Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Honda 740 Codes - Torque Converter Forensics - Sonnax

Caricato da

Robert MoreauTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Honda 740 Codes - Torque Converter Forensics - Sonnax

Caricato da

Robert MoreauCopyright:

Formati disponibili

1/7/14 Honda 740 Codes: Torque Converter Forensics - Sonnax

sonnax.herokuapp.com/articles/40-Honda-740-Codes-Torque-Converter-Forensics 1/5

February, 2010

Honda 740 Codes: Torque Converter Forensics

Ed Lee

Many converter shops have reported having Honda converters returned to their shops because

of 740 codes. In most cases, the remedy was to install a new OE converter. This confirmed that

the code problem was due to an internal converter issue and not due to any valve body or other

nonconverter related problems. Finding the cause of the 740 codes became a priority and a Root

Cause Analysis (RCA) began. The first step of the RCA was to collect as many reportedly

"failed" units as possible. There were many returned units available, but at first, there was no

proven method for determining which converters were actually good and which were bad. The

traditional method used by most transmission shops is to test the holding power of the clutch

(ft-lb of torque) with 40 psi of air over ATF applied to the piston, to create the clamping force

(Figure 1).

When the "failed" units were tested with this method, they all tested good. A better test method

appeared to be in order. An equal number of known good converters were collected and

another series of tests were performed on the combined samples. This time, each unit was

tested by applying varying amounts air pressure/clamping force. The pressure used for the test

varied from 10 psi to 40 psi and was stepped up in 5 psi increments. When the tests were

completed, there was a clear division in the 20 to 25 psi range that separated the good

converters from the converters that had set a 740 code. Converters that previously tested good

at 40 psi were now failing in the lower pressure range.

1/7/14 Honda 740 Codes: Torque Converter Forensics - Sonnax

sonnax.herokuapp.com/articles/40-Honda-740-Codes-Torque-Converter-Forensics 2/5

An additional piece of information was also discovered during these tests. Converters with the

least amount of clamping force had the largest volume of oil escaping from the exhaust hose on

the test fixture. This proved that the poor clamping force was the result of an internal leak.

Leaking converters were cut open and inspected. There are three possible areas for the leaks to

occur. One is where the friction material of the TCC (torque converter clutch) piston mates to

the cover. Since a positive seal is possible in this area, the focus of the inspection moved to the

two areas where there is no provision for a positive seal. The other two areas (turbine shaft to

turbine hub and turbine hub to TCC piston) rely on the clearance between the mating parts to

establish their seal. The most likely area for the leak seemed to be between the turbine shaft and

the turbine hub, but to be certain, individual flow tests were performed on both areas on all

converters. The leak between the input shaft and turbine hub on all converters (both known

good and known bad) would flow between .2 gpm (gallons per minute) and .5 gpm. The leak

between the turbine hub and the piston, on the other hand, would flow .8 gpm to 4.5 gpm. This

leak was obviously a lot more severe.

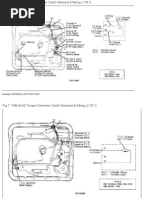

This test also explains why Honda started using a scarf cut PTFE seal in this area on its later

model converters. Since the diameters of the turbine hubs on the earlier and later model

converters were the same, it would be possible to use the later model seal if a groove could be

cut into the hardened surface of the earlier turbine hubs. To cut the groove a special tool was

fabricated from a carbide grooving tool. The end of the tool was cut off, rotated 90 degrees,

and re-welded (Figure 2).

The hardened surface turned out to be only a few thousands of an inch deep and the hub

1/7/14 Honda 740 Codes: Torque Converter Forensics - Sonnax

sonnax.herokuapp.com/articles/40-Honda-740-Codes-Torque-Converter-Forensics 3/5

machined easily. Figure 3 shows a turbine hub after the groove is cut (left), and the same hub

with the late model seal installed (right).

The ultimate test was to put this converer into a vehicle with a 740 code. To date, the converters

with the added sealing ring have a 100% success rate. The folks at Consolidated Vehicle

Converters of Kettering, Ohio used an o-ring from a GM 245mm converter for its seal. Their

converter tested best of the lot on the lockup clutch test fixture (holding over 150 ft-lb of torque

at 20 psi) (Figure 4).

You may be wondering why 20-25 psi was the sweet spot for testing the Honda converters,

rather than the 40 psi that worked on other units. Honda does not use the typical two-path

apply and release circuit that is used in the 4R100, 4L60-E, 5R55E, and many other applications

Instead, it uses a three-path oil circuit that incorporates a converter bypass valve like the circuits

found in some front wheel drive Fords; eg. CD4E, AX4N, and AX4S. For this reason the circuit

is especially sensitive to outside variables such as restricted coolers and cross leaks. A restriction

in the cooler circuit will cause the torque converter check valve to open, which reduces apply

pressure. If the cooler circuit becomes more restricted, it will react on the valve and may

position some valves in a partially stroked position.

Honda converter charge oil comes from the charge oil circuit of the main regulator valve. With

this design, charge pressure is often only half of what line pressure would be. This is why the

lockup clutches of the Honda converters need to be tested at 20 to 25 psi instead of the 40 psi

that is used on other units.

By adding the groove and seal, converter builders are able to not only rebuild the unit, they are

providing their customers a converter that is an improvement over the original early design.

Even though the seal cured the test converters, some of the late model Odyssey converters that

already have the OE seal, still have lockup problems. The problem with these converters has

turned out to be a clearance issue.

1/7/14 Honda 740 Codes: Torque Converter Forensics - Sonnax

sonnax.herokuapp.com/articles/40-Honda-740-Codes-Torque-Converter-Forensics 4/5

In the past, converter technicians who were removing the bearing from the front of the 4R100

turbine hubs to make the clutches apply like the E4OD converters learned that .080" to .090"

clearance was necessary between the hub and cover. That same clearance is needed for most of

the converters that use the E4OD style stack up. The bottom line is that you need sufficient

clearance to allow the piston and/or hub to come to a complete stop on lockup apply before

contact is made with the cover. When GM 's testing proved that the piston was stopped before

it contacted the cover on the early 245 and 298mm converters, they reasoned that it was safe to

remove the friction material stops near the I.D. of those TCC pistons. Some Honda converters

have as little as .045" clearance between the piston and the bearing that rests in the cover. Any

machining of the clutch apply surface on the cover or clutch bonding surface on the piston will

make this clearance even less. Figure 5 shows the proper clearance between the piston and

bearing race. The outer bearing race normally protrudes out of the cover about .030". If the

piston comes into contact with the outer bearing race before the piston comes to a complete stop

during lockup apply, it will rotate the race in the cover. On occasion the rotation of the race will

recess the race down to a point that the top will be flush with the cover. This will affect both the

overall height and clutch release clearance of the converter. To get the piston to bearing

clearance to the proper tolerance, measure the clearance between the piston and bearing outer

race, then machine the front of the piston at the I.D. It is usually only necessary to remove about

.030" to .040".

Ed Lee is a Sonnax Technical Specialist who writes on issues of interest to torque converter

rebuilders. Sonnax supports the Torque Converter Rebuilders Association.

Related Unit(s)

B36A/P36A, Odyssey 07-09

B7TA, B7VA, B7YA

BGRA/PGRA, Odyssey '05-'07

MPYA

1/7/14 Honda 740 Codes: Torque Converter Forensics - Sonnax

sonnax.herokuapp.com/articles/40-Honda-740-Codes-Torque-Converter-Forensics 5/5

While Sonnax makes every effort to ensure the accuracy of technical articles at time of

publication, we assume no liability for inaccuracies or for information which may become outdated

or obsolete over time.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- 6L80E ManualDocumento6 pagine6L80E ManualLeysser Josue67% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- A440FDocumento49 pagineA440FRobert Moreau100% (6)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- 7-Speed 0am VW TrainingDocumento15 pagine7-Speed 0am VW Trainingeddix96% (26)

- Mazda MX-5 Miata New Model Training USADocumento228 pagineMazda MX-5 Miata New Model Training USARobert MoreauNessuna valutazione finora

- B7TA Hydraulics and Principal of OperationDocumento57 pagineB7TA Hydraulics and Principal of OperationRobert Moreau100% (8)

- Vaccum Testing Info SonnaxDocumento34 pagineVaccum Testing Info SonnaxRobert Moreau100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- OB5 Transmission InfoDocumento98 pagineOB5 Transmission InfoRobert Moreau95% (21)

- 286 Ho 722.9 062504Documento79 pagine286 Ho 722.9 062504arkhom196% (28)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- ZF 6HP26 Spare PartsDocumento19 pagineZF 6HP26 Spare PartsOctavian RosuNessuna valutazione finora

- 4L60E Lasy Solenoid CommandDocumento2 pagine4L60E Lasy Solenoid CommandRobert MoreauNessuna valutazione finora

- DSG Dual Clutch GearboxDocumento35 pagineDSG Dual Clutch GearboxKunal Bachhav100% (13)

- RE0F08ADocumento182 pagineRE0F08ARobert Moreau100% (2)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- CX-7 Transmission ManualDocumento186 pagineCX-7 Transmission Manualeric100% (2)

- Massey-Harris Pony Shop Manual: Adjust Front Axle, Steering Knuckles, LinkageDocumento18 pagineMassey-Harris Pony Shop Manual: Adjust Front Axle, Steering Knuckles, LinkageRobert MoreauNessuna valutazione finora

- Biraogo vs. Philippine Truth CommissionDocumento3 pagineBiraogo vs. Philippine Truth CommissionJulesMillanarNessuna valutazione finora

- 05 - SMG IiiDocumento25 pagine05 - SMG IiiRobert MoreauNessuna valutazione finora

- 7-Speed Dual Clutch Gearbox 0AMDocumento127 pagine7-Speed Dual Clutch Gearbox 0AMEduardo Yagüe Gomez94% (16)

- Apartment: TerminologyDocumento19 pagineApartment: TerminologyMahlet AdugnaNessuna valutazione finora

- Corteco 2010 Pocket Guide v20Documento72 pagineCorteco 2010 Pocket Guide v20Ricardo Godoy Muñoz50% (4)

- Annotation On Locus Standi 548 Scra 519Documento4 pagineAnnotation On Locus Standi 548 Scra 519Imee CallaoNessuna valutazione finora

- 90 Cameron Granville V ChuaDocumento1 pagina90 Cameron Granville V ChuaKrisha Marie CarlosNessuna valutazione finora

- CFT30 Assembling PumpDocumento1 paginaCFT30 Assembling PumpRobert MoreauNessuna valutazione finora

- Transmission Digest 2015-02Documento60 pagineTransmission Digest 2015-02Robert MoreauNessuna valutazione finora

- 02EDocumento1 pagina02ERobert MoreauNessuna valutazione finora

- 32RH HydraulicsDocumento10 pagine32RH HydraulicsRobert MoreauNessuna valutazione finora

- 1993 Plymouth Acclaim Transmission DiagramsDocumento8 pagine1993 Plymouth Acclaim Transmission DiagramsRobert Moreau0% (1)

- 700 TCC Wiring DiagramsDocumento7 pagine700 TCC Wiring DiagramsRobert MoreauNessuna valutazione finora

- RE5R05A 2-3 Chatter ATRADocumento9 pagineRE5R05A 2-3 Chatter ATRARobert MoreauNessuna valutazione finora

- Energy Fuels Inc Denison Mines 21Documento6 pagineEnergy Fuels Inc Denison Mines 21Robert MoreauNessuna valutazione finora

- Zip Kit BookletDocumento8 pagineZip Kit BookletRobert MoreauNessuna valutazione finora

- Us 6308125Documento13 pagineUs 6308125Robert MoreauNessuna valutazione finora

- OD Shim MeasurementDocumento4 pagineOD Shim MeasurementRobert MoreauNessuna valutazione finora

- GM Say NO To FlushDocumento5 pagineGM Say NO To FlushRobert MoreauNessuna valutazione finora

- Mutual Fund Industry Study - Final BEDocumento45 pagineMutual Fund Industry Study - Final BEPrerna KhoslaNessuna valutazione finora

- Vol. 499, August 28, 2006 - Supreme Court Rules on Father's Obligation to Support Children Despite Lack of Formal DemandDocumento10 pagineVol. 499, August 28, 2006 - Supreme Court Rules on Father's Obligation to Support Children Despite Lack of Formal DemandPMVNessuna valutazione finora

- PARAMUS ROAD BRIDGE DECK REPLACEMENT PROJECT SPECIFICATIONSDocumento156 paginePARAMUS ROAD BRIDGE DECK REPLACEMENT PROJECT SPECIFICATIONSMuhammad irfan javaidNessuna valutazione finora

- People Vs PalmaDocumento3 paginePeople Vs PalmaNunugom SonNessuna valutazione finora

- City Limits Magazine, January 1991 IssueDocumento24 pagineCity Limits Magazine, January 1991 IssueCity Limits (New York)Nessuna valutazione finora

- Joseph S. Nye JR 1974Documento24 pagineJoseph S. Nye JR 1974joaoNessuna valutazione finora

- NBIMS-US V3 2.4.4.7 OmniClass Table 31 PhasesDocumento8 pagineNBIMS-US V3 2.4.4.7 OmniClass Table 31 Phasesmahmoud mokhtarNessuna valutazione finora

- Magnolia Dairy Products Corporation v. NLRC, G.R. No. 114952, January 29, 1996Documento3 pagineMagnolia Dairy Products Corporation v. NLRC, G.R. No. 114952, January 29, 1996Katrina Pamela AtinNessuna valutazione finora

- Abhivyakti Yearbook 2019 20Documento316 pagineAbhivyakti Yearbook 2019 20desaisarkarrajvardhanNessuna valutazione finora

- Civil Appeal 14 of 2015Documento21 pagineCivil Appeal 14 of 2015JamesNessuna valutazione finora

- Test FAR 570 Feb 2021Documento2 pagineTest FAR 570 Feb 2021Putri Naajihah 4GNessuna valutazione finora

- City Limits Magazine, August/September 1991 IssueDocumento24 pagineCity Limits Magazine, August/September 1991 IssueCity Limits (New York)Nessuna valutazione finora

- v2.6 CCURE Simplex Integration RN 8200-1191-99A0Documento5 paginev2.6 CCURE Simplex Integration RN 8200-1191-99A0Rafael RojasNessuna valutazione finora

- Product CAT RSTI SA - DatasheetDocumento9 pagineProduct CAT RSTI SA - Datasheetvikivarma147Nessuna valutazione finora

- Premachandra and Dodangoda v. Jayawickrema andDocumento11 paginePremachandra and Dodangoda v. Jayawickrema andPragash MaheswaranNessuna valutazione finora

- 2020.11.30-Notice of 14th Annual General Meeting-MDLDocumento13 pagine2020.11.30-Notice of 14th Annual General Meeting-MDLMegha NandiwalNessuna valutazione finora

- CAF608833F3F75B7Documento47 pagineCAF608833F3F75B7BrahimNessuna valutazione finora

- Assignment By: R.AishwaryaDocumento22 pagineAssignment By: R.Aishwaryashrikant rai100% (1)

- Online Tax Payment PortalDocumento1 paginaOnline Tax Payment Portalashish rathoreNessuna valutazione finora

- Cins Number DefinitionDocumento3 pagineCins Number DefinitionJohnny LolNessuna valutazione finora

- Akmal - Assignment On Thinking SkillsDocumento9 pagineAkmal - Assignment On Thinking SkillsChew Cheng HaiNessuna valutazione finora

- Teori Relativitas. Bahasa Inggris - CompressedDocumento189 pagineTeori Relativitas. Bahasa Inggris - CompressedDinda VidyaNessuna valutazione finora

- Characteristics of SovereigntyDocumento9 pagineCharacteristics of SovereigntyVera Mae RigorNessuna valutazione finora

- Bagatsing V RamirezDocumento3 pagineBagatsing V RamirezAnonymous iOYkz0wNessuna valutazione finora

- Affirmative Action in India: Ensuring Equality and Social JusticeDocumento11 pagineAffirmative Action in India: Ensuring Equality and Social JusticeDeepa MoondraNessuna valutazione finora

- Cornell Notes Financial AidDocumento3 pagineCornell Notes Financial AidMireille TatroNessuna valutazione finora