Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

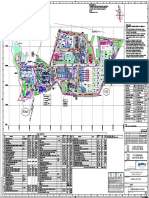

Plot Plan Design Criteria For Process Units

Caricato da

Eddie SantillánTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Plot Plan Design Criteria For Process Units

Caricato da

Eddie SantillánCopyright:

Formati disponibili

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 1 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

Enti re Standard Speci fi cati on has

been rewri tten.

1. GENERAL

1.1 Scope

a. Thi s Standard Speci fi cati on contai ns gui del i nes for devel opi ng safe, operabl e, and

economi cal l ayouts of process equi pment i n new process areas and uni ts.

b. Excepti ons or vari ati ons shown i n the UOP Project Speci fi cati ons take precedence over

the requi rements shown herei n.

1.2 Definitions

a. Pl ot Pl an

A graphi cal l ayout i ndi cati ng the pl acement of equi pment i n a process uni t or uni ts.

b. Process Area

The porti on of a pl ant si te i n whi ch the process uni ts are l ocated.

c. Process Tract

An area contai ni ng one or more process uni ts servi ced by a si ngl e uni t pi pe rack,

surrounded by a conti nuous battery l i mi t, and unpenetrated by i nteruni t roads.

d. Battery Li mi t

The boundary of the process tract.

2. PLANT LAYOUT

2.1 General

a. Establ i sh the l ocati on and di mensi ons of the proposed pl ant si te before begi nni ng

devel opment of the pl ot pl an. Determi ne the current, or future, use of nearby l and (e.g.,

other process uni ts or offsi tes faci l i ti es and publ i c faci l i ti es such as roads or housi ng).

Proper cl earances shal l be mai ntai ned between equi pment and faci l i ti es, both i nsi de and

outsi de of the process tract(s) of concern.

b. The pri mary consi derati on for the l ayout and spaci ng of process uni ts and thei r equi pment

i s safety. Other consi derati ons i ncl ude mai ntenance, operati on, constructi on, and

economi cs (capi tal , operati ng, and mai ntenance costs).

c. Process uni ts and thei r equi pment shal l be arranged to conform as cl osel y as possi bl e to

the general process fl ow scheme after the requi rements of thi s speci fi cati on, the UOP

Project Speci fi cati ons, and the UOP Pi pi ng and I nstrument Di agrams have been

accommodated. Process uni ts that are part of the same overal l pl ant shal l be l ocated

together.

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 2 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

d. Equi pment that i s to be i n a curbed or di ked area shal l be l ocated together to faci l i tate

spi l l control and col l ecti on, and to mi ni mi ze the number and extent of the curbed or di ked

areas.

e. When mul ti pl e process uni ts are present, each uni ts equi pment shal l be grouped together,

i .e., do not i ntermi ngl e equi pment from di fferent process uni ts. Provi de for the safe

shutdown and mai ntenance of any uni t(s) whi l e other process uni ts conti nue to operate.

Operati ng equi pment and pi pi ng shal l not be present wi thi n the battery l i mi ts of the

shutdown uni t. The uni t pi pe rack i s i ncl uded when equi pment for the shutdown process

uni t i s on both si des of the rack. Process uni ts that operate together and cannot be shut

down i ndependentl y may be consi dered as one uni t.

f. Pi pi ng wi thi n the process area shal l be supported on el evated pi pe racks. An accessway

shal l be provi ded beneath each pi pe rack. Sl eepers and trenches shal l not be used.

g. Access to the process uni t, bui l di ngs, stai rways, etc. shal l be provi ded di rectl y from the

battery l i mi ts, wi thout passi ng by process equi pment.

2.2 Terrain

a. The topographi c characteri sti cs of the si te may greatl y affect the pl ant l ayout. Exi sti ng

soi l condi ti ons, drai nage, sl ope, accessi bi l i ty, etc. shal l be consi dered.

b. Process uni ts shal l be l ocated together, on a l evel si te at a hi gher el evati on than the

storage tank and waste treatment areas. Where thi s i s not feasi bl e, drai nage shal l be

arranged to separate the process area from the other areas.

2.3 Wind

a. Consi derati on of the i nfl uence of wi nd di recti on i s cri ti cal to the creati on of a pl ot pl an

because the wi nd wi l l carry and di stri bute any rel eased materi al . A good pl ot pl an

maxi mi zes the potenti al for the wi nd to carry any rel eased materi al s away from

occupi ed areas, sources of i gni ti on, or other areas of concern.

b. The governi ng wi nd di recti on shal l be determi ned from a wi nd "rose." A wi nd "rose"

i ndi cates the frequency (i .e., percentage of the ti me) the wi nd bl ows from each di recti on.

The governi ng wi nd may be from a speci fi c or general i zed di recti on.

2.4 Access

a. A conti nuous strai ght, unobstructed road shal l be provi ded al ong each si de of each

process tract. Each tract i s therefore compl etel y surrounded by i nterconnected access

roads. The overal l area wi thi n the roads shal l not exceed 180,000 square feet (16,700

square meters). The maxi mum l ength of the tract shal l be 600 feet (185 meters) wi th a

recommended l i mi t of 400 feet (120 meters). The maxi mum wi dth of the tract shal l be

300 feet (90 meters), wi th a recommended l i mi t of 200 feet (60 meters).

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 3 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

b. Process uni ts and equi pment shal l be spaced to permi t use of mobi l e equi pment and

power tool s for servi ci ng and mai ntai ni ng equi pment duri ng operati on and turnaround

peri ods. Provi de overhead cl earance under pi peways and other structural supports for

personnel and for passage of fi re-fi ghti ng vehi cl es and mobi l e equi pment. Access shal l

be provi ded from two di recti ons to al l poi nts between process tracts. At l east one of the

access routes shal l not pass beneath any overhead obstructi ons such as a pi pe rack.

Addi ti onal access wi thi n process uni ts shal l be provi ded as needed.

c. Provi de a mi ni mum spaci ng of 50 feet (15 meters) between process tract battery l i mi ts.

Roadways may be l ocated wi thi n thi s space.

2.5 Unit Pipe Rack

Uni t pi pe racks support the el ectri cal , i nstrument, pneumati c, process, and uti l i ty l i nes

servi ci ng the process uni t(s) wi thi n the process tract. They al so provi de support for ai r cool ed

heat exchangers and wal kways. Wi th the excepti on of ai r cool ed heat exchangers, process

equi pment shal l not be pl aced above or bel ow any uni t pi pe rack.

2.6 Main Pipe Racks

Mai n pi pe racks contai ni ng feed, product, and uti l i ty l i nes for a number of process tracts shal l

be l ocated outsi de the battery l i mi ts of process tracts. They shal l not be routed through

process uni ts. Process equi pment shal l not be l ocated over, under, or adjacent to a mai n pi pe

rack. Provi de overhead cl earance for vehi cl es as requi red when the pi pe racks pass over

roadways and rai l road tracks.

2.7 Roadways

Roadways shal l be strai ght, unobstructed, and l ocated i n a symmetri cal manner, provi di ng

servi ce to al l process uni ts. Roadways shal l enci rcl e each process tract, provi di ng access for

operati on, mai ntenance, and fi refi ghti ng. Dead end roads are not permi tted. Road wi dths and

cl earances shal l be si zed to handl e emergency vehi cl es and l arge movi ng equi pment. The

mi ni mum wi dth, excl udi ng shoul ders, shal l be 28 feet (8.5 meters) for a 2-l ane road. The

mi ni mum overhead cl earance shal l be 18 feet (5.5 meters).

2.8 Railroad Tracks

Spur tracks shal l be outsi de the process tract battery l i mi ts and a mi ni mum of 50 feet

(15 meters) from process equi pment. The mi ni mum overhead cl earance shal l be 23 feet

(7 meters).

2.9 Maintenance

a. Major equi pment shal l be di rectl y accessi bl e from a roadway.

b. Space for al l uni t mai ntenance shal l be provi ded wi thi n the battery l i mi ts of each

process uni t. Exampl es i ncl ude heater tube removal ; exchanger bundl e pul l i ng; catal yst

handl i ng; tray, packi ng, or gri d handl i ng; compressor mai ntenance; and crane access to

ai r cool er and equi pment for whi ch heavy mai ntenance l i fts are expected (e.g., FCC

Reactor/Regenerator and Stacked Pl atformi ng Reactors).

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 4 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

2.10 Process Tract Arrangement

I n general , the opti mal shape for the process tract i s a rectangl e wi th a central i zed uni t pi pe

rack. Process equi pment i s pl aced al ong both si des of the uni t pi pe rack. The uni t pi pe racks,

and the process tracts, are arranged perpendi cul ar to, and al ong one or both si des of, the mai n

pi pe rack.

2.11 Construction

The l ayout of process equi pment shal l faci l i tate the entry and pl acement of heavy constructi on

equi pment (e.g., cranes). The abi l i ty to bri ng the process equi pment to i ts fi nal si te and

compl ete the erecti on process shal l al so be consi dered. Provi si on of l aydown areas wi thi n the

process tract may be necessary. Wi thi n the constrai nts i mposed by process operati on, safety,

mai ntenance, etc., l arge process equi pment shal l be l ocated to mi ni mi ze the number of crane

posi ti ons requi red to make the l i fts.

2.12 Future

Provi de space wi thi n the process uni ts for future expansi on or modi fi cati on. Provi de space

wi thi n the process area for future process uni ts. The space provi ded for future expansi on

shal l remai n free of obstructi ons; e.g., underground pi pi ng or uti l i ti es.

3. PROCESS EQUIPMENT LAYOUT

3.1 General

The mi ni mum spaci ng of process equi pment shal l be as shown i n Tabl e-1A (Engl i sh Uni ts) or

Tabl e-1B (Metri c Uni ts). Unl ess noted, the spaci ngs gi ven are to the edge of the equi pment or

structure. These spaci ngs are based upon recogni zed good practi ce devel oped from operati ng

experi ence. When anal yti cal methods such as the predi cti on of vapor cl oud expl osi on

overpressure ci rcl es (or spheres) requi re the use of greater spaci ngs, those greater spaci ngs

shal l govern.

3.2 Heaters

a. Heaters shal l be posi ti oned upwi nd of process equi pment and storage tanks to reduce

exposure of possi bl e vapor l eaks to i gni ti on sources. Uni ts wi th heaters shal l be l ocated

together to al l ow the heaters to be opti mal l y l ocated wi th respect to the governi ng wi nd

di recti on and to i sol ate the potenti al fi re hazard(s).

b. Heaters shal l be pl aced at the open end of the process tract pi pe rack, i .e., the end away

from the connecti on to the mai n pi pe rack, unl ess thi s confl i cts wi th the requi rements of

Secti on 3.2a.

c. Process equi pment shal l be l ocated a mi ni mum of 50 feet (15 meters) from fi red heaters.

I n cases where equi pment i s di rectl y connected to the heater, the heater feed i s al l vapor

above i ts auto-i gni ti on temperature, and mi ni mum spaci ng i s cri ti cal to the process, the

equi pment may be cl oser to the heater, provi ded there i s access for mai ntenance and

fi re-fi ghti ng. Reactor ci rcui ts are an exampl e of where a reduced heater-reactor spaci ng

may be consi dered.

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 5 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

d. Avoi d l ocati ng tal l equi pment or structures (e.g., fracti onati ng col umns) downwi nd of,

and near, heater stacks. The stack must extend above the hi ghest nearby pl atform,

whi ch may be greater than the hei ght otherwi se requi red for the stack.

e. Provi de tube pul l i ng space wi thi n battery l i mi ts. Bundl es shal l be pul l ed towards the

uni t boundary.

f. Knockout drums for fuel gas suppl y to heaters shal l be l ocated as cl ose as possi bl e to,

but not l ess than 25 feet (7.5 meters) from, any fi red heater.

3.3 Vessels and Reactors

a. Vessel s up to 10 feet (3 meters) i n di ameter shal l be a mi ni mum of 8 feet (2.5 meters)

apart. Vessel s 10 feet (3 meters) to 16 feet (5 meters) i n di ameter shal l be at l east 10

feet (3 meters) apart. Vessel s l arger than 16 feet (5 meters) i n di ameter shal l be a

mi ni mum of 13 feet (4 meters) apart.

b. Smal l , non-hydrocarbon contai ni ng vessel s (e.g., chemi cal i njecti on and wash water

tanks) may be pl aced i mmedi atel y adjacent to the uni t pi pe rack. The vessel centerl i ne

i s normal l y 8-10 feet (2.5-3 meters) from the pi pe rack.

c. Reactors and vessel s wi th trays shal l have an adjacent drop area wi thi n the battery

l i mi ts for i nstal l i ng and removi ng the trays and i nternal s.

d. Vessel s contai ni ng packi ng, catal yst, cl ay, si eves, etc. shal l have an adjacent drop area

wi thi n the battery l i mi ts for materi al l oadi ng and unl oadi ng.

3.4 Tubular Heat Exchangers

a. Locate exchangers at grade unl ess an el evated l ocati on i s requi red by the process.

Group exchangers together when possi bl e.

b. Heat exchangers contai ni ng fl ammabl e l i qui ds above 500F (260C) shal l not be l ocated

beneath other equi pment.

c. When mul ti pl e shel l s are used for a si ngl e servi ce, the arrangement shal l consi der

whether the fl ow i s i n seri es or paral l el and shal l provi de for symmetri cal di stri buti on

when requi red.

d. Exchangers shal l not be stacked over two shel l s hi gh. Do not i ncl ude reboi l er

exchangers i n a stack.

e. Provi de exchangers wi th an area for tube bundl e pul l i ng. Bundl e pul l i ng shal l be

towards the uni t boundary and shal l be enti rel y wi thi n the process uni t's battery l i mi ts.

f. Unfi red reboi l er exchangers shal l be l ocated a maxi mum of 5 feet (1.5 meters) from the

vessel they serve. Do not l ocate reboi l er exchangers beneath structures or other

equi pment.

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 6 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

g. Verti cal reboi l ers attached to fracti onators shal l be l ocated as speci fi ed i n the UOP

Project Speci fi cati on for Vessel s and the UOP Pi pi ng and I nstrument Di agram. The axi s

between the reboi l er and the fracti onator i s paral l el to the uni t pi pe rack. Provi de

approxi matel y 3 feet (1 meter) cl earance between the shel l s.

3.5 Air Cooled Heat Exchangers

a. Process equi pment shal l not be l ocated above or bel ow ai r cool ed heat exchangers.

b. Ai r cool ed heat exchangers shal l be l ocated above the uni t pi pe rack or on a structure

used onl y for ai r cool ed heat exchanger support

c. Ai r cool ed heat exchangers shal l not be l ocated where the di scharge ai r from one

exchanger can become the i ncomi ng ai r to another exchanger.

d. Provi de crane access 30 feet (9 meters) wi de to ai r cool ed heat exchangers for

mai ntenance.

e. Provi de room for at l east one addi ti onal bay adjacent to each effl uent and overhead

condenser.

f. When speci fi c i nformati on i s not avai l abl e, consi der the i nl et and outl et to be at the

same end of the ai r cool ed exchanger. For fracti onator overhead condenser rundown

l i nes where a mi ni mum run of hori zontal pi pe i s speci fi ed on the UOP Pi pi ng and

I nstrument Di agram, the condenser outl et shal l be l ocated on the same si de of the pi pe

rack as the associ ated recei ver vessel . The di stance between the ai r condenser outl et

and the recei ver shal l be mi ni mi zed fol l owi ng normal pi pi ng and equi pment l ayout

practi ces. The l ength of the hori zontal porti on of the rundown l i ne shal l be 70 l i neal

feet (20 meters) or l ess.

3.6 Pumps

a. Pumps shal l be l ocated at grade.

b. Pumps shal l be l ocated so that sucti on l i ne l engths are mi ni mi zed.

c. Pumps shal l not be l ocated beneath equi pment or structures.

d. Locate pumps i n a row outsi de of and paral l el to the uni t pi pe rack, wi th the dri ver

(motor or turbi ne) towards the rack. The di scharge nozzl e shal l be at l east 10 feet (3

meters) from the pi pe rack. There shal l be a mi ni mum of 10 feet (3 meters) of cl ear

space behi nd the dri ver.

e. Pump foundati ons shal l be a mi ni mum of 3 feet (1 meter) apart.

3.7 Compressors

a. Compressors shal l be l ocated downwi nd from heaters.

b. The compressors for each process uni t shal l be l ocated together.

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 7 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

c. Compressors shal l be l ocated i n an open-si ded shel ter wi th a vented roof. Provi de a drop

area adjoi ni ng the compressor shel ter and di rectl y accessi bl e from a road. Locati ng the

drop area at an i ntersecti on i s i deal . The drop area shal l be enti rel y wi thi n the battery

l i mi ts.

d. Al l ow space near each compressor for auxi l i ary equi pment (e.g., l ube oi l systems).

e. Compressors shal l be l ocated adjacent to a roadway for ease of mai ntenance.

f. Compressors shal l not be l ocated beneath equi pment or pi pe racks.

g. Sucti on and i nterstage knockout drums shal l be l ocated as cl ose as possi bl e to the

compressors.

3.8 Process Area Tanks

a. General

(1) The requi rements of thi s secti on appl y to tanks l ocated wi thi n the process area,

general l y wi thi n a process tract. Tanks i n other l ocati ons; e.g., the tank farm,

waste treatment area, and uti l i ty area, are not addressed.

(2) The requi rements of thi s secti on appl y to atmospheri c and l ow pressure tanks (l ess

than 15 psi g (1.05 kg/cm

2

(g)). Hi gh pressure and refri gerated tanks are not

i ncl uded.

(3) The requi rements of thi s secti on appl y to tanks contai ni ng fl ammabl e

(combusti bl e), hot, hazardous, dangerous, or harmful l i qui ds. Among the

materi al s i ncl uded are hydrocarbons, causti cs, and aci ds. The provi si ons are not

requi red for tanks contai ni ng water or other non-hazardous materi al s.

(4) The requi rements of thi s secti on appl y to tanks that may retai n contents whi l e the

process uni t(s) are shut down and drai ned ((e.g., duri ng mai ntenance or

modi fi cati on).

(5) Tanks shal l be pl aced wi thi n the process area onl y when requi red for proper,

economi cal operati on of the process. These tanks are i denti fi ed on the UOP

Process and I nstrument Di agrams. Otherwi se tanks shal l be l ocated i n the tank

farm or other non-process area.

(6) Equi pment other than tanks (e.g., pumps) shal l not be l ocated wi thi n the di ked

encl osure. Pumps shal l be l ocated as cl ose as possi bl e to the tank from whi ch they

take sucti on.

b. Tank Locati on and Spaci ng

(1) Each tank shal l be exposed to, adjacent to, and accessi bl e from a road. No tank

shal l be pl aced behi nd another.

(2) The di stance between adjacent tanks shal l be at l east equal to the di ameter of the

l arger tank.

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 8 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

(3) Tanks shal l be at l east 30 feet (9 meters) from the nearest process equi pment.

(4) The di ke shal l be at l east 15 feet (4.5 meters) from nei ghbori ng process equi pment

(other than the contai ned tanks and the associ ated pumps) and enti rel y wi thi n the

battery l i mi ts of the process uni t.

(5) The mi ni mum di stance from each tank shel l to the i nsi de base of the di ke shal l be

one-hal f the hei ght of the tank.

c. Di kes

(1) Tanks wi thi n the process area shal l be surrounded by a di ke. Mul ti pl e tanks may

be wi thi n a si ngl e di ke. When more than one tank i s wi thi n a si ngl e di ke, each

tank shal l be separated from the others by an i ntermedi ate di ke.

(2) The di ked area shal l contai n the enti re contents of the l argest tank, excl usi ve of

the vol ume occupi ed by the other tanks.

(3) I ntermedi ate di kes shal l contai n 10 percent of the vol ume of the contai ned tank,

excl usi ve of the vol ume occupi ed by the tank.

(4) Di kes and i ntermedi ate di kes shal l be constructed of concrete.

(5) Di kes shal l be at l east 10 feet (3 meters) from the uni t battery l i mi ts.

(6) The maxi mum hei ght of a di ke i s 6 feet (1800 mm) above the i nteri or grade. The

mi ni mum di ke hei ght i s 3 feet (900 mm) above the i nteri or grade. The di ke shal l

be at l east 6 i nches (150 mm) hi gher than the maxi mum l evel of the contai ned

fl ui d.

(7) I ntermedi ate di kes shal l be at l east 18 i nches (450 mm) shorter than the

surroundi ng di ke. The mi ni mum hei ght above the i nteri or grade i s 18 i nches (450

mm). The i ntermedi ate di ke shal l be at l ast 6 i nches (150 mm) hi gher than the

l evel of the contai ned fl ui d.

3.9 Piping

a. The equi pment l ayout shal l al l ow pi pi ng runs to be as short as possi bl e wi th the

mi ni mum number of el bows, especi al l y for hot, al l oy, l arge di ameter, or heavy wal l l i nes.

b. Thermal expansi on of hot, al l oy, heavy wal l , or l arge di ameter pi pi ng shal l be consi dered

duri ng the equi pment l ayout, so that whenever feasi bl e the expansi on can be

accommodated wi thout the use of expansi on compensators.

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 9 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

4. MISCELLANEOUS

4.1 Control Houses

a. Control houses shal l be separated from process equi pment and l ocated adjacent to

roadways. Pl acement outsi de of process tracts, even outsi de of the process area, i s

preferred. I f l ocated wi thi n the process tract, control houses shal l be pl aced at the

peri phery of the process tract.

b. Control houses shal l be l ocated upwi nd of process equi pment.

4.2 Unit Substation

Process uni t substati ons shal l be l ocated near a control house and adjacent to a roadway,

upwi nd of process equi pment.

4.3 Outdoor Electrical Switch Racks

El ectri cal swi tch racks shal l be upwi nd of equi pment handl i ng hydrocarbons. They shal l be a

mi ni mum of 20 feet (6 meters) from process equi pment, except that 50 feet (15 meters) shal l

be provi ded from fi red heaters and compressors.

4.4 Emergency Booths and Change Houses

a. When requi red, emergency booths shal l be l ocated beneath the edge of the pi pe rack,

spaced a maxi mum of 100 feet (30 meters) apart. Emergency booths shal l be l ocated as

cl ose as practi cal to the source of danger.

b. When requi red, uni t change houses shal l be l ocated upwi nd of the process equi pment

and between the process uni t and the control house.

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 10 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

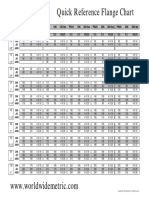

Table 1A

Minimum Spacing for Process Equipment (English Units)

Legend:

NA = Not appl i cabl e.

NM = No mi ni mum spaci ng requi rement has been establ i shed. Use engi neeri ng judgement for spaci ng.

Notes:

1. Hori zontal di stances are i n feet.

2. Mi ni mum hori zontal di stances between bui l di ngs, process equi pment, and property l i nes are edge-to-

edge di mensi ons.

3. Pump cl earances are to the di scharge nozzl e. See Secti on 3.6 for further i nformati on.

4. See Secti on 3.3a. for further i nformati on.

5. Provi de the same cl earance as between 2 vessel s, see Secti on 3.3a. Al so see Secti on 3.4f. for further

i nformati on.

6. Verti cal vessel s, and hori zontal vessel s that are ori ented paral l el to the uni t pi pe rack, shal l be at

l east 20 feet from the uni t rack. Hori zontal vessel s ori ented perpendi cul ar to the uni t pi pe rack shal l

be at l east 15 feet from the uni t pi pe rack.

7. These are structures and pl atforms supporti ng and provi di ng access to process equi pment.

Cl earances are to nei ghbori ng equi pment.

8. Pumps, excepti ng those taki ng sucti on from the tank(s), shal l be a mi ni mum of 30 feet from the

tank(s). Pumps taki ng sucti on from the tank(s) shal l be l ocated adjacent to the di ke.

9. See Secti on 3.8b. for further i nformati on.

Revi si on

I ndi cati on

UOP LLC 25 East Algonquin Road Des Plaines, Illinois 60017-5017 USA

STANDARD SPECIFICATION

9-51-1 Page 11 of 11

PLOT PLAN DESIGN CRITERIA FOR PROCESS UNITS

Form QUA-03-2

DATE STATUS APVD AUTHD

24MAY00 Revised RGP KAR

Table 1B

Minimum Spacing for Process Equipment (SI/MKS Units)

Legend:

NA = Not appl i cabl e.

NM = No mi ni mum spaci ng requi rement has been establ i shed. Use engi neeri ng judgement for spaci ng.

Notes:

1. Hori zontal di stances are i n meters.

2. Mi ni mum hori zontal di stances between bui l di ngs, process equi pment, and property l i nes are edge-to-

edge di mensi ons.

3. Pump cl earances are to the di scharge nozzl e. See Secti on 3.6 for further i nformati on.

4. See Secti on 3.3a. for further i nformati on.

5. Provi de the same cl earance as between 2 vessel s, see Secti on 3.3a. Al so see Secti on 3.4f. for further

i nformati on.

6. Verti cal vessel s, and hori zontal vessel s that are ori ented paral l el to the uni t pi pe rack, shal l be at

l east 6 meters from the uni t rack. Hori zontal vessel s ori ented perpendi cul ar to the uni t pi pe rack

shal l be at l east 4.5 meters from the uni t pi pe rack.

7. These are structures and pl atforms supporti ng and provi di ng access to process equi pment.

Cl earances are to nei ghbori ng equi pment.

8. Pumps, excepti ng those taki ng sucti on from the tank(s), shal l be a mi ni mum of 9 meters from the

tank(s). Pumps taki ng sucti on from the tank(s) shal l be l ocated adjacent to the di ke.

9. See Secti on 3.8b. for further i nformati on.

Potrebbero piacerti anche

- Develop Plot Plans for Piping ProjectsDocumento9 pagineDevelop Plot Plans for Piping ProjectsTom0% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Refinery Layout FactorsDocumento194 pagineRefinery Layout FactorsLuis Enrique Leyva Ovalle100% (1)

- Gap 2.5.2 PDFDocumento13 pagineGap 2.5.2 PDFRoberto MendozaNessuna valutazione finora

- Piping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDocumento5 paginePiping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDhiren PatelNessuna valutazione finora

- Check List For Piping Material Take-OffDocumento10 pagineCheck List For Piping Material Take-OffKyaw Kyaw AungNessuna valutazione finora

- Ashwin Udhe 1 Introduction To Piping Engineering PDFDocumento6 pagineAshwin Udhe 1 Introduction To Piping Engineering PDFPoonam AshwinNessuna valutazione finora

- Pipe Stress Manhours Estimation (Node Wise)Documento7 paginePipe Stress Manhours Estimation (Node Wise)pipestressNessuna valutazione finora

- Overpressure and Thermal ReliefDocumento6 pagineOverpressure and Thermal ReliefHamid Alilou100% (1)

- Chapter Wise QuestionsDocumento6 pagineChapter Wise QuestionsDr. B. Sree Giri Prasad100% (2)

- GR TWC1 7211 5202Documento97 pagineGR TWC1 7211 5202Sulist N WahyudieNessuna valutazione finora

- Column Piping: Study Layout, Nozzle Orientation & Platforms RequirementsDocumento23 pagineColumn Piping: Study Layout, Nozzle Orientation & Platforms Requirementsreach_arindomNessuna valutazione finora

- What Is Piping MTO or Material Take-OffDocumento4 pagineWhat Is Piping MTO or Material Take-Offvenkatraju.Y100% (1)

- Design Practice General PipeDocumento8 pagineDesign Practice General PipedevNessuna valutazione finora

- Flange ChartDocumento4 pagineFlange ChartEddie SantillánNessuna valutazione finora

- About The Dyes: Dyes For Cellulose FibersDocumento4 pagineAbout The Dyes: Dyes For Cellulose FibersmanqabatNessuna valutazione finora

- Astm A681 PDFDocumento14 pagineAstm A681 PDFraulNessuna valutazione finora

- DEP 31.38.01.11-Gen. (Piping General Requirements) - InformativeDocumento24 pagineDEP 31.38.01.11-Gen. (Piping General Requirements) - InformativeDarrel Espino AranasNessuna valutazione finora

- SAMSUNG SEM-3074E - Piping Design Manual (Pump Piping)Documento21 pagineSAMSUNG SEM-3074E - Piping Design Manual (Pump Piping)Tanveer Ahmad100% (2)

- PVE Piping Layout Presentation - Part 2Documento117 paginePVE Piping Layout Presentation - Part 2Nguyen Quang NghiaNessuna valutazione finora

- Trg-B1008-COMPRESSOR HOUSE PIPINGDocumento12 pagineTrg-B1008-COMPRESSOR HOUSE PIPINGVijay Gupta50% (2)

- No.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDocumento38 pagineNo.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDarshan PanchalNessuna valutazione finora

- MTO - Check List For Piping Material Take-Off (MTO) - Piping-EngineeringDocumento7 pagineMTO - Check List For Piping Material Take-Off (MTO) - Piping-EngineeringD K SNessuna valutazione finora

- SEM 3037E Tower Piping.Documento52 pagineSEM 3037E Tower Piping.Kodali Naveen KumarNessuna valutazione finora

- Column Piping - Study Layout, Nozzle Orientation & Platforms RequirementsDocumento37 pagineColumn Piping - Study Layout, Nozzle Orientation & Platforms RequirementsvasuNessuna valutazione finora

- Monitor Piping Construction Progress with WCS and ITPDocumento8 pagineMonitor Piping Construction Progress with WCS and ITPAsraf Ali100% (1)

- Pipe RoutDocumento10 paginePipe Routghkashyap1Nessuna valutazione finora

- Engineering Piping Drawing Index SheetsDocumento181 pagineEngineering Piping Drawing Index SheetsAde FaruroziNessuna valutazione finora

- UndergroundDocumento31 pagineUndergroundJOEL ARNAO CORTEGANANessuna valutazione finora

- Rack Piping For A Piping Stress EngineerDocumento4 pagineRack Piping For A Piping Stress EngineerFaizal Khan100% (2)

- FEEDDocumento6 pagineFEEDxam marNessuna valutazione finora

- 3.plotplan and Equipment LayoutDocumento12 pagine3.plotplan and Equipment LayoutAmarKumarNessuna valutazione finora

- Piping PhilosophyDocumento15 paginePiping PhilosophyRagh100% (1)

- Reactivity Series Worksheet - 8B and 8CDocumento6 pagineReactivity Series Worksheet - 8B and 8CHighlightNessuna valutazione finora

- Mod2 - Topic3 - Operating FacilitiesDocumento14 pagineMod2 - Topic3 - Operating Facilitiessteve devlinNessuna valutazione finora

- Process Design CriteriaDocumento23 pagineProcess Design CriteriaDoctorOberman100% (1)

- Check List Piping Project Start Kick-Off Meeting DiscussionDocumento5 pagineCheck List Piping Project Start Kick-Off Meeting DiscussionAnonymous PsafDWSiOoNessuna valutazione finora

- Pipes, Tubes, Fittings, FlangesDocumento121 paginePipes, Tubes, Fittings, FlangesCarl Jones100% (2)

- Piping - Foster Wheeler - Standards Tuyauterie (En)Documento191 paginePiping - Foster Wheeler - Standards Tuyauterie (En)ANTHONY VERNAT100% (2)

- Flare Piping Stress NalysisDocumento7 pagineFlare Piping Stress Nalysisgpskumar22100% (1)

- NEUROPHYSIOLOGYDocumento224 pagineNEUROPHYSIOLOGYKheliwi100% (2)

- Piping Material Take-off Process OverviewDocumento4 paginePiping Material Take-off Process Overviewkacang meteNessuna valutazione finora

- PIPING PROCEDURESDocumento9 paginePIPING PROCEDURESippon_osotoNessuna valutazione finora

- Training Manual-Piping: Piping Study Underground PipingDocumento30 pagineTraining Manual-Piping: Piping Study Underground Pipingrams789100% (2)

- D6251D6251MDocumento16 pagineD6251D6251MUriel OlivaresNessuna valutazione finora

- Piping Engineering CourseDocumento2 paginePiping Engineering CourseprasannaNessuna valutazione finora

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Documento11 pagineDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanNessuna valutazione finora

- A 01Documento34 pagineA 01NizarHamrouniNessuna valutazione finora

- Plot Plan DevelopmentDocumento18 paginePlot Plan DevelopmentJOBIN YOHANNANNessuna valutazione finora

- Elsanhouty Pharma Hold Time Study NotesDocumento6 pagineElsanhouty Pharma Hold Time Study NotesHuỳnh Ngọc SángNessuna valutazione finora

- PMS Eil PDFDocumento132 paginePMS Eil PDFAravind Dhudaka100% (1)

- Piping Plot Plan and Layout EngineeringDocumento12 paginePiping Plot Plan and Layout EngineeringKagira Drawing SoltuionNessuna valutazione finora

- Piping Design Requirements PDFDocumento6 paginePiping Design Requirements PDFkarunaNessuna valutazione finora

- OISD Tank Farm Rules The Piping Engineering WorldDocumento1 paginaOISD Tank Farm Rules The Piping Engineering Worldrenger20150303Nessuna valutazione finora

- MR ValvesDocumento56 pagineMR ValvesIdris SiddiquiNessuna valutazione finora

- Pi Ups 1004Documento39 paginePi Ups 1004JOEL ARNAO CORTEGANANessuna valutazione finora

- Piping Notes 1Documento47 paginePiping Notes 1sanjay421100% (1)

- FS PipingDocumento317 pagineFS PipingOthman RejabNessuna valutazione finora

- PRV 2 Size Quick Start GuideDocumento36 paginePRV 2 Size Quick Start GuideAlcides Llanque ChoqueNessuna valutazione finora

- CCR Platforming LayoutDocumento3 pagineCCR Platforming Layoutermusat100% (1)

- Plot PlanDocumento5 paginePlot PlandasubhaiNessuna valutazione finora

- Plot Plan and Equipment LayoutDocumento23 paginePlot Plan and Equipment Layoutravirawat15Nessuna valutazione finora

- WS 3Documento9 pagineWS 3Eddie SantillánNessuna valutazione finora

- Proper Piping For Vacuum SystemsDocumento5 pagineProper Piping For Vacuum SystemsDowni Oader100% (1)

- 008 Choke ValveDocumento3 pagine008 Choke ValveEddie SantillánNessuna valutazione finora

- Petrofac Pipeline Documents TransmittalDocumento2 paginePetrofac Pipeline Documents TransmittalbelhaskaNessuna valutazione finora

- 500050-00-000-PP12PP-001-OVERALL PLOT PLAN - Rev C - BindDocumento1 pagina500050-00-000-PP12PP-001-OVERALL PLOT PLAN - Rev C - BindSachin ShindeNessuna valutazione finora

- 3PS Gaw 002Documento6 pagine3PS Gaw 002ravi00098Nessuna valutazione finora

- Lift Station DesignDocumento3 pagineLift Station DesignPaolo De PeraltaNessuna valutazione finora

- Spe 0798 0039 JPTDocumento3 pagineSpe 0798 0039 JPTNew Auto TVNessuna valutazione finora

- BN-DG-C01A Plant Layout - General RequirementsDocumento11 pagineBN-DG-C01A Plant Layout - General RequirementsatramanathanNessuna valutazione finora

- Macdonald 2020Documento14 pagineMacdonald 2020Rizky WahyuNessuna valutazione finora

- WAPUG User Note 21Documento3 pagineWAPUG User Note 21saurabh singhNessuna valutazione finora

- HSBEI-1294-0314 Piling Rigs Overturning On Construction SitesDocumento4 pagineHSBEI-1294-0314 Piling Rigs Overturning On Construction SitestsuakNessuna valutazione finora

- Spe - 9979 Overview of Artificial Lift SystemDocumento13 pagineSpe - 9979 Overview of Artificial Lift Systemmartin_montana55_479Nessuna valutazione finora

- S M S LT S FT Q: Velocidad Absoluta Del FluidoDocumento3 pagineS M S LT S FT Q: Velocidad Absoluta Del FluidoEddie SantillánNessuna valutazione finora

- Construction and Performance Evaluation of A Michell-Banki Turbine PrototypeDocumento9 pagineConstruction and Performance Evaluation of A Michell-Banki Turbine Prototypemichael1135Nessuna valutazione finora

- Ma&Gnie Etsc HD 2000 2Documento6 pagineMa&Gnie Etsc HD 2000 2Amir AbbaszadehNessuna valutazione finora

- Coa48 TCDocumento4 pagineCoa48 TCEddie SantillánNessuna valutazione finora

- Pump CoolingDocumento1 paginaPump CoolingEddie SantillánNessuna valutazione finora

- JMNMMDocumento2 pagineJMNMMEddie SantillánNessuna valutazione finora

- Cross Flow Turbine DesignDocumento3 pagineCross Flow Turbine DesignEddie SantillánNessuna valutazione finora

- Ejma DSDocumento1 paginaEjma DSEddie SantillánNessuna valutazione finora

- Stainless Steel Needle Tubing: Standard Specification ForDocumento2 pagineStainless Steel Needle Tubing: Standard Specification ForEddie SantillánNessuna valutazione finora

- FC Mag - Keys To Effective Valve Sizing & Selection PDFDocumento4 pagineFC Mag - Keys To Effective Valve Sizing & Selection PDFEddie SantillánNessuna valutazione finora

- Coa48 TCDocumento4 pagineCoa48 TCEddie SantillánNessuna valutazione finora

- Section F Section F: WeldingDocumento3 pagineSection F Section F: WeldingEddie SantillánNessuna valutazione finora

- Control Valve Noise Control Manual - DresserDocumento24 pagineControl Valve Noise Control Manual - DresserTrevor KanodeNessuna valutazione finora

- Station Equipment: Pump CoolingDocumento3 pagineStation Equipment: Pump CoolingEddie SantillánNessuna valutazione finora

- IRITS-0617-034 HLA Heatless Desiccant Air DryerDocumento2 pagineIRITS-0617-034 HLA Heatless Desiccant Air DryerEddie SantillánNessuna valutazione finora

- Up6s 30 125Documento1 paginaUp6s 30 125Eddie SantillánNessuna valutazione finora

- TM PT501 Tank HeatDocumento30 pagineTM PT501 Tank HeataufacikNessuna valutazione finora

- Reporte ValvulaDocumento1 paginaReporte ValvulaEddie SantillánNessuna valutazione finora

- Valve Testing StandardsDocumento2 pagineValve Testing StandardsPrashant Puri0% (1)

- Epri - 25KW High Concentration Photovoltaic PDFDocumento4 pagineEpri - 25KW High Concentration Photovoltaic PDFEddie SantillánNessuna valutazione finora

- Models 180-LD 181-LDDocumento2 pagineModels 180-LD 181-LDEddie SantillánNessuna valutazione finora

- Compressed Air SystemDocumento29 pagineCompressed Air SystemPrathmesh GujaratiNessuna valutazione finora

- Ver. 7.5.9.3.4, Build Date: Sep 14, 2010 Cashco Valve Sizing (CV Calculation) 12-Sep-17Documento1 paginaVer. 7.5.9.3.4, Build Date: Sep 14, 2010 Cashco Valve Sizing (CV Calculation) 12-Sep-17Eddie SantillánNessuna valutazione finora

- International Abbreviations For Polymers and Polymer ProcessingDocumento226 pagineInternational Abbreviations For Polymers and Polymer ProcessingTrevor J. HutleyNessuna valutazione finora

- Designs CatalogDocumento77 pagineDesigns CatalogGen MendozaNessuna valutazione finora

- Pharmacological and Toxicological Screening Methods I (MPL 103T)Documento50 paginePharmacological and Toxicological Screening Methods I (MPL 103T)Sandeep MewadaNessuna valutazione finora

- API Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationDocumento4 pagineAPI Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationFabioSalaNessuna valutazione finora

- Storage ProteinDocumento3 pagineStorage ProteinprincessicyjulietNessuna valutazione finora

- I) Introduction To Polymer Nanocomposites For Food Packaging Applications II) Overview On An European Activity in The FieldDocumento39 pagineI) Introduction To Polymer Nanocomposites For Food Packaging Applications II) Overview On An European Activity in The FieldNormanBatesNessuna valutazione finora

- Drilling Engineering Fluid PropertiesDocumento29 pagineDrilling Engineering Fluid PropertiesDeepak RanaNessuna valutazione finora

- NG-018-D1-PNL-406701 - Rev06 UnsignedDocumento111 pagineNG-018-D1-PNL-406701 - Rev06 UnsignedFolarin AyodejiNessuna valutazione finora

- Customer ListDocumento10 pagineCustomer ListMohammed Tausif100% (1)

- Ecological Effects Test Guidelines: OPPTS 850.3020 Honey Bee Acute Contact ToxicityDocumento8 pagineEcological Effects Test Guidelines: OPPTS 850.3020 Honey Bee Acute Contact ToxicityNatalie Torres AnguloNessuna valutazione finora

- Evacuated Tube SystemDocumento2 pagineEvacuated Tube SystemAaron James RuedasNessuna valutazione finora

- Limiting Stoich 203Documento2 pagineLimiting Stoich 203api-284934591Nessuna valutazione finora

- Phosphate solubilizing bacteria promote tomato growthDocumento10 paginePhosphate solubilizing bacteria promote tomato growthVijay Singh KunwarNessuna valutazione finora

- Davey XS250HG ManualDocumento2 pagineDavey XS250HG Manualcoolestkiwi100% (1)

- LIST OF TSD FACILITIESDocumento18 pagineLIST OF TSD FACILITIESAmelia SantosNessuna valutazione finora

- Balauro Worksheet Protein SynthesisDocumento4 pagineBalauro Worksheet Protein SynthesisHami BalauroNessuna valutazione finora

- Process Systems ReviewDocumento2 pagineProcess Systems ReviewjokishNessuna valutazione finora

- Using psychrometric charts to analyze HVAC systemsDocumento18 pagineUsing psychrometric charts to analyze HVAC systemsRockydel MontesNessuna valutazione finora

- Kartu Stock Obat: Apotek EmpangDocumento17 pagineKartu Stock Obat: Apotek EmpangKlinik EmpangNessuna valutazione finora

- Micropitting Can Lead To Macro ProblemsDocumento2 pagineMicropitting Can Lead To Macro ProblemsAnonymous alQXB11EgQNessuna valutazione finora

- Tài liệu ôn tập tiếng anh 4Documento7 pagineTài liệu ôn tập tiếng anh 4Ngọc AmiiNessuna valutazione finora

- MSDS ScaleChem SI-7022Documento5 pagineMSDS ScaleChem SI-7022Muaz Haziq MusaNessuna valutazione finora