMENSIONS

AQUACIAT 2 size 540 to - 700

423

385

1b

4

2

3

2

0

4

0

2

7

8

Outdoor air discharge

Outdoor air intake

5: G1"1/2 M hot water inlet

6: G1"1/2 M hot water outlet

E: Power supply x 60

Wooden handling blocks to

be removed when installing

4 removable

lifting lugs

holes x 20.5

Leave a space of 1 metre around the unit

for maintenance

Aquaciat 2

Position of mounts Anti-vibration mounts Weight (kg)

A B C D Qty F G H empty in operation

LD 540

150 422,5 1017,5 P25 50 x700 6

271

661

1530 1553

ILD 540 1570 1593

LD 600 1666 1691

ILD 600 1706 1731

LD 700 1732 1757

ILD 700 1878 1903

LDC 540

150 422,5 445 P25 50 x700 8

1725 1760

ILDC 540 1675 1710

LDC 600 1845 1880

ILDC 600 1804 1839

LDC 700 1911 1946

ILDC 700 1976 2011

LDH 540

550

1790 2070

ILDH 540 1748 2028

LDH 600 1908 2188

ILDH 600 1868 2148

LDH 700 1974 2254

ILDH 700 2040 2320

Size K Pump Chilled water inlet Chilled water outlet

LD - ILD 1a 2a

LDC - ILDC 330

No.140-240-138-238-139-239

1b 2a

No.117-217-118-218-119-219

LDH - ILDH 330

No.140-240-138-238-139-239

1b 2b

No.117-217-118-218-119-219

1a-1b: DN80 chilled water inlet

2a -2b: DN80 chilled water outlet

XTRAFAN OPTION

with connection sleeve

Position of hydraulic connections

A

Q

U

A

C

I

A

T

2

E

V

O

L

U

T

I

O

N

Water chillers

Heat pumps

66 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.590 A

This document is not legally binding. As part of our continuous drive to improve our products, CIAT reserves the right to make any technical modifications without prior notice.

Registered address

Avenue J ean Falconnier - B.P. 14

01350 - Culoz - France

Tel.: +33 (0)4 79 42 42 42

Fax: +33 (0)4 79 42 42 10

info@ciat.fr - www.ciat.com

Compagnie Industrielle dApplications Thermiques - S.A. with a registered capital of 26,728,480 - R.C.S. Bourg-en-Bresse B 545 620 114

CIAT Service

Tel.: 08 11 65 98 98 (0.15 /min)

Fax: 08 26 10 13 63 (0.15 /min)

Potrebbero piacerti anche

- Na14590a - Aquaciat 2Documento16 pagineNa14590a - Aquaciat 2Toader MihaelaNessuna valutazione finora

- Data Book - i-KIR-MTD 0075 - 0151Documento57 pagineData Book - i-KIR-MTD 0075 - 0151mahroof mkuttyNessuna valutazione finora

- Clint Cha k726p 36012p Brochure 0325 enDocumento2 pagineClint Cha k726p 36012p Brochure 0325 enDorin100% (1)

- Edm Aq410 2 S.1GB02.12 40-75Documento52 pagineEdm Aq410 2 S.1GB02.12 40-75Advokat HadziTonicNessuna valutazione finora

- NA592 - Powerciat LX R134aDocumento57 pagineNA592 - Powerciat LX R134apaldopalNessuna valutazione finora

- CSRH.c-y Water Cooled Chiller - R134aDocumento12 pagineCSRH.c-y Water Cooled Chiller - R134antt_121987Nessuna valutazione finora

- Ycsa 50 60 80 100Documento48 pagineYcsa 50 60 80 100george1582100% (1)

- Air Cooled Scroll Chillers 30RBMDocumento7 pagineAir Cooled Scroll Chillers 30RBMAhmadNessuna valutazione finora

- 30RB 039-160/30RQ 039-160: Air-Cooled Liquid Chillers Reversible Air-to-Water Heat PumpsDocumento28 pagine30RB 039-160/30RQ 039-160: Air-Cooled Liquid Chillers Reversible Air-to-Water Heat Pumpsdimkost2Nessuna valutazione finora

- Water Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35Documento28 pagineWater Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35jeromeduytscheNessuna valutazione finora

- Technical YCSA 120-150Documento22 pagineTechnical YCSA 120-150nairam2003Nessuna valutazione finora

- High DensityDocumento20 pagineHigh DensityAnzad AzeezNessuna valutazione finora

- 30RB039-160 PSDDocumento16 pagine30RB039-160 PSDrudagochav3096Nessuna valutazione finora

- 30RW/30RWA: Water-Cooled/Condenserless Liquid Chillers With Integrated Hydronic ModuleDocumento20 pagine30RW/30RWA: Water-Cooled/Condenserless Liquid Chillers With Integrated Hydronic ModuleKossu69Nessuna valutazione finora

- Technical Brochures AW HT 0031 0071 enDocumento50 pagineTechnical Brochures AW HT 0031 0071 endouslasNessuna valutazione finora

- Technical YLCSDocumento34 pagineTechnical YLCSnairam2003Nessuna valutazione finora

- Air-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnapDocumento12 pagineAir-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnappuertoparaisoNessuna valutazione finora

- Air To Water Heat Pumps 30RH040 240Documento16 pagineAir To Water Heat Pumps 30RH040 240konstantinosNessuna valutazione finora

- Liquid30RW 30RWADocumento20 pagineLiquid30RW 30RWAkonstantinosNessuna valutazione finora

- 08 - Florida Heat Pumps WPDocumento13 pagine08 - Florida Heat Pumps WPpablofr_92Nessuna valutazione finora

- Anexo 9 - 30RQ182Documento20 pagineAnexo 9 - 30RQ182melodyNessuna valutazione finora

- Technical YLAEDocumento16 pagineTechnical YLAEnairam2003Nessuna valutazione finora

- RDG RDF Room Thermostats A6V10254838 HQ enDocumento32 pagineRDG RDF Room Thermostats A6V10254838 HQ endimlou1Nessuna valutazione finora

- FHP Apseries WSHPDocumento16 pagineFHP Apseries WSHPsajuhereNessuna valutazione finora

- 1.0 Chiller UnitDocumento12 pagine1.0 Chiller UnitfebousNessuna valutazione finora

- Yccd Chillers 46 152 KWDocumento26 pagineYccd Chillers 46 152 KWPaul PaulistaNessuna valutazione finora

- Millennium: R134A Refrigerant Cooling Capacities 336 KW To 1090 KWDocumento26 pagineMillennium: R134A Refrigerant Cooling Capacities 336 KW To 1090 KWttt449Nessuna valutazione finora

- Wespwer Alp 09Documento16 pagineWespwer Alp 09JIMMYNessuna valutazione finora

- TM sls407 W 3gbDocumento52 pagineTM sls407 W 3gbJasenko Nino GrboNessuna valutazione finora

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDocumento8 pagine30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersvickersNessuna valutazione finora

- Technical YCSA 50-100Documento28 pagineTechnical YCSA 50-100nairam2003Nessuna valutazione finora

- Lennox MS8H Mini Split Heat Pump SpecsDocumento16 pagineLennox MS8H Mini Split Heat Pump SpecsMeselao Meselao MeselaoNessuna valutazione finora

- PressedDocumento18 paginePressedahmedalgaloNessuna valutazione finora

- TP3 Toplotna PumpaDocumento24 pagineTP3 Toplotna PumpaDavid BlagojevicNessuna valutazione finora

- Energy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134aDocumento30 pagineEnergy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134atechnokakiNessuna valutazione finora

- LCA LGA LHA 088 & 100 Eng Product Cat.Documento22 pagineLCA LGA LHA 088 & 100 Eng Product Cat.JakeHabingNessuna valutazione finora

- Bollettini Tecnici NECS-N 1314 3218 GBDocumento67 pagineBollettini Tecnici NECS-N 1314 3218 GBHector TosarNessuna valutazione finora

- Ruud UMPC Series ManualDocumento8 pagineRuud UMPC Series ManualisothermNessuna valutazione finora

- 30XA China CatalogDocumento24 pagine30XA China CatalogagbekasNessuna valutazione finora

- Chiller Selection Building A+j Cooling Only Rev 2Documento7 pagineChiller Selection Building A+j Cooling Only Rev 2Anton WelgemoedNessuna valutazione finora

- TM HRW W 2GBDocumento36 pagineTM HRW W 2GBQYTREWPOIUDNessuna valutazione finora

- VRVII Cooling Only Specification SMC 1-8-03Documento7 pagineVRVII Cooling Only Specification SMC 1-8-03mohamed mansyNessuna valutazione finora

- Compu Mate Brochure v2Documento11 pagineCompu Mate Brochure v2pabloabelgilsotoNessuna valutazione finora

- AG HA Eng PDFDocumento20 pagineAG HA Eng PDFΓεώργιος ΠαπαδόπουλοςNessuna valutazione finora

- Multipower Cha K 726-P÷36012-P CLB 41.7Documento40 pagineMultipower Cha K 726-P÷36012-P CLB 41.7Xavi Tendre100% (1)

- Application Note: Improving FAN Control On Cooling TowersDocumento4 pagineApplication Note: Improving FAN Control On Cooling TowersMarcelo LeiteNessuna valutazione finora

- Quotation Cold Room An NAM Group - 17 Aug 2010Documento12 pagineQuotation Cold Room An NAM Group - 17 Aug 2010huyly34Nessuna valutazione finora

- Water ChillerDocumento32 pagineWater ChillerPaing Phyo Ko78% (9)

- Fandrivesystem W SeriesDocumento3 pagineFandrivesystem W Seriesado_22Nessuna valutazione finora

- Carrier 30RBDocumento25 pagineCarrier 30RBHamo HamoNessuna valutazione finora

- PSD 61af 022 105 - enDocumento23 paginePSD 61af 022 105 - enDavid BlagojevicNessuna valutazione finora

- Blue Box Zeta2002 Manual4Documento14 pagineBlue Box Zeta2002 Manual4Carlos MartinezNessuna valutazione finora

- 30GXDocumento12 pagine30GXAdolfo Riquelme Novoa0% (1)

- VRVII Cooling Only Specification SMC 1-8-03 - TestDocumento7 pagineVRVII Cooling Only Specification SMC 1-8-03 - TestAlexOdarteyBannermanNessuna valutazione finora

- SSCDW-1112 R134a Water Cooled Screw Chiller SSCX (55-300RT) (Rev2 230413)Documento12 pagineSSCDW-1112 R134a Water Cooled Screw Chiller SSCX (55-300RT) (Rev2 230413)Naing Oo KyawNessuna valutazione finora

- 61af - 022 - 105 - P DataDocumento16 pagine61af - 022 - 105 - P DatasarcitoNessuna valutazione finora

- Air Blue UFC ChillerDocumento130 pagineAir Blue UFC ChillerAashanram SayeeramNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDa EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Analog Circuit Design Volume Three: Design Note CollectionDa EverandAnalog Circuit Design Volume Three: Design Note CollectionValutazione: 3 su 5 stelle3/5 (2)

- 600VPR-1 Voltage Protection Relay: FeaturesDocumento1 pagina600VPR-1 Voltage Protection Relay: FeaturesduiechNessuna valutazione finora

- Thongbao: Ngan Hang TMCP Cong Thijong CQNG Hoa Xa Iiqi Chu Nghia Vidt Nam Phong Quan TriDocumento2 pagineThongbao: Ngan Hang TMCP Cong Thijong CQNG Hoa Xa Iiqi Chu Nghia Vidt Nam Phong Quan TriduiechNessuna valutazione finora

- Facility Maintenance SupervisorDocumento3 pagineFacility Maintenance SupervisorduiechNessuna valutazione finora

- Itq0100 W Onoff 1phaseDocumento1 paginaItq0100 W Onoff 1phaseduiechNessuna valutazione finora

- Vav Terminal Units Ceiling DiffusersDocumento7 pagineVav Terminal Units Ceiling Diffusersckyee88Nessuna valutazione finora

- Boiler Efficiency FactsDocumento21 pagineBoiler Efficiency FactschikukotwalNessuna valutazione finora

- Diagram Booster PumpDocumento1 paginaDiagram Booster PumpduiechNessuna valutazione finora

- ZR57KC TFDDocumento1 paginaZR57KC TFDduiechNessuna valutazione finora

- Coolfreeze Time CalculatationDocumento21 pagineCoolfreeze Time CalculatationduiechNessuna valutazione finora

- Fifa Head Office 1-21 Crawford Streeet, Suit 287, London United Kingdom W1H 1PjDocumento1 paginaFifa Head Office 1-21 Crawford Streeet, Suit 287, London United Kingdom W1H 1PjduiechNessuna valutazione finora

- ZR61KS TFDDocumento1 paginaZR61KS TFDduiechNessuna valutazione finora

- LS 826+sustainability in Closed Loop Chilled Water Systems IDEA PDFDocumento12 pagineLS 826+sustainability in Closed Loop Chilled Water Systems IDEA PDFWirote DewilaiNessuna valutazione finora

- MACHINHANHDocumento4 pagineMACHINHANHduiechNessuna valutazione finora

- Hå S Quyõt To N: C NG Ty Cæ PHÇN Néi Thêt Ho PH TDocumento37 pagineHå S Quyõt To N: C NG Ty Cæ PHÇN Néi Thêt Ho PH TduiechNessuna valutazione finora

- Setup LogDocumento7 pagineSetup LogAgung SuryaNessuna valutazione finora

- Let's Go To PartyDocumento1 paginaLet's Go To PartyduiechNessuna valutazione finora

- New WordsDocumento2 pagineNew WordsduiechNessuna valutazione finora

- EulaDocumento10 pagineEulaWisnu SudarmadiNessuna valutazione finora

- 694 Pressure Sensor HubaDocumento5 pagine694 Pressure Sensor HubaduiechNessuna valutazione finora

- Segment 2Documento1 paginaSegment 2Mihaela456Nessuna valutazione finora

- OEWABLogDocumento4 pagineOEWABLogduiechNessuna valutazione finora

- Condensing Unit 1068155Documento36 pagineCondensing Unit 1068155duiechNessuna valutazione finora

- RD W L1e Gt02aDocumento2 pagineRD W L1e Gt02aPhạm ĐạtNessuna valutazione finora

- Ar CarrosDocumento82 pagineAr Carroskeila_aline_2Nessuna valutazione finora

- Refference Appendeccies For 2016 Building Energy Efficiency StandardsDocumento503 pagineRefference Appendeccies For 2016 Building Energy Efficiency StandardsCvijetinTodorovicNessuna valutazione finora

- Dimplex PHB Kuehlen GB 122008 PDFDocumento101 pagineDimplex PHB Kuehlen GB 122008 PDFDaniel MilosevskiNessuna valutazione finora

- Contractor 1Documento2 pagineContractor 1lhhjklll100% (2)

- WP45L BA1 ET1 en 1104Documento158 pagineWP45L BA1 ET1 en 1104ggpp1175% (4)

- Bachelor of Engineering Technology (Energy and Environmental)Documento49 pagineBachelor of Engineering Technology (Energy and Environmental)Angle Judie100% (1)

- Whirlpool User Instructions (EnFr) - W10597594Documento44 pagineWhirlpool User Instructions (EnFr) - W10597594tomj0001Nessuna valutazione finora

- PSC-A32MN User ManualDocumento56 paginePSC-A32MN User Manualnaveed khanNessuna valutazione finora

- WWW - Bis.gov - In: Products Indian Standards For Preparation of DocumentsDocumento22 pagineWWW - Bis.gov - In: Products Indian Standards For Preparation of DocumentsC. M. JebinNessuna valutazione finora

- Manual de Bombas GrundfosDocumento144 pagineManual de Bombas Grundfosgri32Nessuna valutazione finora

- AES - GIZ Magnum Cafe Energy Audit 20150304Documento18 pagineAES - GIZ Magnum Cafe Energy Audit 20150304Andre SNessuna valutazione finora

- CM61 Installation Guide PDFDocumento2 pagineCM61 Installation Guide PDFjosep sampolNessuna valutazione finora

- Final Blue Star ProjectDocumento46 pagineFinal Blue Star ProjectVikas Thakran67% (6)

- GB-X18JR GU-X18JR GB-X24JR GU-X24JR GB-X36JR GU-X36JR: Indoor Unit Outdoor UnitDocumento80 pagineGB-X18JR GU-X18JR GB-X24JR GU-X24JR GB-X36JR GU-X36JR: Indoor Unit Outdoor UnitMohamed SaadAllahNessuna valutazione finora

- Compressor Installation InstructionsDocumento2 pagineCompressor Installation Instructionsrobbin3024803Nessuna valutazione finora

- Project Ideas PDDocumento56 pagineProject Ideas PDrobiromasNessuna valutazione finora

- Aermec GR 3 User Manual EngDocumento76 pagineAermec GR 3 User Manual EngSoufien AtouiNessuna valutazione finora

- Edmt281930 PDFDocumento312 pagineEdmt281930 PDFThuan TaNessuna valutazione finora

- Chapter 3-2Documento48 pagineChapter 3-2AHMEDNessuna valutazione finora

- DCS601C51 - ITC - Operation Manuals - EnglishDocumento86 pagineDCS601C51 - ITC - Operation Manuals - EnglishAutomatika ATHNessuna valutazione finora

- KeepRite 8P BrocherDocumento8 pagineKeepRite 8P BrochergoodtiNessuna valutazione finora

- Operational Manual (Screw Air Compressor)Documento33 pagineOperational Manual (Screw Air Compressor)purchase sigmaairsource100% (1)

- Ac Daikin VRV Iv SDocumento15 pagineAc Daikin VRV Iv SSolihin PandawaNessuna valutazione finora

- Full N Final-Compressed - Compressed (1) (1) - Reduce PDFDocumento100 pagineFull N Final-Compressed - Compressed (1) (1) - Reduce PDFMateeNessuna valutazione finora

- Principles of Air ConditioningDocumento23 paginePrinciples of Air ConditioningGeorgios Roumpies100% (2)

- Chalmers Report EABS ModelDocumento52 pagineChalmers Report EABS ModelArtur BauerNessuna valutazione finora

- Rar 6 N 2Documento282 pagineRar 6 N 2ChrisNessuna valutazione finora

- SE7000 Series Product Comparison Guide PDFDocumento32 pagineSE7000 Series Product Comparison Guide PDFEdgar GomezNessuna valutazione finora