Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Li Ion Vs Lead Acid

Caricato da

dchattaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Li Ion Vs Lead Acid

Caricato da

dchattaCopyright:

Formati disponibili

Li-Ion vs.

Lead Acid

2 Ultralife Corporation

Summary of Li-Ion advantages compared to Lead Acid

Li-Ion Advantages

Higher voltage in Lithium Ion over Lead Acid 3.7v vs 2.0v (almost 2x)

Greater Energy Density per unit Weight (3x), Volume (6x)

Lighter / smaller providing more portability, less storage space, could even eliminate storage boxes

Tolerates Higher Temp (140F vs 80F), No Air Conditioning required (vs spending 10% of capacity)

Faster recharge time, and More time between recharges (26 wks vs continuous or max 2 wks)

Higher turnaround charge efficiency (97% vs 75%)

More Discharge Cycles (2x)

Deeper Discharge Tolerance (95% vs 50%) Can offset cost due to shallow Lead Acid discharge

State of Health and State of Charge can be readily and remotely monitored

Longer time between service (24-36+mos vs 6 mos)

Replacement timeframe Li-Ion 5-7 years Lead Acid 1.5 - 2 years

Li-Ion Disadvantages

Li-Ion Protection Circuitry is custom & expensive

Lead Acid Overall Circuitry is Commercial off the Shelf (COTS) & inexpensive

Li-Ion volatility must be closely managed and addresses with safety considerations in design

Individual Cell cost ROM Li-Ion $300-$400 / kWhr vs Lead Acid $80-$100 / kWhr

Sys Cost (with circuitry) ROM $500 / kWhr $125 / kWhr

3 Ultralife Corporation

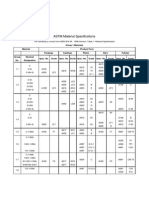

Details of Comparison: Lead Acid - Li-Ion

Lead Acid Li-Ion (Cobalt)

Energy Density

Nominal Cell voltage 2.0v 3.7v

Voltage operating range 1.8-2.1v 3.2-4.1v

Wh/kg 35-40 140-150

Wh/liter 70 400

Size of a 1 kWh battery 14 Liters 2.5 Liters

873 cubic inches 153 cubic inches

Weight of a 1 kWh battery 25kg, 55lbs 6.7kg, 14.8 lbs

Size of a 1 MWh battery 14,285 Liters, 2,500 Liters,

504 cubic feet 88 cubic feet

(1/2 of a 20 shipping container)

Weight of a 1 MWh battery 25,000kg, 6,700kg,

55,115 lbs 14,770 lbs

Reference sizes and weights

20 Ft Shipping container 1160 cu ft, 4928 lbs

40 Ft Shipping container 2360 cu ft, 7392 lbs

4 Ultralife Corporation

Details of Comparison: Lead Acid - Li-Ion

Lead Acid Li-Ion (Cobalt)

Temperature Requires Air temp Control >75F

Loses 50% every 10F >77F

High temp Survival / Life Reduction OK to 25C (77F) OK to 60C (140F)

Life % remaining at Disch Temp 100% at 77F 100%

50% at 87F 100%

25% at 97F 100%

12% at 107F 100%

6% at 117F 100%

3% at 127F 100%

0% at 137F (60C) 100%

Low Temp (Partial Functionality) To -40C To -25C

Charging

Over-chargeability Tolerant (forms H

2

gas) Intolerant - Vents

Protection Circuitry COTS, inexpensive Custom, expensive

(Overvoltage and Discharge)

Constant Charging rate in terms of C 0.07C rate C rate (10x faster)

Recharging time duration 10 x the capacity 1x the capacity

Recharge interval needs recharge weekly needs recharge every 6 mos

Turnaround Charge Efficiency 75% 97%

Temp range of Charge -40C (-40F) +27C (80F) -20C (-4F) +55C(131F)

Cost to recharge (as % of capacity)

Self Discharge %/month or year 8%/month, 63%/year 1.5%/month, 17%/year

5 Ultralife Corporation

Details of Comparison: Lead Acid - Li-Ion

Lead Acid Li-Ion (Cobalt)

Operation

Voltage profile (during discharge) Sloping Flat

Failure mode will not accept charge predictive based on cycles

(assumes traditional control circuits) and efficiency

Cycles

At 10% discharge 1750 4000+

At 50% discharge 500 1000

At 95% discharge 250 500

State of charge measured by Voltage level Coulombs transferred

Rough Exact

Costs

Cell cost $80-$100 / kWhr $300-$400 / kWhr

Assembled Sys Cost (with circuitry) $125 / kWhr $500 / kWhr

Maintenance costs and frequency SLA =2% None

VRLA=10%

Operating costs

Air conditioning 8% of capacity None required

Service Interval 6 mos 12 mos

Replacement timeframe 2 years 5-7 years

Assumes life is not limited by number of discharge cycles, instead by time

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Kashmiri Rituals Kah-NaetherDocumento1 paginaKashmiri Rituals Kah-NaetherdchattaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Tonight I Can Write (The Saddest Lines) : Pablo NerudaDocumento2 pagineTonight I Can Write (The Saddest Lines) : Pablo NerudadchattaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- ASTM Material SpecificationsDocumento1 paginaASTM Material SpecificationsdchattaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- PoetryDocumento3 paginePoetrydchattaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Machhail MataDocumento2 pagineMachhail MatadchattaNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- As 2402.1.1-2005 Traction Batteries - Lead-Acid Vented Cells - RequirementsDocumento7 pagineAs 2402.1.1-2005 Traction Batteries - Lead-Acid Vented Cells - RequirementsSAI Global - APACNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Service LetterDocumento9 pagineService Letter风压缩100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Handbook - AGM, Part 2, Edition 7, Jan - 2012 PDFDocumento51 pagineHandbook - AGM, Part 2, Edition 7, Jan - 2012 PDFCarlos SopasNessuna valutazione finora

- Service Manual: Developed and Collected By: Done/Techn. Doc - LTDocumento139 pagineService Manual: Developed and Collected By: Done/Techn. Doc - LTRomanNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- S 2807914Documento4 pagineS 2807914Rafat ThongNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Iec 60095 7 2019Documento13 pagineIec 60095 7 2019udwzxcapxnrttqybixNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- BatteryDocumento46 pagineBatterysssenaka100% (2)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Proposal Title: Design and Construction of 12V Car Battery Charger Circuit With Phone Charging USB PortDocumento22 pagineProposal Title: Design and Construction of 12V Car Battery Charger Circuit With Phone Charging USB PortobaidNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Electrical General Ipcl-Mgcc SMP No: NC/MAINT/ELE/2041 Battery ChargingDocumento2 pagineElectrical General Ipcl-Mgcc SMP No: NC/MAINT/ELE/2041 Battery ChargingFarooq SiddiquiNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Ata 24. Electrical As-03-02 (Plan-05)Documento117 pagineAta 24. Electrical As-03-02 (Plan-05)faisal100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Toyama Battery ManualDocumento5 pagineToyama Battery ManualmarckalhiNessuna valutazione finora

- AURETR025 - Assessment 1 - Written Knowledge Questions - V2Documento23 pagineAURETR025 - Assessment 1 - Written Knowledge Questions - V2Nikhil Dhawan100% (1)

- ELC-SU-6026-B.1 Flooded-Cell Lead-Acid Batteries For Electrical StationsDocumento5 pagineELC-SU-6026-B.1 Flooded-Cell Lead-Acid Batteries For Electrical StationsOSSAI IFEANYI ANTHONYNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Automotive BatteryDocumento45 pagineThe Automotive Batteryمحمد القدوميNessuna valutazione finora

- Battery and SwitchDocumento21 pagineBattery and SwitchJulius BoitizonNessuna valutazione finora

- Solar LED Street Light - Technical SpecsDocumento3 pagineSolar LED Street Light - Technical SpecsPrathesh Kumar MNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Grid Power VH Brochure enDocumento6 pagineGrid Power VH Brochure enAlexandru GaşpărNessuna valutazione finora

- Craft & Technique: A Pulse DesulfatorDocumento4 pagineCraft & Technique: A Pulse DesulfatorIon Marius100% (1)

- TS21TS1182817 - Baterias 12 V GSCB003Documento19 pagineTS21TS1182817 - Baterias 12 V GSCB003diegofer1Nessuna valutazione finora

- Battery Charger Basics - ChargetekDocumento4 pagineBattery Charger Basics - ChargetekgeonoNessuna valutazione finora

- VRNM Nickel-Cadmium Battery: Ultimate Ultra-Low Maintenance SolutionDocumento7 pagineVRNM Nickel-Cadmium Battery: Ultimate Ultra-Low Maintenance SolutionchetanNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- EnerSys Mseries SpecsDocumento2 pagineEnerSys Mseries Specsibs434Nessuna valutazione finora

- Research Article: Quality Control of Lead-Acid Battery According To Its Condition Test For UPS Supplier and ManufacturersDocumento11 pagineResearch Article: Quality Control of Lead-Acid Battery According To Its Condition Test For UPS Supplier and ManufacturersbenaliNessuna valutazione finora

- Energy Storage LawDocumento17 pagineEnergy Storage LawKushal MishraNessuna valutazione finora

- Ev 1Documento11 pagineEv 1pepgoteNessuna valutazione finora

- Battery InformationDocumento3 pagineBattery InformationDean OriendNessuna valutazione finora

- Autumn 2018Documento14 pagineAutumn 2018Sudipto Ranjan DassNessuna valutazione finora

- High Rate Series: CCB 12HD-310Documento1 paginaHigh Rate Series: CCB 12HD-310orunmila123Nessuna valutazione finora

- Voltage Standby Rating (Esp) Prime Rating (PRP) PFDocumento8 pagineVoltage Standby Rating (Esp) Prime Rating (PRP) PFCristhian ChoqueNessuna valutazione finora

- LPS 1240-Issue 1.1-Requiremects For LPCB Approved Fire Sprinkler Pump Set Used in Automatic Sprinkler Installations PDFDocumento14 pagineLPS 1240-Issue 1.1-Requiremects For LPCB Approved Fire Sprinkler Pump Set Used in Automatic Sprinkler Installations PDFHazem HabibNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)