Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Beeeem

Caricato da

Sarath Teja0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

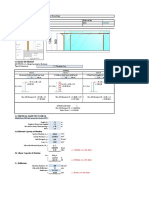

76 visualizzazioni6 pagine1. The document describes procedures for conducting a bending test on metal beams using a UTM apparatus. The test will be conducted on both simply supported and cantilever beams.

2. For each type of beam, the material properties, dimensions, and positions of the load and dial gauges will be recorded. Beams will be loaded incrementally and deflections will be measured and compared to theoretical calculations.

3. Percent errors between theoretical and experimental deflections will be determined. The goal is to analyze how beam geometry and support conditions affect deflection under bending loads.

Descrizione originale:

ggrg

Titolo originale

beeeem

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento1. The document describes procedures for conducting a bending test on metal beams using a UTM apparatus. The test will be conducted on both simply supported and cantilever beams.

2. For each type of beam, the material properties, dimensions, and positions of the load and dial gauges will be recorded. Beams will be loaded incrementally and deflections will be measured and compared to theoretical calculations.

3. Percent errors between theoretical and experimental deflections will be determined. The goal is to analyze how beam geometry and support conditions affect deflection under bending loads.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

76 visualizzazioni6 pagineBeeeem

Caricato da

Sarath Teja1. The document describes procedures for conducting a bending test on metal beams using a UTM apparatus. The test will be conducted on both simply supported and cantilever beams.

2. For each type of beam, the material properties, dimensions, and positions of the load and dial gauges will be recorded. Beams will be loaded incrementally and deflections will be measured and compared to theoretical calculations.

3. Percent errors between theoretical and experimental deflections will be determined. The goal is to analyze how beam geometry and support conditions affect deflection under bending loads.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 6

Apparatus:

1. UTM or Beam apparatus with movable knife frame(bending fixture!

". #ernier $alipers! dial gauge! and a Tape measure. %alipers should be used to measure

the width and thi$kness of the beam. &ial gauge will be used to measure the defle$tion

of the beam. The tape measure is used to measure the length of the test region.

'. Metal beam. The beam should be fairl( re$tangular! thin and long .)pe$ifi$ dimensions

are dependent to the si*e of the test frame and available weights.

Theor(:

Bending test is performed on beam b( using the three point loading s(stem. The bending fixture

is supported on the platform of h(drauli$ $(linder of the UTM. The loading is held in the middle

$ross head. At a parti$ular load the defle$tion at the $enter of the beam is determined b( using a

dial gauge.

a. Simply supported beam: +n simpl( supported the " free ends of the beam are

supported b( knife edged supports of the loading frame and load is applied to a point ,

from the left support.

Above figure shows a simpl( supported beam

of length -! (A! B is the rea$tion for$es and . is

$on$entrated for$e a$ting at a distan$e , from

A. The /ea$tion for$es A and B are $al$ulated

using e0uilibrium e0uations 1MB23! and

1MB23.

)olving for support for$es A and B! as in fig 1

we get:

A2. (14x5l 6 B2.(x5l

The se$tion between the load and the right hand support is s(mmetri$al to this. The maximum

defle$tion is at the $enter of the bar! where x2-5" dire$tl( beneath the load.

b. Cantilever beam:+n a $antilever bar! one side of the bar is fixed and the other side free.

The e0uation for the defle$tion ( of the bar at the point of appli$ation of for$e is

mentioned in the worksheet.

Above figure shows that a load 7 is a$ting at a distan$e x from the fixed end .The length of the

beam being -. The support rea$tions being 7 itself sin$e 1.23 in the verti$al dire$tion. The

moment at the fixed end is given b(

M27.x (a$ting in the $lo$kwise dire$tion.

The influen$e of the length x for the defle$tion at the free end should be demonstrated in this

experiment ..or this purpose the for$e should be $onstant.

7ro$edure and 8xperimental setup

a. for simply supported beam

1. )et the knife supports at determined positions along the frame and mount the beam

to be tested.

". The material! width! thi$kness! and length between supports should be measured

and re$orded for later use.

'. 7la$e dial gauges along lengths of the test area (the area between the knife

supports and set the gauges to read *ero with no load applied (pla$e an( one dial

gauge on the $enter of the simpl( supported beam to measure the a$tual maximum

defle$tion

9. Adding the hook and hanger to the an( preferred point of the beam (where the load

7 will be a$ting at a distan$e , from right support or left support (in our $ase x is

measured from left support! re$ord the new readings for the gauges.

:. Add new loads onto the hanger! re$ording the new defle$tions for ea$h gauge after

ever( loading and the support rea$tions are $al$ulated b( using e0 1.

;. The theoreti$al defle$tion is $al$ulated b( using the formula mentioned in the

worksheet provided.

<. The $omparison is done with the theoreti$al and a$tual defle$tions and 7er$entage

error is $al$ulated.

b. for cantilever beam

1. Mount the beam to be tested to the loading frame of the UTM with bending fixture at

spe$ified at appropriate point (for $antilever $ase

". The material! width! thi$kness! and length between supports should be measured

and re$orded for later use.

'. 7la$e dial gauge at the $enter of the beam and set the gauge to read *ero with no

load applied.

9. Adding the hook and hanger to the an( preferred point of the beam (where the load

7 will be a$ting at a distan$e , from right hand side or left hand side (in our $ase x

is measured from the left hand side! re$ord the new readings for the gauges.

:. Add new loads onto the hanger! re$ording the new defle$tions for ea$h gauge after

ever( loading and the support rea$tions are $al$ulated b( using e0uation

(mentioned above in the theor( se$tion.

;. The theoreti$al defle$tion is $al$ulated b( using the formula mentioned in the

worksheet provided.

<. The $omparison is done with the theoreti$al and a$tual defle$tions and 7er$entage

error is $al$ulated.

=bservation data:

a. simply supported beam

Material:>>>>...>>>>>>>>>>

Critical dimensions:

-2>>>>>>>.m (test length

w2>>>>>>>m (width

t2 >>>>>>>.m (thi$kness

Positions of Dial gauge:

,12-5"2>>>>.m (at the $enter of beam

Position of Load acting:

,2>>>>>>>>..m

Deflection Data:

)T87 -=A& ?AU?8

/8A&+@?

Theoreti$al defle$tion at the $enter (as $al$ulated e0 in work sheet 2>>>>>>>>>.

A$tual defle$tion at the $enter2>>>>>>>>>>>.

A 8rror in a$tual reading (as $ompared to Theoreti$al 2>>>>>>>>>.

b. cantilever beam

Material:>>>>...>>>>>>>>>>

Critical dimensions:

-2>>>>>>>.m (test length

w2>>>>>>>m (width

t2 >>>>>>>.m (thi$kness

Position of Load acting:

,2>>>>>>>>..m

Deflection Data:

)-. @= -=A& ?AU?8 /8A&+@?

Theoreti$al defle$tion value (from worksheet 2>>>>>>>>>>..

A$tual defle$tion at the free end2>>>>>>>>>>>

A 8rror in a$tual reading (as $ompared to Theoreti$al 2>>>>>>>>>.

8xtra /eading material:

http://www.scribd.com/doc/136561/Mechanics-of-Materials-Beam-Defection-Test

http://nptel.iitm.ac.in/courses/T-M!D"!#/#tren$th%of%Materials/&dfs/5%1.pdf

http://www.cla$.or$.u'/beam-menu.html

Bui*:

Chi$h beam setup will defle$t to the maximum from the original shape for the given load

and beam dimensionD

&efle$tion of the $antilever beam is>>>>>>>>>

&efle$tion of a simpl( supported beam is>>>>>>>>.

&efle$tion is dire$tl( proportional to>>>>>>>.

&efle$tion is inversel( proportional to >>>>>>>>>>

Moment of inertia for a $ir$ular se$tion is given b( >>>>>>>>

8+ 2 flexural rigidit(. (T5.

The Maximum defle$tion for a $antilever beam when subEe$ted to U&- is at the $enter

(T5.

Moment of inertia for a re$tangular se$tion is given b( +2bdF'51" (T5.

Potrebbero piacerti anche

- Structural Analysis With Strain Gage Measurements: Experiment 1Documento7 pagineStructural Analysis With Strain Gage Measurements: Experiment 1Yılmaz GürpınarNessuna valutazione finora

- Modul 3 Strain Measurement v2 PDFDocumento11 pagineModul 3 Strain Measurement v2 PDFFachrudin HanafiNessuna valutazione finora

- Aircraft Structures II LabDocumento15 pagineAircraft Structures II Labproxymo10% (1)

- 1.105 Solid Mechanics Laboratory Fall 2003: Experiment 6 The Linear, Elastic Behavior of A BeamDocumento7 pagine1.105 Solid Mechanics Laboratory Fall 2003: Experiment 6 The Linear, Elastic Behavior of A Beamprieten20006936Nessuna valutazione finora

- Lab 4 - Strain Gages: F o R M A TDocumento3 pagineLab 4 - Strain Gages: F o R M A Tnauji_kNessuna valutazione finora

- ENME 317 Lab 4 - Bending - W2020Documento7 pagineENME 317 Lab 4 - Bending - W2020Annemarie SummersNessuna valutazione finora

- Calibration of Metal TapesDocumento16 pagineCalibration of Metal Tapesarabcal100% (1)

- 1.105 Solid Mechanics Laboratory Fall 2003: Experiment 4 The Linear, Elastic Behavior of A TrussDocumento24 pagine1.105 Solid Mechanics Laboratory Fall 2003: Experiment 4 The Linear, Elastic Behavior of A Trussprieten20006936Nessuna valutazione finora

- SM Lab ManualsDocumento27 pagineSM Lab ManualspraveenampilliNessuna valutazione finora

- Young Modulus ExpDocumento9 pagineYoung Modulus ExpUmarKhalifNessuna valutazione finora

- Lab ManualDocumento14 pagineLab ManualBenni AmirNessuna valutazione finora

- Cantilever Lab PDFDocumento6 pagineCantilever Lab PDFDuminduJayakodyNessuna valutazione finora

- Cantilever Beam Experiment B58SBDocumento9 pagineCantilever Beam Experiment B58SBSunNessuna valutazione finora

- Tensile TestDocumento7 pagineTensile TestDhedhe PrasetyaNessuna valutazione finora

- Lab Report: Tensile TestDocumento5 pagineLab Report: Tensile TestMostafa HamawandyNessuna valutazione finora

- Aircraft Structures II LabDocumento14 pagineAircraft Structures II LabkarthikspeedNessuna valutazione finora

- 2.simply Supported Beam - IC 2 (Exp-2)Documento8 pagine2.simply Supported Beam - IC 2 (Exp-2)Nikhil KautilyaNessuna valutazione finora

- EMCH 361 - Mechanical Engineering Lab I: Lab V - Strain MeasurementDocumento3 pagineEMCH 361 - Mechanical Engineering Lab I: Lab V - Strain MeasurementJoanna SimmonsNessuna valutazione finora

- Aerospace Structures Lab Manual - 2018 RegDocumento29 pagineAerospace Structures Lab Manual - 2018 Regbasha.arshad.mullaNessuna valutazione finora

- Young 2Documento8 pagineYoung 2UmarKhalifNessuna valutazione finora

- LAb Manual For Deflection of Beam Experiment Three Handout PDFDocumento6 pagineLAb Manual For Deflection of Beam Experiment Three Handout PDFmehwish arshadNessuna valutazione finora

- SM 4 ExperimentsDocumento19 pagineSM 4 ExperimentsSarath TejaNessuna valutazione finora

- MAE 212: Spring 2001 Module III: Material Property Characterization Using Strain Gage InstrumentationDocumento7 pagineMAE 212: Spring 2001 Module III: Material Property Characterization Using Strain Gage InstrumentationChulbul PandeyNessuna valutazione finora

- Mos Lab Manual PDFDocumento34 pagineMos Lab Manual PDFs.rihanaNessuna valutazione finora

- Deflection of Beam Lab ReportDocumento23 pagineDeflection of Beam Lab ReportJayle Pengiran Francis69% (16)

- BME Mannual BT 203-1Documento41 pagineBME Mannual BT 203-1shivanshu tiwariNessuna valutazione finora

- Som Manual-2013 RegDocumento26 pagineSom Manual-2013 RegsugunavidiyadarNessuna valutazione finora

- LEEA Correspondence Courses: Assignment 2.8Documento4 pagineLEEA Correspondence Courses: Assignment 2.8jithinjose86Nessuna valutazione finora

- Strength of Materia Lab Manual UET, LahoreDocumento14 pagineStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- Physics Lab ManualDocumento58 paginePhysics Lab ManualREDDYGAARI ABBAYINessuna valutazione finora

- Experiment 1: Strain MeasurementDocumento9 pagineExperiment 1: Strain MeasurementHoa LeNessuna valutazione finora

- RILEM TC 162-TDF Test and Design Methods For Steel Fibre Reinforced ConcreteDocumento3 pagineRILEM TC 162-TDF Test and Design Methods For Steel Fibre Reinforced ConcreteAbdul GhaffarNessuna valutazione finora

- Wave LoadingDocumento10 pagineWave Loadingmyusuf_engineerNessuna valutazione finora

- Department of Aerospace Engineering: Strength of Materials Laboratory ManualDocumento36 pagineDepartment of Aerospace Engineering: Strength of Materials Laboratory ManualSriharicharan K SNessuna valutazione finora

- Laboratory Manual: MEC259 Unified Mechanical Engineering IIDocumento35 pagineLaboratory Manual: MEC259 Unified Mechanical Engineering IIHimanshu Kumar Raut100% (2)

- Asl AZ - Moghavemat 18Documento44 pagineAsl AZ - Moghavemat 18eqranavidNessuna valutazione finora

- Recommended Standard Operations Procedure ForDocumento12 pagineRecommended Standard Operations Procedure Forprasadjoshi781429Nessuna valutazione finora

- Determination of Strain in A Steel Bar PDFDocumento8 pagineDetermination of Strain in A Steel Bar PDFEarl AradoNessuna valutazione finora

- Jse 2003Documento45 pagineJse 2003^passwordNessuna valutazione finora

- Tensile TestDocumento8 pagineTensile TestItzmichael EzNessuna valutazione finora

- AruanDocumento3 pagineAruanlatifuarunarashNessuna valutazione finora

- 50 FMCDocumento4 pagine50 FMCTran Tuan KietNessuna valutazione finora

- EXP4 Bending and TorsionDocumento2 pagineEXP4 Bending and Torsionaman chopraNessuna valutazione finora

- Am LabDocumento22 pagineAm LabJayavel123Nessuna valutazione finora

- Bending Moment of BeamDocumento11 pagineBending Moment of BeamAin Sherin100% (1)

- Experiment - Buckling of StrutDocumento2 pagineExperiment - Buckling of StrutKubenKrishNessuna valutazione finora

- Pile To Slab Bridge Connections: Mohamed I. Ayoub, David H. Sanders and Ahmed IbrahimDocumento10 paginePile To Slab Bridge Connections: Mohamed I. Ayoub, David H. Sanders and Ahmed IbrahimIsom Bahri BahriNessuna valutazione finora

- Transverse Shear 1Documento48 pagineTransverse Shear 1Amira SyazanaNessuna valutazione finora

- Department of Civil Engineering Lab Manual OF Structural Analysis-Ii (Ece-305)Documento30 pagineDepartment of Civil Engineering Lab Manual OF Structural Analysis-Ii (Ece-305)doktorterNessuna valutazione finora

- Shear Center of Closed SectionDocumento6 pagineShear Center of Closed SectionVijay Shet33% (3)

- Lab 11 Annotated PDFDocumento11 pagineLab 11 Annotated PDFC CNessuna valutazione finora

- Physics: Cambridge International Examinations General Certificate of Education Ordinary LevelDocumento8 paginePhysics: Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456Nessuna valutazione finora

- ME 354 - Mechanics of Materials Lab 01Documento15 pagineME 354 - Mechanics of Materials Lab 01Lei Chi HouNessuna valutazione finora

- Atp Revision Paper 6bDocumento7 pagineAtp Revision Paper 6bSuha AbdullahNessuna valutazione finora

- National Advisor Committee For Aeronautics": Technical Note NO. 1205Documento42 pagineNational Advisor Committee For Aeronautics": Technical Note NO. 1205wsjouri2510Nessuna valutazione finora

- Ramkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryDocumento34 pagineRamkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryMaynak DeyNessuna valutazione finora

- Beam BendingDocumento9 pagineBeam BendingAayush BhambureNessuna valutazione finora

- Experiment 1: Young's ModulusDocumento18 pagineExperiment 1: Young's ModulusSepi Itu IndahNessuna valutazione finora

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDa EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNessuna valutazione finora

- Velpur Undrajavarm Nowduru Jagnadhapuram Tadepalligudem Badampudi Velpur Velivennu Kamavarapukota Gopalapuram D Muppavaram Tanuku Town AdavikolanuDocumento6 pagineVelpur Undrajavarm Nowduru Jagnadhapuram Tadepalligudem Badampudi Velpur Velivennu Kamavarapukota Gopalapuram D Muppavaram Tanuku Town AdavikolanuSarath TejaNessuna valutazione finora

- GGGHHB VGHJJJB-WPS OfficeDocumento1 paginaGGGHHB VGHJJJB-WPS OfficeSarath TejaNessuna valutazione finora

- HGDZFGDFDocumento1 paginaHGDZFGDFSarath TejaNessuna valutazione finora

- Computatinal Fluid Dynamics Lab Part-ADocumento3 pagineComputatinal Fluid Dynamics Lab Part-ASarath TejaNessuna valutazione finora

- Bus CoordinatorDocumento6 pagineBus CoordinatorSarath TejaNessuna valutazione finora

- Gas Dynamics - Assignemt SolutionsDocumento53 pagineGas Dynamics - Assignemt SolutionsSsheshan Pugazhendhi100% (1)

- Unit IDocumento2 pagineUnit ISarath TejaNessuna valutazione finora

- Eeeee RDFDocumento1 paginaEeeee RDFSarath TejaNessuna valutazione finora

- HmlabDocumento38 pagineHmlabSarath TejaNessuna valutazione finora

- HJHDocumento28 pagineHJHSarath TejaNessuna valutazione finora

- Bhima VaDocumento2 pagineBhima VaSarath TejaNessuna valutazione finora

- HMT LabDocumento43 pagineHMT LabSarath TejaNessuna valutazione finora

- ME Block-Drawing Hall:: Machine Drawing Mech-BDocumento2 pagineME Block-Drawing Hall:: Machine Drawing Mech-BSarath TejaNessuna valutazione finora

- Calibration of Precision Measuring InstrumentsDocumento28 pagineCalibration of Precision Measuring InstrumentsSarath TejaNessuna valutazione finora

- Mechanics of SolidsDocumento54 pagineMechanics of Solidsarsalan_ghoraNessuna valutazione finora

- 5 UhuhgugDocumento11 pagine5 UhuhgugSarath TejaNessuna valutazione finora

- Validation 1Documento10 pagineValidation 1Sarath TejaNessuna valutazione finora

- TTT EeeDocumento2 pagineTTT EeeSarath TejaNessuna valutazione finora

- AMEM - 314 - Labs - 7 Deflection of Beams - 8 Macalay's MethodDocumento7 pagineAMEM - 314 - Labs - 7 Deflection of Beams - 8 Macalay's MethodtsunaseetNessuna valutazione finora

- Measurement of Length, Height & Diameter by Vernier Calipers, MicrometerDocumento2 pagineMeasurement of Length, Height & Diameter by Vernier Calipers, MicrometerSarath TejaNessuna valutazione finora

- Unit 2 58Documento63 pagineUnit 2 58Suresh Babu DNessuna valutazione finora

- 3.1 Width CalculationDocumento7 pagine3.1 Width CalculationSarath TejaNessuna valutazione finora

- SM 4 ExperimentsDocumento19 pagineSM 4 ExperimentsSarath TejaNessuna valutazione finora

- Introductory InformationDocumento7 pagineIntroductory InformationSarath TejaNessuna valutazione finora

- Expression of Interest Form For Setting Up Energy EnterpriseDocumento3 pagineExpression of Interest Form For Setting Up Energy EnterpriseSarath TejaNessuna valutazione finora

- Expression of Interest Form For Setting Up Energy EnterpriseDocumento3 pagineExpression of Interest Form For Setting Up Energy EnterpriseSarath TejaNessuna valutazione finora

- SssoooDocumento2 pagineSssoooSarath TejaNessuna valutazione finora

- HhoooDocumento2 pagineHhoooSarath TejaNessuna valutazione finora

- Expression of Interest Form For Setting Up Energy EnterpriseDocumento3 pagineExpression of Interest Form For Setting Up Energy EnterpriseSarath TejaNessuna valutazione finora

- R 1631014112018Documento8 pagineR 1631014112018bhanu jammuNessuna valutazione finora

- Horak - Bowl ParametersDocumento18 pagineHorak - Bowl ParametersAnonymous JYoBN3spNNessuna valutazione finora

- Analisis Struktur C4Documento47 pagineAnalisis Struktur C4Hazyema HarunNessuna valutazione finora

- Three-Storey Apartment Building With Structural Analysis: Page - 0Documento142 pagineThree-Storey Apartment Building With Structural Analysis: Page - 0Jed Christian Dagatan MedranoNessuna valutazione finora

- RC Salient PointsDocumento9 pagineRC Salient PointsJoraindo InovejasNessuna valutazione finora

- PROKON Structural Analysis and Design PDFDocumento27 paginePROKON Structural Analysis and Design PDFAL Sniper0% (1)

- Study Note - Statically Indeterminate BeamsDocumento6 pagineStudy Note - Statically Indeterminate BeamsSboniso KhethukuthulaNessuna valutazione finora

- Ros Example PDFDocumento30 pagineRos Example PDFdoutorNessuna valutazione finora

- 04 EC2WS Walraven ULSSLSDocumento104 pagine04 EC2WS Walraven ULSSLSSES DESIGNNessuna valutazione finora

- Limit State of Servicibility Is800Documento2 pagineLimit State of Servicibility Is800ANIL KUMAR PRAJAPATNessuna valutazione finora

- Beam - XLS: Shear, Moment, Angle, and Deflection Calculator For Statically Determinant Beams of Constant I and EDocumento8 pagineBeam - XLS: Shear, Moment, Angle, and Deflection Calculator For Statically Determinant Beams of Constant I and EnachiNessuna valutazione finora

- Dynamic Analysis Stranded Wire SpringsDocumento71 pagineDynamic Analysis Stranded Wire SpringsJoseph J. ZajkNessuna valutazione finora

- Sample Railing Calculation To Euro Code PDFDocumento4 pagineSample Railing Calculation To Euro Code PDFphuckha2012100% (1)

- Facade DesignDocumento34 pagineFacade Designddevilived0% (1)

- S475Documento33 pagineS475Barjam KafexhiuNessuna valutazione finora

- Structural Analysis ExampleDocumento4 pagineStructural Analysis ExampleHong VeasnaNessuna valutazione finora

- Reinforced High-Strength Concrete Beams in FlexureDocumento11 pagineReinforced High-Strength Concrete Beams in FlexureAndrei IancuNessuna valutazione finora

- Radians CalculationDocumento4 pagineRadians CalculationDonald HamiltonNessuna valutazione finora

- Example Case Study-Milwaukee Art MuseumDocumento26 pagineExample Case Study-Milwaukee Art MuseumZhihui HuangNessuna valutazione finora

- Warner R.F. - Simplified Analysis of Creep in Prestressed Concrete BeamsDocumento9 pagineWarner R.F. - Simplified Analysis of Creep in Prestressed Concrete BeamsCristóbal BerríosNessuna valutazione finora

- Unit 8 Design of Beams PDFDocumento28 pagineUnit 8 Design of Beams PDFveenuNessuna valutazione finora

- EXAMENDocumento39 pagineEXAMENAlex Asdasd MCNessuna valutazione finora

- Experimental Investigation of Load Deflection Characteristics of Beam With Various End Conditions of Different MaterialsDocumento5 pagineExperimental Investigation of Load Deflection Characteristics of Beam With Various End Conditions of Different MaterialsInternational Journal of Innovative Science and Research Technology100% (2)

- 1IRC-117 2015 Excel SheetDocumento6 pagine1IRC-117 2015 Excel Sheetniranjanchou100% (3)

- Amare Final Pro.Documento202 pagineAmare Final Pro.Alex KumieNessuna valutazione finora

- Full SynopsisDocumento12 pagineFull SynopsisAg NeerajNessuna valutazione finora

- 8-Deflection of Curved Bars: ObjectiveDocumento4 pagine8-Deflection of Curved Bars: ObjectiveMalik TaimoorNessuna valutazione finora

- Design Optimization of GFRP Pole Structures Using Finite Element Analysis PDFDocumento8 pagineDesign Optimization of GFRP Pole Structures Using Finite Element Analysis PDFAhmed TahaNessuna valutazione finora

- Nema Standard Ve 1: 1. Load Capacity and Safety FactorDocumento3 pagineNema Standard Ve 1: 1. Load Capacity and Safety FactorNguyễn TấnNessuna valutazione finora

- IGJ - 17 - 03 - 249-258 Ramasamy Gopal Ranjan Modifications To The IS Method For Lateral Capacity of PileDocumento10 pagineIGJ - 17 - 03 - 249-258 Ramasamy Gopal Ranjan Modifications To The IS Method For Lateral Capacity of Pileu19n6735Nessuna valutazione finora