Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Propiedades Fisico Quimicas Quinoa

Caricato da

Adisson Villalta QuispeDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Propiedades Fisico Quimicas Quinoa

Caricato da

Adisson Villalta QuispeCopyright:

Formati disponibili

http://fst.sagepub.

com

Food Science and Technology International

DOI: 10.1177/1082013203009002006

2003; 9; 101 Food Science and Technology International

H. Dogan and M. V. Karwe

Physicochemical Properties of Quinoa Extrudates

http://fst.sagepub.com/cgi/content/abstract/9/2/101

The online version of this article can be found at:

Published by:

http://www.sagepublications.com

On behalf of:

Consejo Superior de Investigaciones Cient-ficas (Spanish Council for Scientific Research)

can be found at: Food Science and Technology International Additional services and information for

http://fst.sagepub.com/cgi/alerts Email Alerts:

http://fst.sagepub.com/subscriptions Subscriptions:

http://www.sagepub.com/journalsReprints.nav Reprints:

http://www.sagepub.co.uk/journalsPermissions.nav Permissions:

http://fst.sagepub.com/cgi/content/refs/9/2/101 Citations

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

Physicochemical Properties of Quinoa Extrudates

H. Dog an

1

and M.V. Karwe

2,

*

1

TUBITAK Marmara Research Center, Food Science and Technology Research Institute,

P.O. Box 21, Gebze/Kocaeli, 41470, Turkey

2

Food Science Department, Rutgers University, 65 Dudley Road, New Brunswick, NJ, 08901 USA

Response surface methodology (RSM) was used to analyse the effect of temperature, screw speed, and

feed moisture content on physicochemical properties of quinoa extrudates. A three-level, three-variable,

Box-Behnken design of experiments was used. The experiments were run at 1624% feed moisture content,

130170

C temperature, and 250500 rpm screw speed with a fixed feed rate of 300 g/min. Second order

polynomials were used to model the extruder response and extrudate properties as a function of process

variables. Responses were most affected by changes in feed moisture content and temperature, and to a

lesser extent by screw speed. Calculated specific mechanical energy (SME) values ranged between 170

402 kJ/kg which were lower than those observed for other cereals, most likely due to high (7.2%) fat

content of quinoa. High levels of feed moisture alone, and in combination with high temperature, resulted

in poor expansion. The best product, characterised by maximum expansion, minimum density, high degree

of gelatinization and low water solubility index, was obtained at 16% feed moisture content, 130

C die

temperature, and 375 rpm screw speed, which corresponds to high SME input. It was demonstrated that

the pseudo-cereal quinoa can be used to make novel, healthy, extruded, snack-type food products.

Key Words: quinoa, extrusion cooking, physico-chemical properties

INTRODUCTION

Quinoa (Chenopodium quinoa Willd.) is a disc shaped

small seed that looks like a cross between sesame seed

and millet. It is a crop that has been grown in South

American countries for centuries and has many poten-

tially beneficial properties such as resistance to cold

(Becker and Hanners, 1990; Coulter and Lorenz, 1991a;

Prakash et al., 1993). It can be grown in poor soil and at

high altitude (Ng et al., 1994). The edible seed of the

quinoa plant has been called both a pseudo-cereal and a

pseudo-oilseed because of its unique nutritional profile.

It has been recently identified to have promising

potential to overcome worlds food shortage (Ahamed

et al., 1996). The seeds have protein quality comparable

to that of whole dry milk in terms of balanced amino

acid composition (Ng et al., 1994). Quinoa protein is

rich in lysine, methionine and cysteine (Becker and

Hanners, 1990). Thus, it is a good complement for

legumes, which are often low in methionine and

cysteine. Some types of wheat come close to matching

protein content of quinoa, but cereals such as corn and

rice generally have less than half the protein content of

quinoa. In addition, quinoa is a relatively good source

of vitamin E, and several of the B vitamins (Ruales and

Nair, 1993; Ahamed et al., 1996). It also has desirable

fatty acid composition, and high levels of calcium, iron

and phosphorous (Ruales and Nair, 1993; Przybylski

et al., 1994) which make it a unique food source.

The Aztecs and Incas credited quinoa with medicinal

properties including lowering blood cholesterol, improv-

ing glucose tolerance and reducing insulin requirements

(Guzman-Maldonado and Paredes-Lopez, 1998). In

recent years, scientific information supporting the

health benefits of quinoa has accumulated (Guzman-

Maldonado and Paredes-Lopez, 1998). Quinoa contains

significant amounts of flavonoids and phenolic acids,

and a number of structurally diverse saponins (Ridout

et al., 1991; Gee et al., 1993; Ng et al., 1994;

Masterbroek et al., 2000). Saponins can help lower

cholesterol blood levels, inhibit growth of cancer cells,

eliminate digestive toxins, and strengthen the immune

system (Arditi et al., 2000). Phenolic derivatives act as

natural antimicrobial agents. They have been proven to

be very good antioxidants, scavenging free radicals and

providing metal chelating activities. Polyphenols have

been implicated in health benefits, such as prevention of

cancer and cardiovascular diseases.

This unique added chemical composition makes

quinoa an ideal candidate to be further studied for

establishing it as a functional food. Processing of

traditional grains like quinoa into products that deliver

nutritive as well as physiologically active components

represents a major opportunity for food processors

catering to the health-food market.

Extensive studies on extrusion processing of cereals,

such as corn and wheat, to generate ready-to-eat

*To whom correspondence should be sent

(e-mail: karwe@aesop.rutgers.edu).

Received 11 July 2002; revised 18 December 2002.

Food Sci Tech Int 2003;9(2):010114

2003 Sage Publications

ISSN: 1082-0132

DOI: 10.1177/108201303033940

101

+ [14.5.20031:16pm] [101114] [Page No. 101] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

breakfast cereals and snacks, have been carried out

(Chinnaswamy and Hanna, 1990; Case et al., 1992; Cai

and Diosady, 1993; Guha et al., 1997). The only study

reported in literature on extrusion of quinoa (Coulter

and Lorenz, 1991a, b) is about the nutritional, sensory

and physical characteristics of quinoa-corn grit blends

(up to 30 : 70 ratio) extruded at 1525% feed moisture

content, 100150

C, 100200 rpm screw speed, and at

1 : 1 and 3 : 1 compression ratios on a Brabender

Plasticorder single-screw extruder. Although the pro-

ducts extruded at 15% moisture content and a 3 : 1

compression ratio had a greater expansion, lower

density and lower shear strength, addition of quinoa

to corn grit resulted in a general decrease in product

quality and an increase in extrusion rate under all

processing conditions.

In our research we focused on the investigation of

processability of quinoa flour by twin-screw extrusion

and the evaluation of physicochemical properties of

extruded quinoa in comparison to unprocessed grains.

This paper treats the effect of feed moisture content,

die temperature, and screw speed on process and

product responses during twin-screw extrusion of

quinoa flour.

MATERIALS AND METHODS

Material

Quinoa seeds (Chenopodium quinoa Willd) were

obtained from Quinoa Corporation (Torrance, CA)

and milled into flour using a Fitz Mill (Model D).

Proximate Analysis

For the proximate composition analysis of quinoa

flour the following methods were used (AACC, 1984).

Moisture: oven drying at 103

C (method no. 4415A).

Ash: calcination at 550

C (method no. 0801)

Lipids: defatting in a soxhlet apparatus with petro-

leum ether (method no. 3010)

Protein: micro Kjeldahl (N6.25) (method no. 4613)

CHOfiber: by the difference.

Amylose content was determined by the method

proposed by Chrastil (1987). The method is based on

spectrophotometric measurement of the intensity of blue

color formed due to complex formation between

amylose and iodine.

Extrusion

Extrusion experiments were carried out on a twin-

screw extruder (ZSK-30, from Krupp Werner &

Pfleiderer, Ramsey, New Jersey). The extruder has two

co-rotating, self-wiping screws (30.7 mm diameter,

4.7 mm channel depth, and 878 mm processing length;

L/D28.6) in a steel barrel with five zones. Each zone is

heated by resistive electric heaters and the temperature of

each zone can be controlled independently. The screw

configuration used in extrusion experiments consisted of

forward conveying elements, mild mixing elements,

kneading elements and reverse elements (Table 1). Die

pressure was measured using a Dynisco pressure trans-

ducer (TPT463E, Dynisco, Sharon, MA). The die had

two circular orifices (3 mm diameter, 5 mm long). Quinoa

flour was metered into the feed section of the extruder

with a volumetric feeder (K-Tron Corp., Pitman, NJ).

Water was injected into the feed section of the extruder

immediately after the feed port using a triple action

piston pump (US Electric Co., Milford, CT). Both the

feeder and the pump were calibrated prior to extrusion

runs to determine the set points required for desired mass

flow rates of quinoa flour and water, respectively.

Throughput or the total mass flow rate (flour water)

was kept constant at 300 g/min for all experiments.

Temperatures at zones I, II, and III were set to room

temperature, 80 and 120

C, respectively, while the

temperatures at zones IV and V were adjusted such that

the desired die temperatures could be maintained.

Table 1. Screw configuration used for quinoa extrusion.

Extrusion zones*

Feed zone

(84mm)

Zone I

(196mm)

Zone II

(210mm)

Zone III

(178mm)

Zone IV

(98mm)

Zone V

(84mm)

Die zone

(28mm)

SK 42/42 42/21 T 28/28 28/14 20/10 KB 45/5/14 14/14

SK 42/42 42/42 28/28 KB 45/5/14 20/10 KB 45/5/14 LH 14/14

42/42 IGEL 42 20/20 KB 45/5/20 14/14

42/21 28/28 20/20 20/10 LH 14/14

IGEL 42 28/28 20/20 20/10 14/14

28/28 KB 45/5/28 20/20 20/10 14/14

28/14 20/20 14/14

28/14 KB 45/5/20 14/14

20/10 LH

20/10

20/10

*IGEL: mild kneading element. KB: kneading block. LH: left handed (reverse) element. SK: feed element.T: transition element.

102 H. DOG

AN AND M.V. KARWE

+ [14.5.20031:16pm] [101114] [Page No. 102] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

Experimental Design

Response surface methodology was used to investi-

gate the effects of extrusion conditions on the product

and process responses of quinoa. Results from pre-

liminary trials were used to select suitable extruder

operating window. The independent variables con-

sidered in this study were feed moisture content

(1624%w.b.), die temperature (130170

C), and

screw speed (250500 rpm). A three-variable, three-

level, Box-Behnken design (Table 2) was employed to

determine the extrusion conditions. Experiments were

randomized in order to minimize the systematic bias in

the observed responses due to extraneous factors.

Preparation of Samples

Samples were collected under steady state conditions

of pressure, torque and temperature. Immediately after

extrusion, extrudates were cooled, packed into glass jars,

flushed with nitrogen gas, sealed and kept refrigerated

(5

C) until analysis.

Process Responses

The ZSK-30 extruder is equipped with a torque

indicator which shows % torque which is proportional

to the current drawn by the drive motor. A reading

of 100% torque corresponds to the max allowable

torque of 172 Nm. The specific mechanical energy

(SME) was calculated from the measured torque reading

as follows (Godavarti and Karwe, 1997):

SME kJ=kg

Total torque (%) Friction torque (%) N9:1

100 500m

f

1

The drive motor has a rated power of 9.1 kW at a

rated screw speed of 500 rpm. The friction torque was

measured with screws attached to the drive and the

barrel empty.

The determination of specific energy delivered

(SED) to the extrudate is based on the energy balance

(Figure 1) between the inlet and just before the exit at

the die of the extruder under steady state conditions

computed from the following equations,

m

f

C

p

i

T

i

Q

H

Q

C

ME m

f

C

p

o

T

p

2

Q

H

Q

C

m

f

ME

m

f

C

p

o

T

p

C

p

i

T

i

3

SME and SED were measured from experimental

conditions and STE was calculated from Equation (4).

STE SME SED 4

Negative value of specific thermal energy (STE)

indicates net cooling at the barrel.

Product Responses

Extrudate samples used for determination of the

degree of gelatinization (DG), water solubility index

(WSI), and water absorption index (WAI), were dried at

45

C overnight to 45% moisture. Dried samples were

ground and passed through 28-mesh sieve (590 mm

opening), and the flour samples were placed in glass

jars and sealed. The method proposed by Birch and

Priesty (1973) was used for determination of the DG.

The method was based on the monitoring of the

complexation of iodine with amylose released due to

starch gelatinization. The results reported are the mean

of five measurements for each extrudate sample.

Water solubility index and water absorption index of

both unprocessed quinoa and extrudate samples were

determined by the method of Anderson et al. (1969) with

Table 2. Experimental design for extrusion of quinoa.

Coded Levels Actual Levels

X

1

X

2

X

3

M (% wb) T (

C) S (rpm)

1 1 0 24 170 375

1 1 0 24 130 375

1 1 0 16 170 375

1 1 0 16 130 375

0 1 1 20 170 500

0 1 1 20 170 250

0 1 1 20 130 500

0 1 1 20 130 250

1 0 1 24 150 500

1 0 1 24 150 250

1 0 1 16 150 500

1 0 1 16 150 250

0 0 0 20 150 375

0 0 0 20 150 375

0 0 0 20 150 375

Figure 1. Schematic diagram showing the barrel of

extruder and various energy flows.

Quinoa Extrudates 103

+ [14.5.20031:16pm] [101114] [Page No. 103] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

some modifications. WSI was calculated as follows:

WSI

g water soluble matter

g dry sample

5

For the calculation of WAI the total solids in the

original sample were corrected for the loss of solubles in

the supernatant and WAI was expressed as,

WAI

g water absorbed

g dry sample 1 soluble fraction

6

Product density (

e

) was measured by volumetric

displacement method as described by Hic s as maz and

Clayton (1993). Glass beads of 0.5 mm diameter

(Biospec Products, Inc., Bartlesville, OK) were used as

displacement medium. Density of glass beads was

determined as 1550 kg/m

3

, then the density of extrudates

was calculated as

e

W

e

W

gb

gb

7

The

e

values were obtained from five random

samples for each extrusion condition, with three

replications.

The sectional expansion index (SEI) of extrudate was

measured as the ratio of the diameter of the extrudate to

that of the die. The extrudate diameter was measured

with a digital Vernier caliper and the results were

expressed as the average of hundred measurements on

each condition. The longitudinal (LEI) and volumetric

expansion (VEI) indices were calculated according to

Alvarez-Martinez et al. (1988).

Textural properties of extrudates were measured using

TA-XT2 texture analyser (Stable Micro Systems, UK).

A three-point bend rig with a support length (bridge) of

30 mm and a rounded plate probe (15 mm5 mm,

D5 mm) exerting force in the middle of bridge were

used to test extrudates in the bend mode (Zasypkin and

Lee, 1998). The test speed was 2 mm/s and the full load

scale was 50 kg. Data were processed with an XT-RA

Dimension software package (Stable Micro Systems,

Haslemere, Surrey, UK). The hardness of dry extrudates

was measured as the peak force offered by the sample

during cutting. Breaking strength (N/mm

2

) was calcu-

lated as the peak breaking force (N) divided by the

cross-sectional area (mm

2

) calculated for each extrudate

sample. The reported values are the averages of 15

measurements.

The color of ground unprocessed quinoa and

extrudate samples was measured in triplicate using

Minolta Chroma Meter (CR-210) in terms of Hunter

Lab values (L, a, b), where L represents lightness with 0

for dark and 100 for bright, a represents the extent of

green colour in the range from 100 to 0 and red in the

range 0 to 100, b quantifies blue colour in the range

from 100 to 0 and yellow in the range from 0 to 100.

The total colour change (E) was then calculated as

E

L

2

a

2

b

2

q

8

where LL L

0,

ia a a

0

, and b b b

0

; the

subscript

0

indicates initial colour values before

processing.

Analysis of Data

Process responses (SME, SED, STE, SME/SED) and

product responses (iE,

e

, WAI, WSI, DG, SEI, LEI,

VEI, hardness and breaking strength) obtained as a

result of the proposed experimental design were

subjected to regression analysis in order to assess the

effects of feed moisture content, extrusion temperature

and screw speed. Second-order polynomials of the form

y

i

b

0

X

3

i1

b

i

X

i

X

3

i1

X

3

ji

b

ij

X

i

X

j

9

were fitted to the independent variables and were

computed by using SAS (version 8.1) statistical package,

where X

i

, X

i

X

i

and X

i

X

j

are linear, quadratic, and

interaction effect of the input variables which influence

the response y, respectively, and b

0

, b

i

, and b

ij

are the

model constants to be determined. All crosscorrelations

between the process and product responses themselves

were also assessed. The response surface plots for these

models were plotted as a function of two variables, while

keeping the third variable constant at its intermediate

value.

RESULTS AND DISCUSSION

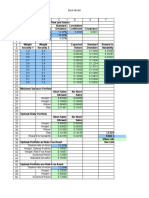

Composition of grain could vary with variety and

growing conditions, even though experimental results for

composition (Table 3) agreed with previous data (Becker

and Hanners, 1990; Coulter and Lorenz, 1990; Guzman-

Maldano and Paredes-Lopez, 1998; Koziol, 1992;

Prakash et al., 1993; Ruales and Nair, 1993). The

quinoa seeds used in this study have high crude protein,

crude fat and ash than common cereals, such as rice and

corn. Extrudates of widely different physical structure

were obtained by twin-screw extrusion of quinoa flour at

different combinationsofprocessingparameters(Table2).

Regression analyses of the physicochemical properties of

quinoa extrudates (Table 4) indicated that all the second

104 H. DOG

AN AND M.V. KARWE

+ [14.5.20031:16pm] [101114] [Page No. 104] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

order polynomial models correlated well with the mea-

sured data and were statistically significant ( p <0.05).

Process Responses

Calculated SME values ranged between 170 and

402 kJ/kg. The regression analysis results (Table 4)

revealed that temperature (T), feed moisture content

(M) and screw speed (S) had linear and significant

( p<0.01) effects on SME followed by the quadratic

effect of temperature (TT) ( p<0.05). SME increased

with decreasing die temperature, decreasing feed moist-

ure content, and increasing screw speed, as expected.

Specific mechanical energy values were lower than

those observed for extrusion cooking of other cereals

(Bhattacharya, 1997; Singh and Smith, 1997; Ilo et al.,

1999) most likely due to the composition of quinoa

grains. In our study, quinoa was found to have a high

fat (7.2%) and low amylose (11.1%) content which

agreed with the published data (Atwell et al., 1982;

Qian and Kuhn, 1999). Important differences in the

viscous behavior depending on the amylose content

have been reported by Lai and Kokini (1990) and

Della Valle et al. (1996 and 1997). It has been found

that viscosity increases with increase in amylose

content. The dependence of melt viscosity on tempera-

ture, moisture and fat content is also well known (Ilo

et al., 1999). The drop in melt viscosity with increasing

feed moisture content is in agreement with the expected

role of water as a plasticiser. However, Della Valle et al.

(1996) showed that the drop in viscosity with increase

in moisture is more as amylose content decreases.

Moreover, Kokini et al. (1992) reported that 70%

amylose starch gives higher overall viscosity than 98%

amylopectin starch. Any variable which affects viscos-

ity would correspondingly affect torque and SME

(Akdog an, 1996). Due to high lipid and low amylose

content of quinoa used in this study we expect to have

low melt viscosity. Therefore, any factor that may lead

to a further decrease in viscosity such as high feed

moisture content and die temperature resulted in a

decrease in SME.

The quality of extrudate depends on the various

physicochemical changes occurring during extrusion

such as gelatinization, melting of starch, and compo-

nent interactions. The extent of these reactions is a

function of both thermal energy input and viscous

dissipation of the mechanical energy due to shear. The

activation energy for starch conversion induced by

mechanical energy is much lower than that for

conversion induced by thermal energy (Wang et al.,

1992). Simulation studies for starch conversion during

extrusion have shown that mechanical energy is far

more important during extrusion than is thermal

energy (Kokini, 1993). In this study, SME, STE, and

SED to the product during extrusion cooking were

computed for all the operating conditions. The rela-

tions between these quantities and product trans-

formations were examined by taking the ratio of

SME to SED. SME/SED and STE/SED represent the

contributions of mechanical energy and thermal

energy, respectively, under different extrusion condi-

tion. They are related as follows, which is obtained

from Equation (4).

SME

SED

STE

SED

1 10

When SME/SED ratio is greater than 1.0, STE/SED

is negative which implies cooling at the barrel.

Experimental SME/SED ratio ranged between 0.54

and 1.85. The best product characterized by maximum

expansion, minimum product density, high DG and low

WSI was obtained at maximum value of SME/SED.

SME/SED was found to be the most important

parameter which had the highest crosscorrelation

coefficients with almost all product responses (Table 5)

except WAI, WSI, and iE.

Although a great deal of mechanical energy is

converted to thermal energy, it has a major impact on

feed material through shear. Lower SME values usually

results in a lower molecular breakdown of starch

(Akdog an, 1996). A good correlation was found

between the degree of starch gelatinization and SME/

SED (Figure 2). Even though the experimental data had

significant scatter, DG clearly increased as SME/SED

increased indicating the role of mechanical energy on the

conversion of starch.

Degree of Gelatinization

Starch was found to be partially gelatinized in all the

extruded samples with a maximum of 84.4% which

corresponds to 16% feed moisture content, 150

C die

temperature and 500 rpm screw speed (SME386 kJ/

kg, SME/SED1.85). The linear effects of temperature

Table 3. Proximate composition and some properties

of unprocessed quinoa flour.

Quinoa Flour Characteristics

Proximate composition (g/100g) MeanSD (n3)

Moisture 10.960.06

Protein 11.950.12

Lipid 7.190.02

Ash 2.150.02

CHOfiber 67.75

Colour

L 87.270.30

a 0.480.03

b 11.940.41

Water absorption index (g H

2

O/g dry sample) 1.690.11

Water solubility index (g water soluble

matter/g dry sample)

0.0730.003

Amylose content (%) 11.10.04

Quinoa Extrudates 105

+ [14.5.20031:16pm] [101114] [Page No. 105] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

Table 4. Results of regression analysis (calculated on coded levels where all independent variables are in the range 1).

Levels

Degree of

Geltn

Density

(kg/m

3

)

Sectional

Expansion

Index

Longitudinal

Expansion

Index

Volumetric

Expansion

Index

Water

Solubility

Index

(g/g)

Water

Absorption

Index

(g/g) iE

Hardness

(N)

Breaking

Strength

(N/mm

2

)

Specific

Mechanical

Energy

(kJ/kg)

Specific

Energy

Delivered

(kJ/kg)

Specific

Thermal

Energy

(kJ/kg) SME/SED

C 0.781*** 246.7*** 2.75*** 0.630** 4.78*** 0.202*** 6.03*** 21.35*** 3.62*** 0.068*** 258.0*** 260.8*** 2.9

ns

0.989***

M 0.046*** 88.1*** 0.43*** 0.090

ns

1.67*** 0.025*** 0.57*** 1.88*** 0.19

ns

0.041*** 37.9*** 13.8*** 51.9*** 0.206***

T 0.058*** 30.4*** 0.73*** 0.650*** 0.99** 0.017*** 0.14** 0.84** 1.04*** 0.028*** 59.3*** 40.8*** 100.1*** 0.407***

S 0.034*** 38.0*** 0.15* 0.010

ns

0.61

ns

0.021*** 0.20*** 0.53

ns

0.17

ns

0.016** 51.3*** 0.0

ns

51.0*** 0.203***

MM 0.033** 57.9*** 0.24** 0.296

ns

0.33

ns

0.026*** 0.33*** 1.49** 0.46* 0.017* 15.6* 0.1

ns

24.1

ns

0.041

ns

T T 0.037*** 34.6** 0.39*** 0.711** 0.96

ns

0.031*** 0.15* 2.67*** 0.62** 0.021** 23.8** 0.1

ns

24.1* 0.155***

SS 0.041*** 38.2** 0.04

ns

0.364

ns

0.77

ns

0.009** 0.19** 0.25

ns

0.34

ns

0.001

ns

9.8

ns

0.1

ns

9.8

ns

0.031

ns

MT 0.015

ns

4.0

ns

0.17

ns

0.218

ns

0.92

ns

0.002

ns

0.53*** 0.10

ns

0.07

ns

0.017* 11.6

ns

2.2*** 9.8

ns

0.092**

MS 0.015

ns

18.8

ns

0.10

ns

0.038

ns

0.05

ns

0.003

ns

0.02

ns

0.76

ns

0.32

ns

0.006

ns

9.0

ns

0.0

ns

9.0

ns

0.044

ns

T S 0.009

ns

26.8** 0.02

ns

0.098

ns

0.66

ns

0.011** 0.06

ns

0.10

ns

0.15

ns

0.004

ns

7.9

ns

0.0

ns

8.0

ns

0.066

ns

R

2

0.98 0.98 0.98 0.90 0.89 0.99 0.98 0.96 0.94 0.97 0.97 1.00 0.99 0.99

F 28.28 28.68 24.65 5.25 4.59 102.6 27.13 13.97 9.48 16.14 21.06 infty 43.22 52.85

Sig. F 0.001 0.001 0.001 0.041 0.052 0.000 0.001 0.005 0.012 0.003 0.002 0.000 0.000 0.000

C: model constant; M, T and S: linear effects of moisture content, die temperature and screw speed, respectively. MM, T T and SS: quadratic effects of moisture content, die temperature and screw speed,

respectively;. MT, MS and T S: interaction effects of moisture content and die temperature, moisture content and screw speed, and die temperature and screw speed, respectively; ***significant at p<0.01,

**significant at p<0.05, *significant at p<0.10,

ns

non-significant at p0.10.

1

0

6

H

.

D

O

G

A

N

A

N

D

M

.

V

.

K

A

R

W

E

+

[

1

4

.

5

.

2

0

0

3

1

:

1

6

p

m

]

[

1

0

1

1

1

4

]

[

P

a

g

e

N

o

.

1

0

6

]

F

I

N

A

L

P

R

O

O

F

S

I

:

/

S

a

g

e

/

F

s

t

/

F

s

t

9

-

2

/

F

S

T

-

3

3

9

4

0

.

3

d

(

F

S

T

)

P

a

p

e

r

:

F

S

T

-

3

3

9

4

0

K

e

y

w

o

r

d

a

t

U

N

I

V

D

E

S

A

O

P

A

U

L

O

B

I

B

L

I

O

T

E

C

A

o

n

S

e

p

t

e

m

b

e

r

2

5

,

2

0

0

9

h

t

t

p

:

/

/

f

s

t

.

s

a

g

e

p

u

b

.

c

o

m

D

o

w

n

l

o

a

d

e

d

f

r

o

m

(T), screw speed (S) and moisture (M), and the

quadratic effects of screw speed (SS) and tempera-

ture (TT) had the highest impact, significant at

p<0.01, on the DG (Table 4). During extrusion cooking

both temperature and shear are responsible for starch

gelatinization (Della Valle et al., 1989; Kokini, 1993).

Although at high screw speeds the residence time is low,

an increase in screw speed increased the DG signifi-

cantly ( p<0.01) for all combinations of feed moisture

content and temperature (Figure 3). This confirmed that

shear is a significant contributor to starch gelatinization.

This was supported by stronger effect of moisture on

DG at lower temperatures. These results agreed with

those of Gomez and Aguilera (1984), Bhattacharya and

Hanna (1987) and Cai and Diosady (1993) for other

grains.

Figure 3. Effect of feed moisture content, die tem-

perature and screw speed (rpm) on the degree of

gelatinization (DG).

Table 5. Cross-correlation coefficients between product and process responses.

DG PD SEI LEI VEI WSI WAI iE H BS SME SED STE SME/SED

DG 1 0.60 ** 0.91*** 0.75*** 0.57** 0.19

ns

0.14

ns

0.33

ns

0.60** 0.85*** 0.81*** 0.73*** 0.83*** 0.79***

PD 1 0.62** 0.17

ns

0.89*** 0.66*** 0.46* 0.24

ns

0.05

ns

0.78*** 0.74*** 0.48* 0.70*** 0.70***

SEI 1 0.80*** 0.65*** 0.02

ns

0.26

ns

0.27

ns

0.72*** 0.85*** 0.78*** 0.88*** 0.86*** 0.83***

LEI 1 0.16

ns

0.33

ns

0.05

ns

0.33

ns

0.90*** 0.64*** 0.46* 0.69*** 0.57** 0.49*

VEI 1 0.47* 0.41

ns

0.04

ns

0.09

ns

0.68*** 0.77*** 0.58** 0.75*** 0.79***

WSI 1 0.10

ns

0.15

ns

0.48* 0.03

ns

0.39

ns

0.18

ns

0.22

ns

0.24

ns

WAI 1 0.23

ns

0.09

ns

0.53** 0.18

ns

0.41

ns

0.27

ns

0.25

ns

E 1 0.06

ns

0.43

ns

0.11

ns

0.08

ns

0.11

ns

0.17

ns

H 1 0.42

ns

0.37

ns

0.72*** 0.51* 0.47*

BS 1 0.73*** 0.70*** 0.76*** 0.71***

SME 1 0.74*** 0.97*** 0.97***

SED 1 0.88*** 0.86***

STE 1 0.99***

SME/SED 1

DG: degree of gelatinization; PD: product density; SEI: sectional expansion index; LEI: longitudinal expansion index; VEI: volumetric expansion index; WSI: water

solubility index; WAI: water absorption index; iE: total color change; H: hardness; BS: breaking strength; SME: specific mechanical energy, SED: Specific energy

delivered; STE: specific thermal energy; ***significant at p<0.01, **significant at p<0.05, *significant at p<0.10,

ns

non-significant at p0.10.

Figure 2. Variation of degree of gelatinization (DG)

with SME/SED.

Quinoa Extrudates 107

+ [14.5.20031:16pm] [101114] [Page No. 107] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

In general, low feed moisture and high product

temperature have been found to increase the DG in

extrusion of starchy materials (Bhattacharya and

Hanna, 1987; Cai and Diosady, 1993). However, in the

presence of lipids, extrusion temperature required for

maximum DG was in the intermediate range. Lower

temperatures compensated for the decrease in melt

viscosity due to lipids (Dog an, 2000). In high lipid

containing cereals like quinoa, excessive feed moisture

acts as a secondary lubricant which prevents the

achievement of appropriate development or cooking of

dough by shear induced disruption. In this study, DG

was found to be highly correlated (0.81, p<0.01) with

SME, which confirmed that quinoa flour needs high

shear environment for effective extrusion processing.

Density of Extrudates,

e

The density of dry extrudates varied between 117 and

507 kg/m

3

. Low density, which is a desirable character-

istic of the expanded product, was achieved with low

feed moisture content, low temperature, and high screw

speed combination. The response surface (Figure 4)

shows that feed moisture content had a dominant effect

on density followed by screw speed, whereas tempera-

ture seems to have a minor effect. Minimal product

density was obtained at feed moisture of 17.1%, 161

C

die temperature, and 392 rpm screw speed.

Expansion Indices

The measured SEI of quinoa extrudates ranged from

0.92 to 3.58 whereas LEI ranged from 0.50 to 2.95

(Table 4). SEI was significantly affected by temperature,

feed moisture content and screw speed while for LEI

both feed moisture content and screw speed were found

to be insignificant. High expansion ratio at low feed

moisture content for extruded products is typical for

cereals (Coulter and Lorenz, 1991b; Faubion and

Hoseney, 1982; Gomez and Aguilera, 1984).

Moreover, Singh and Smith (1997) reported a decrease

in expansion with increasing temperature and feed

moisture content for wheat starch, wheat meal, and

oat flour. At higher moisture content, further decrease

in viscosity by increase in temperature results in a

reduced sectional expansion. At high feed moisture

content SEI increased with increasing screw speed while

at low moisture content levels effect of screw speed was

not significant (Figure 5). The positive effect of die

temperature on LEI (Figure 6) indicated the strong

dependency of elongation on extensional viscosity,

which decreases with increase in temperature, as

reported by Alvarez-Martinez et al. (1988). This is also

evident by the high negative correlation (0.75,

p<0.01) between DG and LEI (Table 5). Expansion

phenomena have been known to be basically dependent

on viscous and elastic properties of melted dough

(Launay and Lisch, 1983). Viscosity of feed melt

increases with an increase in DG (Bhattacharya and

Choudhury, 1994), therefore, LEI decreases.

It has been reported that the dough elasticity forces

contribute to radial expansion and axial contraction

(Padmanabhan and Bhattacharya, 1989). This relation

was also apparent in our experimental results with a

high negative correlation between SEI and LEI of 0.80

( p<0.01). Starch gelatinization is the functional prop-

erty that is directly related with physical properties of

the extruded products (Ghiasi et al., 1983). In the

present study, DG was found to be highly correlated

with SEI (0.91, p<0.01). As a measure of the extent of

molecular transformations during extrusion cooking

SME also correlated well with SEI (0.78, p<0.01).

Launay and Lisch (1983) suggested that the sectional

expansion and longitudinal expansion were dependent

on melt elasticity and melt viscosity, respectively. SEI

Figure 4. Effect of feed moisture content, die tem-

perature and screw speed on product density.

108 H. DOG

AN AND M.V. KARWE

+ [14.5.20031:16pm] [101114] [Page No. 108] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

decreased with increasing temperature (Figure 5), which

can be explained by the negative effect of temperature

on the elasticity of extrusion cooked melts (Launay and

Lisch, 1983). This result is in agreement also with the

work of Ilo et al. (1999). On the other hand, longitudinal

expansion appeared to be extensively favored by lower

melt viscosity at higher temperature and higher moisture

level (Figure 6).

Volumetric expansion index, the multiplication pro-

duct of SEI and LEI, was affected only by feed moisture

content ( p<0.01) and temperature ( p<0.05). As in the

case of SEI, high SME input resulted in higher

volumetric expansion (0.79, p<0.01) possibly due to

higher degree of gelatinization observed under these

conditions. The correlation between product density and

VEI (0.89, p<0.01) was expectedly better because

product density is inverse of VEI.

Hardness and Breaking Strength

Hardness, the maximum force to break the sample,

ranged between 1.31 and 4.64 N. Although, the coeffi-

cient of determination for hardness was high (R

2

0.94),

feed moisture content and screw speed were found to

have no contribution. However, the breaking strength

(N/mm

2

) values gave even higher coefficient of determi-

nation (R

2

0.97) and contribution of all linear terms of

the independent variables (Table 4) was significant.

Response surface plots (Figure 7) showed that at all feed

moisture content levels, decrease in die temperature

increased the product hardness giving a maximum at

about 134

C, 408 rpm screw speed and 21.5% feed

moisture content. However, as a consequence of

increased expansion, breaking strength decreased with

decreasing temperature and moisture content (Figure 8)

Figure 6. Effect of feed moisture content, die tem-

perature and screw speed on longitudinal expansion

index (LEI).

Figure 5. Effect of feed moisture content, die tem-

perature and screw speed on sectional expansion

index (SEI).

Quinoa Extrudates 109

+ [14.5.20031:16pm] [101114] [Page No. 109] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

giving a minimum value at about 140

C die tempera-

ture, 19.1% feed moisture, and 425 rpm screw speed.

The mechanical properties of extruded products can

be described either by compressive deformation or by

breaking strength (Colonna et al., 1989). Breaking

strength is the measure of the strength of cell wall

which is expected to affect the texture and sensory

crispiness of the extruded product (Chen et al., 1991).

Breaking strength was found to be highly correlated

with SEI (0.85, p<0.01), indicating that the increase in

pore size together with a decrease in cell wall thickness

results in weak extrudate structures (Table 5). Generally,

breaking strengths of extrudates reflect expansion

volume (Chavez-Jauregui et al., 2000). High density

product naturally offers high breaking strength evident

by high correlation between product density and break-

ing strength (0.78, p<0.01 ). Chemical changes taking

place during extrusion cooking influence the develop-

ment of textural and mechanical properties such as

hardness and breaking strength in extrudates. Breaking

strength is affected by the strength of cell walls, as

influenced by starch gelatinization and protein dena-

turation (Martinez-Serna and Villota, 1992). The high

correlation found between DG and hardness (0.60,

p<0.05) and DG and breaking strength (0.85,

p<0.01) supports this relation.

Water Solubility and Absorption Indices

Water solubility index is related to the quantity of

soluble solids, which is related to dextrinization. The

coefficient of determination for WSI was highly

significant as revealed by a high value of R

2

(0.99).

The linear and quadratic effects of feed moisture (M)

content, linear effect of screw speed (S), and the linear

(T) and quadratic (TT) effects of temperature had

significant effect on WSI. In general ,WSI increased with

increasing temperature and screw speed and decreasing

Figure 7. Effect of feed moisture content, die tem-

perature and screw speed on product hardness.

Figure 8. Effect of feed moisture content, die tem-

perature and screw speed on breaking strength.

110 H. DOG

AN AND M.V. KARWE

+ [14.5.20031:16pm] [101114] [Page No. 110] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

feed moisture content due to the fact that high thermal

and mechanical energy inputs favour starch dextriniza-

tion (Figure 9). Low WSI values were observed at

intermediate to low temperature levels at all processing

conditions. The increase in WSI with increasing

temperature was consistent with the results reported

for oat extrudates (Singh and Smith, 1997). The

WSI decreased with the increase in moisture. Similar

effects of decreasing moisture on WSI have been

reported earlier for starch, maize grits, wheat and pea

flour (Della Valle et al., 1994; Kirby et al., 1988).

Minimum WSI of 0.186 g/g was achieved at 18.3% feed

moisture content, 140

C die temperature, and 192 rpm

screw speed.

The poor correlation between WSI and most of the

process and product responses (Table 5) may be

explained by the fact that WSI includes the opposing

effects of starch dextrinization and the molecular level

interactions between degraded components, which may

not be favoured at the same condition. An increase in

the amount of dextrinized starch during extrusion

cooking results in an increase in WSI. However,

molecular interactions between degraded starch, pro-

tein, and lipid components, which in turn lead to an

increase in molecular weight, may decrease the solubi-

lity, thus WSI. Moreover, according to the model

proposed by Gomez and Aguilera (1984) for starch

degradation during extrusion cooking, three pure states,

i.e., raw, gelatinized, and dextrinized, of starch exist

together. Due to different states in which starch is found

in extrudates, some granules may be underprocessed,

while some others may be overprocessed or dextrinized.

According to the same model, dextrinization can be

considered to take place together with or right after

adequate gelatinization. According to our experimental

results, thermal and mechanical input seemed to be

enough for sufficient starch gelatinization but not severe

enough to favour starch dextrinization. SME values

were not high enough to cause dextrinization, which in

turn increases WSI. This is also evident by the high

correlation coefficient between SME and DG (0.81,

p<0.01) and a poor correlation coefficient between

SME and WSI (0.39, p >0.10).

Water absorption index depends on the availability of

hydrophilic groups and on the gel formation capacity of

the macromolecules (Gomez and Aguilera, 1983). It is a

measure of damaged starch together with protein

denaturation and new macromolecular complex forma-

tions. WAI of extrudates ranged between 4.45 and

6.72 g/g which was significantly higher than that of

(1.69 g/g) unprocessed quinoa. The regression analysis

(Table 4) showed that the linear effect of feed moisture

content (M), and the interaction effect of die tempera-

ture and moisture content (TM) were highly sig-

nificant on WAI. Singh and Smith (1997) reported an

increase in WAI with the increase in moisture and

temperature during extrusion of oats, which is in

agreement with our experimental results (Figure 10).

WAI had poor correlations with almost all process and

product responses except product density (Table 5). This

is an expected result since it includes the effect of starch

gelatinization, protein denaturation and molecular level

crosslinking reactions which are not always favoured at

the same conditions.

Colour

Colour is an important quality parameter since it

reflects the extent of chemical reactions and degree of

cooking or degradation that take place during extrusion

cooking. In this study, E represents the total colour

difference compared to the colour of unprocessed

quinoa. Higher E means darker products with more

Figure 9. Effect of feed moisture content, die tem-

perature and screw speed on water solubility index

(WSI, g soluble matter/g dry sample).

Quinoa Extrudates 111

+ [14.5.20031:16pm] [101114] [Page No. 111] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

intense yellow and red colour. The total colour change

in extruded products ranged between 15.5 and 23.7

(Table 4). Quadratic effect of temperature (TT) and

the linear effect of feed moisture content (M) were

found to have the highest contribution to total colour

change. Low feed moisture content and high tempera-

ture increased the total colour change possibly due to

increased extent of browning reactions under this

condition (Figure 11). Although, the screw speed was

not a significant parameter (Table 4), at low screw

speeds a slight increase in colour change observed due to

longer residence times which might increase the extent of

chemical reactions.

In summary, because the high lipid and low amylose

contents, extrusion cooking of quinoa required proces-

sing conditions that provide high shear environ-

ment indicated by high SME values which disrupts

starch granules. Extrusion cooking conditions that

produced quinoa products with desirable expansion

characteristics were at low moisture, low temperature

and medium screw speed within the range of our process

variables.

NOMENCLATURE

C

p

heat capacity (kJ/kg.K)

LEI longitudinal expansion index (dimensionless)

ME rate of mechanical energy input (dissipa-

tion) (W)

m

f

total mass flow rate (kg/s)

Nscrew speed (rpm)

Q

C

rate of energy removal by the cooling sys-

tem (W)

Q

H

rate of heat generation (W)

SEDspecific energy delivered (kJ/kg)

SEI sectional expansion index (dimensionless)

Figure 10. Effect of feed moisture content, die

temperature and screw speed on water absorption

index (WAI, g H

2

O/g dry sample).

Figure 11. Effect of feed moisture content, die

temperature and screw speed on total color change

(E).

112 H. DOG

AN AND M.V. KARWE

+ [14.5.20031:16pm] [101114] [Page No. 112] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

SME specific mechanical energy (kJ/kg)

STE specific thermal energy (kJ/kg)

T

i

inlet temperature of the product (

C)

T

o

outlet temperature of the product (

C)

T

d

die temperature or product temperature (

C)

VEI volumetric expansion index (dimensionless)

WAI water absorption index (g water absorbed/g dry

sample)

W

e

weight of extrudate (kg)

W

gb

weight of glass beads displaced by the extru-

dates (kg)

WSI water solubility index (g water soluble matter/g

dry sample)

E total colour change

e

density of extrudate (kg/m

3

)

gb

density of glass beads (kg/m

3

)

ACKNOWLEDGEMENTS

This is publication No. D 01544-01-01 of the New

Jersey Agricultural Experiment Station supported by

State funds and the Center for Advanced Food

Technology (CAFT). The Center for Advanced Food

Technology is a New Jersey Commission on Science

and Technology Center. Author H. Dog an acknowl-

edges the financial support from TUBITAK Marmara

Research Center, Food Science and Technology Res-

earch Institute, Turkey.

REFERENCES

AACC (American Association of Cereal Chemists, 1984).

AACC Approved Methods. Vol. II. Minneapolis,

Minnesota: AACC.

Ahamed N.T., Singhal R.S., Kulkarni P.R. and Pal M.

(1996). Physicochemical and functional properties of

Chenopodium quinoa starch. Carbohydrate Polymers 31:

99103.

Akdog an H. (1996). Pressure, torque, and energy response

of a twin screw extruder at high moisture contents. Food

Research International 29: 423429.

Alvarez-Martinez L., Kodury K.P. and Harper J.M.

(1988). A general method for expansion of extruded

products. Journal of Food Science 53: 609615.

Anderson R.A., Conway H.F., Pfeifer V.F. and Griffin

L.E.J. (1969). Gelatinization of corn grits by roll-and

extrusion cooking. Cereal Science Today 14: 412.

Arditi T., Meredith T. and Flowerman P. (2000). Renewed

interest in soy isoflavonoids and saponins. Cereal Foods

World 45: 414417.

Atwell A., Patrick B.M., Johnson L.A. and Glass R.W.

(1982). Characterization of quinoa starch. Cereal

Chemistry 60: 911.

Becker R. and Hanners G.D. (1990). Compositional and

nutritional evaluation of quinoa whole grain flour and

mill fractions. Lebensmittel-Wissenschaft und-Technolo-

gie-Food Science and Technology 23: 441444.

Bhattacharya M. and Hanna M.A. (1987). Kinetics of

starch gelatinization during extrusion cooking. Journal of

Food Science 52: 764766.

Bhattacharya S. and Choudhury G.S. (1994). Twin-screw

extrusion of rice flour: effect of extruder length-to-

diameter ratio and barrel temperature on extrusion

parameters and product characteristics. Journal of Food

Processing and Preservation 18: 389406.

Bhattacharya S. (1997). Twin-screw extrusion of rice-green

gram blend: extrusion and extrudate characteristics.

Journal of Food Engineering 32: 8399.

Birch G.G. and Priesty R.J. (1973). Degree of gelatinization

of cooked rice. Starch-Staerke 25: 98103.

Cai W. and Diosady L.L. (1993). Model for gelatinization

of wheat starch in a twin-screw extruder. Journal of Food

Science 58: 872887.

Case S.E., Hamann D.D. and Schwartz S.J. (1992). Effect

of starch gelatinization on physical properties of

extruded wheat-and corn-based products. Cereal

Chemistry 69: 401404.

Chavez-Jauregui M.E., Silva M.P. and Areas J.A.G.

(2000). Extrusion cooking process for amaranth.

Journal of Food Science 65: 10091015.

Chen J., Serafin F.L., Pandya R.N. and Daun H. (1991).

Effects of extrusion conditions on sensory properties of

corn meal extrudates. Journal of Food Science 56: 8489.

Chinnaswamy R. and Hanna M.A. (1990). Macromolecular

and functional properties of native and extrusion cooked

corn starches. Cereal Chemistry 67: 490499.

Chrastil J. (1987). Improved calorimetric determination of

amylose in starch or flour. Carbohydrate Research 159:

154158.

Colonna P., Tayeb J. and Mercier C. (1989). Extrusion

cooking of starch and starchy products. In: Mercier C.,

P. Linko and J. M. Harper (eds), Extrusion Cooking.

Minneapolis, Minnesota: AACC. pp. 247319.

Coulter L.A. and Lorenz K. (1990). Quinoa: composition,

nutritional value, food applications. Lebensmittel-

Wissenschaft und Technologie-Food Science and

Technology 23: 203207.

Coulter L.A. and Lorenz K. (1991a). Extruded corn grits-

quinoa blends: I. Proximate composition, nutritional

properties and sensory evaluation. Journal of Food

Processing and Preservation 15: 231242.

Coulter L.A. and Lorenz K. (1991b). Extruded corn grits-

quinoa blends: II. Physical characteristics of extruded

products. Journal of Food Processing and Preservation 15:

231242.

Della Valle G., Kozlowski A., Colonna P. and Tayeb J.

(1989). Starch transformations estimated by the energy

balance on a twin-screw extruder. Lebensmittel

Wisensachft und Technologie 22: 279286.

Della Valle G., Oullien L. and Geuguen J. (1994).

Relationships between processing conditions and starch

and protein modifications during extrusion cooking of

pea flour. Journal of the Science Food and Agriculture 64:

509517.

Quinoa Extrudates 113

+ [14.5.20031:16pm] [101114] [Page No. 113] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

Della Valle, G., Colonna P. and Patria A. (1996). Influence

of amylose content on the viscous behavior of low hyd-

rated molten starches. Journal of Rheology 40: 347262.

Della Valle G., Vergnes B., Colonna O. and Patria A.

(1997). Relations between rheological properties of

molten starches and their expansion behavior in extru-

sion. Journal of Food Engineering 31: 277296.

Dog an H. (2000). The effect of component interactions on

the structural and functional properties of legume extru-

dates. Ph.D. Thesis, Middle East Technical University,

Ankara-Turkey.

Faubion J.M. and Hoseney R.C. (1982). High temperature

short time cooking of wheat starch and flour I. Effect of

moisture and flour type on extrudate properties. Cereal

Chemistry 59: 529533.

Gee J.M., Price K.R., Ridout C.L., Wortley G.M., Hurrel

R.F. and Johnson I.T. (1993). Saponins of quinoa:

Effects of processing on their abundance in quinoa

products and their biological effects on intestinal

mucosal tissue. Journal of the Science of Food and

Agriculture 63: 201209.

Ghiasi K., Hoseney R.C. and Varriano-Marston E. (1983).

Effects of flour components and dough ingredients on

starch gelatinization. Cereal Chemistry 60: 5861.

Godavarti S. and Karwe M.V. (1997). Determination of

specific mechanical energy distribution on a twin-screw

extruder. Journal of Agricultural Engineering Research

67: 277287.

Gomez M.H. and Aguilera J.M. (1983). Changes in the

starch fraction during extrusion cooking of corn. Journal

of Food Science 48: 378381.

Gomez M.H. and Aguilera J.M. (1984). A physicochemical

model for extrusion of starch. Journal of Food Science 49:

4043, 63.

Guha M, Ali S.Z. and Bhattacharya S. (1997). Twin-screw

extrusion of rice flour without a die: Effect of

barrel temperature and screw speed on extrusion and

extrudate characteristics. Journal of Food Engineering 32:

251267.

Guzman-Maldonado S.H. and Paredes-Lopez O. (1998).

Functional products of plants indigenous to Latin

America: Amaranth, quinoa, common beans and bota-

nicals. In: Mazza G. (ed), Functional Foods: Biochemical

and Processing Aspects. Lancaster: Technomic

Publishing Company. pp. 293328.

Hic s as maz Z. and Clayton J.T. (1993). Characterization of

the pore structure of starch based food materials. Food

Structure 11: 115132.

Ilo S., Liu Y. and Berghofer E. (1999). Extrusion cooking

of rice flour and amaranth blends. Lebensmittel-

Wissenschaft und Technologie Food Science and

Technology 32: 7988.

Kirby, A.R., Ollett A.L., Parker R. and Smith A.C. (1988).

An experimental study of screw configuration effects in

the twin-screw extrusion cooking of maize grits. Journal

of Food Engineering 8: 247272.

Kokini J.L., Lai L.S. and Chedid L.L. (1992). Effect of

starch structure on starch rheological properties. Food

Technology 46: 124139.

Kokini J.L. (1993). The effect of processing history on

chemical changes in single- and twin-screw extruders.

Trends in Food Science and Technology 4: 324329.

Koziol M.J. (1992). Chemical composition and nutritional

evaluation of quinoa (Chenopodium quinoa Willd).

Journal of Food Composition and Analysis 5: 3568.

Lai L.S. and Kokini J.L. (1990). The effect of extrusion

operation conditions on the on-line apparent viscosity of

98% amylopectin and 70% amylose corn starches during

extrusion. Journal of Rheology 34: 12451266.

Launay B. and Lisch J.M. (1983). Twin-screw extrusion

cooking of starches: Flow behavior of starch pastes,

expansion and mechanical properties of extrudates.

Journal of Food Engineering 2: 259280.

Martinez-Serna M.D. and Villota R. (1992). Reactivity,

functionality and extrusion performance of native and

chemically modified whey proteins. In: Kokini J.L., Ho

C.T. and Karwe M.V. (ed.), Food Extrusion Science and

Technology. New York: Marcel Dekker, Inc. pp. 387415.

Masterbroek H.D., Limburg H., Gilles T. and Marvin

H.J.P. (2000). Occurrence of sapogenins in leaves and

seeds of quinoa (Chenopodium quinoa Willd). Journal of

the Science of Food and Agriculture 80: 152156.

Ng K.G., Price K.R. and Fenwick G.R. (1994). A TLC

Method for the analysis of quinoa saponins. Food

Chemistry 49: 311315.

Padmanabhan M. and Bhattacharya M. (1989). Extrudate

expansion during extrusion cooking of foods. Cereal

Foods World 34: 945949.

Prakash D., Nath P. and Pal M. (1993). Composition,

variation of nutritional contents in leaves, seed protein,

fat and fatty acid profile of Chenopodium species. Journal

of the Science of Food and Agriculture 62: 203205.

Przybylski R., Chauhan G.S. and Eskin N.A.M. (1994).

Characterization of quinoa (Chenopodium quinoa) lipids.

Food Chemistry 51: 187192.

Qian J.Y. and Kuhn M. (1999). Characterization of

Amaranthus cruentus and Chenopodium quinoa starch.

Starch-Staerke 51: 116120.

Ridout C.L., Price K.R., DuPont M.S., Parker M.L. and

Fenwick G.R. (1991). Quinoa saponins Analysis and

preliminary investigations into the effects of reduction by

processing. Journal of the Science of Food Agriculture 54:

165176.

Ruales J. and Nair B.M. (1993). Content of fat, vitamins

and minerals in quinoa (Chenopodium quinoa Willd)

seeds. Food Chemistry 48: 131136.

Singh N. and Smith A.C. (1997). A comparison of wheat

starch, whole wheat meal and oat flour in the extrusion

cooking process. Journal of Food Engineering 34: 1532.

Wang S.S., Chiang W.C., Zheng X., Zhao B., Yeh A. and

Cho M.H. (1992). Application of an energy equivalent

concept to the study of the kinetics of starch conversion

during extrusion. In: Kokini J.L., Ho C.T. and Karwe

M.V. (eds), Food Extrusion Science and Technology. New

York: Marcel Dekker, Inc. pp. 165176.

Zasypkin D.V. and Lee T.-C. (1998). Extrusion of soybean

and wheat flour as affected by moisture content. Journal

of Food Science 63: 10581061.

114 H. DOG

AN AND M.V. KARWE

+ [14.5.20031:16pm] [101114] [Page No. 114] FINAL PROOFS I:/Sage/Fst/Fst9-2/FST-33940.3d (FST) Paper: FST-33940 Keyword

at UNIV DE SAO PAULO BIBLIOTECA on September 25, 2009 http://fst.sagepub.com Downloaded from

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Derivative Investment!Documento24 pagineDerivative Investment!Asif Riaz100% (2)

- BKM 10e Ch07 Two Security ModelDocumento2 pagineBKM 10e Ch07 Two Security ModelJoe IammarinoNessuna valutazione finora

- (Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)Documento4 pagine(Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)nguyen duong trungNessuna valutazione finora

- Aakanksha ProjectDocumento32 pagineAakanksha ProjectAakash murarkaNessuna valutazione finora

- Biodegradable Plastic Bag Manufacturing Industry-800655 PDFDocumento68 pagineBiodegradable Plastic Bag Manufacturing Industry-800655 PDFAryanNessuna valutazione finora

- Tri-Partite Agreement AssociationDocumento9 pagineTri-Partite Agreement AssociationThiyagarjanNessuna valutazione finora

- Plumbing Breakup M 01Documento29 paginePlumbing Breakup M 01Nicholas SmithNessuna valutazione finora

- Key ScientificDocumento4 pagineKey ScientificGarrettNessuna valutazione finora

- Resume Massage Therapist NtewDocumento2 pagineResume Massage Therapist NtewPartheebanNessuna valutazione finora

- EF4e Beg Quicktest 05Documento3 pagineEF4e Beg Quicktest 05terrenoruralcamboriuNessuna valutazione finora

- Tcu Module Pe1 Lesson 1Documento7 pagineTcu Module Pe1 Lesson 1Remerata, ArcelynNessuna valutazione finora

- FennelDocumento2 pagineFennelAlesam44bNessuna valutazione finora

- L A R G e - S C A L e M e T H A M P H e T A M I N e M A N U F A C T U R eDocumento21 pagineL A R G e - S C A L e M e T H A M P H e T A M I N e M A N U F A C T U R eDaria Schka100% (1)

- ECC83/12AX7: Quick Reference DataDocumento4 pagineECC83/12AX7: Quick Reference DataLuisNessuna valutazione finora

- DR K.M.NAIR - GEOSCIENTIST EXEMPLARDocumento4 pagineDR K.M.NAIR - GEOSCIENTIST EXEMPLARDrThrivikramji KythNessuna valutazione finora

- Universal ING - LA.Boschi Plants Private LimitedDocumento23 pagineUniversal ING - LA.Boschi Plants Private LimitedAlvaro Mendoza MaytaNessuna valutazione finora

- Практичне 25. Щодений раціонDocumento3 pagineПрактичне 25. Щодений раціонAnnaAnnaNessuna valutazione finora

- ContinueDocumento2 pagineContinueNeal ReppNessuna valutazione finora

- ClistDocumento14 pagineClistGuerraNessuna valutazione finora

- My Public Self My Hidden Self My Blind Spots My Unknown SelfDocumento2 pagineMy Public Self My Hidden Self My Blind Spots My Unknown SelfMaria Hosanna PalorNessuna valutazione finora

- 21A Solenoid Valves Series DatasheetDocumento40 pagine21A Solenoid Valves Series Datasheetportusan2000Nessuna valutazione finora

- Menu Siklus RSDocumento3 pagineMenu Siklus RSChika VionitaNessuna valutazione finora

- Facts About Concussion and Brain Injury: Where To Get HelpDocumento20 pagineFacts About Concussion and Brain Injury: Where To Get HelpJess GracaNessuna valutazione finora

- OM Hospital NEFTDocumento1 paginaOM Hospital NEFTMahendra DahiyaNessuna valutazione finora

- Glycolysis Krebscycle Practice Questions SCDocumento2 pagineGlycolysis Krebscycle Practice Questions SCapi-323720899Nessuna valutazione finora

- Bitumen BasicsDocumento25 pagineBitumen BasicsMILON KUMAR HORENessuna valutazione finora

- Liebherr 2956 Manual de UsuarioDocumento27 pagineLiebherr 2956 Manual de UsuarioCarona FeisNessuna valutazione finora

- Uttarakhand District Factbook: Almora DistrictDocumento33 pagineUttarakhand District Factbook: Almora DistrictDatanet IndiaNessuna valutazione finora

- Form - Pelaporan B3Documento16 pagineForm - Pelaporan B3sukma nugraNessuna valutazione finora

- Safety Tips in Playing ArnisDocumento2 pagineSafety Tips in Playing ArnisDensyo De MensyoNessuna valutazione finora