Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tehnology

Caricato da

Bursuc Sergiu EmanuelCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tehnology

Caricato da

Bursuc Sergiu EmanuelCopyright:

Formati disponibili

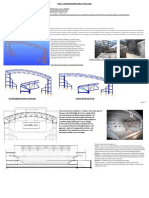

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

3. PERSONAL PROJECT PLAN

TECHNOLOGY ELEMENTS

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

3.1 Personal part description

Technological design

1. General conditions for construction execution:

The works are executed taking into account medium work conditions, considering that

the materials will be provided at the construction site, in the range of the mechanized

equipment from the location. With new construction materials which have the optimum

mechanical and physical property with respect to the actual standards.

The building phases must take place at day light or using artificial light. The temperature

must be higher than +5C, in order to provide optimum work condition and an open

construction front.

2. Materials

The material names are those used in the actual standards. The measurement units for

materials and for other works are according to the international system for units (I.S).

They must be tested either visually or using other methods (Laboratory) in order to provide

the required strength, stiffness and property.

They must be kept in safe conditions before using them in order to avoid their deterioration or

other unfortunate factor which may affect their structural integrity. All materials must be

included in the specific consumption norms.

3. Technological stages

3.1.Choosing of the building location

Through building location it must be understood the place on which the future construction

will be placed. Building location must respect the technical-economic, the exploatation, the

transport, the hygiene and the functional aspects.

Choosing the construction site must respect a series of factors as: surface and shape of the

terrain, connections with the communication networks, the status of the terrain, relief and

subsoil, natural clime. The social-cultural buildings must not be placed in the industrial area.

Links with the existent networks have an important role in order to provide the building an

easy access. The water and electricity must be permanently available on the field and on the

need of a neighborhood network is utterly necessary. The opinion of creating an internal

water installation is taken into account.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

3.2. Setting of the axes and establishing the 0 cote.

In order to draw the axes of the building the following pieces are required:

- General situation plan;

- Drawing of the main axis of the construction plan;

- Foundation plan

The main axis situated on the field is the base of the wall execution. The exterior perimeter is

delimited; afterwards the foundation axis will be established and the columns contour will be

drawn. After finishing the upward works, a set of auxiliary axis are drawn in order to provide

a support for the future works.

Drawing of the elements on the vertical axis will be realized by setting up the

beginning of the works some initial exterior landmarks (a minimum number of 3 such

landmarks is needed) from which the future distances will be measured.

3.3. Mechanical excavation

General principles that must be respected when executing the excavation works:

- The natural equilibrium of the terrain surrounding the foundation hole must not be

affected;

- The natural mechanical characteristics of the soil near foundation are maintained or

improved;

- The work security must be assured;

The mechanical excavation offers a faster and more accurate work. The devices used for

these kind of works are excavators with hydraulic commands. The excavators with twisted

hoe will be used for these kind of works because it is used for silty soils.

3.4. Transport for the excavation works

The transport of the soil which had been excavated is an important part of the technological

process which influences in a decisive manner the productivity of these works. The soil

resulted from the excavation is transported using trucks. A flux of trucks must be assured in

order not to cause the stopping of the excavators. The standard dump truck is a full truck

chassis with the dump body mounted onto the frame. The dump body is raised by a hydraulic

ram lift that is mounted forward of the front bulkhead, normally between the truck cab and

the dump body.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

3.5. Drawing of the pad and column axis

Depending on the drawing of the axis with respect to the project and determining the 0 cote,

the next step is to draw the foundation toe (block) and the pad. The excavation works for

foundation take place.

3.6. Execution of the foundation works for spread and continuous foundation

After digging the trench, a layer of minimum 5 cm is poured beneath the foundation

toe. After that the concrete is poured into the foundation. The pouring operations will be

realized using concrete pumps and transit mixers. When pouring the foundation block, a

continuous flux must be achieved in order not to stop the complex process of concrete

pouring.

The next step is to set up the wood formwork for the pad and to prepare the

reinforcements for the works. The formwork will be realized of pine wood using kneels and

steel wire for joints. The reinforcements must be put into place respecting the imposed

distances from the project. In this stage the reinforcement for the column must be also

positioned in the foundation pad, leaving only a distance of 80 cm of reinforcement over the

ground(whiskers). Pouring the concrete for the foundation and removing the formworks will

be the last step for these processes. The work point must be equipped with vibrators.

The filling soil is set up in order to achieve the required height where the 0 cote was

established. A layer of gravel having 5 cm is used in order to break the capillarity. A layer of

Kraft paper is set up over the foundation in order to avoid the water infiltrations.

The pouring of the leveling concrete at the pads and mounting of the reinforcement

for all foundations and columns take place. The pouring operations will not take place until

the state inspection, projection and the owner will be there and verify. A verbal process is

done which confers the quality of the works. Depending on the concrete class, concrete is

required from the supply deposits.

3.7. Elevation execution

After pouring the concrete into the foundation pads and leaving outside the proper

whiskers for joining the reinforcements between the columns from the ground floor with the

ones from the foundation, it is proceeding to the mounting of the formwork. At the execution

of the formwork for the building elevations, between the columns of the ground floor with a

pre check by the state inspection it is preceding to the concrete pouring. After concrete

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

hardening (28 days) the formwork removal is done for the elevations and the execution of the

filling operations between the empty spaces which will be properly compacted with vibrators.

3.8. Column reinforcement

The reinforcements are realized in special workshops on marks and pieces.

The columns reinforcement is placed with respecting the dimensions between bars

and between stirrups. The reinforcements which are to be set up are cut-up in centralized

workshops or in the construction site, being executed with respect to the project and

execution plans. The bars are positioned longitudinally, a minimum necessary of 4 bars being

required from constructive reasons (which have to be positioned in each corner of the

column). The minimum covering of the bars is done in order to provide protections from the

external factors. The longitudinal bars are solidified all across their length with stirrups

having the minimum diameter of 6 mm.

3.9. Concrete pouring

The concrete is brought in concrete mixers, being accompanied by certificates which attest

the class and physical properties of them. After that it is poured using concrete pumps. A

continuous flux must be assured.

3.10. Plate reinforcement, formwork and pouring

The next stage is positioning the formworks for plate. The formworks are realized is special

workshops. They are set up with respect to project prescriptions. After setting up the

formwork, a recheck of the axis is necessary. Special columns are provided made of wood

having 15-25 cm diameter to take the loads from concrete pouring. At each square meter one

such strut will be disposed.

After that, the reinforcement is positioned respecting the distances and project indications.

Some special devices are positioned in order to keep the bars in position when pouring the

concrete.

Before pouring the concrete, the concrete is necessary, in order that the hardening of the

concrete to take place in normal conditions. In 12 hours from pouring, the wetting of the plate

and formwork is done (at each 2 hours). In summer time, when there are high temperatures,

the covering of the plate is necessary using bags, sand and wood chips. On rainy weather, the

concrete is protected using panels so that the cement would not be washed from the surface.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

3.11. Girder reinforcement, formworks and pouring

The formworks for girders are realized from short sawn wood and whitewood or beech. They

are supported with single struts with crosses and braces. They can also be supported with

metallic struts. The addings for the panels are necessary and they are done in length, at the

ends of them (for accomplishment of the project prescriptions). The lateral panels including

the adding parts have the length equal with the height of the girder plus the formwork end.

The lateral panels are kept together with the end panels with kneels which have assembly

role. First, the bottom formwork is set in position, after that the fixing of the lateral panels

being realized.

The reinforcement positioning respecting the technical rues is done, after the reinforcements

were prepared in workshops: manufactured and bent where necessary. The distances between

bars are respected placing first the longitudinal bars, then the repartition bars. The stirrups are

set up in position before pouring the concrete.

4. Formwork design

The formwork are auxiliary constructions, mostly there are used as temporary structures

and have the role of shaping the concrete, dimensions and surface aspect until the concrete

reaches its desired mechanical properties which assures the safe formwork removal.

A correct formwork realizing can highly influence the complex technological process, as

the technological process influences the formwork setting.

The formwork cost, also they are temporary constructions can vary from 20% to 60% of

the total cost of the concrete works.

The parts of a formwork are:

- Solid part;

- Primary sustaining elements;

- Secondary sustaining elements;

- Bracing elements;

The main purpose when elaborating a formwork is to obtain the best technological and

economical solution;

The labour consumption is an important factor, the entire labour consumption

representing 40% to 60% of the labour used for a concrete work.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

5. Materials transportation with tower cranes. Lifting devices

Choose the tower crane necessary to lift different loads. Establish the lifting device

type.

5.1. Short history of cranes

There are several types of cranes, each of them with specific features in order to fulfill

the demands for particular jobs:

a). Truck -mounted crane:

A crane mounted on truck carrier which provides the mobility for the crane.

Outriggers that extend horizontally and vertically are used to level and stabilize crane for

hoisting.

b). Loader crane:

A loader crane offloads aerated concrete bricks at a building site. This is a

hydraulically -powered articulated arm fitted to a trailer, used to move goods onto or off of

the trailer. Unlike most cranes the operator must move around to be able to view his load;

hence he will have a portable cabled or radio linked control system.

c).Rough terrain crane

A crane mounted on an undercarriage with four rubber tires that is designed for pick -

and -carry operations and for off -road and rough terrain applications. Outriggers that extend

horizontally and vertically are used to level and stabilize the crane for hoisting. These

telescopic cranes are single-engine machines where the same engine is used for powering the

undercarriage as is used for powering the crane, similar to a crawler crane. However, in a

rough terrain crane, the engine is usually mounted in the undercarriage rather than in the

upper, like the crawler crane.

d).Crawler crane

A crawler is a crane mounted on an undercarriage with a set of tracks that provide for

the stability and mobility of the crane. Crawler cranes have both advantages and

disadvantages depending on their intended use. The main advantage of a crawler is that they

can move on site and perform lifts with very little set -up, as the crane is stable on its tracks

with no outriggers. In addition, a crawler crane is capable of moving with a load. The main

disadvantage of a crawler crane is that they are very heavy, and cannot easily be moved from

one job site to the next without significant expense. Typically, a large crawler must be

disassembled or moved by barge in order to be transported.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

e).Gantry crane

A Gantry crane has a hoist in a trolley which runs horizontally along gantry rails,

usually fitted underneath a beam spanning between uprights which themselves have wheels

so that the whole crane can move at right angles to the direction of the gantry rails. These

cranes come in all sizes, and some which are extremely large for use in shipyards or

industrial installations can move very heavy loads.

f).Tower crane

The tower crane is a modern form of balance crane. Fixed to the ground, tower cranes

often give the best combination of height and lifting capacity and are used in the construction

of tall buildings. To save space and to provide stability the vertical part of the crane is often

braced onto the completed structure which is normally the concrete lift shaft in the center of

the building. A horizontal boom is balanced asymmetrically across the top of the tower. Its

short arm carries a counterweight of concrete blocks, and its long arm carries the lifting gear.

The crane operator either sits in a cabin at the top of the tower or controls the crane by radio

remote control from the ground, usually standing near the load. In the first case the operator's

cabin is located at the top of the tower just below the horizontal boom. The boom is mounted

on a slewing bearing and is rotated by means of a slewing motor. The lifting hook is operated

by a system of sheaves. A jack up mast supports a tower crane. The inner element is moved

upward with jacks and a new outer section is assembled around the exposed portion. A tower

crane is usually assembled by a telescopic crane of smaller lifting capacity but greater height

and in the case of tower cranes that have risen while constructing very tall skyscrapers, a

smaller crane will sometimes be lifted to the roof of the completed tower to dismantle the

tower crane afterward. A self-assembling tower crane has been demonstrated, which lifts

itself off the ground using jacks, allowing the next section of the tower to be inserted at

ground level.

5.2. Mechanical principles

There are two major considerations that are taken into account in the design of cranes.

The first is that the crane must be able to lift a load of a specified weight and the second is

that the crane must remain stable and not topple over when the load is lifted and moved to

another location.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

5.3. Lifting capacity

Cranes illustrate the use of one or more simple machines to create mechanical

advantage: The lever: a balance crane contains a horizontal beam pivoted about a point.

The principle of the lever allows a heavy load attached to the shorter end of the beam to be

lifted by a smaller force applied in the opposite direction to the longer end of the beam. The

ratio of the load's weight to the applied force is equal to the ratio of the lengths of the longer

arm and the shorter arm, and is called the mechanical advantage.

The pulley: a jib crane contains a tilted strut that supports a fixed pulley block. Cables

are wrapped multiple times round the fixed block and round another block attached to the

load. When the free end of the cable is pulled by hand or by a winding machine, the pulley

system delivers a force to the load that is equal to the applied force multiplied by the number

of lengths of cable passing between the two blocks. This number is the mechanical

advantage.

The hydraulic cylinder: this can be used directly to lift the load, or indirectly to move

the jib or beam that carries another lifting device.

Cranes, like all machines, obey the principle of conservation of energy. This means

that the energy delivered to the load cannot exceed the energy put in to the machine. For

example, if a pulley system multiplies the applied force by ten, then the load moves only one

tenth as far as the applied force. Since energy is proportional to force multiplied by distance,

the output energy is kept roughly equal to the input energy (in practice slightly less, because

some energy is lost to friction and other inefficiencies).

5.4. Stability of crane

In order for a crane to be stable the sum of all moments about any point such as the

base of the crane must equate to zero. In practice the magnitude and combination of

anticipated loads is increased so that a crane should have a factor of safety against toppling of

about ten times.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

3.2 Personal part content

Technological design

Concrete is an artificial material consisting of ingredients, which are coarse and fine

aggregates forming inert materials and cement, which acts as the binding material. It is

usually made in a plastic state and gets hardened thereby achieving strength. The properties

of aggregates, cement and mixing water should be suitably checked and must be of approved

specifications. Plain, reinforced and prestressed concrete is being usually used in the

construction of buildings. The quickness and ease of construction in the case of concrete

work is a great advantage. The improved appearance and the types of different finishes,

which can be given to concrete surfaces, are added advantages in adopting these types of

construction buildings.

Good concrete, for economical results, can be made with materials a bulk of which is

generally obtainable near the site. Clean sand, strong coarse aggregates and good Portland

cement are necessary for making good concrete. These materials are to be mixed in the

proportions that all produce concrete having necessary strength and other properties

combined with the greatest economy.

The design of the concrete mix should be based on the following factors:

- the grade of designation;

- the type of cement;

- the minimum water-cement ratio;

- the workability;

- the durability.

The grade designation gives the characteristic compression strength

requirements of the concrete. The characteristic compression strength is defined as the value

below which not more than 5% of the test results are expected to fall. It is the major factor

influencing the mix design.

The type of cement is important mainly through its influence on the rate of

development of compressive strength of the concrete.

The maximum size of the aggregate is determined by the sieve analysis. It may be

as large as possible, within specified limits because larger the size of aggregates smaller is the

cement quantity for a particular cement-water ratio. The workability also increases with the

increase in maximum size.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

The water-cement ratio gives at a specific age and under normal temperatures the

compressive strength. The lower the water-cement ratio is the greater the compression

strength is

The workability of the concrete for satisfactory placing and compaction is controlled

by the size and shape of the section to be concreted, the quantity and spacing the

reinforcements and the methods to be employed for transportation, placing and compaction

the concrete.

A. Load evaluation

a) self weight of the formwork p

a

= 25 daN/m

2

b) weight of the reinforced concrete :

3

( ) /

b b

P H A daN m = +

c)technological loading uniformely distributed (circulation paths and people agglomeration) :

- for the formwork fullness p

c

= 250 daN/m

2

- for horizontal sustains p

c

= 150 daN/m

2

- for vertical sustains p

c

= 100 daN/m

2

d) loading due to consolidation through vibration of the concrete

p

c

= 120 daN/m

2

.

Loadings :

- for the resistance calculus :

2

v a b c

P (p p p )daN/ m = + +

- for the rigidity calculus :

v

' 2

a b

P (p p )daN/ m = +

No.

Construct

ion

element

Formw

ork type

H

(m)

b

daN/m

3

b

+ A

daN/m

3

Loads

Pa Pb Pc Pe Pv Pv

1

Slab

Filled

0,12 2500 2650 25 345

250

120

740

370 2 ESO 150 640

3 ESV 100 590

4

Girders

Filled

0,5 2500 2650 25 1193

250

120

1588

1218 5 ESO 150 1488

6 ESV 100 1438

B. Horizontal loads acting on the side of the formwork

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

-

f

P loading from concrete casting:

2

1 2 3 4

[ / ]

f b

P H daN m =

-

1

coefficient depending on the speed of casting

-

2

concrete workability coefficient

-

3

coefficient that takes into account the maximum size of the item section of casted

concrete

-

4

coefficient that takes into account the temperature of the casted concrete

-

g

P dynamic horizontal loading of the shocks produced in the discharge of concrete :

2

600[ / ]

g

P daN m =

-

o

P total horizontal load;

o f g

P P P = +

-

' o

P permanent horizontal load;

' o f

P P =

No.

Element

H

[m]

b

[daN/m

3

]

v

[m/h

]

1

2

3

4

Loads [daN/m

2

]

P

f

P

g

P

o

P

o

1 girders 0.5 2500 10 1 1 0,95 0,95 1015.3 600 1615.3

101

5.3

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

max

1 1615.3 / q P m daN m = =

8mm o =

10 M cm =

9.20 H M cm o = =

4.4 c =

Elements:

- A, simply framed surface, boarding made of pine boards of 2,4 x 15 x

400 cm;

- B, primary supports, braces made of pine boards 8 x 9,8 x 400 cm; -

B', primary supports, braces made of pine boards 9,8 x15 x 400 cm;

- C, secondary supports of simple posts, circular pine -

D, ties made of pine boards 2,4x15x400 cm.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

C. Provided resistance

The rib is a continous beam (with d

ge

opening) subjected to bending.

q

W

l

W M

l q M

M M

pl apl

pl apl

cap

c

c

cap

c c

=

=

=

s

o

o

8

8

1

2

max

max

l max distance, [cm];

pl

permissible resistance to moisture of the plywood :

apl

= 120 daN/cm2

q uniformly distributed load for a strip width of 1 m;

n number of fields;

A

i

width of the plywood, [cm];

n

c

number of ribs;

2 2 2

3

100 100 9.20

1410

6 6 6

pl

b h H

W cm

= = = =

8 150 1410

32.36

1615.3

l cm

s =

32.36

' 30.82

1.05 1.05

l

l cm = = =

2

max

1

1615.3 32.36 211436

8

c

M daNcm = =

120 1410 169200

c

cap apl pl

M W daNcm o = = =

c l

c A

n

i

+

>

'

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

1

2

3

4

30 4.4

30 0.72 1; 2

30.82 4.4

40 4.4

40 1.01 1; 2

30.82 4.4

50 4.4

50 1.29 1; 2

30.82 4.4

100 4.4

100 2.71 3; 4

30.82 4.4

c

c

c

c

A cm n n n

A cm n n n

A cm n n n

A cm n n n

= = = = =

+

= = = = =

+

= = = = =

+

= = = = =

+

46 . 27

3

4 . 4 4 100

2 . 41

1

4 . 4 2 50

2 . 31

1

4 . 4 2 40

2 . 21

1

4 . 4 2 30

'

'

'

'

=

=

=

=

=

=

=

=

ef

ef

ef

ef

l

l

l

l

C.1 Checking

300 >

f

l

,

'

1.05 l l =

I E

l q

f

=

4

'

385

5

, where:

- l max distance [cm]

- E elasticity modulus;

2

150000 / E daN cm =

- I moment of inertia ;

3

4

12

b h

I cm

=

- q permanent load, [daN/cm]

pl

adm

pl

f f s

max

300

5

384

384

5

3 '

max

4 '

max

>

= s

=

l q

I E

f

l

I E

l q

f

pl pl

pl pl

pl

E

pl

= 150000daN/cm

2

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

4

3 3

26 . 4

12

8 . 0 100

12

cm

h b

I

pl

=

=

'

1 1015.3 / 10.153 /

o

q P m daN m daN cm = = =

'

1.05 41.2 1.05 43.26

ef

l l m m cm = = =

3

max

384 150000 4.26

59.70 300

5 10.153 43.26

l

f

= = <

The condition is not fulfilled and we insert an additional rib to the current panel of 50 cm

and resume the calculation of stiffness for the panel of 40 cm with l

ef

= 31,2 cm.

'

1.05 31.2 1.05 32.76

ef

l l m m cm = = =

3

max

384 150000 4.26

137.47 300

5 10.153 32.76

l

f

= = <

The condition is not fulfilled so we insert an additional rib to the current panel of 40 cm and

repeat the calculation of the stiffness for the panel of 100 cm with l

ef

=27,46cm.

'

1.05 27.46 1.05 28.83

ef

l l m m cm = = =

3

max

384 150000 4.26

201.71 300

5 10.153 28.83

l

f

= = <

The condition is not fulfilled sowe insert an additional rib to the current panel of 100

cm and resume the calculation of stiffness for the panel of 30 cm with l

ef

=21.20 cm.

'

1.05 21.20 1.05 22.26

ef

l l m m cm = = =

3

max

384 150000 4.26

438.22 300

5 10.153 22.26

l

f

= = >

The rigidity checking is satisfied

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

Slab formwork

a. Strength of the panel

max

c c

cap

M M s

8 8

2

2

ge

c

mac

d q

l q

M

=

=

c c

cap a c

M W o =

, where:

q uniformly distributed load for a strip of width 1m;

d

ge

distance between extensible girders;

a

c

= 120daN/cm

2

W

c

strength modulus

c

c

a

ge

W

d q

s

o

8

2

2 2 2

3

( ) 4.4 (10 0.8)

62.06

6 6 6

c

b h c M

W cm

o

= = = =

( ) ( )

'

max max max

740 0.312 0.044 263 /

c

af ef

q P l P l c daN m = = + = + =

cm

W

d

c c

a

ge

148

72 . 2

06 . 62 120 8

72 . 2

8

=

=

=

o

2

2

2.63 148

7200.9 / 120 62.06 7447.2 /

8 8

ge c

a c

q d

daN cm W daN cm o

= = < = =

b.

max

c c

adm

f f s

4

4 4

max

'

5 ' 5 5 1.317 188.14

0.63

384 384 384 120000 285.5

ge c

c c c c

q d

q l

f cm

E I E I

= = = =

300

ge

c

adm

d

f =

300

'

384

5

4

ge

c c

ge

d

I E

d q

=

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

3

' 300 5

384

q

I E

d

c c

ge

=

d

ge

distance between extensible girders;

E

c

elasticity modulus, E

c

= 120000daN/cm

2

I

c

moment of inertia

3 3 3

4

( ) 4.4 9.2

285.5

12 12 12

c

b h c M

I cm

o

= = = =

( ) ( )

' '

max max max

370 0.312 0.044 131.7 /

c

af ef

q P l P l c daN m = = + = + =

3

120000 285.5 384

188.14

5 300 1.317

ge

d cm

= =

4

max

5 1.317 188.14 188.14

0.63 0.62

384 120000 285.5 300

c c

adm

f cm f cm

= = > = =

c. The bearing capacity of the extensible girders

max

ge ge

cap

M M s

8 8

2

max

2

max

L d p

L q

M

ge

ge

=

=

ge

cap

ge

M

L d p

s

8

2

max

2

max

8

L P

M

d

ge

cap

ge

s

2

8 1500

0.57

640 5.75

ge

d m

s =

, se adopt 0.50

ge

d m =

2

max

640 0.50 5.75

1322.5

8

ge

M daNm

= =

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

We will use extensible girders GE with 6 9 L m = and bending moment

1500

c

cap

M daNm =

d. Positioning the props

max

pop pop

cap

N N s

max

2

pop pop

v af v ge

L

N p S p d = =

max

5.75

590 0.50 848.12

2

pop

N daN = =

H

pop

=2.8m

PE 3100R with 1.70 3.10 H m = i 2 4.5

cap

N tf = .

2

2 2000

1.18

590 5.75

cap

ge

v

N

d cm

p L

s = =

The concrete mix

The preliminary mix is obtained by taking into consideration the theoretical

information given by standards and the material characteristics (the cement type). The

assumption is that the aggregates are dry and that the water/cement ratio remains constant.

Computing steps:

a) Concrete class : C20/25;

- Workability : L3

- Maximum dimension of the aggregates : D=31mm.

b) Water quantity

-C20/25

3

185 / A l m beton =

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

c) Cement quantity

K

A

C = (Kg/m

3

beton ), where

C

A

K =

=

c b

R R o ) 5 . 0 (

A

C

c b

c

R R

R

C

A

K

+

= =

o

o

5 . 0

5 . 0 = o - for river aggregates

max

0.5 35

0.52 0.57

25 0.5 0.5 35

K K

= = s =

+

K

max

the maximum value allowed for W/C ;

K

A

C =

3

/ 356

52 . 0

185

m Kg C = = beton>C

min

=240Kg/m

3

beton

d) Overall aggregate quantity

(1000 10 )

g ag

c

c

A q A

q

c =

3

356

2.7 (1000 185 10 2) 1826 /

3

g

A kg m beton = =

2% c = - airvolum in the concrete

4 types of aggregate (0/3; 3/7; 7/16; 16/31), in proportion of :

3 3

0/ 3

32

1826 584 /

100 100

g

P

N A kg m beton = = =

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

3 7 3

3/ 7

50 32

1826 329 /

100 100

g

P P

N A kg m beton

= = =

3 16 7

7/16

72 50

1826 402 /

100 100

g

P P

N A kg m beton

= = =

3 31 16

16/ 31

100 72

1826 511 /

100 100

g

P P

N A kg m beton

= = =

TOTAL:

3

1826 /

g

A kg m beton =

The laboratory mix:

Check and adjust if it is necessary. This means checking the concrete for workability,

cohesion and surface finish and testing cubes or cylinders for determining the compressive

strength.

After the mix proportions are determined, in the preliminary mix, a trial mix is made.

That means to check the assumptions and establish the effect of the variation on water

requirements.

The laboratory mix is meant to provide 12 specimens (cubes and cylinders) for testing

concrete in strength at 7 days and at 28 days. It is prepared an informative mix of minimum

30 dm with the proportions of cement and aggregate found in the preliminary mix. The water

will be inserted step by step, until is obtained the desired workability. It will appear a new

quantity of water and a new specific weigh.

3

185 (7 6) 2 187 / A l m beton = + =

3

187

359 /

0.52

C kg m beton = =

3

356

2.7 (1000 187 10 2) 1818 /

3

g

A kg m beton = =

' 3

187 359 1818 2364 /

b

kg m beton = + + =

3

'

'

2367

1800 1800 1802 /

2364

ef

g

b

A kg m beton

= = =

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

On sorts:

3

0/ 3

1802

584 576 /

1826

N kg m beton = =

3

3/ 7

1802

329 325 /

1826

N kg m beton = =

3

7/16

1802

402 397 /

1826

N kg m beton = =

3

16/ 31

1802

511 504 /

1826

N kg m beton = =

TOTAL:

3

1802 /

g

A kg m beton =

The working mix

The working mix comes from the laboratory mix by correcting it with the real aggregate

humidity. The real aggregate humidity is usually known for each size fraction and is denoted:

ij

u .

0/ 3 3/ 7 7/16 16/ 31

2.5%; 2%; 1%; 1%;

N N N N

U U U U = = = =

100

i

g g gi

U

A A A A = A =

0/ 3

2.5

576 14

100

N l A = =

3/ 7

2

325 6.5

100

N l A = =

7/16

1

397 4

100

N l A = =

16/ 31

1

504 5

100

N l A = =

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

TOTAL: 29.5

g

A l A =

Water mixture:

' 3

187 29.5 157.5 /

g

A A A l m beton = A = =

Wet aggregate:

' 3

1802 29.5 1831.5 /

g g g

A A A l m beton = +A = + = , of which:

' 3

0/ 3

576 14 590 / N kg m beton = + =

' 3

3/ 7

325 6.5 331.5 / N kg m beton = + =

' 3

7/16

397 4 401 / N kg m beton = + =

' 3

16/ 31

504 5 509 / N kg m beton = + =

Technological sheet for concrete mix

Component

Composition for 1 m

3

beton Obs.

U

i

% Preliminary mix Laboratory mix Working mix

Water (l) 185 187 157.5 -

W/C 0.52 0.52 0.52 -

Cement 356 359 359 -

A

g

r

e

g

a

t

e

(

k

g

)

N

0/3

584 576 590 2.5

N

3/7

329 325 331.5 2.0

N

7/16

402 397 401 1.0

N

16/31

511 504 509 1.0

A

g

2367 2345 2356 -

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

Working mix in a mortar mixer with a capacity q = 500L

'

1000

r

q

G g = , where:

g quantity for mixture

G quantity for 1 m

3

concrete

q capacity of the mortar mixer

' '

500

157.5 0.8 63

1000 1000

b

q

A A r l = = =

'

500

359 0.8 144

1000 1000

b

q

C C r kg = = =

' '

0/ 3 0/ 3

590 0.40 236

1000

b

q

N N r kg = = =

' '

3/ 7 3/ 7

331.5 0.40 133

1000

b

q

N N r kg = = =

' '

7/16 7/16

401 0.40 161

1000

b

q

N N r kg = = =

, ,

16/ 31 16/ 31

500

509 0.8 204

1000 1000

b

q

N N r kg = = =

' '

16/ 31 16/ 31

510 0.35 179

1000

b

q

N N r kg = = =

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

Pouring the concrete

The placing methods and the vibration methods depend on the type of construction

element to be done (columns, wall, slab and beams) and also depend on the concrete

workability and on the consolidation equipment that is available. Concrete consolidation is

meant to remove the entrapped air voids. The bigger the water contents of the concrete (the

consistency) the smaller the consolidation effort required. Consolidation is normally achieved

through the use of mechanical vibrators.

The simple act of vibrating concrete does not confer on it any properties differing

from those it possesses when compacted to the same extent by other means.

min b exm

Q P s , where:

min b

Q minimum flow of concrete work being assessed the relationship:

ef

strat

b

t t

V

Q

1 2

min

= , where:

V

strat

concrete volume in a layer (strip);

t

2

minimum age at;

t

1ef

age of the concrete at the end of the pouring

P

exm

crane productivity in the concrete work, assessed the relationship:

b

c

exm

v

t

P =

1

,

t

c

duration of a transport cycle.

Concreting the columns

- Dimensions of the columns: 5050 cm;

- Height of the formwork: 2.75 m;

- Age of the concrete at the end of the pouring : 1.21h;

- Number of columns :15 on each floor;

Necessary concrete for the column on a floor is:

0.5x0.5x2.75x15=10.35 mc

On each column the concrete pouring is made with a concrete pump. For a beter vibration the

concrete will be placed on layer of 60 cm at a time folowed by a vibration time. The vibrator

should penetrate the layer of concrete vertically and into the underlying layer previously

vibrated when possible. The vibrator should then be slowly withdrawn to ensure closing the

whole resulting from its insertion. Satisfactory mixes, properly placed require more than 5 to

15 seconds of vibration.

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

Materials transportation with tower cranes. Lifting devices

Choose the tower crane necessary to lift different loads. Establish the lifting device type.

1.1. Calculation steps.

1. Establish the loads characteristics.

2. Determine the working fronts of the lifting device

3. Evaluate the necessary technological parameters for the lifting device.

4. Chose the lifting device.

1.2. The assignment content

a). Computation notes in order to choose the tower crane necessary for a particular

job, evaluation of the necessary technological parameters for the lifting device.

b). Technological sheet for materials transportation with tower cranes:

- working front.

-lifting device

1.3. Solving steps

Choose the tower crane necessary to lift a certain number of bricks and a given

quantity of concrete to the upper floor of a block of flats (ground floor and two floors).

1. Estimate the loads characteristics

Gr -the load that is lifted [kN];

hr -the height of the load that is lifted [m];

br -the width of the load that is lifted [m];

lr -the length of the load that is lifted and of the lifting device [m];

ho -the height of the lifting device measures from the upper part of the lifted load and

the clamping point to the crane's hook.

The bricks are lifted to the top of the building by using a special device named box -

pallet having the dimensions given in the technological sheet.

With this device there can be lifted a number of 80 (POROTHERM 25/30 LIGHT)

bricks with the weight of a single one equal with 11.5 daN. So:

G1 = 80 pieces x 11.5 g = 920 daN = 9.20 kN

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

hr = 0.8 m (the box -pallet height) in order to lift the load is necessary to use a device

made of four inclined cables. The weight of the lifting device is given by the weight of the

box -pallet (90 daN) and the weight of the inclined cables

gd = 90 + (2*45) = 180 daN = 1.80 kN;

hl = 1.65 m (the height of the device; 0.8 m the box-pallet and 0.85 m length of the

cables)

2. Determine the working fronts of the lifting device.

The dimensions of the structure are:

H = 13.30 m - the height;

B = 14.10m- the width;

L = 9.80 m- the length.

It will be used a tower crane that is placed on a rolling way situated along the block of

flats at 5 meters (d). The rolling way of the crane is arranged to H = + 0.50 m with respect

to the zero quota of the building.

3. Determine the necessary technological parameters needed to choose the lifting

device.

The crane's working parameters:

Qcnec. = Gl + gd

Where:

Qcnec. -the necessary load [kN];

Gl - the load that is lifted [kN];

gd - the weight of the lifting device [kN].

Qcnec. = 9.20 kN + 1.80 kN = 11.00 [kN] = 1.1 tones

Hcnec = H H + hl + hd + hs

Where:

Hcnec = the necessary height [m];

H = the difference between the crane's circulation level and the ground level [m];

hl = the height of the load that is lifted [m];

hs = the safety height (2.00 meters).

Hcnec = 13.30 m 0.5 m + 1.65 m + 2.00 m = 16.45 m

Rcnec = B + d

Where:

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

Rcnec = the necessary range for the lifting device so that the crane's hook vertical to

overtake the farthest point where the load has to be placed [m];

B = the structures width [m];

d = the distance between the rolling way and the structure [m].

Rcnec = 14.10 + 5.00 = 19.60 m

4. Choose the lifting device

The following conditions have to be simultaneously complied:

-Qc nec< Qc ef

-Hcnec<Hcef

-Rcnec< R ef

We choose the following lifting device: URW-506

Qc ef = 3.0 tf> Qc nec = 1.1 tf

Rcef =15.71m>Rcnec = 10.5 m

Hcef =16m>Hcnec = 12.95 m

Diploma Project Personal project plan

Student : NOVAC DANIEL PETRICA

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Chet Holmes MM WorkbookDocumento28 pagineChet Holmes MM Workbookflints100% (6)

- Connections in Steel Structures PDFDocumento54 pagineConnections in Steel Structures PDFsmmsajediNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Bs 6173Documento30 pagineBs 6173Tom50% (2)

- Corrosion Resistance of MiTek Metal ConnectorsDocumento4 pagineCorrosion Resistance of MiTek Metal ConnectorsEduardo Depiné TarnowskiNessuna valutazione finora

- DS11S1 - (1970) An Evaluation of The Elevated Temperature Tensile and Creep-Rupture Properties of Wrought Carbon Steel PDFDocumento102 pagineDS11S1 - (1970) An Evaluation of The Elevated Temperature Tensile and Creep-Rupture Properties of Wrought Carbon Steel PDFJacques StrappeNessuna valutazione finora

- Overview of Refractory MaterialsDocumento54 pagineOverview of Refractory MaterialsHenrique Alvr100% (5)

- Main Alloys PDFDocumento6 pagineMain Alloys PDFMohan RajNessuna valutazione finora

- Austentite Steel Thermal StabilizationDocumento17 pagineAustentite Steel Thermal StabilizationArangamar KumaranNessuna valutazione finora

- Case Study of Multi-Functional Sports Hall at RomaniaDocumento4 pagineCase Study of Multi-Functional Sports Hall at Romaniadamandadino50% (2)

- Hot Rolled Steel SheetsDocumento14 pagineHot Rolled Steel SheetssuvraNessuna valutazione finora

- Viking Post Indicator PDFDocumento12 pagineViking Post Indicator PDFpequenita34Nessuna valutazione finora

- Basicv 7Documento29 pagineBasicv 7ashok kulkarniNessuna valutazione finora

- 03 Site Administation InstructionsDocumento1 pagina03 Site Administation InstructionsBursuc Sergiu EmanuelNessuna valutazione finora

- PRO100 Quick StartDocumento19 paginePRO100 Quick StartGhita PlicNessuna valutazione finora

- Evidenta de Betoane TurnateDocumento1 paginaEvidenta de Betoane TurnateBursuc Sergiu EmanuelNessuna valutazione finora

- Safeguarding of Vulnerable Adults: Sergiu BursucDocumento1 paginaSafeguarding of Vulnerable Adults: Sergiu BursucBursuc Sergiu EmanuelNessuna valutazione finora

- Pro100 ManualDocumento61 paginePro100 ManualMiha AnghelNessuna valutazione finora

- Anexa 1 LaborDocumento1 paginaAnexa 1 LaborBursuc Sergiu EmanuelNessuna valutazione finora

- SB Certificate ICDocumento1 paginaSB Certificate ICBursuc Sergiu EmanuelNessuna valutazione finora

- SB Certificate FADocumento1 paginaSB Certificate FABursuc Sergiu EmanuelNessuna valutazione finora

- Moving and Handling Theory: Sergiu BursucDocumento1 paginaMoving and Handling Theory: Sergiu BursucBursuc Sergiu EmanuelNessuna valutazione finora

- Plan Etaj Curent-Layout1Documento1 paginaPlan Etaj Curent-Layout1Bursuc Sergiu EmanuelNessuna valutazione finora

- Model Scrisoare de Recomandare Pentru Masterat Din Partea Angajatorului EnglezaDocumento1 paginaModel Scrisoare de Recomandare Pentru Masterat Din Partea Angajatorului EnglezaBursuc Sergiu EmanuelNessuna valutazione finora

- To Whomsoever It May ConcernDocumento1 paginaTo Whomsoever It May ConcernBursuc Sergiu EmanuelNessuna valutazione finora

- PT DebugDocumento530 paginePT DebugBursuc Sergiu EmanuelNessuna valutazione finora

- Test Exemplu Futures First ADocumento2 pagineTest Exemplu Futures First ACornelius Paul AsoltaneiNessuna valutazione finora

- SF7138-00 Plan Cofraj Panouri 7138 - Plan Cofraj Panouri 7138 PDFDocumento1 paginaSF7138-00 Plan Cofraj Panouri 7138 - Plan Cofraj Panouri 7138 PDFBursuc Sergiu EmanuelNessuna valutazione finora

- Note 4 Engleza MQDocumento5 pagineNote 4 Engleza MQBursuc Sergiu EmanuelNessuna valutazione finora

- Dan M Dan M Dan M: External WallDocumento5 pagineDan M Dan M Dan M: External WallBursuc Sergiu EmanuelNessuna valutazione finora

- Test Exemplu Futures First ADocumento2 pagineTest Exemplu Futures First ACornelius Paul AsoltaneiNessuna valutazione finora

- ReadmeDocumento2 pagineReadmeBursuc Sergiu EmanuelNessuna valutazione finora

- ReadmeDocumento2 pagineReadmeBursuc Sergiu EmanuelNessuna valutazione finora

- Civil Constructions: A Lecture Delivered To The 3d Year StudentsDocumento75 pagineCivil Constructions: A Lecture Delivered To The 3d Year StudentsRadu TaşcăNessuna valutazione finora

- May - 2013 MicromechanicsDocumento44 pagineMay - 2013 MicromechanicsBursuc Sergiu EmanuelNessuna valutazione finora

- 1PAG Asdasdasd Awlfjdlkj Alkjwejf Wdkfjwekjf Jwefijwfj Kjfwjef 'WJF WKG KLWJG' Owjfw JDocumento1 pagina1PAG Asdasdasd Awlfjdlkj Alkjwejf Wdkfjwekjf Jwefijwfj Kjfwjef 'WJF WKG KLWJG' Owjfw JBursuc Sergiu EmanuelNessuna valutazione finora

- ExtrasDocumento1 paginaExtrasBursuc Sergiu EmanuelNessuna valutazione finora

- Outline of Lecture 4: Structural DynamicsDocumento49 pagineOutline of Lecture 4: Structural DynamicsBursuc Sergiu EmanuelNessuna valutazione finora

- Daniel KOTTFER, Milan Ferdinandy, Pavol HVIZDOŠ, Lukasz KaczmarekDocumento8 pagineDaniel KOTTFER, Milan Ferdinandy, Pavol HVIZDOŠ, Lukasz KaczmarekJigar M. UpadhyayNessuna valutazione finora

- DLP-8 Base Metal Preparation in Welding.Documento6 pagineDLP-8 Base Metal Preparation in Welding.Chinelle Joseph Sollano TinoyNessuna valutazione finora

- Determination of Ductility of BitumenDocumento2 pagineDetermination of Ductility of BitumenRakesh77700% (1)

- A Comprehensive Review of Vibration Energy Harvesting System and Comparison Between Piezo-Eletric and Electromagnetic Energy HarvestersDocumento10 pagineA Comprehensive Review of Vibration Energy Harvesting System and Comparison Between Piezo-Eletric and Electromagnetic Energy HarvestersNavraj SinghNessuna valutazione finora

- Aquashield: DescriptionDocumento3 pagineAquashield: DescriptionRana MahatoNessuna valutazione finora

- Composition of PCDDocumento3 pagineComposition of PCDHarsha MPNessuna valutazione finora

- Oman-1800x2100-Center Opening Auto Door-b+g+m+5-Sheet No - 01 of 05Documento5 pagineOman-1800x2100-Center Opening Auto Door-b+g+m+5-Sheet No - 01 of 05Lakhwinder SainiNessuna valutazione finora

- E3-11 Preparation of Metallographic Specimens PDFDocumento12 pagineE3-11 Preparation of Metallographic Specimens PDFevelyn50% (2)

- Thermal Performance Analysis On Staggered Finned Absorber Solar Air HeaterDocumento12 pagineThermal Performance Analysis On Staggered Finned Absorber Solar Air HeaterTJPRC PublicationsNessuna valutazione finora

- Chemical Exergy CalculationDocumento7 pagineChemical Exergy CalculationmaheshNessuna valutazione finora

- Design and Construction of A Deep Shaft For Crossrail: P. R. J. Morrison, A. M. Mcnamara and T. O. L. RobertsDocumento10 pagineDesign and Construction of A Deep Shaft For Crossrail: P. R. J. Morrison, A. M. Mcnamara and T. O. L. RobertsÜlgen ÜmitNessuna valutazione finora

- Alucobond ProductDocumento27 pagineAlucobond ProductYus wantoNessuna valutazione finora

- Week 11 - Trial PavementsDocumento11 pagineWeek 11 - Trial PavementstaglehayaNessuna valutazione finora

- Tds Dura-Pure sn95-sb5Documento1 paginaTds Dura-Pure sn95-sb5agus sutiawanNessuna valutazione finora

- Spesifikasi LiftDocumento2 pagineSpesifikasi LiftfahisawaodeNessuna valutazione finora

- Miele F 1901 SF Specification Sheet 747974Documento3 pagineMiele F 1901 SF Specification Sheet 747974Trần Quang TuyênNessuna valutazione finora

- BROCHURE Solatube PDFDocumento2 pagineBROCHURE Solatube PDFSoumikNessuna valutazione finora

- Experimental Study of Strengthening For Increased Shear Bearing CapacityDocumento9 pagineExperimental Study of Strengthening For Increased Shear Bearing CapacityBenzaamia AliNessuna valutazione finora

- AntiferroelectricDocumento6 pagineAntiferroelectricCristina ChirilaNessuna valutazione finora

- Cash Valve E-55 SeriesDocumento4 pagineCash Valve E-55 SeriesByron PanchiNessuna valutazione finora