Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Boq

Caricato da

Pradeep Yallanki100%(1)Il 100% ha trovato utile questo documento (1 voto)

397 visualizzazioni18 pagineThis document provides specifications for equipment related to a 8 MW turbine generator set. It includes 17 sections listing details of the turbine, generator, lubricating oil system, cooling water system, deaerator, condensate extraction pump, and other ancillary equipment. Section 32 lists the weights of the major components including the turbine (29 tons), generator (14.2 tons), and exciter (1.5 tons). Section 33 provides specifications for the 10000 KVA, 6600 V generator including phase, speed, cooling type and other details.

Descrizione originale:

Turbine boq

Copyright

© © All Rights Reserved

Formati disponibili

XLSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document provides specifications for equipment related to a 8 MW turbine generator set. It includes 17 sections listing details of the turbine, generator, lubricating oil system, cooling water system, deaerator, condensate extraction pump, and other ancillary equipment. Section 32 lists the weights of the major components including the turbine (29 tons), generator (14.2 tons), and exciter (1.5 tons). Section 33 provides specifications for the 10000 KVA, 6600 V generator including phase, speed, cooling type and other details.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

397 visualizzazioni18 pagineBoq

Caricato da

Pradeep YallankiThis document provides specifications for equipment related to a 8 MW turbine generator set. It includes 17 sections listing details of the turbine, generator, lubricating oil system, cooling water system, deaerator, condensate extraction pump, and other ancillary equipment. Section 32 lists the weights of the major components including the turbine (29 tons), generator (14.2 tons), and exciter (1.5 tons). Section 33 provides specifications for the 10000 KVA, 6600 V generator including phase, speed, cooling type and other details.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 18

S.

no Equipment Unit Ratings

De coupling &

Dismantling

15 Days 3 Gangs oil system Type of Transportation - Assembled/Disassembled

1.1 NCR Rating(KW) KW 3500

Packing &

Shifting

10 Days 3 gangs Auxillary Eq-15 Days Tools & Material for packing

1.2 MCR Rating (KW) KW 7300 inspection for healthieness of Equipment

1.3 Main steam pressure ATA 70

1.4 Main steam temp (Deg C) 500

1.5 Main steam flow Kg/Hr 31000

1.6 Exhaust Pressure ATA 0.1

1.7 Turbine Cycle Heat Rate Kcal/kwh

1.8 Normal speed (RPM) 7545

1.90 Trip speed (RPM) (RPM) 8300 / 8676

1.10 No. of bleeds Nos 1 at 6.0 ata

1.11 Type Condensing

2

2.1 Make TEIL Mysore

2.2 Type Double Helical

2.3 Model N 2219C

2.4 Speed / Input RPM 7545 - 1500

3

3.1 Lubricating oil ISO-VG-46

3.2 Oil Reservior Capacity LTR 3500

3.3 1st Fill Oil Requirement LTR 5000

3.4 Flushing Oil Requirement LTR 4000

3.5 Lube Oil Pressure Range Kg/cm

2

1.8 - 2

3.6 Control Oil pressure Kg/cm

2

4.5 - 5.5

4

4.1 Manufacturer David Brown UK

4.2 Type Geared

4.3 Model M30H-1FL-AM,4,5" FW

4.4 Capacity IGPM 120

4.5 Driver Gear Box

5

5.1 Manufacturer Rotodel

5.2 Model RDN X -300 RHS

5.3 Type Geared

5.4 Capacity IGPM 120

5.5 Speed RPM 1440

5.6 Motor HP 15 - 415 V AC Supply

6

6.1 Manufacturer Rotodel

6.2 Model RDN X -125L

6.3 Type Geared

6.4 Capacity IGPM 15

6.5 Motor HP 2 -110V DC Supply

7 Plate Heat Exchanger

7.1 Make Alfa - Laval (India) Ltd.

7.2 Model M10-BFM (2822577)

7.3 Type Plate Type

7.4 Capacity IGPM 120

7.5 Oil Temperature Inlet Deg C 60

7.6 Oil Temperature Outlet Deg C 45

7.7 No. Of Plates 73

7.8 Surface Area M

2

17

7.9 Cooling Water Temp. Inlet Deg C 35

7.10 Cooling Water Temp. Outlet Deg C 40

7.11 Cooling Water Flow M

3

/Hr 42

7.12 Qunatity Nos 2

8

8.1 Manufacturer

Industrial Enterprises (IEH -

1405)

8.2 Type Duplex

8.3 Capacity IGPM 120

8.4 Grade of Filteration Microns Oct-15

8.5 Elements No. BT0160041

8.6 Quantity Nos 2

9

9.1 Manufacturer

Industrial Enterprises (IEH -

1435)

9.2 Model Simplex

9.3 Capacity IGPM 8

9.4 Grade of Filteration Microns 15

9.5 Elements No. BT0160042

9.6 Qunatity Nos 1

10

10.1 Manufacturer

Industrial Enterprises (IEH -

1427)

10.2 Model Simplex

10.3 Capacity IGPM 15

10.4 Grade of Filteration Microns 15

10.5 Elements No. BT0160049

10.6 Quantity Nos 1

11 Pressure Relief Valve (MOP) IMO190005

11.1 Make Hopkinsons, U.K.

11.2 Duty Oil - MOP

11.3 Size Inlet / Outlet 1" NB

Oil Cooler

OIL Filter (Lubricating Oil)

Control Oil Filter

EOP Filter

GEAR BOX

OIL System

Main Oil Pump

A.C. Auxiliary Oil Pump

Emergency Oil Pump (DC)

BOQ Of 1x8 MW TG SET

1

Make

TURBINE

11.4 Set Pressure Kg/cm

2

6.05

11.5 Discharge Capacity IGPM 25

12 Pressure Relief Valve (AOP) VL0100032

12.1 Make Nirmal Industries

12.2 Duty Oil - AOP

12.3 Size Inlet / Outlet 40 X 50 NB-ANSI 150# RF

12.4 Set Pressure Kg/cm

2

5.9

12.5 Discharge Capacity IGPM 120

13

Pressure Relief Valve (Lube

Oil)

IMO190007

13.1 Make Hopkinsons, U.K.

13.2 Duty Lube Oil

13.3 Size Inlet / Outlet 1" NB

13.4 Set Pressure Kg/cm

2

1.8

13.5 Discharge Capacity IGPM 25

14

14.1 Manufacturer Fawcet - India

14.2 Model 2000A-00-201

14.3 Pre Changed Pr. Kg/cm

2

3.9

14.4 Capacity Ltrs 20

15

15.1 Make ASCO

15.2 Volts 110 DC

15.3 Connection 3/4" NPT (F)

15.4 Action De Energise to Trip

16

16.1 Throttle Valve Lift No. 1 mm 32.50

16.2 Throttle Valve Lift No. 2 mm 19.50

16.3 Throttle Valve Lift No. 3 mm 5.00

16.4 Throttle Lift (Available) mm 57.00

16.5 Pass Out Valve lift mm 30.50

17

17.1 Manufacturer

Euroflex Transimission (I) Pvt

Ltd.

17.2 Model 8 GBH-260S (Without S Pin)

17.3 Drawing No. 02126-00

18

18.1 Manufacturer

Euroflex Transimission (I) Pvt

Ltd.

18.2 Model 10GBH-300S (With S Pin)

18.3 Drawing No. 04245-00

19

19.1 Type Woodward

19.2 Model 505 E - Digital

20

20.1 Manufacturer Woodward

20.2 Type TG 13E

20.3 Operating Speed RPM 1004

21

21.1 Manufacturer Woodward

21.2 Type TG 13E

21.3 Operating Speed RPM 1440

21.4 Motor HP 0.5 -415 V AC Supply

22

22.1 Make Mazda Ltd

22.2 Type Surface, Fixed Tube Type

22.3 Number of Pass Two

22.4 Water Box Type Divided

22.5 Steam Flow Kg/Hr 31000

22.6 Steam Pressure ATA 0.095

22.7 Cleanliness Factor 0.85

22.8 Cooling Water Temp. Inlet Deg C 33

22.9 Cooling Water Temp. Outlet Deg C 41

22.10 Cooling Water Pressure Kg/cm

2

2.5

22.11 Cooling Water Quantity M

3

/Hr 2081

22.12 CW Inlet / Outlet Sizes NB 18" NB X2

22.13 Weight (Working) Kgs 40535

22.14 No. Of Tubes 2468-SS 304

3/4

" X BWG - 20

22.15 Surface Area M

2

1078

23

23.1 Manufacturer Mazda Ltd

23.2 Capacity Kg/Hr 33.7 W.V. + 15.3 Air

23.3 Motive Steam pressure Kg/cm

2

5

23.4 Steam Temperature Deg C 215

23.5 Steam Consumption Kg/Hr 875

23.6 Evacuation Time minutes 20

24

24.1 Manufacturer Mazda Ltd

24.2 Capacity Kg/Hr 33.7 W.V. + 15.3 Air

24.3 Motive Steam pressure Kg/cm

2

5

24.4 Motive Steam temperature Deg C 215

24.5 Steam Consumption Kg/Hr 320

25

25.1 Manufacturer

Eskay Heat Transfers Pvt Ltd

EI/GC 3111

25.2 Type Horizontal Shell and Tube

25.3 Steam Flow Kg/Hr 350

25.4 Condensate Flow Kg/Hr 31000

25.5

Condensate Temperature Inlet /

Outlet

Deg C 53.95 / 61.6

Gland Vent Condensor

Actuator (HP)

Actuator (LP)

Condensor

Ejector (Startup)

Ejector System

Solenoid Valve

Throttle Valve Lift

High Speed Coupling

Low Speed Coupling

Governor

Accumulator

25.6 Condensate Pressure Kg/cm

2

8

25.7 Surface Area M

2

9.7

26

26.1 Manufacturer Nadi Airtechnics

26.2 Capacity CFM 650 Air at 2" WC

26.3 Model SAW-21-ACW-11 ARRT-4

26.4 Motor HP 0.5 - 415 V AC Supply

27

27.1 Manufacturer KSB Pumps Ltd

27.2 Type Horizontal

27.3 Model CPKGCM-50-250

27.4 Speed RPM 2945

27.5 Motor HP 29.5 - 415 V AC Supply

28

28.1 Type Motorised

28.2 Barring speed (rpm) rpm 150

29

29.1 Capacity L 1000

29.2 Material SS

30 Alfa - Laval (India) Ltd.

30.1 Type Centrifuge

30.2 Max Density of feed Kg/m

3

1100

30.3 Centrifuge/ pump rating (KW) KW 0.75

30.5 Heater rating (KW)

31

31.1 Nos 1

32

32.1

Complete assembled turbine

Including Gear Box, Baseplate

Including Oil

MT 29

32.2 Max Lifting Weight MT 23.3

32.3 Turbine rotor MT

32.4 Generator Stator MT 14.2

32.5 Generator Rotor MT 6.9

32.6 Generator Bearings MT 2.2

32.7 Exciter MT 1.5

32.8 Foundation frame and bolts MT

32.9 Closed circuit Air Cooling MT 3.5

32.10

Maximum Transport weight for

Gen

MT 28.3

33

33.1 Type TC 145

33.2 Output KVA 10000

33.3 Standard IS 4722

33.4 Year Of Manufacturing 2009

33.5 Phase 3

33.6 No Of poles 4

33.7 Voltage V 6600

33.8 Current A 875

33.9 Exciter Voltage (DC) V 130

33.10 Exciter Current (DC) A 586

33.11 Power Factor 0.8

33.12 Speed RPM 1500

33.13 Limiting Speed RPM 1800

33.14 Connection Star

33.15 Type Of cooling Water Cooled

33.16 Colling Water Temp Deg C 33

34

34.1 Type Brushless Excitation System

34.2 Output (DC) KW 110

34.3 Voltage (DC) V 156

34.5 Current (DC) A 703

34.6 Excitation Voltage (DC) V 142

34.7 Excitation Current (DC) A 10.2

34.8 Enclosure Sustem IP 54

34.9 Cooling System IC 31

34.10 Class of Insulation F

34.11 Standard IS 4722

35

35.1 Make Kirloskar

35.2 Discharge M3/Hr 1600

35.3 Head M 50

35.4 Prime Mover Rating KW / HP 290

35.5 Volts V 6600

35.6 Amps A 32

35.7 Quantity Nos 4

36

36.1 Make Alstom

36.2 Voltage V 41.5

36.3 Frequency Hz 50

36.4 Power KW 5.5

36.5 HP HP 75

36.6 Current A 96

36.7 Speed RPM 1470

36.8 Quantity NOS 4

37

37.1 Capacity M3/Hr 10

37.2 Multi Grade Filter Nos 1

37.3 Iron Removal Filter Nos 1

37.4 De Gasser Nos 1

37.5 Strong Base Anion Nos 1

37.6 Mixed Bed Nos 1

Cooling Water Pumps

Cooling Tower Fans

DM Water System +RO System

OIL PURIFIER

OIL Vapour Extraction Fan

WEIGHTS (TONS)

GENERATOR

Exciter

GVC Blower

Condensate Extraction Pump

Turning Gear

OVERHEAD OIL TANK

37.7 Strong Acid Cation Nos 1

37.8 Caustic Tanks Nos 2

37.9 HCl Tanks Nos 1

37.10 Make Up Pumps Nos 2

38

38.1 Make HEBENKRAFT

38.2 Capacity T 15

39

39.1 Design Max Allowable pressure Kg/cm2 3

39.2 Design Temperature Deg C 200

39.3 Hydraulic Test pressure Kg/cm2 4.5

39.4 Deareation Capacity m3/hr 39

39.5 Storage Capacity m3 15

40

40.1 Make KSB

40.2 Type Multistage Centrifugal

40.3 Head M 940 mtr

40.4 Rated Flow Cumtr/h 44 Cumtr/hr

40.5 Motor KW 200 KW

40.6 rpm RPM 3000

BFP

EOT Crane

Deaerator

Remarks

S.No. ITEMS QTY. UNIT

A UPS System

a.1 Main UPS (redundent 2x20 KVA) 2 nos

a.2 Redundent Battery Bank nos

a.3 Electronic Earthing for PLC nos

a.4 Electronic Earthing pit & pit material sets

B Main Plant PLC system

b.1 PLC system for TG control Panel 1 Sets

b.2 TSI Panel 1 no

b.3 Operator station 1 nos

b.4 Printers 1 nos

b.5 Ethernet Switch 1 no

b.6 PLC Controller & accessories 1 lot

C Cables & Trays

c.1 3C x 2.5sq.mm 1500 Mtrs

c.2 5C x 2.5sq.mm 800 Mtrs

c.3 12C x 1.5sq.mm 850 Mtrs

c.4 1P x 1 sq.mm 100 Mtrs

c.5 1P x 1 sq.mm (Screen) 200 Mtrs

c.6 8P x 0.75 sq.mm 100 Mtrs

c.7 8P x 0.75 sq.mm (Screen) 260 Mtrs

c.8 1T x 1.0 sq.mm 50 Mtrs

c.9 2 x 1T x 1.0 sq.mm 60 Mtrs

c.10 8T x 0.75 sq.mm 250 Mtrs

c.11 Earthing cable for DCS Mtrs

c.12 Compensating Cable 200 Mtrs

c.13 UTP cable Mtrs

c.14 Cable Tray (600MM,300MM,150MM & 100MM) Mtrs

c.15 Cable glands Lot

D Field Instruments

d.1 Temp. Gauges 25 nos

d.2 Pr. Gauges 40 nos

d.3 Temp. Switches 3 nos

d.4 Pr. Switches 21 nos

d.5 Level Switches 8 nos

d.6 Over speed switch 1 nos

d.7 Vibration switch 2 nos

d.8 Axial movement switch 2 nos

d.9 Temp. Transmitters 7 nos

d.10 Pr. Transmitters 13 nos

C&I BILL OF MATERIAL FOR 8MW PLANT

d.11 Flow Transmitters 6 nos

d.12 Level Transmitters 1 no

d.13 Vibration Transmitters 8 nos

d.14 Speed Transmitter 1 no

d.15 Axial Displacement transmitter 2 nos

d.16 TE & RTDs 26 nos

d.17 Control valves 9 nos

d.18 SOVs 9 nos

d.19 I/P convertors 9 nos

d.20 Air Filter Regulator(AFR) 9 nos

d.21 Junction Boxes nos

F INSTRUMENTS FITTINGS (pneumetic, Brass & CS)

f.1 Copper Tube Lot

f.2 Copper fittings Lot

f.3 SS tubing Lot

f.4 SS fittings Lot

f.5 Implus tube & fittings Lot

f.6 Special adopters Lot

f.7 Special fittings Lot

f.8 Other erection materials Lot

Transferable - Available at Barbil, to be shifted

STATUS

Transferable

Transferable

Needs Procurement

Needs Procurement

1. With redundant processor

2. Satisfactory working & transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

C&I BILL OF MATERIAL FOR 8MW PLANT

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

Transferable

1.Needs Procurement if damage after dismentaling

SL NO NAME OF EQUIPMENT Remarks QTY Make

ELECTRICAL EQUIPMENTS: SPECIFICATION/Rating

1

8MW, 6.6 KV 1500 RPM synchronous

generator with brush less exciter

8 MW,6.6 KV,1500 rpm,875

A.

1 TDPS

2

Panels and other associated Electrical

Item

AVR Panel Digital 1A + 1 M (Basler) 1 SANELEC

Relay Panel 1 AREVA

Metering Cum Synchronising Panel 1 VEE VEE

Battery 100 AH, 110 V DC 1 AMARARAJA

100AH, 110 V DC

AC Distribution Panel 415V, 63 A 1 VEE VEE

DC Motor starter panel VEE VEE

Motor Control Center 415V, 630A. 1 VEE VEE

LASCPT Panel 1 VEE VEE

NGR Panel 1 VEE VEE

VCB Panel 6.6KV, 1250A. 1 SIEMENS

LPBS 9

3 TG Drives:

. 11KW 1

BARRING GEAR 11KW 1

CEP-1 22KW 1

CEP-2 22KW 1

GVC MOTOR 0.37KW 1

VAPOUR EXTRACTOR 0.37KW 1

LP ACTUATOR 0.37KW 1

ACDB 63 AMPS 1

BATTERY CHARGER 63 AMPS. 1

AVR 63 AMPS. 1

OIL CENTRIFUGE 63 AMPS. 1

PVC insulated 1100V

grade cable:

3C x 2.5 Cu

1000

3C x 4 Cu

200

3C x 16 Cu 200

3C x 25 Cu 200

5C x 2.5 Cu

1000

12C x 1.5 Cu

700

450x 75x 2.5 mm Ladder Type 100

300X 75X2.5 mm perforated type 100

150X50X2.5 mm perforated type 100

50X 30X2.5 mm perforated type 100

GI Earth Flat

5 Cable trays

6 Earthing flat:

LIST OF EQUIPMENTS FOR 8 MW GENERATOR PACKAGE

Battery Charger 1 AMARARAJA

4 LT Power & Control Cables:

75 x 10 mm

2

Earth mat and HT panel body 250 meters

50 x 6 mm

2

LT panel body / Instruments 100 meters

25 x 6 mm

2

Instruments 80 meters

16 SWG Motors of less than 5.5 KW 80 meters

7

Cable glands

Double compression Ni plated

cable gland

8

Cable Lugs:

1.5 mm

2

. Pin type 450 nos.

1.5 mm

2

. Ring type 50 nos.

1.5 mm

2

. U- type 50 nos.

2.5 mm

2

. Pin type 350 nos.

2.5 mm

2

. Ring type 50 nos.

2.5 mm

2

. U- type 50 nos.

4.0 mm

2

. Pin type 25 nos.

4.0 mm

2

. Ring type 25 nos.

16.0 mm 2. Pin type 20 nos.

16.0 mm 2. Ring type 20 nos.

25.0 mm 2. Pin type 20 nos.

25.0 mm 2. Ring type 20 nos.

9 6.6 KV HT Cable:

9R X 1CX 500 sqmm. from Gen to LAPT 100 mtr

6R X 1C X 500 sqmm From Gen to NGR 75 mtr

4R X 3C X 300 sqmm From LAPT to 6.6 KV Swgr 250 mtr

DM PLANT AREA:

10 DM PLANT MCC, 63A

AIR BLOWER 2 HP

EFFLUENT DISPOSAL PUMP 4 HP

RAW WATER FEED PUMP 6 HP

ANION FEED PUMP 6 HP

DM WATER TRANSFER PUMP. 6 HP

LBP for motors

11 LT Cable details:

3CX 6 sqmm Al Cable

12 Earth Flat:

50 x 6 mm

2

50 Mtr

16 SWG 50 Mtr

13 Cable Trays:

600x 75x 2.5 mm

300X 75X2.5 mm

14 15T EOT Crane

15T, 10.8mtr span moving

pendant operated

OBSERVATION

Generator was commissioned on Feb,2011.and was synchronised on

feb,2014.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

Available

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

In healthy condition.

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

LIST OF EQUIPMENTS FOR 8 MW GENERATOR PACKAGE

**Cable In cut piece is available

To be procured

To be procured

To be procured

To be procured

Qty to be finalised after detailed engg

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

To be procured

can be used in identical layout.

can be used in identical layout.

can be used in identical layout.

1 no of 63 A feeder is required to charge the MCC.

Available

Available

Available

Available

Available

Available

To be procured and qty can be finalised after layout is finalised.

To be procured and qty can be finalised after layout is finalised.

In healthy condition.

SL NO NAME OF EQUIPMENT Remarks QTY Make

1 Power & Distribution Transformer

16.5 MVA Power Trafo 16.5 MVA, 6.6/33 KV 2 CGL

2MVA Service Transformer 6.6KV/0.433 KV, 2 MVA 4 Areva T&D

NGR For 16.5 MVA Trafo 10 OHM 2

16.5 MVA Remote tap changer control

panel 2

2 HT/LT Switchgear

33 KV HT Swgr 33KV,800A 8 panel Siemens

6.6 KV HT Swgr 6.6KV,1250A 27 Panels Siemens

415 V Common Service MCC 415V,1600A 1 L&T

415V Gassifier MCC# 1 415V,800A 1 L&T

415V Gassifier MCC# 2 415V,800A 1 L&T

415V Main PDB 415V,1600A 1 L&T

Aux power Distribution Board# 1 415V,100A 1 L&T

Aux power Distribution Board# 2 415V,100A 1 L&T

Aux power Distribution Board# 3 415V,100A 1 L&T

Aux power Distribution Board# 4 415V,100A 1 L&T

415V MLDB 415V,800A 1 L&T

415V WET ESP MCC 415V,1600A 1 L&T

3 HT Cable:

33KV grade HT Cable (E) 1CX500 sqmm 160 MTR

6.6KV Grade HT Cable(UE) 3CX300 sqmm 700 MTR

3CX 185 sqmm 1500 MTR

3C X150 sqmm 400 MTR

LT Power Cable: 3.5CX300 sqmm 1000 MTR

4 6.6 KV SPBD 6.6 KV,2000 A 20 mtr

5 415V NSPBD 415V,3200A 40 Mtr

6 Battery & Charger 220AH,220V FC/BC 1

7 DC Distribution Board 220V DC 1

Total balance of equipments for Complete P/G Plant

OBSERVATION

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Can be spared

Available in cut pieces

Can be spared in case

of identical layout

Can be spared in case

of identical layout

Can be spared

Can be spared

Total balance of equipments for Complete P/G Plant

Available in cut pieces

Sl No. Package Name

Remarks

Remarks

1 CW Pumps @ 1600 M3/hr, 50 Meters

4 Pumps are avialable out of which 2 are required to Run the

Plant.

2

Hot Well Make-up pumps/Misc Pumps/Boiler Fill

Pump

Hotwell Makeup Pumps Can Be Spared

3 AC and Ventilation

Infrastructure available here can be used and balance can be

procured

4 Compressors Can not be spared from this plant.

5 PT & DM Plant/ Condensate storage tank Can Be Spared

10 M3/Hr Dm Plant (RO

System) Is available with 100

M3 Capacity Storage Tank

which can be used.

6 Colling Tower

Not Feasible to relocate as made of wood, fan and gear box to be

dismantled and shifted

To be procured new

7 Civil and Structural, roads, drains, fencing etc. To be procured new

8 EOT Crane Can be Spared

15 T EOT Crane is Available

and Can be Used.

9 Earthing and Electrical Illumination Lightings Can be Used

10 Switchyard Cannot be spared

11 Control and Instrumentation Only turbine parts can be spared

12 CW and ACW Piping Can be Spared

13 LP Piping Can be Spared

14 Chimney needs to be procured / new contract to be awarded

15 Transformers, GT,SAT,UAT, Distribution 2 Transformers of 16.5 MVA are avialable

16 HT/LT Switchgear Can Be spared

17 Cables, termination and jointing kits To be Procured New

18 B/F valve Can be Spared

19 RE Joint Can be Spared

20 Battery and Battery Charger Can be Spared

21 Fire detection and protection system To be Procured

22 PA Communication System Not Available

BOP Packages

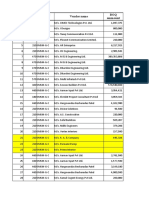

S.No Equipment Unit

Approx.

Weight

(MT)

1 CEP MT 0.31

2 GVC MT 0.45

3 EJECTOR MT 1.30

4 OIL COOLER MT 0.85

5 OIL FILTER MT 0.28

6 OVERHEAD OIL TANK MT 0.35

7 CENTRIFUGE MT 1.20

8 CONDENSOR MT 28.81

9 GEN STATOR MT 14.20

10 GEN ROTOR MT 6.90

11 GEN AIR COOLER MT 3.50

12 GEN BEARINGS MT 2.20

13 EXCITOR MT 1.50

14

TURBINE , GEARBOX, BASEPLATE

(INCLUDING OIL)

MT 29.00

15 DEAREATOR MT 25.00

16 ELECTRICAL SYSTEM MT 200.00

17 DMPLANT + RO SYSTEM MT 60.00

18 STRUCTURES MT 140.00

19 EOT Crane MT 35.00

20 PIPELINES MT 20.00

21 CT FANS AND GEARBOX MT 10.00

22 CWP MT 10.00

23 SPARES MT 10.00

600.841

TOTAL

Potrebbero piacerti anche

- F0512 Manhole DatasheetDocumento2 pagineF0512 Manhole DatasheetAbrar HussainNessuna valutazione finora

- Manhole Cover, Steel Marine Cover, Watertight Manhole Cover Product On AlibabaDocumento5 pagineManhole Cover, Steel Marine Cover, Watertight Manhole Cover Product On AlibabapaulsonNessuna valutazione finora

- Atlas Copco - Auditorium BOQ 170919Documento4 pagineAtlas Copco - Auditorium BOQ 170919calvin.bloodaxe4478Nessuna valutazione finora

- Tender For Hiring of Porta Cabin in Rajamundhary 19.12.2017Documento133 pagineTender For Hiring of Porta Cabin in Rajamundhary 19.12.2017Tarun MaheshwariNessuna valutazione finora

- 130 - S-HZL Storage tankBOQ - 20.12.19Documento4 pagine130 - S-HZL Storage tankBOQ - 20.12.19ananthu.uNessuna valutazione finora

- Purchase Saving Detailed Action Plan 2013 - RepairDocumento47 paginePurchase Saving Detailed Action Plan 2013 - RepairNiceman NiceNessuna valutazione finora

- Fire Fighting Works: S.No. Description Unit Qty 1.0 Fire Hydrant SystemDocumento7 pagineFire Fighting Works: S.No. Description Unit Qty 1.0 Fire Hydrant SystemRakesh Karan SinghNessuna valutazione finora

- PE Design OnDocumento13 paginePE Design OnMASITAH MUHAMMADNessuna valutazione finora

- Zakum Development Company (Zadco) : Description of Inspection SL. No. Fit-Up Inspection Date Weld Visual Inspection DateDocumento4 pagineZakum Development Company (Zadco) : Description of Inspection SL. No. Fit-Up Inspection Date Weld Visual Inspection DateYousab CreatorNessuna valutazione finora

- C823-3-Doc-Mat-Ele-017-01 R3Documento365 pagineC823-3-Doc-Mat-Ele-017-01 R3721917114 47Nessuna valutazione finora

- PRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2Documento13 paginePRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2AliZenatiNessuna valutazione finora

- Annexure - I Comments On Eot Cranes in Msds (Package - 087) (Make - Century Cranes)Documento2 pagineAnnexure - I Comments On Eot Cranes in Msds (Package - 087) (Make - Century Cranes)eagles1109Nessuna valutazione finora

- BMS Cable MeasurmentDocumento2 pagineBMS Cable MeasurmentsamhardworkerNessuna valutazione finora

- New Quotation For 2 Ton UfDocumento9 pagineNew Quotation For 2 Ton UfFatima Anwar100% (1)

- GFS Tank Quotation C20210514Documento4 pagineGFS Tank Quotation C20210514Francisco ManriquezNessuna valutazione finora

- BargeDocumento5 pagineBargeBudimanNessuna valutazione finora

- 132 EC - A 10 - VIT - Chennai - Meggger & Multimeter - JE QTNDocumento4 pagine132 EC - A 10 - VIT - Chennai - Meggger & Multimeter - JE QTNDr. Chandan SharmaNessuna valutazione finora

- Electrical Price List 2016Documento23 pagineElectrical Price List 2016shivamNessuna valutazione finora

- Butterfly Valve CatalogueDocumento6 pagineButterfly Valve CatalogueromeshmoreyNessuna valutazione finora

- Daily ReportDocumento39 pagineDaily ReportLe TuanNessuna valutazione finora

- Sarthi Skybay - D - Plumbing Internal, Duct, Terrace BOQDocumento171 pagineSarthi Skybay - D - Plumbing Internal, Duct, Terrace BOQamolNessuna valutazione finora

- Structural Steel Design DetailsDocumento7 pagineStructural Steel Design DetailsJanya AssociatesNessuna valutazione finora

- 11qvul PDFDocumento14 pagine11qvul PDFghaffaryanNessuna valutazione finora

- Lift SpecificationDocumento19 pagineLift SpecificationlahiruNessuna valutazione finora

- Osp 0158 10Documento47 pagineOsp 0158 10Eduardo CondeNessuna valutazione finora

- Project Report - MFG of Specialty Chemicals by Krishna Antioxidants PVT LTDDocumento8 pagineProject Report - MFG of Specialty Chemicals by Krishna Antioxidants PVT LTDAshok PatilNessuna valutazione finora

- Phong Nha Cargo BargeDocumento1 paginaPhong Nha Cargo BargehaydarburedahNessuna valutazione finora

- Sensor Price List 2020 PDFDocumento31 pagineSensor Price List 2020 PDFSyed Rohail AhmedNessuna valutazione finora

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CDocumento8 pagineSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CAgus MarpaungNessuna valutazione finora

- Format For Purchase Order DataDocumento16 pagineFormat For Purchase Order Datakamal haiderNessuna valutazione finora

- Linear Bearings-HiwinDocumento0 pagineLinear Bearings-Hiwinqi_1986Nessuna valutazione finora

- The Quotation of 30TPD Palm Oil Refinery Fractionation PlantDocumento16 pagineThe Quotation of 30TPD Palm Oil Refinery Fractionation PlantKen MbayiNessuna valutazione finora

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Documento31 pagineSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12Nessuna valutazione finora

- Technical Specfications For 5 Ton EOT CraneDocumento10 pagineTechnical Specfications For 5 Ton EOT CraneMoses_JakkalaNessuna valutazione finora

- Armada Tuah 83: 65M Anchor Handling / Offshore Support VesselDocumento2 pagineArmada Tuah 83: 65M Anchor Handling / Offshore Support VesselClaudio SantellanesNessuna valutazione finora

- NewAge - Pricelist (Residential Commercial Building) 29 09 22Documento8 pagineNewAge - Pricelist (Residential Commercial Building) 29 09 22vinayak abhaleNessuna valutazione finora

- Wilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetDocumento3 pagineWilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetViral ParmarNessuna valutazione finora

- Air ConDocumento32 pagineAir ConMef AnisemNessuna valutazione finora

- List of Approved Makes / Agencies: - Signature of Contractor NBCCDocumento13 pagineList of Approved Makes / Agencies: - Signature of Contractor NBCCaman3327Nessuna valutazione finora

- Technical Data Sheet For Air Washer Unit 10000 CFM AND 25000 CFMDocumento3 pagineTechnical Data Sheet For Air Washer Unit 10000 CFM AND 25000 CFMSupport aeronomNessuna valutazione finora

- Se Supreme Price List 15-02-2016 PDFDocumento20 pagineSe Supreme Price List 15-02-2016 PDFsdagnihotri86% (7)

- Detail Boq CG - For EfsDocumento3 pagineDetail Boq CG - For EfsVaibhav SawantNessuna valutazione finora

- K S Engineering PO 187Documento1 paginaK S Engineering PO 187Anonymous VjP75VWXIjNessuna valutazione finora

- Specification or EOTDocumento8 pagineSpecification or EOTMurthy NLNNessuna valutazione finora

- Tube Mill PatraDocumento30 pagineTube Mill PatraRitz HindustanNessuna valutazione finora

- 4538 - Drawing RegisterDocumento1 pagina4538 - Drawing RegisterRenuka GunawardhanaNessuna valutazione finora

- LC1 - C2001-33BQ-0000 - Pump Room - Rev01Documento111 pagineLC1 - C2001-33BQ-0000 - Pump Room - Rev01suheil samaraNessuna valutazione finora

- Elsr Boq ExamplDocumento30 pagineElsr Boq Examplprasadnn2001Nessuna valutazione finora

- Material List PDFDocumento231 pagineMaterial List PDFMangleshMishraNessuna valutazione finora

- Quotation For Industrial Pipling MaterialsDocumento6 pagineQuotation For Industrial Pipling MaterialsKingsley MNessuna valutazione finora

- Dung Quat Refinery Additional Sulfur Recovery Unit: V-2151-201-A - 002 D BSR1301-025-A1101-0800-001-001 DDocumento2 pagineDung Quat Refinery Additional Sulfur Recovery Unit: V-2151-201-A - 002 D BSR1301-025-A1101-0800-001-001 DdnbinhNessuna valutazione finora

- Pricing Schedule r2 - Bafo Stage 17 08 2017-No Reg Off-IctasDocumento82 paginePricing Schedule r2 - Bafo Stage 17 08 2017-No Reg Off-IctasSatish KapoorNessuna valutazione finora

- 2015 Foster HVAC Selection GuideDocumento2 pagine2015 Foster HVAC Selection Guidesiva_nagesh_2Nessuna valutazione finora

- Bom Sp4081ab PDFDocumento10 pagineBom Sp4081ab PDFBraulioMosqueraUribeNessuna valutazione finora

- MoEF ManualDocumento256 pagineMoEF Manualjack jNessuna valutazione finora

- Low Table/table Top Semi Automatic Carton Strapping Machine: Wz-443 GF, Naraina Village, New Delhi - 110028Documento2 pagineLow Table/table Top Semi Automatic Carton Strapping Machine: Wz-443 GF, Naraina Village, New Delhi - 110028Shekhar SrivassNessuna valutazione finora

- Some Tips For Mechanical Engineer - PipingDocumento5 pagineSome Tips For Mechanical Engineer - PipingJawed AkhterNessuna valutazione finora

- TSP Work - Estimate - Template 330Documento6 pagineTSP Work - Estimate - Template 330shivapannaleNessuna valutazione finora

- Min1244a12 - Tag 130-Pu-029Documento7 pagineMin1244a12 - Tag 130-Pu-029Monty MathewsNessuna valutazione finora

- AGYF Floor Service ManualDocumento22 pagineAGYF Floor Service ManualAmanda Mack100% (1)

- GQ Patrol Service Manual - Y60Documento1.038 pagineGQ Patrol Service Manual - Y60Jan Antonius Djunaedi77% (13)

- Targets Onboard Hydro StorageDocumento2 pagineTargets Onboard Hydro StorageCindy FengNessuna valutazione finora

- F 85353ee5307eb87fDocumento62 pagineF 85353ee5307eb87fEQ13Nessuna valutazione finora

- Flammable Gas and VapoursDocumento1 paginaFlammable Gas and Vapoursanais trifanNessuna valutazione finora

- ENSCO-107 (With Cementing Unit)Documento1 paginaENSCO-107 (With Cementing Unit)Deni SetiawanNessuna valutazione finora

- DF 300Documento6 pagineDF 300ruge13484246Nessuna valutazione finora

- Man B&W ManualDocumento12 pagineMan B&W ManualJayantaDebnath50% (2)

- Myanmar Oil Gas Trends Market Opportunities andDocumento8 pagineMyanmar Oil Gas Trends Market Opportunities andKhin Maung KyuNessuna valutazione finora

- HazopDocumento5 pagineHazopMohammed KhatibNessuna valutazione finora

- Final PPT On Gas TurbinesDocumento31 pagineFinal PPT On Gas TurbinesKRISHNA KUMARI100% (2)

- Saufer Danfoss Load Sensing Steering UnitsDocumento92 pagineSaufer Danfoss Load Sensing Steering UnitsaapereirazNessuna valutazione finora

- Screw Compressor PDS100S 6B4 PDS130S 6B4 PDS185S 6B4 39600 64220 PDFDocumento65 pagineScrew Compressor PDS100S 6B4 PDS130S 6B4 PDS185S 6B4 39600 64220 PDFKeith McCannNessuna valutazione finora

- Transformer 7Documento1 paginaTransformer 7KhajaBurhanNessuna valutazione finora

- MV Toronto TraderDocumento3 pagineMV Toronto TraderPapitas FritasNessuna valutazione finora

- AC250 Data SheetDocumento5 pagineAC250 Data SheetAshutosh SinghNessuna valutazione finora

- Mari-Clean MH 300-20 (Stromme)Documento55 pagineMari-Clean MH 300-20 (Stromme)GeorgeSergiu50% (2)

- Disk EngDocumento8 pagineDisk EngLeonardo CanditoNessuna valutazione finora

- Is 13694Documento11 pagineIs 13694Yashu HandaNessuna valutazione finora

- Experiment No.: 1: Engine & Working PrinciplesDocumento10 pagineExperiment No.: 1: Engine & Working PrinciplesJatin prasad TandanNessuna valutazione finora

- Telecom Appnote IdatechDocumento3 pagineTelecom Appnote Idatechapolinario mabiniNessuna valutazione finora

- Gastech2014 Day4 PDFDocumento24 pagineGastech2014 Day4 PDFamirlngNessuna valutazione finora

- Hyosung MS3-250 Serice ManualDocumento257 pagineHyosung MS3-250 Serice ManualLaze LakiNessuna valutazione finora

- Atomic Four Service ManualDocumento108 pagineAtomic Four Service ManualSteveNessuna valutazione finora

- Cutter Suction Dredger 650 - 25 M: Picture of Similar Vessel General Tank CapacitiesDocumento2 pagineCutter Suction Dredger 650 - 25 M: Picture of Similar Vessel General Tank Capacitieslukman hakimNessuna valutazione finora

- Flushing Procedure 9E UnitsDocumento33 pagineFlushing Procedure 9E UnitsKamal Arab100% (2)

- PEUGEOT 3008 HYbrid4Documento21 paginePEUGEOT 3008 HYbrid4Tom CotterNessuna valutazione finora

- 1997 2003 Dt444 Engine Service Manual PDFDocumento298 pagine1997 2003 Dt444 Engine Service Manual PDFYeison Suarez100% (3)

- SuperchargerDocumento24 pagineSuperchargerpravat dalai100% (1)

- Lesson 1Documento14 pagineLesson 1marpelNessuna valutazione finora

- DAF Components PACCAR MX 11 EngineDocumento2 pagineDAF Components PACCAR MX 11 EngineНедељко АнђелићNessuna valutazione finora