Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

What Is Creep

Caricato da

Krishnan Santhanaraj0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

37 visualizzazioni12 pagineCREEP

Titolo originale

What is Creep

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCREEP

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

37 visualizzazioni12 pagineWhat Is Creep

Caricato da

Krishnan SanthanarajCREEP

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 12

What is creep?

Creep may be defined as a time-dependent deformation at elevated

temperature and constant stress. It follows, then, that a failure from such a condition is

referred to as a creep failure or, occasionally, a stress rupture. The temperature at which

creep begins depends on the alloy composition. For the common materials used in

superheater and reheater construction, Table I see below! gives the appro"imate

temperatures for the onset of creep. It should be pointed out that the actual operating

stress will, in part, dictate or determine the temperature at which creep begins.

The end of useful service life of the high-temperature components in a boiler the

superheater and reheater tubes and headers, for e"ample! is usually a failure by a

creep or stress-rupture mechanism. The root cause may not be elevated temperature,

as fuel-ash corrosion or erosion may reduce the wall thic#ness so that the onset of

creep and creep failures occur sooner than e"pected.

$owever, regardless of the cause, the failure will e"hibit the characteristics of a creep or

stress rupture. Indeed, the ASME Boiler and Pressure Vessel Code recogni%es creep

and creep deformation as high-temperature design limitations and provides allowable

stresses for all alloys used in the creep range. &ne of the criteria used in the

determination of these allowable stresses is '( creep e"pansion, or deformation, in

')),))) hours of service. Thus, the code recogni%es that over the operating life, some

creep deformation is li#ely. *nd creep failures do display some deformation or tube

swelling in the immediate region of the rupture.

Figure '. +chematic creep curve. Courtesy ,abcoc# - Wilco".

*t elevated temperatures and stresses, much less than the high-temperature yield

stress, metals undergo permanent plastic deformation called creep. Figure ' shows a

schematic creep curve for a constant load. a plot of the change in length verses time.

The weight or load on the specimen is held constant for the duration of the test. There

are four portions of the curve that are of interest/

*n initial steep rate that is at least partly of elastic origin, from point 0)0 to point

0*0 in Figure '.

This is followed by a region in which the elongation or deformation rate

decreases with time, the so-called transient or primary creep, from region 0*0 to

0,0 of Figure '. The portion from point 0)0 to point 0,0 occurs fairly 1uic#ly.

The ne"t portion of the creep curve is the area of engineering interest, where the

creep rate is almost constant. The portion from 0,0 to 0C0 is nearly linear and

predictable. 2epending on the load or stress, the time can be very long. two

years in a test and several decades in service.

The fourth portion of the creep curve, beyond the constant-creep-rate or linear

region, shows a rapidly increasing creep rate which culminates in failure. 3ven

under constant-load test conditions, the effective stress may actually increase

due to the damage that forms within the microstructure.

Without going into a detailed discussion of the atom movements involved in creep

deformation, suffice it to say that creep deformation occurs by grain-boundary sliding.

That is, ad4acent grains or crystals move as a unit relative to each other. Thus, one of

the microstructural features of a creep failure is little or no obvious deformation to

individual grains along the fracture edge.

The first two stages will not leave any microstructural evidence of creep damage.

+omewhere along the linear portion of Figure ', the first microstructural evidence of

damage appears as individual voids or pores. The location of these first voids or holes

varies, often noted at the 4unction of three or more grains, occasionally at nonmetallic

inclusions. These individual voids grow and lin# to form crac#s several grains long, and

finally failure occurs. The ultimate rupture is by a tensile overload when effective wall

thic#ness is too thin to contain the steam pressure.

+ince creep deformation occurs by grain-boundary sliding, the more grain boundary

area, the easier creep deformation will be. Creep deformation and creep strength are a

grain-si%e sensitive property. Thus a larger grain si%e improves creep strength. For

austenitic stainless steels, +*5'6 T765'$ for e"ample, the code re1uires a grain si%e

of 89 or coarser, to assure ade1uate creep strength. The elevated temperatures where

creep occurs lead to other microstructural changes. Creep damage and microstructural

degradation occur simultaneously. For carbon steels and carbon-':5 molybdenum

steels, iron carbide will decompose into graphite. For the low-alloy steels of T-'' and T-

55, the carbide phase spheroidi%es. Thus, creep failures will include the degraded

microstructures of graphite or spheroidi%ed carbides along with the grain-boundary

voids and crac#s characteristic of these high-temperature, long-time failures.

While creep failures are e"pected for superheaters and reheaters operating at design

conditions, deviations from these parameters will promote early failures. The steam

temperature always varies some from individual tube to tube, and the design allows for

this variability. $owever, when the range of temperatures is larger than accounted for,

the hottest tubes fail sooner than e"pected. * more li#ely cause of premature failure is

the slow increase in tube-metal temperatures due to the formation of the steam-side

scale.

+team reacts with steel to form iron o"ide along the I2 surface of the tube.

The microstructures themselves will show the grain-boundary sliding and the resultant

creep crac#s or voids. For stainless steels, the microstructures are similar in that the

failure is by grain-boundary-sliding and crac# formation.

In a superheater or reheater tube, often the very first sign of creep damage is

longitudinal crac#s in the steam-side scale. *s creep deformation e"pands the tube

diameter, the brittle I2 scale cannot follow the e"pansion. Crac#s develop in an a"ial or

longitudinal direction which is perpendicular to the principle hoop stress. With time, the

tube continues to e"pand, and these crac#s widen. This wide crac# shortens the path

from steam to steel. iron o"ide forms preferentially at the tip of the crac#, as there is less

o"ide thic#ness to protect the steel. and a cusp forms within the steel tube. The cusp

acts as a notch or a stress raiser, reducing the local wall thic#ness. Creep voids form

here, often before any other obvious grain-boundary damage appears elsewhere within

the microstructure. With continued high-temperature operation, creep crac#s grow from

the cusp and ultimately wea#en the cross section to the point where failure occurs.

Creep failures are characteri%ed by/

o bulging or blisters in the tube

o thic#-edged fractures often with very little obvious ductility

o longitudinal 0stress crac#s0 in either or both I2 and &2 o"ide scales

o e"ternal or internal o"ide-scale thic#nesses that suggest higher-than-

e"pected temperatures

o intergranular voids and crac#s in the microstructure

Editor's note: +ome ASME Boiler and Pressure Vessel Code re1uirements may have

changed because of advances in material technology and:or actual e"perience. The

reader is cautioned to refer to the latest edition and addenda of the ASME Boiler and

Pressure Vessel Code for current re1uirements.

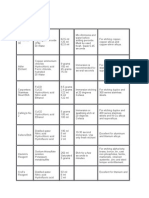

Table I

Initial Creep Temperature

For superheaters and reheaters, the scale that forms is essentially magnetite alloyed

with chromium, molybdenum, manganese, and silicon from the alloy steels of T-'' and

T-55. For waterwalls, the iron o"ide may be contaminated with impurities from the boiler

water and corrosion debris from the pre-boiler circuits of condenser and feedwater

heaters. In any event, the thermal conductivity of the steamside scale is about ;( of the

thermal conductivity of the steel tube. Thus, an effective insulating layer forms and

prevents proper cooling of the tube metal by the steam. The net effect of the scale is to

raise the tubemetal temperature. 2epending on the scale thic#ness, which is dependent

on the time and temperature of operation, tube-metal temperature increases of 5; -

9;

o

F are li#ely. +uch a large increase raises tubemetal temperatures beyond the safe

design range. These elevated temperatures result in increased creep deformation rates,

more rapid o"idation and corrosion thinner walls and higher stress! and hasten the

onset of creep failures. *n increase of <)

o

F from ')=)

o

F to ''))

o

F for e"ample! will

decrease creep life by >)(. *n increase of <)

o

F due to steam-side scale formation in a

superheater or reheater is not unusual.

Carbon steel....................... ?))

o

F

Carbon @ ':5 Aolybdenum............ ?;)

o

F

'-':= Chromium-':5 Aolybdenum...... >;)

o

F

5-' := Chromium-' Aolybdenum....... ')))

o

F

+tainless steel.................... ');)

o

F

7riority ' items should be considered for inspection with in the ne"t 9,;)) hours or ;)

thermal cycles of operation.

Bocations with no #nown or documented inspection history and are considered high-ris#

areas associated with steam lea#s, crac#s and ruptures. i.e. boiler outlet connection.

wye bloc# : lateral fittings. longitudinal seam welds traffic areas!. attemporator spools.

drain penetrations

Steam Boiler Inspections Using Remote Field Testing

)6:)':5)''

By Mynor Celis, 7.3ng, Cussell D23 +ystems

Forced outages of steam boilers due to tube lea#ages remain the leading cause of lost

production in plants. 2ue to hundreds, if not thousands of linear feet of pipe, there is a

high potential for failure without notice. &ne of the biggest challenges for maintenance

and operations personnel is the prevention of tube failures in boilers and heat

e"changers without causing significant loss to the company. When e"cursions from

normal operating conditions occur, the 1uestion must be raised, Eif our boiler tubes were

damaged by the e"cursion for e"ample, overheating, or a condenser tube lea#!, how

do we find out if we have a problem that could lead to failure?F

,oiler operation always involves harsh wor#ing conditions. &n the fuel side of tubes,

high operating temperatures and corrosive by-products from burning fossil fuels or solid

waste can seriously degrade the life-e"pectancy of the boiler tubes. &n the water:steam

side, there is a high potential for o"idi%ation of boiler tubes due to high temperature

steam and the corrosive action of chemicals in the water supply. These conditions may

cause metal to overheat, corrosive wall thinning, and locali%ed pitting, any or all of which

can lead to premature failure of the tubes, possible in4uries to personnel, damage to

ad4acent tubes and a forced outage.

In spite of these adverse operating conditions, boilers have a life e"pectancy upwards of

6) years and most premature failures are due to conditions that ma#e operational

variables deviate from e"pected parameters.

Industrial best practice is to inspect all tubes periodically, chec#ing to ensure that

mechanical properties of the materials are intact and that material thic#ness is within

normal e"pectations. * proper and rigorous inspection regimen will go a long way to

reduce the probability of premature boiler failures.

Thomas C. +chmidt of +hell &il headed the initial development of the remote field

testing CFT! techni1ue for measuring oil well casings. *fter that, several tools have

entered the mar#et using CFT for multiple speciali%ed applications.

The primary benefit of this techni1ue is that it does not re1uire contact with the ob4ect

under test to measure material thic#ness and condition. *dditionally, a high-1uality

inspection can be assured without re1uiring couplant and with minimal surface

preparation. CFT also shows high sensitivity to detection of defects on the I2 or &2 of

the tube in 1uestion and can measure through non-ferromagnetic coatings, linings and

scale.

There are two approaches to doing maintenance of any #ind/ a preventative approach

or a corrective approach pro-active or reactive!. This holds true with boiler inspections.

* preventative approach see#s to loo# at the long-term wear-and-tear tendencies on the

e1uipment, with an eye towards improving operations through improvements to the fuel-

air mi"ture, flow balancing and the creation of a maintenance specification for tube

repair or replacement. Gnderta#ing a corrective approach loo#s to inspect the boiler

after a failure to loo# for collateral damage and to ensure that the failure mechanism has

not affected other areas in the boiler.

&f the two, the former is more advantageous from the perspective of being performed

before failure, within the conte"t of the firmHs long-range operational plan, resulting in a

reduced effect to the operations budget and significantly reduced time lost due to

une"pected outages.

Longterm o!er"eating #creep$: This type of failure occurs when the operating

temperature of the boiler tubes e"ceeds the operational limits for an e"tended period of

time. These limits are variable based on the tube si%e and thic#ness, operating

pressures, as well as the tube locations in the boiler and construction materials.

&verheating leading to creep damage can be caused by internal deposits, which reduce

flow through the tubes or, more commonly, sudden spi#es in operating temperature due

to increasing load or issues with the temperature control. These reduce the resistance

of the tubes.

Figure % Longterm

o!er"eating #creep$

How to detect creep damage: 2uring the period of long-term overheating, the surface of

the tube will develop blisters at the locations sub4ect to the highest temperature and will

develop elongated a"ial crac#s. ,oth of these failures will reduce overall tube thic#ness

and material properties of the tube. *dditionally, thic#, dar#, brittle o"ides will appear on

the internal and e"ternal surfaces of the tube. *ll of these conditions can be detected

through CFT as the changes in the tubes electrical permeability can be easily

measured.

How to prevent creep damage: &ften, when boilers are operating outside of standard

operational parameters, it goes unrecorded or unnoticed by the operator. 3ither of these

issues can lead to premature failure, as the degradation of the tubeHs material properties

is not being accurately recorded. *s such, it is necessary to run periodic performance

evaluations on the boiler. 3nsuring fre1uent calibration of the thermostats is the best

way to prevent une"pected temperature spi#es and to help ensure that the unit is

warmed up in accordance with the manufacturerHs recommended specifications.

Fre1uent sampling of the unitHs feed water supplyIideally once per shiftIwill help to

ensure that the feed water 1uality is within the manufacturerHs recommended

parameters. Cegular internal flushing of the boiler tubes will ensure removal of any

material deposits clogging the tubes. *ny deposits must be measured fre1uently, and

chemical cleaning is recommended when the deposit density e"ceeds '; g:s1.ft.

Cleaning becomes mandatory as the density reaches 6) g:s1:ft. Fre1uent drum

inspections are mandatory according to the maintenance manual of the manufacturer.

2epending on the hours of service, it is necessary to determine how well the e1uipment

is wor#ing, the effectiveness of the water treatment and that there are no failure

mechanisms affecting the internal surface, mainly in the area of water-steam interface

line.

Bastly, it is necessary that all spare parts used in maintenance or repairs are correct to

the manufacturerHs specifications. It should be noted that when any tube fails as a result

of creep damage, there will be a rupture with slightly rounded edges and 4agged edges

with crac#s or brea#s in the vicinity of the rupture. * thic#, fragile layer of magnetite will

appear near the failure, indicative of long-term overheating.

S"ort Term &!er"eating: Aost often, these failures occur when the tubes are left

without sufficient cooling and occur in short order. Failures caused by short-term

overheating fre1uently occur at the top of the tubes or close to the steam collector. If the

failure occurs in a single tube and if surrounding tubes have no appearance of

alteration, it suggests that the failed tube was at least partially obstructed, causing the

temperature to rapidly e"ceed material limits, causing an e"plosion or lea# in the tube.

Figure ' S"ortterm

o!er"eating

How to detect short-term overheating: *s these failures occur rapidly, it is recommended

that the tubes be inspected visually through the inspection ports during start-up. If red

spots suddenly appear on a tube, it is a signal that the tube may be plugged. This type

of inspection is necessary after chemical cleaning, tube replacement or re-

commissioning after a long period of dormancy.

How to prevent short-term overheating: *s a result of the rapid occurrence of this type

of failure, it is not readily detectable through non-destructive testing methods. The best

way to prevent it is to flush the tubes with water to ensure all obstructions are removed

prior to startup and by ensuring that the purge and bottom headers are open as the

pressure is increased. This type of failure can be recogni%ed by the longitudinal rupture,

smooth edges and no loss of wall thic#ness as the rupture.

&(ygen Corrosion: &"ygen corrosion occurs in a boiler due to small corroded regions

which acts as an anode to the rest of the boiler, causing further corrosion. This process

is e"acerbated by the presence of dissolved o"ygen in the boiler system. Ideally, the

boiler surface would be covered with a protective layer of iron o"ide, preventing the

attac# of free o"ygen in the water supply. The small pits that result from o"ygen

corrosion can cause significant stress, and will result in the formation of crac#s in the

region

Figure ) &(ygen

corrosion

How to detect oxgen corrosion: CFT is one of the most effective methods used to

detect o"ygen corrosion if it is located at the fire side. $igh tool sensitivity and accuracy

J':?F diam.! allows for the early detection of initial defects, providing data necessary to

determine a repair or replacement protocol before the tube fails. Gltrasonic testing GT!

can also be used, but is limited by significantly slower inspection time and the fact that

')) percent coverage is impossible. The latter increases the ris# that serious damage to

tubes could go unnoticed.

How to prevent oxgen corrosion: The most effective way to prevent o"ygen corrosion

in boiler tubes is to prevent o"ygen from entering the system in the first place.

&"ygen enters a boiler system primarily through three means/ air can be trapped during

normal operation when internal pressure is less than the ambient atmospheric pressure.

when the system is left open for maintenance. and as a result of molecular dissociation

of water in the system. &ther critical factors are the presence of ambient moisture in the

system and, the loss of a passivation layer after chemical cleaning. 3liminating these

factors can successfully prevent o"ygen corrosion. It is recommended that all metal

surfaces be #ept dry using positive-pressure inert gas, moisture-absorbing materials, or

a continuous flow of dry, dehumidified K6) percent! air.

Caustic Corrosion: Caustic corrosion refers to the corrosive action of sodium

hydro"ide with a metal and is restricted to/ water-cooled tubes in regions of high heat

fluctuation. regions with heat transfer in welding rings or other devices that disrupt flow.

hori%ontal or inclined tubes. places with thic# internal deposits reducing flow rates. This

penetration may be filled with dense corrosion products which sometimes contain

magnetite crystals. Aost often, the metal surface has a smooth contour and laminations.

+odium hydro"ide is added to boiler water in non-corrosive concentrations. however

other physical factors tend to concentrate it further, leading to the production of

corrosive al#aline in the boiler.

Figure * Caustic

corrosion

*d by websave L Close This

*d

How to detect caustic corrosion: Caustic corrosion is easily detected using non-

destructive testing methods, because the affected area is found with reduced wall

thic#ness. If this is in its early stage there may not be any blister, but if the thic#ness is

reduced there is li#ely to be a blister or deformation in the tube. Cemote field testing is

the most suitable method. These tools have high sensitivity and inspection speed,

allowing for rapid detection of corrosive damage. GT can also be used, once the

affected region has been located.

How to prevent caustic corrosion: When sodium hydro"ide is presentIeither by itself,

or as a salt-producing al#alineIwith a concentration mechanism, there e"ists the

possibility of caustic corrosion. To reduce the li#elihood of caustic corrosion damage in a

boiler, the amount of free sodium hydro"ide available to produce al#aline salts in the

condenser water must be controlled at the purification stage. This will prevent nucleate

boiling, and the formations of water-level lines. 7roper purging will prevent the formation

of sludge deposits.

+cidic Corrosion: There are two necessary conditions for this type of failure to occur/

the boiler must be operated with a p$ below normal parameters, and there must be a

means to concentrate the acid-producing salts that are responsible for the low-p$

environment. If both of these conditions are met, then the protective layer of iron o"ide

is dissolved, and the bare metal is left unprotected.

Figure , +cidic corrosion

How to detect acidic corrosion: Corrosion of this type primarily results in metal loss on

the interior surface of the tube. +imilar to caustic corrosion, areas affected by a low p$

environment tend to have smooth edges and lamination. The difference between the

two is that the region affected by acidic corrosion is often covered with iron o"ide.

Cemote field testing has high sensitivity, and can detect minimal corrosion accurately

from ':?F diameter, ma#ing it one of the most effective ways to detect acidic corrosion.

The Gltrasonic testing to determine the e"tent of wall loss however this can only be

effectively utili%ed once the affected region is #nown.

How to prevent acidic corrosion: Two ways e"ist to reduce the probability of acidic

corrosion in the boiler. The first involves reducing the availability of free acid, or acid

producing salts in the boiler, avoiding ma#e up water with Bow 7h. The second involves

eliminating the means to concentrate the acid in the boiler, such as bubble formations,

water-side deposits, and water-level lines. This can be achieved through regular, proper

purging of the boiler.

Stress Corrosion: +tress corrosion is caused by a combination of two separate factors/

tensile stresses on the pipe caused by internal pressure, or residual stresses induced

by improperly-applied heat treatment, or tube bending. and a corrosive material such as

sodium hydro"ide or chlorine. This combination results in crac#ing near the stressed

region. +tress corrosion usually occurs near welds, or tube bends.

Figure - Stress corrosion

How to detect stress corrosion: +tress corrosion displays as crac#ing near welds

sub4ect to tensile stresses. While stress corrosion crac#ing can be difficult to see, it can

be detected visually. Bi1uid penetrant inspection provides a surer means of detection.

*dditionally, ultrasonic testing or radiographic testing can detect stress corrosion

crac#ing.

How to prevent stress corrosion: *nnealing will relieve residual stresses from welding or

bending. *dding phosphates to the operating environment will help prevent the

formation of free sodium, reducing the concentration of corrosion products.

.ydrogen /amage: When chemicals are added to boiler water to balance p$, an

electrochemical reaction can occur, releasing free hydrogen atoms into the

environment. This can cause decarburi%ation, embrittlement and the formation of

molecular hydrogen and methane in the steel. $ydrogen damage is restricted to

evaporator tubes with pre-e"isting corrosion problems. $ydrogen atoms diffuse into the

steel of the boiler tubes. +ome of these atoms bond with either each other, or the

carbon in the steel, forming molecular hydrogen or methane. These gasses accumulate

until the pressure causes the separation of the metal along the granular borders,

producing inter-granular micro-crac#s. This in turn reduces the mechanical strength of

the tube, which causes it to burst. *ny tubes suspected of failing due to hydrogen

damage should have samples ta#en and sent for metallographic analysis in a lab.

Figure 0 .ydrogen

damage

How to detect hdrogen damage: $ydrogen damage is hard to detect visually, e"cept in

the advanced stages when the pipe has visible crac#s. Cemote field testing is highly

effective in detecting hydrogen damage because the changes in the electrical properties

of the material due to hydrogen damage are readily detected.

How to prevent hdrogen damage: The two critical factors in reducing a boilerHs

susceptibility to hydrogen damage are the amount of hydrogen available, and the

means to increase its concentration. 7roper chemical treatment of feed water, combined

with a stringent p$ control system is the best way to prevent hydrogen damage.

1rap"iti2ation: Mraphiti%ation is caused by small structural changes of low-carbon

steels at moderate temperatures over e"tended periods of time. Mraphiti%ation causes

the decomposition of pearlite in ferrite, wea#ening the steel. The e"tent of the

decomposition is dependent on the temperature. This phenomenon generally occurs

due to long-term overheating, during which, the graphite nodules are lin#ed to each

other, reducing the resistance to internal pressure, causing the metal to tear.

Figure 3 1rap"iti2ation

How to detect graphiti!ation: Mraphiti%ation occurs internally, with the graphite

detaching from the steel reducing the total wall thic#ness. *s with hydrogen damage,

the electrical properties of the material changes when graphiti%ation is present. For this

reason, remote field testing is the most effective means of detection.

How to prevent graphiti!ation: The primary concern with respect to the susceptibility to

embrittlement due to graphiti%ation is tube 1uality. Bow carbon content steel is more

susceptible to graphiti%ation and long-term overheating is liable to e"acerbate the

problem. * good metal passivation program and treating the boiler feed water with

phosphate will reduce the probability of graphiti%ation.

Fire Side Corrosion: Aost fuel components can cause corrosion on boiler tubes. 2ue

to incomplete combustion, deposits of combustion residue can change the heat transfer

characteristics with potentially severe effects on system efficiency. Aost solid fuels

contain ') to 5) percent ash that remains in the boiler after combustion, leading to lost

heat transfer and corrosion. While li1uid fuels do not e"ceed 5 percent ash, they do

contain elements such as vanadium and sodium.

Figure 4 Fireside

corrosion

How to detect "ire side corrosion: When the surface of the boiler tubes are e"posed to

combustion gases, the damaged area of the surface will change color. Bong-term

corrosion of this type affects the permeability and conductivity of boiler tubes, as well as

causing pitting.

How to prevent "ire side corrosion: Fuel selection is of primary concern in addressing

the issue of fire-side corrosion. Fuels should be selected containing minimal corrosive

agents such as sulfur, sodium and calcium. +econd, optimi%ing the combustion 1uality

through control of temperature, fuel-air mi"ture, and air balancing will reduce the ash

deposits in tubes. Thermocouples should be installed throughout the boiler to indicate

when heat transfer is outside optimal operating range, which could be indicative of ash

deposits on the tubes. Third, continuous cleaning programs should be implemented in

the boiler.

The probability of steam boiler failure is dependent on numerous operational and

maintenance factors. The implementation of preventative inspection and tube profile

measurements will help to ensure that boilers are active for their e"pected 6)-year

average operational lives. *n active regime of preventative maintenance will be effective

at reducing the financial impact of une"pected shut-downs due to boiler tube failures.

&perations staff need to be trained in preventative maintenance procedures and

processes. &ften, when boiler tubes undergo catastrophic failure, ad4acent tubes are

often damaged as well, increasing the outage time. 7eriodic inspections and follow-up

preventative maintenance is necessary to ensure the boiler system remains in good

repair, and potentially e"tend its life-e"pectancy. With this in mind, we can conclude that

periodic boiler inspection is a vital part of any maintenance regime, and that remote field

testing is the optimal means for early detection of most causes of boiler tube failure.

*uthor/ Aynor Celis, currently is Aar#eting Aanager for Batin *merica for Cussell D23

+ystems, 3dmonton, *,. Canada, $e has previous e"perience as operation manager in

a coal-fired power plant, having responsibility for the operation of the boiler, water and

wastewater systems, high and low boiler steam pressure. $e is a mechanical and

electrical engineer with A,* speciali%ation.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- NTPC Safety Rules SummaryDocumento109 pagineNTPC Safety Rules SummaryVivek Kakkoth100% (2)

- Shutdown Maintenance ScaffoldDocumento1 paginaShutdown Maintenance ScaffoldKrishnan SanthanarajNessuna valutazione finora

- Instant Up Right Cat 2015Documento40 pagineInstant Up Right Cat 2015Krishnan SanthanarajNessuna valutazione finora

- Rim and Face Shaft AlignmentDocumento38 pagineRim and Face Shaft AlignmentJaime Berry100% (2)

- Us5282442 PDFDocumento6 pagineUs5282442 PDFKrishnan SanthanarajNessuna valutazione finora

- Bowl Mill-Feb 2009Documento12 pagineBowl Mill-Feb 2009Krishnan SanthanarajNessuna valutazione finora

- Unit I Divisional Superheater Coil Puncture On 10Documento1 paginaUnit I Divisional Superheater Coil Puncture On 10Krishnan SanthanarajNessuna valutazione finora

- Managing Air To Improve Combustion EfficiencyDocumento12 pagineManaging Air To Improve Combustion EfficiencyKrishnan SanthanarajNessuna valutazione finora

- A System For Suppressing and Inhibiting Fires in Coal Pulverizer MillsDocumento25 pagineA System For Suppressing and Inhibiting Fires in Coal Pulverizer MillsKrishnan SanthanarajNessuna valutazione finora

- NTPC Safety Rules SummaryDocumento109 pagineNTPC Safety Rules SummaryVivek Kakkoth100% (2)

- Pulverizer Fire and ExplosionDocumento4 paginePulverizer Fire and ExplosionKrishnan SanthanarajNessuna valutazione finora

- 212292Documento91 pagine212292Jaime BerryNessuna valutazione finora

- Review of Type IV Cracking of Weldments in 9Documento64 pagineReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajNessuna valutazione finora

- The Thrust PadDocumento2 pagineThe Thrust PadKrishnan SanthanarajNessuna valutazione finora

- Turbine Operational ProblemsDocumento35 pagineTurbine Operational Problemsna2011100% (1)

- Plant Schematics Rev.01Documento67 paginePlant Schematics Rev.01Krishnan SanthanarajNessuna valutazione finora

- Tri Sec AphDocumento36 pagineTri Sec AphKrishnan Santhanaraj100% (1)

- Sag ChartDocumento1 paginaSag ChartKrishnan SanthanarajNessuna valutazione finora

- Thrust Bearing End PlayDocumento3 pagineThrust Bearing End PlayKrishnan SanthanarajNessuna valutazione finora

- 226Documento2 pagine226Krishnan SanthanarajNessuna valutazione finora

- 33-1985 Evaluating Thrust Bearing Operating TemperaturesDocumento7 pagine33-1985 Evaluating Thrust Bearing Operating TemperaturesMohammad Fikri JalaludinNessuna valutazione finora

- Boilers 1Documento29 pagineBoilers 1Thakur Kamal Prasad50% (2)

- NTPC Quality InspectionDocumento39 pagineNTPC Quality InspectionPower Power60% (5)

- History of Hitachi Power EuropeDocumento4 pagineHistory of Hitachi Power EuropeKrishnan SanthanarajNessuna valutazione finora

- Dry Flue Gases Losses in BoilerDocumento2 pagineDry Flue Gases Losses in BoilerKrishnan SanthanarajNessuna valutazione finora

- Tri Sec AphDocumento36 pagineTri Sec AphKrishnan Santhanaraj100% (1)

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Documento74 paginePresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Krishnan SanthanarajNessuna valutazione finora

- Operators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineDocumento8 pagineOperators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineKrishnan SanthanarajNessuna valutazione finora

- NTPL U1 Edta Prog 200214Documento2 pagineNTPL U1 Edta Prog 200214SethuRamalingamNessuna valutazione finora

- Governor TutorialDocumento13 pagineGovernor TutorialWalid Fattah100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Metallurgy-Investigatory Project PDFDocumento20 pagineMetallurgy-Investigatory Project PDFAbhishek yadav80% (5)

- Vol-1, Issue-4Documento13 pagineVol-1, Issue-4Ijrei JournalNessuna valutazione finora

- Astm E1025 PDFDocumento6 pagineAstm E1025 PDFmga_4566472Nessuna valutazione finora

- RG 1.43 PDFDocumento3 pagineRG 1.43 PDFAlex GutierrezNessuna valutazione finora

- 2015 Widin CatalogueDocumento413 pagine2015 Widin Catalogue*mile*Nessuna valutazione finora

- Xia 2013Documento13 pagineXia 2013Mashfiqul IslamNessuna valutazione finora

- Australian Standards-projects-by-sector-31-Jan-2013 PDFDocumento36 pagineAustralian Standards-projects-by-sector-31-Jan-2013 PDFAbhijit Kumar GhoshNessuna valutazione finora

- Essar Steel India Marketing DepartmentDocumento10 pagineEssar Steel India Marketing DepartmentJaydeep SolankiNessuna valutazione finora

- Bearing N PDFDocumento160 pagineBearing N PDFAnonymous hxQ7PNOQNessuna valutazione finora

- 5 - Cast Iron and Tool SteelsDocumento25 pagine5 - Cast Iron and Tool Steelsbarry nancooNessuna valutazione finora

- Astm 856Documento3 pagineAstm 856Nirmal Wires100% (1)

- List of Etchant For MetallographyDocumento3 pagineList of Etchant For Metallographyniraj_hwbNessuna valutazione finora

- Chinese Standards On Steel Materials-1Documento3 pagineChinese Standards On Steel Materials-1mesmerize59100% (2)

- Drop Forged Chain PDFDocumento8 pagineDrop Forged Chain PDFluiNessuna valutazione finora

- Saep 324Documento13 pagineSaep 324Hansel Francis100% (4)

- Astm A276Documento7 pagineAstm A276Joffre ValladaresNessuna valutazione finora

- PQR GmawDocumento4 paginePQR GmawEr Sumant Kumar Singh0% (1)

- WPSDocumento1 paginaWPSRodica TimofteNessuna valutazione finora

- Main Roads Specifications and Technical Standards MRTS78 Fabrication of Structural SteelworkDocumento20 pagineMain Roads Specifications and Technical Standards MRTS78 Fabrication of Structural Steelworkmohamed salahNessuna valutazione finora

- Aisi 5160 Alloy Steel (Uns g51600)Documento4 pagineAisi 5160 Alloy Steel (Uns g51600)Rizki RiantoniNessuna valutazione finora

- JI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDocumento2 pagineJI S (Japanes E) Stand Ards For ST EE L Ma TE RI ALSDamar Wardhana100% (1)

- PT ZUG WELDING QUALIFICATIONDocumento4 paginePT ZUG WELDING QUALIFICATIONMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- ICSECM - 2017 - Research PaperDocumento6 pagineICSECM - 2017 - Research PaperdilrangiNessuna valutazione finora

- Documents - Tips - Cswip 322 Questions PDFDocumento37 pagineDocuments - Tips - Cswip 322 Questions PDFJithuJohn83% (6)

- Crafting Strong Relationships in SteelDocumento15 pagineCrafting Strong Relationships in SteelOnkar DograNessuna valutazione finora

- FM130036 - EnC 18 - Stairway SpecificationDocumento20 pagineFM130036 - EnC 18 - Stairway Specificationayman ammar100% (1)

- A312 TP316Documento12 pagineA312 TP316Ramana NatesanNessuna valutazione finora

- Aa 036007 001Documento1 paginaAa 036007 001narutothunderjet216Nessuna valutazione finora

- Ugiweb 913082Documento128 pagineUgiweb 913082psychedelic_lullabyNessuna valutazione finora

- DESPONIA 1545enDocumento8 pagineDESPONIA 1545enkad-7Nessuna valutazione finora