Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

20004E00

Caricato da

brome2014Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

20004E00

Caricato da

brome2014Copyright:

Formati disponibili

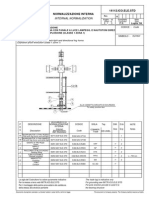

0 ISSUE STIN OFFS STIN 11-96

REV. DESCRIPTION COMP. VERIF. APPR. DATE

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

FUNCTIONAL SPECIFICATION

PROTECTIVE TREATMENTS OF METAL STRUCTURES

BY METAL COATINGS

20004.VAR.PAI.FUN.

Rev 0

May 1996

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 2

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

FOREWORD

Rev. 0 Total Number of Sheets: 17

May 1996

This Specification was issued in agreement to E.E.C. Directives.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 3

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

CONTENTS

1. GENERAL

1.1 Scope

1.2 Normative References

1.2.1 European Normative References

1.2.2 Normative References of ISO, IEC and national organizations

1.2.3 Normative References of other Organizations

1.2.4 Legislation

2. FUNCTIONAL NORMATIVE REQUIREMENTS

2.1 Operative environment

2.2 Functional requirements

2.2.1 Coating

2.2.2 Material properties

2.2.3 Coating thickness

2.2.4 Surface preparation

2.2.5 Spray metallizing processes

2.2.6 Sealer application

2.3 Safety

2.4 Ergonomics

2.5 Requirements for Quality Management and Quality Assurance

2.6 Additional Requirements for Review

2.6.1 Assistance by the Supplier of coating products

2.6.2 Reception of the coating materials

2.6.3 Production process control

2.6.4 Checks, inspections and testing

2.6.5 Warranties and final acceptance

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 4

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

2.7 Documentation

2.7.1 Documents to be submitted at the start of work

2.7.2 Documents to be submitted during work progress

2.7.3 Documents to be submitted at the completion of work

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 5

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

1. GENERAL

1.1 Scope

This Specification defines the functional requirements of metal coatings applied

to offshore structures, onshore and offshore production plants, machinery and

packages.

1.2 Normative References

1.2.1 European Normative References

At the time this Specification was issued no European Standards or Directives

applicable to the matter were available.

1.2.2 Normative References of ISO, IEC and national organizations

UNI-ISO 2063 Rivestimenti metallici ed altri rivestimenti inorganici,

metallizzazione termica a spruzzo, zinco, alluminio e loro

leghe (tape method).

ISO 8502-4 Preparation of steel substrates before application of paint and

related products. Tests for the assessment of surface

cleanliness. Part 4: Guide on the estimation of the probability

of condensation prior to paint application.

ISO 8503-1 Preparation of steel substrates before application of paint and

related products. Surface roughness characteristics of blast-

cleaned steel substrates.

Part 1: Specifications and definitions for ISO surface profile

comparators for the assessement of abrasive blast-cleaned

surfaces.

ISO 8503-2 Preparation of steel substrates before application of paint and

related products. Surface roughness characteristics of blast-

cleaned steel substrates.

Part 2: Method for the calibration of ISO surface profile

comparators and for the determination of surface profile.

Comparator procedure.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 6

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

ISO 8503-4 Preparation of steel substrates before application of paint and

related products. Surface roughness characteristics of blast-

cleaned steel substrates.

Part 4: Method for the calibration of ISO surface profile

comparators and the determination of surface profile.- Stylus

instrument procedure.

ISO 8504-1 Preparation of steel substrates before application of paint and

related products. Surface preparation methods. Part 1: General

principles.

ISO 8504-2 Preparation of steel substrates before application of paint and

related products. Surface preparation methods. Part 2:

Abrasive blast cleaning.

ISO 8504-3 Preparation of steel substrates before application of paint and

related products. Surface preparation methods. Part 3: Hand

and power-tool cleaning.

ISO 2409 Paints and varnishes - Cross-cut test.

ISO 9227 Corrosion tests in artificial atmospheres - salt spray tests.

UNI 9852 Prodotti vernicianti.- Determinazione del grado di

reticolazione.

BS 729 Specification for hot dip galvanized iron and steel articles.

DIN 8566 Metals for thermal spraying.

1.2.3 Normative References of other organizations

ASTM D 4587 Practice for conducting test on paint and related coatings and

materials using a fluorescent UV-condensation light-and-water

exposure apparatus.

AICC N. 11 Associazione Italiana Coil Coating - Prove di durezza

1.2.4 Legislation

D.P.R. del 27 Aprile 1955, N. 547 Norme per la prevenzione degli infortuni

sul lavoro.

D.P.R. del 19 Marzo 1956, N. 303 Norme generali per ligiene del lavoro.

Legge del 29 Maggio 1974, N. 256 Classificazione e disciplina

dellimballaggio e delletichettatura delle sostanze e dei preparati pericolosi.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 7

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

Ministero della Sanit - Decreto N. 50 del 16 Febbraio 1993.

In Countries other than Italy these regulations may be complemented,

integrated or substituted by applicable local Laws and regulations.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 8

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

2. FUNCTIONAL NORMATIVE REQUIREMENTS

2.1 Operative environment

Components protected according to the requirements of this specification can

be subjected to quite different environmental service conditions.

The environment conditions in which coating operations will take place are

however a determining factor for a satisfactory outcome of these operations; to

this purpose the Contractor is requred to keep climatic conditions under careful

control while coating operations are going on. The conditions for application

specified in the Supplier's technical sheet shall be always observed.

This specifications refers to the usual conditions that can be found in site yards,

in shops and anyway in the typical premises of an oil producing enterprise.

2.2 Functional requirements

Spray metal coating of metal structures shall be performed in accordance to the

requirements specified in the data sheets and in the documentation specific to

the individual job.

2.2.1 Coating

Metal coating is performed using metals exhibiting anodic behaviour in respect

to Iron. These sacrificial anodic coatings offer to the substrate an active

protection of electrochemical nature. Zinc and Aluminium are commonly used.

Aluminium is usually more resistant than Zinc in marine environment, and is

preferable for industrial areas where the atmosphere contains high levels of

Sulphur or of Sulphur compounds; Zinc is to be used for protective coatings

where the atmosphere contains alkaline corrosive agents (pH 7 12) or is of a

rural type, or is dry and warm.

The metal coating shall be sealed with fluoro-polymer based paints, having a

minimum of 16% Fluorine in respect to the dry base paint.

2.2.2 Material properties

2.2.2.1 Aluminium

The following aluminium alloys may be used:

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 9

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

1) 99.9% aluminium alloys

2) 90% aluminium and 10% alumina alloys (in order to improve surface wear

resistance).

Other alloys may be used, however only if complying with the requirements of

DIN 8566 Standard.

2.2.2.2 Zinc

99.9% pure zinc alloy, complying with the requirements of BS 729 Std.

2.2.2.3 Sealer

The sealing material shall have the following properties:

1) Fluoro-polymer based enamel, two-component, having a minimum of 16%

Fluorine in respect to the dry base paint.

2) Physical properties:

Adhesion (on 1 sq.mm) - (ISO 2409) Grade zero

Pencil hardness - (AICC N 11) H

Curing degreee - (UNI 9852) >100

60 gloss 80 - 100 gloss

3) Resistance to accelerated ageing

QUV 1000 H (cycle 4 + 4 - after rinsing)

(ASTM D-4587)

60 gloss variation

<10%

Weather-o-meter 4000 hours 60 gloss variation

<10%

Salt fog (ISO 9227) After 4000 hours, 1

mm max blistering on

scribe marks.

60 gloss variation

<10%

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 10

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

2.2.3 Coating thickness

Zinc coating Minimum thickness 250 m

Aluminium coating Minimum thickness 200 m

Sealer Minimum thickness 30 m

2.2.4 Surface preparation

All steel surfaces to be metal coated shall be cleaned until a substrate is

obtained complying with the requirements of the coating process.

To this purpose the surfaces shall be abrasive blast cleaned in accordance to

ISO 8504-2 and to the following requirements:

- only dry abrasive shall be used

- silica abrasives shall not be used.

Subject to the Company's approval, limited surfaces may be cleaned by

mechanical or hand brushing in accordance to ISO 8504-3. Welding slag and

spatter, residual flux, and any other foreign body not removed at the previous

fabrication stage and found before or during blast cleaning shall be eliminated

using an appropriate mechanical tool; sharp corners shall be rounded off.

Blast cleaning may not be carried out in night time unless as preliminary

cleaning or when performed inside factory buildings.

All blast cleaned surfaces shall be coated within four hours from the blast

cleaning.

Blast cleaning shall be extended for a distance of 2.5 cm (1 in) on the nearby

surfaces alreay coated. Acids, detergents in solution, or solvents may not be

used to wash the blast cleaned surfaces. This also applies to rust inhibitors.

No blast cleaning may be carried out on wet or damp surfaces nor on surfaces

that may become damp before the coating is applied.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 11

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

2.2.5 Spray metallizing processes

The different spraying techniques are listed here and a comparison is given.

2.2.5.1 Flame spraying

The material to be sprayed is brought into a flame which burns compressed gas

and oxygen. Particles are accelerated by an air jet.

2.2.5.2 Gas-explosion spraying

The material to be sprayed is placed with oxygen and acetylene into a gun

where an explosion takes place at intervals. The particles are thus heated and

projected onto the substrate.

The process is applicable to powders of any material. The temperature

obtainable is relatively low (4700 K), but spraying speed is very high, well in

excess of the one obtainable by the other spraying methods. The coatings show

good adhesion and density values.

2.2.5.3 Arc spraying

The material to be deposited is supplied as metal wires that constitute two

electrodes between which an arc is struck. Particles are accelerated by a gas jet.

This process is suitable only for metallic materials, electrically conductive.

A 6000 K temperature is obtained, overheating the particles and a strong gas

absorption may take place. Problems may arise due to difference in

temperature between the cathode (hotter, producing smaller particles) and the

anode (colder, producing larger particles). This process is the most economical

one.

2.2.5.4 Plasma spraying

The material to be sprayed is brought as powder into a plasma jet. The particles

are accelerated and melted by the jet thrust and temperature. Very high

temperatures are obtained (up to 15000 K) allowing the spraying of refractory

materials. It is anyway necessary that the evaporation temperature of the

material be at least 300 K higher than its fusion one, in order to avoid particle

vaporization. The substrate can be kept at low temperature (even below

100C), thus allowing deposition also on polymers. The wide difference in

temperature of the particles (fused or almost fused) and of the substrate causes

fast cooling (10

3

10

7

K/s) allowing metastable phases to form.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 12

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

2.2.6 Sealer application

All the surfaces must be perfectly clean and free from oil, grease and/or

residues.

Paints and solvents shall be supplied in their original containers accompanied

by the Supplier's Technical Data Sheets.

The Supplier's indications shall be observed, giving special attention to :

- choice of solvents

- mixing instructions

- time required for the paint to dry before another coat layer can be applied

- equipment required for paint application.

Once the time limit for application is reached, the spraying equipment shall be

emptied, the leftover material scrapped, the equipment cleaned and filled with

new product.

All paint spraying equipment shall be inspected and approved by the Customer

before any application work is started.

Filters shall always keep oil or water from entering the air circuit.

Paints containing heavy or metallic pigments that tend to settle shall have these

kept in suspension by a mechanical mixer acting within the pressurized tank.

The spray gun shall be kept at a distance of 45 cm min and 60 cm max from the

surface to be painted, and always at a right angle to the surface. Spraying

passes shall be uniform and parallel.

Each pass shall overlap the preceding one by approx. 50%.

All drippings and overspraying shall be removed at once using a brush, the

paint shall be removed and the surface repainted.

2.3 Safety

It is the Contractor's duty to observe the regulations on safety and health

preservation applicable to his premises. Special consideration is to be given to

the following:

- painting products mixing and handling shall be performed in areas where air

can circulate freely and that are distant from zones of danger;

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 13

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

- the abrasives for blast cleaning shall be chosen among those not harmful to

operators' health.

The paints storerooms shall be appropriately ventilated and complying with

applicable law provisions on safety and fire prevention.

All paints, solvents, fluidizers, catalysts, etc. shall bear on their container the

data required by the Decreto Ministero della Sanit (Health Ministry Decree)

N 50 of 16 February 1993, and/or be accompanied by the relevant safety data

sheets mentioned in that Decree.

In Countries other than Italy, these regulations may be complemented,

integrated or substituted by applicable local Laws and regulations .

2.4 Ergonomics

Not applicable.

2.5 Requirements for Quality Management and Quality Assurance

The additional requirements for Quality Management and/or Quality Assurance

are contained in the applicable Quality and Execution Requirements

Specification attached to the Invitation to Bid.

2.6 Additional Requirements for Review

2.6.1 Assistance by the Supplier of coating products

The Supplier of coating materials shall provide assistance to the job, and:

- shall check and certify that the surfaces of components were correctly

prepared;

- shall supervise coating application and certify its correctness.

In connection to this, the Supplier, acting jointly with the Contractor, shall

appoint, subject to the Companys agreement, an independent third Party as

Supervisor of all operations.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 14

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

2.6.2 Reception of the coating materials

The Contractor shall ensure that purchased products comply with the

requirements specified.

The Contractor shall purchase the products to be used for coating from

Suppliers qualified by the Company.

The Contractor shall file and retain all the technical and administrative

documents related to the purchase, both those issued by himself and by the

Supplier, for at least 3 years.

All coating materials shall be delivered on the job site in their original factory

containers with intact labels and seals. The containers shall be provided with

identifying documents or inscriptions, stating clearly their content and its

validity expiry date.

The containers shall be stored in a closed, well ventilated storeroom, observing

the range of allowable temperatures recommended by the Supplier.

2.6.3 Production process control

The Contractor shall possess an appropriate organization able to perform the

following functions:

- prepare written work instructions describing how operations are to be

performed, the proper equipment to be used, the adequate work

environment, and the compliance with reference Standards and codes and

with the Companys requirements.

- monitoring and checking of specific characteristics of the process and of

application.

2.6.4 Checks, inspections and testing

2.6.4.1 Preliminary tests

Upon arrival of a load of coating materials, the Contractor shall provide to

verify:

- the integrity of the containers;

- the date of expiry of validity for the materials;

- correspondence of the shipping documents with the identification of the

containers.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 15

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

The storeroom where the materials will be placed shall be checked to ensure a

constant temperature of +20C (5 C) and adequate air flow.

2.6.4.2 Inspection and tests during work progress

The Contractor shall perform at the start, middle, and end of every work shift a

check of ambient temperature and relative humidity using appropriate

instruments, and calculate the probability of moisture condensation according

to ISO 8502-4 Standard; the values shall all be recorded in the relevant work

log book section.

When surface preparation is completed, appropriate checks must be carried out

in order to ensure that the substrate is adequate for the subsequent coating

operations:

- visual check: shall be performed in accordance to ISO 8501 - 1 Std.; the

substrate finish shall be as specified in the Suppliers Technical Data Sheets.

- dust level check: shall be performed in accordance to ISO 8502-3 Std., the

number of checks shall be established by agreement with the Company,

depending on the surface and homogeneousness of the component

examined; acceptance level per class 1.

- surface roughness test: shall be performed according to ISO 8503-1 and

8503-2 Standards, using the "comparator method; the number of tests shall

be established by agreement with the Company, depending on the surface

and on the homogeneousness of the component; the acceptance level shall

be the "medium" one. As alternative, the "stylus method" of ISO 8503-4

Std. may be used.

- check of welding flux removal: when requested by the Company, the pH

value of the surface near the welded joints shall be checked, wetting the area

and applying litmus paper; acceptance level is neutral pH.

The following tests and checks must be performed before and during

application of the coating:

- check of the wet paint thickness; while paint coats are being applied, the

Contractor shall sistematically check the wet paint thickness using a "comb

type" (Rosemann) or a "wheel type" (Gardner and Erichsen) measuring

instrument.

2.6.4.3 Final Inspection

Once the coating application is completed, and the film has fully hardened, the

following checks shall be performed:

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 16

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

- thickness check: groups of 20 measurements shall be carried out on surface

parts, their number to be agreed with the Company depending on the surface

and the homogeneousness of the component; the average value, obtained

discarding the highest and lowest value measured shall not be less than the

design thickness value;

- visual check: the coated surface shall be 100% inspected visually; for

acceptance it is required that no paint runs, foreign bodies, orange peel,

oxidized or deteriorated areas are present.

2.6.5 Warranties and final acceptance

Final acceptance of the coating is given upon satisfactory result of a visual

check that will take place one year after completion of the coating. The

Supplier shall give joint warranty with the Contractor to this purpose.

The acceptance criterion is the absence of traces of corrosion or of deterioration

of the coated component, that can be attributed to defects in the coating or to a

defective application of it. Any exfoliation, whatever small, is equivalent to a

deterioration.

No deterioration is acceptable; the Contractor is invited to ascertain the ones

found and to provide for repair as soon as possible.

2.7 Documentation

2.7.1 Documents to be submitted at the start of work

Prior to starting activity the Contractor shall submit to the Company the

following documents:

- plan and schedule of operations for surface preparation and coating;

- characteristics and location of the place where coating materials will be

stored;

- planning of controls to be performed before, during and at the end of

operations;

- type of products to be used.

20004.VAR.PAI.FUN

Rev. 0 May 1996

Sheet 17

Il presente documento RISERVATO ed di propriet dell'AGIP. Esso non sar mostrato a Terzi n sar utilizzato per scopi diversi da quelli per i quali stato inviato

This document is CONFIDENTIAL and the sole property of AGIP . It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

2.7.2 Documents to be submitted during work progress

While work is in progress the Contractor shall keep a Work Data Log, that shall

be available at all times to the Company, and record in it all the following

information:

- temperature, humidity and dew point measurements performed at the start,

middle and end of every work shift;

- tests performed during operations and their results;

- order progress status.

Technical data sheets of coating materials also shall be always available.

2.7.3 Documents to be submitted at the completion of work

When work on the order is completed the Contractor shall prepare a final report

including in it:

- surface preparation characteristics;

- trade name and characteristics of the paints used;

- quality certificates of the paint materials, divided by manufacturing batches;

- number of coating layers applied;

- atmospheric conditions;

- inspections and tests performed and the relevant results, inclusive of the final

acceptance tests;

- if and what repairs were made.

Potrebbero piacerti anche

- 20476E00Documento11 pagine20476E00brome2014Nessuna valutazione finora

- 20003E00Documento19 pagine20003E00brome2014Nessuna valutazione finora

- Functional Specification: Offshore TerminalsDocumento10 pagineFunctional Specification: Offshore Terminalsbrome2014Nessuna valutazione finora

- 20024E00Documento13 pagine20024E00brome2014Nessuna valutazione finora

- 20013E00Documento13 pagine20013E00brome2014Nessuna valutazione finora

- 20208E00Documento28 pagine20208E00brome2014Nessuna valutazione finora

- 20020E00Documento15 pagine20020E00brome2014Nessuna valutazione finora

- 20001E00Documento21 pagine20001E00brome2014Nessuna valutazione finora

- 20023E00Documento18 pagine20023E00brome2014Nessuna valutazione finora

- 20162E00Documento26 pagine20162E00brome2014Nessuna valutazione finora

- 20012E00Documento13 pagine20012E00brome2014Nessuna valutazione finora

- Agip 20214 E00Documento22 pagineAgip 20214 E00brome2014Nessuna valutazione finora

- 14117B00Documento1 pagina14117B00brome2014Nessuna valutazione finora

- 20176E00Documento17 pagine20176E00brome2014Nessuna valutazione finora

- 20160E00Documento22 pagine20160E00brome2014Nessuna valutazione finora

- 14117B00Documento1 pagina14117B00brome2014Nessuna valutazione finora

- 20180E00Documento34 pagine20180E00brome2014Nessuna valutazione finora

- 14117B00Documento1 pagina14117B00brome2014Nessuna valutazione finora

- 06221E02Documento28 pagine06221E02brome2014Nessuna valutazione finora

- 14117B00Documento1 pagina14117B00brome2014Nessuna valutazione finora

- 14117B00Documento1 pagina14117B00brome2014Nessuna valutazione finora

- 06960B02Documento1 pagina06960B02brome2014Nessuna valutazione finora

- 20088B00Documento3 pagine20088B00brome2014Nessuna valutazione finora

- 20088B00Documento3 pagine20088B00brome2014Nessuna valutazione finora

- 14112B00Documento1 pagina14112B00brome2014Nessuna valutazione finora

- 06710B01Documento1 pagina06710B01brome2014Nessuna valutazione finora

- 06705B01Documento1 pagina06705B01brome2014Nessuna valutazione finora

- 06960B02Documento1 pagina06960B02brome2014Nessuna valutazione finora

- Normalizzazione Interna 06029.MAT - ELE.STD: Internal NormalizationDocumento2 pagineNormalizzazione Interna 06029.MAT - ELE.STD: Internal Normalizationbrome2014Nessuna valutazione finora

- Advanced Squat - #2 - La Fiaba Dello Sticking PointDocumento10 pagineAdvanced Squat - #2 - La Fiaba Dello Sticking PointIronPaolo DangerousFitnessNessuna valutazione finora

- La Mia Preghiera Elevo A TeDocumento1 paginaLa Mia Preghiera Elevo A TeAlessandroMilaniNessuna valutazione finora

- Vasco Radiatori PDFDocumento320 pagineVasco Radiatori PDFCARLANessuna valutazione finora

- Berti - Phronesis Nella Filosofia AnticaDocumento15 pagineBerti - Phronesis Nella Filosofia Anticapontexmaximus50% (2)

- Protocollo Acqua OssigenataDocumento2 pagineProtocollo Acqua OssigenataaskyNessuna valutazione finora