Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Specific Gravity & Water Absorption Test (I S 2386 Iii/63)

Caricato da

End End0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

155 visualizzazioni11 pagineThis document contains test results from specific gravity and water absorption tests on sand according to IS 2386 Part III. It includes the weights of various components measured and calculations of specific gravity and water absorption percentage. The average specific gravity was found to be 2.79 and the average water absorption was 1.01%. Gradation test results on fine and coarse aggregates are also presented showing the material conforming to the specified zones.

Descrizione originale:

concrete

Titolo originale

Mix+Design+2

Copyright

© © All Rights Reserved

Formati disponibili

XLSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document contains test results from specific gravity and water absorption tests on sand according to IS 2386 Part III. It includes the weights of various components measured and calculations of specific gravity and water absorption percentage. The average specific gravity was found to be 2.79 and the average water absorption was 1.01%. Gradation test results on fine and coarse aggregates are also presented showing the material conforming to the specified zones.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

155 visualizzazioni11 pagineSpecific Gravity & Water Absorption Test (I S 2386 Iii/63)

Caricato da

End EndThis document contains test results from specific gravity and water absorption tests on sand according to IS 2386 Part III. It includes the weights of various components measured and calculations of specific gravity and water absorption percentage. The average specific gravity was found to be 2.79 and the average water absorption was 1.01%. Gradation test results on fine and coarse aggregates are also presented showing the material conforming to the specified zones.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 11

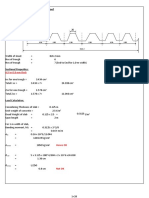

Name of Work : Trial

SPECIFIC GRAVITY & WATER ABSORPTION TEST (I S 2386 III/63)

Test 1 Test 2

Weigt of Pycnometer (gms) W1 664.5 670

Weigt of Pycnometer + Sand (gms) W2 1665 1654.5

Weigt of Pycnometer + Water +Sand (gms) W3 2185 2177.5

Weigt of Pycnometer + Water (gms) W4 1545 1544

W2-W1 W5 1000.5 984.5

W3-W4 (W4-W1)-(W3-W2) W6 360.5 351

Specific Gravity=(W2-W1)/(W2-W1)-(W3-W4) 2.78 2.80

Average Specific Gravity

WATER ABSORPTION TEST

Test 1 Test 2

Weigt of Saturated Aggregate in Air (gms) W1 1997 1325

Weigt of Oven Dried Aggregate (gms) W2 1972 1315

Weigt of water Absorbed (W3-W4) (gms) W3 25 10

Percent Water Absorption=W6/W4X100(%) 1.27 0.76

Average Aggregate Water Absorption(%)

Observations

2.79

1.01%

Observations

Name of Work : Trial

SPECIFIC GRAVITY & WATER ABSORPTION TEST (I S 2386 III/63)

Test 1 Test 2

Weigt of Saturated Aggregate + Basket in water (gms) W1 3000 2000

Weigt of Basket in water (gms) W2 500 500

Weigt of Saturated Aggregate in water (W1-W2) (gms) W5 2500 1500

Weigt of Saturated Aggregate in Air (gms) W3 3550 3000

Weigt of Oven Dried Aggregate (gms) W4 3501 2960

Weigt of water Absorbed (W3-W4) (gms) W6 49 40

Percent Water Absorption=W6/W4X100(%) 1.40 1.35

Average Aggregate Water Absorption(%)

Specific Gravity=W4/(W3-W5) 3.33 1.97

Average Specific Gravity 2.65

1.38

Observations

Name of Work : Trial

Weight of Sample Taken 1000 Gms

10 mm 0.00 0.00% 0.00% 100.00% 100 100

4.75 mm 92.00 9.20% 9.20% 90.80% 90.80 90.80

90--100 90--100

2.36 mm 43.00 4.30% 13.50% 86.50% 86.50 86.50

60--95 75--100

1.18 mm 150.00 15.00% 28.50% 71.50% 71.50 71.50

30--70 55--90

600 Micron 130.00 13.00% 41.50% 58.50% 58.50 58.50

15--34 35--59

300 Micron 110.00 11.00% 52.50% 47.50% 47.50 47.50

5--20 8--30

150 Micron 400.00 40.00% 92.50% 7.50% 7.50 7.50

0--10 0--10

Concluded Sand Zone

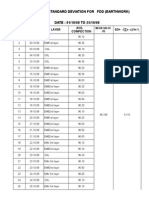

Name of Work :

Weight of Sample Taken 12530 Gms

63 mm 0.00 0.00% 0.00% 100.00% 100

40 mm 45.00 4.50% 4.50% 95.50% 95.50 95.50

95--100 100

20 mm 650.00 65.00% 69.50% 30.50% 30.50 30.50

30--70 95--100

10 mm 75.00 7.50% 77.00% 23.00% 23.00 23.00

10--35 25--55

4.75 mm 210.00 21.00% 98.00% 2.00% 2.00 2.00

0--5 0--10

40MM 20MM

Gradation of Course Aggregate

I.S.Sieve

Size MM

Weight

Retained in

Percent

Retained %

Cummulative

Percent

Percent

Passing %

Zone II

Gradation of Fine Aggregate

I.S.Sieve

Size MM

Weight

Retained in

Gms

Percent

Retained %

Cummulative

Percent

Retained %

Percent

Passing %

Zone I Zone II

Concluded Metal Size 20mm

100 100

90.80 90.80

90--100 95--100

86.50 86.50

85--100 95--100

71.50 71.50

75--100 90--100

58.50 58.50

60--79 80--100

47.50 47.50

12--40 15--50

7.50 7.50

0--10 0--15

Zone III Zone IV

Zone II

Name of Work:

1. Decide Grade of Concrete to be designed M25

2. Characteristic Strength required (Fck) 25N/sq.mm.

3. Maximum size of Aggregates #REF!

4. Degree of Quality Control Fair

5. Degree of Exposure Moderate -RCC

6. Minimum Cement Content (For Above Exposure as per table 5) 300Kg/Cum

7. Maximum water Cement Ratio (For Above Exposure as per table 5) 0.50

8. Degree of Workability 50 mm. Slump

9. Whether Plasticizer to be used No

1. Cement Used 43 Grade with 28 days strength 43N/sq.mm.

2. Specific Gravity of Cement 3.15

3. Specific Gravity of CA 2.65

4. Specific Gravity of FA 2.79

5. Water Absorption of CA 1.38

6. Water Absorption of FA 1.01

7. Sand Conforms ot Grading Zone Zone II

For Degree of QC Good and M25, K=4 Mpa

as per Para 4 ( Increase 1 Mpa for lower

5

Target Strenght is goven by Ft=Fck+KS 33.25Mpa

K= 1.65

C

Hence, for a target Mean strenght of 33.25Mpa W/C Ratio-0.42

Check

Whether, this water cement ration is less than permissible 0.50 ? 0.42

Yes.. Hence ok, use water cement ration as determined above

hence the water

content wiill be

In this case, . aggregates are used,

20MM

Lit/Cum-186

Since, Plasticizer is not used, no reduction in

water quantity is made.

0.42

443Kg/Cum

From Table 5, minimum cement content for Above exposure condition = 300Kg/Cum

Hence OK

Step C : Target Strength

STEP A : Design Stipulation

Step B : Test Data of Material : Tests to be Conducted in Laboratory

Note. It is not necessary to conduct cement testing first, and then carry out mix design.

You can also gety 28 days strenght of cement from manufactures test certificate (MTC). If

such certificate is niot available, you can always consider 28 days strenght as 43 or 53

N/sq.mm. for 43 or 53 grade respectively. in that case though, number of trails may

increase.

Concrete mix design(IS 10262-2009)

Step E : Calculation of Cement Content

Water Cement ratio

Cement Content = Water Content / Water Cement ratio -- kg/cu.m.

Step D : Selection Free Water Cement Ratio

Step E : Selection of Water Content

For a given target strength of concrete and 28 days strenght of cement, free WCR is

determined form following figure. Six curves are given for six ranges of 28 days cement

strength

Having decided the water cement ratio, next is to decide water content. Water content is

related to maximum aggregate size used. For - standard 50 mm. slump.

if Water cenment ratio exceeds 0.50 restrict it to 0.50 because it is the maximum water

cement ratio

Table 5

Exposure

Min.

Cement

Max. WCR Min.

Grade

Mild-RCC 300 0.55 M20

Moderate -RCC 300 0.50 M25

Severe -RCC 320 0.45 M30

Very severe -RCC 340 0.45 M35

Extreme -RCC 360 0.40 M40

ZoneIV Zone III Zone II Zone I

10 mm 0.5 0.48 0.46 0.44

20 mm 0.66 0.64 0.62 0.6

40 mm 0.75 0.73 0.71 0.69

0.62

Furter water cement ration is Less than 0.50 hence correction will be

0.60

and thus vollume of sand will be 1-** 0.40

Now we know

Weight of Cement : 443 Kg/Cum

Weight of water : 186 Kg/Cum

volume of sand : 0.40 Cum

volume of coarse aggregate : 0.60 Cum

a. volume of concrete = 1 cum = a a= 1 Cum

b. volume of cement = Mass of cement / sp.gr.of cement * 1/1000 b= 0.1406 Cum

c. volume of water = Mass of water / sp.gr.of water * 1/1000 c= 0.186 Cum

d volume of all in aggregate = a-(b+c) d= 0.673 Cum

e. mass of coarse aggregate = d*vol. of CA * sp.gr of CA * 1000 1079 Kg

f. mass of fine aggregate = d*vol.of FA * sp.gr of FA *1000 744 Kg

Based on weights calculated determine mix proportion as follows

C : Cement content 443Kg/Cum Cement F.A. C.A. W.C. Ratio

FA : fine aggregate content 744Kg/Cum 1 1.68 2.44 0.42

CA : Coarse aggregate content 1079Kg/Cum

W : water content 186Kg/Cum

If aggregates are dry correction for water absorpton is to be applied as under Water content w.rt. Free WCT - 186Kg/Cum

Absorption of Aggregare = 1.38 %

Extra for WA of C. A.= 14.84 kg/cum

Absorption of Sand = 0.80 %

Sand content * WA Sand / 100 Extra for WA of Sand = 5.95 kg/cum W.C. Ratio

Total Water content 206.79 kg/cum 0.47

IS specify volume of coarse

aggregate depends on zone of

sand, but for 50 mm. standard

slump as follows

Step H : Determine Mix Proportion

Step F : Proportion of Coarse aggregate And Fine aggregate

Maximum Aggregate Size Volume of Coar. Aggre. for sand zone

Note - if water cement ratio is lower than 0.50 the proportionof volume of coarse

aggregate is varies at the rate of - / + 0.01 for every +- 0.05 change in water cement ratio

In this usingabove chart volume of coarse agregate is

0.01 * (0.50 - *) / 0.05 = ** and the corrected aggreagte contendt will be***-**=

Step J : Corrections for Absorption

Step G : Mix Calculation

Step L : Trials

Prepare mix using above mix proportion. Observe slump, texture cohesiveness, workaility of fresh

concrete. Make necessary adjustments based on observations. Take atleaset three trials by increasing

an / or decreasing the water cement ratio. For economy utilise miximum water cement ration. observe

7 days and 28 days strengths of cubes. finalise the mix based on strength.

Name of Work :

Consistancy of Standard Cement Paste(IS 4031(Part 4)-1988)

Sr.

No

.

Wt. of Cement( C ) Percentage of

Water

Quantity of

Water

Depth of Penetration

from bottom in MM

1

2

3

Setting Time of Cement (IS 4031(Part 5)-1988)

1 Wt. of Water in Gms

2 Wt. of Cement( C )in Gms

3 Time at which water is mixed with cement

3 Time at which needle( C ) fails to pierce the test block

4

A FInal Setting Time of Cement sample in minutes

B Initial Setting Time of Cement sample in minutes

Time at which needle (F) makes an impression while annual ring

fails to do so

Potrebbero piacerti anche

- Revised Design Mix of M60 Grade As Per MK SootaDocumento2 pagineRevised Design Mix of M60 Grade As Per MK SootaMukesh SharmaNessuna valutazione finora

- TW-02 Inverted T-Shape TypeDocumento28 pagineTW-02 Inverted T-Shape TypeDanni Arman, STNessuna valutazione finora

- Combined Footing For TwoDocumento15 pagineCombined Footing For Twoer.praveenraj30Nessuna valutazione finora

- Design of Claritube SettlerDocumento19 pagineDesign of Claritube SettlerGomatesh PatilNessuna valutazione finora

- BBS of StaircaseDocumento232 pagineBBS of StaircaseTotal Care100% (1)

- PDF Wind Load Calculations As Per Is 875 Part 3xls CompressDocumento85 paginePDF Wind Load Calculations As Per Is 875 Part 3xls CompressNews Side Effects.Nessuna valutazione finora

- Bore Pile DesignDocumento2 pagineBore Pile DesignOng George SammyNessuna valutazione finora

- Single Footing Design - SI UnitsDocumento2 pagineSingle Footing Design - SI UnitsA.K.M Shafiq MondolNessuna valutazione finora

- Mix Design - m40 - Modified 28 Days CcsDocumento23 pagineMix Design - m40 - Modified 28 Days CcsKuldeep Chakerwarti100% (2)

- Slab Design ExcelDocumento6 pagineSlab Design ExcelCHANDI KHANRANessuna valutazione finora

- Is 13920 DetailingDocumento3 pagineIs 13920 Detailingasingh400Nessuna valutazione finora

- DEEP BEAM DesignDocumento2 pagineDEEP BEAM DesignmangeshNessuna valutazione finora

- Abutment A1 On Counterfort Wall - 03.07.2020 1.04 PMDocumento34 pagineAbutment A1 On Counterfort Wall - 03.07.2020 1.04 PMVikas KushwahaNessuna valutazione finora

- Calculating Bulk Volumes Using Simpson Rule PDFDocumento10 pagineCalculating Bulk Volumes Using Simpson Rule PDFEng Ravi Kant SharmaNessuna valutazione finora

- Model Sluice EstimateDocumento24 pagineModel Sluice EstimateRAMACHANDRA MOORTHY100% (1)

- Deck SheetDocumento3 pagineDeck SheetPoulomi BiswasNessuna valutazione finora

- Calculation Summary of Pile FoundationDocumento24 pagineCalculation Summary of Pile FoundationdedydarwisNessuna valutazione finora

- Isolated Footing DesignDocumento24 pagineIsolated Footing DesignSANJEEV GANDOTRANessuna valutazione finora

- Slope Stability Analysis Using Soil Anchor - Design ReportDocumento17 pagineSlope Stability Analysis Using Soil Anchor - Design ReportPrakash Singh RawalNessuna valutazione finora

- Combined Footing 33Documento4 pagineCombined Footing 33Narayan WNessuna valutazione finora

- RR Masonary Retaing Wall DesignDocumento41 pagineRR Masonary Retaing Wall DesignAbhay KumarNessuna valutazione finora

- Design of Bored Piles Is 2911-Part 1sec2Documento5 pagineDesign of Bored Piles Is 2911-Part 1sec2Armaan GuptaNessuna valutazione finora

- GSB Mix Design Summary-1Documento3 pagineGSB Mix Design Summary-1Dontha SrikanthNessuna valutazione finora

- Spreadsheets To BS 8110: Henry Level - 1 Base B1 RMW 113Documento1 paginaSpreadsheets To BS 8110: Henry Level - 1 Base B1 RMW 113ojok100% (1)

- Given Data: Given Data:: Design of Raft Foundation Design of Raft FoundationDocumento8 pagineGiven Data: Given Data:: Design of Raft Foundation Design of Raft FoundationBikram BhusalNessuna valutazione finora

- Design of RCC Column: DataDocumento3 pagineDesign of RCC Column: DataamokeNessuna valutazione finora

- Haryana TestDocumento1 paginaHaryana TestPankaj SherwalNessuna valutazione finora

- Z Purlin Design Span 12 SL 0.3Documento1 paginaZ Purlin Design Span 12 SL 0.3arman malikNessuna valutazione finora

- Cantilever Retaining WallDocumento4 pagineCantilever Retaining Wallsharath mathewNessuna valutazione finora

- Staad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1Documento17 pagineStaad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1kardels100% (14)

- Continous Composite Beam13Documento27 pagineContinous Composite Beam13Matthew ChinNessuna valutazione finora

- Sample No. Total Weight (GMS)Documento4 pagineSample No. Total Weight (GMS)Soundar PachiappanNessuna valutazione finora

- Design of Steel BeamDocumento1 paginaDesign of Steel Beamgaurav sharmaNessuna valutazione finora

- Retaining Wall DesignDocumento126 pagineRetaining Wall DesignSeph RjyNessuna valutazione finora

- OHT DesignDocumento55 pagineOHT Designdheeraj tiwariNessuna valutazione finora

- Reinforced Concrete Retaining Wall Design To BS 8110Documento10 pagineReinforced Concrete Retaining Wall Design To BS 8110thabisoNessuna valutazione finora

- Water Tank DesignDocumento9 pagineWater Tank DesigncadetpalangNessuna valutazione finora

- Column Capacity RevisedDocumento7 pagineColumn Capacity RevisedlohithaNessuna valutazione finora

- Spreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3Documento4 pagineSpreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3Camel FangNessuna valutazione finora

- CF1Documento9 pagineCF1joeNessuna valutazione finora

- Data Required For Concrete Mix Design (I) Concrete Mix Design StipulationDocumento7 pagineData Required For Concrete Mix Design (I) Concrete Mix Design Stipulationmeetshah92Nessuna valutazione finora

- Concrete Mix Design M30 Grade: An Illustrative Example (M20, M25, M30, M40 Grade Concrete)Documento16 pagineConcrete Mix Design M30 Grade: An Illustrative Example (M20, M25, M30, M40 Grade Concrete)Diwakar JoshiNessuna valutazione finora

- Data Required For Concrete Mix DesignDocumento9 pagineData Required For Concrete Mix DesignNyan Lin100% (1)

- Concrete Mix Design M20 - MMRDocumento9 pagineConcrete Mix Design M20 - MMRMitendra Kumar ChauhanNessuna valutazione finora

- Concrete Mix Design M20 - MMR - KICODocumento7 pagineConcrete Mix Design M20 - MMR - KICOMitendra Kumar ChauhanNessuna valutazione finora

- Concrete Mix Design, Is StandardDocumento12 pagineConcrete Mix Design, Is StandardKumaresvaranNessuna valutazione finora

- Ce Board 1Documento18 pagineCe Board 1Ricardo DalisayNessuna valutazione finora

- Concrete Mix Design C30 - MDocumento7 pagineConcrete Mix Design C30 - MMitendra Kumar ChauhanNessuna valutazione finora

- Concrete Mix Design CalculationDocumento10 pagineConcrete Mix Design CalculationHari RNessuna valutazione finora

- Cc-Mix DesignDocumento37 pagineCc-Mix DesignManoj Kumar SinghNessuna valutazione finora

- Concrete Mix Design 10262Documento57 pagineConcrete Mix Design 10262Anujm67Nessuna valutazione finora

- Design Mix Calculation Grade 30NDocumento6 pagineDesign Mix Calculation Grade 30NikhwanNessuna valutazione finora

- New Microsoft Word DocumentDocumento5 pagineNew Microsoft Word DocumentDattatreya Dattu0% (1)

- Concrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDocumento5 pagineConcrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDattatreya DattuNessuna valutazione finora

- New Microsoft Word DocumentDocumento5 pagineNew Microsoft Word DocumentDattatreya DattuNessuna valutazione finora

- 2.2 ACI Method of Mix DesignDocumento7 pagine2.2 ACI Method of Mix Designtiwari.dipesh001Nessuna valutazione finora

- Concrete Mix Design 10262Documento75 pagineConcrete Mix Design 10262Anujm67100% (1)

- Concrete Mix Design M25 PDFDocumento8 pagineConcrete Mix Design M25 PDFJEFFY JACOBNessuna valutazione finora

- M25 DesignDocumento4 pagineM25 DesignAmit KumarNessuna valutazione finora

- 08 Mix DesignDocumento44 pagine08 Mix DesignTroy DanielsNessuna valutazione finora

- Quality Audit - Check Sheet - Carriage WorkshopDocumento24 pagineQuality Audit - Check Sheet - Carriage WorkshopEnd End100% (1)

- BS 598 104 1989 PDFDocumento18 pagineBS 598 104 1989 PDFEnd EndNessuna valutazione finora

- AsphaltDocumento182 pagineAsphaltEnd EndNessuna valutazione finora

- Flexible Pavement Design ToolDocumento13 pagineFlexible Pavement Design ToolRolando LópezNessuna valutazione finora

- Performance Evaluation of Polymer Modified Asphalt MixDocumento39 paginePerformance Evaluation of Polymer Modified Asphalt MixEnd End100% (1)

- RIDOT Highway Design ManualDocumento104 pagineRIDOT Highway Design ManualEnd EndNessuna valutazione finora

- Bentley MicroStation CONNECT Edition v10 00 00 25 x64 Torrent - Kickass TorrentsDocumento4 pagineBentley MicroStation CONNECT Edition v10 00 00 25 x64 Torrent - Kickass TorrentsEnd End0% (3)

- Material Specific Gravity Weight (KG) Volume (Cum) : Age Date of Testing Weight Load Strength Average RemarksDocumento8 pagineMaterial Specific Gravity Weight (KG) Volume (Cum) : Age Date of Testing Weight Load Strength Average RemarksEnd EndNessuna valutazione finora

- Upgradation of Gurgaon - Faridabad & Ballabgarh - Sohna Roads On BOT BasisDocumento2 pagineUpgradation of Gurgaon - Faridabad & Ballabgarh - Sohna Roads On BOT BasisEnd EndNessuna valutazione finora

- BLENDING of MSS Mix Design TypeDocumento3 pagineBLENDING of MSS Mix Design TypeEnd EndNessuna valutazione finora

- Test Method OthersDocumento15 pagineTest Method OthersEnd End100% (1)

- SD of HighwayDocumento8 pagineSD of HighwayEnd EndNessuna valutazione finora

- Bituminous MacadamDocumento3 pagineBituminous MacadamEnd EndNessuna valutazione finora

- (CRMB) 60 Bitumen Test Results Nov 10Documento26 pagine(CRMB) 60 Bitumen Test Results Nov 10End EndNessuna valutazione finora

- CBR - 3 - EnergyDocumento187 pagineCBR - 3 - EnergyEnd End100% (1)

- Calibration of Rapid Moisture Meter No. R-1Documento20 pagineCalibration of Rapid Moisture Meter No. R-1End EndNessuna valutazione finora

- StripDocumento666 pagineStripEnd EndNessuna valutazione finora

- FloodDocumento5 pagineFloodEnd End100% (1)

- DBMDocumento29 pagineDBMEnd EndNessuna valutazione finora

- 1 (Varaha) (Suh)Documento7 pagine1 (Varaha) (Suh)End EndNessuna valutazione finora

- WMM Mix DesignDocumento23 pagineWMM Mix DesignEnd EndNessuna valutazione finora

- Summary of Concrete Mix Design With Ultratech Cement Opc-53Documento6 pagineSummary of Concrete Mix Design With Ultratech Cement Opc-53End EndNessuna valutazione finora

- BitumenDocumento35 pagineBitumenamanbhu1991100% (5)

- FNL SRNMP Vol 2 Uppwd r2Documento271 pagineFNL SRNMP Vol 2 Uppwd r2End EndNessuna valutazione finora

- M1 ForcesDocumento77 pagineM1 ForcesMusa AamirNessuna valutazione finora

- Fluid - Properties & BehaviorDocumento11 pagineFluid - Properties & BehaviorZaidNessuna valutazione finora

- Power Development Through Complex Training For The.3Documento14 paginePower Development Through Complex Training For The.3PabloAñonNessuna valutazione finora

- API Manual of Petroleum Measurement Standards Chapter 17 - Marine MeasurementDocumento38 pagineAPI Manual of Petroleum Measurement Standards Chapter 17 - Marine MeasurementAgus MoesNessuna valutazione finora

- MIT Towing Tank PDFDocumento33 pagineMIT Towing Tank PDFSérgio Roberto Dalha ValheNessuna valutazione finora

- Basic Approach: 111equation Chapter 1 Section 1 Weight EstimationDocumento16 pagineBasic Approach: 111equation Chapter 1 Section 1 Weight EstimationgksahaNessuna valutazione finora

- Ch01-Walding 4thDocumento24 pagineCh01-Walding 4thazs1925Nessuna valutazione finora

- ProjectilesDocumento5 pagineProjectilesShinjiNessuna valutazione finora

- GravitationDocumento13 pagineGravitationNinja NinjaNessuna valutazione finora

- Elements and PrinciplesDocumento9 pagineElements and PrinciplesLyne SombrioNessuna valutazione finora

- Dead Weight CalibratorDocumento4 pagineDead Weight Calibratorarun2386Nessuna valutazione finora

- Report On Nutritional Status (Baseline)Documento1 paginaReport On Nutritional Status (Baseline)janice alquizarNessuna valutazione finora

- CworkbookDocumento77 pagineCworkbookSonit KumarNessuna valutazione finora

- Nutrition and Light Requirement of LettuceDocumento18 pagineNutrition and Light Requirement of LettuceCopyright FreeNessuna valutazione finora

- Ctivity: Physical Fitness 41Documento1 paginaCtivity: Physical Fitness 41Dani DaniNessuna valutazione finora

- Manual-FLYNET50 EN PDFDocumento132 pagineManual-FLYNET50 EN PDFLa bendición De DIOSNessuna valutazione finora

- Chapter 1-Unit of MeasurementsDocumento60 pagineChapter 1-Unit of MeasurementsNajma AqilahNessuna valutazione finora

- ParachuteDocumento11 pagineParachuteRonaldo UlisiNessuna valutazione finora

- HSC Physics Notes KISSDocumento45 pagineHSC Physics Notes KISSAnita James100% (2)

- Bret's Preference: Full Body Training: MondayDocumento4 pagineBret's Preference: Full Body Training: MondaySaddam KhanNessuna valutazione finora

- Moments Centre of Mass QP PDFDocumento14 pagineMoments Centre of Mass QP PDFshradhaNessuna valutazione finora

- Mechanism For Determination of Prolongation CostsDocumento10 pagineMechanism For Determination of Prolongation CostswisnuNessuna valutazione finora

- Specific Criteria For Calibration Laboratories in Mechanical Discipline: MASS (Weights)Documento24 pagineSpecific Criteria For Calibration Laboratories in Mechanical Discipline: MASS (Weights)kumarNessuna valutazione finora

- ExplosivePowerTrainingForSportsPerformance 1 NefrmhDocumento15 pagineExplosivePowerTrainingForSportsPerformance 1 NefrmhchrisNessuna valutazione finora

- Loss Analysis in Bread Production Process Using Material Flow Cost Accounting TechniqueDocumento16 pagineLoss Analysis in Bread Production Process Using Material Flow Cost Accounting TechniqueGlobal Research and Development ServicesNessuna valutazione finora

- Sartorius (BL310) - Operating InstructionsDocumento29 pagineSartorius (BL310) - Operating InstructionsMauricioGSNessuna valutazione finora

- Copy of Scoring in PFTDocumento4 pagineCopy of Scoring in PFTChenee Bulawan PontilloNessuna valutazione finora

- Forces and Newton'S Laws: Types of Forces WeightDocumento6 pagineForces and Newton'S Laws: Types of Forces WeightSenuja ChammithaNessuna valutazione finora

- Forces and MotionDocumento22 pagineForces and MotiongamahimeNessuna valutazione finora

- Crane Scale CS-2000ManualDocumento18 pagineCrane Scale CS-2000ManualMauricio Rodolfo Cuevas DonaireNessuna valutazione finora