Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Different Parts of Lathe Machine and Their Functions Print

Caricato da

dempe24Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Different Parts of Lathe Machine and Their Functions Print

Caricato da

dempe24Copyright:

Formati disponibili

Jimcy S.

Navida

BSMar-E III-C

MASHOP 3

DIFFERENT PARTS OF LATHE MACHINE AND THEIR FUNCTIONS

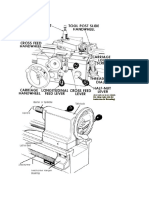

The five main parts of the lathe are: the bed, the headstock, the carriage, the tailstock, and the

gearbox. Below are illustrations of different lathes and lathe parts. Study these parts and be ready

to answer questions concerning their names and locations.

Bed: Usually made of cast iron. Provides a heavy rigid frame on which all the main

components are mounted. The bed of the lathe provides the foundation for the whole machine

and holds the headstock, tailstock and carriage in alignment. The surfaces of the bed that are

finely machined - and upon which the carriage and tailstock slide - are known as "ways".

Some beds have a gap near the headstock to allow extra-large diameters to be turned. Sometimes

the gap is formed by the machined ways stopping short of the headstock, sometimes by a piece

of bed that can be unbolted, removed--and lost.

Some very large lathes have a "sliding bed" where the upper part, on which the carriage and

tailstock sit, can be slid along a separate lower part - and so make the gap correspondingly larger

or smaller.

Saddle : The casting that fits onto the top of the bed and slides along it is known, almost

universally, as the "Saddle" - a self-explanatory and very suitable term.

Ways: Inner and outer guide rails that are precision machined parallel to assure accuracy of

movement.

Headstock: mounted in a fixed position on the inner ways, usually at the left end. Using a

chuck, it rotates the work. The lathe Headstock used, at one time, to be called the "Fixed

Headstock" or "Fixed Head", and the rotating shaft within it the "Mandrel". Today the mandrel

is usually called the "Spindle", but this can cause confusion with the tailstock, where the sliding

bar is known variously as the "ram", "barrel" - and "spindle".

The headstock is normally mounted rigidly to the bed (exceptions exist in some production,

CNC, automatic and "Swiss-auto" types) and holds all the mechanisms, including various kinds

and combinations of pulleys or gears, so that the spindle can be made to turn at different speeds.

Headstock Spindle : The end of the headstock spindle is usually machined so that it can carry

a faceplate, chuck, drive-plate, internal or external collets - or even special attachments

designed for particular jobs. In turn, these attachments hold the workpiece that is going to be

machined.

The "fitting" formed on the end of the spindle is normally one of five types:

1) - a simple flange through which threaded studs on a faceplate or chuck (for example) can

pass and be tightened into place with nuts. This is a secure method, and allows high-speed

reverse, but is very inconvenient on a general-purpose lathe.

2) - A threaded nose onto which fittings screw. This is perfectly acceptable for smaller

lathes, but unsatisfactory on larger industrial machines where, for reasons of production

economy, the spindle may need to be reversed at high speed. Reversing a screwed-on chuck

causes it to unscrew - with potentially disastrous results.

3) - A "D1-taper Camlock" fitting - a long-used, standard system that employs three or more

"studs" that are turned to lock into the back of chucks and faceplates, etc.

4) - A taper - either of the simple Hardinge type or, for bigger lathes, the "taper-nose, long-

key drive" - an older but excellent American design where a large screwed ring was held captive

on the end of the spindle and used to draw the chuck, or other fitting, onto a long, keyed taper

formed on the spindle end. An ideal system for the rigid mounting of heavier chucks, it has now

largely fallen into disuse. The fitting was available in various sizes starting at L00 (L zero zero)

and worked up through L0, L1, L2, etc.

5) - various fittings that became increasingly complex and apparently invented for the sake

of being able to claim a National Standard (the famous not-invented-here syndrome). All these

succeeded in doing was to raise manufacturing costs by preventing the interchange of spindle-

nose tooling between machines and requiring firms to keep larger inventories of spares and

numbers of duplicated firings. Some of these included: British and ISO Standard Spindle Noses

- Direct Mounting; British & ISO Short Taper with Bolt or Stud Fixing; British & ISO Short

Taper with Camlock Fixing; British & ISO Short Taper with Bayonet Ring Fixing and, of

course, German Standard Spindle Noses. Unbelievably, there appears never to have been a

French standard - and we still await official announcement of the rumoured Botswana-

Standard Triple-cam with Over-locking Nose and Chinese-designedNew Moon Slide-and-Snap-

Approximately fittings.

Gearbox: inside the headstock, providing multiple speeds with a geometric ratio by moving

levers.

Spindle: Hole through the headstock to which bar stock can be fed, which allows shafts that

are up to 2 times the length between lathe centers to be worked on one end at a time.

Chuck: 3-jaw (self centering) or 4-jaw (independent) to clamp part being machined.

Chuck: allows the mounting of difficult workpieces that are not round, square or triangular.

Tailstock: Fits on the inner ways of the bed and can slide towards any position the headstock

to fit the length of the work piece. An optional taper turning attachment would be mounted to

it. The Tailstock was once known in England as the "loose stock", " Ppoppet head" or "loose

head" - the latter old-fashioned term being used by Harrison and other English firms in some of

their advertising literature until the early 1970s. The unit is arranged to slide along the bed and

can be locked to it at any convenient point; the upper portion of the unit is fitted with what is

variously called a "barrel", "spindle" "ram" or "shoot" that can be moved in and out of the main

casting by hand, lever or screw feed and carries a "Dead Centre" that supports the other end of

work held (by various means) in the headstock.

Special centres, which rotate with the work, can be used in the tailstock ; these are known as

"Rotating Centres" and should not be referred to as "live centres" - that term being reserved for

the centre carried in the headstock spindle.

Long ago centres were referred to by turners as "Poppets" - presumably from "pop it in" - and

they carried their own with them, secured in cotton waste and jealously guarded in the top

pocket of their overalls.

Tailstock Quill: Has a Morse taper to hold a lathe center, drill bit or other tool.

Carriage: Moves on the outer ways. Used for mounting and moving most the cutting tools.

The whole assembly of Saddle, Apron, Top and Cross Slide is known as the "Carriage". Some

American publications (even makers' handbooks) have been known to casually refer to this as

the "Saddle" - but this incorrect.

Cross Slide: Mounted on the traverse slide of the carriage, and uses a handwheel to feed tools

into the workpiece.

Tool Post: To mount tool holders in which the cutting bits are clamped.

Compound slide rest consisting of the CROSS SLIDE and TOP SLIDE : Sitting on top of

the "Saddle" is the "Cross Slide" - that, as its name implies, moves across the bed - and on top

of that there is often a "Top Slide" or "Tool Slide" that is invariably arranged so that it can be

swivelled and locked into a new position.

Very early lathes had a simple T-shaped piece of metal against which the turner "rested" his tool

(all turning being done by hand) but when it became possible to move this "Rest" across the bed

by a screw feed it became known, appropriately enough, as a "Slide-rest". The earliest known

example of a "Slide-rest" is illustrated inMittelalterliche Hausbuch, a German publication of

about 1480.

After the "Top Slide" became a more common fitting the term "Slide-rest" was not so frequently

used - and the different functions of the two slides led to their specific names being more widely

adopted.

When two slides are provided (or sometimes, on watchmaker's lathes, three) the complete

assembly is known as the "Compound" or "Compound Slide" or even "Compound Slide-rest".

Some makers have been known to label the "Top Slide" as the "Compound Rest" or even the

"Compound Slide" - but as "to compound" means the 'joining of two or more' - not 'one' - this

use of the term in incorrect. The top and cross slide together should be referred to as "the

compound".

Apron: Attached to the front of the carriage, it has the mechanism and controls for moving the

carriage and cross slide.

Feed Rod: Has a keyway, with two reversing pinion gears, either of which can be meshed

with the mating bevel gear to forward or reverse the carriage using a clutch.

Lead Screw: For cutting threads. Originally termed a "master thread", or described as the

"leading screw", but now always referred to as the "leadscrew", this is a long threaded rod

normally found running along the front of the bed or, on some early examples running between

the bed ways down the bed's centre line. By using a train of gears to connect the lathe spindle to

the leadscrew - and the leadscrew to the lathe carriage - the latter, together with its cutting tool,

could be forced to move a set distance for every revolution of the spindle.

Split Nut: When closed around the lead screw, the carriage is driven along by direct drive

without using a clutch.

Quick Change Gearbox: Controls the movement of the carriage using levers.

Steady Rest: Clamped to the lathe ways, it uses adjustable fingers to contact the workpiece

and align it. Can be used in place of tailstock or in the middle to support long or unstable parts

being machined.

Follow Rest: Bolted to the lathe carriage, it uses adjustable fingers to bear against the

workpiece opposite the cutting tool to prevent deflection.

Apron : The vertical, often flat and rectangular "plate" fastened to the front of the "Saddle" is

known as the "Apron" and carries a selection of gears and controls that allow the carriage to be

driven (by hand or power) up and down the bed. The mechanism inside can also engage the

screwcutting feed and various powered tool feeds, should they be fitted. The leadscrew, and

sometimes a power shaft as well, are often arranged to pass through the apron and provide it with

a drive for the various functions. The sophistication of the apron-mounted controls, and their

ease of use, is a reliable indicator of the quality of a lathe. Virtually all screw-cutting lathes have

what is commonly-called a "half-nut" lever that closes down one and sometimes two halves of a

split nut to grasp the leadscrew and provide a drive for screwcutting.

Apron design can be roughly divided into "single-wall" and "double-wall" types. The "single-

wall" apron has just one thickness of metal and, protruding from it (and unsupported on their

outer ends) are studs that carry gears. The "double-wall" apron is a much more robust structure,

rather like a narrow, open-topped box with the gear-carrying studs fitted between the two walls -

and hence rigidly supported at both ends. This type of construction produces a very stiff structure

- and one that is far less likely to deflect under heavy-duty work; another advantage is that the

closed base of the "box" can be used to house an oil reservoir the lubricant ion which is either

splashed around or, preferably, pumped to supply the spindles, gears and even, on some lathes,

the sliding surfaces of the bed and cross slide as well.

Backgear : As its name implies, "backgear" is a gear mounted at the back of the headstock

(although in practice it is often located in other positions) that allows the chuck to rotate slowly

with greatly-increased torque (turning power). Backgeared lathes are sometimes referred to a

"BG" or "BGSC" - the latter meaning "backgeared and screwcutting". At first, the ability to run a

workpiece slowly might seem unnecessary, but a large-diameter casting, fastened to the faceplate

and run at 200 rpm (about the slowest speed normally available on a lathe without backgear)

would have a linear speed at its outer edge beyond the turning capacity of a small lathe. By

engaging backgear, and so reducing the speed but increasing the torque, even the largest

faceplate-mounted jobs can be turned successfully.

Screwcutting also requires slow speeds, typically between 25 and 50 rpm - especially if the

operator is a beginner, or the job tricky. A bottom speed in excess of those figures (as usually

found on most Far Eastern and European machines but not those built in the United Kingdom)

means that screwcutting - especially internally, into blind holes - is, in effect, impossible. These

lathes are advertised as "screwcutting" but what that means in reality is just power feed along the

bed. Even if you go to the trouble of making up a pulley system to reduce the spindle speeds you

will find the torque needed to turn large diameters at low speeds causes the belts to slip. The only

solution is agear-driven low speed and so a proper small lathe, with a backgear fitted, not only

becomes capable of cutting threads but can also tackle heavy-duty drilling, big-hole boring and

large-diameter facing: in other words, it is possible to use it to the very limits of its capacity and

strength.

Beginners are sometimes confused about how to engage backgear - especially if the lathe lacks a

handbook - but with a little care anyone can work out how it should be done, at least on a

conventional machine. On the main spindle of the lathe, the one carrying the drive pulley, will be

found a large gear, generally referred to as the "Bull Wheel". The Bull Wheel is attached to the

pulley by a nut and bolt, a spring-loaded pin, a pawl that presses into a gear on the pulley (or

some other means) and, if this fastening is undone - by slackening the nut and pushing it towards

the pulley, or by pulling the pin out - it should be found that the pulley will spin freely on the

shaft. By moving the "backgears" into position - they generally slide sideways, or are mounted

on an eccentric pin - the mechanism will come into operation. If the pulley will not spin on the

shaft, or there seems to be no obvious way of disconnecting the Bull Wheel from the pulley, it

may be that you are dealing with an "over-engineered" machine where some clever device has

been introduced to make life "easy" for the operator. Sometimes there will be a screw, flush with

the surface of the drive pulley and beneath this a spring-loaded pin that pushes into the back face

of the Bull Wheel. Quick-action "Sliding-cam" mechanisms are occasionally used (as on the

Drummond and Myford M Series lathes) where a knob on the face of the Bull Wheel has to be

pushed sideways, and so ride up a ramp, which action disengages the connecting pin

automatically. Some lathes, with enclosed headstocks (like later Boxford models) have a "single-

lever" backgear; in this system moving the first part of the lever's movement disengages the

connection whilst the next brings the backgear into mesh.

Countershaft : Most small electric motors in Britain spin at 1425 rpm, while those in the USA

and Europe are usually marked a little faster at 1600 to 1700 rpm or so.

If the lathe spindle was to be driven directly from one of these motors, even using a small pulley

on the motor shaft, and a larger one on the lathe, it would be turning far too quickly to be useful

for the great majority of jobs; hence, it is necessary to introduce some way of reducing the lathe's

spindle speed - and that is the job of thecountershaft.

In a typical arrangement, illustrated here, the motor is fastened to an upright, hinged, cast-iron

plate and fitted with a small pulley on its spindle. Because the 1500 rpm motor is driving a much

larger pulley in a ratio of something like 5 : 1 - the speed is reduced to 300 rpm (1500 divided by

5).

On the same shaft as the very large pulley is a set of three smaller pulleys, arranged in the

"reverse" order from those on the lathe. If the middle pulley on the countershaft is made to drive

the identically-sized pulley on the lathe spindle that too, of course, will turn at 300 rpm. The

pulleys each side of it are normally arranged to halve and double that speed - hence the creation

of a speed set covering a useful 150 rpm, 300 rpm and 600 rpm.

It is a simple matter to fit both a small and a large pulleys to the motor shaft, and two

correspondingly larger pulleys on the countershaft, and so double the number of available speeds

to six. If a two-speed electric motor is used the range doubles again to 12 and, should the lathe

designer have managed to squeeze a four-step pulley between the spindle bearings, a total of 16

would be available; with a backgear fitted the total would rise to thirty-two speeds that, typically,

might start at 25 r.p.m. and extend all the way up to over 3000 rpm.

Changewheels and Tumble Reverse : These are the gears that take the drive from the

headstock spindle down to the leadscrew. They are normally contained within a cover at the

extreme left-hand side of the lathe - but many older lathes, built in times when manufacturers

were not concerned with saving people from their own carelessness, left them exposed.

Called "changewheels" because of the necessity to change them every time a different thread, or

rate of tool feed, was required, the expression goes back to the earliest time that gears were used

for this purpose. The gear train is usually carried on a quadrant arm able to be adjusted by

being swung on its mounting to allow the mesh of the topmost gear with the output gear on the

spindle (or tumble reverse mechanism) to be set. In Great Britain the arm is sometimes called the

"Banjo" - although this expression should really be limited to those types with just one slot.

Some manufacturers, to make life difficult for themselves and their customers, tried other

systems as well. A drive through changewheels often incorporates a tumble-reverse mechanism

by which means the drive to the leadscrew can be instantly reversed - and hence the cutting tool

made to move towards or away from the headstock at will. In its "neutral" position it also allows

the headstock spindle to rotate freely and quietly without having to drive the screwcutting

changewheels and leadscrew.

Potrebbero piacerti anche

- Lab Session Introduction To Lathe MachineDocumento5 pagineLab Session Introduction To Lathe MachineAqib ZamanNessuna valutazione finora

- Lathe Machine: Description and Function of Lathe PartsDocumento16 pagineLathe Machine: Description and Function of Lathe PartsRenjith Rajendraprasad100% (1)

- Lathe MachineDocumento16 pagineLathe MachineVanamali Thirumalai100% (4)

- Technical Drawings For Toaster Automata 1Documento8 pagineTechnical Drawings For Toaster Automata 1api-371765117Nessuna valutazione finora

- Shop Practice No.1 Dust Pan: Mapua UniversityDocumento6 pagineShop Practice No.1 Dust Pan: Mapua UniversityKyle LoveNessuna valutazione finora

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDocumento7 pagineLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaNessuna valutazione finora

- Mech Lathe Machine ReportDocumento15 pagineMech Lathe Machine ReportLary Dela Cruz Guevarra100% (1)

- Lab Report 3Documento7 pagineLab Report 3mamoona noreen100% (1)

- Report WeldingDocumento11 pagineReport WeldingSomasundaram SomanoNessuna valutazione finora

- Introduction To Fitting Shop.Documento11 pagineIntroduction To Fitting Shop.Mahmood AliNessuna valutazione finora

- Basic Principle of Grinding MachineDocumento10 pagineBasic Principle of Grinding Machinecrank88100% (1)

- EDM Lab ReportDocumento12 pagineEDM Lab ReportAli Hassan100% (1)

- Surface GrindingDocumento14 pagineSurface GrindingariefNessuna valutazione finora

- PLC Based Automatic Car Washing System-18849Documento6 paginePLC Based Automatic Car Washing System-18849Jok ZamNessuna valutazione finora

- Lathe MachineDocumento22 pagineLathe MachineKa Tze TingNessuna valutazione finora

- Bench WorkingDocumento11 pagineBench WorkingMonica MagdyNessuna valutazione finora

- Name of The Experiment:: Study and Operation Bench Drilling MachineDocumento5 pagineName of The Experiment:: Study and Operation Bench Drilling MachinemadNessuna valutazione finora

- LATHE - WriteupDocumento21 pagineLATHE - WriteupMERISH GURU100% (1)

- Broaching MachineDocumento8 pagineBroaching MachineJaya RamanNessuna valutazione finora

- Machine Lab - ReportDocumento11 pagineMachine Lab - Reportsaiq kamranNessuna valutazione finora

- BroachingDocumento22 pagineBroachingvijchoudhary16Nessuna valutazione finora

- 5.0 Conclusion SMFDocumento2 pagine5.0 Conclusion SMFAlimin AnniNessuna valutazione finora

- Fitting ShopDocumento19 pagineFitting ShopRitikNessuna valutazione finora

- Drilling MachineDocumento9 pagineDrilling MachineAqib ZamanNessuna valutazione finora

- Fitting LabDocumento8 pagineFitting LabArun kumar rouniyarNessuna valutazione finora

- Machining 2 ReportDocumento11 pagineMachining 2 ReportTan Jun ZheNessuna valutazione finora

- Metal Forming Lab - Experiment No 5 - Sheet Metal FormingDocumento4 pagineMetal Forming Lab - Experiment No 5 - Sheet Metal FormingSubhasis BiswalNessuna valutazione finora

- Milling MachineDocumento20 pagineMilling MachineMohd Radzi Kaki Limo100% (1)

- Experiment No. 9: To Perform Parting Operation On LatheDocumento3 pagineExperiment No. 9: To Perform Parting Operation On LatheHasnain AshrafNessuna valutazione finora

- EDM Die Sinking AKMDocumento7 pagineEDM Die Sinking AKMAhmad Sabree Abdul BasitNessuna valutazione finora

- A Lab Report On Fitting Workshop Practice PDFDocumento6 pagineA Lab Report On Fitting Workshop Practice PDFSorna Kailash50% (4)

- Lab 2 TurningDocumento12 pagineLab 2 TurningLuqman HakimNessuna valutazione finora

- JIG & FixtureDocumento2 pagineJIG & Fixturesandeep100% (1)

- Lab Sheet Djj5113Documento27 pagineLab Sheet Djj5113Munisprasad MuniandyNessuna valutazione finora

- Report Benchwork DrillingDocumento14 pagineReport Benchwork DrillingKhairunnisaSyahirah100% (2)

- JJ104 Workshop Technology Chapter7 Grinding MachineDocumento19 pagineJJ104 Workshop Technology Chapter7 Grinding MachineAh Tiang100% (1)

- Metal Forming Chapter 4 and ConclusionDocumento4 pagineMetal Forming Chapter 4 and ConclusionNo NameNessuna valutazione finora

- Types of Screw Threads PDFDocumento1 paginaTypes of Screw Threads PDFkeyur1109100% (1)

- Lathe MachineDocumento16 pagineLathe MachineM Arslan AshrafNessuna valutazione finora

- PDF File of Machine Shop Report PDFDocumento8 paginePDF File of Machine Shop Report PDFNur Akmal100% (1)

- GegasDocumento18 pagineGegasPiraven Casanova II50% (2)

- Mech-V-Design of Machine Elements I (10me52) - AssignmentDocumento10 pagineMech-V-Design of Machine Elements I (10me52) - AssignmentArunNessuna valutazione finora

- Principle of Lathe MachineDocumento23 paginePrinciple of Lathe MachineMuhammad ArifNessuna valutazione finora

- Abstract Book Acex2010Documento225 pagineAbstract Book Acex2010Schmetterling TraurigNessuna valutazione finora

- Product Realization by Manufacturing: Lab ManualDocumento75 pagineProduct Realization by Manufacturing: Lab ManualjasvindersinghsagguNessuna valutazione finora

- Mechanical Work Shop Lab ReportDocumento9 pagineMechanical Work Shop Lab ReportOG HackNessuna valutazione finora

- Lecture - 4 Notes: Drilling Basic Mechanical Engineering (Part - B) 1Documento5 pagineLecture - 4 Notes: Drilling Basic Mechanical Engineering (Part - B) 1Roop LalNessuna valutazione finora

- Assignment 02 - Machine DesignDocumento2 pagineAssignment 02 - Machine DesignRatan Sadanandan O MNessuna valutazione finora

- Grinding AssignmentDocumento4 pagineGrinding AssignmentSyed Ashmal Hashmi100% (1)

- Welding ReportDocumento11 pagineWelding ReportJia Yee Ten100% (1)

- Workshop Practice II (MEng4191)Documento35 pagineWorkshop Practice II (MEng4191)Tesema TeshomeNessuna valutazione finora

- Types of Pattern and Its ApplicationDocumento27 pagineTypes of Pattern and Its ApplicationKarthik GanesanNessuna valutazione finora

- Broaching NotesDocumento5 pagineBroaching NotesfaNessuna valutazione finora

- Step and V-FittingDocumento11 pagineStep and V-FittingME Rgukt100% (1)

- Eccentric Turning Attachment On Three Jaw LatheDocumento50 pagineEccentric Turning Attachment On Three Jaw LatheSushant MahajanNessuna valutazione finora

- Report Screw Jack (1) TDocumento47 pagineReport Screw Jack (1) TAshish Sharma80% (5)

- Lathe Machine PartsDocumento10 pagineLathe Machine PartsJoydeep MajumdarNessuna valutazione finora

- Mesin BubutDocumento5 pagineMesin BubutMacda Coby PratamaNessuna valutazione finora

- Assignment NO: 2: Mechanical Engineering DepartmentDocumento16 pagineAssignment NO: 2: Mechanical Engineering DepartmentMohsin TariqNessuna valutazione finora

- Turning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningDa EverandTurning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningValutazione: 2.5 su 5 stelle2.5/5 (2)

- FOLK DANCES in The PhilippinesDocumento4 pagineFOLK DANCES in The Philippinesdempe24Nessuna valutazione finora

- Once Upon A Time: Mackaylha JoyDocumento1 paginaOnce Upon A Time: Mackaylha Joydempe24Nessuna valutazione finora

- The Beautiful Malaysia: Malaysia Is A Federal Constitutional Monarchy LocatedDocumento1 paginaThe Beautiful Malaysia: Malaysia Is A Federal Constitutional Monarchy Locateddempe24Nessuna valutazione finora

- Second Periodical Test in English 3Documento2 pagineSecond Periodical Test in English 3dempe24Nessuna valutazione finora

- AO - 2004-019.PDF Minors Travelling AbroadDocumento10 pagineAO - 2004-019.PDF Minors Travelling Abroaddempe24Nessuna valutazione finora

- Conclusion and RecommendationDocumento3 pagineConclusion and Recommendationdempe24Nessuna valutazione finora

- Table of ContentDocumento29 pagineTable of Contentdempe24Nessuna valutazione finora

- Bulletin 4Documento1 paginaBulletin 4dempe24Nessuna valutazione finora

- Daily LogDocumento14 pagineDaily Logdempe24Nessuna valutazione finora

- Montoya vs. Transmed Manila Corp. Et AlDocumento8 pagineMontoya vs. Transmed Manila Corp. Et Aldempe24Nessuna valutazione finora

- NFD International Manning Agency vs. Illescas 1Documento10 pagineNFD International Manning Agency vs. Illescas 1dempe24Nessuna valutazione finora

- Sunga vs. Virjen Shipping Corp.Documento6 pagineSunga vs. Virjen Shipping Corp.dempe24Nessuna valutazione finora

- Changing Asia: Conflicts Disrupts Southeast Asia: World History and Civilization 2Documento1 paginaChanging Asia: Conflicts Disrupts Southeast Asia: World History and Civilization 2dempe24Nessuna valutazione finora

- Agusan Del SurDocumento1 paginaAgusan Del Surdempe24Nessuna valutazione finora

- Bulletin 6Documento2 pagineBulletin 6dempe24Nessuna valutazione finora

- John Lester Erro Jyle Antonette Tuesday CJDocumento2 pagineJohn Lester Erro Jyle Antonette Tuesday CJdempe24Nessuna valutazione finora

- Bulletin 3Documento1 paginaBulletin 3dempe24Nessuna valutazione finora

- Golden Pen: Journalism WriteshopDocumento2 pagineGolden Pen: Journalism Writeshopdempe24Nessuna valutazione finora

- Girl Scouts of The Year: District CoordinatorsDocumento1 paginaGirl Scouts of The Year: District Coordinatorsdempe24Nessuna valutazione finora

- CRIS Co-Curricular (Version 1)Documento30 pagineCRIS Co-Curricular (Version 1)dempe24Nessuna valutazione finora

- List of Out-Of-School Youths Without Skills Training: Desired Skill/s (TESDA Assisted) (Pls. Write Options, 1-3)Documento6 pagineList of Out-Of-School Youths Without Skills Training: Desired Skill/s (TESDA Assisted) (Pls. Write Options, 1-3)dempe24Nessuna valutazione finora

- V GFGV Gftt6t4gfqu7t F VDocumento2 pagineV GFGV Gftt6t4gfqu7t F Vdempe24Nessuna valutazione finora

- 2recog Deped AwardeesDocumento1 pagina2recog Deped Awardeesdempe24Nessuna valutazione finora

- Tarp Golden Pen11Documento1 paginaTarp Golden Pen11dempe24Nessuna valutazione finora

- Dongon Elementary School Teaching Staff: Mrs. Rosie B. ReyesDocumento1 paginaDongon Elementary School Teaching Staff: Mrs. Rosie B. Reyesdempe24Nessuna valutazione finora

- Hsgfroemk Sjbe Frowmn NDocumento4 pagineHsgfroemk Sjbe Frowmn Ndempe24Nessuna valutazione finora

- Dongon Elementary School 1 Grading No - Name Written Works Performance Task Quarterly Assessment Initial Grade Quarter Ly GradeDocumento2 pagineDongon Elementary School 1 Grading No - Name Written Works Performance Task Quarterly Assessment Initial Grade Quarter Ly Gradedempe24Nessuna valutazione finora

- Eng - Puma SMX5100L-LSDocumento28 pagineEng - Puma SMX5100L-LSRajiv GandhiNessuna valutazione finora

- Knuth For Education en 09 2019 PDFDocumento28 pagineKnuth For Education en 09 2019 PDFKali AbdennourNessuna valutazione finora

- Multi-Function CNC Lathe: FCL-18/25 SERIESDocumento10 pagineMulti-Function CNC Lathe: FCL-18/25 SERIESBhargav SaiNessuna valutazione finora

- APS Engine LatheDocumento8 pagineAPS Engine LatheAdmin 300moviesNessuna valutazione finora

- Commutator Under CuttersDocumento17 pagineCommutator Under Cutterssalekojic5332Nessuna valutazione finora

- Lathe AccessoriesDocumento6 pagineLathe AccessoriesAnand Balaji100% (1)

- Thuat NguDocumento43 pagineThuat NguCarlosNessuna valutazione finora

- Ikegai Machine Tools For Customized UseDocumento34 pagineIkegai Machine Tools For Customized UseJi-Wei HoNessuna valutazione finora

- Thread Cutting On LatheDocumento12 pagineThread Cutting On Latheashoku24007Nessuna valutazione finora

- Circular Home MadeDocumento96 pagineCircular Home MadeFlorinNessuna valutazione finora

- Analysis and Design OF Tailstock Assembly: Presented byDocumento14 pagineAnalysis and Design OF Tailstock Assembly: Presented bygunadi katonNessuna valutazione finora

- Panther 6610 ManualDocumento82 paginePanther 6610 ManualGezahegnNessuna valutazione finora

- Simb Catalogue 2014-15Documento132 pagineSimb Catalogue 2014-15Pcfs100% (2)

- ME 2207 - Manufacturing Technology 1 - Lab ManualDocumento57 pagineME 2207 - Manufacturing Technology 1 - Lab ManualMohan Prasad.M71% (17)

- PD 250e PDFDocumento26 paginePD 250e PDFBL LNessuna valutazione finora

- Question Answer On Lathe Milling Drilling Grinding (Join AICTE Telegram Group)Documento74 pagineQuestion Answer On Lathe Milling Drilling Grinding (Join AICTE Telegram Group)Vivek SharmaNessuna valutazione finora

- MCP101 Lab Manual 2023 - UpdatedDocumento85 pagineMCP101 Lab Manual 2023 - UpdatedGautam AhujaNessuna valutazione finora

- Machining Process Lab ReportDocumento31 pagineMachining Process Lab ReportHafiz Hamza83% (12)

- 12Documento110 pagine12SarjitoNessuna valutazione finora

- Types of Boring MachineDocumento12 pagineTypes of Boring MachineBenz Andrew RegisNessuna valutazione finora

- Micro Lathe Upgrade - 7 Steps - InstructablesDocumento16 pagineMicro Lathe Upgrade - 7 Steps - Instructables宛俊Nessuna valutazione finora

- Canadian Machinery 4Documento476 pagineCanadian Machinery 4loosenut100% (1)

- Machine Tool Failure Data AnalysisDocumento9 pagineMachine Tool Failure Data AnalysisPatrisonNessuna valutazione finora

- LatheDocumento130 pagineLatheAjay Sharma86% (7)

- Man ENDocumento94 pagineMan ENEnrique Ferrando BarbenaNessuna valutazione finora

- FGDocumento22 pagineFGRishabh PandeyNessuna valutazione finora

- tiếng anh-lab-report-for-machine-tool-and-machiningDocumento71 paginetiếng anh-lab-report-for-machine-tool-and-machiningNhư QuỳnhNessuna valutazione finora

- Diff BWN Turret and Capstan LatheDocumento2 pagineDiff BWN Turret and Capstan LatheManojKumarVempatiNessuna valutazione finora

- 8l Pkgcomparison 1220a 003Documento1 pagina8l Pkgcomparison 1220a 003Ben LernerNessuna valutazione finora

- Machine WorskopDocumento20 pagineMachine WorskopnaemaNessuna valutazione finora