Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Julie Skiff

Caricato da

Dan100%(1)Il 100% ha trovato utile questo documento (1 voto)

159 visualizzazioni4 pagineNotes

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoNotes

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

159 visualizzazioni4 pagineJulie Skiff

Caricato da

DanNotes

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

The intheboatshed.

net Julie skiff

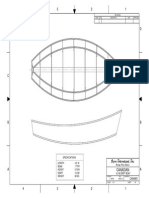

15ft 6in length overall by 4ft beam, by 450lbs displacement and 33.5sq ft wetted area, designed for stitch and

glue construction using 46mm 4ft by !ft plywood

This boat has been designed by an amateur with no qualifications in boat design or boatbuilding and should be

regarded as experimental until several have been built. The designer accepts no liability for any loss or accident

that may result from following these instructions or their attendant plans or from any loss or accident that may

follow from using the boat.

- Design points

The "ulie s#iff as laid out in these plans is a lightweight stitch and glue flattie skiff that would be a nice rower for

one and can carry two at a pinch. The name came from my partner, who took rather a shine to the boat.

It's designed easy to build and use, to be a pleasure to row, easy on the eye, and to be dry and comfortable. I've

drawn what I consider to be a very attractive sheerline, a moderately large transom that should keep out

following waves, and a bows intended to lift over oncoming swells.

Another feature designed for comfort is the sunken foredeck, which drains back into the water and not into the

boat. It's intended to provide a convenient space to put potentially wet and mucky things such as a painter or a

small anchor and rode, and will also redirect splashes back into the water. If anyone wishes to sit at the front of

this little boat, they'll have to sit on the bottom, but I don't think that will be any great loss.

n the lines, I have to say that I've never known a small boat design that defined itself as this one did. In fact,

within the confines of the beam, length and displacement there weren't too many options for making a new flattie

skiff that was radically different or better than many of the existing designs. !evertheless, the "ulie s#iff is all my

own work and does not share her lines or construction with any other existing skiff design that I know about. Any

similarities with other boats that may be found by others are purely coincidental.

"y approach has been to make the forward lines fairly straight, while making those aft more curvy in order to

place the centre of bouyancy in the conventional place, a little aft of the half way mark. This approach seems to

have worked well with another design of mine, the #ight Trow, which is another light$displacement flattie design

of about this si%e and is reported to row very well.

I've also varied the flare $ the angle between the sides of the boat and its bottom $ throughout the length of the

boat. In the forward quarter of the boat flare has been used to create a shape that will turn back small waves,

while at the centre of the boat it is reduced in order to work in the necessary displacement.

&urther aft, however, it has been allowed to increase again in an attempt to reduce the potential for the hard

chine to create eddies, and also to ensure that the stern has plenty of bouyancy if the user wishes to transport

something heavy $ or someone heavy $ in the stern.

- Construction issues

$eaders may with to read my boo# Ultrasimple Boatbuilding published by International Marine and available

from high street and online boo#stores.

'efore going any further, it's important to check the si%e of the plywood available to you, as it comes in different

si%es in different countries around the world. A sheet of ply in the () and the (*A is likely to be +ft ,-../mm0

wide, and 1ft ,.++/mm0 or a little more in length, and this is the si%e these plans are made for. 2owever, in the

rest of the world including Australia, !ew 3ealand an continental 4urope ply si%es can vary considerably.

I'd like also to emphasise the importance of model$making. The download package for this boat includes

drawings intended to be used to make a model, and I'd ask you to please make a model first as it will show you

first how the boat will look but perhaps more importantly how each component part goes together and

contributes it's pennyworth towards creating a usable boat with a rigid structure.

The system of coordinates I use to define the shapes of the panels on the + by 1ft plywood panels is the aspect

of the plans most likely to cause fear, uncertainty and doubt. This is simply because the approach seems

unfamiliar, but in fact the technique is the same as the one most of us used to draw graphs when we were at

school $ though I'd argue that building a boat is a darn site more fun than maths lessons.

4ach pair of coordinates describes a particular point on a plywood sheet. The first number ,the 5$coordinate0 in

each pair of coordinates is a measurement along the bottom of the sheet, while the second in the pair ,the 6

coordinate0 is a measurement up from the bottom $ that is along a line that is a right angle ,or 7/ degrees0 from

our point along the bottom.

'efore plotting each of these coordinates one by one, I find it best to square off the material into twelve$inch

squares, as it's so much easier to plot from your squaring off than it is to mark out each measurement from the

panel edge, but also because it helps to show whether you material is really 1ft long.

8ly is frequently a little longer than it's supposed to be, and if you don't remove the extra before starting to build

the boat, you could be in trouble, with some components longer than others.

&or squaring off ply, I often like to use a drywall square, but a tape measure and the side and edge of another

sheet of plywood will do the 9ob perfectly well, if slightly less conveniently.

nce the lines have been drawn, you need to draw your cutting lines. I do this by first finding a flexible batten to

help re$create create the curves, and I've found that perhaps the best thing to use is an 1ft plastic moulding of

the kind one can buy in any do$it$yourself story.

To make the curves, drive small nails into the material at each of the plotted points, lay the batten along the nails,

using weights to hold it up to the nails. :hen the batten is in place and reasonably secure, draw along the length

of the cutting line using a soft carpenter's pencil. After a few hours of plotting and drawing, you should be able to

see that the lines on your ply correspond to those on my plans.

A final word of warning on marking out. There are a lot of coordinates to plot here, and that means there are a lot

of opportunities to make mistakes, both for the builder and for the designer. If when you have plotted the points

and drawn the lines there are any that don't look right, check them, and check them again. ;emember the old

carpenter's advice that one should measure two or three times before cutting once. If after all this checking

you're in doubt that I may have made an error please contact me at gmatkin<clara.net $ I don't want you to risk

wasting material unnecessarily because of a mistake I have made.

The next 9ob is to cut the material out, and to build the boat using the stitch and glue boatbuilding method,

otherwise known as tack and tape construction.

Anyone who has used this method before will see immediately how it will work with this design, but if any of you

reading this haven't worked this way before I won't explain it here but I would recommend reading it up at almost

any epoxy supplier's website. ne example is the () 4poxy website= http=>>www.epoxy$resins.co.uk>.

I'd make only three general construction points.

&irst, these drawings have been created with the intention that the fore and aft sections of the bottom and sides

should be 9oined by epoxy tape on either side of the 9oin, rather than using butt blocks or a scarf. I often prefer

this method for several reasons= it's easy, it allows me to get the longest boat possible from two sheets of ply,

and unlike using butt blocks, I don't afterwards have to cut the thickness of the butt block from any frames they

happen to coincide with. If you do build this boat using butt blocks, you'll no doubt have to cut some material

from the central frames to make up.

*econd, the bows of this lightweight boat have no special reinforcing. This is because builders working in stitch

and glue are expected and advised to reinforce the inside of the bows with several layers of epoxy and tape

instead of the usual single layer. I'd suggest applying a single layer of tape, then two further layers laid each to

either side, and finally a fourth and perhaps a fifth layer of tape over the 9oint on the centreline. 4ach layer of

tape should be extended onto the bottom of the boat to make a smooth and strong 9oint, with each layer of tape

extend s little further aft. f course, if you'd rather make a false stem to fit on the inside of the bows, that's fine

with the designer, but please don't forget to include a knee against the bottom and foredeck.

Third, once the sides are bent around the frames, you'll find that the sides become slightly curved where they

meed the frames, and that there will be a small gap between the frame and the side$plank. That's only to be

expected from the geometry of the side planks. All you have to do is to make sure this gap gets well filled with

epoxy and covered over with tape in the usual way. The 9oint will be as strong or stronger than a similar 9oint with

no small gap.

There are a several special construction features of this boat that require a little explanation.

%oredec# scuppers There are two drains or scuppers on each side of the boat at the aft end of the foredeck.

These aren't absolutely essential but I think they should be cut after the boat has been assembled in order to

prevent water accumulating in the sunken foredeck. The holes for the drains should be .$?in in length by - in

from top to bottom.

&nwales and frames I'm very much in favour of gapped inwales, which can be made to look as they appear in the

drawings $ they make a boat very rigid, and they look good. A typical gapped inwale might be made up of a -.@

deep by -in wide inwale ,I'd make these up from two - by ->.in laths laminated together0 on -in square spacers

at -.$-Ain distancesB of course, you'll have to ad9ust your spacing and notch the frames so that the inwales fit

nicely into them.

2owever, in a rowing boat built to this design they may not be strictly necessary, so long as you enlarge the

gunwales to make up for the loss. I'd suggest laminating two lengths of - by - ->.in material to make a gunwale

that's close to two inches wide. If you decide to go without the inwale, you'll find that the frames I've drawn leave

a hard corner that you will want to round off.

'reasthoo# and quarter #nees If you build with inwales, you'll need to cut them down to accept the breasthook

and the quarter knees, but if you build with a heavier external gunwale, I'd suggest they can be attached by

simple stitch and glue. The breasthook and quarter knees I've drawn here represent the minimum, by the way C

if you'd like to make them larger and more elegant, perhaps with a curved form, go ahead but try not to cut into

the minimum area I've defined.

(imber holes I've drawn large$ish limber holes in the centre of each frame. These are optional and I'd probably

prefer to seal up these areas, fit drain plugs or rotating hatches in pairs and use them for built in bouyancy and

dry storage. 2owever, others will prefer to include the limber holes in order to keep rot to a minimum, and yet

others working with stitch and glue construction may prefer to site them at the chines, so long at they're using @$

Amm ply. The limber holes I've drawn will also be particularly useful to those builders who decide to build this

boat from material lighter than the @$Amm the designer envisaged, as it will allow them to build in a keelson for

most of the length of the boat.

)oubled stern *terns have to be strong and I'd prefer to double this part of the boat. 2owever if this boat is build

in @$Amm ply, is to be rowed only ,that is, not sculled, sailed or driven using an outboard0, and won't ever be

used for towing another boat, the double$thickness stern may be dispensed with.

*ositioning of oarloc#s I haven't drawn a position for the oarlocks as this can be a matter of taste. The standard

is that they should be about -.in aft of the aft edge of the transom, but some argue this distance should be the

length of the rower's forearm, and this may be particularly important for taller rowers. arlocks should be

mounted on solid blocks of 1$-.in in length, @in in depth and .in thick or so. They will have to be shaped to

match the curve of the boat, and if you are using gapped inwales they should be cut so that they fit into the

inwale and can be glued to it ,with the gapped inwale installed first, naturally0.

+hwart If there is anywhere on this boat where a piece of good quality timber with nicely shamfered or rounded

edges, this may be it. Think of the hours you're looking forward to spending on itD

,ar length There are a lot of views about oar length. *ome say the length of an oar should be of half the beam

,from lock to lock0 times three, plus A inches ,Aft Ain0, others that the length of an oar from lock to grip should be

half the beam times three plus . inches ,Aft .in0, still others use much more complicated calculations based on

the speed of the boat and how lightly it rows. 2owever, I'd say about Eft will be perfectly acceptable where this

boat is concerned.

+rim line In some of the drawings I've included a piece of ->.in material @in below the lower edge of the

gunwale, starting the same distance back from the bows and running all the way to the stern. I'd suggest it

makes an elegant decoration, but adds little to the structure of the boatD

%oot brace If the boat is to be used as a tender, a foot brace might get in the way, but if it is to be used for

pleasure rowing, then I'd suggest knocking up a a comb and using something like the drawing below=

Potrebbero piacerti anche

- The New Picnic Cookbook - A Picn - BookSumo PressDocumento205 pagineThe New Picnic Cookbook - A Picn - BookSumo PressDan100% (1)

- Ultrasimple Boat Building: 18 Plywood Boats Anyone Can BuildDa EverandUltrasimple Boat Building: 18 Plywood Boats Anyone Can BuildValutazione: 4.5 su 5 stelle4.5/5 (2)

- Instant Boatbuilding with Dynamite Payson: 15 Instant Boats for Power, Sail, Oar, and PaddleDa EverandInstant Boatbuilding with Dynamite Payson: 15 Instant Boats for Power, Sail, Oar, and PaddleValutazione: 4.5 su 5 stelle4.5/5 (3)

- 16 Foot Apache Outboard - PlansDocumento8 pagine16 Foot Apache Outboard - PlansRolando DaclanNessuna valutazione finora

- Construction Techniques, Stitch and Glue or Plywood On Frame - SpiraDocumento3 pagineConstruction Techniques, Stitch and Glue or Plywood On Frame - SpiraSean Conley100% (1)

- t3 Free PlansDocumento46 paginet3 Free PlansDan100% (1)

- A Practical Course in Wooden Boat and Ship BuildingDa EverandA Practical Course in Wooden Boat and Ship BuildingValutazione: 4 su 5 stelle4/5 (1)

- Pippie8Tender PDFDocumento32 paginePippie8Tender PDFleonel montillaNessuna valutazione finora

- Model: Length: Hull Weight: Beam: Max Payload: Rowing Draft: Sailing Draft: Sail AreaDocumento8 pagineModel: Length: Hull Weight: Beam: Max Payload: Rowing Draft: Sailing Draft: Sail AreaMariusz Piotr TorchałaNessuna valutazione finora

- 8ft Handy AndyDocumento6 pagine8ft Handy AndyAlphamatrix01100% (2)

- 095-067 - Build A Bent-Plywood KayakDocumento5 pagine095-067 - Build A Bent-Plywood Kayakkkd108100% (3)

- BSA Kayak PlansDocumento25 pagineBSA Kayak PlansTodd R Taylor50% (2)

- Crouch HydroDocumento12 pagineCrouch HydroKeith WilliamsNessuna valutazione finora

- Aquaply OnesheetdingyDocumento3 pagineAquaply OnesheetdingyJim100% (3)

- TeslinDocumento9 pagineTeslinJim100% (2)

- Mason 33 Practical ReviewDocumento5 pagineMason 33 Practical ReviewManuelPérez-Sola100% (1)

- AYRS Projects - A.Y.R.S. Publication No.112, 1993Documento72 pagineAYRS Projects - A.Y.R.S. Publication No.112, 1993VitBarNessuna valutazione finora

- Mistral HullDocumento5 pagineMistral HullmikeNessuna valutazione finora

- ZF Marine Propellers 18 enDocumento12 pagineZF Marine Propellers 18 enThant SinNessuna valutazione finora

- Notice: Spira International, IncDocumento2 pagineNotice: Spira International, InclcortezbrNessuna valutazione finora

- The Jersey Albatross - A Free-Flight Model Airplane (Glider)Documento4 pagineThe Jersey Albatross - A Free-Flight Model Airplane (Glider)Bob Kowalski100% (1)

- Trixie 7 Dinghy - Study PlansDocumento16 pagineTrixie 7 Dinghy - Study Planssaiga30894170% (1)

- 22ft BoatDocumento14 pagine22ft BoatDaniel Bagiński75% (4)

- Build StornDocumento7 pagineBuild Storndavidantoni100% (2)

- Renault Megane-Scenic 1996-2002 GeneralDocumento40 pagineRenault Megane-Scenic 1996-2002 GeneralDanNessuna valutazione finora

- Nine Motor Boats and How To Build ThemDocumento136 pagineNine Motor Boats and How To Build ThemMaxi Sie100% (1)

- DolphinDocumento5 pagineDolphinAlphamatrix01Nessuna valutazione finora

- Kiwi PDR: Instructions & Drawings by John WelsfordDocumento30 pagineKiwi PDR: Instructions & Drawings by John WelsfordJUAN PABLO MORENONessuna valutazione finora

- How To Plank The Hull of A Sharp Bow Model ShipDocumento22 pagineHow To Plank The Hull of A Sharp Bow Model Shiproman5791100% (2)

- Yacht Designing and Planning for Yachtsmen, Students and AmateursDa EverandYacht Designing and Planning for Yachtsmen, Students and AmateursValutazione: 5 su 5 stelle5/5 (1)

- The 23.5ft Light Schooner Full PlansDocumento7 pagineThe 23.5ft Light Schooner Full PlansAlphamatrix01100% (1)

- Build A Boat!: Step 1: Materials SelectionDocumento9 pagineBuild A Boat!: Step 1: Materials SelectionDan0% (1)

- Concrete Construction Article PDF - Ferro-Cement YachtDocumento3 pagineConcrete Construction Article PDF - Ferro-Cement Yachtrafael espinosa semperNessuna valutazione finora

- Seafoam Kayak The Unsinkable Foam Kayak Anyone CanDocumento42 pagineSeafoam Kayak The Unsinkable Foam Kayak Anyone Canecalzo100% (1)

- Sabot 8 FT Pram DinghyDocumento6 pagineSabot 8 FT Pram DinghyFrenchwolf420100% (2)

- Two DoriesDocumento10 pagineTwo DoriesAlphamatrix01Nessuna valutazione finora

- Hull Building BoardDocumento19 pagineHull Building BoardAlexander Florin100% (1)

- A Model Boat Builder's Guide to Sail Making - A Collection of Historical Articles on the Planning and Construction of Model SailsDa EverandA Model Boat Builder's Guide to Sail Making - A Collection of Historical Articles on the Planning and Construction of Model SailsNessuna valutazione finora

- Greenhill B Archaeology of The Boat A New Introductory StudyDocumento324 pagineGreenhill B Archaeology of The Boat A New Introductory StudyΝικολαος Βλαβιανος100% (1)

- Dudley Dix-Dudley Dix Design Cape Henry 21 Sailboat Boat Yacht Plan Plans-WoodenBoat Magazine (2010)Documento6 pagineDudley Dix-Dudley Dix Design Cape Henry 21 Sailboat Boat Yacht Plan Plans-WoodenBoat Magazine (2010)cochelo777100% (2)

- Pudgy A 12 Foot Canvas Runabout Boat PlansDocumento5 paginePudgy A 12 Foot Canvas Runabout Boat PlansJim100% (5)

- Rolling Home by John WintersDocumento3 pagineRolling Home by John WintersSwift Canoe And Kayak100% (1)

- South Haven Dory PlansDocumento9 pagineSouth Haven Dory PlansAlphamatrix01Nessuna valutazione finora

- Universal TheosophyDocumento132 pagineUniversal TheosophyDanNessuna valutazione finora

- Building A Wood Epoxy SharpieDocumento12 pagineBuilding A Wood Epoxy SharpieAmy Rodriguez0% (2)

- How To Make A Batwing Sail PDFDocumento2 pagineHow To Make A Batwing Sail PDFTom BeeNessuna valutazione finora

- Unsinkable UniboatDocumento6 pagineUnsinkable UniboatJim100% (4)

- Boat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsDa EverandBoat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsValutazione: 1 su 5 stelle1/5 (1)

- Le Ptit GrosDocumento10 pagineLe Ptit GrosKeith Williams100% (1)

- Project PaltusDocumento22 pagineProject PaltusJoao CalinhoNessuna valutazione finora

- Various Part of The Ship: WEEK 2, 3, and 4Documento9 pagineVarious Part of The Ship: WEEK 2, 3, and 4Cazy DuabanNessuna valutazione finora

- River Boat Built For White WaterDocumento5 pagineRiver Boat Built For White WaterJim100% (2)

- Duck SkiffDocumento61 pagineDuck SkiffKay Pratt100% (2)

- How To Build A Wood Paddle BoardDocumento8 pagineHow To Build A Wood Paddle BoardJavi JaviNessuna valutazione finora

- DIY Kitchen Island: Tools ListDocumento14 pagineDIY Kitchen Island: Tools ListDanNessuna valutazione finora

- Barton Skiff... 15ft 4in, by 4ft 8in, by 650lbs Displacement Outboard SkiffDocumento9 pagineBarton Skiff... 15ft 4in, by 4ft 8in, by 650lbs Displacement Outboard SkiffStanlei FernandaNessuna valutazione finora

- Guenther GarveyDocumento4 pagineGuenther GarveyJim100% (1)

- Polytarp Sprit-Boom Sail 101 - Todd BradshawDocumento11 paginePolytarp Sprit-Boom Sail 101 - Todd BradshawJames Deboo100% (1)

- Lopez vs. DurueloDocumento2 pagineLopez vs. DurueloKrizzia GojarNessuna valutazione finora

- Simple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardDa EverandSimple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardNessuna valutazione finora

- Fast Rescue BoatsDocumento74 pagineFast Rescue BoatsAmit Pandey83% (6)

- Canoe and Kayak Building the Light and Easy Way: How to Build Tough, Super-Safe Boats in Kevlar, Carbon, or FiberglassDa EverandCanoe and Kayak Building the Light and Easy Way: How to Build Tough, Super-Safe Boats in Kevlar, Carbon, or FiberglassNessuna valutazione finora

- Devlopment of The Rêvo Wasp 743 PDFDocumento14 pagineDevlopment of The Rêvo Wasp 743 PDFrobertoNessuna valutazione finora

- 'Blondie' (8'4" X 4'3") 2001-John Bell, Kennesaw, GA JMB-002Documento13 pagine'Blondie' (8'4" X 4'3") 2001-John Bell, Kennesaw, GA JMB-002Isaac Perez Garcia100% (1)

- Adjective Order WorksheetDocumento2 pagineAdjective Order Worksheetraquelgonzalezpalacios100% (1)

- Design and Build Dinghy Manual 2020Documento78 pagineDesign and Build Dinghy Manual 2020Joao Calinho100% (2)

- Sailing CanoeDocumento2 pagineSailing CanoeFrenchwolf420Nessuna valutazione finora

- The Pippie Tender: Mike Waller Yacht Design PO Box 383 Morayfield Brisbane, QLD, AustraliaDocumento0 pagineThe Pippie Tender: Mike Waller Yacht Design PO Box 383 Morayfield Brisbane, QLD, AustraliaacastromNessuna valutazione finora

- Max JonDocumento2 pagineMax Jontwinscrewcanoe100% (1)

- Burritos Ingredients: Sausage and Egg CasseroleDocumento17 pagineBurritos Ingredients: Sausage and Egg CasseroleDanNessuna valutazione finora

- How To Replace An Engine Air Filter On Mercedes W245Documento15 pagineHow To Replace An Engine Air Filter On Mercedes W245DanNessuna valutazione finora

- Canadian Metric StudyDocumento2 pagineCanadian Metric StudyDanNessuna valutazione finora

- 23 Mai 2014 Desfasurator MatinalDocumento1 pagina23 Mai 2014 Desfasurator MatinalDanNessuna valutazione finora

- DocDST2000 EnglishDocumento12 pagineDocDST2000 EnglishDanNessuna valutazione finora

- Successful Goose FarmingDocumento14 pagineSuccessful Goose FarmingDanNessuna valutazione finora

- 2021 Avalon Catalog ReducedDocumento76 pagine2021 Avalon Catalog ReducedOtithi AlifNessuna valutazione finora

- Manual GTR57JYF-specDocumento6 pagineManual GTR57JYF-specAmanda ViverosNessuna valutazione finora

- Basic Ship TerminologiesDocumento15 pagineBasic Ship Terminologiesobaidullah khanNessuna valutazione finora

- Tenders ToysDocumento14 pagineTenders ToysPaolo VelcichNessuna valutazione finora

- Moral DilemmasDocumento6 pagineMoral DilemmasOwais Afzal JanNessuna valutazione finora

- 60F 70B 90A Manual YamahaDocumento215 pagine60F 70B 90A Manual YamaharenatoNessuna valutazione finora

- Klbasshoundmanual (PDF Library)Documento10 pagineKlbasshoundmanual (PDF Library)halimNessuna valutazione finora

- CaballeroDocumento3 pagineCaballeroNicoara VladNessuna valutazione finora

- Fixed Pitch Propellers: Marine Propulsion SystemsDocumento8 pagineFixed Pitch Propellers: Marine Propulsion SystemsKevin TrujilloNessuna valutazione finora

- National Standard For Commercial Vessels: Australian Transport CouncilDocumento26 pagineNational Standard For Commercial Vessels: Australian Transport CouncilCarl FranksNessuna valutazione finora

- BG Product Identification and AT Status V1.3Documento30 pagineBG Product Identification and AT Status V1.3BetaLavalNessuna valutazione finora

- Siop Revised Template 2017Documento3 pagineSiop Revised Template 2017api-346333308Nessuna valutazione finora

- BoatDocumento21 pagineBoatsuperheroblackduckNessuna valutazione finora

- CC Marine 2013-14 Catalogue - SeatingDocumento34 pagineCC Marine 2013-14 Catalogue - SeatingGregGGHNessuna valutazione finora

- 2015 Catalog Med Res PDFDocumento40 pagine2015 Catalog Med Res PDFdavidNessuna valutazione finora

- LB Winch Final DW Part IDocumento10 pagineLB Winch Final DW Part IMUHAMMED ANEESNessuna valutazione finora

- MYP Portfolio Scaffolds WordDocumento27 pagineMYP Portfolio Scaffolds Wordjdeng25Nessuna valutazione finora

- ENGLISH FOR MARITIME - Group 4Documento8 pagineENGLISH FOR MARITIME - Group 4MukhlisIbrahimNessuna valutazione finora

- Kok OlogyDocumento14 pagineKok OlogyDhiraj PatilNessuna valutazione finora

- Incident Report BlankDocumento5 pagineIncident Report BlankVictorAblan182Nessuna valutazione finora

- Aquastar Ocean Ranger 38 LodsenDocumento16 pagineAquastar Ocean Ranger 38 Lodsenp752h52n5kNessuna valutazione finora