Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Diode Failure Tlittler

Caricato da

dag570 valutazioniIl 0% ha trovato utile questo documento (0 voti)

66 visualizzazioni2 pagineGenerators

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoGenerators

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

66 visualizzazioni2 pagineDiode Failure Tlittler

Caricato da

dag57Generators

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

SCHOOL OF ELECTRICAL AND ELECTRONIC ENGINEERING

PROJECTS 2006 / 2007

Title: Identification of Bridge-Rectifier Diode Failure in a Brushless Alternator

Supervisor: Dr. Tim Littler

Moderator: Dr. D.J. Morrow

Areas: Power and Machines / Digital Signal Processing

Basic Specification:

The brushless AC generator (alternator) is in general use particularly for three-phase power generation. The brush-

less alternator dispenses with direct contact slip - rings, commutators, and brushes for field excitation. The absence of

excitation brushes means that contact wear and arcing (particularly at high-altitudes, as in aircraft power systems) is

eliminated.

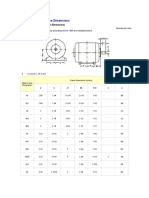

The brushless alternator is characterised by an integral AC field excitation system mounted on the rotor shaft adjacent

to the main field windings, Figure 1. The output stage comprises a rotating field exciting a stationary armature (stator)

that provides the alternators output power. The alternators output voltage is governed by control of the exciter field

using an automatic voltage regulator (AVR). The excitation for the rotating field comes from the rotating AC armature

(exciter) fitted to the main generator shaft. The exciter - armature AC output is rectified by shaft-mounted diodes and

fed to the main field in the machines output stage. A six-diode bridge is a common configuration for the AC rectifier.

Figure 1. Brushless alternator basic electrical schematic

The design of the exciter rectifier system must allow for a range of operating conditions, including; sudden load

change, load short-circuit, unbalanced phase loading, rectifier failure, field winding faults, and synchronism slacking or

total loss. Rectifier diodes must be chosen to take account of all conditions. A means of assessing the operating

condition of the rectifier-bridge diodes is important and, although not directly measurable, is achievable by non-invasive

monitoring of the exciter field, using a current transformer (CT).

This project will build on work developed in previous final year projects. The project will implement a real-time

technique for bridge rectifier diode failure in a brushless alternator.

The objectives of this project are to:

1. Understand the operation of the brushless alternator.

2. Acquire field excitation signals from a lab alternator for different load and fault conditions (single-diode

failure).

3. Examine abnormal excitation signals using wavelet analysis (and apply Fourier analysis to extract the failure

signature).

4. Develop real-time (rapid) detection of diode failure using a wavelet method.

5. Evaluate real-time detection using a lab-alternator under different load and fault conditions (for single diode

failure).

MEng Extensions

1. Determine the effect of multiple diode failure and methods of discriminating failure signatures from normal

load conditions.

2. Develop an algorithm to detect single and multiple diode failure under specified conditions.

As this is predominantly a software project, a student undertaking the project should be confident in the use of

computer programming languages, including C/C++ and Matlab M scripts.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Reiki AttunementManualDocumento36 pagineReiki AttunementManualtimsmith1081574100% (3)

- Minor Home Repair and Maintenance ManualDocumento55 pagineMinor Home Repair and Maintenance Manualdag57Nessuna valutazione finora

- River of Light Self AttunementDocumento3 pagineRiver of Light Self Attunementdag57100% (1)

- Masonry Chimney Maintenance / RepairDocumento2 pagineMasonry Chimney Maintenance / Repairdag57Nessuna valutazione finora

- Attunements of Reiki RyohoDocumento21 pagineAttunements of Reiki Ryohokoochimetal100% (3)

- Gardening TipsDocumento2 pagineGardening Tipsdag57Nessuna valutazione finora

- PM819 Vegetable GardeningDocumento4 paginePM819 Vegetable Gardeningdag57Nessuna valutazione finora

- Water Conservation TipsDocumento4 pagineWater Conservation Tipsdag57Nessuna valutazione finora

- X FDD TechDocumento2 pagineX FDD Techdag57Nessuna valutazione finora

- X FDD TechDocumento2 pagineX FDD Techdag57Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- DCNM - Wliion - Dicentis Battery PackDocumento3 pagineDCNM - Wliion - Dicentis Battery PackAndrew Halim RamadanNessuna valutazione finora

- jBASE Command LanguageDocumento137 paginejBASE Command LanguageVictor WoodrowNessuna valutazione finora

- Infineon-CE222306 - PSoC - 4 - I2C - Communication - With - Serial - Communication - Block - (SCB) - Code Example-V03 - 00-ENDocumento10 pagineInfineon-CE222306 - PSoC - 4 - I2C - Communication - With - Serial - Communication - Block - (SCB) - Code Example-V03 - 00-ENPiyush Kumar SahooNessuna valutazione finora

- Valentines Day - PPTMONDocumento28 pagineValentines Day - PPTMONZuzanna NowackaNessuna valutazione finora

- Compiler Design NCS-603 PDFDocumento3 pagineCompiler Design NCS-603 PDFEkansh GuptaNessuna valutazione finora

- PDF 1st Quarter Exam Empowerment TechDocumento3 paginePDF 1st Quarter Exam Empowerment Techlawrence100% (1)

- SIERRA CIRCULAR Bosch CS10 Circular SawDocumento40 pagineSIERRA CIRCULAR Bosch CS10 Circular Sawrenzo yauriNessuna valutazione finora

- STK1R-EN-61-0-A Rev0-1Documento98 pagineSTK1R-EN-61-0-A Rev0-1LudovicoNessuna valutazione finora

- Nema Electrical Motors FrameDocumento11 pagineNema Electrical Motors FrameLuckie IbrahimNessuna valutazione finora

- Ultipleat High Flow Series Filter Cartridges: DescriptionDocumento2 pagineUltipleat High Flow Series Filter Cartridges: DescriptionPillai S KumarNessuna valutazione finora

- Build EKS Cluster With Terraform. A Simple Infrastructure-As-Code Way - by Nico Singh - Sep, 2020 - ITNEXTDocumento19 pagineBuild EKS Cluster With Terraform. A Simple Infrastructure-As-Code Way - by Nico Singh - Sep, 2020 - ITNEXTaaaa100% (1)

- Paper Kajian Peran Cyber LawDocumento14 paginePaper Kajian Peran Cyber LawYopi MauminumNessuna valutazione finora

- L-Series Position Controller Rohs Compliant: Product Manual 35154 (Revision - , 07/2019)Documento74 pagineL-Series Position Controller Rohs Compliant: Product Manual 35154 (Revision - , 07/2019)CH MUBASHER MAQSOOD ALAMNessuna valutazione finora

- C-Bus Basics Training Manual - Vol 1Documento64 pagineC-Bus Basics Training Manual - Vol 1jakkyjeryNessuna valutazione finora

- UsbFix ReportDocumento2 pagineUsbFix ReportMUNEEB JAVEDNessuna valutazione finora

- NTE2389 Mosfet N CH, Enhancement Mode High Speed Switch TO220 Type PackageDocumento2 pagineNTE2389 Mosfet N CH, Enhancement Mode High Speed Switch TO220 Type PackagetoroalNessuna valutazione finora

- Cme Ordering GuideDocumento27 pagineCme Ordering GuideDavid EcheverriNessuna valutazione finora

- 3D People Counter API Introduction - EN - V1.6-1Documento8 pagine3D People Counter API Introduction - EN - V1.6-1Fernando A. García M.Nessuna valutazione finora

- Cryptography and Network Security: Seventh Edition by William StallingsDocumento34 pagineCryptography and Network Security: Seventh Edition by William StallingsvanithaNessuna valutazione finora

- Definition and Description: 6.1 Bench TerracesDocumento22 pagineDefinition and Description: 6.1 Bench Terracesshafiullah NaseriNessuna valutazione finora

- Stiff OdeDocumento25 pagineStiff OdeBereket HidoNessuna valutazione finora

- Deepija Telecom Pvt. LTD.: Omni Channel Contact Center SolutionDocumento28 pagineDeepija Telecom Pvt. LTD.: Omni Channel Contact Center SolutionSanjeev SinghNessuna valutazione finora

- The Journal of The Experimental Analysis of Behavior at FiftyDocumento15 pagineThe Journal of The Experimental Analysis of Behavior at FiftyNatália MarquesNessuna valutazione finora

- ISO-28591-2017 - PreviewDocumento13 pagineISO-28591-2017 - PreviewGuven MarangozNessuna valutazione finora

- Emerson Automation Solutions Process Systems and Solutions Product Support GuidelineDocumento6 pagineEmerson Automation Solutions Process Systems and Solutions Product Support Guidelineandres garciaNessuna valutazione finora

- ASB 2011 12 09 TCR Containment-1Documento3 pagineASB 2011 12 09 TCR Containment-1K MNessuna valutazione finora

- De VILBISSDocumento64 pagineDe VILBISSAlejandro NietoNessuna valutazione finora

- Mohammad Gufran Inst. Tech - MaintenanceDocumento3 pagineMohammad Gufran Inst. Tech - Maintenancerazaullahkhan37Nessuna valutazione finora

- Assignment 6Documento3 pagineAssignment 6Nicole ElominaNessuna valutazione finora

- Hearing Aid Amplification: Sandlin's Textbook ofDocumento10 pagineHearing Aid Amplification: Sandlin's Textbook ofAmit SinghNessuna valutazione finora