Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

US942699 Bakelite

Caricato da

bobokor0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni3 pagineji

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoji

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni3 pagineUS942699 Bakelite

Caricato da

bobokorji

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

. i s a s peci ?ca ti on.

' UNITED S TA TES , PA TENT cl a r i on.

LEO H . BA EKELA ND, 0 F _ . Y ONKEBS , NEW v Y OR K.

ms r non or MA KING INS OLUBLE r a onu c' r s or r r r eu on A ND ' r onmnnmr ,

9 4 2 , 6 9 0 .

No Dr a wi ng. - ' .

To a l l whom i t ma y concer n:

l l e i t known tha t 1 , Leo II. Ba r nes / mo,

a ci ti z en of the Umtcd S ta tes , r es i di ng a t.

S nu g l l ock, , . ' l l a r mony l a r l c, Y onker s , i n

the cou nty of \ \ " es tches ter a nd S ta te of New

Y or k, ha v e i nv ented cer ta i n new a nd u s ef u l .

l mpr ov emeu ts - i n Methods of Ma ki ng l i t-

s ol u b l e C ondens a ti on l r odu cts ' ot l henol s

a ml l t or ma l dchj yde, of whi ch the f ol l owi ng

i n my pr i or a ppl i ca ti on S er f No . 3 5 8 , 1 5 6 ,

i i l ed l t eb r u a r y l b , 1 9 0 ?, l ha v e des cr i b ed

a nd cl a i med a method of i ndu r a ti ng, r l i b r ou s

or cel l u l a r . ma ter i a l s whi ch cons i s ts i n i m

pr egna ti ng or mi x i ng them wi tha phenol i c

b ody a nd f or ma l dehyde, a nd ca u s i ng the

s a me to r ea ct. wi thi n the b ody of the ma te

r i a l to yi el d a n i ns ol u b l e i u du r a ti ng con

' dens a ti on J n' otl nct, the r ea cti on b ei ng a ccel

es n' cd b y the u s e of hea t or con. .

er u tcd i t

( l ens i ng a gents . i n the cou r s e of thi s r e

a cti on cons i der a b l e q u a nti ti es of wa ter a r e

pr odu ced, a nd a dr yi ng oper a ti on i s r es or ted

to to ex pel i t. - _ _ -

The pr es ent. i nr eu ti on r el a tes toi the pr o

du cti on of ha r d, i ns ol u b l e a nd i nf u s i b l e con

dens a ti on pr odu cts of phenol s a nd f or ma l

dehyde. ' -

l n pr a cti ci ng the i nv enti on 1 - r ea ct u pon.

a phenol i c b ody wi th f or ma l dehyde to ob

ta i n a r ea cti on n' odnct whi ch i s ca pa b l e of

tr a ns f or nmti on y hea t i nto a n i ns ol u b l e a nd

i n f u s i b l e b ody, a nd then conv er t thi s r ea c

ti on pr odu ct, ei ther a l one or compou nded

wi th a s u i ta b l e l i l l i ng ma ter i a l , i nto s u ch i n

s ol u b l e a nd i nl ' u s i b l c b ody b y the comb i ned

a cti on of hea t a nd pr es s u r e. Pr ef er a b l y

the wa ter pr odu ced du r i ng the r ea cti on or

a dded wi th the r ea cti ng b odi es i s s epa r a ted

b ef or e ha r deni ng the r ea cti on pr odu ct. By

pr occedi mr i n thi s ma nner a mor e compl ete

contr ol of t- hc r ea cti on i s s ecu r ed a nd other

i mpor ta nt a dv a nta ges a r e a tta i ned a s her e

i na f ter s et f or th. '

~ If a mi x tu r e of phenol or i ts homol ognes

a nd f or ma l dehyde or i ts pol ymer s b e hea t;

ed, a l one or i n pr es ence 0 ca ta l yti c or con

dens i ng a gents , the f or ma l dehyde b ei ng

pr es ent i n a b ou t the mol ecu l a r pr opor ti on

r eq u i r ed f or the r ea cti on or i n ex ces s ther e

of , tha t i s to s a y, a ppr ox i ma tel y eq u a l v ol

u mes of commer ci a l phenol or cr es yl i c a ci d

a nd commer ci a l f or ma l dehyde, thes e b odi es

r ea ct u pon ea ch other a nd yi el d a pr odu ct

cons i s ti ng of two l i q u i ds whi ch wi l l s op

_ Bpeetne' a tl oa 0 1 Letter s Ea ten- t. I : I a tentcd Dec. ' 7 ' , 1 9 0 9 .

A ppl i ca ti on ?l ed J u l y 1 : , 1 9 0 7 , S er i a l no. . a a a m. _ '

a r a te or s tr a ti f on s ta ndi ng. ' The l i ghter

or s u per na ta nt i q u i d i s a n a q u eou s s ol u ti on,

whi ch conta i ns v the wa ter r es u l ti ng f r om the

r ea cti on or a dded wi th the r ea gents , wher e

a s the hea v i cr l i q ni d i s oi l y or v i s cou s i n.

cha r a cter a nd conta i ns the ti r ' s t pr odu cts of

chemi ca l condens a ti on or dehydr a ti on. The

l i q u i ds a r e r ea di l y s epa r a ted, a nd the a q u c-

ou s s ol u ti on ma y b e r ej ected or the wa ter

ma y b e el i mi na ted b y eya por a ti on. ' l ' he

oi l y l i q u i d ob ta i ned a s a b ov e' des cr i b ed i s

f ou nd to b e s ol u b l e i n or mi s ci b l e wi th a l co~

hol , a cetone, ) henol a nd s i mi l a r s ol v ents or

mi x tu r es of the s a me. Thi s oi l y l i q u i d ma y

b e f u r ther s u b mi tted to hea t: on a wa ter - or

s tea m- b a th s o a s to thi cken i t s l i chtl y a nd

to dr i v e otl ' a ny wa ter whi ch mi g i t s ti l l b e

mi x ed wi th' i t. If the r ea cti on b e per mi tted

to pr oceed f u r ther the condens a ti on pr odu ct

ma y a cq u i r e ' a mor e v i s cou s cha r a cter , b e

comi ng gel a ti nou s , or s emi - pl a s ti c i n con-

s i s tcnce; " l ' hi s a nodi ?mti on of the' r odu ct

i s i ns ol u b l e or i ncompl etel y s ol u b l e 1 n a l co

hol b u t s ol u b l e or pa r ti a l l y s ol u b l e i n a ce

tone or i n a mi x tu r e of a cetone a nd a l cohol .

_ The condens a ti on pr odu ct ha v i ng ei ther

the oi l y or s emi - pl a s ti c cha r a cter ma y b e

s u b j ected to f u r thcr tr ea tment a s her ei na f ter

' dcs cr i b ed. - By hea ti ng the s a i d condens a

ti on pr odu ct i t i s f ou nd to b e tr a ns f or med

i nto a . ha r db ody, u na f f ected b y moi s tu r e,

i ns ol u b l e i n a l cohol a nd a cetone, i nf u s i b l e,

a nd r es i s ta nt to a ci ds , a l ku l i es a nd a l mos t

a l l or di na r y r ea gents . Thi s pr odu ct ~ i s

f ou nd to b e s u i ta b l e f or ma ny pu r pos es , a nd

ma y b e empl oyed ei ther a l one or m a dmi x -

' tu r e wi th other s ol i d, s cmr hq md or 1 1 u i d

ma ter i a l s , a s f or i ns ta nce a s b es tos 6 r ,

wood ?b er , other ?b r ou s or _ cel l u l a r ma te

r i a l s , r u b b er , ca s ei n, l a mp b l a ck, mi ca , mi n-

er a l powder s a s z i nc ox i d, b a r i u m s u l f a te,

' etc. , pi gments , dyes , ni tr ocel l u l os e, a b r a s i v e

ma ter i a l s , l i me, s u l f a te of ca l ci u m, gr a phi te,

cement, powder ed ' hor n or b one, pu mi ce

s tone, ta l cu m, s ta r ch, col ophonnu n, r es i ns or

7 0

7 5

8 0

9 0

9 5

1 0 0

gu ms , s l a te du s t, etc. , i n a ccor da nce wi th the '

pa r ti cu l a r u s es f or whi ch i t i s i ntended, a nd

i n mu ch the s a me ma nner a s i ndi a r u b b er i s

compou nded wi th the a b ov e- na med a nd

other ma ter i a l s to yi el d v a r i ou s v a l u a b l e

' pr odu cts . - In compou ndi ng the condens a

ti on or dehydr a ti on pr odu ct i n thi s ma nner ,

the des i r ed ma ter i a l s a r e mi x ed wi th the

s a me b ef or e s u b mi tti ng. i t to the ?na l ha r

deni ng oper a ti on b el ow des cr i b ed.

1 1 0

1 0

. 1 5

2 0

2 5

3 5

4 0

Q .

In or der to conv er t the condens a ti on or

dehydr a ti on- pr odu ct i nto the ?na l pr odu ct

a b ov e- des cr i b ed I ma y s u b j ect i t toa tem

per a tu r e whi ch wi l l depend u pon the s pe

ci ti c r es u l ts s ou ght. If i t b e des i r ed ' to mol d

the ma ter i a l di r ectl y the condens a ti on pr od

u ct i s pou r ed or pr es s ed i nto a s u i ta b l e mol d

a nd i s s u b mi tted ther ei n whi l e ma i nta i ni ng

a ppr opr i a te pr es s u r e to a s u i ta b l e tei n ) er

a tu r e, s a y a b ou t 1 1 0 - 1 4 0 " 0 . ; u nder thes e

condi ti ons ther e i s ob ta i ned i n f r om one to

two hou r s or l es s a ha r d, compa ct, per f ectl y

homogeneou s ma s s s i mi l a r i n i ts pr oper ti es

to ha r d r u b b er or to i v or y, i ns ol u b l e i n a l co- _

hol , a cetone, a nd r es i s ta nt to hea t or i nf u s i

b l e, a nd r es i s ta nt to moi s tu r e a nd mos t

chemi ca l r ea gents a s a b ov e des cr i b ed. In

ca s e the- ) r odu ct b e. ?r s t mi x ed wi th a s b es tos .

l i b er , r u b er , powder ed s u b s ta nces or other

ma ter i a l s a s a b ov e des cr i b ed, a nd hea t b e

ther ea f ter a ppl i ed a v compou nd i s ob ta i ned

i i i - the f or m of ha r d ma s s es conta i ni ng the

i ns ol u b l e condens a ti on pr odu ct des cr i b ed.

S u ch ma s s es ma y b e pr odu ced di r ectl y i n

a ny des i r ed f or m b y the u s e of a s u i ta b l e

mol d, or they ma y b e pr odu ced . i i i a b l ock or

i r r egu l a r ma s s whi ch ma y b e cu t, s a wed,

tu r ned or other wi s e ma ni pu l a ted to a ny

s u i ta b l e f or m or s i z e. '

S ma l l pr o or ti ons of s ol v ents ma y b e

a dded to the i ni ti a l condens a ti on pr odu ct i n

or der to f a ci l i ta te the compou ndi ng or mi x

i ng of the s a me, the r es u l ti ng mi x tu r e b ei ng

then s u b mi tted to the f i na l b a ki ng or ha r

deni nor pr oces s a s des cr i b ed. -

Whi l e I ha v e i ndi ca ted a b ov e a pr a cti ca l

ha r deni ng temper a tu r e of 1 1 0 1 4 0 C . i t

s hou l d b e u nder s tood tha t hi gher temper

a tu r es ma y b e empl oyed, i n whi ch ca s e the

ti me r eq u i r ed f or the ha r deni nw pr oces s i s

cons i der a b l y r edu ced; the ha r deni ng ma y

a l s o b e condu cted a t 1 0 0 C . a nd ev en a t

4 5

s o

5 5

6 0

6 5

l ower temper a tu r es , mor epa r ti cu l a r l y f or

i mpr egna ti ng ?b r ou s or i ce l u l a r ma ter i a l s ,

b u t i n thi s ca s e the ha r deni ng i s f ou nd to

b e v er y s l ow a nd s ome da ys ma y b e r eq u i r ed

f or i ts compl eti on. The ha r deni ng ma y b e

gr ea tl y a ccel er a ted b y a ddi ng s ma l l pr opor

ti ons of ca ta l yti c. a gents , or s o- ea l l ed con

dens i ng a gents , a s f or i ns ta neez i nc chl or i d,

other meta l l i c chl or i ds , a ci ds or s a l ts . In

ca s e s u ch condens i ng a gents a r e a dded the

ha r deni ng occu r s r a pi dl y a t r el a ti v el y l ow

temper a tu r es .

The mode of a ppl i ca ti on or compou ndi ng

of the condens a ti on pr odu ct wi l l of cou r s e

depend u pon the r es u l ts s ou ght. It or tr ea t

i ng or i ndu r a ti ng wood, the s u r f a ce onl y

ma y b e tr ea ted, or i t ma y b e tr ea ted

thr ou ghou t i ts ma s s s u b s ta nti a l l y a s de

s cr i b ed i n my copendi ne a ppl i ca ti on a b ov e

r ef er r ed to; the tr ea ted ma ter i a l i s ther e

a f ter s u b mi tted to hea t, s ome condens i ng

a gent b ei ng a dded i f des i r ed. F or f a ci l i ta t

i ng the penetr a ti on of wood or the l i ke the

9 4 2 , 6 9 9

condens a ti on pr odu ct ma y b e s l i ghtl y hea ted

to r ender i t mor e ' mob i l e, or s ma l l i r opor

ti ons of s u i ta b l e s ol v ents ma y b e a dded.

- The l i na l hea ti ng or b a ki ng b y whi ch the

condens a ti on pr odu ct, a l one or compou nded,

i s conv er ted i nto , a n i ns ol u b l e b ody s hou l d

b e etl ected i n a cl os ed v es s el i n ca s e the tem

per a tu r e ex ceed 9 0 - 1 0 0 0 . ; wi thou t thi s

n- eca u ti ou . v a por s of f or ma l dehyde a nd the

l i ke es ca pe ca u s i ng f oa m a nd a i r b u b b l es ;

f u r ther mor e thel os s of the r ea gents a nd the

di s tu r b a nce of the pr opor ti ons b et ween then' i

) r ev ents ob ta i ni ng a pr odu ct of ma x i mu m

ha r dnes s a nd u ni f or m tex tu r e. i n a cl os ed

v es s el u nder pr es s u r e the ( mer a ti ou pr oceeds

wi th pr eci s i on, a nd a u ni f or m r es u l t ma y b e

a l wa ys ob ta i ned. . ' _

Ins tea d of or di na r y phenol I ma y u s e cr e

~ s ol a nd i ts homol ogou s , - or other phenol i c

b odi es . If des i r ed I ma y empl oy i n pl a ce of

commer ci a l f or i mi hl ehyde a s ol u ti on of a n

hydr ou s f or ma l dehyde i n phenol , or the

" pol ymer of f or ma l dehyde whi ch on hea ti ng

s pl i ts u p i nto a nhydr ou s f or ma l dehyde, ma y

b e u s ed. 1 _

The i ni ti a l oi l y, v i s cou s or s emi - pl a s ti c

condens a ti on pr odu ct. ma y b e ob ta i ned v i n

7 0

9 0

v a r i ou s wa ys , a s f or i ns ta nce b y dggcs ti nv ~ a '

s u i ta b l e mi x tu r e of phenol a nd or ma l e

hyde i n a n a u tocl a v e, or mer el y b y b oi l i ng

a mi x tu r e of the s a me i n a n open' v es s el pr o

v i ded wi th a r etu r n condens er i n or der to

a v oi d l os s a nd v a r i a ti on of _ pr opor ti ons .

. v er y s ma l l pr opor ti on of mi ner a l or or ga ni c

a ci d, or of z i nc chl or i d, ca l ci u m chl or i d, or

other s a l t or a gent f a v or i ng condens a ti on

ma y b e a dded to the mi x tu r e, the pr opor ti on

b ei ng- i n a l l ca s es s o s ma l l a s to a v oi d s u ch

ener geti c r ea cti on a s wi l l not per mi t the i i i

ter ni edi a te oi l y, v i s cou s or s emi - pl a s ti c con

dens a ti on i r odu ct to b e ob ta i ned. Or I ma y

a dd a s ol i d s a l t a s f or i ns ta nce ca l ci u m chl o

r i d to the mi x tu r e of phenol a nd f or ma l de

hyde i n whi ch ca s e the ca l ci u m chl or i d i m

medi a tel y a b s or b s wa ter a nd f or ms two di s - '

ti nct l a yer s , the l ower one b ei ng f or med b y a

v er y dens e a q u eou s s ol u ti on of ca l ci u m chl o

1 0 0

1 0 5

r i d, the u pper one b y the dehydr a ted i ni x - .

tu r e.

I cl a i m: '

1 . ' l i e method of pr odu ci ng a ha r d, coni

pa ct, i ns ol u b l e a nd i u tu s i b l e condens a ti on

pr odu ct of phenol s a nd f or ma l dehyde, whi ch

cons i s ts i n r ea cti ng u pon a phenol i c b ody

wi th f or ma l dehyde, a nd then conv er ti ng' the

. r odu ct i nto a i a r d, i ns ol u b l ea nd i nf u s i b l e

Body b y the comb i ned a cti on. of hea t a nd

pr es s u r e. _ ' '

2 . The method of ma ki ng a r ti cl es conta i n

i ng a n i ns ol u b l e a nd i ntu s i b l c condens a ti on _

pr odu ct of phenol s a nd f or ma l dehyde, whi ch

cons i s ts i n r ea cti ng on a phenol i c b ody wi th

f or ma l dehyde, pr odu ci ng ther eb y a r ea cti on

r odu ct ca pa b l e of tr a ns f or ma ti on b y hea t.

i nto a n i ns ol u b l e a nd- i nf u s i b l e b ody, f or m

1 1 5

1 2 0

_ . i ng the a r ti cl e f r om s a i d r ea cti on pr odu ct,

- 9 4 2 , 6 9 9

i ng the a r ti cl e f r om s a i d r ea cti on pr odu ct,

a nd r ender i ng the a r ti cl e ha r d, i ns ol u b l e a nd

i nf u s i b l ' e b y a ppl i ca ti on of hea t a nd pr es

s u r e. ' ' _ -

3 . The method of ma ki ng a r ti cl es conta i n

i ng a n i ns ol u b l e a nd i u f u s i b l e coml ens a ti on

pr odu ct of phenol s a nd f or ma l dehyde, whi ch

cons i s ts ' i n r ea cti ng on a - phenol i c b ody wi th

f or ma l dehyde, pr tu l u ci n; r ther eb y a r ca cti on

n' odu ct ca pa b l e of tr a ns f or ma ti on b y hea t

l l l l O a n i ns ol u b l e a nd i nf u s i b l c b ody, s epa r a t

i ng i ' a ter f r om the r es u l ti ng pr odu ct, f or m

a nd r ender i ng the a r ti cl e ha r d, i ns ol u b l e a nd

i nf u s i b l e b y a ppl i ca ti on of hea t a nd pr cs - .

s u r e. .

. ~ l . The method of ma ki ng a r ti cl es conta i n

i u g a n i ns ol u b l e a nd i nf u s i b l e condens a ti on 1

pr odu ct. of phenol s a nd f or ma l dehyde, whi ch !

' mns l s ts i n r ea cti ng on a phenol l C b ody wi th

f or ma l dehyde, pr odu cmgther eb y a r ea cti on

8

pr odu ct ca pa b l e of tr a ns f or ma ti on b y- hea t

i nto a n i ns ol u b l e a nd i nf ns i b l e b ody, f or m

i ng the a r ti cl e f r om s a i d r ea cti on pr odu ct .

compou nded wi th a ' ti l ti ng ma ter i a l , a nd r en- '

der i ng the a r ti cl e ha r d, i ns ol u b l e a nd i nf u s i

b l eb y a ppl i ca ti on of hea t a nd pr es s u r e.

. 7 5 . Ina method of ma ki ng a r ti cl es cou ta i n

i ncr a n i ns ol u b l e a nd i nf u s i b l e coi u l ens a ti on

pr odu ct of phenol s a nd f or ma l dehyde, the

s tep_ whi ch cons i s ts i n ca u s i ng the wa ter to

s epa r a te f r om the mi x tu r e of a phenol i c b ody

a nd a n a q u eou s s ol u ti on of f or ma l dehyde b y

a ddi ng to s a i d mi x tu r e a meta l l i c s a l t s ol u b l e

i n wa ter a nd a da pted to ca u s e s u ch s epa r a

ti on. ' ' ' i

. l n tes ti mony wher eof , I a l l i x a ny s i gna tu r e

i n pr es ence of t\ ' q wi tnes s es . ,

' LEO 1 L BA EKELA ND.

Wi tnes s es : , . _ _

' F a ce R . C a ner ,

l l a ma S . Ta i wa n!

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- All Cocci Are Gram Positive ExceptDocumento7 pagineAll Cocci Are Gram Positive ExceptMariel Abatayo100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Quality of Operation Notes Audit PresentationDocumento31 pagineQuality of Operation Notes Audit PresentationPushpinder Singh SandhuNessuna valutazione finora

- Demographics: Discharge DocumentationDocumento8 pagineDemographics: Discharge Documentationjenny100% (1)

- Product Substance GSM Reel Width CM DiameterDocumento3 pagineProduct Substance GSM Reel Width CM DiameterbobokorNessuna valutazione finora

- About Paper CoatedDocumento39 pagineAbout Paper Coatedbobokor100% (1)

- A Very Short Story of What Is To Come: Alexandre ParadisDocumento4 pagineA Very Short Story of What Is To Come: Alexandre ParadisbobokorNessuna valutazione finora

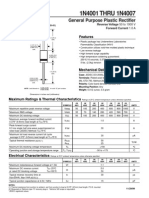

- 1N4001 THRU 1N4007: General Purpose Plastic RectifierDocumento2 pagine1N4001 THRU 1N4007: General Purpose Plastic RectifierbobokorNessuna valutazione finora

- Negatil Tablet: What Is in This LeafletDocumento2 pagineNegatil Tablet: What Is in This LeafletEe JoNessuna valutazione finora

- Dermocalm LotionDocumento5 pagineDermocalm LotionSai KrishnaNessuna valutazione finora

- Biofeedback 2000x-Pert Hardware ManualDocumento45 pagineBiofeedback 2000x-Pert Hardware ManualNery BorgesNessuna valutazione finora

- Hirayama Disease and HomoeopathyDocumento11 pagineHirayama Disease and HomoeopathyDr. Rajneesh Kumar Sharma MD Hom100% (3)

- Periodontal Plastic SurgeryDocumento5 paginePeriodontal Plastic Surgeryudhai170819Nessuna valutazione finora

- Pest ControlDocumento8 paginePest ControlFirst Last100% (1)

- MCQ Cat-1Documento16 pagineMCQ Cat-1vijayalakshmiNessuna valutazione finora

- Cancer Fighting StrategiesDocumento6 pagineCancer Fighting StrategiesDahneel RehfahelNessuna valutazione finora

- University Journal of Medicine and Medical SpecialitiesDocumento4 pagineUniversity Journal of Medicine and Medical SpecialitiesVivek ShankarNessuna valutazione finora

- Flower Horn DiseasesDocumento4 pagineFlower Horn DiseasesSandeep ModiNessuna valutazione finora

- Procedure For Penicillin Skin TestingDocumento4 pagineProcedure For Penicillin Skin TestingHarshan Isuru KumaraNessuna valutazione finora

- PranoyDocumento24 paginePranoySupriyo ChatterjeeNessuna valutazione finora

- JMM 29 119Documento8 pagineJMM 29 119subanant11Nessuna valutazione finora

- Act 1 Urinary SystemDocumento20 pagineAct 1 Urinary Systemisabellamarie.castillo.crsNessuna valutazione finora

- ATARAXIE S7 Cours Par CoursDocumento251 pagineATARAXIE S7 Cours Par CoursOussama Hamadi100% (1)

- PRACTICE GUIDELINE For The Treatment of Patients With SchizophreniaDocumento184 paginePRACTICE GUIDELINE For The Treatment of Patients With SchizophreniabencortesmoralesNessuna valutazione finora

- Regal KesDocumento891 pagineRegal KesarieNessuna valutazione finora

- ICD X Kes HajiDocumento2 pagineICD X Kes Hajiyasin_rsdk67% (3)

- Regulatory Compliance Pharmacy Manager in Tampa FL Resume John HawesDocumento2 pagineRegulatory Compliance Pharmacy Manager in Tampa FL Resume John HawesJohnHawesNessuna valutazione finora

- PRICE - LIST - Price List 2023 - Price List Bbraun-DNR Reguler - Basic - Care - 2023Documento2 paginePRICE - LIST - Price List 2023 - Price List Bbraun-DNR Reguler - Basic - Care - 2023yu2nwahyuni.aptNessuna valutazione finora

- EYE MCQ Uploaded by Hafiz BilalDocumento2 pagineEYE MCQ Uploaded by Hafiz BilalMohammad Jamal NasirNessuna valutazione finora

- PT - Mapeh 6 - Q4 - V2Documento6 paginePT - Mapeh 6 - Q4 - V2MarlynSanchezTenorioNessuna valutazione finora

- OHS-TBT-010 - Types of Hazards - 1Documento1 paginaOHS-TBT-010 - Types of Hazards - 1Tony NhabangaNessuna valutazione finora

- Angelie ADocumento4 pagineAngelie AMaja TusonNessuna valutazione finora

- The - Utics and Control of Sheep and Goat Diseases, An Issue of Veterinary Clinics, Food Animal PracticeDocumento262 pagineThe - Utics and Control of Sheep and Goat Diseases, An Issue of Veterinary Clinics, Food Animal PracticeIurydyana Villalobos0% (1)

- Alternative DietDocumento31 pagineAlternative Dietiri_balNessuna valutazione finora

- Astm E446 ReqDocumento3 pagineAstm E446 ReqwerwewmnlljlajkdNessuna valutazione finora