Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lower Temperature Formation of Alumina Thin Films Through Sol-Gel Route Al2o3 Riaz

Caricato da

Eero IiskolaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lower Temperature Formation of Alumina Thin Films Through Sol-Gel Route Al2o3 Riaz

Caricato da

Eero IiskolaCopyright:

Formati disponibili

Surface Review and Letters, Vol. 15, No.

5 (2008) 681688

c World Scientic Publishing Company

LOWER TEMPERATURE FORMATION OF ALUMINA

THIN FILMS THROUGH SOLGEL ROUTE

S. RIAZ

,

, S. SHAMAILA

, B. KHAN

and S. NASEEM

,

Centre for Solid State Physics,

Punjab University, Lahore 54590, Pakistan

State Key Laboratory of Magnetism,

Chinese Academy of Sciences, Beijing 100080, China

Department of Chemistry, LCW University,

Lahore, Pakistan

shahzad naseem@yahoo.com

Received 29 February 2008

Bayerite sol is spun onto single crystal Si substrate, after synthesis and optimization, to obtain

lms of thickness 0.2 m. The deposited lms are room temperature dried and then heated

up to a temperature of 350

C in order to obtain Al

2

O

3

. Surface and structural changes, during

heating, are observed with optical microscopy. Scanning electron microscopy (SEM) and X-ray

diraction (XRD) are used for post-treatment analyses/characterization. The as-deposited and

heated samples surfaces are smooth as seen with optical and scanning electron microscope

in case of optimized conditions. XRD patterns show the change from amorphous to crystalline

behavior of these lms when heated under various conditions. The most stable form of aluminum

oxide, i.e. -Al

2

O

3

, is obtained when samples are heated up to a temperature of as low as

350

C. The thin lms are also deposited onto sodalime glass substrates in order to conrm

Al

2

O

3

formation through band gap probing. Photoconduction is used to nd the energy band

gap, which comes out to be 4.7 eV; lower value is correlated to the defect induced states in the

band gap.

Keywords: Alumina; solgel; corrundum; low-temperature.

1. Introduction

Aluminum oxide or alumina is one of the groups of

inorganic chemicals currently produced in very large

volumes.

1

Alumina (Al

2

O

3

) exhibits several attrac-

tive properties such as good corrosion resistance,

high dielectric strength, resistance to the diusion

of impurity, and high chemical and thermal stabil-

ity. These characteristics motivate its use for var-

ious applications, such as electrical,

2

optical,

3

wear

resistant coating for cutting tools,

4

and diusion bar-

rier coating for nonvolatile memories

5

where dense

and closed structures are required, and also as cata-

lyst support where, in contrast, highly porous lms

are required.

6

Several routes such as chemical vapor deposition,

7

electrochemical anodic oxidation,

8

electroless plat-

ing,

9

and spray pyrolysis of metal-organics

10

have

been developed for preparation of nano-materials.

Among these, the solgel method is an emerg-

ing route with high promise for very homogeneous

lms, which can be carried out at relatively low

temperatures.

11,12

Corresponding author.

681

682 S. Riaz et al.

Al

2

O

3

exists in more than 15 distinct crystallo-

graphic phases, and it can undergo a variety of tran-

sitions until the most-stable corundum structure, i.e.

-Al

2

O

3

, forms at high temperature, i.e. 1200

C.

13

However, this temperature is reduced by the intro-

duction of additives such as CuO and Fe

2

O

3

1416

or

-Al

2

O

3

1720

before gelation. Hence, the transforma-

tion is observed at 1050

C.

11

Another alternative is

the modication of the sol formulation,

2125

which

allows conversion to -Al

2

O

3

without additives or

seeding. In this process, the presence of water in the

prepared sol retards the conversion to -Al

2

O

3

,

23

favoring transition via -Al

2

O

3

, which is remarkably

stable.

19

Tsay et al.

24

demonstrated that sols pre-

pared with a reduced amount of water experienced a

direct transformation to -Al

2

O

3

, whereas the water-

containing sol passed through several transition

structures, such as -Al

2

O

3

and -Al

2

O

3

. Indeed, the

measured activation energy of -Al

2

O

3

-Al

2

O

3

transition is 650 kJ/mol, which is in contrast to that

of the induced -Al

2

O

3

-Al

2

O

3

transformation

(360431kJ/mol).

19

Therefore, the key to perform-

ing the -Al

2

O

3

transformation at lower tempera-

tures is to avoid the transition via -Al

2

O

3

.

As solgel precursors, aluminum alkoxides dif-

fer signicantly from other metal-alkoxides in terms

of their chemical reactivity and complex-forming

ability. These dierences dictate the adoption of dif-

ferent strategies for the creation of alumina based

solgel products. The solgel reactions in usual

metal-alkoxides/silica-based system are rather slow

and often require the use of catalysts to acceler-

ate the process. This is explained by the fact that

aluminum alkoxides (e.g., aluminum sec-butoxide)

are very reactive toward nucleophilic reagents like

water.

26

They readily undergo hydrolysis, which

results in a very fast solgel process, as shown in

Fig. 1. Even if the solution of aluminum sec-butoxide

is stirred vigorously, the rates of these reactions

are so high that large agglomerated alumina parti-

cles precipitate out instantaneously when the sol

gel ingredients are mixed together. Such fast pre-

cipitation makes it dicult to reproducibly prepare

alumina-based sol materials.

The hydrolysis activity of aluminum sec-butoxide

can be controlled by chelating it with various -

ketoesters (or R-acetoacetates) through a steric

eect, e.g., ethyl acetoacetate,

28

acetylacetone,

29

which are capable of undergoing ketoenol

Al

OCH(CH

3

)

2

(H

3

C)

2

HCO OCH(CH

3

)

2

+

3H

2

O Al

OH

HO OH

+ 3(CH

3

)

2

CHOH

Aluminum Isopropoxide Aluminum Hydroxide

(a)

Al

OH

HO

OH

+

Al

OH

HO

n

OH

Al

O

HO OH

( O Al

)

n

O Al

O

O

(b)

Al

OCH(CH

3

)CH

2

CH

3

H

3

CH

2

C(H

3

C)HCO OCH(CH

3

)CH

2

CH

3

+ 3H

2

O

Al

OH

HO OH

+ 3CH

3

CH

2

(CH

3

)CHOH

Aluminum sec-butoxide Aluminum Hydroxide

(a)

Al

OH

HO OH

+

Al

OH

HO

n

OH

Al

O

HO OH

( O Al )

n

O Al

O

O

(b)

Fig. 1. Chemical reactions of alumina sols show (a)

hydrolysis and (b) poly-condensation for both Al-

isopropoxide and Al-sec-butoxide (adapted from Ref. 27).

tautomerism. The formation of the stabilized

chelated complex reduces the hydrolysis and conden-

sation rates of aluminum sec-butoxide by decreasing

the number of available alkoxy groups.

Thus, as compared to other metals, alumina is

capable of both ion and ligand exchange.

27

The lig-

and exchange ability of alumina originates from the

presence of Lewis acid sites on the surface, i.e. coor-

dinatively unsaturated Al

3+

, and water molecules or

other easily displaced ligands coordinatively bonded

to the sites, as shown in Fig. 2.

27

Lewis basic ana-

lytes containing polar functional groups such as car-

boxylic, phenolic-OH or amino groups can substitute

for the surface hydroxyl group or coordinated water

molecules and form complexes with the metal ions

of the oxide surface.

30

Therefore, precursors of alu-

mina, such as aluminum sec-butoxide and aluminum

iso-propoxide, are very attractive and are chosen, for

Lower Temperature Formation of Alumina Thin Films Through SolGel Route 683

H

2

O

2(aq)

H

2

O

(l)

+ 1/2 O

2(g)

+ H

O

H

Al

X

O

H

2

O

2(aq)

H

2

O

(l)

O

H

Al

O

OH

Al

O

Strong Bronsted acid site Weak Bronsted Acid Site

Fig. 2. A representation of Lewis acid sites for alumina.

the current work, to prepare alumina lms by the

solgel method that may lead to novel applications.

In this paper, we report on the detailed charac-

terization of solgel based alumina thin lms from

locally synthesized precursors. According to the best

of our knowledge this is the rst alumina report

in which the most stable phase, i.e. corundum, is

achieved at a reaction temperature of 350

C.

2. Experimental Details

2.1. Synthesis of alumina sol

Aluminum foil was rst activated chemically so that

it may become reactive for the next steps. This

pre-activated aluminum foil went through dierent

chemical reactions at various stages to produce the

desired product. Finally, aluminum hydroxide solu-

tion was obtained from two dierent sources sepa-

rately, i.e. aluminum iso-propoxide and aluminum

sec-butoxide by following the hydrolysis and poly-

condensation. The chemical reactions/chains can be

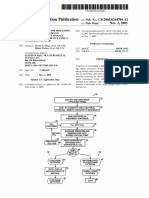

followed through owcharts of Figs. 3(a)3(c).

2.2. Deposition of alumina

thin lms

Silicon (100), 55 mm, substrates were used for thin

lm deposition. An ultrasonic bath for 30 min with

acetone, and 20 min with isopropyl alcohol was given

to the substrates in order to make them free of any

Aluminum Foil

HgCl

2

distilled water

Heatedand aged at room temperature

Activated aluminum foil

washed with distilled water

(a)

Stirring

Refluxing

Activated Al foil Isopropyl Alcohol

Alumnum Iso-propoxide

Adding CCl

4

Vacuum distilation

Stirring

Refluxing

Activated Al foil Absolute sec-butanol

Aluminum sec-butoxide

Adding CCl

4

Vacuum distilation

(b)

AluminumIso-propoxide HNO

3

based solution

Stirring

Refluxed

Sol A(AlOOH)

HNO

3

basedsolution

Aluminumsec-butoxide

Stirring

Refluxed

Sol B(AlOOH)

(c)

Fig. 3. Flowcharts of solgel processes.

contamination and gas residues on the surface after

giving an HF etch. After cleaning, the substrate was

held by vacuum on a homemade spinner (Fig. 4).

Sol (A&B separately) is dropped on surface of the

substrate and spun for half a minute at a speed of

4000 rpm. Thickness of 0.2 m was achieved in this

way. These samples were then dried at room temper-

ature for 20 min. After drying, the samples were sub-

jected to heat treatment at dierent temperatures for

varying times. The whole process can be understood

in a better way diagrammatically as shown in Fig. 5.

2.3. Characterization of alumina

thin lms

Leica DM4000 optical microscope, equipped with a

heating stage, was used to observe the general surface

character and to check the ongoing surface changes

with variation in temperature. The current to the

heating stage was provided by the current controller

system that utilizes Testo 925 digital temperature

684 S. Riaz et al.

Fig. 4. Photographs of the homemade spinner; (a) com-

plete spinner set-up along with a rotary pump and

(b) magnied image of spinner stage.

As-deposited AlOOH

thin film

Characterizations

Wet gel

Heat treatment at different

temperatures

Dried

Aged at room temperature

Spin Coating of Sols (A & B)

Fig. 5. Block diagram of lm deposition.

display. Hitachi S-3400N scanning electron micro-

scope equipped with EDX was used to check the sur-

face and composition of these solgel prepared thin

lms. Alumina thin lms were characterized struc-

turally with the help of Rigaku D/MAX-IIA X-ray

diractometer. For measuring the photoconductivity,

thin lms were prepared on glass substrate. Ohmic

contacts were made on the thin lm of Al

2

O

3

by

evaporating semi-transparent and thick aluminum

lms and then pasting copper wires with conduct-

ing silver epoxy.

Samples were mounted on a test shield model

5104 by Keithley Instruments and Bausch & Lomb

monochromator was used for photoconduction mea-

surements. A 610-C Digital Electrometer was

attached with this assembly in order to measure the

current. The voltage was applied using power supply

model IZS 5165. The photocurrents were normalized

to unit radiant ux incident on the sample at any

wavelength.

3. Results and Discussion

Viscosity of both the sols was checked periodically

and it was found that both sols were very stable for

a long time period as shown by Fig. 6.

The freshly spun transparent sol of aluminum

hydroxide is left to cure at room temperature for

at least 20 min. This room temperature cured sam-

ple is then transferred to metallurgical optical micro-

scope equipped with a heating stage. The sample is

then heated, mostly up to 350

C, while the surface

being micrographed every 15 min. The heat treat-

ment, at the optimum temperature, lasts usually

60 min, which varies from sample to sample. A typ-

ical optical micrograph of the as-deposited sample

(sol A) is shown in Fig. 7. The surface is quite

smooth and featureless but as the reaction tempera-

ture is increased, chained structure appears as shown

in Fig. 8. Appearance of chained structure is indica-

tive of chemical reaction occurring at early stages

of the lm growth. Scanning electron micrograph

Fig. 6. Viscosity vs. time plotted for alumina sols.

Lower Temperature Formation of Alumina Thin Films Through SolGel Route 685

Fig. 7. Optical micrograph of as-deposited thin lm of

sol A (50).

Fig. 8. Optical image of the chained structure of

deposited lm during heat treatment (sol A).

(Fig. 9) shows featureless surfaces at higher magni-

cations for the lm prepared from sol A. However, in

case of sol B lm, there are some voids observed in

the electron micrograph (Fig. 10). These voids show

the poly-condensation of alumina molecules and thus

support the formation of chained network. These

voids have been found to be on the surface alone

rather than through the lm.

Fig. 9. SEM image of optimized Al

2

O

3

thin lm syn-

thesized from sol A.

Fig. 10. SEM image of optimized Al

2

O

3

thin lm syn-

thesized from sol B.

The aluminum based sols A and B, spin coated

onto silicon (100) substrates, were checked for their

crystal structure, phase transformation, and conr-

mation of the nally synthesized product at various

stages. Figure 11 shows XRD patterns of the as-

deposited (room temperature aged) and heated sam-

ples prepared from sol A. It is evident, from the pat-

tern [Fig. 11(a)], that initially the lm exhibits amor-

phous behavior. However, the few emerging peaks

belong to Al(OH)

3

, which are indicative of the for-

mation of Bayerite sol.

31

The aluminum hydroxide

phase is transformed to -alumina

32

after heating

at 350

C for 60 min as shown in Fig. 11(b). Tsay

et al.

24

have demonstrated that sols prepared with a

686 S. Riaz et al.

Fig. 11. XRD patterns of Sol A for (a) as-deposited

Al-hydroxide thin lm and (b) heated at 300

C for

60 min.

reduced amount of water experienced a direct trans-

formation to -Al

2

O

3

, whereas the water-containing

sol passed through several transition structures, such

as -Al

2

O

3

and -Al

2

O

3

. This means that sol A pre-

pared in our case was water-free since a direct tran-

sition to -Al

2

O

3

is observed. This alpha phase of

alumina is more favored in the dielectric applications.

Figure 12 shows the XRD patterns of the

deposited (room temperature aged) and heated sam-

ples of alumina lm prepared from sol B. This pat-

tern (Fig. 12(a)) also shows the amorphous behavior

of the deposited lm along with the presence of alu-

minum hydroxide peaks of varying intensities. It can

be seen from the comparison of Figs. 11(a) and 12(a)

that the peaks of Al(OH)

3

are smaller in case of sol

B. This may be due to the reason that the sol synthe-

sized from Al-sec butoxide based precursor does not

readily react with other constituents of the product

under these conditions. Figure 12(b) shows the XRD

pattern taken after heating of aluminum hydroxide

Fig. 12. XRD patterns of Sol B for (a) as-deposited

Al-hydroxide thin lm and (b) heated at 300

C for

60 min.

(sol B) at 350

C for 60 min. Various peaks of alu-

mina are observed in this gure due to hydrolysis

followed by condensation at this temperature. The

major peak though belongs to -Al

2

O

3

,

32

few peaks

of -Al

2

O

33

3

are also present. This means that sol B

contained some water content as discussed above.

The grain size of these alumina lms was

calculated from the WilliamsonHall plot of the

relation

34,35

:

2

f

cos

K

=

1

D

+

4e

K

sin ,

where 2

f

is in radians, K is the shape factor of the

crystalline particles, is the wavelength, e (= d/d)

is the microstrain, D is the particle size, and is the

Bragg angle.

The extrapolation method for the elimination of

the instrumental broadening of diraction lines has

been used since it does not require a standard sam-

ple. This method is valid for the conventional powder

X-ray diractometer with the BraggBrentano focus-

ing geometry

36,37

that was used in the present case.

The resultant grain size, for both the sols, comes out

to be of the order of 1215 nm.

Lower Temperature Formation of Alumina Thin Films Through SolGel Route 687

Fig. 13. Photoconduction measurements of Al

2

O

3

thin

lm.

The band gap of these Al

2

O

3

lms was deter-

mined by photoconduction measurements. Photo-

conductivity of the sample is plotted in Fig. 13,

which shows the relative photocurrent vs. energy of

the incident photons. The optical band gap (E

g

) of

Al

2

O

3

thin lms was determined from the straight

line intercept at the photon energy axis. For an

applied potential of 0.5 V, the energy band gap is

4.7 eV. At room temperature, the energy band gap

of bulk Al

2

O

3

is 6.2 eV.

38

The discrepancy of about

1.5 eV in the energy band gap of Al

2

O

3

is due to the

fact that we have studied Al

2

O

3

in thin lm form.

In addition, lowering of the band gap value may also

be associated with defect induced states in the band

gap.

39

This idea is supported by the peaks at 3.8 eV

and 4.3 eV in Fig. 13.

4. Conclusions

Alumina sol was spin coated onto silicon sub-

strates after optimization of synthesis of the sol. Al-

isopropoxide based sol (A) and Al-sec-butoxide sol

(B) were optimized for deposition of alumina thin

lms through solgel route. Bayerite [Al(OH)

3

] phase

of both the sols was observed in the room temper-

ature aged samples as conrmed by the XRD pat-

terns. Direct transition of sol A into -Al

2

O

3

was

observed at a temperature of 350

C whereas sol

B exhibited indirect transition to -Al

2

O

3

through

-Al

2

O

3

. Optical and scanning electron micrographs

showed continuous lm surfaces resulting from opti-

mized conditions. The energy band gap value of the

alumina lm was 4.7 eV, which has been attributed

to defect induced states in the band gap.

References

1. L. K. Hudson, C. Misra, A. J. Perrotta, K. Wefers

and F. S. Williams, Ullmanns Encyclopedia of

Industrial Chemistry, Electronic Release, 7th edn.

(V.C.H. Weinheim, 2004).

2. Q. Fu, C. B. Cao and H. S. Zhu, Thin Solid Films

348 (1999) 99.

3. B. Ksapabutr, E. Gulari and S. Wongkasemjit, Col-

loid Surf. A 233 (2004) 145.

4. S. Ruppi, J. Phys. 11 (2001) 847.

5. S. S. Kim, Y. J. Oh and C. E. Kim, Thin Solid Films

305 (1997) 321.

6. R. Kikuchi, S. Maeda, K. Sasaki, S. Wennerstrfm,

Y. Ozawa and K. Eguchi, Appl. Catal. A 239 (2003)

169.

7. Y. S. Lin and A. J. Burggraaf, AIChE J. 38 (1992)

445.

8. N. Itoh, K. Kato, T. Tsuji and M. Hongo, J. Membr.

Sci. 117 (1996) 189.

9. J. Shu, B. P. A. Grandjean, E. Ghali and

S. Kaliaguine, J. Membr. Sci. 77 (1993) 181.

10. Z. Y. Li, H. Maeda, K. Kusakabe, S. Morooka,

H. Anzai and S. Akiyama, J. Membr. Sci. 78 (1993)

247.

11. S. Sakka, Trans. Ind. Ceram. Soc. 46 (1987) 1.

12. S. Riaz, S. Shamaila, B. Khan and S. Naseem, Surf.

Rev. Lett. 15 (2008) 2.

13. N. Bahlawane and T. Watanabe, J. Am. Ceram. Soc.

83 (2000) 2324.

14. Y. Wakao and T. Hibbino, Nagoya Kogyo Gijutsu

Shikensko Hokoku 11 (1962) 588.

15. G. C. Bye and G. T. Simkin, J. Am. Ceram. Soc. 57

(1974) 367.

16. K. Okada, A. Hattori, T. Tanigushi, A. Nikui and

R. N. Das, J. Am. Ceram. Soc. 83 (2000) 928.

17. M. Kumagai and G. L. Messing, J. Am. Ceram. Soc.

68 (1985) 500.

18. V. Srdic and L. Radonjic, Ceram. Int. 21 (1995) 5.

19. H.-C. Kao and W.-C. Wei, J. Am. Ceram. Soc. 83

(2000) 362.

20. K. R. Han, C. S. Lim, M. J. Hong, J. W. Jan and

K. S. Hong, J. Am. Ceram. Soc. 83 (2000) 750.

21. S. Resgui and B. C. Gates, J. Non-Cryst. Solids 210

(1997) 287.

22. J. Nair, P. Nair, J. G. V. Ommen, J. R. H. Ross,

A. J. Burggraaf and F. Mizukami, J. Am. Ceram.

Soc. 81 (1998) 2709.

23. B. E. Yoldas, J. Am. Ceram. Soc. 65 (1982) 387.

24. C. S. Tsay, C. K. Lee and A. S. T. Chiang, Chem.

Phys. Lett. 278 (1997) 83.

688 S. Riaz et al.

25. J. Masalski, J. Gluszek, J. Zabrzeski, K. Nitsch and

P. Gluszek, Thin Solid Films 349 (1999) 186.

26. M. Liu, Y. Liu, Z. Zeng and T. Peng, J. Chro-

matogr. A 1108 (2006) 149.

27. J. Nawrocki, C. Dunlap, A. McCormick and P. W.

Carr, J. Chromatogr. A 1028 (2004) 1.

28. M. S. M. Saifullah, D. J. Kang, K. R. V. Subrama-

nian, M. E. Well, K. Yamazaki and K. Kurihara,

J. SolGel Sci. Technol. 29 (2004) 5.

29. N.

O. Zer, J. P. Cronin, Y. J. Yao and A. P. Tomsia,

Sol. Energy Mater. Sol. Cells 59 (1999) 355.

30. B. Kasprzyk-Hordern, Adv. Colloid Interface Sci.

110 (2004) 19.

31. Powder Diraction File: Joint Committee on Powder

Diraction Standards, ASTM, Philadelphia, 1967,

Card No. 20-0011.

32. Powder Diraction File: Joint Committee on Powder

Diraction Standards, ASTM, Philadelphia, 1967,

Card No. 10-173.

33. Powder Diraction File: Joint Committee on Powder

Diraction Standards, ASTM, Philadelphia, 1967,

Card No. 11-517.

34. H. P. Klug and L. E. Alexander, X-ray Diraction

Procedures for Polycrystalline and Amorphous Mate-

rials (Wiley, New York, 1974).

35. S. Riaz and S. Naseem, J. Mater. Sci. Tech. 23

(2007) 4.

36. M. Cernansky, Mater. Struct. 7 (2000) 3.

37. S. Riaz and S. Naseem, A. J. Mater. Sci. 2008, in

press.

38. G. V. Samsonov, HandBook of Oxides (Academy of

Sciences of Ukraine, USSR, 1969).

39. I. Costina and R. Franchy, Appl. Phys. Lett. 78

(2001) 4139.

Potrebbero piacerti anche

- j.surfcoat.2005.11.031Documento5 paginej.surfcoat.2005.11.031rahul.meenaNessuna valutazione finora

- PhasetransitionsDocumento11 paginePhasetransitionsRakesh PatnaikNessuna valutazione finora

- Macro Materials Eng - 2010 - Yuzay - Poly Lactic Acid Aluminum Oxide Composites Fabricated by Sol Gel and MeltDocumento10 pagineMacro Materials Eng - 2010 - Yuzay - Poly Lactic Acid Aluminum Oxide Composites Fabricated by Sol Gel and MeltMADHESWARAN SNessuna valutazione finora

- Using Microstructural Analysis To Solve Practical ProblemsDocumento9 pagineUsing Microstructural Analysis To Solve Practical ProblemskawtherahmedNessuna valutazione finora

- Structural Changes of Soda-Lime Silica Glass Induced by A Two-Step Ion ExchangeDocumento7 pagineStructural Changes of Soda-Lime Silica Glass Induced by A Two-Step Ion ExchangeyounessinaNessuna valutazione finora

- Al-Zn AlloyDocumento7 pagineAl-Zn Alloymohamad60Nessuna valutazione finora

- Synthesis, Characterization and Catalytic Properties of PtCeO2-Al2O3 and PtLa2O3-Al2O3 Sol-Gel Derived CatalystsDocumento9 pagineSynthesis, Characterization and Catalytic Properties of PtCeO2-Al2O3 and PtLa2O3-Al2O3 Sol-Gel Derived CatalystsSangHao NgNessuna valutazione finora

- Zolotov Ski I 1995Documento13 pagineZolotov Ski I 1995KaterinaNessuna valutazione finora

- Low-Temperature Electrodeposition of Aluminium From Lewis Acidic 1-Allyl-3-Methylimidazolium Chloroaluminate Ionic LiquidsDocumento10 pagineLow-Temperature Electrodeposition of Aluminium From Lewis Acidic 1-Allyl-3-Methylimidazolium Chloroaluminate Ionic LiquidsterNessuna valutazione finora

- Al PDFDocumento9 pagineAl PDFovi saputra astamaNessuna valutazione finora

- Effects of Gallium On Electrochemical Discharge Behavior of Al MG SN in Alloy Anode For Air Cell or Water-Activated CellDocumento6 pagineEffects of Gallium On Electrochemical Discharge Behavior of Al MG SN in Alloy Anode For Air Cell or Water-Activated CellAna Emily PrentissNessuna valutazione finora

- 3.1.1 Sol-Gel Preparation Techniques: Advanced CeramicDocumento5 pagine3.1.1 Sol-Gel Preparation Techniques: Advanced CeramicRawlinsonNessuna valutazione finora

- 2017 Inter JEnergy Research 1Documento11 pagine2017 Inter JEnergy Research 1Omar BarrientosNessuna valutazione finora

- Ukessays - co.Uk-Carbon HallHeroult CelDocumento19 pagineUkessays - co.Uk-Carbon HallHeroult CelMahmoud Ahmed AlyNessuna valutazione finora

- Hydrogen in Aluminum Lithium AlloysDocumento25 pagineHydrogen in Aluminum Lithium AlloysMitone DiazNessuna valutazione finora

- Ho2016 Enhancement of Hydrogen Generation Using WasteDocumento7 pagineHo2016 Enhancement of Hydrogen Generation Using WasteNur FadhilahNessuna valutazione finora

- Aluminium AnodizationDocumento12 pagineAluminium AnodizationTomas MancinNessuna valutazione finora

- Preparation of Alumina ®lms From A New Sol Gel Route: Qiang Fu, Chuan-Bao Cao, He-Sun ZhuDocumento4 paginePreparation of Alumina ®lms From A New Sol Gel Route: Qiang Fu, Chuan-Bao Cao, He-Sun ZhuGuru VelmathiNessuna valutazione finora

- Synthesisof2KAlSO42 12H2OfromwastecanDocumento7 pagineSynthesisof2KAlSO42 12H2Ofromwastecanzulfan jordanNessuna valutazione finora

- Low-Temp Synthesis of α-AluminaDocumento10 pagineLow-Temp Synthesis of α-AluminaIngrith Perez LacatoNessuna valutazione finora

- Copper Electrode PositionDocumento4 pagineCopper Electrode Positioncharles-oscar-requiez-4181Nessuna valutazione finora

- Aluminum CorrosionDocumento1 paginaAluminum CorrosionthanhnguyenhhvnNessuna valutazione finora

- Inorganic Chemistry: Group 13 AluminiumDocumento38 pagineInorganic Chemistry: Group 13 AluminiumLooi Chui Yean0% (1)

- Propiedades y Usos de Fluxes en AluminioDocumento1 paginaPropiedades y Usos de Fluxes en AluminioninzauNessuna valutazione finora

- Paper - 1 (Aluminum, Low Temperatures, Hydrogen Energy, 2016)Documento8 paginePaper - 1 (Aluminum, Low Temperatures, Hydrogen Energy, 2016)Lesya B-yaNessuna valutazione finora

- Phung 2014Documento12 paginePhung 2014KaterinaNessuna valutazione finora

- Aluminum Water HydrogenDocumento27 pagineAluminum Water HydrogenjbolzanNessuna valutazione finora

- Determination of Copper Complex II Coordination NumberDocumento18 pagineDetermination of Copper Complex II Coordination NumberHasrilia BeskaraNessuna valutazione finora

- Principles of Heterogeneous Catalysis CHE633A, IIT KanpurDocumento12 paginePrinciples of Heterogeneous Catalysis CHE633A, IIT KanpurRajendra SahuNessuna valutazione finora

- Aluminium and Aluminium-Silicon Alloy Phase Diagram AluminiumDocumento10 pagineAluminium and Aluminium-Silicon Alloy Phase Diagram AluminiumAnkit MauryaNessuna valutazione finora

- Hyrolysis of AL Dross To Achieve Zero Hazardous WasteDocumento9 pagineHyrolysis of AL Dross To Achieve Zero Hazardous WasteXantos YulianNessuna valutazione finora

- Isothermal Oxidation Behavior of Aluminized AISI 1020 Steel at The Temperature of 700 CDocumento6 pagineIsothermal Oxidation Behavior of Aluminized AISI 1020 Steel at The Temperature of 700 CRela FaradinaNessuna valutazione finora

- Influence of Si:Al Ratio On The Microstructural and Mechanical Properties of A Fine-Limestone Aggregate Alkali-Activated Slag ConcreteDocumento11 pagineInfluence of Si:Al Ratio On The Microstructural and Mechanical Properties of A Fine-Limestone Aggregate Alkali-Activated Slag ConcreteAndrew PiNessuna valutazione finora

- Aluminium Water HydrogenDocumento26 pagineAluminium Water Hydrogenjitendra.paliyaNessuna valutazione finora

- 7 01-7 11Documento12 pagine7 01-7 11Surya PrakashNessuna valutazione finora

- Biblio 4-September 2004Documento12 pagineBiblio 4-September 2004bedghiou djohraNessuna valutazione finora

- Yoshimura 2008Documento11 pagineYoshimura 2008Nitin RautNessuna valutazione finora

- Journal Pre-Proof: Powder TechnologyDocumento33 pagineJournal Pre-Proof: Powder TechnologyDinana Anissatul FuadiyahNessuna valutazione finora

- Sol-Gel Synthesis of Alumina Using Inorganic Salt PrecursorDocumento6 pagineSol-Gel Synthesis of Alumina Using Inorganic Salt PrecursordgslkbmalkdNessuna valutazione finora

- Ijct 16 (3) 216-220 PDFDocumento5 pagineIjct 16 (3) 216-220 PDFrapidremi100% (1)

- Aluminium MetallurgyDocumento3 pagineAluminium MetallurgyShubham ShuklaNessuna valutazione finora

- Fletcher 2005Documento7 pagineFletcher 2005Vidyadhara VNessuna valutazione finora

- Crystallization of Belite - Melilite Clinker Minerals in The Presence of Liquid PhaseDocumento5 pagineCrystallization of Belite - Melilite Clinker Minerals in The Presence of Liquid PhaseAnonymous NxpnI6jCNessuna valutazione finora

- Chemical Reaction Aluminum and KohDocumento7 pagineChemical Reaction Aluminum and KohCarlosMarioGonzalezNessuna valutazione finora

- RE Xtraction ProcessingDocumento12 pagineRE Xtraction ProcessingMarwanEl-JanzoriNessuna valutazione finora

- So SoDocumento15 pagineSo SoSurya SinghNessuna valutazione finora

- Synthesis of Common Alum: Chrome Alum KCR (So) - 12H ODocumento11 pagineSynthesis of Common Alum: Chrome Alum KCR (So) - 12H OidaayudwitasariNessuna valutazione finora

- Effectsof Different Barium Compoundsonthe CorrosionDocumento14 pagineEffectsof Different Barium Compoundsonthe CorrosionDavid KehindeNessuna valutazione finora

- Synthesis of Coal O Spinel From Cobalt-Loaded Zeolite-A: American Journal of Engineering Research (Ajer)Documento7 pagineSynthesis of Coal O Spinel From Cobalt-Loaded Zeolite-A: American Journal of Engineering Research (Ajer)AJER JOURNALNessuna valutazione finora

- Meille Review CorrectedDocumento45 pagineMeille Review CorrectedThiago AlvesNessuna valutazione finora

- Effect of Caf On Interfacial Phenomena of High Alumina Refractories With Al AlloyDocumento10 pagineEffect of Caf On Interfacial Phenomena of High Alumina Refractories With Al Alloyretnadiah354Nessuna valutazione finora

- SeminarDocumento24 pagineSeminarLalit GuptaNessuna valutazione finora

- A Novel Aluminium Air Rechargeable BatteryDocumento6 pagineA Novel Aluminium Air Rechargeable Batteryjro84Nessuna valutazione finora

- Al-Si-Cu-Mg Alloy PDFDocumento18 pagineAl-Si-Cu-Mg Alloy PDFRocio LopezNessuna valutazione finora

- DIMOXDocumento27 pagineDIMOXdia_8347928Nessuna valutazione finora

- The Activation of Aluminium by Mercury Ions in Non Aggressive Media 2006 Corrosion ScienceDocumento14 pagineThe Activation of Aluminium by Mercury Ions in Non Aggressive Media 2006 Corrosion SciencehortalemosNessuna valutazione finora

- Akira Mikuni Et - Al 2007, Dissolution Properties of Some Fly Ash Fillers Applying To Geopolymeric Materials in Alkali SolutionDocumento5 pagineAkira Mikuni Et - Al 2007, Dissolution Properties of Some Fly Ash Fillers Applying To Geopolymeric Materials in Alkali SolutionSatya ChaitanyaNessuna valutazione finora

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksDa EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNessuna valutazione finora

- Molecular Modeling of Corrosion Processes: Scientific Development and Engineering ApplicationsDa EverandMolecular Modeling of Corrosion Processes: Scientific Development and Engineering ApplicationsChristopher D. TaylorNessuna valutazione finora

- Blues Bass Lines GuideDocumento15 pagineBlues Bass Lines GuideMichele Conni83% (6)

- Synthesis and Characterization of 5 Meo-Dmt Succinate For Clinical UseDocumento9 pagineSynthesis and Characterization of 5 Meo-Dmt Succinate For Clinical UseChris GuarascioNessuna valutazione finora

- Chlorophyll Does Not Reflect Green Light How To Correct A Misconception Olli Virtanen 2020Documento9 pagineChlorophyll Does Not Reflect Green Light How To Correct A Misconception Olli Virtanen 2020Eero IiskolaNessuna valutazione finora

- Ziegler-Natta MgCl2-supported Catalysts Relationship Between Titanium Oxidation States Distribution and Activity in Olefin Polymerization 2001 SacchiDocumento7 pagineZiegler-Natta MgCl2-supported Catalysts Relationship Between Titanium Oxidation States Distribution and Activity in Olefin Polymerization 2001 SacchiEero IiskolaNessuna valutazione finora

- A Comparative Study of Ethylene and Propylene Polymerization Over Titanium-Magnesium Catalysts of Different Composition 2014 ZakharovDocumento7 pagineA Comparative Study of Ethylene and Propylene Polymerization Over Titanium-Magnesium Catalysts of Different Composition 2014 ZakharovEero IiskolaNessuna valutazione finora

- US7192564 Method For Recycling Spent Lithium Metal Polymer Rechargeable Batteries and Related Materials 2007Documento15 pagineUS7192564 Method For Recycling Spent Lithium Metal Polymer Rechargeable Batteries and Related Materials 2007Eero IiskolaNessuna valutazione finora

- Learn Jazz Standards The Smart Way PDFDocumento10 pagineLearn Jazz Standards The Smart Way PDFShreyans JainNessuna valutazione finora

- New Evidence On The Nature of The ActiveDocumento5 pagineNew Evidence On The Nature of The ActiveNamruthaNessuna valutazione finora

- Evidence For Silica Surface Three - and Five-Membered Metallacycle Intermediates in The Catalytic Cycle of Hydroaminoalkylation of Olefins Using Single-Ti-Metal Catalysts 2020Documento8 pagineEvidence For Silica Surface Three - and Five-Membered Metallacycle Intermediates in The Catalytic Cycle of Hydroaminoalkylation of Olefins Using Single-Ti-Metal Catalysts 2020Eero IiskolaNessuna valutazione finora

- Bad Affects of PlasticDocumento2 pagineBad Affects of PlasticMariaNilaZaragozaPalacioNessuna valutazione finora

- Fortunes in High Tech Asml Book Order 1Documento7 pagineFortunes in High Tech Asml Book Order 1Eero IiskolaNessuna valutazione finora

- Fortunes in High Tech Asml Book Order 1 Chapter 24Documento28 pagineFortunes in High Tech Asml Book Order 1 Chapter 24Eero IiskolaNessuna valutazione finora

- US20050244704A1 System and Method For Processing An End-Of-Life or Reduced Performance Energy Storage Lithium Battery 2005Documento16 pagineUS20050244704A1 System and Method For Processing An End-Of-Life or Reduced Performance Energy Storage Lithium Battery 2005Eero IiskolaNessuna valutazione finora

- 1-Chloro-2,3-Epoxypropane+reaction+with+wood Epichlorohydrin 1994 Epichlorohydrin Coupling Reactions With WoodDocumento6 pagine1-Chloro-2,3-Epoxypropane+reaction+with+wood Epichlorohydrin 1994 Epichlorohydrin Coupling Reactions With WoodEero IiskolaNessuna valutazione finora

- Basic A Minor Blues Melody A La Kenny BurrellDocumento1 paginaBasic A Minor Blues Melody A La Kenny BurrellEero IiskolaNessuna valutazione finora

- Heterogeneous Enantioselective Catalysts Strategies For The Immobilisation of Homogeneous Catalysts 2003Documento15 pagineHeterogeneous Enantioselective Catalysts Strategies For The Immobilisation of Homogeneous Catalysts 2003Eero IiskolaNessuna valutazione finora

- Heterogeneous Enantioselective Catalysts Strategies For The Immobilisation of Homogeneous Catalysts 2003Documento15 pagineHeterogeneous Enantioselective Catalysts Strategies For The Immobilisation of Homogeneous Catalysts 2003Eero IiskolaNessuna valutazione finora

- US9972830 Method For The Recovery of Lithium Cobalt Oxide From Lithium Ion Batteries 2018Documento12 pagineUS9972830 Method For The Recovery of Lithium Cobalt Oxide From Lithium Ion Batteries 2018Eero IiskolaNessuna valutazione finora

- Morphology Evolution in The Early Stages of Olefin Polymerization Masy.200690063Documento10 pagineMorphology Evolution in The Early Stages of Olefin Polymerization Masy.200690063Eero IiskolaNessuna valutazione finora

- Jimi Hendrix View Band of Gypsies 2Documento1 paginaJimi Hendrix View Band of Gypsies 2Eero IiskolaNessuna valutazione finora

- Spain 1Documento1 paginaSpain 1Eero IiskolaNessuna valutazione finora

- Spain Piano Intro Chick CoreaDocumento1 paginaSpain Piano Intro Chick CoreaEero Iiskola0% (2)

- (2-Pyridyloxy) Silanes As Ligands in Transition Metal Coordination Chemistry 2018 Xray PDFDocumento19 pagine(2-Pyridyloxy) Silanes As Ligands in Transition Metal Coordination Chemistry 2018 Xray PDFEero IiskolaNessuna valutazione finora

- Jimi Hendrix View Band of Gypsies 1Documento1 paginaJimi Hendrix View Band of Gypsies 1Eero IiskolaNessuna valutazione finora

- Hiirikin Pystyy Tähän Vappuna 01052020Documento1 paginaHiirikin Pystyy Tähän Vappuna 01052020Eero IiskolaNessuna valutazione finora

- Play A major piano sheet musicDocumento4 paginePlay A major piano sheet musicEero IiskolaNessuna valutazione finora

- Vappumuna 01052020 Ja Ajan Virta Tiimalasissa Jossa Hiekka Ei Tiedä Suuntaaa PDFDocumento1 paginaVappumuna 01052020 Ja Ajan Virta Tiimalasissa Jossa Hiekka Ei Tiedä Suuntaaa PDFEero IiskolaNessuna valutazione finora

- ArticlesDocumento6 pagineArticlesEero IiskolaNessuna valutazione finora

- Organometallic Hydroxides of Transition Elements Review 2006Documento31 pagineOrganometallic Hydroxides of Transition Elements Review 2006Eero IiskolaNessuna valutazione finora

- Alkylsilane-SiO2 Hybrids. A Concerted Picture of Temperature Effects in Vapor Phase Functionalization Aminosilane Ald JPhysChemC2015 - SIDocumento4 pagineAlkylsilane-SiO2 Hybrids. A Concerted Picture of Temperature Effects in Vapor Phase Functionalization Aminosilane Ald JPhysChemC2015 - SIEero IiskolaNessuna valutazione finora

- MatchboxDocumento2 pagineMatchboxCastro CarlosNessuna valutazione finora

- Experiment 3 (B) : Basics of OR Gate and Its Application in Industrial ControlDocumento3 pagineExperiment 3 (B) : Basics of OR Gate and Its Application in Industrial ControlDivyanshu BoseNessuna valutazione finora

- MX711 MX81x Machine Type 7463Documento834 pagineMX711 MX81x Machine Type 7463Cristian Leonardo Lalangui Ruiz0% (1)

- Yyy Yyyyyy Yyyyyy Yyyyyyyyyy Yyyy Yyyyy YyyyyyyDocumento10 pagineYyy Yyyyyy Yyyyyy Yyyyyyyyyy Yyyy Yyyyy Yyyyyyyhill_rws407Nessuna valutazione finora

- Automatic aeroponic irrigation system based on ArduinoDocumento13 pagineAutomatic aeroponic irrigation system based on ArduinoDheeraj ThakurNessuna valutazione finora

- Advance Elevator SystemDocumento16 pagineAdvance Elevator SystemAyeshaNessuna valutazione finora

- Introduction of The ILS, VOR, DMEDocumento43 pagineIntroduction of The ILS, VOR, DMEChiranjivi Kuthumi100% (1)

- Split Systems Brochure - PCSSUSE08-08B - DaikinDocumento20 pagineSplit Systems Brochure - PCSSUSE08-08B - DaikinyogeshyankeeNessuna valutazione finora

- Devising a solar powered standalone vehicle using GSM communication network for remote control and surveillanceDocumento3 pagineDevising a solar powered standalone vehicle using GSM communication network for remote control and surveillancePooja BanNessuna valutazione finora

- GD32F130xx Datasheet Rev2.1Documento41 pagineGD32F130xx Datasheet Rev2.1Moez MizouNessuna valutazione finora

- Annual Market Review & Forecast: Laser WeldingDocumento40 pagineAnnual Market Review & Forecast: Laser WeldingwwwpolNessuna valutazione finora

- AnsysDocumento22 pagineAnsysAbhijeetSethiNessuna valutazione finora

- AMI-1200 Distributor ManualDocumento77 pagineAMI-1200 Distributor ManualorodriguezNessuna valutazione finora

- Pendulum Wave EssayDocumento8 paginePendulum Wave EssaySamuel PetersNessuna valutazione finora

- 74HC14 PDFDocumento8 pagine74HC14 PDFNielsy R. Aparicio QuirogaNessuna valutazione finora

- Vme Bus: Starter KitDocumento2 pagineVme Bus: Starter Kitihab_abdullahNessuna valutazione finora

- Atsc Digital TV Tuner ReceiverDocumento16 pagineAtsc Digital TV Tuner ReceiverGerardo Espinosa EspinosaNessuna valutazione finora

- Training Manual PDFDocumento12 pagineTraining Manual PDFOwen kamazizwaNessuna valutazione finora

- Part 1.1 Overview Telecom NetworkDocumento39 paginePart 1.1 Overview Telecom NetworkEithu ThutunNessuna valutazione finora

- Introduction To Electricity & Electrical Systems: Prelim Learning ResourcesDocumento41 pagineIntroduction To Electricity & Electrical Systems: Prelim Learning ResourcesKib-anne Miguel PasikanNessuna valutazione finora

- 1176 PDFDocumento169 pagine1176 PDFJoshua PalizaNessuna valutazione finora

- Basics of SAW Sensor TechnologyDocumento5 pagineBasics of SAW Sensor TechnologyManmohan HarilalNessuna valutazione finora

- Interfacing LED With 8086 PDFDocumento9 pagineInterfacing LED With 8086 PDFqnu0750% (6)

- Electricity HOTS Questions and Answers from www.studiestoday.comDocumento2 pagineElectricity HOTS Questions and Answers from www.studiestoday.comDeepak PatelNessuna valutazione finora

- MagnaBend UserManualDocumento32 pagineMagnaBend UserManualLuo AmyNessuna valutazione finora

- So NetDocumento110 pagineSo NetRaj_Jai03Nessuna valutazione finora

- Unids6 Manual v100Documento24 pagineUnids6 Manual v100oya27910Nessuna valutazione finora

- Monochrome LedsDocumento1 paginaMonochrome Ledsy lNessuna valutazione finora

- Coke IotDocumento18 pagineCoke IotTarunVReddyNessuna valutazione finora

- Introduction To Sensors and Actuators: S. Senthil RajaDocumento38 pagineIntroduction To Sensors and Actuators: S. Senthil RajassrgmanNessuna valutazione finora