Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1KHF334933 - AHS-PS32-1402-B - SAS Functional Description For CCR Rev1

Caricato da

kytongTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1KHF334933 - AHS-PS32-1402-B - SAS Functional Description For CCR Rev1

Caricato da

kytongCopyright:

Formati disponibili

We reserve all rights in this document and in the information contained therein.

Reproduction, use or disclosure to third parties without express authority is strictly forbidden.

Copyright 2013 ABB

FORMOSA HA TINH STEEL CORPORATION

FORMOSA CHEMICALS & FIBRE CORPORATION ENG. & UTILITY DIVISION

Document Code : AHS-PS32-1402-B

CUSTOMER :

FORMOSA CHEMICALS & FIBRE CORP.

PROJECT :

HA-THINH STEEL PLANT PROJ ECT VIETNAM

220KV SUBSTATIONS

B 2013-07-04 SL SL SL

Rev Date Prepared /

Revised

Checked Approved Note / Detail of Revision

Prepared :S.Lemmerann Based on : / Replaces :

AHS-PS32-1402-A

Sep.PL same No.

Without separ. PL

Scale : Doc.Type : Format :

Sep. PL anoth. No.

NA A4

Checked :S.Lemmermann Responsible department : PSSA-P Title :

SAS functional description for CCR

Approved : M.Gnter Take over department : NA Language :

EN

R

e

v

i

s

i

o

n

:

1 2013-07-04/SL No Sheets :

34

ABB Switzerland Ltd.

Document Number : 1KHF334933

Sheet No :

1

Copyright 2011 ABB. All rights reserved.

Customer doc. no.

-

Based on -

Customer

FCFC Eng. & Utility Division

Prepared Lemmermann 2012-01-07

Project

Ha Thinh Steel Plant

Approved M.Gnter 2012-01-07

Order

16234

Title

SAS functional description for CCR

Ref.

des.

-

Resp. dept.

PSSA-P

Doc. no. Language Rev.

Sheet

1

ABB Switzerland Ltd 1KHF334933 EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Customer FCFC Eng. & Utility Division

Main contractor ABB CH - PSSS

Order 16234

Plant Ha Thinh Steel Plant - PPCCR

Equipment Substation Automation - mSCADA

Title SAS functional description for CCR

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

2

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Index

1. Preface ....................................................................................................................................... 3

1.1 Contents of this document .............................................................................................. 3

1.2 Target group of readers .................................................................................................. 3

1.3 Definitions and Abbreviations ......................................................................................... 3

2. Introduction ............................................................................................................................... 5

2.1 Scope of this document .................................................................................................. 5

2.2 Application Area ............................................................................................................. 5

2.3 System Description ......................................................................................................... 6

3. System Architecture ................................................................................................................. 8

3.1 System Hierarchy ........................................................................................................... 8

3.2 Communication system to PMS, EC and EVN Control Center (on hold by

customer) ...................................................................................................................... 11

4. Functional Description ........................................................................................................... 12

5. Hardware and Software Components ................................................................................... 13

5.1 Front End ...................................................................................................................... 13

5.2 Operator Workstation ................................................................................................... 15

5.3 Engineering Notebook .................................................................................................. 17

5.4 Training Workstation ..................................................................................................... 17

5.5 Simulation Workstation ................................................................................................. 18

5.6 Gateway ....................................................................................................................... 22

5.7 Video wall ..................................................................................................................... 23

5.8 Ethernet Switch ............................................................................................................ 23

5.9 Peripheral devices ........................................................................................................ 24

7. Appendix: Fiber Optic Cable Specification .......................................................................... 27

7.1 Fiber Optic Components ............................................................................................... 27

7.2 Standard Wavelengths ................................................................................................. 28

7.3 Fiber Optic Standards ................................................................................................... 28

7.4 Fiber Optic Cables inside cubicles ............................................................................... 29

8. Revision ................................................................................................................................... 33

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

3

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

1. Preface

1.1 Contents of this document

The purpose of this Document is to describe the implemented functions of the SAS station

mentioned in the first page of this document. All pictures and examples, which are shown,

are of general manner, but cover all the needs.

1.2 Target group of readers

This functional description is intended for customer to see which functions are

implemented in his SCMS system, where to find it and how to use it.

1.3 Definitions and Abbreviations

The following table is a list of abbreviations and acronyms used in this document. Product

names are not taken into this list.

ACP Application Communication Protocol

CD-ROM Compact disk - read only memory

CE Certified standard: The device conforms to the

directive 89/336/EWG on the approximation of the

law of the member states of the European

Community relating to electromagnetic compatibility.

COM Serial interface

CPU Central processor unit

DCS Digital Control System

DDE Dynamic Data Exchange

DOI Double Operating Interlock

FBS Fall-Back Switch

FUPLA Function Plan Programming Language for the ABB

IEDs

GIS Gas Insulated Switchgear

GPS Global Positioning System

HSB Hot Stand-By

IED Intelligent Electronic Device

IP Ingress Protection standard IEC60529

ISA Industrial Standard Architecture

LDC Load Dispatch Centre

LAN Local Area Network

MicroSC

ADA Pro

Version of the base software, on which the SAS

application is developed

HMI Man machine program for ABB IEDs

MMI

MMS Manufacturing Message Specification

ISO 9506-1 and ISO 9506-2

NCC Network Control Centre

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

4

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

NIC Network Interface Card

NV Network Variable

ODBC Open Database Communication/Connectivity

OLE Object Linking and Embedding

OPC OLE for Process Control

PCMCIA Personal Computer Memory Card International

Association

PC-NET Communication software for personal computers

RAM Random Access Memory

RAS Remote Access Service

RCC Remote Control Centre

RDBMS Relational Database Management System

RTU Remote Terminal Unit

SA Substation Automation

SAS Substation Automation System

SCIL Supervisory Control Implementation Language

SQL Structured Query Language

TCP/IP Transmission Control Protocol / Internet Protocol

TCS Tap change Control and Supervision

UPS Uninterruptible Power Supply

PPCCR Power Plant Control Center Room

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

5

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

2. Introduction

2.1 Scope of this document

The Substation Automation System (SAS) functional description presents the design,

functions, features and facilities of the SAS system.

This functional description is intended to provide an overview of the functions which are

implemented in the SA system. For more detailed information and specifications, consult

the Data Sheets of the relevant product. The software or hardware described in this

document is furnished under a license and may be used, copied, or disclosed only in

accordance with the terms of such license.

SAS built in PPCCR is a mirrored system of the 4 substations ESP01, ESP02, ESM01

and ESH01. Means that functionality will be same as in local Micro SCADA system

Therefore this document will reference at several points to functional descriptions of local

Micro SCADA at substations.

Project specific pictures will be submitted for approval at detail engineering phase for

substations ESP01, ESP02, ESM01 and ESH01 as appendix.

2.2 Application Area

The substation automation system SAS600 Series is designed for controlling and

monitoring the primary and secondary equipment of a substation. Typical applications are

substations for power utilities on

distribution,

sub-transmission,

high-voltage transmission

extra high voltage transmission

new installations and refurbishment of existing substations

gas and air-insulated switchgear

The SAS600 series solutions for substation automation are based on and fully compliant

with IEC61850. They provide the communication and integration of ABB's bay control and

bay protection solutions (BCS6xx and BPS6xx), all the station level functions and as an

option the remote link to e.g. a network control center.

The SAS provides an extensive range of Supervisory Control and Data Acquisition

(SCADA) functions.

Control and supervision of switching devices, transformers, etc.

Bay and station interlocking

Current, voltage, frequency and power measurement

Alarm functions, storage and evaluation of events

Time synchronization of the system

User management

Disturbance recording and evaluation

Serial connection to all numerical relays

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

6

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

2.3 System Description

The SAS600 series are state-of-the art solutions based on IEC61850 for operation under

electrical conditions present in high-voltage substations, follow the latest engineering

practice, ensure long-term compatibility requirements and continuity of equipment supply

and the safety of the operating staff.

The system is designed in such a way that personnel without any background knowledge

in microprocessor-based technology are able to operate the system easily after having

received some basic training.

Cubicles that incorporate the control, monitoring and protection functions provide self-

monitoring, signaling and testing facilities, measurement as well as memory functions,

event recording and disturbance recording. The basic control functions are derived from a

modular standardized and type-tested software library.

Maintenance, modification or extension of components does not cause a shut down of the

whole substation automation system. Self-monitoring of single components, modules and

communication is incorporated to increase the availability and the reliability of the system

and minimize maintenance.

Protection and control devices are freely adaptable to the required application

functionality.

The SAS conforms fully to the IEC61850 standard and has a decentralized architecture

consisting of the following main hardware components:

Application server and Human Machine Interface (HMI)

Managed switched fiber-optic Ethernet LAN in a fault tolerant ring architecture

Gateway for remote communication to Remote Control Centre (RCC) and / or

National control Center (NCC), communicating for example on IEC 60870-5-101

protocol

Dot matrix printer (DMP) for alarms and events

Laser printer for printing graphics and reports

GPS receiver per station to synchronize the time of SAS including the IEDs.

IEDs for bay and station protection

IEDs for bay control and monitoring

Disturbance Recorder (DR) evaluation workstation

Multi-Meters and energy meters for measurement report

The basic functions / features of a Substation Automation System are listed below:

Supervision and control of switching devices, transformers, tap changers and other

controllable primary equipment

Local as well as remote control of the substation switching devices

Safety checks, station and bay interlocking

Time synchronization of the SA system

Current, voltage, frequency and power measurement

System supervision of the secondary and station level devices

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

7

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Alarm functions, storage and evaluation of events, blocking lists

Time scheduled activities

User management

Optional advanced functions provided in the SAS are:

Trend recording and storage

Measurement reports

IED parameterization

Disturbance recording, upload and analysis

Trip counter table

Dynamic busbar coloring

Perform auto electrical billing calculation

The above in this chapter describes in general the possible features of SAS600 series,

which will be implemented in ESP01, ESP02, ESM01 and ESH01. SAS built in PPCCR is

a mirrored system of the 4 substations. Means that functionality will be same as in local

Micro SCADA system Therefore this document will reference at several points to

functional descriptions of local Micro SCADA at substations.

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

8

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

3. System Architecture

3.1 System Hierarchy

This chapter will explain system hierarchy between local Micro SCADA at the 4 substations

ESP01, ESP02, ESM01 and ESH01. For system hierarchy within the substation please refer to

document:

AHS-PS32-2406 SAS Functional description - ESP01

AHS-PS32-2406 SAS Functional description - ESP02

AHS-PS32-3406 SAS Functional description - ESM01

AHS-PS32-4406 SAS Functional description - ESH01

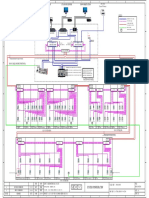

Fig. 3.1-1: System Hierarchy

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

9

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

The system architecture of the PPCCR SAS as shown above (Fig. 3.1-1) is designed in a manner

which facilitates different hierarchical levels:

EVN Control Center

PMS

Energy Center

PPCCR

ESP01 back up of PPCCR

Local Micro SCADA at Substations

These are described in detail below.

Control and monitoring of all 4 substations is only possible in PPCCR and ESP01 back up of

PPCCR. Monitoring function between substation will be realized via remote desktop application

with Micro SCADA viewer access.

3.1.1 EVN Control Center

EVN Control Center A0 & A1 have only switching authority (in parallel) via gateway for CB, DS, ES

HSES in AA2.D1.

EVN Control Center A0 & A1 have only switching authority (in parallel) for CB, DS, ES HSES for

generator feeder (D2.Q09, D2.Q11, D2.Q12, D2.Q19, D2.Q20) in AA2.D2.

Following signals shall be provided for all feeders of AA2.D1 and AA2.D2

Measurement

o Busbar: kV, Hz

o Generator feeder: MW, Mvar, high-limit control (MW), low-limit control

(MW)

o Transformer feeder (220/220kV & 220/35kV): MW, Mvar, kV, A

o Transmission line: Mw, Mvar, kV, A

o Power Plant total active power, total reactive power

Alarm signals

Control mode indication (station & bay level)

Tap Changer indication (tap, raise, lower, faulty)

Operation mode of IED (faulty, healthy, testmode)

Protection Trip & Alarm (Mechanical Protection & numerical protection)

ES/DS/CB position (double point)

Communication protocol is IEC 60870-5-101 slave.

3.1.2 Power Management System (PMS)

PMS requirements (only applicable for ESP01 and ESP02):

Analogue signals from ESP01 & ESP02 to PMS system:

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

10

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Feeder kW/T (via transducer 4 to 20mA) for all 220kV Feeder and 35kV outgoing

feeder exclude capacitor.

Main bus (BB1A, BB1B, BB2A, BB2B of AA2.D2) frequency and voltage (via

transducer 4 to 20mA)

Binary signals from ESP01 & ESP02 to PMS system:

220kV Lockout relay (86) operated (2 dry contact)

220kV and 35kV CB and DS status On and Off (1 dry contact per object/status)

Main bus (BB1A, BB1B, BB2A, BB2B of AA2.D2) 81U1 (1 dry trip contact), 81U2

(1 dry trip contact), 81O1 (1 dry trip contact), 27 (1 dry trip contact),

Binary signals from PMS System to ESP01 and ESP02:

Load shedding: 1 dry contact for tripping on TC1 and 1 dry contact for alarm to

BCU/Micro SCADA) for =AA2.D2.Q21 =AA2.D2.Q22

Load shedding: 35kV Feeder (ESP01/ESP02): 1 dry contact for tripping on TC1

and 1 dry contact for alarm to BCU/Micro SCADA)

Dynamic breaking: 1 dry contact for tripping on TC1 and 1 dry contact for alarm to

BCU/Micro SCADA) for =AA2.D2.D2.Q09, =AA2.D2.D2.Q11, =AA2.D2.D2.Q12,

=AA2.D2.D2.Q19, =AA2.D2.D2.Q20

Signals shall be hardwired directly to PMS panel.

No communication protocol provided. One spare LAN Card port (RJ45) will be reserved at

Gateway 1 and Gateway 2.

3.1.3 Energy Center (EC) (on hold by customer)

Energy Center has no control authority. EC will only receive measurement values collected by

metering equipment.

Communication protocol is Modbus TCP/IP & IEC 60870-5-104.

3.1.4 Power Plant Control Center Room (PPCCR)

PPCCR has control authority of ESP01, ESP02, ESM01 and ESH01, if local Micro SCADA at

substation is set to Remote Control commands can be issued to OLTC, earthing switch,

disconnector and circuit breakers. PPCCR will receive same signals as local Micro SCADA

substation.

Signals, commands and measurement values are mirrored from local Micro SCADA at substation

to PPCCR.

3.1.5 ESP01 back up of PPCCR

ESP01 back up of PPCCR has control authority of ESP01, ESP02, ESM01 and ESH01, if local

Micro SCADA at substation is set to Remote Control and if there is no communication between

PPCCR and ESP01 back up of PPCCR. In that case authority control needs to be set manually to

active at ESP01 back up of PPCCR and same functionality of PPCCR applies.

Signals, commands and measurement values are mirrored from local Micro SCADA at substation

to ESP01 back up of PPCCR.

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

11

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

3.2 Communication system to PMS, EC and EVN Control Center (on hold by customer)

This is a communication software package / HW providing gateway services for routing the data

flow between the process and network control systems. The data transfer usually involves protocol

conversion. It also handles system coordination tasks, such as dynamic assignments of the control

command authorities. A variety of protocols for connecting upper level systems are supported.

For EC Modbus TCP/IP and for EVN Control Center IEC 60870-5-101 slave is assigned.

3.2.1 Station Level

The components at PPCCR are Front End Computers, Workstations, Gateways, printers, master

clock for synchronization and video wall system. These are connected together via an Ethernet

LAN utilizing the TCP/IP protocol.

A dedicated GPS master clock is provided for the synchronization of the entire system. This master

clock is independent of the station computers and gateways, and it synchronizes all devices via the

station bus.

The communication gateway enables communication to the next higher level system, for data and

information exchange with PMS, EC and EVN Control Center.

In order to increase the reliability, local Hot-Standby workstation located in ESP01 is dedicated as

backup system of main control system in CCR.

Additional an engineering workstation laptop including docking station is foreseen, which can be

used at PPCCR or any of the 4 substations for engineering work. Laptop needs to be connected to

certain station or bay level LAN switches (or directly to IED) for engineering and maintenance

work.

3.2.2 Station Level LAN

The Ethernet based on IEEE 802.3 (CSMA/ CD) and OSI TCP/IP is used to interconnect the

subsystems (ESP01, ESP02, ESM01, ESH01) of superior system at PPCCR. Front End computer,

workstations, communication units (routers, repeaters) and print servers are connected to the local

area network (LAN) with a communication speed of 100 or 1000Mbit/s depending on the device

speed.

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

12

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

4. Functional Description

Micro SCADA in PPCCR is only a mirrored application of local Micro SCADA systems of

substations ESP01, ESP02, ESM01 and ESH01. Therefore, please refer to documents:

AHS-PS32-2406 SAS Functional description - ESP01

AHS-PS32-2406 SAS Functional description - ESP02

AHS-PS32-3406 SAS Functional description - ESM01

AHS-PS32-4406 SAS Functional description - ESH01

for detailed information of following topics:

System Overview

Software Description

Process Database

Overview

Process object function

Process object types

Data processing

Report Database

System objects

Base tools

Application Engineering

System Functions

Station HMI

Login and User Management

Monitor Layout

Time Synchronization

Control Authority handling

Station Local/Remote control

Bay Local/Remote control

Basic Monitoring and Control Functions

Colors and Symbols

Busbar and line colors

Symbol Colors

Symbols for Switching Objects

Process Displays Level

Level 1: Overall Single Line Picture

Level 2: Single Line Picture

Level 3: Bay View Picture

System Self Supervision

Event List

Alarm List

Blocking List

Control Concept

Select before operate

Synchrocheck bypass and interlocking bypass

Measurement presentation

Advanced Monitoring and Control Functions

Trends and Process Value Measurements

Parameter setting in IEDs

Busbar Coloring

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

13

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

5. Hardware and Software Components

5.1 Front End

5.1.1 Redundant Station Computer

The redundant station computers contain the supervisory and control functions. The station

computers are high-profile pre-tested industrial PCs running under the Windows 2003 operating

system and the MicroSCADA application software. The redundant station computers work in a hot

standby configuration. During normal operation, the standby station computer mainly works as a

second workplace. The mutual supervision of the station computers and the database shadowing is

performed via the redundant station LAN. In the event that the hot station computer fails, the standby

station computer takes over the process control immediately. Getting all actual process data at any

time via the IEC61850 bus supports the actuality of data. Also manual changes in the database of

the hot station computer, e.g. pictures or limit values, are automatically copied to the standby station

computer. In order to communicate with the IEDs using the IEC61850 protocol for each bus segment,

one LAN card in each station computer is required. The redundant station computers also serve as

redundant operator/engineering workstations.

5.1.2 Hot standby Station Computer

The two Front End computer base systems are working in a hot standby configuration. The hot

system performs the communication tasks to the process and to the printer.

The hot standby concept is based on data shadowing of disk-resident data as well as RAM-resident

data between the two base systems. The entity subject to shadowing is the application of Micro

SCADA. In case of

Failure of the hot station computer

Failure of the hot application

Failure of the communication between the hot and stand-by PC

Failure of communication between hot station computer and local Micro SCADA at ESP01,

ESP02, ESM01 and ESH01

a take-over will take place meaning that the application receiving the shadowed data in stand-by

mode will become hot and the application activities are started. The stand-by application is an

identical copy of the hot application both in respect of disk data and in respect of RAM-resident data.

Data is shadowed on event basis, i.e. during the run-time only changed data items are shadowed.

Temporary disk and RAM resident-data such as picture and report caches, printer spools, execution

states and monitor states are not shadowed. At start-up, a complete copy is made from the hot

application to the stand-by application. The shadowing is fully symmetric meaning that the application

may be shadowed in both directions in turn. Take-over may also be initiated manually. After a take-

over, the shadowing will automatically start in the reversed direction when the system detects that

the failed station computer is available.

The interconnected station computers are connected with a TCP/IP link with a bit rate of 1000 Mbit/s.

5.1.3 System startup

The station computers are always running and it is usually not allowed to shut them down.

After a power loss they are starting up automatically:

Operating system Windows 2008 Server will start.

MicroSCADA and its applications will start.

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

14

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

The station computer, which comes up first, will take over the hot state

The Terminal connections to the application data of the actual running hot station computer will be

done and the operator will be asked for his MicroSCADA username and password.

The operator will only be able to operate from the SAS according his user authorization level.

5.1.4 Front End Software

Item Description Remark

1 Windows 2008 Server R2 64bit Base

2 Print Key Base

3 Internet Explorer Base

4 Adobe Reader Base

5 Obermeier Base

6 mSCADA Professional Base

7 Terminal server (open licence) Base

5.1.5 Front End Hardware

The Front-End computer is provided with monitor, keyboard and mouse. It is mainly used for

operating of the SAS.

Item Description Detail

1 Industrial PC 19-inch slide-in

2 Housing 7-slot slide-in housing ATX for 19-inch

racks, 4 rack units

3 Slots all for full-length plug-in cards

3 PCI Express x1

3 PCI slots

1 PCI Express x16

4 Front flap Lockable

5 Card holders

6 Protection class IP60 when operating

7 Operating temperature 055 C

8 Weight of the basic

configuration

17.0 kg (37.5 lbs)

9 Dimensions 483 x 177 x 500 mm / 19" x 7" x 19.5" (W x

H x D)

10 Processor

2nd Generation Intel Core i7, 2.1 GHz,

4 cores (TC3: 80)

11 Motherboard ATX motherboard for 2nd Generation Intel

Core i3, Core i5, Core i7 or Celeron

12 RAM 4 GB DDR3 RAM

13 Graphic adapter Integrated inside the Intel processor: 1

DVI-I

1 DVI-D

1 Display Port connector

2 of 3 connectors useable at same time

14 Dual Ethernet adapter On-board with 2 x 10/100/1000BASE-T

connector

1 Dual Port Gigabit-Ethernet-PC network

cards, PCI-Express-x1-Bus

15 RAID on-board SATA RAID 1 controller, Intel

Rapid Storage Technology

16 Hard disk 1. 3-inch, 500 GB

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

15

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

2. 3-inch, 320 GB

17 Serial ports 4xRS232 1 of these RS232 ports are led

out with 9-pin D-sub connectors; 14 USB

2.0, 4 of these USB ports are led out at the

rear side and 2 are behind the front flap

18 Keyboard socket PS/2

19 Mouse socket PS/2

20 Power Supply Redundant

100240 V AC (50/60Hz) full range power

supply

5.2 Operator Workstation

The operator workstation is provided with monitor, keyboard and mouse. It is mainly used for

operating of the SAS. The operator workstation knows, which station computer is the hot base

system, and the data will be fetched from there. The process pictures shown on the operator

workplace are stored in the front-end computers. The operator workstation calls the picture from

the actual running hot base system.

5.2.1 Operator Workstation Software

Item Description Remark

1 Windows 7 Base

2 Print Key Base

3 Internet Explorer Base

4 Adobe Reader Base

5.2.2 Operator Workstation Hardware

Item Description Detail

1 Industrial PC 19-inch slide-in

2 Housing 7-slot slide-in housing ATX for 19-inch

racks, 4 rack units

3 Slots all for full-length plug-in cards

3 PCI Express x1

3 PCI slots

1 PCI Express x16

4 Front flap Lockable

5 Card holders

6 Protection class IP60 when operating

7 Operating temperature 055 C

8 Weight of the basic

configuration

17.0 kg (37.5 lbs)

9 Dimensions 483 x 177 x 500 mm / 19" x 7" x 19.5" (W x

H x D)

10 Processor Intel Celeron 1.6 GHz, 2 Core (TC3: 50)

11 Motherboard ATX motherboard for 2nd Generation Intel

Core i3, Core i5, Core i7 or Celeron

12 RAM 4 GB DDR3 RAM

13 Graphic adapter Integrated inside the Intel processor: 1

DVI-I

1 DVI-D

1 Display Port connector

2 of 3 connectors useable at same time

14 Dual Ethernet adapter On-board with 2 x 10/100/1000BASE-T

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

16

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

5.2:2 OWS installed in Front End Cubicle

Item Description Detail

1 Industrial PC ATX-Midi Tower

2 Processor IIntel Core2 Quad Processor Q9400

(6M Cache, 2.66 GHz, 1333 MHz FSB)

3 Motherboard Intel Q35 and ICH9 DO supporting

800/1066/1333 MHz FSB

Supports dual core and quad core process

with 45nm processing

Dual channel DDR2 667/800 SDRAM up to

8 GB

PCIe x 16 slot for external VGA card

Supports 4 PCI and 2 PCIe x1

1 parallel (SPP/EPP/ECP)

2 PS/2

Supports 6 SATA II and software RAID 0, 1,

5, 10

Built in with dual GbE controllers

support optional TPM module

4 RAM 4GB DDR2 800MHz RAM

5 Graphic adapter Chipset integrated VGA controller

6 LAN Card Network Card 1x 10/100-RJ45, 1x 100-ST,

PCI

7 DVD/CD Writer CD-DVD-RW Drive, 20X IDE

DVD+/-RW DL

8 Hard disk 500GB SATA Harddisk

3.5" SATA 7KRPM

9 Serial ports 4 USB 2.0 ports on rear

4 serial ports (3 of RS-232, 1 of RS-

232/422/485)

10 Keyboard socket PS/2

11 Mouse socket PS/2

12 Power Supply 450W AC-DC ATX Power Supply

5.2:2 Desktop OWS

connector

1 Dual Port Gigabit-Ethernet-PC network

cards, PCI-Express-x1-Bus

15 RAID on-board SATA RAID 1 controller, Intel

Rapid Storage Technology

16 Hard disk 3-inch, 500 GB

17 Serial ports 4xRS232 1 of these RS232 ports are led

out with 9-pin D-sub connectors; 14 USB

2.0, 4 of these USB ports are led out at the

rear side and 2 are behind the front flap

18 Keyboard socket PS/2

19 Mouse socket PS/2

20 Power Supply 100240 V AC (50/60Hz) full range power

supply

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

17

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

5.3 Engineering Notebook

The engineering notebook is provided with docking station, keyboard and mouse. It is mainly used

for engineering of the SAS but could also be used in the same manner as the operator workstation.

The engineering workstation knows, which front-end computer is the hot base system, and the data

will be fetched from there. The process pictures shown on the engineering workplace are stored in

the front-end computers. The engineering notebook calls the picture from the actual running hot base

system.

5.3.1 Engineering Notebook Software

Item Description Remark

1 Windows 7 Base

2 Print key Base

3 Internet Explorer Base

4 Adobe Reader Base

5 Microsoft Office Professional

5.3.2 Engineering Notebook Hardware

5.4 Training Workstation

On a separate workstation as build mSCADA application will be installed. All data points will be set

to fictive. Real time data update is not possible.

With this training workstation the staff will be able to train the mSCADA handling. Commands can

be issued and object feedback (open/close) will be simulated. Busbar coloring and event-list

update is activated. Blocking and Interlocking conditions will not be realized.

Item Description Detail

1 Docking Station Sony VGP-PRS30 500 GB Hard disk

2 Laptop Sony SVS1313C5E

Processor Intel CoreTM i7-3540M, 3

GHz

Keyboard US

RAM 8 GB 1333 MHz DDR3L-

SDRAM

Display 33.7cm LCD

Resolution 1366x768 Intel GPU

Graphic card Intel HD Graphics 3000

Hard disk 500 GB Serial ATA (7200

U/Min)

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

18

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

5.5 Simulation Workstation

5.5.1 Definition of the network size for licensing

Medium size

Number of primary substations <15

Number of MV/LV subst.(load points) <1000

Number of switching devices <2000

5.5.2 Implemented functions

Base System (Topology Management)

Network Analysis

General Extensions

HSB support

HSB support means that DMS 600 can always use the active MicroSCADA Pro SYS 600 server in

SCADA interface. DMS 600 is using one MS SQL Server database and database servers are not

redundant.

5.5.3 The substation parts/voltage levels that are connected to DMS 600 system:

220 kV network and outgoing 35 kV feeders to load points like e.g. 35/6 kV transformers.

Totally 124 ( 32 + 60 + 32 ) outgoing feeders. Each feeder is having only one load point e.g. 35/6

kV transformer.

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

19

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

5.5.4 Overview of Network Analysis

Network analysis functions offer load flow and fault current calculations and

over-current protection analysis of radially operated and meshed networks. The generators are

taken into account during the network analysis. Additionally, the distributed generators and

capacitors are taken into account in the load flow calculations. The protection analysis function can

analyze definite time-delay and inverse time type overcurrent relays. Also the medium voltage

fuses are taken into account during protection analysis. The solid earthed networks and networks

earthed via resistor are supported in the protection analysis.

Network analysis is used to define the electrical state of the distribution network in a Real-time or

simulated network topology using network calculations, i.e. the load flow and fault current

calculations. Calculations can also use measurement data provided by MicroSCADA. Manually

updateable measurements can be used to model the separate load point, load of border switch or

backup feeder. Load estimation means the correction of the feeders and substations loads

calculated using static load data such that the loads of the feeders approximate the current

measurement of the feeder from MicroSCADA. The electrical state of the network can then be

calculated as accurate as possible.

The following network data is needed for calculation purposes during network analysis in WS:

Distribution network data.

1. Electrical properties of conductors.

2. Switching state of the network.

3. Load data for load flow calculation.

4. Relay data for protection analysis.

Load data is needed for the load flow calculation. Load data can be entered and edited by using

the load info forms, which are available for MV/LV substations. Relay data is used in protection

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

20

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

analysis. It can be changed via the circuit breaker data forms. Load and relay data is saved as a

part of the network database. The electrical properties of conductors are also stored in the network

database.

During simulations in DMS 600 WS, the relay settings, load calculation methods, and network

topology can be changed. The load forecasting starts automatically every hour. It creates dynamic

load curves for feeders and provides also short-term (1 hour to 1 week) load forecasts for

secondary substation loads. The calculation uses the latest MicroSCADA measurements).

Additionally, Load Estimation using available hourly current or P and Q measurements from

SCADA can be used to improve the network analysis accuracy and to form short-term forecasts for

secondary substation loads for radial feeders.

The network topology is automatically updated and networks analysis executed after every

switching state change, if the feature is not disabled by settings. Network calculation results can be

seen as colors in the network window, reflecting voltage drops, detection ability for short-circuit,

three-phase short-circuit capacity, detection ability of earth fault and load levels. The results are

shown as selected in the viewing settings. Warning level and alarm level colors are used in

presenting network analysis results when the calculated values exceed the corresponding settings

for the limits.

The representation of the calculation result depends on the user-defined settings. The switching

state of a distribution network is changed periodically to keep the network near optimal state. Load

changes, maintenance and service tasks together with fault situations also cause a need for

changes in the switching state. All switching actions can be checked beforehand by using the

simulation of WS. After changing the switching state, network analysis can be used to determine

the electrical state of the distribution network with the changed network topology. In order to

analyze the settings of protection relays or the influence of the network analysis settings (for

example load modeling), changes to this data are made and analysis executed again.

5.5.5 Meshed network analysis

In meshed network analysis all the networks having a voltage level under the defined transmission

voltage level are included in the MV network and analyzed. The primary transformers that have

one nominal voltage above the transmission voltage level are used as feeding points having the

defined busbar voltage as nominal voltage. The nodes of node type 'Feeding point' can be used in

the transmission network for topology analysis but the transmission network is not analyzed for

load flow or fault currents. However, radial or meshed sub-transmission network can be included in

network analysis. For example, one or several 400/220 kV primary transformers can be used as

feeding points for 220 kV network when transmission voltage level is set to over 220 kV but less

than 400 kV. Naturally, other primary transformers are used to transform the voltage to medium

voltage levels.

After a change in network and/or switching state data, the meshed network load flow and

maximum short-circuit current calculation for the whole included network is automatically

performed, if this is defined by the settings and the time interval from the last calculation has

elapsed.

5.5.6 Meshed network load flow calculation

The meshed network load flow for the whole MV network is calculated using a modified Newton-

Raphson algorithm. The meshed network load flow cannot use voltage measurements at primary

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

21

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

substations to set busbar voltages. The nominal voltages of the network are directly used to

transform the feeding busbar voltage to lower voltage levels.

The load flow is calculated for the total network even if it consists of several isolated islands. An

isolated island is a part of the network fed by one or several feeding primary transformers but

isolated from the rest of the network. The islands can be connected to each other but isolated by

an open switch.

The load flow supports generators where generators are producing active power and reactive

power by regulating the reactive power produced. These generators can be connected to the

network model using a 'block transformer', which is modeled in the network model as a

transformer, but getting the power from the generator. Primary transformer tap changer positions

are given for the calculation. Calculation is not solving possible new tap changer positions after

possible tap changer control actions.

A current measurement, an active power (P) measurement, or a reactive power (Q) measurement

connected to a generator node that is connected to Generator Block Transformer affects the

meshed network load flow calculation results in loop calculation of WS.

As a result of the meshed network load flow analysis the node voltages and power flows of line

sections are calculated and used in network voltage drops and load levels coloring.

5.5.7 Ha Thinh implementation

EVN feeding network is modeled as a 440/220 kV transformer being the only slack (reference)

node where P and Q are freely changing. Power plants are modeled as generators where P and Q

are known. In real-time mode P and Q is received from SCADA measurement and in simulation

mode P and Q can be modified manually (based on the previous SCADA measurements). When

network is disconnected from EVN network a virtual primary transformer must be switched to

network to provide a slack node and power balance difference can be seen from the loads of this

transformer. This way load shedding needs in island operation mode can be simulated. No stability

analysis is included in the calculations.

DMS 600 Installation:

DMS 600 is installed on a separate server computer having both network database server and

DMS600 software for network analysis, simulation and network maintenance. On MicroSCADA Pro

SYS 600 computers the SCADA integration components of DMS 600 are installed.

DMS600 functionality is limited to 220kV voltage level of ESP01, ESP02, ESH01, ESM01 and

35kV voltage level outgoing feeders of ESP01, ESP02, ESH01.Only load points within above

mentioned feeders are considered for DMS600. Any other load points are excluded from modeling

(out of scope).

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

22

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

5.6 Gateway

The Gateway is configured as Hot-Hot System. Signals will be sent via modem to A0 control center

and A1 control center via IEC 60870-5-101 slave. To PMS and Engineering center used protocol is

Modbus TCP/IP

5.6.1 Gateway Software

Item Description Remark

1 Windows 2008 Server R2 64bit

2 Print Key

3 Internet Explorer

4 Adobe Reader

5.6.2 Gateway Hardware

The Front-End computer is provided with monitor, keyboard and mouse. It is mainly used for

operating of the SAS.

Item Description Detail

1 Industrial PC 19-inch slide-in

2 Housing 7-slot slide-in housing ATX for 19-inch

racks, 4 rack units

3 Slots all for full-length plug-in cards

3 PCI Express x1

3 PCI slots

1 PCI Express x16

4 Front flap Lockable

5 Card holders

6 Protection class IP60 when operating

7 Operating temperature 055 C

8 Weight of the basic

configuration

17.0 kg (37.5 lbs)

9 Dimensions 483 x 177 x 500 mm / 19" x 7" x 19.5" (W x

H x D)

10 Processor

2nd Generation Intel Core i7, 2.1 GHz,

4 cores (TC3: 80)

11 Motherboard ATX motherboard for 2nd Generation Intel

Core i3, Core i5, Core i7 or Celeron

12 RAM 4 GB DDR3 RAM

13 Graphic adapter Integrated inside the Intel processor: 1

DVI-I

1 DVI-D

1 Display Port connector

2 of 3 connectors useable at same time

14 Dual Ethernet adapter On-board with 2 x 10/100/1000BASE-T

connector

3 Dual Port Gigabit-Ethernet-PC network

cards, PCI-Express-x1-Bus

15 RAID on-board SATA RAID 1 controller, Intel

Rapid Storage Technology

16 Hard disk 1. 3-inch, 500 GB

2. 3-inch, 320 GB

17 Serial ports 4xRS232 1 of these RS232 ports are led

out with 9-pin D-sub connectors; 14 USB

2.0, 4 of these USB ports are led out at the

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

23

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

5.7 Video wall

The video wall system will be supplied with 12 46inch monitors (brand AUO) and one video wall

controller. On each screen one picture can be shown. Facility to extend pictures over several

monitors to have one big picture is provided.

Fig. 5.7-1: 12 46inch screen video wall

5.7.1 Video wall Hardware

5.8 Ethernet Switch

The Station Level LAN is built by using managed Ethernet Switches. Those switches have the

advantage that they do not need any configuration there for they also can easily be replaced by

any unmanaged switch.

rear side and 2 are behind the front flap

18 Keyboard socket PS/2

19 Mouse socket PS/2

20 Power Supply Redundant

100240 V AC (50/60Hz) full range power

supply

Item Description Detail

1 Video wall controller 4U IPC chassis

Windows 7 Professional 64-bit

RGB: 640x480,800x600,1024x768,

1280x1024, 1600x1200,1920x1080 DVI-I:

640x480,800x600, 1024x768, 1280x1024,

1600x1200,1920x1080 HDMI: 1080P,

720P, 576P

Power Input 100~240V AC

2 Screen AUO

46" Measured Diagonally

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

24

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Item Description Detail

1 Unmanaged Ethernet switch ABB AFS675

5.9 Peripheral devices

5.9.1 Event Printer

A matrix line printer with integrated printer server is provided for printing the events. It is connected

to the station automation system through the station level LAN. Events are printed out

spontaneously as they are acquired in the database. Each event contains the following information

e.g. according to ANSI or ISO standards.

Event date and time (17.01.2002 - 20 35 25, 087 <dd.mm.yyyy - hh mm ss,ms>)

Name of the event object (A03 Q0 - <bay name / circuit breaker>)

Descriptive text (CB Open command - <description of the event>)

State or value of the object (EXECUTED - <status>).

5.9.2 Hardcopy Printer

Two color laser printer are provided as hardcopy printer. These printer offer high resolution for data

reports with graphics, tables, curves and process picture snapshot. The color laser printer may be

connected directly to a specific user or shared in the system when connected directly to the

separate station level LAN.

Item Description Detail

1 Epson AcuLaser C1100 DIN A4

color laser printer

2 Epson AcuLaser C9200N DIN A3

color laser printer

5.9.3 Monitor

In order to provide the optimal solution within an EMI-critical environment, LCD color monitors are

used. LCD monitors have a very low start-up current when switched on. This reduces the demands

on the Power Inverter. Standard size is 24", bigger sizes are available as an option.

5.9.4 Ethernet Firewall

An industrial Ethernet Firewall/VPN-Router will be used. The Industrial Ethernet Firewall is the link

between secure network cells and the unsecured outside word. In this function as a link, the

Industrial Ethernet Firewall protects the security-sensitive cell from undesired data traffic along the

connection to the outside world.

Item Description Detail

1 Ethernet Firewall/VPN-Router AFF650

5.9.5 Station Level Cubicle

The cubicle satisfies protection class IP54 according to EN60529.

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

25

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Fig. 5.6.5-1: Layout for Front End Cubicle

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

26

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Fig. 5.6.5-2: Layout for Front End Cubicle

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

27

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

7. Appendix: Fiber Optic Cable Specification

7.1 Fiber Optic Components

7.1.1 Fiber Cabling Overview

To better understand fiber performance and operational specifics, we must first look to the

fiber cable for a good basis of understanding.

All fiber optic cables consist of three layers:

1. Core - An extremely thin single strand of glass or high quality plastic. This single strand

is layer that carries the data.

2. Cladding - Another layer of glass with a slightly different index of refraction from the

core. This slight difference can either allow light energy out from the core or keep the

majority of energy within the core (via reflections).

3. Jacket - Usually the last outer layer of plastic intended to protect the core and the

cladding. The composition of this layer greatly depends on the intended installation

Fig. 7.1-1 Fiber Optic Cable Construction

7.1.2 Fiber Optic Transceiver

A fiber optic transceiver is simply a transmitter receiver pair. A transceiver is tasked with

transmitting and receiving data (1s and 0s). A fiber optic transceiver accomplishes this

task by either turning the light source on or off.

7.1.3 Multi-Mode Communication Links

Multi-mode communication links are generally the most common. When forming a multi-

mode link, one must use multi-mode transceivers as well as multi-mode cabling.

Multi-mode fiber cable is generally specified as two numbers such as 62.5/125m or

50/125m. This implies a core size of 62.5m in diameter and a cladding size of 125m.

62.5/125m cabling is generally the most popular, followed by 50/125m. For historical

reasons 62.5/125m cabling has a large install base, but generally 50/125m cabling is

recommended for all new installations to allow for an upgrade path to gigabit (and beyond)

speeds.

Multi-mode is called such because the light used to transmit the data actually travels

multiple paths within the core. The fiber cable is designed with a core/cladding index

difference to keep the majority of light energy within the fiber so that it bounces around.

At the other end of the fiber, a data signal is composed of both the light that took straight

paths through the center of the core as well as the light beams that bounced around. This

phenomenon is called modal dispersion and is the primary characteristic that limits multi-

mode link distances.

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

28

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

7.1.4 Single-Mode Communication Links

Single-mode communication links are less common than multi-mode links, but are quickly

gaining ground when longer link distances (> 3 km) are required. When constructing a

single-mode link, one must use single-mode transceivers with single-mode cabling.

Single-mode fiber is also specified as two numbers such as 9/125 m. This implies a core

of just 9m, and a cladding 125m in diameter. 9/125m Cabling is generally the most

common, followed by 8/125m.

The whole idea behind a single-mode link path is that light carrying the data travels a

single path. Light energy that strays away from the center path leaves the core and

become trapped in the cladding due the properties of single-mode cabling. Because

almost all the light received at the opposite end travels approximately the same path,

modal dispersion (or timing jitter) is no longer a factor. The primary distance-limiting factor

for single-mode links is signal power (or amplitude).

7.2 Standard Wavelengths

Fiber optic transceivers generally use four wavelengths (analogous to colors) of light. The

following is a table for reference only, as links should be designed with fiber standards in

mind as opposed to wavelengths of light.

Fig. 7.2-1 Fiber Optic Wavelengths

7.3 Fiber Optic Standards

The Institute of Electrical and Electronic Engineers (IEEE) is one of the most widely

recognized standards body in the world. The IEEE has had a large involvement

developing electrical and communications standards including fiber optic communications.

The following table lists several of the industry accepted IEEE fiber optic standards:

Fig. 7.3-1 IEEE Fiber Optic Standards

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

29

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

7.4 Fiber Optic Cables inside cubicles

This chapter defines the characteristics of the Fiber Optic Cables which are in the scope

of ABB and that will be installed inside cubicles.

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

30

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

31

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

32

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

Copyright 2011 ABB. All rights reserved. ABB 2012

Title

SAS functional description for CCR

Customer FCFC Eng. & Utility Division

Project

Ha Thinh Steel Plant

Order 16234

Doc. no. Language Rev.

Sheet

33

ABB Switzerland Ltd

1KHF334933

EN 1

No. sheets

33

Print: 4/07/2013 File: 1KHF334933 - AHS-PS32-1402-B- SASfunctional description for CCRrev1.docm; Rev. 1

8. Revision

Rev. Page (P)

Chapt. (C)

Description Date Dept./Init.

0

- First Issue

2013-01-11 / SL

1 6-7, 2.3

8-9, 3.1

9, 3.1.1

9, 3.1.2

9, 3.1.3

9, 3.2

12, 5.1.2

16, 5.3.1

16, 5.3.2

16, 5.4

16, 5.5

18, 5.7

18, 5.7.1

24-27, 7.4

Customer comments 2013-04-09 and week 17

2013. Changes highlighted in blue

2013-05-14 / SL

Potrebbero piacerti anche

- Substation - Project List: SR - No. Project Title Customer Consultant End Client Scope of WorkDocumento7 pagineSubstation - Project List: SR - No. Project Title Customer Consultant End Client Scope of WorksunjeyNessuna valutazione finora

- Ky 7 LDocumento59 pagineKy 7 LIbrahim IslamiNessuna valutazione finora

- Ut Relay PanelDocumento25 pagineUt Relay PanelPamela BradleyNessuna valutazione finora

- 220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Documento200 pagine220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Văn Ngọc NguyễnNessuna valutazione finora

- YN1M303223 CDA - 110kV - Line Trafo - CRP 2018 01 19 CST en PDFDocumento85 pagineYN1M303223 CDA - 110kV - Line Trafo - CRP 2018 01 19 CST en PDFTukaram PawarNessuna valutazione finora

- 4a1fn3 6se7134+l08Documento31 pagine4a1fn3 6se7134+l082003vinay100% (1)

- TKT-CM-01-OM-1060-I-R1-O&M Manual - Control & Monitoring System PDFDocumento144 pagineTKT-CM-01-OM-1060-I-R1-O&M Manual - Control & Monitoring System PDFThái Đức NhơnNessuna valutazione finora

- n59 Srep1 Ach Arc Rev ADocumento1 paginan59 Srep1 Ach Arc Rev AedemmikeNessuna valutazione finora

- SMART Control Bujagali - DCS System Architecture Rev D PDFDocumento1 paginaSMART Control Bujagali - DCS System Architecture Rev D PDFBlažević JosipNessuna valutazione finora

- Rtu - SasDocumento19 pagineRtu - SasNitin KumarNessuna valutazione finora

- 1KHW000890 en NSD570Documento562 pagine1KHW000890 en NSD570jckrishnah100% (1)

- WI-NG-6460-002-36 Work Instruction-230kV and 380kV XLPE Cables Rev00Documento7 pagineWI-NG-6460-002-36 Work Instruction-230kV and 380kV XLPE Cables Rev00MohamedElmahdyNessuna valutazione finora

- Gen First Sync Procedure - Rev01Documento12 pagineGen First Sync Procedure - Rev01O P Sridharan PerumalNessuna valutazione finora

- TSF12 09 02 Hail 1150 P10 2Documento9 pagineTSF12 09 02 Hail 1150 P10 2Arif MohammedNessuna valutazione finora

- IRTU and IGW User Manual Eng Rev2 0Documento190 pagineIRTU and IGW User Manual Eng Rev2 0Bear DguNessuna valutazione finora

- Abb 61850 Sas GeneralDocumento33 pagineAbb 61850 Sas GeneralantanaNessuna valutazione finora

- AHS-KRS-30-BUB - DC-UPS2 - 00E652A3 - RedCorrex PDFDocumento24 pagineAHS-KRS-30-BUB - DC-UPS2 - 00E652A3 - RedCorrex PDFArchiford NdhlovuNessuna valutazione finora

- E38000744 D334 - HIDD C03 400kV Cable Feeder Local and Remote Reactor - REV 0 - 2017-11-13 PDFDocumento164 pagineE38000744 D334 - HIDD C03 400kV Cable Feeder Local and Remote Reactor - REV 0 - 2017-11-13 PDFSatish KumarNessuna valutazione finora

- 220kV Sicam Panel 2 (BOP) PDFDocumento23 pagine220kV Sicam Panel 2 (BOP) PDFAnonymous SWz3bgcUNessuna valutazione finora

- Ne02 Sas ArchitectureDocumento5 pagineNe02 Sas ArchitectureApoorva BhushanNessuna valutazione finora

- Technical Description of The Digital Turbine GovernorDocumento20 pagineTechnical Description of The Digital Turbine GovernorLe Hoang HaoNessuna valutazione finora

- PH12-3H-76-40-T002 - Rev ADocumento27 paginePH12-3H-76-40-T002 - Rev ABalakrishnan KrishnanNessuna valutazione finora

- Siemens AG: Circuit Diagram Energy Management - Medium Voltage & SystemsDocumento170 pagineSiemens AG: Circuit Diagram Energy Management - Medium Voltage & SystemsEdciel EbuenNessuna valutazione finora

- Protection Overview Station Transformer CCPDocumento1 paginaProtection Overview Station Transformer CCPJorge Andres PavónNessuna valutazione finora

- K02ELBD005016P0Documento16 pagineK02ELBD005016P0KhalidNessuna valutazione finora

- Schema ELECDocumento133 pagineSchema ELECMeyerNessuna valutazione finora

- Installation: Order No.: Customer: Equipment: Converter Type: Document: 3BHS213774E01 ACS 1000 WDocumento73 pagineInstallation: Order No.: Customer: Equipment: Converter Type: Document: 3BHS213774E01 ACS 1000 WBastian ParedesNessuna valutazione finora

- CRP OhlDocumento75 pagineCRP OhlRachmad Ady SetiawanNessuna valutazione finora

- Signal Exchange Between Power Plant - Substation &Documento16 pagineSignal Exchange Between Power Plant - Substation &Nasiruddin Abdullah HussainNessuna valutazione finora

- IEC61850 ProtocolDocumento24 pagineIEC61850 ProtocolDevas ShuklaNessuna valutazione finora

- Synchro TactDocumento36 pagineSynchro Tactbuianhtuan1980Nessuna valutazione finora

- Telecom System Design Document Rev-ADocumento18 pagineTelecom System Design Document Rev-ARashad SarwarNessuna valutazione finora

- 1200 403 R7 New Al QumriyahDocumento187 pagine1200 403 R7 New Al QumriyahNadeem Qureshi100% (1)

- PT. PLN (Persero) : Schematic Diagram of ZDT Line Differential Relay GD StadionDocumento23 paginePT. PLN (Persero) : Schematic Diagram of ZDT Line Differential Relay GD StadionendriyaNessuna valutazione finora

- GCP - Technintegral - Rev00 - 21.07.2021Documento60 pagineGCP - Technintegral - Rev00 - 21.07.2021edwinNessuna valutazione finora

- Panel Construction - Remote End - Rev-A - 03.06.2013Documento4 paginePanel Construction - Remote End - Rev-A - 03.06.2013ADE mrtNessuna valutazione finora

- SYS500 System Management 844Documento198 pagineSYS500 System Management 844mathew227Nessuna valutazione finora

- Water - Plant Rev03Documento51 pagineWater - Plant Rev03Tarek KhafagaNessuna valutazione finora

- Tor1-22015mv001 r8 MV-VFD Elect Drawings 220-Er-015 260kw Referencial Abb RockwellDocumento22 pagineTor1-22015mv001 r8 MV-VFD Elect Drawings 220-Er-015 260kw Referencial Abb Rockwellsareluis30Nessuna valutazione finora

- DNF7 Selection Manual in SCHNEIDERDocumento12 pagineDNF7 Selection Manual in SCHNEIDERsayeem bikashNessuna valutazione finora

- Visio-C System Overview JEC PAS V2-0Documento5 pagineVisio-C System Overview JEC PAS V2-0باسم العوفيNessuna valutazione finora

- UPSDocumento28 pagineUPSAdetunji TaiwoNessuna valutazione finora

- Ban Ve Nhi Thu DCL Alstom 123 - S2daDocumento15 pagineBan Ve Nhi Thu DCL Alstom 123 - S2datuantz206Nessuna valutazione finora

- INPSNM-SA04 Substation Automation With IEC61850-Rev-BDocumento1 paginaINPSNM-SA04 Substation Automation With IEC61850-Rev-BMichael Parohinog GregasNessuna valutazione finora

- Ae1172 Efa020 81mky01 116111 00Documento1 paginaAe1172 Efa020 81mky01 116111 00Mayur GuptaNessuna valutazione finora

- Generator Control Panel XX MW: Wiring Diagram, Outline, Terminal Block List, and BOMDocumento6 pagineGenerator Control Panel XX MW: Wiring Diagram, Outline, Terminal Block List, and BOMashraf abdelrahmanNessuna valutazione finora

- TJ01 NN VD LG010SG20001 Is1 PDFDocumento6 pagineTJ01 NN VD LG010SG20001 Is1 PDFNiño DioknoNessuna valutazione finora

- 32 Mva Power Expansion Pt. Bekaert: B For Approval FADocumento23 pagine32 Mva Power Expansion Pt. Bekaert: B For Approval FAaditya agasiNessuna valutazione finora

- 3 545 398aDocumento78 pagine3 545 398aezze72x5058Nessuna valutazione finora

- Gw1300174.Pg011 34.5kv Control Panel c6Documento33 pagineGw1300174.Pg011 34.5kv Control Panel c6Nick CorrosivesnareNessuna valutazione finora

- M.V. Anil Kumar Kumar: Summary: Work HistoryDocumento3 pagineM.V. Anil Kumar Kumar: Summary: Work HistoryNarendra LakkojuNessuna valutazione finora

- Hamidullah Siddiqui PresentationDocumento35 pagineHamidullah Siddiqui PresentationrjchpNessuna valutazione finora

- Comet Gland CatalogueDocumento12 pagineComet Gland CataloguePrabhudatta KarNessuna valutazione finora

- Control Cable Schedule (A) - Armoured Cable, (F) - Flexible Cable, (S) - Cable With Screen. KWPCL/DRG/CS/018 Rev. 1 Sheet 1 of 3Documento3 pagineControl Cable Schedule (A) - Armoured Cable, (F) - Flexible Cable, (S) - Cable With Screen. KWPCL/DRG/CS/018 Rev. 1 Sheet 1 of 3ARIJIT KUNDUNessuna valutazione finora

- CE-429149 Protection Cubicle F71 RevBDocumento74 pagineCE-429149 Protection Cubicle F71 RevBMuhammad NasirNessuna valutazione finora

- Drawings For MV Switchgear Unigear Zs3.2: Ampliacion Se Sur WSPDocumento4 pagineDrawings For MV Switchgear Unigear Zs3.2: Ampliacion Se Sur WSPfrankrosseliNessuna valutazione finora

- Connection Cable SelectionDocumento258 pagineConnection Cable SelectionGiovanni TrinidadNessuna valutazione finora

- 3bl61719aaaapbzza 08 enDocumento152 pagine3bl61719aaaapbzza 08 enRajesh PalandeNessuna valutazione finora

- Engineering Service Revenues World Summary: Market Values & Financials by CountryDa EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Multifunctional Generator Rotor Protection Relay PDFDocumento16 pagineMultifunctional Generator Rotor Protection Relay PDFSurachat SannokNessuna valutazione finora

- MR-JE Troubleshoot AlarmDocumento18 pagineMR-JE Troubleshoot AlarmHiren PotdarNessuna valutazione finora

- PZ1000 Protección de LíneaDocumento16 paginePZ1000 Protección de Líneagusfaj100% (1)

- C&S DMPR PDFDocumento19 pagineC&S DMPR PDFDipankar Chakraborty100% (1)

- 1MDS06004 en en REL 100 RELZ 100 Numerical Line Protection TerminalDocumento8 pagine1MDS06004 en en REL 100 RELZ 100 Numerical Line Protection TerminalRuhuluruj100% (1)

- Circuit Breaker GTSDocumento31 pagineCircuit Breaker GTScpandey01_688066930Nessuna valutazione finora

- Unit 1Documento13 pagineUnit 1engshimaaNessuna valutazione finora

- Symmetrical Faults On 3 Phase SystemDocumento11 pagineSymmetrical Faults On 3 Phase SystemChelle Mendoza EslavaNessuna valutazione finora

- Short-Circuit Calculations - The Easy WayDocumento3 pagineShort-Circuit Calculations - The Easy WaymshahidshaukatNessuna valutazione finora

- Comparison of International Regulations For Connections of Wind Turbines To The NetworkDocumento7 pagineComparison of International Regulations For Connections of Wind Turbines To The NetworkjomoranNessuna valutazione finora

- Installation Manual T4900CRDocumento36 pagineInstallation Manual T4900CRmayNessuna valutazione finora

- Compact 80-1250Documento356 pagineCompact 80-1250rocketvtNessuna valutazione finora

- DDPSMVol 2Documento22 pagineDDPSMVol 2LawrieNessuna valutazione finora