Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dpe

Caricato da

Marian DunareanuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dpe

Caricato da

Marian DunareanuCopyright:

Formati disponibili

Freduct 8pecificatiens

Voltage 24 V00

Power Nax. 40 w

0perating Temperature 5 l 50 0 (40 l 120F)

Protection Class |P54

Clean Room 100

Clean Room with 8cavenge Port* 10

*Contact Tech 8upport.

Maintenance 8pecificatiens

Field Repairaole Yes

AppIicatien 8estrictiens

Timing, power and load oe]ond specifications

8uitaole for external gripping onl]

Teohnioa| 8eoifioations:

6ripper can be meunted and eperated in any erientatien

Nountin Information:

IectricaIIy Actuated

24 VDC, 4-wire input. power, ground, open & closed signals.

1OO7 dut] c]cle for high throughput.

"Light 8witch" 8impIicity

Plug and pla]. ho programming, tuning or adjusting required.

As eas] as a pneumatic gripper to control and operate.

nergy fficient

0nl] 8w required. Can oe driven directl] o] most PlC's

without a separate power suppl]. Can oe oatter] driven

for remote applications.

igh 0ycIe Life

2O+ million c]cles with zero maintenance!

High reliaoilit] eliminates down time.

lowest cost of ownership of an] gripper,

pneumatic or electric.

8uiIt-in Iectrenics

All electronics are sealed

within the gripper. ho external

control ooard needed.

4-pin/wire control caole

sold separatel].

Leng 8treke, Fast Actuatien

25mm stroke for picking multiple sized parts.

Full actuation in O.25 second. Pick up to 15O

parts per minute (with reduced strokej.

FaiIsafe eperatien

ln case of a power loss, the jaws will not

separate out grip force will oe diminished.

Finger design should include features other

than just friction to retain part for critical

applications.

0P Para||e| 0rier-

|eotrio 0rier 8eries

Patent Pending.

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Bod] mounts with screws

and locates with slip fit

dowel pins for accurac]

Fingers attach to jaws

with screws and locate

with dowel pins

1.8

0

P

8

I

8

Produot Features

Appl] +24 VDC from the PlC to the gripper "Close" wire.

The motor rotates a planetar] gear reduction oox that is connected to the drive

pinion o] a coupling

The pinion drives the integral jaw racks causing the jaws to close s]nchronousl]

Power is maintained to the closed signal to continue gripping force throughout

the grip c]cle.

To open, remove signal to "Close" wire and appl] +24 VDC from the PlC to the

gripper "0pen" wire

Design is suitaole for external gripping

8ty|e-0P

8ize -200-25

8ee

Page 1.10

Sty|e: 0P-200-25

Stroke: 25 mm O.98 in

6r|p Force: 9O h 2O los

we|ght: O.58 Kg 1.1O los

8Iip Fit 0eweI

Fin eIes

located in ood] and jaws

for precision mounting.

0ne-Fiece 8edy

0ne-piece, lightweight aircraft

qualit] aluminum ood] ensures

product accurac].

ardceat Anedize

The ood] and jaws are hard-

coat anodized to OORC with

Teflon impregnation.

8eaIed 0esign

lP 54 rating for tough

application environments.

8uperier Jaw

8uppert

Ridged design and full ood]

support of the jaws allows

for long finger lengths.

0irect0ennect Meunting

Nounts directl] to other automation

products without adaptor plates.

Versatile mounting on top, side front

and oack of ood].

0over

0ap

Notor + 6earbox

0o0p||og

|ectroo|cs

Jaw

0eratin Prinoi|e

8ody

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Fatent Fending

8ack 8 Finien 0rive

Precision drive components for

smooth actuation. Zero oacklash

while gripping ensures excellent

repeataoilit] and accurac].

MuItipIe Fesitien 8ensing

8lot mounted magneto-resistive sensing. 8ense up

to 4 gripping positions. lnternal magnetic targets

and external sensor mounting slots come standard.

8ensors & quick disconnect caoles sold separatel].

1.9

0

P

8

I

8

|1.2]

41.0

|5.03]

128.0

2.12

|54.0]

1.121

|28.5]

|.375]

.5

38.1

|1.500]

2X M5 |H7] X .2 DF

(MEAk & FAk 5DE}

2X M5 X .2 DF

5.0

|2.20]

CLO5ED A5 5HOWM

81.0

|3.1]

OFEMED

38.10

(DOWEL}

|1.5000]

38.1

|1.500]

38.10

(DOWEL}

|1.5000]

38.1

|1.500]

38.10

(DOWEL}

|1.5000]

|.75]

1.1

4X M5 X 10.0 DF

2X M5 (H7} X .4 DF

|.75]

1.0

A

|.472]

12.0

|.23]

.0

|.472]

12.0

|.787]

20.00

|.2]

1.00

4X M3 X DF

2X 2|H7] X DF

(1AW FEATUkE5-FMGEk MOUMT}

4X M5 X 0.8 X 10.0 DF

2X M5 |H7] X .2 DF

1.1

|.750]

|.5]

24.2

|4.85]

11.0

|1.102]

28.0

M8X1 MALE

(CA8LE 5OLD

5EFAkATELY}

Pk8kLLL 08IPP8 0P-200-25

-08IPP8 88I8

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

0F-200-25

8k8I0 N00L

Loadin Information

Leading 0apacity

|

8tatic

NaximumTensile 75 los [1O h|

Naximum Compressive 0 75 los [1O h|

Naximum Noment M

x

12O lof-in [14 hm|

Naximum Noment M

y

15O lof-in [17 hm|

Naximum Noment M

z

12O lof-in [14 hm|

|

Capacities are per set of jaws and are not simultaneous

44

35

16

18

9

0

h

10

8

6

4

2

0

|bs.

EFFECTlVE Flh0ER lEh0TH - L

F

l

h

0

E

R

F

0

R

C

E

-

F

l

2

F080 VS Lh6Th

0 0.5 1.0 1.5 2.0 2.5 3. 0 |o.

0 13 25 38 51 64 76 mm

wk8hIh6!

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

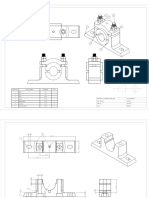

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

Netr|c [mm]

[O.| = [.25|

[O.O| = [.18|

[O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance .O18mm

0L88 08wI8 00 ALL 0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

k008808I8*

4-wire Power and 8ignal Caole, 5m long 0k8L-046 1

hPh Nagneto Resistive 8ensor 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor 0h8P-017 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

|

*8ensor and caoles sold separatel].

|

Power caole plus 1 or 2 sensor caoles.

8pecificatiens 0F-200-25

Naximum Finger length . . . . . . . . 7O.2 mm (8.OO inj

8troke . . . . . . . . . . . . . . . . . . . . . . . 25 mm (O.98 inj

0ripping Force in Closing . . . . . . . . 9O h (2O losj

Closing Time/0pening Time . . . . . . 25O ms (25O msj

Repeataoilit] . . . . . . . . . . . . . . . . . . O.O25 mm (O.OO1 inj

Accurac] . . . . . . . . . . . . . . . . . . . . . O.O51 mm (O.OO2 inj

Voltage . . . . . . . . . . . . . . . . . . . . . . 24 VDC

Power Req. @ 1OO7 Dut] C]cle . . 8 watts

Current - Peak . . . . . . . . . . . . . . . . O.5 Amps Nax.

Current - Continuous . . . . . . . . . . . . O.125 Amps

Nin./Nax 0perating Temperature . . 5 / OO C (4O / 14O Fj

Protection Class . . . . . . . . . . . . . . . lP54

Clean Room . . . . . . . . . . . . . . . . . . 1OO

Clean Room with 8cavenge* . . . . . 1O

weight . . . . . . . . . . . . . . . . . . . . . . O.58 Kg (1.1O losj

*Contact Tech 8upport.

lNSTALL MAGNET HEAD lNTO THE SLOT,

ADJUST lT'S LOCATlON, AND LOCK lTS

POSlTlON WlTH THE PROvlDED

LOCK SCREW.

SENSOR TARGET SUPPLlED

lNSlDE WlTH THE JAWS

CUSTOMER SUPPLED FlNGER

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

1.10

0

P

8

I

8

Pk8kLLL 08IPP8 0P-200-25

-08IPP8 88I8

InstaIIatien and 0peratien.

1. Nount fingers (customer suppliedj to gripper jaws using dowel pins and threaded fasteners. 8ee dimensional drawing for hole sizes.

Use loctite

242 threadlocker or equivalent.

2. Nount gripper using dowel pins and threaded fasteners. 0ripper can oe mounted and operated in an] orientation. 8ee dimensional drawing

for mounting hole pattern and sizes. Use loctite

242 threadlocker or equivalent.

8. To operate the DPE gripper, follow the instructions oelow.

Appl] +24VDC to pin 1 (orownj and 0round to pin 8 (oluej to turn on the gripper. To open the fingers, appl] +24VDC to pin 2 (whitej.

To close the fingers, remove +24VDC from pin 2, and appl] +24VDC to pin 4 (olackj. +24VDC signal must remain present on the open / close

line to maintain the force output. The gripper will do nothing if a +24VDC signal is present on the open and close lines at the same time.

wA8I6.

0perating gripper outside of power voltages and can cause damage and void warrant]

Disconnect power from gripper oefore performing maintenance or making adjustments.

(LOOKMG MTO HEADEk COMMECTOk OM GkFFEk}

1 ........ 8kOWM

2 ........ WHTE

3 ........ 8LUE

4 ........ 8LACK

(+ 24 VDC}

(OFEM GkFFEk} +24 VDC = ACTVE

(GkOUMD}

(CLO5E GkFFEk} +24 VDC = ACTVE

CA8LE # CA8L-04

ELECTkCAL MTEkFACE

2

4 3

1

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

1.11

0

P

8

I

8

1 2 3 5 7

8

9

32

10

15

33

16

17

18

21

24

20 22

23

4

19

21

27 15

28

25

25

28

30

31

29

6

7 11

12

13

1

14

26

will oe installed

aoove the cover

Item 0ty ame

O1 1 Bod]

O2 1 Bottom Plate

O8 1 Cap

O4 1 Cover

O5 2 Bumper

OO 2 Jaw

O7 2 Coupling Pin

O8 1 Drive Pin

O9 1 Notor Control Board

1O 1 Coupling lnsert

11 2 Tag-Destaco-Rooohand

12 1 Tag-Electric Pin 0ut

18 1 Tag-Production

14 1 Tag-VBl Collar

15 2 Nagnet

1O 1 Bearing

17 8 8HC8, N1.O*5mm, Allo]

18 8 8HC8, N2.5*5mm, Allo]

19 1 Dowel Pin. 1/8 Dia X 8/8

2O 2 Dowel Pin. 2mm

dia*Omm lg

21 8 8crew, Fillister HD,

N2xOmm

22 2 Dowel Pin. 8mm

dia*Omm lg.

28 O Jam hut-Ref 0nl] (Part 0f

Notor Control Boardj

24 8 washer

25 2 8et 8crew

2O O 0-Ring - Ref 0nl] (Comes

with Connectorj

27 1 0-Ring

28 2 8et 8crew

29 1 0-Ring

8O 1 8et 8crew

81 4 0-Ring, Buna, 7Od,

O.O2O C8, .O97id

82 1 0ear Notor

88 1 Ret. Ring

h0I: Contact the DE-8TA-C0 Customer

8ervice for a complete spare parts list

with order numoers and prices.

AssembIy Frecedure

1j Clean all make details free of dirt, oil and

other contaminants.

2j lnsert # 82 motor into the # 1 ood], line up

the motor holes and assemole motor to the

ood] o] using # 18 screws. Nake sure that

the motor wires are carefull] routed to the top

for it's

connection to the motor control ooard.

8j Assemole # 25 set screws one of the # 7

coupling huos, out not all the wa] in. Assem-

ole the coupling to the motor shaft, with flat

on the motor shaft facing one of the set

screws and adjust the inside face of the cou-

pling, flat with end face of the motor shaft.

Tighten the set screw on the motor shaft thru

the acccess

hole at set screw # 8O location.

4j Assemole the # 1O coupling insert into the

# 7 huo, as asssemoled to the motor shaft,

as aoove.

5j Assemole # 8 drive pinion with it's shaft all

the wa] into the second # 7 coupling huo and

tighten the set screws. Assemole # 1O oear-

ing and # 19 dowel pin into the drive pinion.

how install this assemol] huo / insert as-

semol] installed earlier to the motor shaft.

7j Assemole # 15 magnets into # O jaws,

using lok-tite as recommended.

8j luoricate the pinion, the oearing, the jaws

and inside surfaces of jaw-wa]s with luori-

cant as recommended.

9j lnstall the jaws into the ood], meshed with

the pinion and s]mmetricall] positioned w.r.t

the pinion.

1Oj lnstall # 5 stop and # 22 dowel pins into

the jaws.

11j Assemole # 2 cover to the ood], with dowel

pins # 19 and # 29 aligned to the cor-

rosponding holes in the cover. lnstall fasten-

ers # 17 to secure the cover to the ood].

12j lnstall / connect the motor caole connector

the motor control ooard. Use # 21 & # 24

fasteners and install the motor control ooard

to the ood]. hote. Remove the hex nut sup-

plied with the connector on the motor con-

trol ooard.

This hex nut will oe re-installed after # 4

cover is installed.

18j lnstall # 4 cover to the ood] with # 29 gas-

ket and # 21 screws as shown.

14j lnstalled the previousl] removed hex nut

oack to the connector. Caution. 0nl] snug

tighten this hex nut.

15j lnstall # 8 cap with 0 ring and snap ring,

as shown.

1Oj lnstall tags and laoels as shown.

0P 88I8 XPL000 VIw

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Third Angle

Projection

8eal Kit

ltems

Thread

locker

Kr]tox

luoricant

Teflon

Based

0rease

lightweight

Nachine 0il

8uper

Bonder

Sk

k8YT0X k8YT0X

1.12

0

P

8

I

8

Third Angle

Projection

8eal Kit

ltems

Thread

locker

Kr]tox

luoricant

Teflon

Based

0rease

lightweight

Nachine 0il

8uper

Bonder

Sk

k8YT0X k8YT0X

1

2

5

4

3

7

6

8

Item 0ty ame

O1 1 Bod]

O2 2 Jaw

O8 1 Notor/0ear A8N

O4 1 Coupling Asm

O5 1 Pinion

OO 1 Bearing

O7 1 Notor Control Board

84 1 End Cap

h0I: Contact the DE-8TA-C0 Customer

8ervice for a complete spare parts list with

order numoers and prices.

0P 88I8 XPL000 VIw

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

1.13

0

P

8

I

Potrebbero piacerti anche

- RfeDocumento8 pagineRfedunareanu_marian8668Nessuna valutazione finora

- LP C2Documento18 pagineLP C2Marian DunareanuNessuna valutazione finora

- Limba Engleza Curs Practic - Nivel MediuDocumento51 pagineLimba Engleza Curs Practic - Nivel Mediucif_catalin100% (16)

- Curs Limba SuedezaDocumento1 paginaCurs Limba SuedezaMarian Dunareanu0% (1)

- 0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Documento7 pagine0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Marian DunareanuNessuna valutazione finora

- Curs 12 MeeDocumento13 pagineCurs 12 MeeMarian DunareanuNessuna valutazione finora

- GC DGCDocumento10 pagineGC DGCMarian DunareanuNessuna valutazione finora

- RDHDocumento20 pagineRDHMarian DunareanuNessuna valutazione finora

- Round ToolingDocumento18 pagineRound Toolingdunareanu_marian8668Nessuna valutazione finora

- Power CylindersDocumento12 paginePower CylindersMarian DunareanuNessuna valutazione finora

- Au RDocumento7 pagineAu RMarian DunareanuNessuna valutazione finora

- Dpds DPDLDocumento24 pagineDpds DPDLMarian DunareanuNessuna valutazione finora

- DSC Capabilities Neu Eng 09 2011 FinalDocumento12 pagineDSC Capabilities Neu Eng 09 2011 FinalMarian DunareanuNessuna valutazione finora

- Pin PackagesDocumento23 paginePin PackagesMarian DunareanuNessuna valutazione finora

- VacuumDocumento13 pagineVacuumMarian DunareanuNessuna valutazione finora

- Manual Clamping Technology: I-3 - I-6 Section 1 - 9Documento5 pagineManual Clamping Technology: I-3 - I-6 Section 1 - 9Marian DunareanuNessuna valutazione finora

- Automation U1 2011 GBDocumento1 paginaAutomation U1 2011 GBMarian DunareanuNessuna valutazione finora

- 'I 2ii 3 + A : 1C-# @+/ (C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"Documento10 pagine'I 2ii 3 + A : 1C-# @+/ (C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"Marian DunareanuNessuna valutazione finora

- MedicalDocumento12 pagineMedicalMarian DunareanuNessuna valutazione finora

- IntroDocumento1 paginaIntroMarian DunareanuNessuna valutazione finora

- 01 Vertical ClampsDocumento44 pagine01 Vertical ClampsElvin PolancoNessuna valutazione finora

- DPGDocumento12 pagineDPGMarian DunareanuNessuna valutazione finora

- OverviewDocumento4 pagineOverviewMarian DunareanuNessuna valutazione finora

- Intro 00Documento3 pagineIntro 00Marian DunareanuNessuna valutazione finora

- DlttanruDocumento14 pagineDlttanruMarian DunareanuNessuna valutazione finora

- DLT BelDocumento24 pagineDLT BelMarian DunareanuNessuna valutazione finora

- DlbtanruDocumento12 pagineDlbtanruMarian DunareanuNessuna valutazione finora

- Ai 2ii 3 + B : 1C-# @+/ (1: !1C-# @+/ ( 3:+/ ( + @ 1: +/ (-# @+/ ( 3:+/ (:#@C:/ /@#:/ - G - C:+@#! C/ # - ' Eg B 31 +@+1Documento10 pagineAi 2ii 3 + B : 1C-# @+/ (1: !1C-# @+/ ( 3:+/ ( + @ 1: +/ (-# @+/ ( 3:+/ (:#@C:/ /@#:/ - G - C:+@#! C/ # - ' Eg B 31 +@+1Marian DunareanuNessuna valutazione finora

- Pneumatic Clamps: DestacoDocumento32 paginePneumatic Clamps: DestacoMarian DunareanuNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Caparo Price ListDocumento20 pagineCaparo Price ListkutbiahtNessuna valutazione finora

- Spanner Selection For Metric and Imperial Hex BoltsDocumento1 paginaSpanner Selection For Metric and Imperial Hex BoltsMuhammad SaimNessuna valutazione finora

- Bolt (Fastener) - WikipediaDocumento3 pagineBolt (Fastener) - WikipediaaravindNessuna valutazione finora

- IVECO ML120E21-parts CatalogueDocumento680 pagineIVECO ML120E21-parts CatalogueAnto Banaš100% (1)

- Types of Nuts, Bolts & Studs - Method of Removing Broken Studs, Method of Freeing Nuts and Bolts AimDocumento3 pagineTypes of Nuts, Bolts & Studs - Method of Removing Broken Studs, Method of Freeing Nuts and Bolts AimAayush AgrawalNessuna valutazione finora

- Struktur Baja I 7Documento25 pagineStruktur Baja I 7Latifah Meda FerlytaNessuna valutazione finora

- Ford Wa900Documento16 pagineFord Wa900ayazNessuna valutazione finora

- Item by Class y URDocumento1.350 pagineItem by Class y URJorgeSerracín60% (5)

- Eyebolts & Eyenuts: How Should You Select The Right Bolt?Documento4 pagineEyebolts & Eyenuts: How Should You Select The Right Bolt?Lazzarus Az GunawanNessuna valutazione finora

- Metric Bolts - Minimum Ultimate Tensile and Proof LoadsDocumento6 pagineMetric Bolts - Minimum Ultimate Tensile and Proof LoadsJignesh SutharNessuna valutazione finora

- Toyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p007Documento1 paginaToyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p007sơn forkliftNessuna valutazione finora

- Catalogo 495 HR1Documento46 pagineCatalogo 495 HR1Dario Chouger100% (1)

- Fasteners and Welding: Engineering H191 - Drafting / CADDocumento24 pagineFasteners and Welding: Engineering H191 - Drafting / CADDEEPAKNessuna valutazione finora

- Du Lieu San Pham Inv-5!6!2013thieu BichDocumento120 pagineDu Lieu San Pham Inv-5!6!2013thieu BichanhthoNessuna valutazione finora

- Vit MeDocumento1 paginaVit MeBo Cau GaiNessuna valutazione finora

- WE FastenersDocumento120 pagineWE FastenersOmar MokhtarNessuna valutazione finora

- Rahil SahibDocumento16 pagineRahil SahibZohaibShoukatBalochNessuna valutazione finora

- Ua1901a232s 3Documento1 paginaUa1901a232s 3MARTIN GONZALEZNessuna valutazione finora

- UNCUNF Threads - SizeDocumento1 paginaUNCUNF Threads - SizeahmedNessuna valutazione finora

- Transaxle and Differential LockDocumento4 pagineTransaxle and Differential LockNeftali FuentesNessuna valutazione finora

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocumento2 pagine2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebNessuna valutazione finora

- (1-2) and 1111. (1-2) - 2015 - ISO Meteric Hexagon Bolts and ScrewsDocumento88 pagine(1-2) and 1111. (1-2) - 2015 - ISO Meteric Hexagon Bolts and ScrewsMark Carroll-ChiltsNessuna valutazione finora

- Page Intentionally Left Blank: Cl-604 Aircraft Illustrated Parts CatalogDocumento3 paginePage Intentionally Left Blank: Cl-604 Aircraft Illustrated Parts CatalogEmmanuel OnwukaNessuna valutazione finora

- Din 571 Vairados PDFDocumento4 pagineDin 571 Vairados PDFmugiwara ruffyNessuna valutazione finora

- Thread and Connection Identification Guide - MS-13-77 PDFDocumento56 pagineThread and Connection Identification Guide - MS-13-77 PDFjochem_ligthartNessuna valutazione finora

- Imperial Products PDFDocumento13 pagineImperial Products PDFFederico GuillenNessuna valutazione finora

- Jyotish Jha AutoDocumento6 pagineJyotish Jha AutoSafal ShresthaNessuna valutazione finora

- ScrewsDocumento35 pagineScrewsRodel Marata100% (2)

- Bom Its11224Documento3 pagineBom Its11224moldandpressNessuna valutazione finora

- Askew Head BoltsDocumento1 paginaAskew Head BoltsRajed MaglinteNessuna valutazione finora