Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

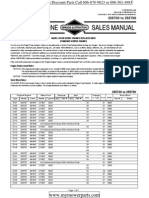

CE8117 - 0908 - BRIGGS & STRATTON Trouble Shooting Flow Chart

Caricato da

Kenn Ferro100%(1)Il 100% ha trovato utile questo documento (1 voto)

742 visualizzazioni16 pagineBriggs and Stratton Factory Service Manual

Titolo originale

CE8117_0908_BRIGGS & STRATTON Trouble Shooting Flow Chart

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoBriggs and Stratton Factory Service Manual

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

742 visualizzazioni16 pagineCE8117 - 0908 - BRIGGS & STRATTON Trouble Shooting Flow Chart

Caricato da

Kenn FerroBriggs and Stratton Factory Service Manual

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 16

TROUBLESHOOTING FLOW CHARTS

For Briggs & Stratton Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Answer Result Question Action Problem

Flow Chart Key

Bowl Style Carburetor Troubleshooting

Yes

Yes

No

Done!

Done!

No

Yes

No

No

Yes

Hunts and Surges

Will Run only on Prime

Will run only if the choke is used

Determine that the governor

system is functioning properly

using the proper isolation techniques

Does the engine still hunt and surge?

Does the engine still hunt and surge?

Does the engine still hunt and surge?

Partially engage choke

or gently touch primer bulb

Does the engine improve?

Inspect, clean or replace

mainjet and retest

Remove and clean

carburetor, retest engine

Replace

Carburetor

Troubleshoot

governor system

Answer Result Question Action Problem

Flow Chart Key

Compression Diagnostics

Troubleshooting Flow Chart

Yes

Yes

No

No

No

No

Is the top no load speed OK?

Is it correct?

Is there a parasitic load?

Still low power?

Perform leakdown test

Reading

acceptable

Yes

Yes

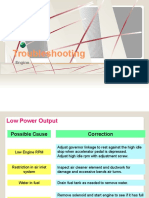

Low Power

Check for proper top

no load speed by

model and type number

Low or High

Partially engage choke

Does speed increase or

engine run more smoothly?

Repair as

needed

No

Repair as

needed

Adjust

valve lash

Repair as

needed

Check bowden wire/throttle

control for full range travel

Disengage load by

removing belts, etc.

Is leakage detected?

Is leakage detected?

Leakage

unacceptable

Overhaul carburetor looking

closely for obstructed jets

Repair load issues

as needed

Check for intake tract leaks,

gasket leaks, loose/leaking

carburetor space blocks,

loose/leaking crossover tubes

Yes Dont Know

Answer Result Question Action Problem

Flow Chart Key

Compression Troubleshooting Flow Chart

Yes

Yes

Yes

Yes

Yes

No No

No

No No

No

No

Check breather system

Check crankcase seals

Check block for porosity

Black/Gray Engine Smokes Excessive Oil Consumption What color is the smoke?

Does oil level drop more

than one ounce per hour?

Check for oil

fouled flter element

Is the flter fouled?

Is it still smoking?

Replace and run

Engine for ten minutes

Rapair/replace

faulty components

Perform Crankcase

Vacuum Test

External oil leaks present?

Repair as

needed

Done!

Done!

Check for overflled oil level

Check for fuel contaminated oil

Check for proper viscosity

Yes

Yes

Yes

Check/repair

fuel system

Was engine tipped?

White/Blue Is Engine Smoking?

Is Vacuum Test OK?

Is vacuum now ok?

Oil use

acceptable

Perform Leakdown Test

Reading

acceptable

Is leakage detected?

Leakage

unacceptable

Re-check all work

Low

Answer Result Question Action Problem

Flow Chart Key

Fuel System

Troubleshooting Flow Chart

Yes

No

No

No

Yes Yes

Yes

Put fuel in spark plug hole Check fuel supply/passages

Flo-jet

Carburetor

No

Yes

Yes

No

Engine Wont Start/Run

Check for: Clean, fresh fuel supply,

shutoff valve open, carb adjustments

properly made, controls functioning

Check carburetor

Put fuel in carburetor

Check spark plug

Recheck other work

Correct and recheck

Check

Compression

All ok?

Does it have a Flo-jet Carburetor?

Does the engine start/run?

No

Does the engine start/run? Does the engine start/run?

What kind of carburetor?

Is the spark plug wet?

Diaphragm

Carburetor

Check carburetor

mounting gasket

Check for: Clogged air cleaner,

stale fuel, oil/water in fuel,

misadjusted controls, choke plate

closed, damaged needle valve

Check for: Inlet valve

stuck open, improper

foat level, dirt in the

carburetor, loose nozzle(s)

Check for: Gummy/dirty

inlet screen, valve stuck,

bad diaphragm, restricted

passages in tank/carburetor

Check for: Clogged fuel line/flter,

fuel inlet valve closed, improper

foat level, carburetor fuel passages

plugged/restricted, faulty fuel pump

Done!

Done!

Done!

Done!

Answer Result Question Action Problem

Flow Chart Key

Systematic Troubleshooting

Electrical System Flow Chart

OK

Yes

OK

No

No

Incorrect

None

Yes

OK

Engine Wont Start

Check spark plug/replace

if necessary. Try to start engine.

Isolate engine

from equipment

Adjust armature air gap

Check coil to block ground.

Will engine start?

Check for spark to ground.

Check for spark to ground. None

Done!

Done!

Yes

None

Will engine start? Will engine start?

Check armature air gap.

Done!

Fix

Replace

Coil

No

Check/replace fywheel key

Check fuel system Check compression system

OK

Check grounding wire

diode (if equipped)

Check for

misadjusted controls

Check interlock switching

Answer Result Question Action Problem

Flow Chart Key

Governor Troubleshooting Flow Chart

Air Vane Governor Overspeeding

Done!

Done!

Replace fywheel if fns are

missing or broken, test engine

No

Is the cooling system ok?

Still overspeeding?

Yes

Yes

Yes

No

Done!

No Still overspeeding?

Yes

No

Done!

Still overspeeding?

No

Replace governor spring or

controls, test engine

Yes Resistance problem?

Inspect governor spring and controls

for damage or improper installation

No

Yes

Check the cooling system

Remove dirt and debris

from outside and inside of

blower housing, test engine

Air Vane Governor Overspeeding

Check fywheel fns

Check for uneven or

binding resistance in air vane

travel from stop to stop

Indentify resistance

and repair, test engine

Are the fywheel fns ok?

Answer Result Question Action Problem

Flow Chart Key

Governor Troubleshooting Flow Chart

Air Vane Governor Engine Runs Too Slow

Done!

Done!

Engine still runs too slow?

No

Replace governor spring or

controls, re-test engine

Yes Resistance problem?

Inspect governor spring and controls

for damage or improper installation

No

Yes

Indentify resistance and

repair, re-test engine

Move trottle control to idle, check

for binding or uneven resistance in

air vane travel from stop to stop

Air Vane Governor Engine Runs Too Slow

Answer Result Question Action Problem

Flow Chart Key

Done!

Done!

Done!

Done!

Hunting and Surging

Adjust carburetor idle speed, idle fuel,

and top no load fuel, test engine

No

Repair or replace link spring

as needed, test engine

Yes

Perform static governor adjustment

procedure, test engine

Still hunting and surging?

Still hunting and surging?

Still hunting and surging?

Yes

Yes

Yes

Inspect governor link spring for

damage or improper installation

No

No

Done!

Still hunting and surging?

No

Link spring need

repair or replacement?

Disconnect governor spring, check

for binding or uneven resistance in

governor arm travel from stop to stop

Replace governor spring

or controls, test engine

Yes Resistance problem?

Inspect governor spring and controls

for damage or improper installation

No

Yes

No

Indentify resistance

and repair, test engine

Governor Troubleshooting Flow Chart

Hunting and Surging

Answer Result Question Action Problem

Flow Chart Key

Governor Troubleshooting Flow Chart

Mechanical Governor Engine Runs Too Slow

Done!

Done!

Engine still runs too slow?

No

Replace governor spring

or controls, test engine

Yes

No

No

Resistance problem?

Inspect governor spring and controls

for damage or improper installation

No

Yes

Indentify resistance and

repair, test engine

Mechanical Governor Engine Runs Too Slow

Disconnect governor spring, check for

binding or uneven resistance in

governor arm travel from stop to stop

Adjust governor spring

tension, test engine

Engine still runs too slow?

Perform the static governor

adjustment procedure, test engine

Yes

Yes

Done!

Done! Engine still runs too slow?

Answer Result Question Action Problem

Flow Chart Key

Governor Troubleshooting Flow Chart

Mechanical Governor Engine Overspeeds

Done!

No

Yes

No

Yes

Done!

Done!

Done!

Still overspeeding?

No

Replace governor spring

or controls, test engine

Yes Resistance problem?

No

Yes

Indentify resistance

and repair, test engine

Done!

Still overspeeding?

No

No

Inspect governor spring and controls

for damage or improper installation

Yes

Yes

Adjust governor spring

tension, test engine

Disconnect governor spring, check

for binding or uneven resistance in

governor arm travel from stop to stop

Remove crankcase cover or sump

and inspect or replace internal

governor mechanism, test engine

Move throttle plate to the wide

open position and start engine

Does engine return to idle?

Perform the static governor

adjustment procedure, test engine

Mechanical Governor Engine Overspeeds Still overspeeding?

Still overspeeding?

Answer Result Question Action Problem

Flow Chart Key

Compression System

Troubleshooting Flow Chart

Leakdown Test

Reading

acceptable

Perform Leakdown Test Recheck other work Is leakdown test ok?

Where is the air primarily leaking from?

Leakage

unacceptable

Muffer

Dipstick

Tube

Air Cleaner

Cylinder

Head

Reset exhaust valve Check rings Reset intake valve Check head gasket

Potential Cause Action Symptom

Flow Chart Key

Gaseous Fueled Engine Troubleshooting

Engine does not accelerate

from low speed to high speed

or run smoothly when loaded.

Plugged vent ports on the regulator.

Less than 11 inches of water

pressure at the inlet of the

secondary regulator.

More than 14 inches of water

pressure at the inlet of the

secondary regulator at full load.

Plugged fuel flter.

Kinked or obstructed fuel hose.

No or low fuel in tank.

Propane tank is too small.

Fuel transfer solenoid in

the wrong position.

Carburetor not adjusted

properly (natural gas only).

Air leak in the fuel line from

secondary to carburetor.

Holes, tears or damaged diaphragm

in secondary regulator.

Debris on inlet needle

of regulator.

Remove plastic shipping plugs.

Adjust the output of the primary

regulator to 11 inches of water pressure.

If natural gas supply is lower than 11 inches

of water, a different secondary regulator

may be required consult factory.

Adjust the primary regulator to achieve 11

inches of water pressure while under load.

Note: if pressure at inlet of secondary regulator

increases upon starting the engine, check

primary regulator for holes or tears in the

diaphragm or dirt on the inlet seat.

Replace fuel flter.

Remove the kink and/or

replace the hose.

Refuel the tank.

Appropriately size the fuel tank

for the engine horsepower and

lowest ambient temperature.

When the fuel solenoid is energized or if the

main mixture adjustment screw is completely

seated, the engine is confgured for propane gas

(too lean of a mixture for natural gas). If the fuel

solenoid is not energized, the engine is confgured

for natural gas (too rich mixture with propane).

Readjust the mixture needles

on the carburetor.

Tighten the clamps or

replace the hose.

Replace damaged part.

Clean system of debris and add

a fuel flter. Use liquid pipe

sealant do not use Tefon tape.

Engine will not start.

Out of fuel. Refuel the tank.

Fuel supply shut off. Open fuel tank.

Filter or vacuum lock off

is not opening.

Check for proper operation of all fuel lock

off (safety) devices. If electrically actuated,

check for dead battery or blown fuse. Replace

lock off device if it is not functioning properly

Vacuum leak in the vacuum

lock off device.

Replace vacuum line or tighten

clamps. Replace vacuum

lock off if damaged.

Filter is plugged. Replace flter.

Frost forming on the regulator

or on the fuel line liquid

(not vapor) entering the system.

Wrong type of propane tank

set up for liquid withdrawal.

Replace the fuel tank or change

to the vapor withdrawal port.

Tank is positioned wrong

(typically tanks that lay on their side).

Fuel tanks have a receptacle for a

locator pin that orients the tank for a

specifc withdrawal. Pin may be in the wrong

location or missing. Reposition tank.

Fuel tank is overflled. Fill to labeled tank capacity only.

Fuel tank is too small,

especially if the ambient is low.

Increase the size of the fuel tank to

increase the vaporization rate of

the fuel. Consult with local gas supplier.

Restriction within the fuel line.

Remove restriction or replace

damaged part.

Gas will not stop fowing

after engine is stopped.

Regulator is not adjusted properly.

Adjust the regulator so that when the

outlet tube is placed in water, a gas

bubble just begins to form. Back off

on the adjustment so that the bubble

is maintained but does not grow.

Atmospheric side of the secondary

regulator is pressurized.

Remove plastic shipping plugs or

revise the regulator venting.

Debris on inlet needle of

secondary regulator.

Clean the system of debris and install

a fuel flter. Use liquid pipe

sealant do not use Tefon tape.

Regulator not positioned vertically.

Regulator may only be positioned

with the outlet pointing straight up.

A directional arrow is also shown

on the smooth side of the regulator.

Gas leak from fuel line.

Loose ftting. Tighten ftting replace if damaged.

Damaged, cracked or worn hose. Replace hose.

Gas leak from regulator.

Damaged diaphragm in regulator. Replace damaged part.

BRIGGS&STRATTON

CORPORATION

CUSTOMER EDUCATION

PO BOX 702

MILWAUKEE, WI 53201 USA

414 259 5333

CE8117-09/08

Potrebbero piacerti anche

- BRIGGS & STRATTON Trouble Shooting Flow ChartDocumento16 pagineBRIGGS & STRATTON Trouble Shooting Flow ChartBerlib75% (4)

- Isuzu Dmax Engine Service ManualDocumento704 pagineIsuzu Dmax Engine Service ManualPAVLOS97% (35)

- Troubleshoot engine issues with this comprehensive guideDocumento20 pagineTroubleshoot engine issues with this comprehensive guideAbdallah MansourNessuna valutazione finora

- Marine Engine Troubleshooting BasicsDocumento66 pagineMarine Engine Troubleshooting BasicsagvassNessuna valutazione finora

- Group 2 Operational Checks and TroubleshootingDocumento7 pagineGroup 2 Operational Checks and TroubleshootingPriscila RodriguesNessuna valutazione finora

- Trouble Shooting Carb and Compression BRIGGS & STRATTONDocumento1 paginaTrouble Shooting Carb and Compression BRIGGS & STRATTONvulpinor100% (1)

- Manual Motor 4ja1Documento704 pagineManual Motor 4ja1Juan Florez92% (26)

- GROUP 2 CHECKS AND TROUBLESHOOTINGDocumento8 pagineGROUP 2 CHECKS AND TROUBLESHOOTINGthierrylindoNessuna valutazione finora

- Troubleshooting Small Engines: This Presentation Has Not Been Edited by The Georgia Curriculum OfficeDocumento32 pagineTroubleshooting Small Engines: This Presentation Has Not Been Edited by The Georgia Curriculum Officechaudharialpesh50% (4)

- Renault Technical Note 3419A Turbocharger DiagnosisDocumento15 pagineRenault Technical Note 3419A Turbocharger DiagnosisClaudiu CondreaNessuna valutazione finora

- Generator in India, Delhi Gensets, India Generator, Gensets Delhi 4Documento3 pagineGenerator in India, Delhi Gensets, India Generator, Gensets Delhi 4gbaludbNessuna valutazione finora

- Wingle Engine ServicemanualDocumento196 pagineWingle Engine ServicemanualJoch Caso Alvariño85% (13)

- General Engine Information: Section: 1ADocumento11 pagineGeneral Engine Information: Section: 1AXavier OrtizNessuna valutazione finora

- Hyundai D6GA Fuel SystemDocumento53 pagineHyundai D6GA Fuel SystemBigfair HD78100% (11)

- Common Maintenance: Finding and Solving ProblemsDocumento3 pagineCommon Maintenance: Finding and Solving Problemsibrahim dimalnaNessuna valutazione finora

- 02-Engine Mechanical SystemDocumento96 pagine02-Engine Mechanical Systemsalvador341100% (1)

- Engine: Workshop ManualDocumento249 pagineEngine: Workshop ManualRiyan Pate Kamang100% (19)

- Weber Carb Troubleshooting GuideDocumento8 pagineWeber Carb Troubleshooting Guideleechyza100% (1)

- INDICATED MALFUNCTION: Engine Has Low RPM, Exhaust Gas Temperature, andDocumento6 pagineINDICATED MALFUNCTION: Engine Has Low RPM, Exhaust Gas Temperature, andRaul DeonarainNessuna valutazione finora

- 160m Hyd TroubleshootDocumento8 pagine160m Hyd TroubleshootDaniel Rhasty-ghee AhmanorNessuna valutazione finora

- Malfunction and Troubleshooting For Diesel EngineDocumento10 pagineMalfunction and Troubleshooting For Diesel Engineعبدالله عمر0% (1)

- Group 2 Operational Checks and TroubleshootingDocumento8 pagineGroup 2 Operational Checks and TroubleshootingPriscila RodriguesNessuna valutazione finora

- Hydraulic Trouble-ShootingDocumento9 pagineHydraulic Trouble-ShootingTrường NguyenNessuna valutazione finora

- Engine Cranks But Will Not StartDocumento52 pagineEngine Cranks But Will Not Startphuong lamhoang100% (8)

- Checklist Pms ObDocumento3 pagineChecklist Pms ObalsitorNessuna valutazione finora

- Checklist Pms ObDocumento3 pagineChecklist Pms ObalsitorNessuna valutazione finora

- WS Manual 1999 F-Super Duty S3 2, G3 - Eng - Powert Con & Emiss Diag-S4 - On BRD Diag II DSL P2Documento309 pagineWS Manual 1999 F-Super Duty S3 2, G3 - Eng - Powert Con & Emiss Diag-S4 - On BRD Diag II DSL P2Osterman NicolasNessuna valutazione finora

- Checklist Pms ObDocumento3 pagineChecklist Pms ObalsitorNessuna valutazione finora

- Hydraulic and Steering System PDFDocumento8 pagineHydraulic and Steering System PDFPutra Jawa100% (1)

- Full Car Service ChecklistDocumento2 pagineFull Car Service ChecklistGregg WookeyNessuna valutazione finora

- TroubleshootingDocumento7 pagineTroubleshootingg665013Nessuna valutazione finora

- Fuel SystemDocumento58 pagineFuel SystemAndrés Felipe Gutiérrez RodríguezNessuna valutazione finora

- Maintenance and Trouble Shooting of Hydraulic SystemsDocumento11 pagineMaintenance and Trouble Shooting of Hydraulic SystemsKannan Devadass100% (1)

- Engine Workshop Manual Section 6 Troubleshooting GuideDocumento360 pagineEngine Workshop Manual Section 6 Troubleshooting GuideAlbert Briceño81% (21)

- PSP-00088EAF 2023/1 1/04 19:19:18-06:00 SENR2132 © 2023 Caterpillar IncDocumento86 paginePSP-00088EAF 2023/1 1/04 19:19:18-06:00 SENR2132 © 2023 Caterpillar IncMario Núñez ObandoNessuna valutazione finora

- Risk assessment mechanical engineering documentDocumento14 pagineRisk assessment mechanical engineering documentAisyah Nur RidhaNessuna valutazione finora

- Tips For Troubleshooting EngineDocumento22 pagineTips For Troubleshooting EngineSandeep NikhilNessuna valutazione finora

- Alarms On Engine and Engine Emergency Operation - AgonoyDocumento3 pagineAlarms On Engine and Engine Emergency Operation - AgonoyRAE ANGELO AGONOYNessuna valutazione finora

- Cocu 3 (Lite) Intro g452 JB1Documento21 pagineCocu 3 (Lite) Intro g452 JB1sreetharanNessuna valutazione finora

- Hydraulic System Troubleshooting GuideDocumento27 pagineHydraulic System Troubleshooting Guidekhumiso100% (1)

- PT6A-27 Engine - Troubleshooting Quick ReferenceDocumento6 paginePT6A-27 Engine - Troubleshooting Quick ReferenceDade Sobarna100% (1)

- VacuumDocumento24 pagineVacuumDani-meganeboy100% (1)

- Diesel Generator TroubleshootingDocumento7 pagineDiesel Generator TroubleshootingChandra Vinoth Senthilnathan100% (4)

- Section 6 - Diagnostic ProceduresDocumento13 pagineSection 6 - Diagnostic Proceduresanon_152488453100% (1)

- Poor Engine Brake PerformanceDocumento8 paginePoor Engine Brake PerformanceEnriqueNessuna valutazione finora

- 06 - Tfheo We 0431Documento486 pagine06 - Tfheo We 0431jrrodrigueza2100% (1)

- Motor Daewoo Lanos Mecanica ElectricidadDocumento615 pagineMotor Daewoo Lanos Mecanica ElectricidadSergio Isaac Lagos LagosNessuna valutazione finora

- Automatic Transmission Troubleshooting GuideDocumento45 pagineAutomatic Transmission Troubleshooting Guideossoski100% (1)

- Massey Ferguson 35 TroubleshootingDocumento3 pagineMassey Ferguson 35 TroubleshootingrickyNessuna valutazione finora

- Cat - Pruebas y Ajustes 3406B S - N 2WBDocumento138 pagineCat - Pruebas y Ajustes 3406B S - N 2WBErika DiazNessuna valutazione finora

- The Unofficial DSA Learner Driver, Practical Driving Lesson and Driving Test Syllabus: You WILL Pass!Da EverandThe Unofficial DSA Learner Driver, Practical Driving Lesson and Driving Test Syllabus: You WILL Pass!Valutazione: 4.5 su 5 stelle4.5/5 (2)

- 50 Years of Engine Repair Solutions for American Muscle Cars, Street Rods, and Kit CarsDa Everand50 Years of Engine Repair Solutions for American Muscle Cars, Street Rods, and Kit CarsNessuna valutazione finora

- Francesco Alfieri - L'Arte Di Ben Maneggiare La Spada Di Francesco AlfieriDocumento228 pagineFrancesco Alfieri - L'Arte Di Ben Maneggiare La Spada Di Francesco AlfieriGeorge FraserNessuna valutazione finora

- (AD 1389) Codex Döbringer (Nurnberger Handschrift GNM 3227a)Documento59 pagine(AD 1389) Codex Döbringer (Nurnberger Handschrift GNM 3227a)Samurai_ChefNessuna valutazione finora

- Cooling Fan PDFDocumento6 pagineCooling Fan PDFigrekqaNessuna valutazione finora

- Trouble Shooting Carb and Compression BRIGGS & STRATTONDocumento1 paginaTrouble Shooting Carb and Compression BRIGGS & STRATTONvulpinor100% (1)

- Common Specifications For Briggs & Stratton Vanguard Ohv V-Twin Cylinder Engine ModelsDocumento2 pagineCommon Specifications For Briggs & Stratton Vanguard Ohv V-Twin Cylinder Engine Modelsvulpinor50% (2)

- MS0900 Power Pack System PDFDocumento16 pagineMS0900 Power Pack System PDFigrekqaNessuna valutazione finora

- Ignition - Wiring Basic Wiring Diagram BRIGGS & STRATTONDocumento1 paginaIgnition - Wiring Basic Wiring Diagram BRIGGS & STRATTONvulpinor58% (12)

- Peugeot 206 Wiring DiagramDocumento19 paginePeugeot 206 Wiring DiagramAdrian Botvinikoff100% (1)

- Illustrated Parts List 255700 To 255799: Model SeriesDocumento14 pagineIllustrated Parts List 255700 To 255799: Model SeriesigrekqaNessuna valutazione finora

- Old Inventory Parts List Please Call 606 561 4983 For Pricing PDFDocumento205 pagineOld Inventory Parts List Please Call 606 561 4983 For Pricing PDFigrekqaNessuna valutazione finora

- Common Specifications For Briggs & Stratton Intek V-Twin Ohv Engines PDFDocumento2 pagineCommon Specifications For Briggs & Stratton Intek V-Twin Ohv Engines PDFigrekqaNessuna valutazione finora

- Common Specifications For Briggs & Stratton All Single Cylinder Ohv Engine Models Except Intek Models PDFDocumento2 pagineCommon Specifications For Briggs & Stratton All Single Cylinder Ohv Engine Models Except Intek Models PDFigrekqaNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Digital Multimeter Instruction Manual MS6574 PDFDocumento16 pagineDigital Multimeter Instruction Manual MS6574 PDFigrekqaNessuna valutazione finora

- Electric Starter Quick Reference Guide For Engines Built After 1976 BRIGGS & STRATTON PDFDocumento1 paginaElectric Starter Quick Reference Guide For Engines Built After 1976 BRIGGS & STRATTON PDFigrekqaNessuna valutazione finora

- Check Chart: Common Specifications For All Single Cylinder Intek Engine ModelsDocumento2 pagineCheck Chart: Common Specifications For All Single Cylinder Intek Engine Modelsvulpinor33% (3)

- Check Chart Common - Specs - Metric - All BRIGGS & STRATTON - EnginesDocumento1 paginaCheck Chart Common - Specs - Metric - All BRIGGS & STRATTON - Enginesvulpinor0% (7)

- Common Specifications For Briggs & Stratton All Single Cylinder L Head Engine Models 270962 PDFDocumento2 pagineCommon Specifications For Briggs & Stratton All Single Cylinder L Head Engine Models 270962 PDFigrekqa100% (2)

- Common Specifications For All Briggs & Stratton Twin Cylinder Engine Models PDFDocumento2 pagineCommon Specifications For All Briggs & Stratton Twin Cylinder Engine Models PDFigrekqaNessuna valutazione finora

- Alternator IdDocumento1 paginaAlternator IdjlfmnessNessuna valutazione finora

- Alternator - Replacement With Wiring DiagrhamsDocumento18 pagineAlternator - Replacement With Wiring DiagrhamsvulpinorNessuna valutazione finora

- Check Chart Common - Specs - English - All BRIGGS & STRATTON - Engines PDFDocumento1 paginaCheck Chart Common - Specs - English - All BRIGGS & STRATTON - Engines PDFigrekqa67% (9)

- Two-Cycle Vertical Engine BRIGGS & STRATTON PDFDocumento59 pagineTwo-Cycle Vertical Engine BRIGGS & STRATTON PDFigrekqaNessuna valutazione finora

- Alternator Chart MS-2288FL - LR 7-09 PDFDocumento1 paginaAlternator Chart MS-2288FL - LR 7-09 PDFigrekqaNessuna valutazione finora

- Illustrated Parts List 255700 To 255799: Model SeriesDocumento14 pagineIllustrated Parts List 255700 To 255799: Model SeriesigrekqaNessuna valutazione finora

- ms9485 0698 PDFDocumento14 paginems9485 0698 PDFigrekqaNessuna valutazione finora

- Twin Cylinder OHV BRIGGS & STRATTON PDFDocumento101 pagineTwin Cylinder OHV BRIGGS & STRATTON PDFigrekqa100% (12)

- MS9676 0406 PDFDocumento2 pagineMS9676 0406 PDFigrekqaNessuna valutazione finora

- Stellarium User Guide-New PDFDocumento123 pagineStellarium User Guide-New PDFigrekqaNessuna valutazione finora