Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

GE Cycles Lecture Info 2009

Caricato da

Sayantan Datta GuptaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

GE Cycles Lecture Info 2009

Caricato da

Sayantan Datta GuptaCopyright:

Formati disponibili

GE Aircraft Engines

g

GE Aviation

The Aircraft Engine Design Project

Fundamentals of Engine Cycles

Ken Gould

Phil Weed

Spring 2009

1

GE Aircraft Engines

g

GE Aviation Technical History GE Aviation Technical History

U.S. jet engine

U.S. turboprop engine

V i bl t t i Variable stator engine

Mach 2 fighter engine

Mach 3 bomber engine

High bypass engine

Variable cycle turbofan engine

Unducted fan engine

I-A - First U.S. jet engine

GE90 on test

(Developed in Lynn, MA, 1941)

Unducted fan engine

30:1 pressure ratio engine

Demonstration of 100k+ engine thrust

Certified double annular combustor engine

First U.S. turboprop powered aircraft, Dec. 1945

2

GE Aircraft Engines

g Flowdown of Requirements

The Customer: Overall system requirements

MTOW, Range, Cost per seat per mile

The Airframer: Sub-system requirements

Technical: Wing (lift/drag),Engines(Thrust/SFC)

C S Program: Cost and Schedule

FAA/J AA

Engines Systems: Module requirements

ff f

FAA/J AA

Safety/reliability

Noise/emissions

Qualified Product

Technical: Pressure ratio, efficiency, weight, life

Program: NRE, part cost, schedule, validation plan

3

Design &

Validation

GE Aircraft Engines

g

The Aircraft Engine Design Project

HPT

Combustor

The Aircraft Engine Design Project

Fundamentals of Engine Cycles

Compressor

Combustor

Exhaust

T b j t E i

airflow

4

Turbojet Engine

Inlet

GE Aircraft Engines

g

Engine Modules and Components

Turbojet Stations

Compressor

Engine Modules and Components

Combustor

HPT

Inlet

Exit

HP Spool

Turbojet Engine Cross-Section

2

3

4

5

9

0

j g

Multi-stage compressor module

5

powered by a single stage turbine

GE Aircraft Engines

g Ideal Brayton Cycle: T-S Representation

HP Turbine Inlet

4

Expansion

5

pressure available for

Turbine Exit Pressure

5

T

Combustor

Inlet

Ambient Pressure

pressure available for

expansion across Exhaust Nozzle

0

2

1

h

W

P

=

Note: 1) Flight Mach = 0

2) P = P

Compression

3

W

Lines of Constant Pressure

2) P

t2

= P

amb

3) P = power

4) W = mass flow rate

5) h

0

= total enthalpy

Compressor Inlet

2

6

S

GE Aircraft Engines

g

Real Brayton Cycle: T-S Representation

HP Turbine Inlet

Expansion

4

Turbine Exit Pressure

5

pressure available for

T

3

pressure available for

expansion across Exhaust Nozzle

0

2

1

h

W

P

=

Ambient Pressure

Combustor

Inlet

Compression

Impact of Real Efficiencies:

Decreased Thrust @ if T4 is maintained

W

2

Or

Increase Temp (fuel flow) to maintain

thrust!

Lines of Constant Pressure

Compressor Inlet

2

7

S

GE Aircraft Engines

g

Engine Inlet

Jet Engine Cycle Analysis

Engine Inlet

Flow capacity (flow function relationship)

Starting with the conservation of mass and substituting the total to g g

static relations for Pressure and Temperature, can derive:

W= Density * Area* Velocity

W*(sqrt(Tt)) = M *sqrt(g

c

*/R)

Pt* Ae [1+ ((-1)/2)*M

2

]

(+1)/[2*(-1)]

where M is Mach number

Tt is total temperature (deg R)

Pt is total pressure (psia)

f ( / )

Turbojet

W is airflow (lbm/sec)

Ae is effective area (in

2

)

gc is gravitational constant

=32.17 lbm ft/(sec

2

lbf)

is ratio of specific heats

Compressor

Combustor

HPT

HP Spool

Inlet

Exit

8

is ratio of specific heats

R is gas constant

(ft-lbf)/(lbm-deg R)

2

3 4 5

9 0

GE Aircraft Engines

g

Compressor

Jet Engine Cycle Analysis

Compressor

From adiabatic efficiency relationship

compressor

= Ideal Work/ Actual Work = Cp*(Texit Tinlet)

Cp*(Texit Tinlet)

=(Pexit/Pinlet)

(-1)/

- 1 (Pexit/Pinlet) 1

Texit/Tinlet - 1

where

Pexit is compressor exit total pressure (psia)

Pinlet is compressor exit total pressure (psia) Pinlet is compressor exit total pressure (psia)

Tinlet is compressor inlet total temperature (deg R)

Texit is compressor exit total temperature (deg R)

Texit is ideal compressor exit temperature (deg R)

Turbojet

Compressor

Combustor

HPT

HP Spool

Inlet

Exit

9

2

3 4 5

9 0

GE Aircraft Engines

g

Combustor

Jet Engine Cycle Analysis

Combustor

From Energy balance/ Combustor efficiency relationship:

combustor

= Actual Enthalpy Rise/ Ideal Enthalpy Rise

= (WF + W)*Cp

combustor

Texit W*Cp

combustor

Tinlet

WF * FHV WF FHV

where W is airflow (lbm/sec)

WF is fuel flow (lbm/sec)

FHV is fuel heating value (BTU/lbm)

Tinlet is combustor inlet total temperature (deg R)

Texit is combustor exit total temperature (deg R)

Cp is combustor specific heat

BTU/(lbm-degR)

Turbojet

BTU/(lbmdeg R)

Can express WF/W as

fuel to air ratio (FAR)

Compressor

Combustor

HPT

HP Spool

Inlet

Exit

10

2

3 4 5

9 0

GE Aircraft Engines

g

Turbine

Jet Engine Cycle Analysis

Turbine

From efficiency relationship

=Actual Work/Ideal Work = Cp*(Tinlet Texit)

turbine

= Actual Work/Ideal Work = Cp (Tinlet Texit)

Cp*(Tinlet Texit)

= 1 - (Texit/Tinlet)

1 (P it/Pi l t)

( 1)/

1 - (Pexit/Pinlet)

(-1)/

Work Balance: From conservation of energy

Turbine Work = Compressor Work + Losses

(W+WF)* C * (Ti l t T it)| W* C * (T it Ti l t)| (W+ WF)* Cp

turb

* (Tinlet - Texit)|

turb

= W * Cp

compressor

* (Texit - Tinlet)|

comp

where

Pexit is turbine exit total pressure (psia)

Turbojet

p (p )

Pinlet is turbine exit total pressure (psia)

Tinlet is inlet total temperature (deg R)

Texit is exit total temperature (deg R)

Texit is ideal exit total temperature (deg R)

Cp is specific heat for turbine or compressor

Compressor

Combustor

HPT

HP Spool

Inlet

Exit

11

Cp is specific heat for turbine or compressor

BTU/(lbm-deg R)

2

3 4 5

9 0

GE Aircraft Engines

g

Jet Engine Cycle Analysis

Nozzle

Isentropic relationship, can determine exhaust properties p p p p

Tt/Ts= (Pt/Ps)

(-1)/

= 1 + (( -1)/2) * M

2

From Mach number relationship can determine exhaust velocity

v= M*a

where a, speed of sound= sqrt(*g

c

*R*Ts)

where

Tt is total temperature (deg R)

Pt is total pressure (psia)

Ps is static pressure (psia)

Ts is static temp (deg R)

g is gravitational constant

Turbojet

g

c

is gravitational constant

=32.17 lbm ft/(sec

2

lbf)

is ratio of specific heats

R is gas constant (ft-lbf)/(lbm-deg R)

v is flow velocity (ft/sec)

Compressor

Combustor

HPT

HP Spool

Inlet

Exit

12

y( )

a is speed of sound (ft/sec)

M is Mach number

2

3 4 5

9 0

GE Aircraft Engines

g

E i P f

Jet Engine Cycle Analysis

Engine Performance

Thrust relationship: from conservation of momentum

Fnet = W9 V9/ g

c

- W0 V0/ g

c

+ (Ps9-Ps0) A9

If flight Mach number is 0, v0 = 0

and if nozzle expands to ambient, PS9=Ps0 and p ,

Fnet = W9 V9/ g

c

where g

c

is gravitational constant

Specific Fuel Consumption (SFC)

SFC = Wf/ Fnet (lbm/hr/ lbf)

(l SFC i b tt )

Turbojet

(lower SFC is better) Compressor

Combustor

HPT

HP Spool

Inlet

Exit

13

2

3 4 5

9 0

GE Aircraft Engines

g

A/B / V i bl E h t N l

Modern Afterburning Turbofan Engine

3-stage fan module

Single-stage HPT module

A/B w/ Variable Exhaust Nozzle

g

Single Stage LPT module

multi-stage compressor module

Typical Operating Parameters:

OPR 25 1

Terms:

Annular Combustor

14

OPR 25:1

BPR 0.34

ITT 2520

o

F

Airflow 142 lbm/sec

Thrust Class 16K-22K lbf

Terms:

blade rotating airfoil

vane static airfoil

stage rotor/stator pair

PLA pilots throttle

GE Aircraft Engines

g Thermodynamic Station Representation

8

9

7 Wf AB

FN

4.5

5

9

7

Wf_comb

Wf_AB

2

2.5

3

4

Nozzle

Expansion

A/B Temp Rise

W2 A8 (nozzle

LP Turbine

expansion

Comb

Temp

Rise

Fan Pr

(P25/P2)

HPC Pr

(P25/P2)

area)

HP Turbine

expansion

15

(P25/P2)

Overall Pressure Ratio (P3/P2)

GE Aircraft Engines

g

Fan

Compressor

Bypass Flow

Air Flow

Bypass Flow

Combustor

HPT

LPT

Afterburner

Inlet

Exit

HP Spool

LP Spool

Augmented Turbofan Engine Cross-Section

16

General Electric Aircraft Engines

GE Aircraft Engines

g

Design Considerations- Process Centering and Variation

Off-Target

Variation

X

X

X

X

X

X

Design Considerations Process Centering and Variation

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

On-Target

X

X

X

Reduce

Spread

Center

Process

X

X

X

X

X

X

X

X

X

X

X

X X

X

Six Sigma Methodology Applies Statistical Analyses to Center

Spread Process

17

g gy pp y

Processes and Minimize Variation

General Electric Aircraft Engines

GE Aircraft Engines

g

Probabilistic Design Techniques Account for Process Variation

General Electric Aircraft Engines

g q

Frequency Chart

041

.054

81

108

2,000 Trials 0 Outliers

Forecast: Margin-: Average Off Target

Frequency Chart

.023 45

2,000 Trials 49 Outliers

Forecast: Margin: High Variation

000

.014

.027

.041

0

27

54

81

000

.006

.011

.017

0

11.25

22.5

33.75

Certainty is 92.50% from 0.00 to +Infinity

.000 0

-2.00 0.00 2.00 4.00 6.00

Certainty is 95.05% from 0.00 to +Infinity

.000 0

-1.00 1.00 3.00 5.00 7.00

Forecast: Margin:On Target-Low Variation

Frequency Chart

.026

.039

.052

52

78

104

2,000 Trials 1 Outlier

Reduce

Spread

Center

Process

.000

.013

0

26

-2.00 0.00 2.00 4.00 6.00

18

Understanding and Accounting for Process Variation Assures

Compliance with Design Limits

Potrebbero piacerti anche

- FORMULAS FOR PREDICTING VGF-GL/GLD/GSID BHP and Intake Manifold PressureDocumento19 pagineFORMULAS FOR PREDICTING VGF-GL/GLD/GSID BHP and Intake Manifold PressureClemente Rafael Marval Escalona100% (1)

- Ata 74 - Engine Ignition CorDocumento8 pagineAta 74 - Engine Ignition CorIdrisNessuna valutazione finora

- Lecture 310 - Fluid Flow MetersDocumento41 pagineLecture 310 - Fluid Flow Metersanonim 1178Nessuna valutazione finora

- Aircraft Gas Turbine Engines Assignment 2Documento13 pagineAircraft Gas Turbine Engines Assignment 2Abdul MuizzNessuna valutazione finora

- Waste Water Piping and Vent System Sir FhaDocumento40 pagineWaste Water Piping and Vent System Sir Fhabradley100% (1)

- A320fam Iae Ata78 Exhaust PDFDocumento42 pagineA320fam Iae Ata78 Exhaust PDFshabbirjama103Nessuna valutazione finora

- Chapter III Propulsion Systems Thrust and Performance ParametersDocumento29 pagineChapter III Propulsion Systems Thrust and Performance ParametersshmyeNessuna valutazione finora

- Critical Radius of InsulationDocumento20 pagineCritical Radius of InsulationAamir ArainNessuna valutazione finora

- 10 1016@j Ijhydene 2010 04 005Documento8 pagine10 1016@j Ijhydene 2010 04 005igor Vladimirovich100% (2)

- APCO. S-200a Air Release ValveDocumento2 pagineAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- Engine Xakimov XDocumento9 pagineEngine Xakimov XXaviNessuna valutazione finora

- v20 - GE-1019 Turbofan and Turbojet Engines Database Handbook-1-8Documento8 paginev20 - GE-1019 Turbofan and Turbojet Engines Database Handbook-1-8MoyiNessuna valutazione finora

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Documento9 pagineEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldNessuna valutazione finora

- Full Thermowell CatalogDocumento12 pagineFull Thermowell CatalogandrademaxNessuna valutazione finora

- Subsonic Ejector RamjetDocumento99 pagineSubsonic Ejector Ramjetmarco20874Nessuna valutazione finora

- Axial Fan NotchDocumento3 pagineAxial Fan NotchhahasiriusNessuna valutazione finora

- Gas Turbine TechnologyDocumento8 pagineGas Turbine TechnologymishraenggNessuna valutazione finora

- MAE 570 Axial Compressors, A - SDocumento67 pagineMAE 570 Axial Compressors, A - SLuiz Felipe Disconzi LopesNessuna valutazione finora

- Assignment Question - Aircraft Cabin Interior System 2020 - Captain Ismail A BakarDocumento24 pagineAssignment Question - Aircraft Cabin Interior System 2020 - Captain Ismail A BakarNaufal NasirNessuna valutazione finora

- A C Engines and Jet Propulsion3Documento152 pagineA C Engines and Jet Propulsion3Mukesh Kumar100% (1)

- Internal Combustion Engines: Laboratory ManualDocumento54 pagineInternal Combustion Engines: Laboratory ManualmulualemNessuna valutazione finora

- Performance Characteristics of Axial FansDocumento4 paginePerformance Characteristics of Axial Fanskutts76Nessuna valutazione finora

- cfm56 7b PDFDocumento6 paginecfm56 7b PDFjouadiNessuna valutazione finora

- Introduction To Aircraft Engines: Tieying WuDocumento54 pagineIntroduction To Aircraft Engines: Tieying WuDennis Padec BwochengoNessuna valutazione finora

- Aeronautical Engineering Units 130710Documento63 pagineAeronautical Engineering Units 130710maitham1000% (1)

- The Nacelle How Does It WorkDocumento2 pagineThe Nacelle How Does It WorkJayDeep KhajureNessuna valutazione finora

- Topic: Starter of Engine Branch: Electrical Engineering: Prepared By:-Guided ByDocumento16 pagineTopic: Starter of Engine Branch: Electrical Engineering: Prepared By:-Guided ByTanvi KhuranaNessuna valutazione finora

- Isidoro Martinez - Aircraft Propulsion PDFDocumento41 pagineIsidoro Martinez - Aircraft Propulsion PDFjoereisNessuna valutazione finora

- Flow Measurement ManualDocumento10 pagineFlow Measurement ManualSHANKARNessuna valutazione finora

- SR TechniquesDocumento673 pagineSR TechniquesReBeL Tv LxNessuna valutazione finora

- Parker TubingDocumento85 pagineParker TubingPatrick StivénNessuna valutazione finora

- Fuel SystemDocumento24 pagineFuel SystemDipranjan GuptaNessuna valutazione finora

- NozzleDocumento20 pagineNozzleAnshul BoharaNessuna valutazione finora

- Compressor Exams SolutionsDocumento18 pagineCompressor Exams SolutionsMohamed BalbaaNessuna valutazione finora

- Module 11.5.1 NotesDocumento9 pagineModule 11.5.1 Notesmanu gargNessuna valutazione finora

- Power Plant Question PapersDocumento76 paginePower Plant Question PapersRowan Rodrigues100% (1)

- GE - FAA CLEEN Consortium 2010 - Unlimited RightsDocumento23 pagineGE - FAA CLEEN Consortium 2010 - Unlimited RightszzzyyyfffNessuna valutazione finora

- Cf6 80c2 Engine.Documento7 pagineCf6 80c2 Engine.Harsh AmbhoreNessuna valutazione finora

- DR Esmaeel System 3 Hydraulic PDFDocumento38 pagineDR Esmaeel System 3 Hydraulic PDFsbhaleshNessuna valutazione finora

- Design and Fabrication of EDF BLEVE Jet Hybrid EngineDocumento6 pagineDesign and Fabrication of EDF BLEVE Jet Hybrid EngineijsretNessuna valutazione finora

- Blade ElementDocumento6 pagineBlade ElementJd ValleNessuna valutazione finora

- Assignment 1Documento4 pagineAssignment 1Ziyad Awali100% (1)

- Aircraft Tank RepairDocumento31 pagineAircraft Tank RepairRoberto Carlos Subauste PérezNessuna valutazione finora

- Syllabus Fans and Blowers: Types, Performance Evaluation, Efficient System Operation, FlowDocumento16 pagineSyllabus Fans and Blowers: Types, Performance Evaluation, Efficient System Operation, FlowGaurav ShrivastavaNessuna valutazione finora

- Jet Pump Technical DataDocumento11 pagineJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- Toaz - Info Air Compressor Seminar PRDocumento15 pagineToaz - Info Air Compressor Seminar PR2AG19ME411 JagadeeshNessuna valutazione finora

- M 17Documento5 pagineM 17amhm2000Nessuna valutazione finora

- Specification Fire Supression StandpipeDocumento11 pagineSpecification Fire Supression StandpipeRaaann100% (1)

- Me8596 Thermal Engineering - IiDocumento16 pagineMe8596 Thermal Engineering - Iimohan velNessuna valutazione finora

- Flow ControlDocumento3 pagineFlow ControlGuilherme PagatiniNessuna valutazione finora

- CFD Analysis of Swept and Leaned Transonic Compressor RotorDocumento5 pagineCFD Analysis of Swept and Leaned Transonic Compressor RotorseventhsensegroupNessuna valutazione finora

- GE Challenge Problem Statement 2009Documento11 pagineGE Challenge Problem Statement 2009looserlooserNessuna valutazione finora

- 16V2000 G83 3B EnglischDocumento10 pagine16V2000 G83 3B EnglischDavid GomezNessuna valutazione finora

- 2 2 3 P SavarinoDocumento1 pagina2 2 3 P Savarinoapi-272976211Nessuna valutazione finora

- 9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏDocumento80 pagine9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏnabil160874100% (2)

- 2 2 3 P TurbinedatasheetDocumento1 pagina2 2 3 P Turbinedatasheetapi-249413102Nessuna valutazione finora

- Qip JP 04 Engine CharacteristicsDocumento36 pagineQip JP 04 Engine CharacteristicspepeNessuna valutazione finora

- 12V4000G23FDocumento10 pagine12V4000G23FZawmin TunNessuna valutazione finora

- Engine Design ReportDocumento7 pagineEngine Design Reportapi-251800888Nessuna valutazione finora

- Transportasi Fluida (Compressible Fluid-Fan Blower)Documento36 pagineTransportasi Fluida (Compressible Fluid-Fan Blower)Evia Salma ZauridaNessuna valutazione finora

- Comic Books 2018 Graphic NovelsDocumento49 pagineComic Books 2018 Graphic NovelsPrimedia BroadcastingNessuna valutazione finora

- Q Q Q Q Q: Appendix: Summary of FormulaeDocumento4 pagineQ Q Q Q Q: Appendix: Summary of FormulaeSayantan Datta GuptaNessuna valutazione finora

- Eurofighter Aero Design MatlDocumento11 pagineEurofighter Aero Design MatlSayantan Datta GuptaNessuna valutazione finora

- M Aerospace Engineering 201201Documento28 pagineM Aerospace Engineering 201201Sayantan Datta GuptaNessuna valutazione finora

- Check List For Applicants To Chalmers Master's ProgrammesDocumento1 paginaCheck List For Applicants To Chalmers Master's ProgrammesSayantan Datta GuptaNessuna valutazione finora

- Application Attachments MEng DDMDocumento7 pagineApplication Attachments MEng DDMSayantan Datta GuptaNessuna valutazione finora

- Rab PlumbingDocumento77 pagineRab Plumbingari wahyuNessuna valutazione finora

- Cim & SKS Price List DT 10-Nov-2021Documento6 pagineCim & SKS Price List DT 10-Nov-2021ISRAR SHAHNessuna valutazione finora

- 52000427BD-Alliance-Airport Expansion (R-2) - EmailDocumento3 pagine52000427BD-Alliance-Airport Expansion (R-2) - EmailTanveer AzizNessuna valutazione finora

- Dsto TR 2757Documento41 pagineDsto TR 2757Muhammet özbekNessuna valutazione finora

- Piping Elbows - Thrust Block ForcesDocumento5 paginePiping Elbows - Thrust Block ForcesSasankNessuna valutazione finora

- Certificacion FM - SCF125-100-300Documento2 pagineCertificacion FM - SCF125-100-300Camilo DazaNessuna valutazione finora

- Turbo 10Documento10 pagineTurbo 10Amitpal SinghNessuna valutazione finora

- Eclips Orfice ValveDocumento4 pagineEclips Orfice Valveاحمد الجزار2007Nessuna valutazione finora

- ME - 312 W2022 Project2Documento4 pagineME - 312 W2022 Project2Mohammed Khalid0% (1)

- Raw Water Inlet: LegendDocumento1 paginaRaw Water Inlet: LegendsugiantoNessuna valutazione finora

- Centrifugal Compressor DesignDocumento81 pagineCentrifugal Compressor DesignMuhammad Usman AzamNessuna valutazione finora

- WH Valves Leak Test TemplateDocumento4 pagineWH Valves Leak Test TemplateHossein100% (1)

- Hydraulic Override - Manual PDFDocumento18 pagineHydraulic Override - Manual PDFDaniel DuongNessuna valutazione finora

- FTMCDocumento12 pagineFTMCELLIN GAMINGNessuna valutazione finora

- Air Compressor MCQ'S: D.Mean Effective PressureDocumento10 pagineAir Compressor MCQ'S: D.Mean Effective PressureAman SheikhNessuna valutazione finora

- Question Bank (ME 401)Documento2 pagineQuestion Bank (ME 401)SK MD WALI ULLAH BULONNessuna valutazione finora

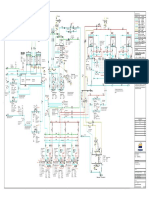

- PID 01 Rev 00 - PI-diag Tekerhat EME 190718Documento1 paginaPID 01 Rev 00 - PI-diag Tekerhat EME 190718Jay RabaneraNessuna valutazione finora

- Performance Curves LKH LKHPF Lkhi LKH Evap 60 50 HZ enDocumento1 paginaPerformance Curves LKH LKHPF Lkhi LKH Evap 60 50 HZ enAhmed AlaaNessuna valutazione finora

- Pratt & Whitney Canada: Illustrated Parts Catalog MANUAL PART NO. 3043324Documento16 paginePratt & Whitney Canada: Illustrated Parts Catalog MANUAL PART NO. 3043324alex castroNessuna valutazione finora

- J2a ElDocumento5 pagineJ2a ElBALAKRISHNANNessuna valutazione finora

- Data Sheet For Line StopDocumento7 pagineData Sheet For Line StopMathi Vinoth PillaiNessuna valutazione finora

- KE01.00.000.KD.P.TD.0015.000: Experimental ProgramDocumento466 pagineKE01.00.000.KD.P.TD.0015.000: Experimental ProgramMaffone NumerounoNessuna valutazione finora

- General 04 Fixed Flow Pump To Three TanksDocumento13 pagineGeneral 04 Fixed Flow Pump To Three TanksjpalauguillemNessuna valutazione finora

- Lab Report For Venturi MeterDocumento9 pagineLab Report For Venturi MeterFirzana AmiraNessuna valutazione finora

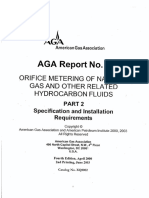

- AGA Report No.3-2000 Part 2 - Orifice Metering of Natural Gas and Other Related Hydrocarbon FluidsDocumento80 pagineAGA Report No.3-2000 Part 2 - Orifice Metering of Natural Gas and Other Related Hydrocarbon Fluidspras_fistek100% (1)

- Hdpe QuotationDocumento3 pagineHdpe Quotationnachiketa99mithaiwalaNessuna valutazione finora

- 01.hazards of Trapped Pressure & Vacuum-10Documento2 pagine01.hazards of Trapped Pressure & Vacuum-10rahulNessuna valutazione finora

- List Barang (Material)Documento128 pagineList Barang (Material)AdzrA RNessuna valutazione finora

- Brosur Pompa DS Dan DVSDocumento4 pagineBrosur Pompa DS Dan DVSBilly Christovel100% (1)

- Water-Tube Boiler Separator For The Steam/water MixtureDocumento1 paginaWater-Tube Boiler Separator For The Steam/water MixtureBrijesh SrivastavNessuna valutazione finora