Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Concrete Block Paving - Dainage of Contrete Block Paving

Caricato da

Trương KhảiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Concrete Block Paving - Dainage of Contrete Block Paving

Caricato da

Trương KhảiCopyright:

Formati disponibili

CONCRET E

BL OCK PAVI NG

A walk-over in cost, looks and

durability for Concrete Block Paving

Drainage of Concrete Block Paving

Surface drainage details

Concrete Block paving (cbp) differs from other forms

of surfacing in that it comprises small segments and

therefore is criss-crossed by a network of close spaced

joints filled with sand. This means cbp is permeable

and drainage of the surface and underlying layers is

important. There is limited full scale testing world wide

but from a study conducted by Dr Brian Shackel of the

University of New South Wales, Australia, the following

conclusions were drawn:-

Between 30% to 35% of rainfall will penetrate

newly laid, untrafficked, and unsealed block

pavements.

Increase in pavement crossfall will increase surface

runoff. (Recommended min. slopes of 2%.)

The permeability of the joints can be reduced by up

to 50% with an application of a water based acrylic

sealer. Similarly infiltration can be inhibited by using

10% of lime or 6% bentonite to the jointing sand.

Generally no attempt is made to seal the joints hence

attention should be directed towards reducing the

consequences of water infiltration, particularly during

the early life of the pavement. In practice care must

be taken to select bedding sands not susceptible

to water or seal the base if it comprises unbound

granular materials or select base materials bound and

waterproofed with cement , lime or bitumen.

The management of water runoff and infiltration

becomes therefore a critical aspect that will

affect the performance and integrity of the cbp.

Good surface and subsoil drainage is essential for

satisfactory pavement performance. Drainage needs

to be considered during the design, specification

construction phases of a project.

The following recommendations and detailing, although

not new, but seldom practiced, are paramount for a

trouble free and structurally sound cbp.

Surface drainage should be designed and installed as

thoroughly as for other pavements noting local site

conditions such as:

Climatic conditions, particularly rainfall.

Ground water levels and seasonal influence ie. flood

or tidal conditions.

Soil profile.

Key detailing notes

Min longitudinal fall of 1% and a crossfall of 2%.

Paving should be set at a min. 5mm higher at

drains, gutters and manhole inlets.

DETAIL A2 MANHOLE INLET

Special attention to compaction and possible

stabilisation of backfill to manholes and inlet to

prevent subsidence.

Min. 100mm Max. 200

DETAIL A1 DRAINS AND GUTTER

Pit or manhole

Kerb and gutter

Min 5mm

Chamfer or rumbled arris

Concrete infll, min

100mm thick 30 MPa

Manhole cover Dimensions must be squared off

and tied in with the paving pattern

BACKGROUND

1 SURFACE DRAINAGE

275 275

2

3

5

1

6

0

Paving blocks

Longitudinal

fownet drain

draining sand bed

Concrete base

Paving blocks

Precast dished

concrete drain

Bedding sand

1:3 cement: sand

mortar bed

Basecourse

Paving blocks

Bedding sand

Sub-base

Concrete base

1:3 cement: sand

mortar bed

DETAIL A5 BLOCK PAVING DRAIN

DETAIL A3 INSITU CONCRETE DRAIN

DETAIL A4 PRECAST CONCRETE DRAIN

The drainage of the bedding sand is crucial particularly

where stabilised bases are used and up against kerbs,

edge beams and manhole inlets. This aspect is often

neglected and leads to a build up or boxing of water,

which pumps under traffic washing out the jointing and

bedding sand leading to progressive failure.

Select bedding sand not susceptible to water and to

the correct grading.

NB: Bituminous seal should be considered for all

unbound base material before placing bedding sand.

2.1 Bedding sand grading

(Nom sieve size mm) % Passing

9,52 100

4,75 95-100

2,36 80-100

1,18 50-85

0,600 25-60

0,300 10-30

0,150 5-15

0,075 0-10

2.2 Jointing sand

Sand should pass 1 18mm sieve and contain 10%

- 50% of material passing a 0,075 sieve.

Bedding sand

5

m

m

m

in

5mm min

Longitudinal fownet

drain draining sand bed

Longitudinal fownet

drain draining sand bed

2 BEDDING LAYER

DRAINAGE

Jointing sand

Paving blocks

Bedding sand

Basecourse

25mm weephole at 1,0m spacing

No-fnes block wrapped in geofabric

Sub-soil drain to longitudinal drain on side of road

Geofabric

Waterproofng membrane

Sand bed drainage details

DETAIL B1 STEEP SLOPES

DETAIL B2 INTO DRAINAGE PITS

USING SUB SOIL DRAINS

DETAILS B3 INFO DRAINAGE PITS

DETAILS B4 INTO SUBSOIL DRAIN

Jointing sand

Paving blocks

Bedding sand

Basecourse

Subsurface drain

Slotted pipe (100mm dia. typical)

PVC pipe (min 20mm dia. at 5m centres)

surrounded with concrete backfll

Geofabric flter covering pipe

Jointing sand Paving blocks

Bedding sand

Basecourse

25mm weephole

at 1,0m spacing

No-fnes block

wrapped in

geofabric

Sub-grade

Geotextile

Drain

Jointing sand

Paving blocks

Bedding sand

PVC pipe

(min. 20mm

dia.) on sides

of pit)

Basecourse

Geofabric flter

covering pipe

Drainage

pit wall

Sub-grade

Bituminous seal

Bituminous seal

Geotextile

Collector drain Main drain

fownet

fownet

Drain spacing

typically 5-6m

Predominant fall (min 2%)

45

To drainage gully

Collector drain

Main drain

DETAIL B5 - PAVING OVER CONCRETE SLAB

Plan view of fishbone drainage below paving

100

FLOWNET DRAINS

200

Geotextile

Jointing sand Paving blocks

Bedding sand

Flownet drain

Concrete slab

Waterproofng

membrane

Jointing sand Paving blocks

Bedding sand

Continuous geotextile

deck drain

Concrete slab

Waterproofng

membrane

ALTERNATIVE DETAIL

I

s

i

k

h

o

v

a

/

1

5

2

8

/

2

0

0

9

Block D, Lone Creek, Waterfall Office Park, Bekker Road, Midrand.

PO Box 168 Halfway House 1685

Tel +27 11 805 6742, Fax +27 86 524 9216

e-mail: main.cma@gmail.com website: www.cma.org.za

PRODUCER MEMBERS

Bafokeng Concor Technicrete 014 538 0818

Baybrick 035 792 5218

Bosun Brick Midrand 011 310 1176

Brick & Concrete Industries (Namibia) 0026 461 321 3009

Brickcast Industries 031 507 5525

Brickbuild T/A Panda (Botswana) 0026 724 42106

Cape Brick 021 511 2006

C.E.L. Paving Products 022 905 5998

Cast Industries 011 316 2375

Columbia DBL 021 905 1665

Concor Technicrete 011 495 2200

Concor Technicrete P.E. 041 372 2230

Conframat 016 987 3381

Corobrik 031 560 3911

Deranco Paving 041 933 2755

Inca Concrete Products 021 904 1620

Inca Masonry Products 043 745 1215

Infraset Gauteng 011 652 0000

KZN 031 569 6900

Kopano 016 363 0340

Mobicast Mossel Bay 044 874 2268

MVA Bricks 012 386 0050

Neat Contech 046 624 3377

Stanger Brick & Tile 032 457 0237

Stone Age Concepts 011 740 0910

Vanstone Precast 012 541 2056

Watson Concrete 011 704 0910

West End Bricks 011 851 1828

Zenzele Brix 012 803 6884

CONTRACTOR MEMBERS

Daron Construction 034 955 1333

Galaxy Paving 011 815 1175

Mondo Paving & Retaining Walls 011 467 1111

PYW Paving 031 763 5771

Roadstone Civil & Paving 011 683 7080

S A Paving Gauteng 031 705 5123

The Paving Creations 031 765 4083

Vesles Civils 012 662 3030/1

Valcal International 011 867 2471

ASSOCIATE MEMBERS

Inca (Cape) 021 904 1620

Smartstone 011 310 1161

PAVING DIVISION MEMBERS (FEBRUARY 2009)

Potrebbero piacerti anche

- Safety at Hand PDFDocumento48 pagineSafety at Hand PDFAdesijiBlessingNessuna valutazione finora

- Automotive Voltage DropDocumento5 pagineAutomotive Voltage Dropashraf.rahim139Nessuna valutazione finora

- 502.00 Asphalt Pavement 502.10 Asphalt Pavement DescriptionDocumento30 pagine502.00 Asphalt Pavement 502.10 Asphalt Pavement DescriptionAdjei BaldanNessuna valutazione finora

- SOP of Conveyor ReplacementDocumento11 pagineSOP of Conveyor ReplacementDwitikrushna Rout100% (1)

- Standard Specification For Roads and Bridges WorksDocumento365 pagineStandard Specification For Roads and Bridges WorksFrank Guo100% (1)

- Engineering Solutions To Concrete Crack RepairDocumento2 pagineEngineering Solutions To Concrete Crack RepairDushyantha JayawardenaNessuna valutazione finora

- Notice of Dissatisfaction With An Instruction Issued by The Engineer's RepresentativeDocumento1 paginaNotice of Dissatisfaction With An Instruction Issued by The Engineer's RepresentativeThe UntamedNessuna valutazione finora

- PNFDocumento51 paginePNFMuhamad Hakimi67% (3)

- Concrete Block Paving - Book 3 - Specification and Installation - Third Edition PDFDocumento32 pagineConcrete Block Paving - Book 3 - Specification and Installation - Third Edition PDFTrương KhảiNessuna valutazione finora

- Guideline 1 Design, Construction and Maintenance of Otta SealsDocumento49 pagineGuideline 1 Design, Construction and Maintenance of Otta SealshiltonrjNessuna valutazione finora

- Concrete Block Paving - Book 2 - Design Aspects Fourth EditionDocumento20 pagineConcrete Block Paving - Book 2 - Design Aspects Fourth EditionTrương Khải100% (2)

- Roller Campacted Concrete Pavements by Robert R.Thompson, Columbus, OhioDocumento133 pagineRoller Campacted Concrete Pavements by Robert R.Thompson, Columbus, Ohiooscargon19100% (1)

- Road Maintenance SpecificationsDocumento89 pagineRoad Maintenance SpecificationsAllan SevumeNessuna valutazione finora

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookDa EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNessuna valutazione finora

- AFCAP MAL 016 Pavement Design Manual MalawiDocumento182 pagineAFCAP MAL 016 Pavement Design Manual Malawitom shibaleNessuna valutazione finora

- ChecklistDocumento42 pagineChecklistOsvaldo C. Nogueira100% (1)

- Zuurbekom Roads Phase 2 Close Out ReportDocumento18 pagineZuurbekom Roads Phase 2 Close Out ReportMichael Benhura100% (2)

- Swamp Embankment Widening - Method StatementDocumento7 pagineSwamp Embankment Widening - Method StatementmemekenyaNessuna valutazione finora

- Section 1200 (Subbase, Base, Hard Shoulder and Gravel)Documento28 pagineSection 1200 (Subbase, Base, Hard Shoulder and Gravel)AmitNessuna valutazione finora

- IRC Draft Specification For Cold Milling 14 April 2011Documento3 pagineIRC Draft Specification For Cold Milling 14 April 2011Sunil BoseNessuna valutazione finora

- Proj Handbook June2014Documento19 pagineProj Handbook June2014Khristine Cloribel100% (1)

- Pavement MaintenanceDocumento72 paginePavement MaintenanceGilang ArinugrahaNessuna valutazione finora

- Stabilised Sub BasesDocumento38 pagineStabilised Sub BasesKiprotich Cherop100% (1)

- MS EARTHEN SLOPE ProtectionDocumento8 pagineMS EARTHEN SLOPE Protectionmoytabura96Nessuna valutazione finora

- Consolidation of ClayDocumento17 pagineConsolidation of ClayMD Anan MorshedNessuna valutazione finora

- (Jill E. Thistlethwaite) Values-Based Interprofess (B-Ok - CC)Documento192 pagine(Jill E. Thistlethwaite) Values-Based Interprofess (B-Ok - CC)Ria Qadariah AriefNessuna valutazione finora

- Concrete Block Paving - Book 4 - Site Management and Laying - Third EditionDocumento20 pagineConcrete Block Paving - Book 4 - Site Management and Laying - Third EditionTrương Khải100% (1)

- Concrete Block Paving - Dainage of Contrete Block PavingDocumento6 pagineConcrete Block Paving - Dainage of Contrete Block PavingTrương KhảiNessuna valutazione finora

- Final Report: Preparatory Survey ON The Project For The Improvement OF The Tema Motorway Roundabout (Phase-2)Documento212 pagineFinal Report: Preparatory Survey ON The Project For The Improvement OF The Tema Motorway Roundabout (Phase-2)Stephen nketiaNessuna valutazione finora

- RE Progress ReportingDocumento19 pagineRE Progress ReportingHedi ZarkounaNessuna valutazione finora

- AcknowledgementDocumento58 pagineAcknowledgementAmaranath RanathungaNessuna valutazione finora

- Quality Control Tests RoadsDocumento171 pagineQuality Control Tests RoadsAvinash Pathania100% (1)

- Specification For Base & Surface CoursesDocumento62 pagineSpecification For Base & Surface Coursessri10888Nessuna valutazione finora

- Botswana - Guideline 5 - Planning and Environmental Impact (2001)Documento108 pagineBotswana - Guideline 5 - Planning and Environmental Impact (2001)وردة حزيرانNessuna valutazione finora

- Structural Design of Block Pavements For PortsDocumento9 pagineStructural Design of Block Pavements For PortsDavid ReyesNessuna valutazione finora

- 017-ITC-056 (1) Reinforced Concrete Works For BridgesDocumento11 pagine017-ITC-056 (1) Reinforced Concrete Works For BridgesJuan Morales0% (1)

- Embankments at Sand Dune AreaDocumento14 pagineEmbankments at Sand Dune AreacenkunalNessuna valutazione finora

- Unbound Aggregates in RoadsDa EverandUnbound Aggregates in RoadsR.H. JonesNessuna valutazione finora

- CESMM4.pdf MeasurementDocumento43 pagineCESMM4.pdf MeasurementEmmanuel NamkumbeNessuna valutazione finora

- P 1-11 Storm Drainage PDFDocumento11 pagineP 1-11 Storm Drainage PDFMahmoud GwailyNessuna valutazione finora

- Procedures For Road Planning and Design Approved January 2003Documento49 pagineProcedures For Road Planning and Design Approved January 2003HanafiahHamzahNessuna valutazione finora

- PW 344 2017 DPW Manual Volume 2-Annexures PDFDocumento266 paginePW 344 2017 DPW Manual Volume 2-Annexures PDFMichael BenhuraNessuna valutazione finora

- Certification Scheme: Presented byDocumento34 pagineCertification Scheme: Presented byMsh SabriNessuna valutazione finora

- Basic Concepts and Applied Aspect of Sharir RachnaDocumento122 pagineBasic Concepts and Applied Aspect of Sharir RachnaRam Krish100% (1)

- Technical Auditing of Road Projects: June 2011Documento49 pagineTechnical Auditing of Road Projects: June 2011yuriga9Nessuna valutazione finora

- Standard System 2015 7th EditDocumento130 pagineStandard System 2015 7th EditLisa Shenton100% (2)

- Guideline 4 Axle Load Surveys BotswanaDocumento53 pagineGuideline 4 Axle Load Surveys BotswanahiltonrjNessuna valutazione finora

- Daily Resource UtilizationDocumento4 pagineDaily Resource Utilizationලහිරු විතානාච්චිNessuna valutazione finora

- Life Orientation Grade 11 Revision Term 2 - 2021 FinalDocumento16 pagineLife Orientation Grade 11 Revision Term 2 - 2021 FinalTeeshan VerappenNessuna valutazione finora

- Specification Design Standards Block PavingDocumento13 pagineSpecification Design Standards Block PavingTrương KhảiNessuna valutazione finora

- Concrete Roads - PQC, Methods of Construction and How It Is MadeDocumento19 pagineConcrete Roads - PQC, Methods of Construction and How It Is Madesravan shettyNessuna valutazione finora

- Tunnel ConstructionDocumento95 pagineTunnel ConstructionKunal Khubani100% (3)

- Ethical Consideration in Leadership and ManagementDocumento6 pagineEthical Consideration in Leadership and ManagementGlizzle Macaraeg67% (3)

- Bituminous Surfacings and Road Bases - UNOPSDocumento137 pagineBituminous Surfacings and Road Bases - UNOPSFranklinNessuna valutazione finora

- REoI - Road Feasibility Study of - 09-03-2020 MIN PDFDocumento33 pagineREoI - Road Feasibility Study of - 09-03-2020 MIN PDFkiflesemusimaNessuna valutazione finora

- Concrete Block Paving - Cost Comparison Between Concrete Block Paving and Premix AsphaltDocumento6 pagineConcrete Block Paving - Cost Comparison Between Concrete Block Paving and Premix AsphaltTrương KhảiNessuna valutazione finora

- Slow Progress of WorksDocumento2 pagineSlow Progress of WorkssamNessuna valutazione finora

- Technical Specification Section 704 - Precast Concrete KerbDocumento1 paginaTechnical Specification Section 704 - Precast Concrete KerbRock AmjathNessuna valutazione finora

- General Conditions of Contract - GCC 2010-15-16 July 2013 DurbanDocumento5 pagineGeneral Conditions of Contract - GCC 2010-15-16 July 2013 DurbanBradley WaltmanNessuna valutazione finora

- MillingDocumento24 pagineMillingBibhuti B. BhardwajNessuna valutazione finora

- G1 Draft Road Construction EMP R61Documento31 pagineG1 Draft Road Construction EMP R61xbitmanNessuna valutazione finora

- 2016 06 22 Concrete Cold JointsDocumento1 pagina2016 06 22 Concrete Cold JointskiranNessuna valutazione finora

- 05-16 QCS 2014Documento10 pagine05-16 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- The Roads Act 2019Documento76 pagineThe Roads Act 2019GCIC100% (3)

- RdaDocumento38 pagineRdaRamanan Raam Jr.100% (1)

- Tender To Provide Consultancy Services For The Design and Construction Supervision of Zra Head Office-201629092016155956 PDFDocumento65 pagineTender To Provide Consultancy Services For The Design and Construction Supervision of Zra Head Office-201629092016155956 PDFengkjNessuna valutazione finora

- Design of Earth DamDocumento53 pagineDesign of Earth Damlehangh90Nessuna valutazione finora

- Stressing RecordDocumento3 pagineStressing RecordaymanNessuna valutazione finora

- IS008 Soil Cement BlocksDocumento4 pagineIS008 Soil Cement BlocksCiddarthnNessuna valutazione finora

- Method Statement Embankment: 1. GeneralDocumento11 pagineMethod Statement Embankment: 1. GeneralReny AkmaliaNessuna valutazione finora

- 21 - Concrete Mix Design and Trial Mixes PDFDocumento45 pagine21 - Concrete Mix Design and Trial Mixes PDFMauridi KaminyuNessuna valutazione finora

- 2 Solid and Hollow Block MSDocumento7 pagine2 Solid and Hollow Block MSGaneshNessuna valutazione finora

- Concrete PRR SCRDocumento366 pagineConcrete PRR SCRdfv91100% (1)

- Construction Submittal and Shop Drawing LiabilityDocumento7 pagineConstruction Submittal and Shop Drawing LiabilityKhue NguyenNessuna valutazione finora

- Mat Bang, Mat Cat Ngang Cong Doan Qua Ham ChuiDocumento7 pagineMat Bang, Mat Cat Ngang Cong Doan Qua Ham ChuiTrương KhảiNessuna valutazione finora

- Keller 32 01E Deep Soil MixingDocumento8 pagineKeller 32 01E Deep Soil MixingPomijaNessuna valutazione finora

- Check Dam Cau Thep Dan SinhDocumento3 pagineCheck Dam Cau Thep Dan SinhKhải TrươngNessuna valutazione finora

- SssssDocumento2 pagineSssssNichole PalmerNessuna valutazione finora

- Pile DiagramDocumento1 paginaPile DiagramTrương KhảiNessuna valutazione finora

- WaboStripSeal 0613 DataSheetDocumento4 pagineWaboStripSeal 0613 DataSheetTrương KhảiNessuna valutazione finora

- WaboModular 1206 DataSheet.4e5e3c4e218b11.89065326Documento4 pagineWaboModular 1206 DataSheet.4e5e3c4e218b11.89065326Trương KhảiNessuna valutazione finora

- AnglesDocumento1 paginaAnglesTrương KhảiNessuna valutazione finora

- Bridge ConcreteColumnDocumento5 pagineBridge ConcreteColumnTrương KhảiNessuna valutazione finora

- Test Your Knowledge - Test 1-Geometric Design Demonstration ToolsDocumento14 pagineTest Your Knowledge - Test 1-Geometric Design Demonstration ToolsTrương KhảiNessuna valutazione finora

- Curve Widening 2011Documento12 pagineCurve Widening 2011Trương KhảiNessuna valutazione finora

- Amazing Computer Graphics and VisualizationsDocumento56 pagineAmazing Computer Graphics and Visualizationsnaizath12Nessuna valutazione finora

- AnglesDocumento1 paginaAnglesTrương KhảiNessuna valutazione finora

- Building Roads - The Preferential Use of Concrete Block PavingDocumento4 pagineBuilding Roads - The Preferential Use of Concrete Block PavingTrương KhảiNessuna valutazione finora

- Concrete Block Paving - Book 1 - IntroductionDocumento32 pagineConcrete Block Paving - Book 1 - IntroductionTrương Khải100% (1)

- Concrete Block Paving - Technical Note For Steep SlopesDocumento6 pagineConcrete Block Paving - Technical Note For Steep SlopesTrương KhảiNessuna valutazione finora

- De Bai Tap Lon PPPTHH Cho LopDocumento12 pagineDe Bai Tap Lon PPPTHH Cho LopTrương KhảiNessuna valutazione finora

- Concrete Block Paving - Efflorescence Is Only A Temporary ProblemDocumento4 pagineConcrete Block Paving - Efflorescence Is Only A Temporary ProblemTrương KhảiNessuna valutazione finora

- Tai Leu Tham KhaoDocumento5 pagineTai Leu Tham KhaoNakkolopNessuna valutazione finora

- Bai Giang CTN Do Thi - Khai NiemDocumento43 pagineBai Giang CTN Do Thi - Khai NiemTrương KhảiNessuna valutazione finora

- Bai Giang PP PTHHDocumento78 pagineBai Giang PP PTHHTrương KhảiNessuna valutazione finora

- Urban Planning 111.Documento44 pagineUrban Planning 111.Trương KhảiNessuna valutazione finora

- DocumentDocumento6 pagineDocumentGlennford Loreto SuyatNessuna valutazione finora

- Unsaturated HydrocarbonsDocumento84 pagineUnsaturated HydrocarbonsHey itsJamNessuna valutazione finora

- 36 Petroland PD Serie DKDocumento7 pagine36 Petroland PD Serie DKBayu RahmansyahNessuna valutazione finora

- Lpalmer ResumeDocumento4 pagineLpalmer Resumeapi-216019096Nessuna valutazione finora

- Optimization Process of Biodiesel Production With Ultrasound Assisted by Using Central Composite Design MethodsDocumento47 pagineOptimization Process of Biodiesel Production With Ultrasound Assisted by Using Central Composite Design MethodsMiftahFakhriansyahNessuna valutazione finora

- Leon County Sheriff'S Office Daily Booking Report 4-Jan-2022 Page 1 of 3Documento3 pagineLeon County Sheriff'S Office Daily Booking Report 4-Jan-2022 Page 1 of 3WCTV Digital TeamNessuna valutazione finora

- 2012 U.S. History End-of-Course (EOC) Assessment Field Test Fact SheetDocumento2 pagine2012 U.S. History End-of-Course (EOC) Assessment Field Test Fact SheetswainanjanNessuna valutazione finora

- Mental Health & TravelDocumento18 pagineMental Health & TravelReyza HasnyNessuna valutazione finora

- Learnership AgreementDocumento10 pagineLearnership Agreementkarl0% (1)

- Maxs AdultDocumento1 paginaMaxs Adultclark lopezNessuna valutazione finora

- MS 1979 2015Documento44 pagineMS 1979 2015SHARIFFAH KHAIRUNNISA BINTI SYED MUHAMMAD NASIR A19EE0151Nessuna valutazione finora

- Concrete and Its PropertiesDocumento24 pagineConcrete and Its PropertiesAmila LiyanaarachchiNessuna valutazione finora

- TextDocumento3 pagineTextKristineNessuna valutazione finora

- Iso 2281 1990Documento8 pagineIso 2281 1990jesus torresNessuna valutazione finora

- Contoh Reflection PaperDocumento2 pagineContoh Reflection PaperClaudia KandowangkoNessuna valutazione finora

- Diplomate Course and Conferment RequirementsDocumento1 paginaDiplomate Course and Conferment Requirementsabigail lausNessuna valutazione finora

- Fire BehaviourDocumento4 pagineFire BehaviourFirezky CuNessuna valutazione finora

- E4-E5 - Text - Chapter 2. ISO 9001-2015 QUALITY MANAGEMENT SYSTEMDocumento17 pagineE4-E5 - Text - Chapter 2. ISO 9001-2015 QUALITY MANAGEMENT SYSTEMAGM S&M-CMNessuna valutazione finora

- Chapter 3.2 Futures HedgingDocumento19 pagineChapter 3.2 Futures HedginglelouchNessuna valutazione finora

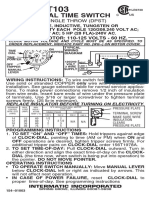

- T103 InstructionsDocumento1 paginaT103 Instructionsjtcool74Nessuna valutazione finora