Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

04 Metal Casting

Caricato da

Jimmy HarvianCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

04 Metal Casting

Caricato da

Jimmy HarvianCopyright:

Formati disponibili

unn +

n+.naalan:

t..nor+o .uao+

a+r+.r+:nlulaen+.uao nn+.ne+ae.+rn:nr.u.o

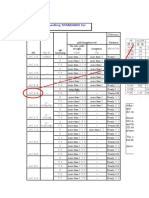

Sand Casting

High Temperature Alloy,

Complex Geometry,

Rough Surface Finish

Investment Casting

High Temperature Alloy,

Complex Geometry,

Moderately Smooth Surface

Finish

Die Casting

High Temperature Alloy,

Moderate Geometry,

Smooth Surface

Casting Methods

oanuo ra+u+lan:

.+nnu (v|.ee.|:,,

.!raa.ar::

.:.aa: (.--:.a,

atr::

:.:r....raa:.ra..:r.a... .z. aa:..:: .a:.:

.+no+u. (se:raec c.|e,

n+.Ina (r|e=,

n+.ar+o.ra+lan:

.ar:r:.a:.:..:.a (oa.-s,

:a:.:r..:.a (oa.- a-a-+a.-s,

a....aa ....:.n:.

.ar:.:a: ::..

..:..:::..a..:.!nn (-.,-,

(.r.......r.:a c--:-..-- s-.--a,-,

n+.ar+o.ra+lan:u.ant

n+.ar+o.ra+lan:uan

.:.a.. (ca:--: u-a:,

Three Cast Structures of Solidified Metals

FIGURE 5.8

Schematic

illustration of three

cast structures of

metals solidified in a

square mold:

(a) pure metals;

(b) solid-solution

alloys; and

(c) the structure

obtained by

heterogeneous

nucleation of grains,

using nucleating

agents.

:.a+un+.ar+o.

Chvorinoys Rule

.tn+.anIr

n.:n+Ile

n+.n+.au

(a|.c:,

lan:aoa:

ru:n

:ua.:zuon+.

no.

naono++nu

n.:a.uru:e. (s||c ,;c ra::c:,

n.:a.uaenI (s;||: ra::c:,

n.:a.u.+ra+.+ (ua|r ra::c:, ru++una.uuuaa:a.ua++:nnaunu

Features of a Sand Mold

Schematic illustration of a sand mold, showing various features.

av

v

.+

n

+n

Electric Furnaces

n.+enaa ( o:cc sae,

.a..:..:.:a. (a.-+-s,

.:.!. r.a.: r.a..+.. (o-:.--,

..:.:a.n.r: ... (Wa:- o.ass, ..+. (-s.-s, r.a+.:.. (c---:,

z:.r. :::.a: :. r.a.!n :.::t a::

.:raa .nar..raa:.:a:.a:. a:.::a..::aa!.:

oanuora+n.+enaa

..:!.:

+!ra.aa!.a:..

.:..:.a:..na.r::

..:.a...ar: .z. .ra.r.:.raa:.::t .saa.ssac

a::z!.a

.:

!:..:.:.: .:a.::r.a

a:a:.ar:

n+.naaun.+enaa (sae c.:|,

auunaan.+e (sae ue|e|,

Steps in Sand Casting

Steps in Sand Casting

n.:u.un+.naa.en..n.tau_ (o:c: r.;cea|c ue|e ca.:| r:eec..c.,

auunaa:uaan (sc|| ue|e.,

Shell Casting

Dump-Box Technique

Figure 11.13 A common method of making shell molds. Called dump-box technique, the

limitations are the formation of voids in the shell and peelback (when sections of the shell

fall off as the pattern is raised). Source: ASM International.

Shell Casting

Dump-Box Technique

.tn+.naaauunu.au (ue: oe. uc:ee,

auunaaa+n+ (vaeee ue|e|,

v---ss

auunaalna:an .u (r.;aece re|,.:,:cc r:eec..,

n+.naaauuau

:.an:nun

(|.c.:c:

ca.:|,

auunaa+.uauIaanIz (coz ue|e r:eec..,

auunaan.+euanz:nuo (sae ue|e =|: ccc: o|ec:,

auunaa:z.+nn (cc:a|eue|e ca.:|,

Operation Sequence of Making a Ceramic Mold

Sequence of operations in making a ceramic mold.

Figure 11.17 A typical ceramic mold (Shaw process) for casting steel dies used in

hot forging.

n+.naa.t a+n+ (vaeee ca.:|,

n+.naa:n.e+ (cc::|rea| ca.:|,

FIGURE 5.30 Schematic illustration of the centrifugal casting process.

Pipes, cylinder liners, and similarly shaped parts can be cast by this

process.

Semicentrifugal Casting

Process

FIGURE 5.31 (a) Schematic illustration of the semicentrifugal casting process. (b)

Schematic illustration of casting by centrifuging. The molds are placed at the

periphery of the machine, and the molten metal is forced into the molds by centrifugal

forces.

Squeeze-Casting Process

uauua

n+.naaauuln.+ (s|e. ca.:|,

Potrebbero piacerti anche

- Material ScienceDocumento125 pagineMaterial ScienceJimmy HarvianNessuna valutazione finora

- Turbines May4 - 2009 - 1 PDFDocumento22 pagineTurbines May4 - 2009 - 1 PDFEmilio BernyNessuna valutazione finora

- Essential MATLAB For Engineers and Scientists - Brian D. Hahn & Daniel T. ValentineDocumento102 pagineEssential MATLAB For Engineers and Scientists - Brian D. Hahn & Daniel T. Valentinegagansingh87Nessuna valutazione finora

- Materials Science 2 - DOEDocumento112 pagineMaterials Science 2 - DOEshiv_1987Nessuna valutazione finora

- Wind Turbine Power CalculationDocumento5 pagineWind Turbine Power CalculationRavi Acharya100% (2)

- McCosker FinalReportDocumento56 pagineMcCosker FinalReportJimmy HarvianNessuna valutazione finora

- Micleaf882004en SM6 Dm1aDocumento4 pagineMicleaf882004en SM6 Dm1aJimmy HarvianNessuna valutazione finora

- Phase Transformations and Heat TreatmentDocumento76 paginePhase Transformations and Heat TreatmentJimmy HarvianNessuna valutazione finora

- Wind Energy Math CalculationDocumento5 pagineWind Energy Math CalculationRafael Lopes CarneiroNessuna valutazione finora

- Corel Draw KunciDocumento3 pagineCorel Draw KunciJimmy HarvianNessuna valutazione finora

- Bismillah PDT ADocumento1 paginaBismillah PDT AJimmy HarvianNessuna valutazione finora

- Integral SMADocumento8 pagineIntegral SMANurwahid Fatchul RachmanNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- iCLPFA3 IDocumento132 pagineiCLPFA3 ICesar NietoNessuna valutazione finora

- PT Perkasa Heavyndo Engineering Welder Qualification RecordsDocumento91 paginePT Perkasa Heavyndo Engineering Welder Qualification RecordstskmechNessuna valutazione finora

- Welding Lens GuideDocumento2 pagineWelding Lens GuideNek Nek Fontbuena-CarpioNessuna valutazione finora

- SyllabusDocumento2 pagineSyllabusDhana MuruganNessuna valutazione finora

- E Joint Factor 2 PDFDocumento1 paginaE Joint Factor 2 PDFMohamed ElsayedNessuna valutazione finora

- Training Handbook ENGDocumento391 pagineTraining Handbook ENGnagaNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNessuna valutazione finora

- 03 WPS PQR For FCAWDocumento3 pagine03 WPS PQR For FCAWBrijesh Yadav100% (1)

- SPM Time ChartDocumento27 pagineSPM Time ChartkarthikNessuna valutazione finora

- F - BoringDocumento44 pagineF - BoringedsaregNessuna valutazione finora

- Procedure Qualification Record PQRDocumento3 pagineProcedure Qualification Record PQRNMBaihakiARNessuna valutazione finora

- Passing A 3G ImportantDocumento10 paginePassing A 3G ImportantKentDemeterioNessuna valutazione finora

- CNC Train PresentationDocumento80 pagineCNC Train PresentationRahul GoudNessuna valutazione finora

- Asirusa WPS-P-002 1FDocumento5 pagineAsirusa WPS-P-002 1FWalter RuedaNessuna valutazione finora

- JIS Standard For Casting MaterialDocumento4 pagineJIS Standard For Casting MaterialTaufiqurrahman DerryNessuna valutazione finora

- WPS PQR FormatDocumento1 paginaWPS PQR FormatJatin Kamdar100% (2)

- DIN 1683 - 1 Rough Steel Casting Tolerance Standard - Dandong Foundry PDFDocumento1 paginaDIN 1683 - 1 Rough Steel Casting Tolerance Standard - Dandong Foundry PDFedwar_12Nessuna valutazione finora

- Welder Qualification Manual Revision 5Documento20 pagineWelder Qualification Manual Revision 5Hugo RodriguezNessuna valutazione finora

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesDocumento9 pagineASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- Weld CalculationDocumento34 pagineWeld CalculationAshwani DograNessuna valutazione finora

- Book 1Documento3 pagineBook 1Vimin PrakashNessuna valutazione finora

- Good Weld Bead Finish (W-10)Documento21 pagineGood Weld Bead Finish (W-10)hardish_trivedi7005Nessuna valutazione finora

- CH 11Documento13 pagineCH 11chaitanyacheggNessuna valutazione finora

- Rohm Drill Chucks Catalogue 2015-16Documento33 pagineRohm Drill Chucks Catalogue 2015-16Steve TaylorNessuna valutazione finora

- GMAW welding parameters for SS400 pipeDocumento2 pagineGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- Identifying Casting DefectsDocumento4 pagineIdentifying Casting Defectsdarwin_huaNessuna valutazione finora

- AWS Standards Library Order FormDocumento3 pagineAWS Standards Library Order FormRafael Torres SabalzaNessuna valutazione finora

- Defect and LimitationDocumento4 pagineDefect and LimitationFirdaus IliasNessuna valutazione finora

- TIG Welding Process GuideDocumento29 pagineTIG Welding Process GuidezahidNessuna valutazione finora