Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Deep Beam Check

Caricato da

Nikhil AgrawalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Deep Beam Check

Caricato da

Nikhil AgrawalCopyright:

Formati disponibili

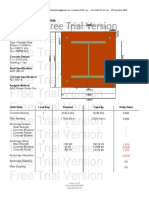

Subject :

Title

Drg.No:

Data

Width of beam B = 1100 mm

Depth of beam D = 8000 mm

Clear cover to reinforcement at top and bottom = 50 mm

Clear cover to reinforcement at sides = 50 mm

Diameter of main reinforcement = 16 mm

Diameter of Stirrup = 0 mm

Effective Span = 13.8 mm

Effective depth beam Deep Beam d = 7918 mm

Lever arm Z = 2402.76 mm

Characteristic strength of concrete f

ck = 40 N/mm

2

Characteristic strength of reinforcement f

y = 500 N/mm

2

Characteristic strength of Shear reinforcement f

y = 415 N/mm

2

Design Moments, torsion & shear

Sl.No.

Shear Force

(T)

1 -

2 -

3 507.94

3 0.00

Design of Top Reinforcement:- Refer Section 41.3 of IS:456-2000

At end support

Support Moment + Torsion :-

Maximum equivalent support moment, M

e1

= M

u

+ M

T

If M

T

> M

u

then M

e2

= M

T

- M

u

acting opposite to sense of M

e1

M

T

= Equivalent Bending moment due to torsion

M

T

= Tu (( 1+D/b)/1.7) = 249.15 T.M

Maximum equivalent support moment M

e1 = 2691 T.m

M

e2 = 0.0 T.m

Limiting Moment capacity of the section M

ulimit = 36689 T.m

Mu

2 = 0.00 T.m

M

top

/(B*d

2

) = 0.390 N/mm

2

M

ulimt/

Bd

2

= 5.320 N/mm

2

Percentage of steel correspong to limiting moment P

tlimit = 1.510 %

Percentage of tensile steel p

t-top = 0.329 %

Reinforcement required at top A

st = 28659.4 mm

2

Minimum reinforcement

Percentage of Reinforcement required p

t, min = 0.21 %

Minimum Reinforcement required A

st, min = 17855.09 mm

2

Diameter of main bar at (top Thru bars) = 32 mm

Number of Bars provided at top (Thru) = 30 Nos

Reinforcement provided @ top thru Zone 1 = 24127.43 mm

2

Moment (T.M)

Staad Memb

No. / Load

Description

-

64.233

2441.503

Torsion (T.M)

51.20

60.65

51.20

Support Moment +

Torsion (maxside)

Beam25 -

LC160

Project :

Client :

Job :

SEG deep beam at retrieval shaft Prepared : Project Code :

Retrieval shaft portion grid 19 to 21 Checked : Job Code :

Date: Rev :

Span Moment + Torsion

Beam9080 -

LC91

Shear Force + Torsion

Beam25 -

LC160

Support Moment +

Torsion on (other end)

Beam - LC - 0.00

Subject :

Title

Drg.No:

Project :

Client :

Job :

SEG deep beam at retrieval shaft Prepared : Project Code :

Retrieval shaft portion grid 19 to 21 Checked : Job Code :

Date: Rev :

Diameter of main bar at (top Extra bars) = 20 mm 25 mm

Number of Bars provided at top (Extra) = 60 Nos 0 Nos

Reinforcement provided @ top Extra Zone 2 = 18849.56 mm

2

Total Reinforcement @TOP = 42977.0 mm

2

Reinforcement provided is adequate

Design of Bottom Reinforcement:-

At mid span

Maximum Span Moment + Torsion :-

Maximum equivalent support moment, M

e1

= M

u

+ M

T

If M

T

> M

u

then M

e2

= M

T

- M

u

acting opposite to sense of M

e1

M

T

= Equivalent Bending moment due to torsion

M

T

= Tu (( 1+D/b)/1.7) = 295.16 T.M

Maximum equivalent support moment M

e1 = 359.39 T.m

M

e2 = 230.92 T.m

Limiting Moment capacity of the section M

ulimit = 36688.95 T.m

Mu

2 = 0.00 T.m

M

bot

/(B*d

2

) = 0.052 N/mm

2

M

ulimt/

Bd

2

= 5.320 N/mm2

Percentage of steel correspong to limiting moment P

tlimit = 1.510 %

Additional % of tensile steel for balancing in DR beam pt

2 = 0.000 %

Percentage of tensile steel p

tbottom = 0.015 %

Percentage of compression steel p

t-top = 0.03 %

Reinforcement required at bottom A

st-bottom = 1287.7 mm

2

Minimum reinforcement

Minimum % of Reinforcement required p

t, min = 0.21 %

Minimum Reinforcement required A

st, min = 17855.09 mm

2

Diameter of main bar at (bottom Thru bars) = 32 mm

Number of Bars provided at bottom (Thru) = 10 Nos

Reinforcement provided @ bottom thru = 8042.48 mm

2

Diameter of main bar at (bottom Extra bars) = 32 mm 25 mm

Number of Bars provided at bottom (Extra) = 0 Nos 0 Nos

Reinforcement provided @ bottom Extra = 0.00 mm

2

Total Reinforcement = 8042.48 mm

2

Reinforcement provided is adequate

Check for Shear Reinforcement:-

Maximum Shear Force + Torsion :-

Maximum equivalent Shear Force V

e

= V

u

+ 1.6(T

u

/b) V

e = 582.42 T

Nominal Shear stress t

v

= 0.67 N/mm

2

% of Reinforcement provided p

t, provided = 0.59 %

Shear strength of concrete t

c

= 0.54 N/mm

2

Provide Shear reinforcement

Refer Section 41.4.3 of IS:456-2000

Shear Reinforcement required A

sv = T

u + Vu mm

2

/mm

s

v

b

1

*d

1

*0.87*f

y

2.5*d

1

*0.87*f

y

b

1 = 1000 mm

d

1 = 7900 mm

Asv/Sv = 0.892 mm

2

/mm

+

+

Subject :

Title

Drg.No:

Project :

Client :

Job :

SEG deep beam at retrieval shaft Prepared : Project Code :

Retrieval shaft portion grid 19 to 21 Checked : Job Code :

Date: Rev :

Diameter of shear link provided = 20 mm 0 mm

Number of legs provided = 2 No's + 0 No's

Spacing of shear reinforcement provided = 150 mm 150 mm

Asv/Sv = 4.189 mm

2

/mm

Reinforcement provided is adequate

Check for Minimum Shear Reinforcement:- Refer Clause 26.5.1.6 of IS:456-2000

Min.Shear reinforcement required

A

sv =

s

v Asv/Sv = 0.38 mm

2

/mm

Diameter of shear link provided = 16 mm

Number of legs provided = 4 No's

Spacing of shear reinforcement provided = 150 mm

Asv/Sv = 9.55 mm

2

/mm

Reinforcement provided is adequate

Side face Reinforcement :-

% of side face Reinforcement required p

t = 0.05 %

Reinforcement required A

st, min = 4354.90 mm

2

Diameter of side face reinforcement = 16 mm

Number of bars provided as side face reinforcement = 22 Nos

Summary

Provide Y - 32 nos(thru) & Y - 20+ Y - 25 nos(extra) as Top reinforcement

Provide Y32 - 10 nos(thru) & Y32 - 0+ Y25 - 0 nos(extra) as bottom reinforcement

Provide 2L-Y 20+ 0L-Y0@150 mm c/c outer ring and 4L-Y16@150mm c/cas Shear reinforcement

Provide Y16 - 22nos as Side face reinforcement on each face

0.87*f

y

(t

v

- t

c

)*b

Contract UAA01

Design and Construction of Underground Stations and Associated Tunnels

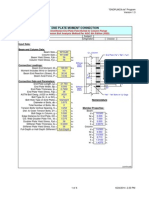

7.0 SLAB LATERAL DESIGN CHECK

7.1 Deep Beam design check

Support reaction = 1244*6.3/2 = 3920 kN

3920 kN

1244 kN/m

3.4

8

m

12 m

Clear span , l = 12 m

depth, D = 8 m

Effective span, l

eff

= 13.8 m

Moment at mid span = 15061 kNm (sagging)

Moment at face = 36555 kNm (hogging)

l

eff

/ D = 1.725 < 2.5

hence design as deep beam in accordance with Section 29

of IS 456 : 2000

Reinforcement

(for continuous beams where 1 < l/D < 2)

lever arm, z = 0.2(l+1.5D)

= 5.16 m

Design for hogging close to the ends (supports)

Mu = 0.87 fy As z = 2.2446 As

= 36555 kNm

As (hogging) = 16286 mm

2

0.5 (leff/ D-0.5) proportion of the above reinforcement should be

placed close to the tension face

Beam Design check

at 2.6m deep portion

239042087.xlsx.ms_office

Deep Beam Design

_______________________________________________________________________________________________

7/21/2014

Contract UAA01

Design and Construction of Underground Stations and Associated Tunnels

61 %= 9975 mm

2

ThisR/f shall be provided in 0.2D from top as = 1.6 m

Refering Section 5 from our reinforcement drawing number

TTA/465/SEG/1275423

The Reinforcment provided in top 1.5m zone is

Bar mark b1, b4 is provided for lateral load resistance

b1 = 9-Y32 = 7238.2 mm

2

b4 = 9-Y25 = 4417.9 mm

2

mm

2

Also slab reinforcement b7 and b9 has been provided

b7 = 8-Y25 = 3927 mm

2

b9 = 8-Y20 = 2513 mm

2

Total R/f in 1.3m zone = 18096 mm

2

Area of R/f provided = 18096 mm

2

Remaining = 6311 mm

2

to be provided in the zone 0.3D on either side of the mid depth

of beam

0.3D = 2.40 m

Distribution reinforcement in this zone is Y-16 @150 c/c

at both top and bottom faces

Total Number of Top bars = 16.00

Total Number of Bottom bars = 16.00

Total bars in this zone = 32

Area of R/f provided = 6434

mm

2

hence ok

hence ok

239042087.xlsx.ms_office

Deep Beam Design

_______________________________________________________________________________________________

7/21/2014

Contract UAA01

Design and Construction of Underground Stations and Associated Tunnels

Design for sagging at mid span

As (sagging) = 6709.9 mm

2

placed within a distance 0.25D-0.05 l i.e. 1.31 m

Reinforcement in this zone is Y-20 @150 c/c at both top

and Y-25 @150 at bottom faces

Total Number of Top bars = 9

Total Number of Bottom bars = 9

Area of R/f provided 7031

mm

2

Note: In addition to this an additional face bar of 7-Y25 has

been provided i.e. 3436 mm2 area

36555

kN-m

5628

kN-m

13217 kN-m

15061 kN-m

(@ 8m from the face of the temp opening)

hence ok

Bending Moment Diagram for given loading

239042087.xlsx.ms_office

Deep Beam Design

_______________________________________________________________________________________________

7/21/2014

Contract UAA01

Design and Construction of Underground Stations and Associated Tunnels

Design of deep beam is presented above

For the portion of 2.75m depth, between permanent and temporary

opening following sections are taken

1. Hogging B.M. at support

2. Sagging B.M. at the face of permanent opening

239042087.xlsx.ms_office

Deep Beam Design

_______________________________________________________________________________________________

7/21/2014

Contract UAA01

Design and Construction of Underground Stations and Associated Tunnels

_____________________________________________________________________________________________________________________________

7.2 Beam Design check at 2.6m deep portion

7.2.1 Design Load Calculations

UOM

Section Number 1 2

STAAD Output

a) Factored Max. B.M.from STAAD (ULS) kN-m 5628 13217

a.i) Load case for Max. B.M. from STAAD ULS

b) Factored Max. B.M.from STAAD (SLS) kN-m 4329 10167

b.i) Load case for Max. B.M. from STAAD SLS

c) Factored Max. S.F. from STAAD (ULS) kN 7528 7528

c.i) Load case for Max. S.F. from STAAD ULS

d) Axial Compression ULS (Pu) kN

e) Axial Compression SLS kN

7.2.2 Load Combinations

1) 1.5*(DL+IL+EP)SERVICE STAGE kN-m 5628 13217

DESIGN LOADS (Mu) kN-m 5628 13217

ii) SLS Load Combinations (B.M.)

1)1.0*(DL+IL+EP)SERVICE STAGE kN-m 4329 10167

SLS MOMENTS (MSLS) kN-m 4329 10167

iii) ULS Load Combinations (S.F.)

1) 1.5*(DL+IL+EP)SERVICE STAGE kN 7528 7528

DESIGN LOADS (Vu) kN 7528 7528

239042087.xlsx.ms_office

design of Beam bet. openings

_____________________________________________________________________________________________________________________________

7/21/2014

Contract UAA01

Design and Construction of Underground Stations and Associated Tunnels

_____________________________________________________________________________________________________________________________

7.2.3 Calculations of Flexural Reinforcement (ULS Design)

UOM

Section Number 1 2

Design Parameters

Actual Clear Cover (c ) mm 75 75

Nominal cover (Cnom) (For Calculating Crack Width) mm 45 45

Width of Section (b) mm 1000 1000

Concrete Grade (f ck) N/mm

2

40 40

Main R/f Steel Grade (f y) N/mm

2

500 500

Stirrup Steel Grade (f ys) N/mm

2

415 415

Dia of each leg of stirrup provided mm 12 12

Maximum Permissible Crack Width mm 0.3 0.3

Modulus of Elasticity of Steel (Es) N/mm

2

2E+05 2E+05

Xu(max) / d 0.456 0.456

Total Depth of Section (D) mm 2600 2600

Distance of compression face to point of crack (a) mm 2570 2570

Dia.of 1st layer of tension R/f Provided (1t) mm 25 32

Number of bars of 1st Layer tension of Reinforcement (n1t) 7 7

Dia.of 2nd layer of tension R/f Provided (2t) mm 20 32

Number of bars of 1st Layer tension of Reinforcement (n2t) 7 7

Dia.of 3rd layer of tension R/f Provided (3t) mm 0 32

Number of bars of 1st Layer tension of Reinforcement (n3t) 7 7

CG. Of Steel from Bottom = Effective Cover (h)BOTTOM mm 118 167

Effective Depth of Section from Bottom (deff)BOTTOM mm 2482 2433

Dia.of 1st layer of compression R/f Provided (1C) mm 0 0

Number of bars of 1st Layer of compression Reinforcement (n1c) 150 150

Dia.of 2nd layer of compression R/f Provided (2c) mm 0 0

Number of bars of 1st Layer of compression Reinforcement (n2c) 150 150

Dia.of 3rd layer of compression R/f Provided (3c) mm 0 0

Number of bars of 1st Layer of compression Reinforcement (n2c) 150 150

CG. Of Steel from Top = Effective Cover (h)TOP mm 0 0

Factored Moment on Section = Mu kN-m 5628 13217

Limiting Moment of Resistance = Mu(lim) kN-m 32703 31425

Type of Section Singly R/f Singly R/f

Ast,required

mm

2

5359 13425

Ast,provided

mm

2

5635 16889

Asc, required = 0.87*fy*( Asc)reqd / (fsc - 0.46*fck) mm

2

0 0

Asc, provided

mm

2

0 0

239042087.xlsx.ms_office

design of Beam bet. openings

_____________________________________________________________________________________________________________________________

7/21/2014

Contract UAA01

Design and Construction of Underground Stations and Associated Tunnels

_____________________________________________________________________________________________________________________________

7.2.4 Servicibility Checks

UOM

Section Number 1 2

Modular Ratio (m) = 280 / fck 7.00 7.00

Percent Reinforcement prov.(p) = (Ast)provided / (b*d) 0.23% 0.69%

Calculating neutral Axis Depth by WSM (n*d) mm 405 649

7.2.5 Crack Width Check

Maximum Permissible Crack Width mm 0.3 0.3

Moment (SLS Normal Case) kN-m 4329 10167

In Tension Steel (f st) kN/m

2

327326 271585

Strain at the centroid of tension steel (e)=f st / Es = 1.6E-03 1.4E-03

Strain at the Tension Face (e1) = 1.7E-03 1.5E-03

7.2.6 Crack Width As Per IS-456 / BS-8110

Reduction in strain due to tension stiffning (e2) =

b*(D-x)*(a-x)

(3* Es*Ast*(d-x))

Avg. steel strain at level considered (em) = e1-e2 = 1.0E-03 1.3E-03

Crack Width (Wcr) =

3*acr*em

(1+2*(acr-Cnom)/(D-x))

* Negative Crack Width indicates absence of Cracking

7.2.7 Calculations of Shear Reinforcement

UOM

Section Number 1 2

tc,max = 0.62*(f ck)

0.5

(Approximately) N/mm

2

3.92 3.92

tc,max (Approximately) kN/m

2

3921 3921

Shear Stresses ( tv) = Vu / (b*d) kN/m

2

3033 3094

Check for Adequacy of Section in Shear O.K. O.K.

Design Shear Strength of Concrete = (tc) * k* kN/m

2

359 583

maximum Vertical stirrup spacing as per caluse 26.5.1.5 mm 300 300

Spacing of Stirrups Provided mm 150 150

Total width of beam mm 1000 1000

No. of Legs of Shear Stirrups-1 Provided in total length 4 4

Dia of each leg of stirrup-1 provided mm 20 20

No. of Legs of Shear Stirrups-2 Provided in total length 0 0

Dia of each leg of stirrup-2 provided mm 0 0

Actual Asv(Required) / m width mm

2

1111 1043

Total Shear R/f Provided Asv(Provided) /m width mm

2

1257 1257

Note:

As per Cl.22.6.1 of IS-456, Critical Section for B.M. should be at the face of support for monolithic construction

As per Cl 22.6.2.1 of IS-456, Critical Section for SF should be at a distance 'd' from face of support

2.1E-04

0.293

6.8E-04

mm 0.245

239042087.xlsx.ms_office

design of Beam bet. openings

_____________________________________________________________________________________________________________________________

7/21/2014

Potrebbero piacerti anche

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Documento5 pagineUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNessuna valutazione finora

- Base Plate1Documento6 pagineBase Plate1jobees7850Nessuna valutazione finora

- Combined Footing DesignDocumento3 pagineCombined Footing Designkvamshi_1971Nessuna valutazione finora

- FOOTING STRESSESDocumento6 pagineFOOTING STRESSESSulaiman Mohsin AbdulAziz100% (1)

- NMDC Limited 3.0 Mtpa Integrated Steel Plant: at Nagarnar, ChhattisgarhDocumento9 pagineNMDC Limited 3.0 Mtpa Integrated Steel Plant: at Nagarnar, ChhattisgarhDanish AhmadNessuna valutazione finora

- Deep BeamDocumento31 pagineDeep BeamEngr Mohammed Ubaid QureshiNessuna valutazione finora

- Base PlateDocumento15 pagineBase PlatemaheshbandhamNessuna valutazione finora

- Trial ExcelDocumento15 pagineTrial ExcelCyndrille John BragatNessuna valutazione finora

- Chequred PlateDocumento2 pagineChequred PlateKumar Prasanna HNNessuna valutazione finora

- Str-1 - Pier Spring ConstantsDocumento2 pagineStr-1 - Pier Spring Constantssatoni12Nessuna valutazione finora

- Calculating Intake Pile CapacityDocumento4 pagineCalculating Intake Pile Capacitykridhakarya kriyakarsaNessuna valutazione finora

- Foundation Design f1Documento2 pagineFoundation Design f1Sampath Kumar KandasamyNessuna valutazione finora

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Documento5 pagineEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNessuna valutazione finora

- Bolted Connection Angle Brace TensionDocumento2 pagineBolted Connection Angle Brace TensionRajib MaharjanNessuna valutazione finora

- Footing Design-Conn & Lift CheckDocumento3 pagineFooting Design-Conn & Lift Checkarif_rubinNessuna valutazione finora

- Bolts Connections DesignDocumento3 pagineBolts Connections DesignChangHangWingNessuna valutazione finora

- Brick Wall Footing Design-1Documento12 pagineBrick Wall Footing Design-1mumarbsc7244Nessuna valutazione finora

- Entrance B: 1008 72 CHS 559x25 (S355) 80.64 1314 72 CHS 610x28 (S355) 105.12Documento2 pagineEntrance B: 1008 72 CHS 559x25 (S355) 80.64 1314 72 CHS 610x28 (S355) 105.12suman_civilNessuna valutazione finora

- Column Design Name of WorkDocumento43 pagineColumn Design Name of WorkPalani KumarNessuna valutazione finora

- Monorail 0.5 TonDocumento9 pagineMonorail 0.5 TonAndreas HendiNessuna valutazione finora

- Steel member design EN1993 (40Documento8 pagineSteel member design EN1993 (40vsnsfbNessuna valutazione finora

- PedestalPC 4 (700x700)Documento23 paginePedestalPC 4 (700x700)basum matNessuna valutazione finora

- Deep Beam Flexural and Shear DesignDocumento6 pagineDeep Beam Flexural and Shear DesignManal ElkasabyNessuna valutazione finora

- Beam Design TorsionDocumento20 pagineBeam Design Torsionmailmaverick8167100% (1)

- Flat Slab Design by FemDocumento7 pagineFlat Slab Design by FemBathrudeen IshakNessuna valutazione finora

- Combined footing design 1000 knDocumento480 pagineCombined footing design 1000 knAnonymous HJ7hmihhNessuna valutazione finora

- APPENDIX-A (Cohesive Soil: Clay) - FIXED: Pile - Lateral Load - Capacity: Is 2911 - Part 1 - Section 2-2010Documento4 pagineAPPENDIX-A (Cohesive Soil: Clay) - FIXED: Pile - Lateral Load - Capacity: Is 2911 - Part 1 - Section 2-2010Kanaiyalal N. ShethNessuna valutazione finora

- ENDPLMC9.xlsDocumento4 pagineENDPLMC9.xlsmahhor82_635643838Nessuna valutazione finora

- 008 - Column Load AnalysisDocumento17 pagine008 - Column Load AnalysisVAIBHAVNessuna valutazione finora

- Four Pile Caps StructvilleDocumento6 pagineFour Pile Caps Structvillemabuhamd100% (1)

- No Passive & WaterDocumento13 pagineNo Passive & WaterArnel Dodong100% (1)

- Rectangular BasePlate DesignDocumento13 pagineRectangular BasePlate DesignMuhammad HasanNessuna valutazione finora

- Earthquake load calculations as per IS1893-2002Documento9 pagineEarthquake load calculations as per IS1893-2002Er Rakesh SharmaNessuna valutazione finora

- Foundation Design SheetDocumento12 pagineFoundation Design SheetShridhar BabuNessuna valutazione finora

- Precast Rib Beam DesignDocumento1 paginaPrecast Rib Beam Designanshutomar7915100% (1)

- Proposed 1450 KL RCC Ground Level Service ReservoirDocumento35 pagineProposed 1450 KL RCC Ground Level Service Reservoirsubramanyam kumarNessuna valutazione finora

- Basic Design Parameters:: Concrete Anchor Bolt Design Based On Aci318-11Documento18 pagineBasic Design Parameters:: Concrete Anchor Bolt Design Based On Aci318-11onlyikramNessuna valutazione finora

- Combined Footing Design2Documento39 pagineCombined Footing Design2sujit naikwadi100% (1)

- Axially Loaded FTNG DSNDocumento12 pagineAxially Loaded FTNG DSNKanaiyalal N. ShethNessuna valutazione finora

- Design of Joint ConnectionDocumento2 pagineDesign of Joint ConnectionSantosh BapuNessuna valutazione finora

- Design Calculation Sheet For Purlins: WL (P) WL (S)Documento1 paginaDesign Calculation Sheet For Purlins: WL (P) WL (S)Ahsan SattarNessuna valutazione finora

- Two Way SlabDocumento48 pagineTwo Way Slabbpkndl7943Nessuna valutazione finora

- BEAM Moment Connection - UB 254x146x37Documento7 pagineBEAM Moment Connection - UB 254x146x37Shriniwas NaikNessuna valutazione finora

- Job Pile Design-450 (R1)Documento3 pagineJob Pile Design-450 (R1)Kyle Foreman100% (1)

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocumento10 pagineR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNessuna valutazione finora

- Strong Col Weak BeamDocumento2 pagineStrong Col Weak BeamlaxmiNessuna valutazione finora

- 1.0 Rectangular Column-BIAXIALDocumento31 pagine1.0 Rectangular Column-BIAXIALFranklyn P. Genove100% (1)

- Isolated Trapezoidal Footing DesignDocumento6 pagineIsolated Trapezoidal Footing Designhemantkle2uNessuna valutazione finora

- Design Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992Documento2 pagineDesign Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992OmPrakashNessuna valutazione finora

- Design of lacing and battens for axial column force of 80 tonsDocumento4 pagineDesign of lacing and battens for axial column force of 80 tonsPrasad SamantNessuna valutazione finora

- Edge Column According To Aci 318-02 (Nonprestressed Slabs) 94-1Documento2 pagineEdge Column According To Aci 318-02 (Nonprestressed Slabs) 94-1Love SemsemNessuna valutazione finora

- Pcc-Retaining-Wall Khari RoadDocumento6 paginePcc-Retaining-Wall Khari RoadDADADADGGGNessuna valutazione finora

- Design Two Way Slab ReinforcementDocumento5 pagineDesign Two Way Slab ReinforcementVinod RevankarNessuna valutazione finora

- Design of Built-Up Column: Section UsedDocumento6 pagineDesign of Built-Up Column: Section UsedKrishna KumarNessuna valutazione finora

- Client: KOC Job No: JI-180 Page: of Prepared By: Nehal Akhter Subject: Design of Foundation, PW7a Checked By: RPM/FSDocumento28 pagineClient: KOC Job No: JI-180 Page: of Prepared By: Nehal Akhter Subject: Design of Foundation, PW7a Checked By: RPM/FSOMARB26Nessuna valutazione finora

- Column DesignDocumento68 pagineColumn DesignPiyush Tiwari100% (1)

- RC Beam Design CCAA - Revised 1.2 JWWDocumento12 pagineRC Beam Design CCAA - Revised 1.2 JWWFerdie TolosaNessuna valutazione finora

- 2.column Base Plate (Fixed Type)Documento15 pagine2.column Base Plate (Fixed Type)ZevanyaRolandTualakaNessuna valutazione finora

- PF2Documento4 paginePF2nhulugallaNessuna valutazione finora

- Design of RCC Building G+4Documento39 pagineDesign of RCC Building G+4D.V.Srinivasa Rao0% (2)

- Live Load EccentrictiyDocumento213 pagineLive Load EccentrictiyNikhil AgrawalNessuna valutazione finora

- Temperature BearingDocumento152 pagineTemperature BearingNikhil AgrawalNessuna valutazione finora

- 2024 Drik Panchang Hindu Calendar v1.0.1Documento25 pagine2024 Drik Panchang Hindu Calendar v1.0.1vmahar06Nessuna valutazione finora

- G. Railway BridgeDocumento4 pagineG. Railway BridgeNikhil AgrawalNessuna valutazione finora

- Detailing of Reinforcement in Concrete Structures 28 Aug 2012Documento82 pagineDetailing of Reinforcement in Concrete Structures 28 Aug 2012Nikhil AgrawalNessuna valutazione finora

- Parapet Wall Typical DetailDocumento1 paginaParapet Wall Typical DetailNikhil AgrawalNessuna valutazione finora

- Scale File For Column InteractionDocumento8 pagineScale File For Column InteractionVikasNessuna valutazione finora

- Capacity 900 Slab Cc27Documento10 pagineCapacity 900 Slab Cc27Nikhil AgrawalNessuna valutazione finora

- Lateral ForcesDocumento2 pagineLateral ForcesNikhil AgrawalNessuna valutazione finora

- Load Test Comparison by HSGDocumento4 pagineLoad Test Comparison by HSGNikhil AgrawalNessuna valutazione finora

- FQP For Chimney 3 MechanicalDocumento4 pagineFQP For Chimney 3 MechanicalKuldeep ChakerwartiNessuna valutazione finora

- Seeing NPR Material From The Mechanic Point of ViewDocumento14 pagineSeeing NPR Material From The Mechanic Point of View施元Nessuna valutazione finora

- Sand Casting Over View and Defect AnalysisDocumento29 pagineSand Casting Over View and Defect AnalysisNindya HauraNessuna valutazione finora

- A Powerpoint Presentaion On Ready-Mix ConcreteDocumento22 pagineA Powerpoint Presentaion On Ready-Mix ConcreteGowriSenthilNessuna valutazione finora

- Tight BiteDocumento1 paginaTight BiteAlex DaniciNessuna valutazione finora

- TRUEDocumento50 pagineTRUECLARISSA TAGUBANessuna valutazione finora

- Richard P Feynman-Surely Youre Joking MR Feynman v5Documento3 pagineRichard P Feynman-Surely Youre Joking MR Feynman v5Anonymous Nayak0% (1)

- Microstructure Characterization and Quantitative Analysis of Copper Alloy Matrix Composites Reinforced With Wc-Xni Powders Prepared by Spontaneous InfiltrationDocumento9 pagineMicrostructure Characterization and Quantitative Analysis of Copper Alloy Matrix Composites Reinforced With Wc-Xni Powders Prepared by Spontaneous Infiltrationnorthpole_plNessuna valutazione finora

- Introduction To Chemical ReactionsDocumento35 pagineIntroduction To Chemical ReactionsHema lathaNessuna valutazione finora

- Packed Beds Safety IssuesDocumento4 paginePacked Beds Safety IssuesrmaganNessuna valutazione finora

- Experiment No. 6: Determination of The Solubility Product Constant of Calcium HydroxideDocumento2 pagineExperiment No. 6: Determination of The Solubility Product Constant of Calcium HydroxideAliaArellano100% (1)

- Group Vii The HalogensDocumento58 pagineGroup Vii The HalogensYuanWei SiowNessuna valutazione finora

- Module 1 - ElectrochemistryDocumento31 pagineModule 1 - ElectrochemistryjeniferNessuna valutazione finora

- 10 - Equipment Damage Curves Motors PDFDocumento5 pagine10 - Equipment Damage Curves Motors PDFMoulay m'hammed LOUKILINessuna valutazione finora

- Thermal ExpansionDocumento2 pagineThermal ExpansionlovemoreworrylessNessuna valutazione finora

- Wax Glue2Documento6 pagineWax Glue2Gamal FouadNessuna valutazione finora

- Cyrstal GrowthDocumento7 pagineCyrstal GrowthkarticNessuna valutazione finora

- SCOPEDocumento5 pagineSCOPEMel FNessuna valutazione finora

- Cold Storage SlidesDocumento37 pagineCold Storage Slidesbal singh ranaNessuna valutazione finora

- Aerospace Material SpecificationDocumento6 pagineAerospace Material SpecificationAnonymous T6GllLl0Nessuna valutazione finora

- CHM 1025c Final Exam Practice WCDocumento5 pagineCHM 1025c Final Exam Practice WCMiguel SuarezNessuna valutazione finora

- E01 PDFDocumento28 pagineE01 PDFAnonymous HJZffHvTNessuna valutazione finora

- IJBE-9-3-2021 Bahrami Guillot 13 30Documento18 pagineIJBE-9-3-2021 Bahrami Guillot 13 30Elina EsfandiariNessuna valutazione finora

- A574m PDFDocumento7 pagineA574m PDFLeonardo GomideNessuna valutazione finora

- DTW 1359Documento35 pagineDTW 1359GANESH GNessuna valutazione finora

- ST7013-Design of Steel Concrete Composite Structures Question BankDocumento11 pagineST7013-Design of Steel Concrete Composite Structures Question BankSarath KumarNessuna valutazione finora

- Geotechnics With GeosyntheticsDocumento24 pagineGeotechnics With GeosyntheticsAnonymous VeDNBhNessuna valutazione finora

- Nde Procedure Magnetic Particle TestingDocumento20 pagineNde Procedure Magnetic Particle Testingryan.s100% (1)

- Welding Types Procedures ParametersDocumento156 pagineWelding Types Procedures ParametersVinodh Kumar YallaNessuna valutazione finora

- Welding Journal 1959 8Documento142 pagineWelding Journal 1959 8AlexeyNessuna valutazione finora