Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Outdoor - Units - MOU 12HDN1 - MOUB 36HDN1 R220075500920 - MOUB 48HDN1 R220075700690 - MOUD 60HDN1 R - MOUA 60HRDN1

Caricato da

Muhidin Kozica0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

574 visualizzazioni48 pagineOutdoor_Units_MOU-12HDN1_MOUB-36HDN1-R220075500920_MOUB-48HDN1-R220075700690_MOUD-60HDN1-R_MOUA-60HRDN1

Titolo originale

Outdoor_Units_MOU-12HDN1_MOUB-36HDN1-R220075500920_MOUB-48HDN1-R220075700690_MOUD-60HDN1-R_MOUA-60HRDN1

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoOutdoor_Units_MOU-12HDN1_MOUB-36HDN1-R220075500920_MOUB-48HDN1-R220075700690_MOUD-60HDN1-R_MOUA-60HRDN1

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

574 visualizzazioni48 pagineOutdoor - Units - MOU 12HDN1 - MOUB 36HDN1 R220075500920 - MOUB 48HDN1 R220075700690 - MOUD 60HDN1 R - MOUA 60HRDN1

Caricato da

Muhidin KozicaOutdoor_Units_MOU-12HDN1_MOUB-36HDN1-R220075500920_MOUB-48HDN1-R220075700690_MOUD-60HDN1-R_MOUA-60HRDN1

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 48

MCAC-UTSM-2010-06

Out door Uni t s

1. Specification ........................................................................................... 1

2. Dimensions.......................................................................................... ..5

3. Service Space.......................................................................................... 6

4. Piping Diagrams ................................................................................... 10

5. Wiring Diagrams ................................................................................... 11

6. Field Wiring ........................................................................................... 16

7. Electric Characteristics ........................................................................ 18

8. Sound Levels ........................................................................................ 19

9. Exploded View ...................................................................................... 20

10. Operation Limits ................................................................................. 31

11. Troubleshooting .................................................................................. 32

The specifications, designs, and information in this book are subject to change without notice for

product improvement.

MCAC-UTSM-2010-06

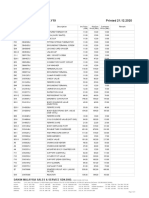

1. Specification

Outdoor

Model

name

MOU-12HDN1 MOUA-18HDN1-C0

Code 220075100071 220075200340

Power

supply

220~240V-1 Ph-50Hz 220~240V-1 Ph-50Hz

Max. input consumption W 1500 2400

Max. current A 7.0 13.1

Compressor

Model

DA108X1C-20FZ3

C-6RVN93H0V

Type Rotary DC Inverter Scroll DC Inverter

Brand

MIDEA TOSHIBA

Shenyang SANYO

Capacity Btu/h

10918.4

19277.8

Input W

855

1470

Rated current(RLA) A

5.3

8.96

Refrigerant oil ml

480ml

350

Outdoor fan

motor

Model YDK24-6G YDK53-6Y

Type

AC MOTOR

AC MOTOR

Input W

67/48

129/86

Capacitor uF

/

3uF/450V

Speed r/min

800/550

770/560

Outdoor coil

Number of rows

2

2

Tube pitch(a)x row pitch(b) mm

25.422

2219.05

Fin spacing mm

1.4

1.4

Fin type (code)

Hydrophilic aluminum

Hydrophilic aluminum

Tube outside dia. and type mm

9.53 Inner grooved

copper tube

7.94 Inner grooved

copper tube

Coil length x height x width mm

654558.844

77866038.1

Number of circuits

2

2

Outdoor air flow(Hi/Low) m

3

/h

2500/1600

2570/2300

Sound level(sound pressure)(Hi/Low) dB(A) 48/44 51/46

Outdoor unit

Dimension(W x D x H) mm

761593279

842695324

Packing (W x D x H) mm

887655355

965x752x399

Net/Gross weight kg

39.5/42.5

59/63

Refrigerant

Type R410A R410A

Charged volume g 1400 1600

Throttle type Capillary

Electronic expansion valve

& Capillary

Design pressure(Hi/Low) MPa 4.2/1.5 4.2/1.5

Refrigerant

piping

Liquid side/ Gas side mm 6.4/12.7 6.4/12.7

Max. refrigerant pipe length m

10

25

Max. difference in level

(Outdoor is up)

m

6

12

Max. difference in level

(Outdoor is down)

m 5 9

Ambient temp (Outdoor)

Cooling-5~43; Heating

-5~24

Cooling-15~43; Heating

-15~24

MCAC-UTSM-2010-06

Outdoor

Model

name

MOUB-24HDN1 MOU-30HDN1

Code 220075301070 220075401041

Power

supply

220~240V-1 Ph-50Hz 220~240V-1 Ph-50Hz

Max. input consumption W 3250 4600

Max. current A 15.48 23

Compressor

Model ATL165SD-C9AU TNB220FLBM1

Type Rotary DC Inverter Rotor DC Inverter

Brand HITACHI MITSUBISHI ELECTRIC

Capacity Btu/h 15525 24328

Input W 1530 2200

Rated current(RLA) A 10.4 9.7

Refrigerant oil ml 68HES-H,880 MEL 56, 670

Outdoor fan

motor

Model YDK53-6Z YDK250-6E

Type AC MOTOR AC MOTOR

Input W 141.5/92 307/194

Capacitor uF 3uF/450V 10uF5% 450V

Speed r/min 815/550 740/530

Outdoor coil

Number of rows 2 2

Tube pitch(a)x row pitch(b) mm 25.4 x 22 25.422

Fin spacing mm 1.5 1.7

Fin type (code) Hydrophilic aluminum Hydrophilic aluminum

Tube outside dia. and type mm

9.53 Inner grooved

copper tube

9.53 Inner grooved

copper tube

Coil length x height x width mm 758x813x44 876x914.4x44

Number of circuits 2 4

Outdoor air flow(Hi/Low) m

3

/h 3200/2850 5000/4800

Sound level(sound pressure)(Hi/Low) dB(A) 53/48 57/50

Outdoor unit

Dimension(W x D x H) mm 895x862x313 990966354

Packing (W x D x H) mm 1043x915x395 11201100435

Net/Gross weight kg 73/76 92/100

Refrigerant

Type R410A R410A

Charged volume g 2300 3350

Throttle type

Electronic expansion valve

& Capillary

Electronic expansion valve

& Capillary

Design pressure(Hi/Low) MPa 4.2/1.5 4.2/1.5

Refrigerant

piping

Liquid side/ Gas side mm 9.5/15.9 9.5/15.9

Max. refrigerant pipe length m 25 25

Max. difference in level

(Outdoor is up)

m 12 15

Max. difference in level

(Outdoor is down)

m 9 9

Ambient temp (Outdoor)

Cooling-15~43; Heating

-15~24

Cooling-15~43Heating

-15~24

MCAC-UTSM-2010-06

Outdoor

Model

name

MOU-36HDN1 MOUB-36HDN1-R

Code 220075500651 220075500920

Power

supply

220~240V-1 Ph-50Hz 380V~3 Ph-50Hz

Max. input consumption W 5500 5500

Max. current A 25 10

Compressor

Model TNB306FPGM TNB306FPNM

Type Rotor DC Inverter Rotary DC Inverter

Brand MITSUBISHI ELECTRIC MITSUBISHI ELECTRIC

Capacity Btu/h 33642 33710

Input W 3080 3010

Rated current(RLA) A 13.5 9.3

Refrigerant oil ml FV50S, 1100 FV50S, 870

Outdoor fan

motor

Model (YDK100-6A)2 YDK250-6E

Type AC MOTOR AC Motor

Input W (185/120)2 307/194

Capacitor uF (3.5uF/450V)2 10uF5% 450V

Speed r/min 860/610 740/530

Outdoor coil

Number of rows 2.5 2

Tube pitch(a)x row pitch(b) mm 25.422 25.422

Fin spacing mm 1.5 1.7

Fin type (code) Hydrophilic aluminum Hydrophilic aluminum

Tube outside dia. and type mm

9.53 Inner grooved

copper tube

9.53 Inner grooved

copper tube

Coil length x height x width mm 887 x 1220x 66 876914.444

Number of circuits 8 4

Outdoor air flow(Hi/Low) m

3

/h 6000/5800 5000/4800

Sound level(sound pressure)(Hi/Low) dB(A) 57/52 55/50

Outdoor unit

Dimension(W x D x H) mm 9401245360 990966354

Packing (W x D x H) mm 10581380438 11201100435

Net/Gross weight kg 106/114 87/95

Refrigerant

Type R410A R410A

Charged volume g 4100 2900

Throttle type

Electronic expansion valve

& Capillary

Electronic expansion valve

& Capillary

Design pressure(Hi/Low) MPa 4.2/1.5 4.2/1.5

Refrigerant

piping

Liquid side/ Gas side mm 9.5/15.9 9.5/15.9

Max. refrigerant pipe length m 30 30

Max. difference in level

(Outdoor is up)

m 20 20

Max. difference in level

(Outdoor is down)

m 12 12

Ambient temp (Outdoor)

Cooling-15~43Heating

-15~24

Cooling-15~43Heating

-15~24

MCAC-UTSM-2010-06

Outdoor

Model

name

MOU-48HDN1 MOUB-48HDN1-R

Code 220075700341 220075700690

Power

supply

220~240V-1 Ph-50Hz 380V~3 Ph-50Hz

Max. input consumption W 6000 6000

Max. current A 28 12

Compressor

Model TNB306FPGM TNB306FPNM

Type Rotor DC Inverter Rotary DC Inverter

Brand MITSUBISHI ELECTRIC MITSUBISHI ELECTRIC

Capacity Btu/h 33642 33710

Input W 3080 3010

Rated current(RLA) A 13.5 9.3

Refrigerant oil ml 1100 870

Outdoor fan

motor

Model (YDK100-6A)2 YDK100-6A(2)

Type AC MOTOR AC Motor

Input W (185/120)2 (185/120)2

Capacitor uF (3.5uF/450V)2 (3.5uF/450V)2

Speed r/min 860/610 860/610

Outdoor coil

Number of rows 2.5 2

Tube pitch(a)x row pitch(b) mm 25.422 25.422

Fin spacing mm 1.5 1.7

Fin type (code) Hydrophilic aluminum Hydrophilic aluminum

Tube outside dia.and type mm

9.53 Inner grooved

copper tube

9.53 Inner grooved

copper tube

Coil length x height x width mm 887 x 1220x 66 887122044

Number of circuits 8 8

Outdoor air flow(Hi/Low) m

3

/h 6000/5800 6000/5800

Sound level(sound pressure)(Hi/Low) dB(A) 59/54 59/54

Outdoor unit

Dimension(W x D x H) mm 9401245360 9401245360

Packing (W x D x H) mm 10581380438 10581380438

Net/Gross weight kg 106/114 99/107

Refrigerant

Type R410A R410A

Charged volume g 4450 3600

Throttle type

Electronic expansion valve

& Capillary

Electronic expansion valve

& Capillary

Design pressure(Hi/Low) MPa 4.2/1.5 4.2/1.5

Refrigerant

piping

Liquid side/ Gas side mm 9.5/15.9 9.5/15.9

Max. refrigerant pipe length m 50 50

Max. difference in level

(Outdoor is up)

m 25 25

Max. difference in level

(Outdoor is down)

m 20 20

Ambient temp (Outdoor)

Cooling-15~43Heating

-15~24

Cooling-15~43Heating

-15~24

MCAC-UTSM-2010-06

Outdoor

Model

name

MOUA-60HRDN1 MOUD-60HDN1-R

Code 220075800161 220075801220

Power

supply

380V~-3 Ph-50Hz 380~415V-3 Ph-50Hz

Max. input consumption W 7500 7200

Max. current A 14 14

Compressor

Model ANB42FBEMT ANB42FBEMT

Type Scroll DC Inverter Scroll DC Inverter

Brand MITSUBISHI MITSUBISHI

Capacity Btu/h 47440 47440

Input W 4160 4160

Rated current(RLA) A 15.2 15.2

Refrigerant oil ml MEL 56, 1700 MEL 56, 1700

Outdoor fan

motor

Model (YDK100-6A)2 (YDK100-6A)2

Type AC MOTOR AC MOTOR

Input W (185/120)2 (185/120)2

Capacitor uF (3.5uF/450V)2 (3.5uF/450V)2

Speed r/min 860/610 860/610

Outdoor coil

Number of rows 2 3

Tube pitch(a)x row pitch(b) mm 25.4 x 22 25.4 22

Fin spacing mm 1.7 1.5

Fin type (code) Hydrophilic aluminum Hydrophilic aluminum

Tube outside dia. and type mm

9.53 Inner grooved

copper tube

9.53 inner grooved

copper tube

Coil length x height x width mm 887122044 887122066

Number of circuits 4 8

Outdoor air flow(Hi/Low) m

3

/h 6000/5800 6000/5800

Sound level(sound pressure)(Hi/Low) dB(A) 59/54 59/54

Outdoor unit

Dimension(W x D x H) mm 9401245360 9401245360

Packing (W x D x H) mm 10581380438 10581380438

Net/Gross weight kg 115/121 124/130

Refrigerant

Type R410A R410A

Charged volume g 3850 4000

Throttle type

Electronic expansion valve

& Capillary

Electronic expansion valve

& Capillary

Design pressure(Hi/Low) MPa 4.2/1.5 4.2/1.5

Refrigerant

piping

Liquid side/ Gas side mm 9.5/15.9 9.5/15.9

Max. refrigerant pipe length m 50 50

Max. difference in level

(Outdoor is up)

m 25 25

Max. difference in level

(Outdoor is down)

m 20 20

Ambient temp (Outdoor)

Cooling-15~43Heating

-15~24

Cooling-15~43Heating

-15~24

MCAC-UTSM-2010-06

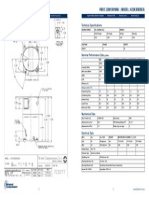

2. Dimensions

Unit: mm

MODEL A B C D E F H

MOU-12HDN1 761 530 290 315 270 279 593

MOUA-18HDN1-C0 842 560 335 360 312 324 695

MOUB-24HDN1 895 862 313 355 302 80 862

MOU-30HDN1 990 624 366 396 340 354 966

MOU-36HDN1 940 600 376 400 340 360 1245

MOUB-36HDN1-R 990 624 366 396 340 354 966

MOU-48HDN1 940 600 376 400 340 360 1245

MOUB-48HDN1-R 940 600 376 400 340 360 1245

MOUA-60HRDN1 940 600 376 400 340 360 1245

MOUD-60HDN1-R 940 600 376 400 340 360 1245

MCAC-UTSM-2010-06

3. Service Space

MCAC-UTSM-2010-06

4. Piping Diagrams

MOU-12HDN1

Compressor

Outdoor unit

4-way valve

Condenser

Indoor unit

Capillary ass'y

Evaporator

MOUA-18HDN1-C0MOUB-24HDN1

T

1

R

o

o

m

te

m

p

. s

e

n

s

o

r

T

2

E

v

a

p

o

r

a

to

r

te

m

p

. s

e

n

s

o

r

T4

Ambient temp. sensor

T3

Condenser temp. sensor

Fil ter Fil ter

T5

Discharge temp. sensor

Compressor

Electronic expansion valve

Evaporator

Capil lary

Indoor unit

4-way valve

High pressure switch

Outdoor unit

Condenser

Low pressure swi tch

Low pressure liquid

accumul ator

MOU-30HDN1 MOU-36HDN1MOU-48HDN1MOUB-36HDN1-RMOUB-48HDN1-RMOUA-60HRDN1

MOUD-60HDN1-R

Electronic

expansion valve

Oil separator

C

o

m

p

r

e

s

s

o

r

Low pressure

switch

Oil return

Capillary

High pressure switch

Low pressure liquid

accumulator

Evaporator

Capillary

Outdoor unit

Indoor unit

4-way valve

Condenser

T5

Discharge temp. sensor

Filter Filter

Condenser temp. sensor

T3

T4

Ambient temp. sensor

Filter

Filter

T2

Evaporator temp. sensor

Room temp. sensor

T1

MCAC-UTSM-2010-06

5. Wiring Diagrams

MOU-12HDN1

MCAC-UTSM-2010-06

MOUA-18HDN1-C0

MOUB-24HDN1

MCAC-UTSM-2010-06

MOU-30HDN1

MOU-36HDN1MOU-48HDN1

MCAC-UTSM-2010-06

MOUB-36HDN1-R

MOUB-48HDN1-RMOUA-60HRDN1

MCAC-UTSM-2010-06

MOUD-60HDN1-R

MCAC-UTSM-2010-06

6. Field Wiring

For 12000Btu/h (with -1Phase outdoor unit)

For 18000-48000Btu/h (with 1-phase outdoor unit)

MCAC-UTSM-2010-06

For 36000-60000Btu/h (with 3-phase outdoor unit)

MCAC-UTSM-2010-06

7. Electric Characteristics

Model

Outdoor Unit Power Supply Compressor OFM

Hz Voltage Min. Max. TOCA MFA RLA kW FLA

MOU-12HDN1 50 220-240 198 254 10 30 5.3 0.024 0.3

MOUA-18HDN1-C0 50 220-240 198 254 20 30 8.96 0.053 0.59

MOUB-24HDN1 50 220-240 198 254 20 30 10.4 0.053 0.67

MOU-30HDN1 50 220-240 198 254 20 40 13.5 0.2 1.4

MOU-36HDN1 50 220-240 198 254 30 40 13.6 0.12 0.8

MOU-48HDN1 50 220-240 198 254 30 40 13.6 0.12 0.8

MOUB-36HDN1-R 50 380 342 440 20 40 9.3 0.2 1.4

MOUB-48HDN1-R 50 380 342 440 20 40 9.3 0.12 0.82

MOUA-60HRDN1 50 380 342 440 20 40 15.2 0.12 0.82

MOUD-60HDN1-R 50 380-415 342 440 20 40 15.2 0.12 0.82

Remark:

TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A)

RLA: Rated Locked Amps. (A)

OFM: Outdoor Fan Motor.

FLA: Full Load Amps. (A)

KW: Rated Motor Output (KW)

MCAC-UTSM-2010-06

8. Sound Levels

Model

Noise level dB(A)

H/L

MOU-12HDN1 48/44

MOUA-18HDN1-C0 51/46

MOUB-24HDN1 58/55

MOU-30HDN1 55/50

MOU-36HDN1 57/52

MOU-48HDN1 59/54

MOUB-36HDN1-R 55/50

MOUB-48HDN1-R 59/54

MOUA-60HRDN1 59/54

MOUD-60HDN1-R 59/54

MCAC-UTSM-2010-06

9. Exploded View

MOU-12HDN1

No. Part Name Quantity No. Part Name Quantity

1 Cover plate 1 17 Condenser ass'y 1

2 E-part box ass'y 1 17.1 Condenser inlet pipe ass'y 1

2.1 Main control board ass'y 1 17.2 Condenser 1

2.2 Radiator 1 17.3 Condenser output pipe 1

3 Grille 1 18 Room temp sensor ass'y 1

4 Axial flow fan 1 19 Low pressure valve ass'y 1

5 Left supporter 1 19.1 Low pressure valve 1

6 Partition board ass'y 1 19.2 Solenoid 1

7 Base ass'y 1 20 High pressure valve ass'y 1

8 Reactance 1 20.1 High pressure valve 1

9 Electric inductance cover ass'y 1 20.2 One way valve 1

10 Sponge 1 21 Temp. sensor ass'y 1

11 Compressor electric heater 1 22 Motor bracket 1

12 Compressor 1 23 Motor 1

13 Right cover 1 24 Front panel 1

14 Drainage pan 1 25 Reactance 1

15 Big handle 1 26 Compressor capacitor 1

16 Discharge temp sensor ass'y 1

MCAC-UTSM-2010-06

MOUA-18HDN1-C0

No. Part Name Quantity No. Part Name Quantity

1 Front panel 1 23 Base ass'y 1

2 Grille 1 24 Inductance board 1

3 Big handle 1 25 Reactance 1

4 Rear right clapboard ass'y 1 26 Temp.sensor ass'y 1

5 Drainage cover 1 27 Condenser ass'y 1

6 Sponge II 1 28 Axial flow fan 1

7 Sponge 1 29 Motor bracket ass'y 1

8 Compressor electric heater 1 30 Motor 1

9 Compressor wire joint ass'y 1 31 Rear net frame ass'y 1

10 Compressor 1 32 Top cover ass'y 1

11 4-way valve ass'y 1 33 Small handle 1

11.1 Pressure controller 1 34 E-part box ass'y 1

11.2 4-way valve 1 34.1 High pressure switch protection wiring 1

11.3 Solenoid 1 34.2 Power board ass'y 1

11.4 Pressure controller 1 34.3 Control board ass'y 1

11.5 Low pressure valve 1 34.4 Communication cable 1

11.6 Muffler 1 34.5 Main control board wire joint ass'y 1

12 Discharge temp. sensor ass'y 1 34.6 Cable 1

13 High pressure valve ass'y 1 34.7 Motor capacitor 1

13.1 Electronic expansion valve 1 34.8 Compressor capacitor 1

13.2 EEV solenoid 1 34.9 Inverter radiator 1

13.3 Strainer 2 34.10 Wire joint, 2p 1

13.4 High pressure valve 1 34.11 Wire joint 1

14 Rubber gasket 2 34.12 Wire joint 1

15 Antivibration rubber 1 34.13 EMC filter 1

16 Front right clapboard ass'y 1 34.14 Transformer 1

17 Valve plate 1 34.15 Power supply transformer 1

18 Partition board ass'y 1 34.16 Rectifier bridge 2

19 Electrical inductance box 1 34.17 Inverter module 1

20 Reactance 1 34.18 Low pressure switch protection cable 1

21 Reactance 1 34.19 RS485 communication connecting wire 1

22 Supporting board 1 35 Room temp. sensor 1

MCAC-UTSM-2010-06

MOUB-24HDN1

No Part Name Quantity

No Part Name Quantity

1 Grille 1 19 Front panel 1

2 Top cover ass'y 1 20 Motor bracket ass'y 1

3 Condenser ass'y 1 21 Left holder 1

4 Rear right clapboard ass'y 1 22 Axial flow fan 1

5 4-way valve ass'y 1 23 Motor 1

5.1 Low pressure valve 1 24 E-part box ass'y 1

5.2 Pressure controller 1 24.1 Wire joint 1

5.3 4-way valve 1 24.2 E-Part box 1

5.4 Pressure controller 1 24.3 E-part box 1

5.5 Solenoid 1 24.4 Rectifier 2

6 Big handle 1 24.5 Radiator 1

7 Handle 2 24.6 Wire joint 1

8 High pressure valve ass'y 1 24.7 Inverter module 1

8.1 High pressure valve 1 24.8 Transformer 1

8.2 Electronic expansion valve 1 24.9 EMC filter 1

8.3 EEV solenoid 1 24.10 Compressor capacitor 1

9 Drainage cover 1 24.11 Motor capacitor 1

10 Valve plate 1 24.12 Wire joint 1

11 Compressor 1 24.13 Transformer 1

12 Compressor electric heater 1 24.14 Power board ass'y 1

13 Base ass'y 1 24.15 DC control board ass'y 1

14 Reactance 1 25 Discharge temp sensor ass'y 1

15 Reactance 1 26 Temp sensor ass'y 1

16 Reactance 1 27 Compressor wire joint ass'y 1

17 Front right clapboard ass'y 1 28 Temp sensor ass'y 1

18 Partition board ass'y 1 29 R410A 2.3

MCAC-UTSM-2010-06

MOU-30HDN1

No Part Name Quantity

No Part Name Quantity

1 Condenser ass'y 1 14 High pressure valve ass'y 1

1.1 Condenser 1 14.1 Electronic expansion valve 1

1.2 Input pipe ass'y 1 14.2 High pressure valve 1

1.3 Output pipe ass'y 1 14.3 EEV solenoid 1

2 Left holder 1 15 4-way valve ass'y 1

3 Rear net 1 15.1 4-way valve 1

4 Temp sensor ass'y 1 15.1 Solenoid 1

5 Top cover ass'y 1 15.3 Low pressure valve 1

6 E-part box ass'y 1 16 Discharge temp sensor ass'y 1

6.1 Main controller ass'y 1 17 Discharge pipe ass'y 1

6.2 Outdoor module ass'y 1 17.1 Pressure controller 1

6.3 Filter board ass'y 1 17.2 Oil separator 1

6.4 Rectifier 2 18 Fixing ring 2

6.5 EMC filter 1 19 Compressor 1

6.6 Capacitor 1 20 Motor 1

6.7 Wire joint 1 21 Partition board ass'y 1

6.8 Compressor capacitor 1 22 Reactance 1

6.9 Transformer 1 23 Reactance 1

6.10 Radiator 1 24 Electrical inductance box 1

6.11 Wire joint 1 25 Base 1

6.12 Wire joint 1 26 Reactance 1

6.13 E-part box 1 27 Motor bracket ass'y 1

6.14 Capacitor Installation board 1 28 Grille 1

7 Rear right clapboard ass'y 1 29 Inductance board 1

8 Big handle 1 30 Inductance cover 1

9 Drainage pan 1 31 Front panel 1

10 Axial flow fan 1 32 Temp sensor ass'y 1

11 Accumulator cylinder 1 33 Copper nut 1

12 Suction pipe ass'y 1 34 Copper nut 1

12.1 Pressure controller 1 35 Compressor electric heater 1

13 Front right clapboard ass'y 1 36 R410A 3.35

MCAC-UTSM-2010-06

MOU-36HDN1

No Part Name Quantity

No Part Name Quantity

1 Top cover ass'y 1 19.4 EEV solenoid 1

2 Base 1 19.5 Electronic expansion valve 1

3 Rear net 1 20 Fixing ring 1

4 Partition board ass'y 1 21 Accumulator cylinder 1

5 Electrical inductance box ass'y 1 22 Axial flow fan 2

6 PFC inductance 1 23 Motor 2

7 Condenser ass'y 1 24 Rear support board 1

7.1 Condenser 1 25 Motor bracket ass'y 1

7.2 Condenser 1 26 E-part box ass'y 1

7.3 Condenser outlet pipe 1 26.1 Filter board ass'y 1

8 Discharge temp sensor ass'y 1 26.2 Main controller ass'y 1

9 Front clapboard ass'y 1 26.3 Inverter module ass'y 1

10 Rear clapboard ass'y 1 26.4 Surge suppresser 1

11 Grille 2 26.5 RS485 communication connect wire 1

12 Front panel 1 26.6 Transformer 1

13 Compressor electric heater 1 26.7 Transformer 1

14 Compressor 1 26.8 Motor capacitor 2

15 4-way valve ass'y 1 26.9 Switch Protection wiring 1

15.1 Low pressure valve 1 26.10 Aluminum electroanalysis capacitor 2

15.2 4-way valve 1 26.11 Three phase bridge 1

15.3 Solenoid 1 26.12 Radiator 1

16 Discharge pipe ass'y 1 26.13 PFC module 1

16.1 Pressure controller 1 26.14 Resistor 1

17 Temp sensor ass'y 1 26.15 Resistance 2

18 Suction pipe ass'y 1 26.16 Contactor 1

18.1 Strainer 1 26.17 Wire joint 1

18.2 Pressure controller 1 26.18 Wire joint 1

19 High pressure valve ass'y 1 27 Valve plate 1

19.1 High pressure valve 1 28 Drainage pan 1

19.2 Strainer 1 29 Temp sensor 1

19.3 Strainer 1

MCAC-UTSM-2010-06

MOU-48HDN1

MCAC-UTSM-2010-06

No Part Name Quantity

No Part Name Quantity

1 Top cover ass'y 1 19.4 EEV solenoid 1

2 Base 1 19.5 Electronic expansion valve 1

3 Rear net 1 20 Fixing ring 1

4 Partition board ass'y 1 21 Accumulator cylinder 1

5 Electrical inductance box ass'y 1 22 Axial flow fan 2

6 PFC inductance 1 23 Motor 2

7 Condenser ass'y 1 24 Rear support board 1

7.1 Condenser 1 25 Motor bracket ass'y 1

7.2 Condenser 1 26 E-part box ass'y 1

7.3 Condenser outlet pipe 1 26.1 Filter board ass'y 1

8 Discharge temp sensor ass'y 1 26.2 Main controller ass'y 1

9 Front clapboard ass'y 1 26.3 Inverter module ass'y 1

10 Rear clapboard ass'y 1 26.4 Surge suppresser 1

11 Grille 2 26.5 RS485 communication connect wire 1

12 Front panel 1 26.6 Transformer 1

13 Compressor electric heater 1 26.7 Transformer 1

14 Compressor 1 26.8 Motor capacitor 2

15 4-way valve ass'y 1 26.9 Switch Protection wiring 1

15.1 Low pressure valve 1 26.10 Aluminum electroanalysis capacitor 2

15.2 4-way valve 1 26.11 Three phase bridge 1

15.3 Solenoid 1 26.12 Radiator 1

16 Discharge pipe ass'y 1 26.13 PFC module 1

16.1 Pressure controller 1 26.14 Resistor 1

17 Temp sensor ass'y 1 26.15 Resistance 2

18 Suction pipe ass'y 1 26.16 Contactor 1

18.1 Strainer 1 26.17 Wire joint 1

18.2 Pressure controller 1 26.18 Wire joint 1

19 High pressure valve ass'y 1 27 Valve plate 1

19.1 High pressure valve 1 28 Drainage pan 1

19.2 Strainer 1 29 Temp sensor 1

19.3 Strainer 1

MCAC-UTSM-2010-06

MOUB-36HDN1-R

No. Part Name Quantity No. Part Name Quantity

1 Top cover ass'y 1 16 Partition board ass'y 1

2 Rear Supporter 1 17 Base 1

3 Condenser ass'y 1 18 Front right clapboard ass'y 1

3.1 Condenser 1 19 Discharge temp sensor ass'y 1

3.2 Output pipe ass'y 1 20 Room temp sensor ass'y 1

3.3 Input pipe ass'y 1 21 Temp sensor ass'y 1

3.4 Input pipe ass'y 1 22 Compressor electric heater 1

4 Rear right clapboard ass'y 1 23 Grille 1

5 Branch pipe ass'y 1 24 Electrical inductance 1

6 Big handle ass'y 1 25 Inductance cover 1

7 4-way valve ass'y 1 26 Inductance Holder 1

7.1 Low pressure valve 1 27 Inductance board 1

7.2 Solenoid 1 28 Front panel 1

7.3 4-way valve 1 29 Axial flow fan 1

8 High pressure valve ass'y 1 30 Motor 1

8.1 Strainer 1 31 Motor bracket ass'y 1

8.2 EEV solenoid 1 32 E-part box ass'y 1

8.3 High pressure valve 1 32.1 Compressor capacitor 1

8.4 Strainer 1 32.2 Wire joint 1

8.5 Electronic expansion valve 1 32.3 Wire joint 1

9 Valve plate 1 32.4 Transformer 1

10 Drainage cover 1 32.5 Transformer 1

11 Discharge pipe ass'y 1 32.6 Contactor 1

11.1 Pressure controller 1 32.7 Single-phase bridge 1

11.2 Oil separator 1 32.8 Three phase bridge 1

11.3 Pipe joint 1 32.9 Capacitor 1

11.4 Strainer 1 32.10 Aluminum electroanalysis capacitor 2

12 Compressor 1 32.11 Resistance 2

13 Suction pipe ass'y 1 32.12 Resistor 2

13.1 Pressure controller 1 32.13 Main control board ass'y 1

13.2 Strainer 1 32.14 Filter board ass'y 1

14 Fixing ring 1 32.15 Inverter module 1

15 Accumulator cylinder 1 33 Left holder 1

MCAC-UTSM-2010-06

MOUB-48HDN1-R

No. Part Name Quantity No. Part Name Quantity

1 Top cover ass'y 1 17 Front panel 1

2 Rear net clip 1 18 Grille 2

3 Condenser ass'y 1 19 Inductance Holder 1

3.1 Fluted pipe ass'y 1 20 Inductance board 1

3.2 Condenser 1 21 Inductance cover 1

3.3 Distributor ass'y 1 22 Electrical inductance 1

4 Rear net 1 23 Partition board ass'y 1

5 Rear clapboard ass'y 1 24 Motor bracket ass'y 1

6 Handle 2 25 Separator 1

7 Valve plate 1 26 Axial flow fan 2

8 Drainage cover 1 27 Motor 2

9 4-way valve ass'y 1 28 Rear support board II 1

9.1 Low pressure valve 1 29 E-part box ass'y 1

9.2 4-way valve 1 29.1 Motor capacitor 2

9.3 Solenoid 1 29.2 Compressor capacitor 1

10 High pressure valve ass'y 1 29.3 Wire joint 1

10.1 Strainer 1 29.4 Wire joint 1

10.2 Strainer 1 29.5 Transformer 1

10.3 High pressure valve 1 29.6 Transformer 1

10.4 EEV solenoid 1 29.7 AC contactor 1

10.5 Electronic expansion valve 1 29.8 Single-phase bridge 1

11 Fixing ring 1 29.9 Three phase bridge 1

12 Discharge pipe ass'y 1 29.10 Aluminum electroanalysis capacitor 2

12.1 Oil separator 1 29.11 Resistance 2

12.2 Strainer 1 29.12 Resistor 2

12.3 Pressure controller 1 29.13 Main control board ass'y 1

13 Suction pipe ass'y 1 29.14 Filter board ass'y 1

13.1 Pressure controller 1 29.15 Inverter module 1

13.2 Strainer 1 30 Compressor electric heater 1

14 Compressor 1 31 Temp sensor ass'y 1

15 Base 1 32 Temp sensor 1

16 Front clapboard ass'y 1 33 Discharge temp sensor ass'y 1

MCAC-UTSM-2010-06

MOUA-60HRDN1

No Part Name Quantity

No Part Name Quantity

1 Top cover ass'y 1 17.1 Pressure controller 1

2 Base 1 17.2 Strainer 1

3 Axial flow fan 2 18 Fixing ring 1

4 Rear clapboard ass'y 1 19 Accumulator cylinder 1

5 Condenser ass'y 1 20 Motor bracket ass'y 1

5.1 Condenser 1 21.1 Rear support board 1

5.2 Input pipe ass'y 21.2 Rear support board 1

5.3 Input pipe ass'y 1 22 Rear net 1

6 Discharge temp sensor ass'y 1 23 Motor 2

7 Front clapboard ass'y 1 24 Inductance Holder 1

8 Partition board ass'y 1 25 Inductance cover 1

9 Grille 1 26 Electrical inductance 1

10 Front panel ass'y 1 27 Board 1

11 Compressor electric heater 1 28 E-part box ass'y 1

12 Compressor 1 28.1 Filter board ass'y 1

13 High pressure valve ass'y 1 28.2 Main controller ass'y 1

13.1 High pressure valve 1 28.3 Inverter module 1

13.2 EEV solenoid 1 28.4 Surge suppresser 2

13.3 Strainer 2 28.5 RS485 communication connect wire 1

13.4 Electronic expansion valve 1 28.6 Transformer 1

14 Temp sensor 1 28.7 Transformer 1

15 Discharge pipe ass'y 1 28.8 Motor capacitor 2

15.1 Pressure controller 1 28.9 Switch Protection wiring 1

16 4-way valve ass'y 1 28.10 Aluminum electroanalysis capacitor 2

16.1 Low pressure valve 1 28.11 Three phase bridge 1

16.2 4-way valve 1 29 Valve plate 1

16.3 Solenoid 1 30 Drainage pan 1

17 Suction pipe ass'y 1

MCAC-UTSM-2010-06

MOUD-60HDN1-R

No. Part Name Quantity No. Part Name Quantity

1 Top cover ass'y 1 17.2 Strainer 1

2 Base 1 18 Fixing ring 1

3 Axial flow fan 2 19 Accumulator cylinder 1

4 Rear clapboard ass'y 1 20 Motor bracket ass'y 1

5 Condenser ass'y 1 21 Rear support board I 1

5.1 Condenser 1 22 Rear net 1

5.2 Condenser 1 23 Motor 2

5.3 Fluted pipe ass'y 1 24 Inductance Holder 1

5.4 Distributor ass'y 1 25 Inductance cover 1

6 Discharge temp sensor ass'y 1 26 Electrical inductance 1

7 Front clapboard ass'y 1 27 Inductance board 1

8 Partition board ass'y 1 28 Valve plate 1

9 Grille 2 29 Drainage cover 1

10 Front panel 1 30 Temp sensor 1

11 Compressor electric heater 1 31 E-part box ass'y 1

12 Compressor 1 31.1 Main control board ass'y 1

13 High pressure valve ass'y 1 31.2 Filter board ass'y 1

13.1 Strainer 2 31.3 Resistor 2

13.2 EEV solenoid 1 31.4 Aluminum electro analysis capacitor 2

13.3 Electronic expansion valve 1 31.5 Single-phase bridge 1

13.4 High pressure valve 1 31.6 Three phase bridge 1

14 Temp sensor ass'y 1 31.7 Transformer 1

15 Discharge pipe ass'y 1 31.8 Wire joint 1

15.1 Strainer 1 31.9 Compressor capacitor 1

15.2 Oil separator 1 31.10 Transformer 1

15.3 Pressure controller 1 31.11 Motor capacitor 2

16 4-way valve ass'y 1 31.12 Inverter module 1

16.1 Low pressure valve 1 31.13 Radiator 1

16.2 4-way valve 1 31.14 AC contactor 1

16.3 Solenoid 1 31.15 E-part box 1

17 Suction pipe ass'y 1 31.16 Resistance 2

17.1 Pressure controller 1 31.17 Wire joint 1

MCAC-UTSM-2010-06

10. Operation Limits

MCAC-UTSM-2010-06

11. Troubleshooting

10.1 Indoor unit malfunction

10.1.1 Display board

Compact 4-way cassette

Ceiling & Floor Normal 4-way cassette

Duct

MCAC-UTSM-2010-06

10.1.2 Troubleshooting

For Normal 4-way cassette

No Malfunction Operation lamp Timer lamp Defrosting lamp Alarm lamp Display

1

Communication malfunction

between in-outdoor unit

LED2

Quick-flash

E1

2

Room temperature sensor

malfunction

LED1

Quick-flash

E2

3

Pipe temperature sensor

malfunction

LED1

Quick-flash

E3

4

Pipe temperature sensor

malfunction

LED1

Quick-flash

E4

5 Water-level alarm

LED4

Quick-flash

EE

6 EEPROM malfunction

LED1

Slow-flash

E7

7 Mode conflicts malfunction

LED3

Quick-flash

E0

8 Outdoor malfunction

LED4

Slow-flash

Ed

For ceiling & floor & compact 4-way cassette

No Malfunction Operation lamp Timer lamp Defrosting lamp Alarm lamp

1

Communication malfunction

between in-outdoor unit

LED2

Quick-flash

2

Room temperature sensor

malfunction

LED1

Quick-flash

3 Water-level alarm

LED4

Quick-flash

4 Mode conflicts malfunction

LED3

Quick-flash

5 Outdoor malfunction

LED4

Slow-flash

For Duct type

No Malfunction & protection define

LED1

OPERATION

LED2

TIMER

LED3

DEF.FAN

LED4

ALARM

Display Digital Tube

1 Collision mode malfunction E0

2

In-Outdoor unit COMM. Checking

channel is abnormal

E1

3

Room TEMP. sensor checking

channel is abnormal

E2

4

Pipe TEMP. Sensor checking

channel is abnormal(T2)

E3

5

Pipe TEMP. Sensor checking

channel is abnormal(T2B)

E4

6 EPPROM malfunction E7

7 Water-level alarm malfunction EE

8 Outdoor malfunction Ed

9

Be closed by the remote control

function

CP

10 Anti-cold & Defrost

Extinguish Flashing at 5HZ Flashing at 1HZ

MCAC-UTSM-2010-06

1. Operation lamp flashes

Operation lamp flashes at 5Hz

Judge 1: Indoor temp. sensor is abnormal

Check whether the resistance of the evaporator temp. sensor is

correct according to Annex 1

Judge 2: Room temp. sensor is abnormal

Replace evaporator temp. sensor

No

Yes

Check whether the resistance of the room temp.

sensor is correct according to Annex 1

Replace room temp. sensor

No

Replace indoor PCB

Yes

MCAC-UTSM-2010-06

2. Timer lamp flashes

3. Alarm lamp slow-flash

Timer lamp flashes at 5Hz

Judge: Indoor/outdoor unit communication is abnormal

Refer to the outdoor unit LED display E2 malfunction in the following part

Indoor alarm lamps flash at 1Hz

Judge 1: Condenser temp. sensor is abnormal

Check whether the resistance of the condenser temp. sensor is

correct according to Annex 1

Judge 2: Outdoor unit is abnormal

Refer to the outdoor unit LED display E4P1P2 malfunction in the

following part

Replace condenser temp. sensor

No

Yes

Condenser temp. sensor or outdoor unit is malfunction

MCAC-UTSM-2010-06

4. Alarm lamp quick-flash

5. Defrost lamp flashes

Alarm lamp flashes at 5Hz

Judge: Water level switch is abnormal.

Select the cooling mode to make water pump work for a few minutes, then check

whether the system can run normally

Replace indoor PCB

Trouble is solved

Yes

No

Check whether the water drain pipe is blocked

No

Solve to make the water can flow

fluently

Yes

Check whether the water pump can work normally

Replace water pump

No

Yes

Defrost lamp flashes

Judge: Mode conflicts malfunction

Turn the indoor unit to heating mode or turn off the unit

MCAC-UTSM-2010-06

11.2 Outdoor unit malfunction

Display Malfunction or Protection

E0 EEPROM malfunction

E2 Communication malfunction between indoor IC and outdoor IC

E3 Communication malfunction in outdoor IC and DSP

E4 Malfunction of outdoor temperature sensor

E5 Voltage protection of compressor

E6 PFC module protection (Only for 30K, 36K & 48K with 1 phase)

P0 Top temperature protection of compressor

P1 High pressure protection

P2 Low pressure protection

P3 Current protection of compressor

P4 Discharge temperature protection of compressor

P5 High temperature protection of condenser

P6 Module protection

1. E0 malfunction

E0 display

EEPROM malfunction

Judge: Check whether the EEPROM is inserted well

Yes

No

Insert the EEPROM well

Replace outdoor main board

MCAC-UTSM-2010-06

2. E2 malfunction

E2 display

Communication malfunction between indoor IC and outdoor IC

Judge 3: Check whether the signal wiring between the indoor and

outdoor units is wrong polarity?

Connect the signal wiring correctly

Yes

No

Judge 4: Check whether the signal wiring between the indoor and

outdoor units is broken?

Yes

Replace the broken wiring

No

Judge 2: Check whether the signal wiring is shield cable or whether

the shield cable is earthed

Yes

Adopt the shield cable/ let shield cable earthed

No

Indoor or outdoor main board is broken. Replace the main

board until the malfunction disappears.

Judge 1: Check whether the indoor unit power is on Turn on the indoor unit power

No

Yes

MCAC-UTSM-2010-06

3. E3 malfunction (For 18K & 24K & 30K)

Check whether the indicator lights LED1 on the main board is flashing

Check whether the connecting wiring between the IPM module and the CN4

on the main board is broken off

Check whether the connecting wiring between the IPM module positive

pole and the CN12 on the power board is broken off

Use the multimeter to measure whether the voltage between the CN12 and

the CN13 on the power board is between +277V~345V

Check whether the connecting wiring between the IPM module negative

pole and the CN13 on the power board is broken off

E3 display

Communication malfunction in outdoor IC and DSP

Replace the outdoor main board

Yes

Insert the connecting wiring well over

again

In

Yes

No

No

Replace outdoor main board

Yes

No

Insert the connecting wiring well over again

Yes

No

No

Replace the IPM module

Yes

Replace the power board

No

Insert the connecting wiring well over again

Yes

Disconnect the connecting wiring between the IPM module and the CN4 on the

main board, use the multimeter to measure the voltage between the IPM module

CN1 ports 3 and 4 pillar, check whether it is 5V, (the third pillar on the main board

labels +5V)

MCAC-UTSM-2010-06

4. E3 malfunction (For 36K & 48K & 60K)

E3 display

Communication malfunction in outdoor IC and DSP

Check whether the indicator lights LED1 or LED2 on the main control

board are flashing

Replace PCB

Yes

Install the IC-U3 chip of the PCB over again, check whether the system

can run normally

Trouble is solved

Yes

No

Check whether the output of the transformer to CN4 socket is well

No

Replace PCB

Yes

No

Replace the transformer

MCAC-UTSM-2010-06

5. E4 malfunction

E4 display

Check whether the wiring of the outdoor ambient temperature sensor (T4) is

broken off

Replace PCB

Judge 1: Outdoor condenser temp. sensor (T3) is malfunction

Check whether the wiring of the condenser temp. sensor is broken off

Connect the wiring well

Yes

No

Check whether the resistance of condenser temp. sensor is wrong

refer to the Annex 1

Yes

Replace condenser temp. sensor

No

Judge 2: Outdoor ambient temp. sensor (T4) is malfunction

Connect the wiring well

Yes

No

Check whether the resistance of outdoor ambient temperature sensor

(T4) is wrong refer to the Annex 1

Yes

Replace outdoor ambient temperature sensor

(T4)

No

MCAC-UTSM-2010-06

6. E5 malfunction

7. E6 malfunction (Only for 30K, 36K & 48K with 1 phase)

E5 display

Voltage protection of compressor

Check the voltage of outdoor unit power supply, whether the voltage

between L(1) and N is about 172-265V

No

Replace the power board, then check whether the system can run normally

Check the power supply

Yes

Replace outdoor main board

Yes

Trouble is solved

No

E6 display

PFC module protection

Check whether the connecting line between main

board and the PFC module is connected tightly

No

Connect it tightly, check normal or not

Yes

Check whether the voltage between P

and N of IPM module is 380-390V

No

Yes

Replace the outdoor main board

No

Replace the PFC module

MCAC-UTSM-2010-06

8. P1 malfunction

P1 display

High pressure protection

Judge 1: Whether the wiring between the high pressure switch and main

control board is connected well or correctly

Judge 2: Whether the high pressure switch is broken

Yes

No

Connect it well

Method: Short connect the high pressure switch socket, check

whether the system can run normally

Yes

Replace high pressure switch

No

Check whether the refrigerant system is ok

Replace outdoor main board

No

Judge 3: Check whether the outdoor ambient temperature is too high

Yes

Stop the unit

No

Judge 4: Check whether the outdoor unit is bad ventilation

Yes

Make the outdoor unit ventilate well

No

Judge 5: Check whether the heat exchanger is dirty

Yes

Clean the heat exchanger

No

Judge 6: Check whether the refrigerant pipe is blocked

Yes

Let the refrigerant out, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize and

charge the refrigerant again

MCAC-UTSM-2010-06

9. P2 malfunction

P2 display

Low pressure protection

Judge 1: The wiring between the low pressure switch and main control

board is connected well or correctly

Judge 2: Whether the low pressure switch is broken

Connect it well

Method: Short connect the low pressure switch socket, check

whether the system can run normally

Check whether the refrigerant system is ok

Yes

No

Judge 3: Check whether the outdoor ambient temperature is too low

Yes

Stop the unit

No

Judge 4: The refrigerant of the system is leakage

Yes

Method: Connect the pressure gauge to the gauge joint of the system,

check whether the pressure is lower than 0.14MPa

Leak hunting: Charge nitrogen or refrigerant to

the system, if the leakage is serious, there will

be distinct gas leakage cici sound; if the

leakage is slight, use the suds (mixture of water

and abluent is also ok if it can make bubble) or

electronic leak detector.

Judge 5: The refrigerant pipe is blocked

Yes Let the refrigerant out, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize and

charge the refrigerant again

No

Replace outdoor main board

No

No

Yes

Replace low pressure switch

MCAC-UTSM-2010-06

10. P3 malfunction

P3 display

Current protection of compressor

Judge 1: Check whether the input current of the power supply wire is more

than 20A (For 36K & 48K with 1 phase, it is 30A)

Check whether the refrigerant system is ok

Yes

Judge 2: Check whether the outdoor ambient temperature is too high

Yes

Stop the unit

Replace outdoor main board

No

No

Judge 3: Check whether the outdoor unit is bad ventilation

Yes

Make the outdoor unit ventilate well

No

Judge 4: Check whether the heat exchanger is dirty

Yes

Clean the heat exchanger

No

Judge 5: The refrigerant pipe is blocked

Yes

Let the refrigerant out, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize and

charge the refrigerant again

MCAC-UTSM-2010-06

11. P4 malfunction

When compressor discharge temperature is higher than 115C, the unit will stop, and unit runs again when

compressor discharge temperature is lower than 90C.

P4 display

Discharge temperature protection of compressor

Check whether the compressor discharge temp. is more than 115C ?

No

Check whether the wiring connection is right

between compressor discharge temp. sensor and

PCB according to wiring diagrams

Yes

Method: Check whether the resistance of compressor discharge

temp. sensor is right refer to the Annex 2

No

Correct the wiring connection

Yes

Replace outdoor main board

Judge: The discharge temp. sensor is broken

No

Replace the compressor

discharge temp. sensor

Check whether the refrigerant is leak

Stop leaking and add refrigerant

Yes

Yes

MCAC-UTSM-2010-06

12. P5 malfunction

When condenser high temp. is more than 65C, the unit will stop, and unit runs again when outdoor pipe

temp. less than 52C.

P5 display

High temperature protection of condenser

Check whether the condenser temperature is more than 65C

No

Check whether the resistance of condenser temp.

sensor is correct refer to the Annex 1

Yes

Replace outdoor main board

No

Replace the temperature sensor

Yes

Judge1: The outdoor temp. is too high

Replace outdoor main board

No

Judge 2: Check whether the heat exchanger is dirty

No

Judge 3: The refrigerant pipe is blocked

Clean the heat exchanger

Yes

Yes Let the refrigerant out, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize and

charge the refrigerant again

Yes

Stop the unit

No

MCAC-UTSM-2010-06

13. P6 malfunction (For single phase units)

P6 display

Module protection

Check whether the voltage range of P-N on

IPM module is normal? DC277-356V for

18K/24K/30KBtu/h; DC277-410V for

36K/48KBtu/h

No

Check whether the input power supply

is correct? 220-240V, 1N, 50Hz

No

Regulate it to correct,

then check whether the

system can work

normally?

Yes

Check whether the power

supply line is connected

correctly and tightly

No

Connect it correctly and

tightly, check ok or not?

No

Yes

Check whether the lines in

E-part box are connected tightly

No

Connect it tightly,

check ok or not?

No

Yes

Check whether the single-phase bridge is

normal? Use the multimeter to measure the

resistance between each two terminals, check

whether there is the condition that value of

resistance is 0

Yes

Replace the

single-phase bridge

No

No

Check whether the connecting line

of every reactor is normal? If the

line is broken, the resistance of the

two ports is

No

Replace the

connecting line

Yes

Check whether the connecting line

between main board and the IPM

module is connected tightly

Yes

Check whether the connecting

line of the compressor is

connected correctly or tightly

Yes

Replace the IPM module, check

whether the system can work

normally?

No

Replace the main board, check

whether the system can work

normally?

Yes

Trouble is solved

No

Replace the compressor, check

whether the system can work

normally?

Connect it tightly,

check ok or not?

No

No

Yes

Trouble is solved

No

No

Yes

Trouble is solved

Yes

Check whether the fuse on

the power board is normal?

No

Replace with

the same model

fuse

Yes

Replace the power board

Connect it well,

check ok or not?

MCAC-UTSM-2010-06

14. P6 malfunction (For three phases units)

P6 display

Module protection

Check whether the voltage range of P-N on

IPM module is normal? DC 350-650V

No

Check whether the input power supply

is correct? 380-415V, 3N, 50Hz

No

Regulate it to correct,

then check whether the

system can work

normally?

Yes

Check whether the power

supply line is connected

correctly and tightly

No

Connect it correctly and

tightly, check ok or not?

No

Yes

Check whether the lines in

E-part box are connected tightly

No

Connect it tightly,

check ok or not?

No

Yes

Check whether the three phase bridge

is normal?

No Replace the three phase

bridge

No

Yes

Check whether the 3300F/400V

electrolytic capacitor is normal?

No

Replace this electrolytic

capacitor

Yes

Check whether the connecting line

between main board and the IPM

module is connected tightly

Yes

Check whether the connecting

line of the compressor is

connected tightly

Yes

Replace the IPM module, check

whether the system can work

normally?

No

Replace the main board, check whether the

system can work normally?

Yes

Trouble is solved

No

Replace the compressor , check whether

the system can work normally?

Yes

Trouble is solved

Connect it tightly,

check ok or not?

No

Connect it tightly,

check ok or not?

No

Yes

Trouble is solved

Potrebbero piacerti anche

- LG THERMA V - Service Manual - MonoblokDocumento126 pagineLG THERMA V - Service Manual - MonoblokMuhidin Kozica100% (2)

- Daikin Print Part ListDocumento4 pagineDaikin Print Part ListPriesilia Presley100% (2)

- ARD Manual (English)Documento3 pagineARD Manual (English)Habibulla Bavaji100% (6)

- SM Auhf12lal Aohb12lall 10 en PDFDocumento25 pagineSM Auhf12lal Aohb12lall 10 en PDFpepondeAviles100% (1)

- DB AVX-B-R134a-50-60HzDocumento32 pagineDB AVX-B-R134a-50-60Hzrahimi mohamadNessuna valutazione finora

- 40LX040 060 (Malaysia)Documento8 pagine40LX040 060 (Malaysia)Leed ENNessuna valutazione finora

- VCV WesperDocumento12 pagineVCV Wesperciperu55Nessuna valutazione finora

- Energy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134aDocumento30 pagineEnergy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134atechnokakiNessuna valutazione finora

- AUX-Service Manual of Multi SplitDocumento60 pagineAUX-Service Manual of Multi Splitrock_music75% (4)

- LN Electrical DataDocumento7 pagineLN Electrical DataBen MusimaneNessuna valutazione finora

- Manual Servicio DCD DBC DBFDocumento247 pagineManual Servicio DCD DBC DBFViorel Cioata100% (1)

- HAIER - HSU-09 12HC Service ManDocumento109 pagineHAIER - HSU-09 12HC Service ManaircoolplusNessuna valutazione finora

- Technical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)Documento32 pagineTechnical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)yusuf mohd sallehNessuna valutazione finora

- 2015 VN Single InverterDocumento29 pagine2015 VN Single InverterMinhvan LeNessuna valutazione finora

- SM Si30-701 Service DiagnosisPocketDocumento403 pagineSM Si30-701 Service DiagnosisPocketstelandreouNessuna valutazione finora

- Catalogue WoteckDocumento32 pagineCatalogue WoteckTuấn MinhNessuna valutazione finora

- CLCP Euro - Commercial May 09: Quick Selection ProcedureDocumento2 pagineCLCP Euro - Commercial May 09: Quick Selection ProcedurehfrankieNessuna valutazione finora

- SB 0018Documento2 pagineSB 0018mikenilsonNessuna valutazione finora

- AS-09UR4SGNPQ-service Manual PDFDocumento51 pagineAS-09UR4SGNPQ-service Manual PDFColesha BarukaNessuna valutazione finora

- Pacv - S - SKM PDFDocumento44 paginePacv - S - SKM PDFomar farukNessuna valutazione finora

- Em-Rxyq-Taydu (Edus341703a-R1)Documento108 pagineEm-Rxyq-Taydu (Edus341703a-R1)Efrain J Colina ANessuna valutazione finora

- 01 Daikin PA Catalogue 240117 - High Res - 0Documento24 pagine01 Daikin PA Catalogue 240117 - High Res - 0T Satheesh KumarNessuna valutazione finora

- T Series EmersonDocumento4 pagineT Series EmersonJose SurielNessuna valutazione finora

- Copeland Parts ListDocumento129 pagineCopeland Parts ListYorkistNessuna valutazione finora

- IPM TroubleshootingDocumento1 paginaIPM TroubleshootingAhmed AzadNessuna valutazione finora

- Fxaq-Avm Wall Mounted Type 60 HZDocumento18 pagineFxaq-Avm Wall Mounted Type 60 HZsander1234silvaNessuna valutazione finora

- 30xa 14pd Carrier-Water CHILLERDocumento168 pagine30xa 14pd Carrier-Water CHILLERbetterone100% (1)

- H23A383DBEADocumento1 paginaH23A383DBEABruno Monteiro0% (1)

- 30ka enDocumento20 pagine30ka enmanchau717Nessuna valutazione finora

- 8 65 105 EvapsDocumento41 pagine8 65 105 EvapsRestino KionyNessuna valutazione finora

- Cassette 28000 Btu PDFDocumento84 pagineCassette 28000 Btu PDFISMAEL ENRIQUE VALENCIA JURADONessuna valutazione finora

- Samsung R600a New Devl MarketingDocumento18 pagineSamsung R600a New Devl MarketingAleksei EvchuNessuna valutazione finora

- Service Manual HaierDocumento259 pagineService Manual HaierManuel Clemente Cañamero Alonso100% (5)

- Ceiling Mounted Duct Type FXMQ20-140PVE 50/60HzDocumento65 pagineCeiling Mounted Duct Type FXMQ20-140PVE 50/60HzTi TiNessuna valutazione finora

- VRV System: Rajeev Khatri Daikin Air Conditioning India Pvt. LTDDocumento52 pagineVRV System: Rajeev Khatri Daikin Air Conditioning India Pvt. LTDAGNIDEEP BAIDYANessuna valutazione finora

- General DataDocumento88 pagineGeneral DataBIMANessuna valutazione finora

- Haier Air ConditionerDocumento31 pagineHaier Air Conditionerhernandez.josedomingo6804Nessuna valutazione finora

- Plethysmometer Instraction ManualDocumento39 paginePlethysmometer Instraction ManualJaime Ferrer100% (1)

- ABY30A (R) BA WPDF PDFDocumento47 pagineABY30A (R) BA WPDF PDFPulfi SgmNessuna valutazione finora

- LG Multi Inverter - Solución de ProblemasDocumento87 pagineLG Multi Inverter - Solución de ProblemasJarvin Saenz PavónNessuna valutazione finora

- Engineer Data VRV IV Cooling Part 2Documento250 pagineEngineer Data VRV IV Cooling Part 2Tấn BìnhNessuna valutazione finora

- Daikin VRV PDFDocumento37 pagineDaikin VRV PDFdanciu_alina_florina100% (1)

- A-W and A-F Oil SeparatorsDocumento1 paginaA-W and A-F Oil SeparatorstribleprinceNessuna valutazione finora

- LG Us-Q186c4a4 - LG Electronics LKDocumento21 pagineLG Us-Q186c4a4 - LG Electronics LKAvk SanjeevanNessuna valutazione finora

- TecumsehDocumento6 pagineTecumsehAndi SantikaNessuna valutazione finora

- Trouble Shooting For VRFDocumento55 pagineTrouble Shooting For VRFFelixNessuna valutazione finora

- EDMT341410 (VRV IV Cooling Only 50Hz)Documento724 pagineEDMT341410 (VRV IV Cooling Only 50Hz)Hai PhanNessuna valutazione finora

- 30hxyhxc-High Cop 2012Documento12 pagine30hxyhxc-High Cop 2012Luciano Lopes Simões100% (2)

- Chiller CGAH 060 - 1Documento1 paginaChiller CGAH 060 - 1dotronganhtuan100% (1)

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento3 pagineGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNessuna valutazione finora

- Lennox Certified VRF Brochure Spanish V6Documento10 pagineLennox Certified VRF Brochure Spanish V6Ariel Calero0% (1)

- SkyAir Standard R32 FBFCDocumento2 pagineSkyAir Standard R32 FBFCTi Ti100% (1)

- 38CKC Product DataDocumento26 pagine38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- Blue Star AHU DetailsDocumento5 pagineBlue Star AHU DetailsdheerajdorlikarNessuna valutazione finora

- Spesifikasi HITACHI RCUG200AHYZ1-Heat RecoveryDocumento1 paginaSpesifikasi HITACHI RCUG200AHYZ1-Heat RecoveryBaelish PeterNessuna valutazione finora

- SM MultiV IV Air Outdoor Units 4 15 - 20150414080917Documento150 pagineSM MultiV IV Air Outdoor Units 4 15 - 20150414080917avelarmatosNessuna valutazione finora

- 30XB - 30XBE - 30XBP: Air-Cooled Screw ChillersDocumento88 pagine30XB - 30XBE - 30XBP: Air-Cooled Screw Chillerssar husNessuna valutazione finora

- Acson Catalogue Air Handling Unit (1201)Documento12 pagineAcson Catalogue Air Handling Unit (1201)William Ball50% (4)

- Om FTKC NewDocumento60 pagineOm FTKC Newbeni.nass8593Nessuna valutazione finora

- NRI LubricantCrsRef CHRTDocumento2 pagineNRI LubricantCrsRef CHRTMuhammad ZubairNessuna valutazione finora

- Midea Modularni Cilleri MGB-service ManualDocumento119 pagineMidea Modularni Cilleri MGB-service ManualGermánCastiglioniNessuna valutazione finora

- New HummerDocumento49 pagineNew HummerFerenc Schmidt100% (1)

- Ispitni Rokovi Iz Otpornosti Materijala II - Mašinski Fakultet U Podgorici - Zoran Ćulafić, Sreten Savićević, Batrić VulićevićDocumento94 pagineIspitni Rokovi Iz Otpornosti Materijala II - Mašinski Fakultet U Podgorici - Zoran Ćulafić, Sreten Savićević, Batrić VulićevićMuhidin KozicaNessuna valutazione finora

- Metoda Konačnih Elemenata - Prof. DR Milisav KalajdžićDocumento121 pagineMetoda Konačnih Elemenata - Prof. DR Milisav KalajdžićMuhidin Kozica100% (1)

- FAP Dubrava D-1426-T1-R15Documento2 pagineFAP Dubrava D-1426-T1-R15Muhidin KozicaNessuna valutazione finora

- Matrična Analiza Konstrukcija - Prof DR Miodrag SekulovićDocumento167 pagineMatrična Analiza Konstrukcija - Prof DR Miodrag SekulovićMuhidin Kozica100% (1)

- FAP Dubrava D-1427S-T1-R15Documento2 pagineFAP Dubrava D-1427S-T1-R15Muhidin KozicaNessuna valutazione finora

- Mašinski Elementi - Zbirka Rešenih Ispitnih Zadataka - V. Miltenović, M. ŠarenacDocumento92 pagineMašinski Elementi - Zbirka Rešenih Ispitnih Zadataka - V. Miltenović, M. ŠarenacMuhidin KozicaNessuna valutazione finora

- Otpornost Materijala II - Kolokvijumi - Masinski Fakultet U Podgorici - Prof. DR Sreten SavićevićDocumento10 pagineOtpornost Materijala II - Kolokvijumi - Masinski Fakultet U Podgorici - Prof. DR Sreten SavićevićMuhidin KozicaNessuna valutazione finora

- FAP Dubrava D-1420-T-R14Documento2 pagineFAP Dubrava D-1420-T-R14Muhidin KozicaNessuna valutazione finora

- THERMA V R32 Monobloc Leaflet - 20180810Documento14 pagineTHERMA V R32 Monobloc Leaflet - 20180810Muhidin KozicaNessuna valutazione finora

- Fap Dubrava D 1420 l1 r14Documento2 pagineFap Dubrava D 1420 l1 r14Muhidin KozicaNessuna valutazione finora

- TCGB0123 - Rev0 - 05-19 - Yutaki R32 PDFDocumento142 pagineTCGB0123 - Rev0 - 05-19 - Yutaki R32 PDFMuhidin KozicaNessuna valutazione finora

- Fap Dubrava 1426v T r15Documento2 pagineFap Dubrava 1426v T r15Muhidin KozicaNessuna valutazione finora

- TCGB0123 - Rev0 - 05-19 - Yutaki R32 PDFDocumento142 pagineTCGB0123 - Rev0 - 05-19 - Yutaki R32 PDFMuhidin KozicaNessuna valutazione finora

- En 469 475 CBM Fid6757Documento7 pagineEn 469 475 CBM Fid6757Muhidin KozicaNessuna valutazione finora

- LG Therma V - R32 - AWHP - Monobloc (R32,50Hz) - MFL66101113 - 5BPM5-01C (Oct.2018)Documento49 pagineLG Therma V - R32 - AWHP - Monobloc (R32,50Hz) - MFL66101113 - 5BPM5-01C (Oct.2018)Muhidin KozicaNessuna valutazione finora

- Navodilo NMTDocumento68 pagineNavodilo NMTMuhidin KozicaNessuna valutazione finora

- FireStop Catalogue 2015 V4Documento48 pagineFireStop Catalogue 2015 V4Muhidin KozicaNessuna valutazione finora

- Toshiba-Digital-Inverter SystemDocumento24 pagineToshiba-Digital-Inverter SystemMuhidin KozicaNessuna valutazione finora

- Fujitsu Klima Uredjaj Kanalski Inverter Aryg54lhta Installation ManualDocumento15 pagineFujitsu Klima Uredjaj Kanalski Inverter Aryg54lhta Installation ManualMuhidin KozicaNessuna valutazione finora

- Klima Celje - VentilatoriDocumento20 pagineKlima Celje - VentilatoriMuhidin KozicaNessuna valutazione finora

- CBMDocumento9 pagineCBMMuhidin KozicaNessuna valutazione finora

- Katalog Za Inst Hot DeepDocumento44 pagineKatalog Za Inst Hot DeepMuhidin KozicaNessuna valutazione finora

- DB - E07 321 01 Appendix - RAV SM - 6 - BT E - 40 45 56 80 110 140 - EN - 00Documento39 pagineDB - E07 321 01 Appendix - RAV SM - 6 - BT E - 40 45 56 80 110 140 - EN - 00Muhidin KozicaNessuna valutazione finora

- HILTI - InstallationDocumento15 pagineHILTI - InstallationMuhidin KozicaNessuna valutazione finora

- TYFOCOR-L - Antifreeze EffectDocumento1 paginaTYFOCOR-L - Antifreeze EffectMuhidin KozicaNessuna valutazione finora

- HILTI - Anchor Systems MechanicalDocumento81 pagineHILTI - Anchor Systems MechanicalMuhidin KozicaNessuna valutazione finora

- ColtDocumento2 pagineColtMuhidin KozicaNessuna valutazione finora

- HILTI - FirestopDocumento38 pagineHILTI - FirestopMuhidin KozicaNessuna valutazione finora

- Tyfocor-L - DenistyDocumento1 paginaTyfocor-L - DenistyMuhidin KozicaNessuna valutazione finora

- AdsasdDocumento3 pagineAdsasdMark Pete Trocio0% (1)

- Additional GPE Calculation ProblemsDocumento3 pagineAdditional GPE Calculation ProblemsIvana Natalia100% (1)

- Specifications Features : Automatic Voltage RegulationDocumento1 paginaSpecifications Features : Automatic Voltage RegulationNguyễn HươngNessuna valutazione finora

- 11 Evaluation and Simulation of Solar Cell by Using MatlabDocumento8 pagine11 Evaluation and Simulation of Solar Cell by Using MatlabPavan KumarNessuna valutazione finora

- Power Generation & Water Balancing SystemDocumento20 paginePower Generation & Water Balancing SystemnamakNessuna valutazione finora

- Electrical Engineering Portal - Com Principles For Controlling HarmonicsDocumento3 pagineElectrical Engineering Portal - Com Principles For Controlling HarmonicsRobert GalarzaNessuna valutazione finora

- MF Series 1 3KVA Catalogue - 1Documento2 pagineMF Series 1 3KVA Catalogue - 1Other UseNessuna valutazione finora

- Hybrid Inverter: Installation & Operation GuideDocumento146 pagineHybrid Inverter: Installation & Operation GuideLUIS ROBERTO ESQUER VALENZUELANessuna valutazione finora

- Bosch C Si p60 Eu30123 Ficha enDocumento2 pagineBosch C Si p60 Eu30123 Ficha enleo_152842979Nessuna valutazione finora

- Ficha Técnica Batería Nimac 200 Ah 12 VoltDocumento2 pagineFicha Técnica Batería Nimac 200 Ah 12 VoltMauricio BarrazaNessuna valutazione finora

- Pennsylvania State UniversityDocumento215 paginePennsylvania State UniversityZefanya Maranatha Mangunsong100% (1)

- Nikola TeslaDocumento3 pagineNikola Teslajose Gutierrez100% (1)

- Screenshot 2022-06-20 at 7.24.17 PMDocumento14 pagineScreenshot 2022-06-20 at 7.24.17 PMNahid IslamNessuna valutazione finora

- United States Patent On Sines Reluctance GeneratorDocumento9 pagineUnited States Patent On Sines Reluctance GeneratorGustavBlitzNessuna valutazione finora

- BHEL Power TransformerDocumento22 pagineBHEL Power TransformerShubham SinghNessuna valutazione finora

- Detail Syllabus Ocean Wave EnergyDocumento3 pagineDetail Syllabus Ocean Wave EnergyecasayangNessuna valutazione finora

- Air-Cooled Chillers: Fast Efficient Dependable Fast Efficient DependableDocumento2 pagineAir-Cooled Chillers: Fast Efficient Dependable Fast Efficient DependableWadis SantanaNessuna valutazione finora

- Fuse MCB ELCBDocumento29 pagineFuse MCB ELCBIshitaBhatt30Nessuna valutazione finora

- D9142 - Fonte Auxiliar Externa Manual PDFDocumento12 pagineD9142 - Fonte Auxiliar Externa Manual PDFArtur HenschelNessuna valutazione finora

- TER SampleDocumento26 pagineTER Samplekenneth molinaNessuna valutazione finora

- Danfoss CI TI ContactorsDocumento27 pagineDanfoss CI TI ContactorsStorm ChasersNessuna valutazione finora

- 03 Literature ReviewDocumento5 pagine03 Literature Reviewshubham joshiNessuna valutazione finora

- 2 Numericals On Energy Transfer in TMDocumento2 pagine2 Numericals On Energy Transfer in TMRahulNessuna valutazione finora

- Jindal Power Limited.: Design & Feature of 600 MW Steam TurbineDocumento70 pagineJindal Power Limited.: Design & Feature of 600 MW Steam TurbineAshish SinghNessuna valutazione finora

- Geep 114Documento5 pagineGeep 114friendkwtNessuna valutazione finora

- Rice Straw AgrisilicaDocumento1 paginaRice Straw AgrisilicaPrasanna ChoudaryNessuna valutazione finora

- Homework WPS OfficeDocumento3 pagineHomework WPS Officeانور الحاجNessuna valutazione finora

- NTPCDocumento49 pagineNTPCMurali Krishna GbNessuna valutazione finora

- Route To MethanolDocumento20 pagineRoute To Methanolruk1921Nessuna valutazione finora