Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fabric Quality Assurance

Caricato da

Radhik Kalra100%(2)Il 100% ha trovato utile questo documento (2 voti)

432 visualizzazioni82 pagineApparel Quality Management

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoApparel Quality Management

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

100%(2)Il 100% ha trovato utile questo documento (2 voti)

432 visualizzazioni82 pagineFabric Quality Assurance

Caricato da

Radhik KalraApparel Quality Management

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 82

FABRIC QUALITY ASSURANCE

SIGNIFICANCE OF TEXTILE TESTING

To determine the suitability of a fabric for a particular end use which

is also the primary concern to both the buyers and sellers of textile

products.

The type of yarn used plays a signifcance role in determining the

quality of the fabric.

The quality of yarn is improvised by improving the various properties

of yarn like yarn count, twist and GS etc depending on the end use.

IMPORTANCE OF TESTING

1 !esearch and development to enable new and desirable textile

products to be produced.

1 "roduct performance and evaluation to determine if the fabric is

suitable for the intended end use.

1 #uality control to ensure that the fabric will be made properly and

e$ciently. Thus claims and returns will be minimi%ed.

1 "roblem analysis to determine why a fabric or textile product is not

performing as desired

1 "roduct comparison to determine which material would be the better

value and to prevent wasteful buying.

1 "roper advertising to enable ads to be truthful and not misleading or

false

1 &dherence to government regulations so that the textile product can

be sold without violating any laws.

TEXTILE TESTING

DEFINITION:

't is used to determine whether or not a product complies with or

performs in a specifed manner in relation to a standard or other

requirement.

Standard atmosp!r!

(ecause of the important changes that occur in textile properties as the

moisture contest changes, it is necessary to specify the atmospheric

conditions in which any testing is carried out. Therefore a standard

atmosphere has been agreed for testing purposes and is defned as a

relative humidity of )*+ and a temperature of ,-

-

.. /or practical

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

purposes certain tolerances in these values are allowed so that the testing

atmosphere is !4 )*+5 ,+, ,- 5 ,

-

..

TYPES OF TEST MET"ODS

P#s$%a& t!sts: These tests are mainly physical or mechanical in

nature and includes breaking strength, abrasion resistance, 6 pilling

propensity.

C!m$%a& T!sts: .hemicals are used includes fber identifcation

using the solubility method, detection of antibacterial activity of

fabrics,6 determination of the presence of merceri%ation in cotton

fabrics.

T!sts to d!t!rm$n! %o&or'astn!ss prop!rt$!s: These tests are

used to determine the resistance of fabrics to color change under

various conditions, includes colorfastness to sunlight, washing,6

crocking.

Opt$%a& T!sts: & microscope or another magnifying device is used,

includes grading of wool fbers, fber identifcation of textile defects.

FORMAT OF TEST MET"ODS

Test name 67or 3umber 0esignation

Scope

0efnition of terms

&pparatus 6 aterials

Test Specimens

Test "rocedure

8valuation7.alculation of !esults

!eport

3otes

P"YSICAL TESTS

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

TYPES OF P"YSICAL TESTS

0urability test

/riction test

&ppearance test

/unctional test

DURABILITY TEST

!8&S93S T9 .&!!: 9;T 0;!&('<'T: T8ST

To check that the fabric conforms to specifcations

To note the e=ects of changes in structural details.

To note the a=ects of physical and chemical treatments, exposure to

weather, launderings etc.

To obtain some indication of probable performance in use

To investigate causes of failure and customer complaints.

To help in the design of a fabric for a specifc purpose.

To study the interaction of fbers, yarns and fabric properties

TYPES OF DURABILITY TESTS

Tensile strength7 breaking strength

Tearing strength

(ursting strength

TENSILE STRENGT" TESTING ( BREA)ING STRENGT"

DEFINITION:

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Tensile strength is the resistance of a material sub>ect to tension by an

external force.

& testing machine used for tests where a pulling force is exerted on

the specimen is called tensile testing machine.

8ach machine has ? basic elements of strength testing machine@

loading mechanism, clamping mechanism, recording

mechanism.

There are ? testing machines@

.onstant rate of traverse A.!TB

.onstant rate of extension A.!8B

.onstant rate of load A.!<B

CRT T!st$n* Ma%$n!+

FABRIC BREA)ING STRENGT"

The breaking strength of the material is the maximum force needed to

resist rupture during the tensile strength. aximum tensile strength of

a specimen is expressed as force per unit of cross sectional area

required to produce rupture.. Akg7cm

,

or lbs7 inch

,

B

(reaking test is one directional test and is suitable for woven fabrics.

The breaking strength is to be evaluated in both warp and the flling

directions. This test can be used to determine the e=ects of

destructive forces on a woven fabric. This force includes such fnishes

as embossing, napping6 resin treatments.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

The breaking strength test is performed on most woven, non woven

and felted fabrics. 't is not recommended for knitted material since

they elongate easily, with the specimen becoming distorted.

This test can be performed with either wet or dry condition

TEST MET"ODS FOR FABRIC BREA)ING STRENGT"

Grab test

!aveled strip test

.ut strip test

odifed grab test

GRAB TEST

This method is used to determine the e=ective strength of the fabric

when in use, and not the strength of the yarns actually gripped

between the clamps.

This test has the advantage of fast specimen preparation.

RA,ELED STRIP TEST

This can be useful for comparing the e=ective strength of yarns in

the material with their strength before being woven into the fabric.

DETERMINING FABRIC BREA)ING STRENGT" - ELONGATION

!eference@ &ST 0C)D,

&pparatus 6 aterials

C. Tensile testing machine

,. <oadEelongation charts for use with the tensile testing machine

?. /abric specimens

F. !uler

*. Scissors

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Sp!%$m!n Pr!parat$on

"repare fve fabric specimens for warp tests 6 fve for flling tests for each

method indicated below@

A+ Gra. T!st M!tod

C. .ut specimens D inches G F inches, with the longer edge in the

direction to be tested

B+ Ra/!&!d Str$p T!st M!tod

C. .ut specimens D inches G CH inches, with the longer length in

the direction to be tested.

,. /or each specimen, unravel to exactly a CEinch width.

T!st pro%!d0r!

C. "roperly prepare the testing machine for the grab method.

,. "roperly position the specimen in the clamps 6 the chart in the holder.

?. 9perate the testing machine, obtaining a loadEelongation curve on the

chart.

F. 0etermine the fabric breaking strength 6 the elongation from the

chart.

*. !eplace the chart 6 the tested specimen.

). !epeat the procedure for the other specimens for the grab test

method.

I. "roperly prepare the testing machine for the raveled stripe test method

using larger si%e >aws.

D. !epeat the test procedure used for the grab test method.

J. .alculate the average fabric breaking strengths 6 percent elongations

for both methods.

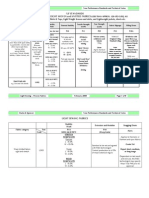

DATA AND RESULTS:

/abric identifcationKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK

Tensile testing achine typeKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK

achine capacity Albs.BKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK

BREA)ING STRENGT":

T!st No+ GRAB L&!"

1&.s+2

MET"OD

FILLING

1&.s+2

RA,ELED

3ARP 1&.s+2

MET"OD

FILLING

1&.s+2

C

,

?

F

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

*

TOTAL

A,ERAGE

"8!.83T 8<93G&T'93 M increase in specimen length GC--

? Ain.B

T!st No+ GRAB

3ARP 1&.s+2

MET"OD

FILLING

1&.s+2

RA,ELED

3ARP 1&.s+2

MET"OD

FILLING

1&.s+2

C

,

?

F

*

TOTAL

A,ERAGE

TEARING STRENGT"

DEFINITION

Tearing strength is the force needed to continue a tear in a fabric. 't is a

unidirectional test like breaking strength testN it is performed in both

the warp and weft directions.

't is only performed on woven fabric. 't is particularly important in

industrial fabrics that are exposed to rough handling in use such as

tents and sacks and also those where propagation of a tear would be

catastrophic such as parachutes. 9utdoor clothing, overalls and

uniforms are types of clothing where tearing strength is of importance.

/abric having a plain weave and a high number of yarns per inch will

tend to exhibit lower tearing strength since the yarn cannot move into

bunches. Lhereas in twill and satin weave the yarn would shift and

bunch together from the tearing force being exerted.

!esin treatments such as crease resistance fnishes which cause the

yarns to adhere to one another also have the same e=ect. The tensile

properties of the constituent fbres have an inOuence on tearing

resistance.

TEST METHODS:

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

C. T93G;8 8T490

,. "830;<; 8T490

DETERMINING FABRIC TEARING STRENGT"

!eference@ &ST 0CF,F, 0,,)C, 0,,),

Apparat0s - Mat!r$a&s

C. /allingEpendulum type tester

,. /abric specimens

F. 0ie cutter for cutting specimen for fallingEpendulum tester

). !uler

I. Scissors

E&m!ndor' T!ar Str!n*t T!st!r 1p!nd0&0m m!tod2

The 8lmendorf tear tester is a pendulum type ballistic tester which

measures energy loss during tearing. The tearing force is related to the

energy loss by the following equation @

8nergy loss M tearing force G distance

<oss in potential energy M work done

C 'n the pendulum test, a small initiating cut is made in a rectangular

specimen and the specimen is gripped in two clamps that are side by

side.

C 9ne of the clamp is stationary and anther is connected to falling

pendulum.

C Lhen pendulum is released, it swings and tears the specimen quickly

C & pointer records the force required to tear the entire specimen from a

graduated scale on the pendulum.

D$*$ta& E&m!ndor' T!ar Str!n*t T!st!r

The model 8<E)F--, meeting &ST standards is suitable for most fabrics

including woven, layered blankets, napped pile, blanket, and air bag

fabrics, and provided the fabric does not tear in the direction crosswise to

the direction of the force application during the test

C. "roperly position the specimen in the clamps 6 release the

pendulum

,. 0etermine the fabric tear strength from the pointer scale

?. The pointer indicates the original potential energy of the pendulum

consumed in tearing the specimen

F. !epeat the procedure for the other specimens for the weft direction

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

*. .alculate the average fabric tearing strengths

T!ar$n* str!n*t

Capa%$t# o' t! ma%$n!4444444444444444444444

S+No+ 3arp5str!n*t *ms 3!'t5str!n*t *ms

C

,

*

Tota&

A/!ra*!

BURSTING STRENGT" TEST

(ursting strength is the force needed to rupture a fabric by distending

it with a force applied at right angle to the material. (ursting strength

is an alternative method of measuring strength in which the material is

stressed in all directions at the same time and is therefore more

suitable for such materials.

This is especially desirable for materials such as knits, laces and

nonwovens. There are also fabrics which are simultaneousl stressed

in all directions during service, such as !arachute fabrics, "lters, sacks

and nets, where it ma be im!ortant to stress them in a realistic

manner. # fabric is more likel to fail b bursting in service than it is to

break b a straight tensile fracture as this is the t!e of stress that is

!resent at the elbows and knees of clothing.

This test has application in testing woven fabrics that are to be

stressed equally in every direction when in use.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

T6o M!tods:

0iaphragm (ursting ethod

(all (ursting ethod

B0rst Str!n*t T!st!r

&STE0,,C-, T&""'ETTF-?, P'SE<C-CD, "DCC,, "DC?7

The (urst Strength tester is used to test the bursting resistance of

leather, synthetic leather and di=erent fbers.

TEST MET"ODS

DIAP"RAGM BURSTING MET"OD

'n this method hydraulic pressure is used to expand a Oexible rubber

diaphragm which exerts pressure on specimen directly above it.

'ncreasing hydraulic Ouid pressure forces the rubber diaphragm to

push on the specimen until the specimen bursts.

DETERMINING FABRIC BURSTING STRENGT"

R!'!r!n%!: ASTM D89:;< D89:9

Apparat0s - Mat!r$a&s

C. 4ydraulic diaphragm bursting tester

,. Tensile testing machine with ball burst attachment

?. /abric specimens

F. !uler

*. Scissor

Sp!%$m!n Pr!parat$on

"repare fve fabric specimens for each method indicated below

The specimens should be cut at least * inches G * inches.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

T!st Pro%!d0r!: D$apra*m B0rst$n* M!tod

C. "repare the bursting tester.

,. "osition the specimen over the rubber diaphragm 6 close the clamp so

the fabric is held securely.

?. Start the tester. Lhen the specimen bursts, stop the machine

immediately.

F. !ecord the gauge reading. This is the total bursting pressure.

*. 9pen the clamp 6 release the specimen pressure on the diaphragm.

!ecord the new gauge reading. This is the tare pressure.

). !emove the tested specimen 6 deOate the diaphragm.

I. !epeat the procedure for the other specimens.

D. .alculate the specimen bursting strength

J. .alculate the average fabric bursting strength.

Data and R!s0&ts: D$apra*m B0rst$n* M!tod

Fa.r$% $d!nt$=%at$on4444444444444444444444444444444444444

Ma%$n! %apa%$t# 1ps$244444444444444444444444444444444444

TEST NO+ Tota& pr!ss0r!

1ps$2

Tar! pr!ss0r!

1ps$2

Sp!%$m!n

B0rst$n*

str!n*t 1ps$2

C

,

?

F

*

T9T&<

&28!&G8

FRICTION TEST5 A.ras$on and P$&&$n*

The friction test which includes abrasion and pilling are greatly a=ects

serviceability performance of fabrics and garments. & garment is

considered to be serviceable when it is ft for its particular end use. after

being used for a certain length of time the garment ceases to be

serviceable when it can no longer fll its intended purpose in the way that

it did when it was new. the particular factors that reduce the service life

of a garment are heavily dependent on its end use. for instance overalls

worn to protect clothing at work would be required to withstand a good

deal of hard usage during their lifetime but their appearance would not be

considered important. 4owever, garments worn purely for their

fashionable appearance are not required to be hard wearing but would be

speedily discarded if their appearance changed noticeably. an exception

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

to this genealisation is found in the case of denim where a worn

appearance is deliberately strived for.

'f asked, many people would equate the ability of a fabric to Qwear wellQ

with its abrasion resistance, but QwearQ, that is the reduction in serviceable

life, is a complex phenomenon and can be brought about by any of the

following factors@

C. .hanges in fashion which mean that the garment is no longer worn

whatever its physical state.

,. Shrinkage or other dimensional changes of such a magnitude that

the garment will no longer ft.

?. .hanges in the surface appearance of the fabric which include@ the

formation of shiny areas by rubbing, the formation of pills or surface

fu%%, the pulling out of threads in the form of sangs.

F. /ading of the colour of the garment through washing or exposure to

light. the bleeding of the colour form one area to another.

*. /ailure of the seams of the garment by breaking of the sewing

thread or by seam slippage.

). Learing of the fabric into holes or wearing away of the surface

fnish or pile to leave the fabric threadbare. wearing of the edges of

cu=s, collars and other folded edges to give a frayed appearance.

I. Tearing of the fabric through being snagged by a sharp ob>ect.

These changes are brought about by the exposure of the garment to a

number of physical and chemical agents during the course of its use.

Some of these agents are as follows@

C. &brasion of the fabric by rubbing against parts of the body or

external surfaces.

,. The cutting action of grit particles which may be ingrained in dirty

fabrics and which may cause internal abrasion as the fabric is

Oexed.

?. Tensile stresses and strains which occur as the garment is put on or

taken o= and when the person wearing it is active.

F. The laundering and cleaning processes which are necessary to

retain the appearance of the garment.

*. &ttack by biological agents such as bacteria, fungi and insects. This

is a particular problem for natural materials.

). 0egradation of the fabric by contact with chemicals which can

include normal household items such as bleach, detergents, antiE

perspirants and perfumes.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

I. <ights, in particular ultraEviolet light, can cause degradation of

polymers leading to a reduction in strength as well as causing fading

of colours.

D. .ontact of the garment with sharp ob>ects leading to the formation

of tears.

The above causes of wear are often acting at the same time. for instance,

chemical or bacterial attack may so weaken a fabric that it can then easily

fail through abrasion or tearing. <aundering of a fabric taken together with

the abrasion that it encounters during use may lead to much earlier

formation of pills or failure through abrasion than would by predicted from

any pilling or abrasion tests undertaken on the new material.

&brasion is the wearing a way of a section of material by the

rubbing against another surface. Tests for abrasion resistance is

very complex because of the many variables that inOuence fabric

wear. /abrics with smooth surface tend to resist the e=ects of

abrasion to greater degree than fabrics with rough, non smooth

surface. aterials made with novelty yarns usually possess lower

abrasion resistance.

The resistance to abrasion of a material is greatly a=ected by the

conditions of the test like specimen tension, type of abradent,

amount of pressure between abradent and specimen.

2arious criteria can be used to determine the end point of the test

The specimen could be tested until the appearance of the frst sign

of wearN or when there is a yarn breakN or with the complete

destruction of the fabric in the test area

T! sp!%$m!n !/a&0at$on %an .! s0.>!%t$/! or o.>!%t$/!

& s0.>!%t$/! evaluation is based on visual examination of the

change in specimen color, luster, or surface appearance.

&n o.>!%t$/! evaluation, by testing the specimen for a change in

breaking strength, air permeability, or light transmission.

Fa%tors a?!%t$n* a.ras$on r!s$stan%!

The evidence concerning the various factors that inOuence the abrasion

resistance of fabrics is contradictory. This is because the experiments

have been carried out under widely di=erent conditions in particular using

di=erent modes of abrasion. Therefore the results are not comparable and

often opposing results have been reported. The factors that have been

found to a=ect abrasion include the following.

F$.r! T#p!

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

't is thought that the ability of a fbre to withstand repeated distortion is

the key to its abrasion resistance. Therefore high elongation, elastic

recovery and work of rupture are considered to be more important factors

for a good degree of abrasion resistance in a fbre than is a high strength.

3ylon is generally considered to have the best abrasion resistance.

"olyester and polypropylene are also considered to have good abrasion

resistance. (lending either nylon or polyester with wool and cotton is

found to increase their abrasion resistance at the expense of other

properties. &crylic and modacrylic have a lower resistance than these

fbres while wool, cotton and high wet modulus viscose have a moderate

abrasion resistance. 2iscose and acetates are found to have the lowest

degree of resistance to abrasion. 4owever, synthetic fbres are produced

in many di=erent version so that the abrasion resistance of a particular

variant may not conform to the general ranking of fbres.

F$.r! prop!rt$!s

9ne of the results of abrasion is the gradual removal of fbres from the

yarns. Therefore factors that a=ect the cohesion of yarns will inOuence

their abrasion resistance. <onger fbres incorporated into a fabric confer

better abrasion resistance than short fbres because they are harder to

remove from the yarn. /or the same reason flament yarns are more

abrasion resistant than staple yarns made from the same fbre. 'ncreasing

fbre diameter ru to a limit improves abrasion resistance. &bove the limit

the increasing strains encountered in bending counteract any further

advantage and also a decrease in the number of fbres in the cross 1

section lowers the fbre cohesion.

Yarn t6$st

There has been found to be an optimum amount of twist in a yarn to give

the best abrasion resistance. &t lowEtwist factors fbres can easily be

removed from the yarn so that it is gradually reduced in diameter. &t highE

twist levels the fbres are held more tightly but the yarn is sti=er so it is

unable to Oatten or distort that enables the yarn to resist abrasion.

&brasion resistance is also reported to increase with increasing linear

density at constant fabric mass per unit area.

Fa.r$% str0%t0r!

The crimp of the yarns in the fabric a=ects whether the warp or the weft is

abraded the most. /abrics with the crimp evenly distributed between warp

and weft give hate best wear because the damage is spread evenly

between them. 'f one set of yarns is predominantly on the surface then

this set will wear mostN this e=ect can be used to protect the loadEbearing

yarns preferentially. 9ne set of yarns can also be protected by using Ooats

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

in the other set such as in a sateen or twill weave. The relative mobility of

the Ooats helps to absorb the stress.

There is an optimum value for fabric sett for best abrasion resistance. The

more threads per centimeter there are in a fabric, the less force each

individual thread has to take. 4owever, as the threads become >ammed

together they are then unable to deOect under load and thus absorb the

distortion.

Important 'a%tors to .! %ons$d!r!d 'or a.ras$on r!s$stan%!

t!st$n*:

.onditioning of the specimen

.hoice of testing instrument

.hoice of abrasion motion

0irection of abrasion

.hoice of abradent

(acking the specimen

.leanliness of the specimen and the instrument

"ressure between abradent and specimen.

TEST MET"ODS

!9T&!: "<&T/9! 09;(<8E48&0 8T490

/<8G'3G &30 &(!&S'93 8T490

'3/<&T80 0'&"4!&G 8T490

9S.'<<&T9!: .:<'308! 8T490

ROTARY PLATFORM DOUBLE "EAD TESTER

&s the rotary platform rotates the attached specimen rubs against the ,

stationary abrading wheels. The abraded area forms the wear track

TABER ABRASER 1ROTATORY PLATFORM DOUBLE "EADS TESTER2

"!9"8!T:@ &brasion

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Test wear and durability of ceramics, plastics, textiles, Oooring,

paper, metals and coated surfaces. Single and dual sample table

models.

DETERMINING FABRIC RESISTANCE TO ABRASION

!eference@ &ST 0?DDF,0?DD*,0?DD)

Apparat0s - Mat!r$a&s

C. !otary platform, doubleEhead tester

,. /abric specimen

?. !uler

F. Scissors

Sp!%$m!n Pr!parat$on

"repare fve fabric specimens for each method indicated below.

A+ Rotar# P&at'orm< Do0.&!5"!ad M!tod

C. .ut specimen ) inches G ) inches. /old specimen twice to form a ?E

inch square

,. .ut the folded corner to form a hole in the center of the specimen,

R Einch in diameter.

?. ;nfold the specimen.

T!st Pro%!d0r!: Rotar# p&at'orm< do0.&! !ad m!tod

C. "repare the abrasion tester

,. "osition the specimen around the blade

?. &brade the specimen until the chosen end point is reached

F. !ecord the number of cycles

*. !epeat the procedure for the remaining specimens

0ata and results@ rotary platform double head method

/abric identifcationKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK

.hosen end pointKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK

T!st No+ No+ o' %#%&!s@ Sp!%$m!n

app!aran%!

C

,

?

F

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

*

Tota&

A/!ra*!

DIAGRAM OF INFLATED DIAP"RAGM ABRASION TESTER

<ow air pressure on the rubber diaphragm keeps the specimen slightly

stretched. The table moves back and forth while the specimen slowly

rotates, causing it to rub against the abradent

D$a*ram o' an os%$&&ator# %#&$nd!r a.ras$on t!st!r+

The wire screen abradant oscillates against the fabric specimen

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

MARTINDALE ABRASION TEST

This apparatus is designed to give a controlled amount of abrasion

between fabric surfaces at comparatively low pressures in continuously

changing directions.

The results of this test should not be used indiscriminately, particularly

not for comparing fabrics of widely di=erent fbre composition or

construction.

'n the test circular specimens are abraded under known pressure on an

apparatus, which gives a motion that is the resultant of two simple

harmonic motions at right angles to one another. The fabric under test is

abraded against a standard fabric. !esistance to abrasion is estimated by

visual appearance or by loss in mass of the specimen.

M!tod

/our specimens each ?Dmm in diameter are cut using the appropriate

cutter. They are then mounted in the specimen holders with a circle of

standard foam behind the fabric being tested. 't is important that the

mounting of the sample is carried out with the specimens placed Oat

against the mounting block.

The test specimen holders are mounted on the machine with the fabric

under test next to the abradant. & spindle is inserted through the top

plate and the correct weight Ausually of a si%e to give a pressure of C,k"a

but a lower pressure of Jk"a may be used if specifedB is placed on top of

this. /igure shows the sample mounted in a holder. The standard abradant

should be replaced at the start of each test and after *-,--- cycles if the

test is continued beyond this number. Lhile the abradant is being

replaced it is held Oat by a weight as the retaining ring is tightened.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

(ehind the abradant is a standard backing felt which is replaced at longer

intervals.

Ass!ssm!nt

The specimen is examined at suitable intervals without removing it from

its holder to see whether two threads are broken. See table for the time

lapse between examinations. 'f the likely failure point is known the frst

inspection can be made at )-+ of that value. The abrading is continued

until two threads are broken. &ll four specimens should be >udged

individually.

Table@ 'nspection intervals for artindale abrasion test

8stimated number of cycles 'ntervals for

inspection

;p to *,--- 8very C,---

(etween *,--- and ,-,--- 8very ,,---

(etween ,-,--- and F-,--- 8very *,---

&bove F-,--- 8very C-,---

The individual values of cycles to breakdown of all four specimens are

reported and also the average of these.

A/!ra*! rat! o' &oss $n mass

This is an alternative method of assessing abrasion resistance which

requires eight specimens for the test. Two of these are abraded to the

endpoint as described aboe and then the other pairs are abraded to the

intermediate stages of ,*+, *-+ and I*+ of the end point. the samples

are weighed to the nearest Cmg before and after abrasion so that a graph

can be plotted of weight loss against the numbers of rubs. /rom the slope

of this graph, if it is a straight line, the average loss in mass measured in

mg7C--- rubs can be determined.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

FABRIC RESISTENCE TO PILLING

"illing is the formation of clusters or balls of tangled fbers on the

surface of a material occurring from surface rubbing.

These pills are attached to the surface of fabric by one or more fbers.

The resistance to pilling by a particular fabric will vary with the

conditions of actual use as well as the way in which the individual

wears the garment.

The pills are more noticeable when the degree of color contrast with

the fabric is great.

$int !ills are usually more noticeable than regular !ills.

The development of pills is accompanied by surface changes, like

change of color, development of fu%%, or reduction of cover.

;sually the pilling specimens are rated by comparing them to actual

samples or photographs showing a range of pilling e=ects.

P$&&$n* rat$n*s ar! as 'o&&o6s:

.lass *@ no pilling

.lass F@ slight pilling

.lass ?@ noticeable pilling

.lass ,@ considerable pilling

.lass C@ severe pilling

T8ST 8T490@ !&309 T;(<8 "'<<'3G 8T490

(!;S4 &30 /&(!'. T9 /&(!'. 8T490

The #.E?,* "illing Tester is designed to test the pilling Ahair ballB

characteristic of fabric and knit fabric cloths.

Simulating the condition of when weaving materials are worn, it will

have the appearance of lint.

!olling the specimen around a rubber tube and turning in a winding

box for a period of time, it is then compared to a standard picture to

determine its grade.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Test results are usually determined after comparing with standard

pictures, the average of four tests per specimen

A.ras$on %0m P$&&$n* T!st!r: To check the abrasion as well as pilling

resistance of the fabric.

!&309 T;(<'3G "'<<'3G A<'38 0'&G!&B

The propeller device rotates at a high speed, causing the specimen to rub

against the cork liner. (oth regular pills and lint pills can result.

DETERMINING FABRIC RESISTANCE TO PILLING

!eference@ &ST 0?*CC,0?*C,

Apparat0s - Mat!r$a&s

C. !andom tumbling pilling tester

,. /abric rating standard photographs

?. 2iewing apparatus for fabric evaluation

F. /abric specimens

*. !uler

). Scissors

Sp!%$m!n Pr!parat$on

"repare six specimens for the random tumble pilling method.

a. Random T0m.&! p$&&$n* M!tod

C. .ut specimen FE ?7C) inchesGFE?7C) inches, at approx F* deg

angle to the warp or flling yarns.

,. Seal the edges of the specimens with an adhesive 6 let dry.

T!st Pro%!d0r!: Random T0m.&! p$&&$n* M!tod

C. "repare the random tumbling pilling tester

,. "lace ? specimens in one of the chambers

?. !un the tester for ?- minutes.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

F. !emove excess lint fbers by lightly vacuuming the samples

with the soft brush attachment.

*. 8valuate the specimen for both resistance to pilling 6 surface

appearance

Data and r!s0&ts: Random t0m.&$n* p$&&$n* m!tod

Fa.r$% $d!nt$=%at$on44444444444444444444444444444444444444

T!st no+ Rat$n* to n!ar!st

a&' /a&

Sp!%$m!n

app!aran%!

C

,

?

Tota&

A/!ra*!

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Yarn D$stort$on

:arn distortion is a condition in which the symmetrical fabric surface

appearance is changed by the sliding or shifting of yarns following the

application of rubbing action or force. 9ne of the basic reasons for yarn

shifting is that the mumber of yarns per inch in the fabric is low. thus, the

yarns can move from side to side. & good example is the ease with which

yarns can shift in cheeseEcloth because the yarns are woven so far apart.

¬her factor contributing to yarn distortion is the type of yarn. /ilament

yarns are soother and more even than spun yarns, so flament yarns slip

more than spun yarns. 3ylon yarns shift more than wool yarns because

the nylon fber has a smooth, rodElike shape, whereas wool has a rough,

irregular surface.

The weave also should be considered. "lain weave, which has many

interlacings, holds the yarns in place better than stinn wearve, which has

a minimum of interlacings. the leno weave is especially suited to reduce

yarn distortion in openEstructure farics such as marquisette. AThe leno

weave holds the weft yarns in pace, but the warp yarns can still shift.B

The fnish a=ects yarn movements, too. !esin fnishes applied to cotton

fabric bind the yarns so that they tend not to slip. Gla%ed fnishes act the

same way. the felting of wool fabrics causes the fbers and yarns to come

together so that there is no yarn distortion. the merceri%ed fnish of

combed cotton yarns tends to increase yarn shifting as the yarns become

smoother and more even.

/abrics in which yarn distortion is a problem may also experience a

problem with yarns slipping in the seam area. &s a result, an area of

distortion may be crated ad>acent to the seam. Someties, the seam may

actually open without any yarns breaking and with the sewing thread still

intact. (ecause seam slippage is virtually impossible to repair, fabrics that

slip under stress should be avoided for apparel and upholstery purposes.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Sna**$n*

& snag is a loop of fbre Aor yarnB that is pulled from a fabric when it is in

contact with a rough ob>ect. Snags detract from the appearance of the

fabric but do not reduce any of its other properties. /abrics made from

bulked continuous flament yarns are particularly susceptible to the

formation of snags although woven fabrics with long Ooats can also su=er

from this problem.

The mace snagging test is a comparative test for the snagging propensity

of knitted fabrics of textured polyester yarn originally developed by '.' to

test .rimplene yarns. 'n the test a metal ball ftted with spikes only catch

loops of thread that are lying in a particular orientation so that it is

important to test both directions of a fabric.

/our specimens each one measuring ,-? mm G ??- mm are testedN tow

with their long direction aligned with the length of the fabric and two with

their long direction aligned with the fabric width. & seam is marked on the

back of the fabric C) mm from the shorter edge. The fabric samples are

then folded face to face and sewn along the seam to from a tube. the tube

is turned inside out so that the face of the fabric is on the outside. 't is

then slid over the cylinder of the machine and secured at each end with a

rubber ring.

& mace is placed on each of the four fabric samples so that the chain

holding it passes around the guide rod as. The machine is then set to run

for )-- revolutions AC- mmB.

Lhen the test is complete the surface appearance of the specimen is

compared with a set of photographic standards and given a rating from *

Ano snaggingB to C Asevere snaggingB.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

FABRIC RESISTANCE TO 3RIN)LING

Lrinkle may be described as a fold in the fabric.

+ Greater the resilience of fbers fewer and less sharp the

wrinkles will be

+ "arameters such as !ercent relative humidit, tem!erature,

time under !ressure, amount of !ressure and recover time must

be controlled in the test.

C 3r$nA&! r!s$stan%! t! 'a.r$% $s d!t!rm$n!d .# /ar$o0s

'a%tors:

& resilient fber content , such as polyester or wool

4ighly twisted yarns

<ow yarns per inch

Thick, lofty construction

/inishes such as .!/A.rease !etention F$n$s2 fnish for cotton

fabrics

& weave with few interlacing, such as FGF basket weave.

TEST MET"ODS

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Two types of tests recommended determining wrinkle resistance of

fabrics@

!ecovery angle method

&ppearance method

R!%o/!r# an*&! m!tod:

;ses a small specimen which is folded under pressure N and angle of the

fold is then measured by wrinkle recovery tester.

App!aran%! M!tod:

'n this a larger specimen is wrinkled using the &&T.. wrinkle tester. The

specimen is hung for ,FE hour period, after which it is evaluated for

wrinkle appearance.

The specimens are rated by comparing them to &T.. three dimensional

wrinkle recovery replicas.

TEST MET"ODS

Two types of tests recommended to determine wrinkle resistance of

fabrics@

!ecovery angle method

&ppearance method

R!%o/!r# an*&! m!tod:

;ses a small specimen which is folded under pressure N and angle of the

fold is then measured by wrinkle recovery tester.

App!aran%! M!tod:

'n this a larger specimen is wrinkled using the &&T.. wrinkle tester. The

specimen is hung for ,FE hour period, after which it is evaluated for

wrinkle appearance.

The specimens are rated by comparing them to &T.. three dimensional

wrinkle recovery replicas.

T! rat$n*s ar! r!port!d as 'o&&o6s:

L!* E no wrinkling

L!F 1 slight wrinkling

L!? E noticeable wrinkling

L!, 1 considerable wrinkling

L!C 1 severe wrinkling

3RIN)LE RECO,ERY TESTER DIAGRAM

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

3umbers and indicating marks appear on a fxed circular scale. The

specimen holder is attached to the transparent movable plate which

contains the vernier scale. 2ernier indicates a J- degree angle of recovery

for the specimen.

3RIN)LE RECO,ERY TESTER: on right the fabric specimen in its holder

is being creased under weight. & timer is also there. The test is performed

in S&T position.

Apparat0s and mat!r$a&s:

Lrinkle recovery tester and accessories.

/abric specimens

!uler

Scissors

Sp!%$m!n pr!parat$onB

.ondition the specimen before testing.

!ecovery angle method@

.ut C, specimens, free from wrinkles, C* mm x CF mm, ) specimens

with their long dimension parallel to the warp yarns and ) parallel to

flling yarns

ark the face of each specimen.

TEST PROCEDURE:

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

;sing twee%ers properly place one of the warp specimens in the

metal specimen holder.

"ut the holder in the plastic press.

&pply *-- gm weight to the plastic press for * minutes.

!emove the weight and properly place the holder in the wrinkle

recovery tester for * minutes.

!ead the angle of the specimen fold from the scale on the wrinkle

recovery tester.

!epeat the procedure until ? warp specimens folded face to face

and ? folded back to back are being tested.

!epeat the procedure for the ) flling specimens.

Data and r!s0&ts: Fa.r$% Lrinkle recovery test

fabric $d!nt$=%at$on44444444444444444444444444444444444

T!st no+ Fa%! to

'a%! 3arp

t!st

F$&&$n* t!st

Ba%A to

.a%A 3rap

t!st

F$&&$n* t!st

C

,

?

Tota&

A/!ra*!

St$?n!ss T!st

C 'n cantilever bending test, a strip of fabric AC inch x D inchB is extended

over a hori%ontal platform.

C The platform moves to extend the fabric strip over the edge until it

bends down to touch a baseline placed at a specifed angle.

C The length of fabric required to reach this base line Atermed the

overhang length, 9B is a measure of sti=ness.

C The longer the length is, the sti=er the fabric.

C The face and back of each end of the strip are measured for a total of

four values for each specimen.

C (y evaluation of bending length and presented a relationship between

sti=ness and fabric weight that is called Oexural rigidity

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

C /abric Oexural rigidity AGB can then be calculated from the mean value

of 9 for each specimen using the following formulas and the fabric

weight ALB in mg7cm

,

C . M 9 7, Lhere c is the bending length in cm

C G M L G c

?

A units of G are mg 7 cm B

Drap! T!st

+ This is usually done on an instrument called 0rape meter, it is to

determine a direct ob>ective measurement of fabric drape.

& fabric circle is draped over a pedestal while a light source

beneath the specimen forms a shadow of the draped image

The image is then reOected on a top panel by a mirror

& piece of paper is placed on a panelN the shadow on the

paper is tracedN and paper image is cut and weighted.

+ The weight of the paper corresponding to the draped image is

divided by the weight of the paper corresponding to an undraped

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

image is the drap! %o!C%$!nt 1 DC2< usually expressed as

percent.

Fa.r$%s 6$t $* DC a/! &o6 drap!a.$&$t#

C The number of folds or nodes, formed is also indication of

drapeability

C 0rapeable fabrics display more nodes in the circular draped

confguration

AIR PERMEABILITY TEST

The air permeability of a fabric is a measure of how well it allows the

passage of air through it. The ease or otherwise of passage of air is of

importance for a number of fabric end uses such as industrial flters, tents,

sailcloths, parachutes, raincoat materials, shirtings, downproof fabric and

airbags.

&ir permeability is defned as the volume of air in milliliters which is

passed in one second through C--s mm

,

of the fabric at a pressure

di=erence of C--mm head of water.

The airOow through a given area of fabric is measured at a constant

pressure drop across the fabric of C-mm head of water. The specimen is

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

clamped over the air inlet of the apparatus with the use of rubber gaskets

and air is sucked through it by means of a pump as shown in fgure. The

air value is ad>usted to give a pressure drop across the fabric of C-mm

head of water and the air Oow is then measured using a Oowmeter.

/ive specimens are used each with a test area of *-Dmm

,

A,*.Fmm

diameterB and and the mean air Oow in ml per second is calculated from

the fve results. /rom this the air permeability can be calculated in ml per

C-- mm

,

per second.

FUNCTIONAL TEST5 FABRIC DIMENSIONAL C"ANGE

f 0imensional change is the increase or decrease in the length or

width of a fabric called growth and shrinkage respectively.

f 'ncrease in dimension s called growth while decrease is called

shrinkage

f .hange is usually expressed in percentage.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

f /abric shrink or grow for various reasons. <ike exposure to heat, water

or dryEcleaning solvent causes some material to change its

dimensionality.

f Some fabrics when dried under tension tend to return to their original

si%e.

f T! .!st 6a# o' t!st$n* 'or sr$nAa*! is to place marks on the

fabric or garment at specifed distances apart before cleaning.

f The distance between the marks is then measured after cleaning and

compared to the original distances marked before cleaning.

f (ecause di=erent types of fabrics are laundered by the consumer in

di=erent ways, it is necessary to have available to test a variety of

washing, drying and restoration methods from which to choose.

ALTERNATI,E CONDITIONS FOR DIMENSIONAL C"ANGE TEST

achine Lashing 0rying !estoration

Lash achine method ethod

Temperature Setting

.old normal <ine dry 4and iron

<ukewarm

AC-* /B

delicate 0rip dry Tension

presser

Larm AC,-

/B

permanent Screen

ArackB

Unit

shrinkage

4ot ACF- /B press dry gauge

2ery hot

AC)- /B

Tumble dry

/latEbed

press

dry

Ca&%0&at$on o' p!r%!nta*! o' sr$nAa*! 1or *ro6t2

D Sr$nAa*! 1or *ro6t2 E Or$*$na& &!n*t F N!6 &!n*t X

7@@

Or$*$na& &!n*t

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

O 'f 3ew length V 9riginal length then calculated percentage is

growth

O 'f 3ew length W 9riginal length then calculated percentage is

shrinkage

S"RIN)AGE MAR)ER AND SPECIMEN

DETERMINING FABRIC DIMENSIONAL C"ANGE AFTER LAUNDERING

Apparat0s and mat!r$a&s :

C. &utomatic home washing machine and detergent

,. &utomatic home dryer

?. C- inch shrinkage markers

F. !estoration apparatus

*. /abric specimens

). !uler

I. Scissors

Specimen preparation

;sing pinking shears to prevent unraveling, cut ? specimens each

measuring C) inches G C) inches. 'ndicate the lengthwise direction with

indelible ink. .ondition the specimen before testing.

ark the specimen with ink as indicated below. The marks are C-

inches apart and on grain.

. M .enter measurement

< M

<eft measurement

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

! M !ight measurement

TEST PROCEDURE

"lace the specimen in the washing machine. &dd additional fabrics to

make a FEpound dry load.

Set the machine for the normal cycle. &dd J-g of detergent and start

the machine.

!emove the fabric from washer immediately after completion of fnal

cycle. Separate the tangled pieces.

"lace the entire load in the tumble dryer.

!emove the specimen from the dryer and examine them. 'f there are

excessive wrinkles, remove them gently using hand iron.

/or each specimen, measure the distances between the indelible

shrinkage marks.

.alculate the average percentage of shrinkage for both the length and

width to the nearest -.*+ .

Data and r!s0&ts:

Fa.r$% $d!nt$=%at$on4444444444444444444444444444444444444444

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

3as$n* ma%$n! :

MaA! and mod!&4444444444444444444444444444444444444444444

3as %#%&! 1s!tt$n*24444444444444444444444444444444444444444

3as t$m!44444444444444444 3as T!mp!rat0r!4444444444444444

Dr#!r :

MaA! and mod!&444444444444444444444444444444444444444444

Dr#!r s!tt$n*44444444444444444 Dr#!r t$m!44444444444444444444

Pr!ss$n* m!tod 1$' 0s!d24444444444444444444444444444444444

D$stan%! .!t6!!n sr$nAa*! marAs .!'or! %&!an$n*KKKKKKKKKKKKKK

FABRIC FLAMMABILITY5TEST

/lammability refers burning behavior, specifcally to ease of ignition

and continued burning after ignition

/abrics can be placed in di=erent categories with regard to

Oammability.

Flammable fabrics will be completely consumed when exposed to fre.

'n order to for such fabrics to be nonOammable it has to undergo some

chemical treatment and then called fame retardant fabric.

%f the fabric is develo!ed from in&ammable "bres like kevlar ' (ome)

is called fame proof fabrics

GH5D!*r!! An*&! T!st

f The specimen, mounted in a holder,is positioned in a metal cabinet at

a F* degree angle, and ignited with a butane gas Oame for one second.

f The ignition Oame is removed and the time for the specimen to burn its

entire length AC*- mmB is recorded.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

T!st no+ MarA!r

&o%at$on

D$stan%!

.!t6!!n

&!n*t

Sr$nAa*!

marAs 6$dt

C .enter

<eft

!ight

, .enter

<eft

!ight

? .enter

<eft

!ight

Tota&

A/!ra*!

f & cotton stop cord at the top of the specimen signals the Oame time

when it burns through.

f The stop cord is attached to a weight that drops onto a stop watch to

measure of burning time.

FLAMMABILITY TESTER

The specimen is in a holder tilted at F* degree angle. The thread across

the top of a specimen when burnt will cause a timer to stop.

Apparat0s and mat!r$a&s

C. /lammability tester with accessories

,. (rushing device

?. 0rying oven

F. 0esiccators

*. /abric specimens

). /orceps

I. !uler

D. Scissors

Sp!%$m!n pr!parat$on

f .ut * specimens , inches G ) inches. The longer direction is the faster

burning direction, determined by a preliminary trial.

f "lace specimens in holders.

f /or raised surface fabrics use the brushing device to raise the pile or

nap.

f "lace the specimen in drying oven for ?- minutes at ,,C degree /.

f !emove the specimens with forceps and place in a desiccators for at

least C* minutes to allow them to cool.

T!st pro%!d0r!

"repare the Oammability tester.

!emove a specimen from the desiccators and place in the Oammability

tester so that the Oame will spread rapidly. The test must be performed

within F* seconds of the time the specimen is removed.

(ring the tip of Oame to the specimen and impinge the Oame on the

fabric surface for C second. !emove the Oame.

!ecord the burning time and the visual results.

!epeat steps CEF for the other specimens.

Data and r!s0&ts

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

fabric identifcationKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK

fabric type Aplain or raised surfaceBKKKKKKKKKKKKKKKKKKKKKKKK

direction of test Alength or widthBKKKKKKKKKKKKKKKKKKKK

T!st no+ Or$*$na& Cond$t$on A't!r Dr#

%&!an$n*

%od! t$m! T!st no+ %od! t$m!

C

,

?

F

*

Total Total

&verage &verage

COLOUR FASTNESS - S"ADE MATC"ING

COLOR FASTNESS

"roperty of a pigment or dye to retain its original hue, especially

without fading, running, or changing when wetted, washed, cleanedN

or stored under normal conditions when exposed to light, heat, or

other inOuences.

Fa%tors A?!%t$n* Co&or Fastn!ss

/iber Type

.lass of 0ye ;sed

0yeing or "rinting "rocess used

Types of /inishing Treatments ;sed

&ction 9f <aundering 0etergents

Q0a&$t$!s O' T! Co&or E/a&0ator

A sp!%$a& $nd$/$d0a& n!!d!d 6o:

+ Unows why color change

+ 's skilled in colorfastness tests and knows their limitations.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

+ "ossesses a knowledge of dyes and pigments.

+ 4as the ability to evaluate and report color changes.

T#p!s O' Co&or'astn!ss

Ad/!rs!&# a?!%t!d .#:

Lashing

<ight

.rocking

&brasion

Gases in &tmosphere

/rosting

"erspiration

4eat

Co&or 'astn!ss $s 0s0a&&# ass!ss!d s!parat!&# 6$t r!sp!%t to :

C. .hanges in the color of the specimen being tested , that is color

change

,. Staining of undyed material which is in contact with the specimen

during the test, that is due to bleeding of color

GRAY SCALE

'n order to give a more ob>ective result a numerical assessment of each

of these e=ects is made by comparing the changes with two sets of

standard grey scales , one for color change and the other for staining

&rrangement of &chromatic gray chips in a scale from light to dark.

3ine pairs of nonEglossy neutral grey colored chips, which illustrate the

perceived color di=erences.

give a corresponding fastness rating of *, FE*, F, ?EF, ?, ,E?, ,, CE,, and

CB

X* has two identical greys, and X C grey scale shows the greatest

contrast, and X ,,? and F have intermediate contrasts

Us$n* a Gra# S%a&!I

;ses a class *EFE?E,EC rating system.

.lass * best, .lass C worst.

4alf !ating, such as ?EF also used.

*E8xcellent, FEgood, ?Efair, ,Epoor, CE very poor.

Specimens of a given hue are matched against these gray chips.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

They equate di=erences in lightness with di=erences in color.

Gr!# s%a&!s 'or sta$n$n*

& di=erent set of grey scales is used for measuring staining

/astness rating is shown by two identical white chips Athat is no

stainingB and rating C shows a white and dark chips. The other

numbers shows geometrical steps of contrast between white and a

series of greys.

&piece of untreated, unstained, undyed cloth is compared with the

treated sample that has been in contact with the test specimen during

the staining test and a numerical assessment of staining given.

Grade of *@ no change in color, no staining

Grade of C@ substantially di=erent. 4eavily stained

M!todo&o*# O' T!st$n*

3ormally a multiEfbre strip of ) fbre components used for staining test@

A%!tat!< Cotton< A%r#&$%< Po&#am$d!< Po&#!st!r and 3oo&+

;sually only one specimen of fabric used.

'f material dyed or printed uniformly throughout the fabric, then specimen

chosen should be representative of entire lot.

/or multi 1colored printed fabric, each color should be tested in order to

evaluate every color.

L$m$tat$ons o' Gr!# S%a&!

0isagreement when bright colors are used.

C"ROMATIC TRANSFERENCE SCALE

's used to evaluate fabrics resistance to crocking.

.onsists of six sets of color chips.

8ach set is graduated from light to dark with di=erent rating.

L$*t$n* Us!d For E/a&0at$on

Lhen visually evaluating or comparing, standardi%ed light source

should be used.

.9<9! &T.4'3G (99T4 frequently used for color checking.

COLOR MATC"ING BOOT"

.ontains F di=erent standardi%ed lights@

+ 0aylight

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

+ 'ncandescent <ight

+ .ool Lhite /luorescent <ight

+ ;ltraviolet <ight

8ach used to view specimens by pushing a switch.

0aylight used when evaluating colorfastness as color appears closer

to way usually seen.

COLORFASTNESS TO 3AS"ING

&bility of the fabric to with stand the e=ect of laundering.

<aunderEoEmeter is used to evaluate color fastness to washing with

the help of grey scales.

The washing of fabric results in the removal of dye, therefore

staining can occur, in order to determine the staining, a white multiE

fber strip is attached to the specimen being tested for ./ to

washing.

The staining e=ect on each fber in the multiEfber test fabric should

be rated by using the grey scale for evaluating staining.

Cond$t$on 'or pr!parat$on o' COLORFASTNESS TO 3AS"ING

TEST <iquor T!mp C T$m! 1m$n2

!eproduces

action of

.-C

-.*+ soap

F- ?-

4and washing

.-,

-.*+ soap

-.,+ soda ash

*- F*

!epeated 4and

washing

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

.-?

-.*+ soap

-.,+ soda ash

)- ?-

edium

cellulosic wash

Severe wool

wash

.-F

-.*+ soap

-.,+ soda ash

J* ?-

Severe

cellulosic wash

.-*

-.*+ soap

-.,+ soda ash

J* ,F-

2ery Severe

cellulosic wash

.-)

F g7l detergent

5 perborate

various various

0omestic

laundering

T! La0ndrom!t!r

Specimen placed in a metal cylinder containing water, detergent,

steel balls, and chlorine.

!otating action of these cylinders produces the same e=ect as

textile products being laundered.

TEST PROCEDURE

S"8.'83 "!8"8!&T'93@

.ut the specimen , x ) inches, stapled with the multi fber fabric.

"!9.80;!8@

"lace the sample in the container along with the steel balls and

detergent

!un the machine for F* minute

&fter taking the specimen rinse it with water and soak it in acetic

solution and rinse it again with water.

!emove the excess solution

0ry the specimen and test fabric together using an hand iron

!emove the test fabric and compare it with the gray scale to fnd

the fastness.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

COLORFASTNESS TO LIG"T

This refers to the ability of the fabric to withstand the sun light.

The resistance of the sunlight depends on@

the intensity of the light

'nherent properties of the fabric.

Season

<itude

0istance from the equator.

LeatherEoEmeter and /adeEoEmeter most widely used instruments.

(oth this instruments use di=erent light source and the temperature

and humidity are controlled with in the machine

Specimens placed around the light source, and remain there until

the end of test.

Then evaluated as to changes in color resulting from radiation

LeatherEoEmeter is a newer and more versatile machine

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

't enables specimen to be sprayed with water during the test, if

desired.

't also is able to alternate light and dark periods if continuous light

exposure is not desired.

These conditions are used in the LeatherEoEmeter to test fabric for

such end uses as outdoor furniture, tents or rainwear.

(oth machines have either a carbonEarc lamp or a xenonEarc lamp

as the light source.

The degree of fastness required depends on end use.

&s an example, a coat material should have more color fastness

than a colored dress shirt. Similarly clothes not intended to worn

outside should also have certain color fastness to enable drying in

sunlight.

3EAT"ER5O5METER

3ewer, versatile.

't enables the specimen to be sprayed with water if needed.

't also manipulates the light and dark period if continuous exposure

is not needed.

These make it most suitable for testing fabrics for end uses like

outdoor furniture, tenting or rainwear.

Us$n* 3!at!r M!t!r

Two testing methods are used@

Time method

Standard fading method

TIME MET"OD

The specimen is exposed to light for a particular amount of time.

&fter the termination of time the specimen is taken out and

evaluated.

Specimen is not exposed to the same amount of light each time the

test is performed.

T!st Pro%!d0r! F standard Fad$n* M!tod

Sp!%$m!n Pr!parat$on

.ut the specimen ,.*T x DT with the longer dimension in lengthwise.

T!st Pro%!d0r!

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

ount the specimen in the cardboard holder and remove the

perforated strips so that half of the specimen area will be

uncovered.

'nsert the cardboard holder into the metal holder and place in to the

machine.

8xpose the specimen for ,- hours.

&t the end of the desired exposure time period, remove the

specimen and allow it to relax in the dark at room temperature for

atleast , hours in order to regain moisture from the air.

;sing the grey scale for evaluating colour change, determine the

colour fastness rating for the test fabric.

COLOR FASTNESS TO CROC)ING

+ The rubbing o= of colors is called as crocking.

/abrics with large amount of surface dyes like dark color cotton

fabric tend to have poor colorfastness to crocking, pigment dyed or

printed fabrics also face the same problem.

Some time in order to increase the depth of the colors the surface

dyes are not washed o= which also results in crocking.

Cro%A M!t!r

The crock meter is used to fnd the color fastness to crocking.

This instrument has a fnger covered by a white cotton fabric which

would rub against the specimen.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

This test should be performed both as wet and dry test.

The wet test is an severe test since moisture helps in removal of

dyes

Sp!%$m!n Pr!parat$on

.ut two specimens on the bias, DTxDT and place the test specimen

on the crock meter so it will be rubbed in the bias direction.

T!st Pro%!d0r!

ount a dry, white crock test cloth over the fnger section of the

crock meter so that it will be rubbed in the bias direction.

<ower the covered fnger, causing the crock test cloth to slide over

the coloured specimen for C- complete cycles.

!emove the specimen and the white crock test cloth.

"erform a wet crocking test by the same procedure.

!ate the crock test cloths using the colour transference chart.

COLOR FASTNESS TO PERSPIRATION+

"erspiration can cause a fabric to change color as well as resulting

in staining of ad>acent material.

The test is attempted to stimulate the actual condition. The

specimen is heated for ) hours at ?DY..

& multifbre test fabric is placed against the specimen, the test is

carried out and later evaluated for bleeding or color migration.

&fter the test is completed, the specimen is evaluated using the

gray scale and the average rating is reported.

TEST PROCEDURE

SPECIMEN PREPERATION:

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

.ut the specimen of , RT x , RT

.ut the multifber fabric to , x , inch

PROCEDURE:

'mmerse the test sample and the specimen in the acid solution for

C* min.

Lith draw the fabric and remove any excess liquor

"lace the specimen in the perspiration tester

<oad the tester with C- pounds of pressure.

"lace the loaded tester in an oven and heat it to C--Zf for ) hours

!emove the tester from oven and allow the fabric to dry at room

temperature.

!emove specimen and test cloth and .ompare with gray scale.

COLOR FASTNESS TO FROSTING

/rosting is the change of color caused by a locali%ed, Oat abrasive

action.

/abrics that have poor dye penetration possess poor colorfastness

to frosting.

/abrics that are cross dyed also possess poor color fastness Adue to

di=erences in the abrasion resistanceB.

TESTING EQUIPMENT

InJat!d D$apra*m A.ras$on T!st!r 3$t Frost$n*

Atta%m!nt

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

The specimen is held in such a way that only small portion is

exposed A, inchB to rubbing force.

Two abradants are used here.

Em!r# M!tod

more severe test

;sed for garments that are exposed to severe abrasion

resistance for a long period of time.

&lso used for fabrics that have low dye penetration.

TESTING EQUIPMENT

S%r!!n 3$r! M!tod

!esults in mild abrasive action.

& fne wire screen is used and the specimen is placed over a

hard sponge material.

This is used for cross dyed and blended fabrics.

'n crocking test the rubbing cloth is evaluated and in this the

specimen is evaluated

D$?!r!n%! .!t6!!n Cro%A$n* T!st and Frost$n* T!st

.rocking evaluates the appearance of the specimen

/rosting only evaluates the rubbing cloth, not the specimen.

INFLATED DIAP"RAGM ABRASION TESTER

The specimen is placed between the abradant and the foam.

The table moves to and fro while the specimen is slowly rotated

causing it to rub against the abradant.

SCREEN 3IRE MET"OD

"lace the screen and the specimen in the tester. The specimen is

mounted over the foam rubber cushion.

&pply a ,.* pound load on the head.

Start the tester and allow it to operate for C,-- continuous cycle.

Stop the machine and remove the specimen.

/rom this continue as previous method and fnd the color fastness.

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

TESTING STANDARDS - MET"ODS

/or test results to correlate between laboratories it is essential that each

test conducted is to a standard test method. Test methods used in

di=erent countries have unique identifcation numbers but are usually

variations on the same basic protocol. the most commonly used test

standards are@

&ST and &&T.. for ;S&

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

&merican society for testing and materials

&merican association of textile chemist and colorist

(S for ;nited Uingdom

.&3 for .anada

DIN 0eutsches 'nstitute for 3ormung @ Germany

P'S for Papan APapan industrial standardB

&S for &ustralia

('S 1 (ureau of 'ndian standard

'S9

83E'S9

&&T.. 6 &ST are the preferred standards for the 3orth &merican

continent while 'S9 is used for the rest of the world. 'ndividual countries

have derived their own standard methodology but are usually based on

either the 'S9, &&T..7&ST or (S test methods. !ecently, with the

8uropean ;nion being formed, a consolidation of all standard methods

used in 8urope is begin done. 'n most cases, common standards are being

evolved which are designated as 83 or 83 'S9. 't is expected that all

8uropean countries adopt these new designated test methods over a

period of time.

ASTM FABRIC PERFORMANCE

SPECIFICATION C"ART

Param!t!rs

M!nKs and

.o#s

S0$t

M!nKs - .o#s

Pa>amas

(reaking strength, lbs F- ,*

:arn slippage, lbs ,* C*

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Tear strength, lbs ,.* C*

(ursting strength, lbs EE EE

0imensional change @ after *

<aunderings

?+ ?+

@ after ? dry

cleanigs

,+ EE

.olorfastness@ shade change,

original fabric

.lass F .lass F

Shade change after C laundering .lass F .lass F

<aundering@ shade change .lass F .lass F

@staining .lass ? .lass ?

0ry cleaning@ shade change .lass F EE

.rocking@ dry .lass F .lass F

@wet .lass ? .lass ?

"erspiration @ shade change .lass F .lass F

@ staining .lass ? .lass ?

Later repellency@ original fabric EE EE

@ after *

launderings

EE EE

/abric appearance 0" ?.* 0" ?

ASTM FABRIC PERFORMANCE

SPECIFICATION C"ART

Param!t!rs

3om!n and

*$r&s Dr!ss

%oat

3om!n - *$r&s

3at!r r!p!&&!nt

ra$n%oat

(reaking strength, lbs ?-

Z

F-

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

:arn slippage, lbs ,-

ZZ

,*

Tear strength, lbs ? ?

(ursting strength, lbs EE EE

0imensional change@ after *

launderings

EE ?+

@ after ? dry

cleanings

EE ,+

.olorfastness@ shade change,

original fabric

.lass F .lass F

Shade change after C laundering .lass F .lass F

<aundering@ shade change EE .lass F

@staining EE .lass ?

0ry cleaning@ shade change .lass F .lass F

.rocking@ dry .lass F .lass F

@ wet .lass ? .lass ?

"erspiration@ shade change .lass F .lass F

@ staining .lass ? .lass ?

Later repellency@ original fabric EE J-7D-

@ after * launderings EE I-

/abric appearance EE 0" ?.*

ASTM FABRIC PERFORMANCE

SPECIFICATION C"ART

Param!t!rs

Upo&st!r# Drap!r#

(reaking strength, lbs *- ,-

:arn slippage, lbs ,* EE

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Tear strength, lbs ) C.*

(ursting strength, lbs EE EE

0imensional change@ after *

launderings

EE ?+

@ after ? dry

cleanings

EE ?+

.olorfastness@ shade change,

original fabric

.lass F .lass F

Shade change after Claundering .lass F .lass F

<aundering@ shade change EE .lass F

@ staining EE .lass ?

0ry cleaning@ shade change .lass F .lass F

.rocking@ dry .lass ? .lass F

@ wet EE .lass ?

"erspiration @ shade change EE EE

@ staining EE EE

Later repellency@ original fabric EE EE

@after *

launderings

EE EE

/abric appearance EE 0" ?.*

ASTM FABRIC PERFORMANCE SPECIFICATION

C"ART

"arameters

)NITS M!nKs - .o#s s&a%As

(reaking strength, lbs EE

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

:arn slippage, lbs EE

Tear strength, lbs EE

(ursting strength, lbs *-

0imensional change@ after *

launderings

?+

@ after ? dry

cleanings

,+

.olorfastness@ shade change, original

fabric

.lass F

Shade change after C laundering .lass F

<aundering@ shade change .lass F

@ staining .lass ?

0ry cleaning@ shade change .lass F

.rocking@ dry .lass F

@ wet .lass ?

"erspiration @ shade change .lass F

@ staining .lass ?

Later repellency@ original fabric EE

@ after *

launderings

EE

/abric appearance 0" ?.*

Not! :

Z not napped

ZZ solid shad

ZZZ after C wash,

*+

Shrinkage,

,+ gain

T#p$%a& T!Lt$&! Sp!%$=%at$ons 'or 3o/!n B&o0s!s and

S$rts

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

Sr+ T!st D!s%r$pt$on M$n$m0m P!r'orman%!

Sp!%$=%at$ons

C Tensile Strength AGrabB C* kgf @ Larp 6 Left

, Tear Strength School wear @ I--g @ Larp 6 Left

9thers @ *-- g@ Larp 6 Left

? Seam Slippage D kgf at S9 ) mm @ Larp 6 Left

F Seam Strength C- kgf Larp 6 Left

* &brasion !esistance C-,--- rubs

) "illing !esistance Afor

blends onlyB

Shirts 6 School wear @ ?EF @ CD,---

rubs

(louses @ ?EF @

CC,--- rubs

I 0imensional Stability 1

achine wash, /lat 0ry

5 ?.-+ <ength 6 Lidth

ZZ

D &ppearance of garment

after laundering

Shade .hange @ F, 3o adverse

change in appearance

J /ibre .omposition 5 ? + of Stated .omposition

C- .olourfastness to <ight Shade .hange @ F

CC .olourfastness to Lashing Shade .hange @ F, Staining @ ?EF

.ross Staining @ FE*

Z

C, .olourfastness to Later Shade .hange @F , Staining @ ?EF

.ross Staining @ FE*Z

C? .olourfastness to !ubbing 0ry @ F Let @ ?

Not!s :

ZZ

@ /or viscose fabrics, a maximum shrinkage of *.-+ may be accepted

Z

@ /or contrasting colours used in the same garment only.

0imensional Stability and .olourfastness to Lashing are to be tested at

the temperature specifed in the care label only.

T#p$%a& T!Lt$&! Sp!%$=%at$ons 'or Str!t% Garm!nts %onta$n$n*

%onta$n$n* E&astan!

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

1In%&0d$n* S6$m6!ar< B!a%6!ar - L!otards2

Sr+ T!st D!s%r$pt$on M$n$m0m P!r'orman%!

Sp!%$=%at$ons

C Stretch 7 !ecovery !esidual 8xtension@ *.- + max. after

?- minutes of recovery in length or

width as applicable.

, 0imensional Stability 1

achine wash, /lat 0ry

E *.- + <ength 6 Lidth, max.

5 ?.- + <ength 6 Lidth, max.

? &ppearance of garment after

laundering

Shade .hange@ F, 3o adverse

change in appearance

F /ibre .omposition 5 ? + of Stated .omposition

* .olourfastness to <ight Swimwear 6 (eachwear@ *

9thers @ F

) .olourfatness to Lashing Shade .hange @ F, Staining @ ?EF

.ross Staining @ FE*

Z

I .olourfatness to Later Shade .hange @ F, Staining @ ?EF

.ross Staining @ FE*

Z

D .olourfatness to !ubbing 0ry @ F Let @ ?

J .olourfastness to .hlorinated

Later

Shade .hange @ F

C- .olourfastness to Sea Later

for (eachwear and Swimwear

only.

Shade .hange @ F

Staining @ ?EF

Not!s:

Z @ /or contrasting colours used in the same garment only.

0imensional Stability and .olourfastness to Lashing are to be tested at

the temperature specifed in the care label only.

Som! ELamp&!s o' Sp!%$a& R!M0$r!m!nts 'or D$?!r!nt End Us!s O'

Fa.r$%s ( Garm!nts

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

It!m Sp!%$a& R!M0$r!m!nts

Garments for &ustralia 'mproved <ight /astness

Swimwear7 (eachwear .hlorinated water 7 Sea water

/astness

Surgical Gowns 7 &pparel &nti (acterial properties

Loolen erchandise oth "roofng

/ire /ighters &pparel /lame "roofng

0efence Textiles Atents 7 .anvas

etc.B

!ot "roofng

Soil 7 Stain resistant materials Soil release treatments

9il 'ndustry applications 9il repellency fnishes

.urtain materials 'mproved <ight /astness

'ndustrial ;niforms Strength, 9il 7 Soil !epellency

Sportswear &brasion 6 Seam Strength

.hildrenQs wear .olourfastness to Saliva

3ightwear /lammability

!ainwear Later repellency, (reathability

Garments for &rctic conditions &bility to withstand extreme cold

Fa.r$% Insp!%t$on

T0 1 /abric #uality &ssurance 1 Study aterial "rof. 2. Sivalingam, 3'/T, (engaluru

The inspection of fabric, madeEup and garments has two primary

functionsN frst to classify the products according to the di=erent