Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thermal

Caricato da

P MuthusamyDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Thermal

Caricato da

P MuthusamyCopyright:

Formati disponibili

Thermal Engineering

Intermittent Combustion means combustion starts and stops

many times during operation. E.g. All standard SI and CI

engines.

Continuous Combustion means that combustion takes place

continuously. E.g. Turbine engines, Rocket engines, Stirling

engines and Jet engines.

Wankel engine is a internal combustion, intermittent

combustion, rotary engine.

Parts Material

1. Cylinder Block Cast Iron or Aluminum

2. Piston High quality Aluminum

3. Connecting Rod Forged Steel

4. Cylinder Head Cast Iron or Aluminum

5. Crankshaft Forged Steel

6. Camshaft Billet Steel or Chilled Iron Casting

Four Stroke Engines Working: SI engines

Cycle of operation is completed in 4-strokes of the piston or 2

revolutions of the crankshaft.

The volume above piston at TDC is called clearance volume.

Each stroke consists of 180, of crankshaft rotation and hence a

cycle consists of 720of crankshaft rotation.

Compression ratio is the ratio of the volume in the cylinder

above the piston at BDC to the volume in the cylinder above

the piston at TDC.

Higher the compression ratio, the greater is the mixing of air

and fuel.

The spark plug is ignited considerably before TDC to obtain

complete combustion of fuel.

The highest efficiency is obtained when the point of ignition

and the point at which the combustion is complete are

symmetric to TDC.

The exhaust valve is opened before BDC and there is a pressure

drop. The difference in pressure drop between the actual and

ideal cycle is called exhaust blow down loss.

Suction stroke- pressure slightly below atmospheric, Exhaust

stroke- pressure slightly above atmospheric. So negative loop is

formed which represents loss of work.

Four stroke CI (Compression Ignition) engine

It differs from SI engine in the following ways:

The compression ratio of diesel engine is very high (20-25), this

accounts for the self ignition of the engine.

The temperature during combustion stroke is in the range

1000F (538C).

The fuel is injected at a very high pressure about 350bar

compared to petrol engine (70 bar approx).

Due to high internal temperature the amount of Nitrogen oxide

(NOx) produced in a diesel engine is high.

Comparison of SI and CI engines:

SI Engines CI Engines

Intake Air-fuel Air

Compression 8-10 ratio

130 psi

285C

16-25 ratio

400-600psi

538C

Air-Fuel mixing point Carburetor or before

intake valve with fuel

injection

Near top dead centre

by injection

Power 464psi 1200psi

Exhaust 704C - 980C

CO = 3%

NOx = low

370C - 480C

CO = 0.5%

NOx = high

Efficiency 22-28% 32-38%

Valve timing diagram:

The above figure shows valve timing diagram for a low speed and

high speed engine.

The inlet valve opens a few degrees before TDC on the exhaust

stroke. This is to ensure that the valve will be fully open and

fresh charge starts to flow into the cylinder as soon as piston

reaches TDC.

The inlet valve closes 10 after BDC for low speed engine and

60 after BDC for high speed engine.[Reason: The inertia of the

charge to move into cylinder after BDC. For low speed engine

inertia is low and for high speed engine inertia is high due to

which there is a ram effect produced by the incoming mixture

which tends to pack more charge into the cylinder]

FORMULA:

Required angle = (Distance) x (360)

Circumference of the flywheel

Where,

Distance = Distance of the valve opening or closing position

marked on flywheel with respect to their dead centre.

The exhaust valve is opened before the piston reaches BDC,

this is to reduce the work necessary to expel the burned gases

during the exhaust stroke.

The exhaust valve is closed after TDC to ensure complete

removal of gas left in the clearance volume by scavenging, so as

to increase the volumetric efficiency.

There is a period of valve overlap during which both the inlet

and outlet remain opened. If the valve overlap is high then

there is chance of burned gas being sucked into inlet manifold.

Two Stroke Engines

In a 2-stroke engine one cycle of operation is completed in 2

strokes i.e. one revolution of the crank shaft.

Here the valves are replaced by ports.

The various ports in a 2-stroke engine are: a.) Intake or crank

case port, b.)Transfer port, c.)Exhaust port.

For the same weight, the power to weight ratio of two stroke

engine is more as there is a power stroke for each revolution of

the crank shaft.

The induction of fresh charge moves out the products of

combustion through exhaust port. So there is no need of

suction and exhaust stroke.

The fresh charge enters the crankcase when the intake port is

opened. From the crankcase the charge is transferred above

the cylinder by transfer port.

Scavenging is the process in which the fresh charge inducted

into the cylinder is used to push out the exhaust gas.

The deflectors play the function of scavenging as well as

prevent the fresh charge from flowing into exhaust ports.

Ideal and Actual cycle of a 2-stroke engine

Vc clearance volume, Vs stroke volume

Port timing Diagram

Theoretically a 2-stroke engine needs to produce power double

that of 4-stroke engine, but in actual practice the power is

increased by only 30% because of

Reduced effective expansion stroke

Increased heating caused by increased number of power

strokes.

Comparison between 2 stroke and 4 stroke engines:

Four stroke engines Two stroke engines

1. Torque produced is not

uniform so heavier fly-

wheel is used

Torque produced is uniform so

lighter fly-wheel is used

2. Low rate of wear and tear High rate of wear and tear

3. Volumetric efficiency is high

due to more time for

induction

Volumetric efficiency is low due

lesser time for induction

4. Thermal efficiency is higher Thermal efficiency is low

FORMULAE:

Brake power: Power available at the crank shaft

B.P = 2 N R (W-S)

60

Where,

N = Engine speed in rpm

R = Brake drum radius in cm

W = Dead weight added in Kg

S = Spring Balance reading in Kg

Total Fuel consumption:

T.F.C = cc x Specific gravity x 3600 kg / hr

t

f

1000

Where,

t

f =

Time taken to consume 10cc of fuel in seconds

cc = Amount of fuel consumption measured in cc

Specific fuel consumption: It is the ratio of fuel consumption to the

brake power produced.

S.F.C. = T.F.C kg / kW hr

B.P

Note: engines are compared based on SFC

Indicated power: It is power produced inside the cylinder.

I.P = B.P + F.P kW

FP- friction power

Mechanical efficiency: It is the ratio of brake power to the indicated

power

Mech

= B.P x 100 %

I.P

Indicated thermal efficiency: It represents the ratio of indicated

power to the fuel power

INDICATED

= I.P x 3600 x 100 %

T.F.C x C.V

Brake thermal efficiency: It is the ratio of brake power to fuel power.

Brake thermal

= B.P x 3600 x 100 %

T.F.C x C.V

Where,

C.V = Calorific value of fuel in kJ / kg

Brake mean effective pressure: It is a theoretical term used to

indicate how much pressure is applied to the piston from TDC to

BDC.

B.M.E.P = B.P x 60000 N/m

2

L.A.N.k

Where,

L = Stroke length, m

A = Area = (/ 4) D

2

D = Bore dia in m

N = Speed / 2

K = Number of cylinders

Volumetric Efficiency:

It is the ratio of the actual volume of air that goes into the cylinder to

the stroke volume of the cylinder.

Piston speed =

Where,

L = length of stroke,

N = RPM of engine

Relative Efficiency:

It is the ratio of thermal efficiency of the engine to the air standard

cycle efficiency on which it works.

Knocking in SI Engines:

Knocking (also called pinking or pinging) occurs when fuel in the

cylinder is ignited by the firing of the spark plug and smooth burning

proceeds but some of the unburned mixture in the combustion

chamber explodes before the flame front can reach it, combusting

suddenly before the optimum moment of the four-stroke cycle.

Higher octane number greater is resistance to knock

Octane number 100 means iso-octane 100% and heptanes 0%.

Retardation of spark plug ignition reduces knocking.

Knocking in Diesel Engines:

Knocking takes place in CI engines due to sudden ignition and rapid

combustion of initially accumulated fuel in the combustion chamber.

An ignition lag between the time of injection and the actual

combustion is the reason for knocking.

Knocking can be reduced by decreasing the ignition lag.

CI engines are rated based on cetane number.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Sabroe CMO Maintenance ScheduleDocumento3 pagineSabroe CMO Maintenance ScheduleOprea Marius100% (1)

- MaK 8M25C MaintenancePlanDocumento36 pagineMaK 8M25C MaintenancePlanЮрий Семёнов100% (1)

- Timming m20Documento5 pagineTimming m20orcr51Nessuna valutazione finora

- Engine Dynamic Properties-3Documento5 pagineEngine Dynamic Properties-3Gthulasi78Nessuna valutazione finora

- Internal Combustion Engines2Documento92 pagineInternal Combustion Engines2Rupinder Rp100% (1)

- Injection Pump Specification ©Documento4 pagineInjection Pump Specification ©Errol HuntNessuna valutazione finora

- Rod Load Calculations and Definitions For Reciprocating Compressor MonitoringDocumento8 pagineRod Load Calculations and Definitions For Reciprocating Compressor MonitoringbilalNessuna valutazione finora

- M14 PropulsionDocumento80 pagineM14 PropulsionArslan Shaukat100% (6)

- Mxu 50 Reverse PDFDocumento122 pagineMxu 50 Reverse PDFtestiNessuna valutazione finora

- Valmet612DSL PDFDocumento94 pagineValmet612DSL PDFSCANIA100% (1)

- Speed R/min Mep Bar KW KW 6L32/44CR 7L32/44CR 8L32/44CR 9L32/44CR 10L32/44CR MCR 100% 85% L32/44CR 7L32/44CR L32/44CR FPP 7L32/44CR FPPDocumento1 paginaSpeed R/min Mep Bar KW KW 6L32/44CR 7L32/44CR 8L32/44CR 9L32/44CR 10L32/44CR MCR 100% 85% L32/44CR 7L32/44CR L32/44CR FPP 7L32/44CR FPPghostt123Nessuna valutazione finora

- MAHLE Product Catalog Cat 3116 Dijelovi MotoraDocumento18 pagineMAHLE Product Catalog Cat 3116 Dijelovi MotoraMile BelojicaNessuna valutazione finora

- Engineering Knowledge (Motor) For Marine EngineersDocumento381 pagineEngineering Knowledge (Motor) For Marine EngineersЛисица Дмитрий100% (1)

- Pinout Nissan Ecr33 Rb25detDocumento1 paginaPinout Nissan Ecr33 Rb25detElmer AlanesNessuna valutazione finora

- Take Home Quiz2Documento2 pagineTake Home Quiz2backstreetguys007Nessuna valutazione finora

- Mechatronics Unit 1Documento53 pagineMechatronics Unit 1ஷாம்லி100% (2)

- Data Slow BpsDocumento13 pagineData Slow Bpsadhie ryanNessuna valutazione finora

- WDS6 Locomotive - Principle of Electrical TransmissionDocumento15 pagineWDS6 Locomotive - Principle of Electrical TransmissionmajjisatNessuna valutazione finora

- 08 Engine MechanicalDocumento80 pagine08 Engine MechanicalmadcostaNessuna valutazione finora

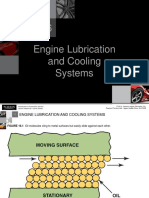

- Intro Chap 16 ImagesDocumento14 pagineIntro Chap 16 ImagesRezende JulioNessuna valutazione finora

- PS Checklist Motor GraderDocumento1 paginaPS Checklist Motor Graderyogi ganda pratamaNessuna valutazione finora

- Luftansa Technical Training - APU Training ManualDocumento98 pagineLuftansa Technical Training - APU Training ManualRobert100% (2)

- 6CTA DataSheet PDFDocumento2 pagine6CTA DataSheet PDFSuttiwat Soontraratpong100% (1)

- Checklist-SWF OHC 3Documento3 pagineChecklist-SWF OHC 3Yuniar WidyaNessuna valutazione finora

- 2009 Polaris Ranger 500 4X4 EFI Service Manual PDFDocumento284 pagine2009 Polaris Ranger 500 4X4 EFI Service Manual PDFRogelio RuizNessuna valutazione finora

- Tca88 20,21,24,26Documento345 pagineTca88 20,21,24,26Elyes ObbaiaNessuna valutazione finora

- 8 Common Problems Found in ShipDocumento3 pagine8 Common Problems Found in ShipAnoop VijayakumarNessuna valutazione finora

- Manual pc130Documento495 pagineManual pc130Farhat100% (1)

- Rotax Installation PDFDocumento68 pagineRotax Installation PDFjulian marinNessuna valutazione finora

- Illustrated Parts Catalogue Woodward Diesel SystemsDocumento110 pagineIllustrated Parts Catalogue Woodward Diesel SystemsFuad100% (1)