Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Eaton: Hydraulic Motor

Caricato da

Fernando SabinoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Eaton: Hydraulic Motor

Caricato da

Fernando SabinoCopyright:

Formati disponibili

No.

7-151

J uly, 1996 Eaton

Hydraulic Motor

45 Seri es

VIS Beari ngl ess Motor 003

Repai r Informati on

2

VIS Beari ngl ess Motors

45 Seri es Gerol er Motors

3

VIS Beari ngl ess Motors

45 Seri es Gerol er Motors

Di sassembl y

Plug/O-ring

Spring

Shims

Poppet

Plug/O-ring

Plug/O-ring

Dash Pot

Spring

Poppet

Shuttle Piston

Poppet

Spring

Dash Pot

Plug

O-ring

End Cap

End Cap (End Ported)

Shuttle/Relief Valve Parts Shown Enlarged Below

Seal, Square Cut

Geroler

Seal, Square Cut

Seal, Square Cut

Valve Plate

Check Ball

Balance Plate

Seal, Square Cut

Seal

Back-up Ring

Back-up Ring

O-ring

O-ring

Flange

Face Seal

Screw, Torx Head

Drive

4

VIS Beari ngl ess Motors

45 Seri es Gerol er Motors

End Cap

Seal, Square Cut

Geroler

Seal, Square Cut

Seal, Square Cut

Valve Plate

Balance Plate

O-ring

Drive

Check Ball

Seal, Square Cut

Backup Ring

Flange

Face Seal

Screw, Torx Head

Backup Ring

Seal

O-ring

Di sassembl y

1 Cleanliness is extremely important when repairing hydraulic

motors. Work in a clean area. Before disconnecting the

hydraulic motor thoroughly clean the exterior. Remove motor

from application and drain the oil from the motor before

disassembly.

2 Remove the 9 cap screws and disassemble the motor in the

vertical position as shown in figures 1 and 2. Note pl acement

of smal l bal l checks i n Gerol er.

3 Remove shuttle valve (and relief valve if applicable) from

end cap.

4 Remove two plugs from end cap, end ported motors only.

5 Check all mating surfaces. To reduce the chance of leakage,

replace any parts that have scratches or burrs. Wash all metal

parts in clean solvent. Blow them dry with pressurized air. Do

not wipe parts dry with paper towels or cloth as lint in a

hydraulic system will cause damage.

Tool s Requi red

1/4 inch Hex Key

3/16 inch Hex Key

5/8 inch Hex Key (End Ported Motor Only)

Torque wrench - 200 Nm [150 lb-ft] capacity

Fi gure 1

5

VIS Beari ngl ess Motors

45 Seri es Gerol er Motors

Reassembl y

Note: Al ways use new seal s when reassembl i ng hydraul i c

motors. Refer to parts l i st 6-153 for seal ki t number, repl ace-

ment parts, and orderi ng i nformati on.

Important: Duri ng reassembl y, l ubri cate the new seal s wi th a

petrol eum j el l y such as Vasel i ne

. Al so l ubri cate machi ned

surfaces wi th cl ean hydraul i c fl ui d.

6 Install one poppet, spring and dash pot into shuttle valve

bore from valve plate side of end cap.

7 Install non-threaded plug with o-ring into end cap shuttle

valve bore. O-ring and plug are to be lightly coated with

petroleum jelly to ease assembly and a plug should be inserted

flush with end cap mounting surface.

8 Install shuttle piston from opposite end of shuttle valve

cavity.

9 Install one shuttle valve poppet, spring and dash pot onto

piston.

10 Install one shuttle valve threaded internal hex plug with

o-ring. Shuttle plug threads may have light coat of oil or

preservative. Torque plug to 37-45 Nm [324-396 lb-in].

11 For a motor with low pressure relief valve, install poppet,

shims, spring and plug. Plug threads may have light coat of oil

or preservative. Torque plug to 23-29 Nm [207-253 lb-in].

12 For a motor without low-pressure relief valve, install plug

with o-ring and torque plug to 23-29 Nm [207-253 lb-in].

Fi gure 2

Plug/O-ring

Spring

Shims

Poppet

Plug/O-ring

Dash Pot

Spring

Poppet

Shuttle Piston

Poppet

Spring

Dash Pot

Plug

O-ring

Shuttl e Val ve Rel i ef Val ve

End Cap (End Ported)

End Cap (Top Ported)

Plug/O-ring

Shuttl e Val ve

Rel i ef Val ve

Plug/O-ring

Plug/O-ring

Spring

Shims

Poppet

Dash Pot

Plug/O-ring

Spring

Dash Pot

Spring

Poppet Poppet

Shuttle Piston

Shuttl e Val ve

Rel i ef Val ve

6

VIS Beari ngl ess Motors

45 Seri es Gerol er Motors

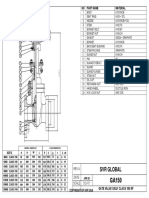

Fi gure 3

End Cap

Seal,

Square Cut

Geroler

Seal, Square Cut

Seal, Square Cut

Valve Plate

Balance Plate

O-ring

Drive

Check Ball

Al i gn Shuttl e Fl ow Hol es

Seal, Square Cut

Backup Ring

Flange

Face Seal

Screw, Torx Head

Backup Ring

Seal

O-ring

Note: Use shuttl e fl ow hol e on back si de of

fl ange for al i gnment Not thi s passage.

Note: Assembl e these parts

as shown bel ow (l eft).

Flange

Seal,

Square Cut

Seal

Backup Ring

Backup Ring

O-ring

Shuttl e

Fl ow Hol e

O-ring

Groove

O-ring

Backup

Ring

Fi gure 4

7

VIS Beari ngl ess Motors

45 Seri es Gerol er Motors

Fl ange Assembl y

Note: Backup ri ngs and seal s must have a coati ng of petro-

l eum j el l y to assi st i n retai ni ng these parts i n a i nverted

posi ti on l ater on i n fi nal assembl y.

14 Position flange on work bench. With seal grooves up (see

Figure 3), install square cut seal, backup ring, seal, backup ring,

and o-ring in flange. Set flange assembly aside, seal side up.

Fi nal Assembl y

15 Place end cap on work bench name tag side down, seal

grooves up (see Figure 4). Install o-ring (26,7 [1.05] ID) and

square cut seal (150,8 [5.94] ID) in appropriate grooves.

16 Place valve plate onto end cap. Align bolt holes and shuttle

flow hole on valve plate with mating holes on end cap.

17 Install two square cut seals, one on each side of the Geroler.

Seal on valve side of Geroler must have a sufficient coating of

petroleum jelly to assist in retaining seal in groove.

18 Place Geroler over valve plate. Align bolt holes and shuttle

flow hole on Geroler with mating holes on valve plate. Position

valve side of star down and spline side up.

19 Place drive into spline of Geroler star with recessed end

down.

20 Place two steel balls into seats of Geroler star (one per

seat).

21 Place balance plate on Geroler. Align bolt holes and shuttle

flow hole on balance plate with mating holes on Geroler.

Note: Before pl aci ng fl ange assembl y from step 14, note the

l ocati on of the shuttl e fl ow hol e. Thi s wi l l expedi te the move

from the work bench over onto the bal ance pl ate.

22 Carefully invert flange assembly and place onto balance

plate with bolt holes and shuttle flow holes in line. Do Not

displace seals and backup rings.

23 Install nine screws lubricated with DTE-26. Pre-torque each

in a crisscross pattern to 61-75 Nm [45-55 lb-ft]. Finally in a

crisscross pattern, tighten screws to 136-149 Nm

[100-110 lb-ft].

Note: Al l beari ngl ess motors must be handl ed wi th the dri ve

end up. Damage to the bal ance pl ate wi l l occur i f these

beari ngl ess motors are l i fted by the dri ve.

4

7

2

1 9

6

3

8

5

Fi gure 5

Copyright Eaton Corporation 1996

All Rights Reserved

Printed in USA Form No. 7-151

For More Detailed Information Contact Eaton Corp. Hydraulics

Division 15151 Highway 5 Eden Prairie, MN 55344.

Specifications and Performance Data, Catalog No. 11-112.

Replacement part numbers and kit information Parts

Information No. 6-153.

Each Order Must Incl ude the Fol l owi ng:

How to Order Repl acement Parts

1. Product Number

2. Date Code

3. Part Name

4. Part Number

5. Quantity of Parts

Product number

Eaton Corp. Hydraulics Div.

Shawnee, OK 74801

Product Number

157 0000 000

Product Line

Identification

Number

Product

Identification

Number

Engineering

Change

Code

Week of

Year 01

Thru 52

Last Two

Numbers

of Year

Date Code

00 00

VIS Beari ngl ess Motors

45 Seri es Gerol er Motors

Eaton Corporation

Hydraul i cs Di vi si on

15151 Hwy. 5

Eden Prairie, MN 55344

Telephone: 612/937-9800

Fax: 612/937-7130

Eaton Ltd.

Hydraul i cs Di vi si on

Glenrothes, Fife

Scotland, KY7 4NW

Telephone: +44 (0)1592-771-771

Fax: +44 (0)1592-773-184

Eaton GmbH

Hydraul i cs Products

Am Schimmersfeld 7

40880 Ratingen, Germany

Telephone: +49 (0)2102-406-830

Fax: +49 (0)2102-406-800

ISO-9001 CERTIFICATED FIRM

DET NORSKE VERITAS INDUSTRY BV, THE NETHERLANDS

ACCREDITED BY

THE DUTCH COUNCIL

FOR CERTIFICATION

Reg. No. 24

Qual i ty System Certi fi ed

Products i n thi s catal og are manufactured

i n an ISO-9001-certi fi ed si te.

http://www.eaton.com

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Series 40 M46 Pump Parts ManualDocumento120 pagineSeries 40 M46 Pump Parts ManualUmar Ikram100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- SD300E ZF TransmissionDocumento29 pagineSD300E ZF TransmissionAimHigh100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Caseih Staiger PBDocumento1.366 pagineCaseih Staiger PBFernando SabinoNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Finotek CatDocumento1 paginaFinotek CatFernando SabinoNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Liebherr Technical Data DpvoDocumento86 pagineLiebherr Technical Data DpvoІгор Веселов100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Volvo BL71 A10vo74dflr31r-R902436775Documento33 pagineVolvo BL71 A10vo74dflr31r-R902436775Mark Dickason100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- V90N DPDocumento18 pagineV90N DPFernando SabinoNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 3410 3411 H179Service TrainingDocumento668 pagine3410 3411 H179Service TrainingWilliam Giovanni Madariaga Malebrán97% (35)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Finotek CatDocumento1 paginaFinotek CatFernando SabinoNessuna valutazione finora

- Folding Stairway: Hitachi EX 1900-6 Excavator (4")Documento39 pagineFolding Stairway: Hitachi EX 1900-6 Excavator (4")pablo moraledaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- New Holland D350 EN PDFDocumento348 pagineNew Holland D350 EN PDFChakrouneNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- 420 Mobile Piston Pump Design Code CDocumento41 pagine420 Mobile Piston Pump Design Code CFernando Sabino100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Travel Motor: Main MenuDocumento24 pagineTravel Motor: Main MenuSavio Rodrigues100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Workshop ManualDocumento837 pagineWorkshop ManualFernando Sabino100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- New Holland D350 EN PDFDocumento348 pagineNew Holland D350 EN PDFChakrouneNessuna valutazione finora

- S3000 H188-H189Documento612 pagineS3000 H188-H189Ingetest Diesel88% (17)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- New Holland D350 EN PDFDocumento348 pagineNew Holland D350 EN PDFChakrouneNessuna valutazione finora

- ZE205E零件图册2013年1月版5 23 PDFDocumento333 pagineZE205E零件图册2013年1月版5 23 PDFnay hlaing Soe100% (3)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 953D PDFDocumento173 pagine953D PDFstodzathegreat100% (2)

- Finotek KomatsuDocumento1 paginaFinotek KomatsuFernando SabinoNessuna valutazione finora

- ZE205E/ZE230E Hydraulic Excavator Maintenance Manual: First Edition of January 2013Documento73 pagineZE205E/ZE230E Hydraulic Excavator Maintenance Manual: First Edition of January 2013nay hlaing Soe100% (4)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Hydraulics Part 3Documento24 pagineHydraulics Part 3MACHINERY101GEAR100% (4)

- Finotek 3Documento1 paginaFinotek 3Fernando SabinoNessuna valutazione finora

- Finotek SolenoidDocumento1 paginaFinotek SolenoidFernando SabinoNessuna valutazione finora

- Finotek KatoDocumento1 paginaFinotek KatoFernando SabinoNessuna valutazione finora

- 10 FIAT KOBELCO Ex255t Service Manual PDFDocumento971 pagine10 FIAT KOBELCO Ex255t Service Manual PDFnajafali100% (8)

- Finotek Komatsu 3Documento1 paginaFinotek Komatsu 3Fernando SabinoNessuna valutazione finora

- Finotek Komatsu 1Documento1 paginaFinotek Komatsu 1Fernando SabinoNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Finotek Doosan CatDocumento1 paginaFinotek Doosan CatFernando SabinoNessuna valutazione finora

- Finotek 1Documento1 paginaFinotek 1Fernando SabinoNessuna valutazione finora

- TB KeyPerformanceEvaluation PDFDocumento2 pagineTB KeyPerformanceEvaluation PDFtomjones77Nessuna valutazione finora

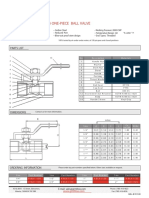

- GA150 CAST STEEL GA Specs 15-200Documento1 paginaGA150 CAST STEEL GA Specs 15-200Priyanka rajpurohitNessuna valutazione finora

- Lec 8-External flow-JU PDFDocumento34 pagineLec 8-External flow-JU PDFVAMSI REDDYNessuna valutazione finora

- Is 6392Documento60 pagineIs 6392Yogesh NadgoudaNessuna valutazione finora

- Parker (NS) Volume Control Valves PDFDocumento5 pagineParker (NS) Volume Control Valves PDFKamal NarangNessuna valutazione finora

- Instant Guide To Flow Profile: ABB InstrumentationDocumento4 pagineInstant Guide To Flow Profile: ABB InstrumentationPeter FormanNessuna valutazione finora

- FM&TM SyllabusDocumento1 paginaFM&TM SyllabusManish KumarNessuna valutazione finora

- D275A-5STD - Hydraulic SystemDocumento64 pagineD275A-5STD - Hydraulic Systemchibssa alemayehu100% (1)

- Nodal AnalysisDocumento24 pagineNodal AnalysisSuhail Al-serriNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- s01 Hydraulic Cartridges Ds311 Sandvik Serial l13b6074Documento42 pagines01 Hydraulic Cartridges Ds311 Sandvik Serial l13b6074OSVALDONessuna valutazione finora

- SprinkCALC III Report2Documento11 pagineSprinkCALC III Report2Khronos TempusNessuna valutazione finora

- Mack ValvesDocumento45 pagineMack ValvesSarbendu PaulNessuna valutazione finora

- "ADCATROL" TDS Blowdown Control Valves VPC SeriesDocumento3 pagine"ADCATROL" TDS Blowdown Control Valves VPC SeriesMuzakir Al ZakirNessuna valutazione finora

- G-104 One-Piece Ball Valve: Parts ListDocumento1 paginaG-104 One-Piece Ball Valve: Parts ListEnrique AssmannNessuna valutazione finora

- Eslon Catalog Eng (07.7-Ver2)Documento60 pagineEslon Catalog Eng (07.7-Ver2)Nguyễn Minh ĐứcNessuna valutazione finora

- INGM 427 Slides - 1 Pump Selection PDFDocumento20 pagineINGM 427 Slides - 1 Pump Selection PDFCornelius RheedersNessuna valutazione finora

- InducerDocumento54 pagineInducerYaswanthNessuna valutazione finora

- Form For Site Visit BN-12 (25!03!2014)Documento28 pagineForm For Site Visit BN-12 (25!03!2014)nadiraNessuna valutazione finora

- 938 GhidraulicaDocumento2 pagine938 GhidraulicaHenry Quisp100% (1)

- Technical Data Sheet D6..NL: Type OverviewDocumento4 pagineTechnical Data Sheet D6..NL: Type OverviewApetrii DoruNessuna valutazione finora

- DR-A1N1: Piping Material SpecificationDocumento5 pagineDR-A1N1: Piping Material Specificationshravan.office11Nessuna valutazione finora

- Module - 8 Lecture Notes - 2 Water Distribution SystemsDocumento7 pagineModule - 8 Lecture Notes - 2 Water Distribution Systemsপ্রিয়দীপ প্রিয়মNessuna valutazione finora

- ISO Valve StandardsDocumento4 pagineISO Valve StandardsLance NguyenNessuna valutazione finora

- Multi Hole DesignDocumento10 pagineMulti Hole DesignAlberto CorticelliNessuna valutazione finora

- 3.9 MM (Dia. 60 MM) 6 MM (Dia. 114 MM) 3.5 MM (Dia. 127 MM) 4.5 MM (Dia. 152 MM)Documento2 pagine3.9 MM (Dia. 60 MM) 6 MM (Dia. 114 MM) 3.5 MM (Dia. 127 MM) 4.5 MM (Dia. 152 MM)Sri HudiNessuna valutazione finora

- Overview Part 2Documento59 pagineOverview Part 2Kim NamjoonNessuna valutazione finora

- Jan 2006 Fluid FlowDocumento15 pagineJan 2006 Fluid Flownurfara39Nessuna valutazione finora

- Instructor:: AEM 313 Aerodynamics IDocumento3 pagineInstructor:: AEM 313 Aerodynamics Ialagarg137691Nessuna valutazione finora

- Conventional JacketsDocumento4 pagineConventional JacketskayeNessuna valutazione finora

- Line Sizing Criteria PDFDocumento8 pagineLine Sizing Criteria PDFwaelNessuna valutazione finora