Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Synthesis of Sno Nano Rods and Their Photocatalytic Properties

Caricato da

Lai van CuongDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Synthesis of Sno Nano Rods and Their Photocatalytic Properties

Caricato da

Lai van CuongCopyright:

Formati disponibili

A

R

T

I

C

L

E

Copyright 2013 by American Scientic Publishers

All rights reserved.

Printed in the United States of America

Journal of Nanoengineering and Nanomanufacturing

Vol. 3, pp. 15, 2013

(www.aspbs.com/jnan)

Synthesis of SnO

2

Nano Rods and

Their Photocatalytic Properties

Jagannath M. Mali, Sudhir S. Arbuj, Jalindar D. Ambekar,

Sunit B. Rane, Uttamrao P. Mulik, and Dinesh P. Amalnerkar

Centre for Materials for Electronics Technology, Off Pashan Road, Panchawati, Pune 411008, India

ABSTRACT

Ultra thin single crystalline SnO

2

nano rods were synthesized using a novel template free chemical method.

The prepared SnO

2

nano rods were characterized using uv-visible and photoluminescence spectroscopy, BET,

XRD, FE-SEM and TEM analysis techniques. The broad XRD peak conrms the formation of nano crystalline

SnO

2

having tetragonal crystal structure. PL spectra exhibit the broad emission peak at 365 nm corresponding

to the band edge excitation. FE-SEM indicates the formation of SnO

2

nanostructures having size less than

10 nm. TEM conrms the formation of rod like morphology having diameter 41 nm and length around 6 to

10 nm. The observed BET surface area for the SnO

2

nanorods is 134 m

2

/gm and this higher surface area

exhibits excellent ability to remove organic pollutant from wastewater by enormous surface adsorption. The

photocatalytic activity of prepared SnO

2

was studied by observing the degradation of aqueous methylene blue

(MB) dye. The rate constant observed for photocatalytic MB degradation using SnO

2

was 5.410

2

min

1

. The

photocatalytic activity was compared with P-25 degussa TiO

2

under same reaction conditions.

KEYWORDS: Tin Oxide, Photocatalysis, Dye Degradation, Methylene Blue.

1. INTRODUCTION

As an important member in the family of wide-band

gap semiconductors, tin dioxide (SnO

2

) has been exten-

sively investigated due to their unique properties and novel

applications.

1

SnO

2

is having band gap of 3.6 eV, it is used

for gas sensors, optical sensors and photoconductors.

2, 3

At the same time, it has been widely used in photo-

catalysis, optoelectronic devices, lithium batteries, solar

cells and eld effect transistors.

47

Many studies have

proven that change in size, shape and morphologies greatly

enhances the optoelectronic properties of SnO

2

.

810

Partic-

ularly, one-dimensional (1D) nanostructures exhibit inter-

esting optoelectronic properties, associated with directional

mobility of charge carrier, a large aspect ratio, and the

quantum connement effect. Also two and three dimen-

sional (2D, 3D) such as sheets and hierarchical nano archi-

tectures exhibit unique properties different from those 1D

structures due to their complicated structures.

1113

In order

to synthesize desired morphology, variety of physical and

chemical methods such as chemical vapor deposition,

physical vapor deposition, solgel, combustion, hydrother-

mal and solvothermal techniques have been used.

1418

Utilizing these methods considerable effort has been

Author to whom correspondence should be addressed.

Email: amalnerkar@cmet.gov.in

Received: xx Xxxx Xxxx

Accepted: xx Xxxx Xxxx

devoted to fabricate various SnO

2

nanostructures includ-

ing nanorods, nanowires, nanobelts, nanosheets, hierarchi-

cal nanostructures and so on.

1923

However most of the

physical techniques require complicated controlling pro-

cesses which are unfavorable for inexpensive and large

scale synthesis. Therefore, it is of great importance and

necessity to develop a technique to synthesize SnO

2

under

ambient reaction conditions. However, the development of

template and surfactant-free low temperature routes for

the synthesis of ultrathin SnO

2

single crystalline nanorods

remains a challenge. For this purpose, hydrothermal is well

suited for synthesis of nanostructure materials, because

of its relatively low processing cost, much milder reac-

tion conditions and the ability to control the grain size.

In this study, we have synthesized SnO

2

nanorods using

hydrothermal method. The synthesized SnO

2

nanostructure

was characterized using different spectroscopic techniques.

The photocatalytic activity was evaluated by following the

degradation methylene blue (MB).

2. EXPERIMENTAL DETAILS

2.1. Synthesis of SnO

2

Nanostructures

In a typical synthesis, 10 mmol of stannic(IV) chloride

hydrated (SnCl

4

5H

2

O, Sigma-Aldrich), was dissolved in

a mixture of 30 mL of ethanol and 10 mL of deionized

(DI) water, these mixture was stirred for 5 min at room

temperature. To the above solution 0.7 g of NaOH was

J. Nanoeng. Nanomanuf. 2013, Vol. 3, No. 2 2157-9326/2013/3/001/005 doi:10.1166/jnan.2013.1116 1

Synthesis of SnO

2

Nano Rods and Their Photocatalytic Properties Mali et al.

A

R

T

I

C

L

E

slowly added with constant stirring. After 10 min vigorous

stirring the mixture was transferred to teon lined auto-

clave, sealed and then heated in an oven at 160

C for 24 h.

The obtained product was washed several times with DI

water and dried at 50

C in oven. The dried powder was

grinded in an agate mortar and pestle and used for further

studies.

2.2. Characterization

The X-ray powder diffraction (XRD) pattern of the syn-

thesized material was recorded on Bruker AXS model

D-8, (10 to 70

range, scan rate = 1

min

1

) equipped

with a monochromator and Ni-ltered Cu Ko radiation.

Crystallite size was calculated using the Scherrers for-

mula, J =0.9\,Bcos 0 where \ is the incident wavelength

(Cu Ko = 1.5406 ), p is the full width at half max-

imum (FWHM) of the corresponding diffraction peaks,

and 0 is the angle of reection. Diffuse reectance UV-

Visible absorbance spectra was recorded using Shimazu

UV-Vis-NIR spectrophotometer (Model UV-3600) over a

wavelength range of 200 to 800 nm. The photolumines-

cence analysis was performed on shimadzu (RF-5301 PC)

spectrophotometer. The BET surface area was calculated

from the N

2

adsorption isotherms of the samples at liquid

N

2

temperature using Quantachrome NOVA-1200 instru-

ment. The morphological characterization of the samples

was performed on HITACHI S-4800. Transmission Elec-

tron micrographs were performed using Technai 20 G2

(FEI, Netherlands) microscope operating at 200 kV.

2.3. Photocatalytic Activity Study

For the evaluation of photocatalytic activity, 50 mg of pow-

dered SnO

2

was suspended in a 100 ml of aqueous MB

solution (10 ppm MB, pH = 7) in a 250 ml conical ask

and stirred for 15 min in dark at room temperature. Then

the mixture was continuously stirred under 400 W mer-

cury lamp irradiation in closed box. The mercury vapour

lamp was kept vertically in the quartz tube, provided with

the water circulation arrangement in order to minimize the

heating effect due to IR radiation. At regular intervals of

time, aliquots of aqueous solution were taken from the

ask, centrifuged and the UV-visible absorption spectrum

of clear solution was recorded using a double beam spec-

trophotometer. The decrease in the absorbance value at

664 nm wavelength, corresponding to the typical peak for

the absorption spectra of MB, was utilized to determine

the extent of degradation of MB and the photocatalytic

acitivity of the sample with respect to irradiation time.

3. RESULTS AND DISCUSSION

3.1. X-Ray Diffraction Analysis

The powder XRD pattern of the synthesized SnO

2

nano-

structures is shown in Figure 1. The diffraton peaks at

Fig. 1. X-ray diffraction of SnO

2

nanostructure.

20 =26.6, 33.9, 37.9, 51.8, 54.7, 57.8, 61.8 and 65.9

cor-

responds to the hkl planes of (110), (101), (200), (211),

(220), (002), (310) and (301), can be readily indexed

to a tetragonal structure of SnO

2

(JCPDS Card File

No. 41-1445) respectively. The broad and intense diffrac-

tion peaks suggest the formation of highly crystalline nano

sized SnO

2

material. The crystallite size calculated using

Scherrers formula was found to be around 4 nm.

3.2. UV-Visible and Photoluminescence Analysis

The UV-visible and diffuse reectance absorbance spec-

trum of SnO

2

nanorods was measured and the result is

depicted in Figure 2. The absorbance at 280 nm indicates

the formation of nano sized SnO

2

(bulk SnO

2

350 nm). The

blue shift conrms the quantum connement effect. DRS

shows the absorbtion edge around 360 nm corresponds

to the band gap 3.4 eV. The maximum absorbance is

observed at 280 nm in liquid as well as solid UV-Visible

absorbance spectra. The photoluminescence spectrum is

shown in Figure 3. For this purpose the SnO

2

powder was

dispersed in DI water and the spectra were recorded at

the excitation wavelength of 250 nm. The emission peak

observed at 365 nm can be attributed to the near band edge

emission. The other emission peaks were not observed

Fig. 2. UV-Visible and diffuse reectance absorbance spectra of SnO

2

nanostructure.

2 J. Nanoeng. Nanomanuf., 3, 15, 2013

Mali et al. Synthesis of SnO

2

Nano Rods and Their Photocatalytic Properties

A

R

T

I

C

L

E

Fig. 3. Photoluminescence spectra of SnO

2

nanostructure.

at 250 nm excitation wavelength conrming formation of

defect free SnO

2

nanorods.

3.3. FE-SEM and TEM Analysis

The morphology and structure of SnO

2

nano structure

were further investigated by FESEM and TEM analysis.

FE-SEM images are depicted in Figure 4 which indicates

Fig. 4. FE-SEM micrographs of SnO

2

.

Fig. 5. TEM micrographs of SnO

2

nanostructures, inset of (a) is

HRTEM of SnO

2

and inset of (b) is SAED pattern of SnO

2

.

J. Nanoeng. Nanomanuf., 3, 15, 2013 3

Synthesis of SnO

2

Nano Rods and Their Photocatalytic Properties Mali et al.

A

R

T

I

C

L

E

the uniformly distributed SnO

2

nanoparticles having size

below 10 nm. TEM conrms the formation of rod like

morphology having size in the range of 36 nm (Fig. 5).

The high resolution images clearly shows inter planar

spacing of 0.25 nm matching with (101) h, k, I plane of

tetragonal SnO

2

structure (inset of Fig. 5(a)). The SAED

pattern shown in the inset of Figure 5(b) conrms the

crystalline nature of SnO

2

nanoparticles and calculated J

values supports the XRD results.

3.4. Photocatalytic Activity

The photocatalytic activity of SnO

2

nanorods was mea-

sured by following the degradation of 10 ppm MB solu-

tion under 400 W mercury vapor lamp. The decrease in

the absorbance of MB with irradiation time is plotted in

Figure 6(a). The 93% of MB degradation was observed

using SnO

2

nanorods in 1 hrs of irradiation time. The

photocatalytic acitivity of SnO

2

was compared with P-25

degussa TiO

2

. P-25 TiO

2

showed higher activity than that

of the synthesized SnO

2

nanostructure. The reason for

lower photocatalytic acitivity of SnO

2

is due its higher

band gap as compare to TiO

2

. As the photocatalytic dye

degradation follows pseudo rst order kinetics and in good

(b)

(a)

Fig. 6. (a) Photocatalytic degradation of MB using SnO

2

catalyst.

(b) Graph of ln C

o

,C

t

versus Irradiation time.

agreement with Langmuir-Hinshelwood equation.

24, 25

For

activity comparison, the plot of ln C

0

,C

t

versus irradia-

tion time are plotted. The slope of the graph indicates the

apparent rate constant. The plot of ln C

0

,C versus irradi-

ation time (shown in Fig. 6(b)) indicates the pseudo rst

order kinetic and observed apparent rate constant for MB

degradation using SnO

2

and P-25 TiO

2

are 5.410

2

and

11.2 10

2

respectively. Means the acitivity of SnO

2

is

almost half than that of P-25 TiO

2

, though the activity of

SnO

2

is lower it provides an alternative catalyst for envi-

ronmental remidiation.

4. CONCLUSIONS

We have successfully synthesized SnO

2

nanorods and

nanoparticles using hydrothermal synthesis technique.

Formation of tetragonal phase was conrmed by XRD

analysis. The UV-visible absorbance and PL analysis indi-

cate absorbance and emission peaks at 280 and 365 nm

respectively. TEM indicates the formation of rod like mor-

phology having size 36 nm. The rate constant observed

for photocatalytic MB degradation using SnO

2

was 5.4

10

2

min

1

. To summarise SnO

2

can be utilized as an

alternative catalyst for MB degradation.

Acknowledgments: One of the author Jagannath M.

Mali would like to thank University Grant Commission,

New Delhi, India, for nancial support and Dr. B. B. Kale,

C-MET, Pune for useful discussion.

References and Notes

1. J. S. Lee, S. K. Sim, B. Min, K. Cho, S. W. Kim, and S. Kim,

J. Cryst. Growth 267, 145 (2004).

2. E. R. Leite, I. T. Weber, E. Longo, and J. A. Varela, Adv. Mater.

12, 966 (2000).

3. J. W. Jeong, J. W. Huh, J. I. Lee, H. Y. Chu, J. J. Pak, and B. K. Ju,

Thin Solid Films 518, 6343 (2010).

4. Z. Y. Tang, Z. L. Zhang, Y. Wang, S. C. Glotzer, and N. A. Kotov,

Science 314, 274 (2006).

5. H. B. Wu, J. S. Chen, X. W. Lou, and H. H. Hng, J. Phys. Chem. C

115, 24605 (2011).

6. D. N. Srivastava, S. Chappel, O. Palchik, A. Zaban, and

A. Gedanken, Langmuir 18, 4160 (2002).

7. J. Sun and Q. X. Tang, Nanotechnology 20, 255202 (2009).

8. Y. Wang and J. Y. Lee, Angew. Chem. Int. Edn. 45, 7039 (2006).

9. H. Huang, Y. C. Lee, O. K. Tan, W. Zhou, N. Peng, and Q. Zhang,

Nanotechnology 20, 115501 (2009).

10. N. H. Zhao, G. J. Wang, Y. Huang, B. Wang, B. D. Yao, and Y. P.

Wu, Chem. Mater 20, 2612 (2008).

11. C. Li, J. Yang, P. Yang, X. Zhang, and H. Lian, J. Lin. Cryst. Growth

Des. 8, 923 (2008).

12. F. Cao, W. Shi, L. Zhao, S. Song, J. Yang, Y. Lei, and H. Zhang,

J. Phys. Chem. C 112, 17095 (2008).

13. Y. Shao, J. Sun, and L. Gao, J. Phys. Chem. C 113, 6566 (2009).

14. C. Cross, J. Hemminger, and R. Penner, Langmuir 23, 10372 (2007).

15. M. Driess, K. Merz, R. Schoenen, S. Rabe, F. E. Kruis, A. Roy,

A. Birkner, and C. R. Chimie, 6, 273 (2003).

16. G. Wu, L. Zhang, B. Cheng, T. Xie, and X. Yuan, J. Am. Chem. Soc.

12, 5976 (2004).

4 J. Nanoeng. Nanomanuf., 3, 15, 2013

Mali et al. Synthesis of SnO

2

Nano Rods and Their Photocatalytic Properties

A

R

T

I

C

L

E

17. X. Wang and Y. Li, J. Am. Chem. Soc. 124, 2880 (2002).

18. K. Anandan and V. Rajendran, Journal of Non-Oxide Glasses 2, 83

(2010).

19. X. Y. Kong, Y. Ding, R. S. Yang, and Z. L. Wang, Science 303, 1348

(2004).

20. L. Manna, E. C. Scher, and A. P. Alivisatos, J. Am. Chem. Soc.

122, 12700 (2000).

21. G. Z. Shen and D. J. Chen, Mater. Chem. 20, 10888 (2011).

22. C. Wang, Y. Zhou, M. Ge, X. Xu, Z. Zhang, and J. Z. Jiang, J. Am.

Chem. Soc. 46, 132 (2010).

23. J. Kang, Q. Kuang, Z. Xie, and L. Zheng, J. Phys. Chem. C

115, 7874 (2011).

24. S. Chakrabarti and B. K Dutta, J. Hazard. Mater. 112, 269

(2004).

25. I. K. Konstantinou and T. A. Albanis, Applied Catalysis B: Environ-

mental 49, 1 (2004).

J. Nanoeng. Nanomanuf., 3, 15, 2013 5

Potrebbero piacerti anche

- Ban 2015Documento11 pagineBan 2015Septian Perwira YudhaNessuna valutazione finora

- Articles: Photoluminescence Properties of Sno Nanoparticles Synthesized by Sol-Gel MethodDocumento5 pagineArticles: Photoluminescence Properties of Sno Nanoparticles Synthesized by Sol-Gel MethodVikas PatilNessuna valutazione finora

- Tin OxidationDocumento7 pagineTin Oxidationsunny kumarNessuna valutazione finora

- Aquier 2018Documento22 pagineAquier 2018William CárdenasNessuna valutazione finora

- Bhuvaneswari Et Al., 2020Documento5 pagineBhuvaneswari Et Al., 2020ASTRID BARCO TULANDENessuna valutazione finora

- Sol-gel synthesis of ZnO/rGO thin film for enhanced photoelectrochemical water splittingDocumento18 pagineSol-gel synthesis of ZnO/rGO thin film for enhanced photoelectrochemical water splittingchtououNessuna valutazione finora

- Pulsed Laser Ablation of Tin Oxide NanoparticlesDocumento9 paginePulsed Laser Ablation of Tin Oxide NanoparticlesAli KhumaeniNessuna valutazione finora

- Effect of 1-Thioglycerol As Capping Agent On ZNS Nanoparticles: Structural and Optical CharacterizationDocumento4 pagineEffect of 1-Thioglycerol As Capping Agent On ZNS Nanoparticles: Structural and Optical CharacterizationInternational Journal of Science and Engineering InvestigationsNessuna valutazione finora

- Synthesis, Characterization and Optical Properties of Zinc Oxide NanoparticlesDocumento6 pagineSynthesis, Characterization and Optical Properties of Zinc Oxide NanoparticlesSyahmi NordinNessuna valutazione finora

- Visible Emission From Zno Nanorods Synthesized by A Simple Wet Chemical MethodDocumento10 pagineVisible Emission From Zno Nanorods Synthesized by A Simple Wet Chemical MethodKenn SenadosNessuna valutazione finora

- 1026chuah LsDocumento4 pagine1026chuah LsSoufianeBenhamidaNessuna valutazione finora

- Sonochemical and Microwave-Assisted Synthesis of Linked Single-Crystalline Zno RodsDocumento6 pagineSonochemical and Microwave-Assisted Synthesis of Linked Single-Crystalline Zno RodssecateNessuna valutazione finora

- Optical MaterialsDocumento9 pagineOptical MaterialsAmrita PalaiNessuna valutazione finora

- You and Your Family, Oct 2011Documento5 pagineYou and Your Family, Oct 2011emediageNessuna valutazione finora

- Journal of Luminescence: Monika Mall, Lokendra KumarDocumento6 pagineJournal of Luminescence: Monika Mall, Lokendra KumarAzie AzuraNessuna valutazione finora

- Synthesis of Zinc Oxide Nanoparticles VIDocumento10 pagineSynthesis of Zinc Oxide Nanoparticles VIHarden PatilNessuna valutazione finora

- The Effect of Synthesis Pressure On Properties of Eu-Doped Zno Nanopowders Prepared by Microwave Hydrothermal MethodDocumento4 pagineThe Effect of Synthesis Pressure On Properties of Eu-Doped Zno Nanopowders Prepared by Microwave Hydrothermal MethodJarosław KaszewskiNessuna valutazione finora

- Green synthesis of ZnO nanoparticles via plant extractDocumento4 pagineGreen synthesis of ZnO nanoparticles via plant extractClaudia UngureanuNessuna valutazione finora

- Applied Surface Science: M.A. Gondal, Q.A. Drmosh, Z.H. Yamani, T.A. SalehDocumento7 pagineApplied Surface Science: M.A. Gondal, Q.A. Drmosh, Z.H. Yamani, T.A. Salehsgc17Nessuna valutazione finora

- Nagara Ju 2017Documento6 pagineNagara Ju 2017AliNessuna valutazione finora

- ZnO Nanorods Optical PropertiesDocumento5 pagineZnO Nanorods Optical PropertiesAndress GuzmanNessuna valutazione finora

- Synthesis and Luminescence Properties of SnO2 NanoparticlesDocumento4 pagineSynthesis and Luminescence Properties of SnO2 Nanoparticlesivan benayaNessuna valutazione finora

- Study of Different Capping Agents Effect On The Structural and Optical Properties of MN Doped ZNS NanostructuresDocumento5 pagineStudy of Different Capping Agents Effect On The Structural and Optical Properties of MN Doped ZNS NanostructuresTI Journals PublishingNessuna valutazione finora

- Electrospun PAN/2D MoS2 Nanofibers: Synthesis and CharacterizationDocumento5 pagineElectrospun PAN/2D MoS2 Nanofibers: Synthesis and CharacterizationAlberto GaxiolaNessuna valutazione finora

- Antibacterial and Photocatalytic Properties of Ag/Tio /zno Nano - Owers Prepared by Facile One-Pot Hydrothermal ProcessDocumento8 pagineAntibacterial and Photocatalytic Properties of Ag/Tio /zno Nano - Owers Prepared by Facile One-Pot Hydrothermal ProcessDaniel ReyesNessuna valutazione finora

- Mani 2018Documento8 pagineMani 2018ASTRID BARCO TULANDENessuna valutazione finora

- Dielectric Properties of MN Doped Zno Nanostructures: S. Ajin Sundar, N. Joseph JohnDocumento4 pagineDielectric Properties of MN Doped Zno Nanostructures: S. Ajin Sundar, N. Joseph JohnerpublicationNessuna valutazione finora

- Optical Properties of SnO2 QDs-Muy Bueno-Paper India.Documento5 pagineOptical Properties of SnO2 QDs-Muy Bueno-Paper India.Paul Wilbert Alvarado AnampaNessuna valutazione finora

- ZNO Nanoparticles 2Documento9 pagineZNO Nanoparticles 2Chirag SheokandNessuna valutazione finora

- Raman y GapDocumento6 pagineRaman y GapZait ACNessuna valutazione finora

- Paper 21Documento6 paginePaper 21Emon AzharNessuna valutazione finora

- N.BANSAL, GC MOHANTA, K SiNGH, CERAM INT. 43 (2017) 7193-7201Documento9 pagineN.BANSAL, GC MOHANTA, K SiNGH, CERAM INT. 43 (2017) 7193-7201Neetu BansalNessuna valutazione finora

- Effect of Porosity On The Absorbed, Reemitted and Transmitted Light by A Geopolymer Metakaolin BaseDocumento4 pagineEffect of Porosity On The Absorbed, Reemitted and Transmitted Light by A Geopolymer Metakaolin BasekhoagleNessuna valutazione finora

- High Sensitivity of Porous Cu-Doped Sno Thin Films To MethanolDocumento9 pagineHigh Sensitivity of Porous Cu-Doped Sno Thin Films To MethanolСара ОрхидеяNessuna valutazione finora

- Phsv04i03p0119 PDFDocumento7 paginePhsv04i03p0119 PDFphysicsjournalNessuna valutazione finora

- Lubna ZnO NPsDocumento4 pagineLubna ZnO NPsUmair ManzoorNessuna valutazione finora

- 6.eng-Synthesis, Optical and Humidity Sensing - Dr. K. C. DubeyDocumento6 pagine6.eng-Synthesis, Optical and Humidity Sensing - Dr. K. C. DubeyImpact JournalsNessuna valutazione finora

- Hong 2009Documento7 pagineHong 2009Saniaputri WulandariNessuna valutazione finora

- Zinc Sulphide CdS Core Shell Nanoparticles Bandgap PropertiesDocumento23 pagineZinc Sulphide CdS Core Shell Nanoparticles Bandgap PropertiesZak KhanNessuna valutazione finora

- Ni Doped Sno2Documento4 pagineNi Doped Sno2Abrar AshrafNessuna valutazione finora

- Preparation, Characterization and Photocatalytic Activity of Nano-Sized Zno/Sno Coupled PhotocatalystsDocumento11 paginePreparation, Characterization and Photocatalytic Activity of Nano-Sized Zno/Sno Coupled PhotocatalystsMuhammad IsmailNessuna valutazione finora

- Composite 2013 991779024Documento9 pagineComposite 2013 991779024PHY MATNessuna valutazione finora

- Materials Science and Engineering BDocumento6 pagineMaterials Science and Engineering BAdi Primanto ShevaNessuna valutazione finora

- Solid State Sciences: C. Karunakaran, V. Rajeswari, P. GomathisankarDocumento6 pagineSolid State Sciences: C. Karunakaran, V. Rajeswari, P. GomathisankarqayesNessuna valutazione finora

- Shape-Controlled Synthesis of 1D MnO2 via Quick-PrecipitationDocumento6 pagineShape-Controlled Synthesis of 1D MnO2 via Quick-PrecipitationAiman ShabbirNessuna valutazione finora

- Zno NanorodsDocumento5 pagineZno NanorodsmirelamanteamirelaNessuna valutazione finora

- Microwave-Assisted Hydrothermal Synthesis of ZnO Rod-Assembled Microspheres and Their Photocatalytic PerformancesDocumento5 pagineMicrowave-Assisted Hydrothermal Synthesis of ZnO Rod-Assembled Microspheres and Their Photocatalytic Performanceskarina CruzNessuna valutazione finora

- El - Chem. SnO2Documento6 pagineEl - Chem. SnO2Doe BlackNessuna valutazione finora

- Full TextDocumento12 pagineFull TextShii WarNyNessuna valutazione finora

- Revier-3 Spectrochimica Acta Part A Molecular and Biomolecular Spectroscopy 142, 405-409, 2015Documento5 pagineRevier-3 Spectrochimica Acta Part A Molecular and Biomolecular Spectroscopy 142, 405-409, 2015Samita ThakurNessuna valutazione finora

- Observation of Phonon Anharmonicity in SnO2 NanoparticlesDocumento14 pagineObservation of Phonon Anharmonicity in SnO2 NanoparticlesmohanNessuna valutazione finora

- Synthesis, Characterization, and Catalytic Performance ofDocumento9 pagineSynthesis, Characterization, and Catalytic Performance ofSena KulaksızNessuna valutazione finora

- Simple Hydrothermal ZnO, 2013Documento7 pagineSimple Hydrothermal ZnO, 2013hellna284Nessuna valutazione finora

- Material Science Research IndiaDocumento10 pagineMaterial Science Research IndiaRing MasterNessuna valutazione finora

- 10.1007/s10854 017 6654 7Documento7 pagine10.1007/s10854 017 6654 7AnaGomezNessuna valutazione finora

- Casiterita ANP - 2016021516120865Documento7 pagineCasiterita ANP - 2016021516120865Haydee ContrerasNessuna valutazione finora

- VAC 108939 - Revised ProofDocumento5 pagineVAC 108939 - Revised Proofamar ratanNessuna valutazione finora

- Simple Hydrothermal Preparation of Zinc Oxide Powders Using Thai Autoclave UnitDocumento7 pagineSimple Hydrothermal Preparation of Zinc Oxide Powders Using Thai Autoclave UnitAlexander Fabián GNessuna valutazione finora

- Correlation Between Experimental and DFT CalculatiDocumento13 pagineCorrelation Between Experimental and DFT Calculatiolfa massaoudigppNessuna valutazione finora

- Surface Plasmon Enhanced, Coupled and Controlled FluorescenceDa EverandSurface Plasmon Enhanced, Coupled and Controlled FluorescenceNessuna valutazione finora

- NASA Technical Note Details Thermally Stable Polyimide CompositesDocumento16 pagineNASA Technical Note Details Thermally Stable Polyimide CompositesLai van CuongNessuna valutazione finora

- UCSF Lab Standard Operating Procedure: Chemical Process, Name or Hazard ClassDocumento5 pagineUCSF Lab Standard Operating Procedure: Chemical Process, Name or Hazard ClassLai van CuongNessuna valutazione finora

- 2 Preparation NanoDocumento5 pagine2 Preparation NanoLai van CuongNessuna valutazione finora

- Decon SOPDocumento17 pagineDecon SOPLai van CuongNessuna valutazione finora

- Us3960759 PDFDocumento2 pagineUs3960759 PDFLai van CuongNessuna valutazione finora

- Bromo Phenol Blue SS Material Safety Data SheetDocumento4 pagineBromo Phenol Blue SS Material Safety Data SheetLai van CuongNessuna valutazione finora

- Bernachrome Yellow GD Sub PDFDocumento4 pagineBernachrome Yellow GD Sub PDFLai van CuongNessuna valutazione finora

- Quotation PDFDocumento1 paginaQuotation PDFLai van CuongNessuna valutazione finora

- 5989-3859EN Pho LC Cua Hop Chat AzoDocumento10 pagine5989-3859EN Pho LC Cua Hop Chat AzoLai van CuongNessuna valutazione finora

- 00 3 PDFDocumento1 pagina00 3 PDFLai van CuongNessuna valutazione finora

- Technical Specification: Tested By: Checked byDocumento1 paginaTechnical Specification: Tested By: Checked byLai van CuongNessuna valutazione finora

- Technical Specification: Tested By: Checked byDocumento1 paginaTechnical Specification: Tested By: Checked byLai van CuongNessuna valutazione finora

- Hello WorldDocumento1 paginaHello WorldLai van CuongNessuna valutazione finora

- Giai Phuong Trinh Bac 2Documento1 paginaGiai Phuong Trinh Bac 2Lai van CuongNessuna valutazione finora

- Paper 2Documento16 paginePaper 2Lai van CuongNessuna valutazione finora

- Hello WorldDocumento1 paginaHello WorldLai van CuongNessuna valutazione finora

- Giai Phuong Trinh Bac 2Documento1 paginaGiai Phuong Trinh Bac 2Lai van CuongNessuna valutazione finora

- ASTM D 6593 - 00 Rdy1otmtmdaDocumento85 pagineASTM D 6593 - 00 Rdy1otmtmdaEnrique Alejandro OvandoNessuna valutazione finora

- PVC StabilisersDocumento20 paginePVC StabilisersGustavo SalazarNessuna valutazione finora

- Chiral Molecules and Optical ActivityDocumento15 pagineChiral Molecules and Optical ActivityAhmad BustamiNessuna valutazione finora

- Habasync® Timing Belts: Habasit - Solutions in MotionDocumento16 pagineHabasync® Timing Belts: Habasit - Solutions in MotionrafacardNessuna valutazione finora

- Company Profile PT Inspektindo PratamaDocumento15 pagineCompany Profile PT Inspektindo PratamaIwan HusdiantamaNessuna valutazione finora

- BITZER Output Data: Created On: 27.07.2019 08:52:49Documento7 pagineBITZER Output Data: Created On: 27.07.2019 08:52:49JcRodriguezNessuna valutazione finora

- Data Biodiesel PosterDocumento4 pagineData Biodiesel PosterAnonymous 2WwOlzfuyNessuna valutazione finora

- NEW!! Speed Tiger General Catalogue PDFDocumento496 pagineNEW!! Speed Tiger General Catalogue PDFAarón MarxellyNessuna valutazione finora

- 420kV Reactor - Rev - 08Documento83 pagine420kV Reactor - Rev - 08Anil Marturi100% (1)

- Effect of Fiber Length on Mechanical Properties of Coir Fiber Reinforced Epoxy CompositesDocumento6 pagineEffect of Fiber Length on Mechanical Properties of Coir Fiber Reinforced Epoxy Compositesbrar_harmanpreet01Nessuna valutazione finora

- Biological IndicatorsDocumento24 pagineBiological IndicatorsLinh Nguyen100% (2)

- Nickel Aluminium Bronze: A Reconsideration For Valve ManufactureDocumento4 pagineNickel Aluminium Bronze: A Reconsideration For Valve ManufactureFred Duarte CaldeiraNessuna valutazione finora

- Vendor Development ProcurementDocumento3 pagineVendor Development ProcurementVishant GoelNessuna valutazione finora

- Med Tech Sept 2019 Histopathologic TechniquesDocumento10 pagineMed Tech Sept 2019 Histopathologic TechniquesDavid DollagaNessuna valutazione finora

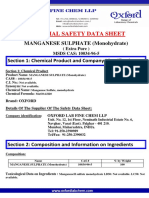

- MANGANESE SULPHATE (Monohydrate) (Extra Pure)Documento8 pagineMANGANESE SULPHATE (Monohydrate) (Extra Pure)Bima KurniawanNessuna valutazione finora

- IYOHA COLLINS 16CF020531 Batch Reactor ReportDocumento19 pagineIYOHA COLLINS 16CF020531 Batch Reactor ReportDavid OvieNessuna valutazione finora

- EXPERIMENT NO. 5 Aqueous Reactions and SolutionsDocumento11 pagineEXPERIMENT NO. 5 Aqueous Reactions and SolutionsChristle Jhaney MoongNessuna valutazione finora

- Silicon Killed Steel Nozzle CloggingDocumento8 pagineSilicon Killed Steel Nozzle CloggingMada TetoNessuna valutazione finora

- Technician Manual for Tuttnauer AutoclavesDocumento134 pagineTechnician Manual for Tuttnauer AutoclavesIngenieria NemoconNessuna valutazione finora

- SLG Chem3 LG 2.15 Application of HalogenoalkanesDocumento4 pagineSLG Chem3 LG 2.15 Application of HalogenoalkanesLorraine CalacsanNessuna valutazione finora

- Zainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsDocumento17 pagineZainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsAbraham AvNessuna valutazione finora

- Plastic Film - Wikipedia, The Free EncyclopediaDocumento2 paginePlastic Film - Wikipedia, The Free Encyclopediadidodido_67Nessuna valutazione finora

- Atomic Absorption SpectrometryDocumento64 pagineAtomic Absorption Spectrometryanilrockzzz786Nessuna valutazione finora

- N5 Biology 2014Documento41 pagineN5 Biology 2014FarooqAhmadLashariNessuna valutazione finora

- Comfort properties of polyester-viscose suiting fabricsDocumento5 pagineComfort properties of polyester-viscose suiting fabricsAditya ShrivastavaNessuna valutazione finora

- Calcium Aluminate Cement ConcreteDocumento6 pagineCalcium Aluminate Cement ConcreteGandhi HammoudNessuna valutazione finora

- Overhaul kit contents for Cummins AFC fuel pumpsDocumento2 pagineOverhaul kit contents for Cummins AFC fuel pumpsJoffre Lautaro Benavides SeminarioNessuna valutazione finora

- Making Lighter Aircraft with Titanium Aluminide Turbine BladesDocumento4 pagineMaking Lighter Aircraft with Titanium Aluminide Turbine BladesZouhair BoukriNessuna valutazione finora

- Applications of HPLC in Clinical DiagnosticsDocumento2 pagineApplications of HPLC in Clinical Diagnosticsmanan259050% (2)

- Spectroscopy Problems Part 1Documento49 pagineSpectroscopy Problems Part 1Partha Samanta100% (1)