Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Overlays Poster

Caricato da

Conifer Yu0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

45 visualizzazioni1 paginaPAVEMENT

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoPAVEMENT

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

45 visualizzazioni1 paginaOverlays Poster

Caricato da

Conifer YuPAVEMENT

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

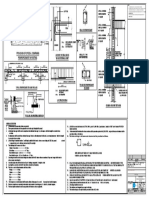

Summary of Concrete Overlays

Existing concrete pavement

with surface distresses

Prepared surface

Monolithic pavement with

new concrete surface

Existing asphalt pavement

with surface distresses

Milled and cleaned

surface

New 25 in. (5.112.7 cm) bonded

concrete overlay with square panels

Existing composite pavement

with asphalt surface distresses

Milled and cleaned surface

New 25 in. (5.112.7 cm) bonded

concrete overlay with square panels

Bonded Concrete Overlays of Concrete Pavements

Overlay and existing concrete pavement act as one monolithic pavement

Bonded Concrete Overlays of Asphalt Pavements

Overlay and existing concrete pavement act as one monolithic pavement

Bonded Concrete Overlays of Composite Pavements

Overlay and existing concrete pavement act as one monolithic pavement

Existing deteriorated

composite pavement

New unbonded overlay

Need for milling determined based

on degree of surface distortions

Existing concrete pavement

New unbonded overlay

Possible preoverlay repairs

Unbonded Concrete Overlays of Concrete Pavements

Overlay serves as a new full-depth pavement on a stable base

Existing deteriorated

asphalt pavement

New unbonded overlay

Need for milling determined based

on degree of surface distortions

Unbonded Concrete Overlays of Composite Pavements

Overlay serves as a new full-depth pavement on a stable base

Unbonded Concrete Overlays of Asphalt Pavements

Overlay serves as a new full-depth pavement on a stable base

Thickness: 25 in. depending on desired life (1525+ years),

anticipated trafc loading, and condition of underlying pavement

Thickness: 411 in. depending on desired life (1530+ years),

anticipated trafc loading, and condition of underlying pavement

Applications

Where increase in trafc loads requires more structural capacity

(related benet: improves friction, noise, and rideability)

To eliminate surface defects such as extensive scaling or surface

cracking

Where vertical clearances must be met

In mill and inlay sections

Keys to success

Existing pavement surface must be prepared to enhance bonding to

the overlay

Overlays aggregate thermal properties (coefcient of thermal

expansion) must be similar to (or lower than) existing pavements to

minimize shear stress in bond

Working cracks in the existing pavement should be repaired (or the

overlay should be sawed over the crack) to prevent the crack from

reecting through the overlay

Existing joints must be in fair condition or repaired

Thinner overlays may shorten sawing window

Transverse joints in the overlay must be sawed full depth plus in.

(1.3 cm); longitudinal joints must be at least T/2

Joints in the overlay must align with those of existing pavement

because the structure must move monolithically

Width of transverse joints in the overlay must be equal to or greater

than the underlying crack width at the bottom of the existing

transverse joint

Application of curing compound or other curing methods must be

timely and thorough, especially at edges

Applications

Where increase in trafc loads requires more structural capacity

To eliminate surface defects such as rutting and shoving

To improve friction, noise, and rideability

Where vertical clearances must be met

Keys to success

Milling of existing asphalt may be required to eliminate surface

distortions of 2 in. (5.1 cm) or more and to help provide good bond;

minimal spot repairs may be required

Asphalt surface temperature must be maintained below 120F (48.9C)

when placing overlay

Joints in overlay should be sawed in small, square panels

Transverse joints must be sawed T/3 (with special attention to

thickened overlay over asphalt ruts)

Joints in the overlay should not be placed in wheel paths, if possible

Thinner overlays may shorten sawing window; additional saws are

likely to be required

Application of curing compound or other curing methods must be

timely and thorough, especially at edges

Applications

Where increase in trafc loads requires more structural capacity

To eliminate surface defects such as rutting and shoving

To improve friction, noise, and rideability

Where vertical clearances must be met

Keys to success

If the existing pavement prole indicates isolated areas of vertical

distortion in the underlying concrete that could signal movement

from drainage or materials-related distresses, repairs may be

necessary

Milling of existing asphalt may be required to eliminate surface

distortions of 2 in. (5.1 cm) or more and to help provide good bond;

minimal spot repairs may be required

Existing asphalt pavement surface temperature must be maintained

below 120F (48.9C) when placing overlay

Joints in overlay should be sawed in small, square panels

Transverse joints must be sawed T/3 (with special attention to

thickened overlay over asphalt ruts)

Joints in the overlay should not be placed in wheel paths, if possible

Thinner overlays may shorten sawing window; additional saws are

likely to be required

Application of curing compound or other curing methods must be

timely and thorough, especially at edges

Applications

To restore or enhance pavements structural capacity

To increase pavement life equivalent to full-depth pavement

To improve surface friction, noise, and rideability

Keys to success

Full-depth repairs should be considered only at isolated spots where

structural integrity needs restoring

A separation layer (typically 1 in. asphalt) is required to separate

overlay from the existing concrete and eliminate reective cracking

(to reduce pore pressure and minimize stripping of this separation

layer under high truck trafc, provide adequate drainage and a more

porous asphalt)

Some states are experimenting with geotextile materials for the

separation layer

Faulting of 3/8 in. (9.5 mm) or less in the existing concrete pavement

is generally not a concern when asphalt separation layer is 1 in. (2.5

cm) or more

Joints should be sawed in overlay as soon as possible because the

sawing window may be short

Shorter joint spacing than normal in the overlay can help reduce

curling and warping stress

It is not critical to mis-match overlay joints to the underlying joints

Applications

To restore or enhance pavements structural capacity

To increase pavement life equivalent to full-depth pavement

To eliminate rutting and shoving problems

To improve surface friction, noise, and rideability

Keys to success

Milling of existing asphalt may be required to eliminate surface

distortions of 2 in. (5.1 cm) or more

Full-depth repairs should be considered only at isolated spots where

structural integrity needs restoring

Concrete patches in the existing pavement should be separated

from the overlay with a thin layer of emulsion, fabric, or other

bond breaker; or joints should be sawed in the overlay around the

concrete patch perimeter

Joints should be sawed in overlay as soon as possible because the

sawing window may be short

Surface temperature of existing asphalt pavement should be

maintained below 120F (48.9C) when placing overlay

Partial bonding between the overlay and the existing asphalt

pavement is acceptable and may even improve load-carrying

capacity

Applications

To restore or enhance pavements structural capacity

To increase pavement life equivalent to full-depth pavement

To eliminate rutting and shoving problems

To improve surface friction, noise, and rideability

Keys to success

Milling of existing asphalt may be required to eliminate surface

distortions of 2 in. (5.1 cm) or more

If the existing pavement prole indicates isolated areas of vertical

distortion in the underlying concrete that could signal movement from

drainage or materials-related distresses, repairs may be necessary

Full-depth repairs should be considered only at isolated spots where

structural integrity needs restoring

Concrete patches in the existing asphalt pavement surface should

be separated from the overlay with a thin layer of emulsion, fabric, or

other bond breaker; or joints should be sawed in the overlay around

the concrete patch perimeter

Joints should be sawed in overlay as soon as possible because the

sawing window may be short

Surface temperature of the asphalt layer of the existing composite

pavement should be maintained below 120F (48.9C) when placing

overlay

Partial bonding between the overlay and the asphalt layer of the

existing composite pavement is acceptable and may even improve

load-carrying capacity

Existing pavement condition

Good structural condition; some surface distress OK

Existing pavement condition

Fair or better structural condition with surface distress

Existing pavement condition

Fair or better structural condition with severe surface distress

Existing pavement condition

Poor condition, including materials-related distress, but stable and uniform

Existing pavement condition

Deteriorated (severe rutting, potholes, alligator cracking, shoving, and pumping)

but stable and uniform

Existing pavement condition

Deteriorated (severe rutting, potholes, alligator cracking, shoving, pumping,

and past materials-related distress) but stable and uniform

Potrebbero piacerti anche

- 0203 ADocumento1 pagina0203 AConifer YuNessuna valutazione finora

- 0206 ADocumento1 pagina0206 AConifer YuNessuna valutazione finora

- FPPR No8Documento6 pagineFPPR No8Conifer YuNessuna valutazione finora

- FPPR No3Documento6 pagineFPPR No3Conifer YuNessuna valutazione finora

- FPPR No11Documento8 pagineFPPR No11Conifer YuNessuna valutazione finora

- 34 Safety NewsDocumento12 pagine34 Safety NewsConifer YuNessuna valutazione finora

- FPPR No10Documento6 pagineFPPR No10Conifer YuNessuna valutazione finora

- Fire Safety in High Rise Apartment BuildingsDocumento38 pagineFire Safety in High Rise Apartment BuildingsConifer YuNessuna valutazione finora

- FPPR No7Documento6 pagineFPPR No7Conifer YuNessuna valutazione finora

- FPPR No9Documento4 pagineFPPR No9Conifer YuNessuna valutazione finora

- FPPR No2Documento4 pagineFPPR No2Conifer YuNessuna valutazione finora

- FPPR No6Documento6 pagineFPPR No6Conifer YuNessuna valutazione finora

- Urban Design GuidelinesDocumento2 pagineUrban Design GuidelinesConifer YuNessuna valutazione finora

- FPPR No5Documento4 pagineFPPR No5Conifer YuNessuna valutazione finora

- 2015 Mu-X BrochureDocumento8 pagine2015 Mu-X BrochureConifer YuNessuna valutazione finora

- PricelistDocumento2 paginePricelistConifer YuNessuna valutazione finora

- BlumDocumento54 pagineBlumConifer YuNessuna valutazione finora

- Keller Africa Cfa Piles Product BrochureDocumento3 pagineKeller Africa Cfa Piles Product BrochureConifer YuNessuna valutazione finora

- 12.3.0 SSMDRMCDocumento1 pagina12.3.0 SSMDRMCConifer YuNessuna valutazione finora

- 12.4.2 SsriccatDocumento1 pagina12.4.2 SsriccatConifer YuNessuna valutazione finora

- Calculate seismic design parameters for a steel special moment frame buildingDocumento2 pagineCalculate seismic design parameters for a steel special moment frame buildingConifer YuNessuna valutazione finora

- Glo Floor SystemsDocumento84 pagineGlo Floor Systemsawie1982Nessuna valutazione finora

- Seismic Force1Documento3 pagineSeismic Force1Conifer YuNessuna valutazione finora

- Singapore Construction Market Review and OUTLOOK 2021Documento18 pagineSingapore Construction Market Review and OUTLOOK 2021Conifer YuNessuna valutazione finora

- Seismic Force2Documento3 pagineSeismic Force2Conifer YuNessuna valutazione finora

- Aviva Car Summary of CoverDocumento5 pagineAviva Car Summary of CoverConifer YuNessuna valutazione finora

- Spon'S: Asia PacificDocumento52 pagineSpon'S: Asia PacificConifer YuNessuna valutazione finora

- Seismic Force2Documento3 pagineSeismic Force2Conifer YuNessuna valutazione finora

- Calculate seismic design parameters for a steel special moment frame buildingDocumento2 pagineCalculate seismic design parameters for a steel special moment frame buildingConifer YuNessuna valutazione finora

- MasterPort Plus Structural CalculationsDocumento12 pagineMasterPort Plus Structural CalculationsConifer YuNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Products Aquapas-Redispersible-PowdersDocumento3 pagineProducts Aquapas-Redispersible-PowdersMauro RicoNessuna valutazione finora

- Framing Plan DetailsDocumento9 pagineFraming Plan DetailsKenneth FungoNessuna valutazione finora

- Structural design details for water tank foundationDocumento1 paginaStructural design details for water tank foundationSimsonNessuna valutazione finora

- Provision of Special Confining Reinforcement in FootingDocumento1 paginaProvision of Special Confining Reinforcement in FootingSS INFRAZONENessuna valutazione finora

- Pressure TestsDocumento3 paginePressure TestsfedermNessuna valutazione finora

- ETAG-020 Guideline Plastic Anchors Annex-CDocumento13 pagineETAG-020 Guideline Plastic Anchors Annex-Cmicru85Nessuna valutazione finora

- Ruth Case StudyDocumento6 pagineRuth Case StudyBamlak YeshigetaNessuna valutazione finora

- Brise Soleil & Architectural Solar ShadingDocumento24 pagineBrise Soleil & Architectural Solar ShadingLuiza Cantu C.Nessuna valutazione finora

- Catalogo-Termostati 209Documento15 pagineCatalogo-Termostati 209congiu lucianoNessuna valutazione finora

- Routing and Sealing of Cracks ConcreteDocumento2 pagineRouting and Sealing of Cracks ConcretePrageeth Nalaka ArambegedaraNessuna valutazione finora

- Single Span Composite Precast Beam and Deck Bridge Design ManualDocumento26 pagineSingle Span Composite Precast Beam and Deck Bridge Design Manualani4576100% (1)

- Manpower RequirementsDocumento12 pagineManpower Requirementslinga2014Nessuna valutazione finora

- Elect M&eDocumento277 pagineElect M&eSOEYUAUNGNessuna valutazione finora

- Internal Wall DocumentDocumento5 pagineInternal Wall DocumentvijinaNessuna valutazione finora

- AHU Fan Room Sizing PDFDocumento7 pagineAHU Fan Room Sizing PDFWing Hong SamNessuna valutazione finora

- Code Generator V2.0Documento11 pagineCode Generator V2.0JobJobNessuna valutazione finora

- Tate Product Brochure WebDocumento44 pagineTate Product Brochure WebDaniel DiazNessuna valutazione finora

- Project Milestone Achievment WIP Facility Deconstraint Stage 2 - Complete Shelter and MCC BuildingDocumento4 pagineProject Milestone Achievment WIP Facility Deconstraint Stage 2 - Complete Shelter and MCC BuildingNofrizal HasanNessuna valutazione finora

- Mock Ale Set 4a Day 1 Part 2Documento41 pagineMock Ale Set 4a Day 1 Part 2john bacaniNessuna valutazione finora

- A Low-Cost Vernacular Improved Housing DesignDocumento8 pagineA Low-Cost Vernacular Improved Housing DesignsfhousingsearchNessuna valutazione finora

- Types of sealants and their applicationsDocumento6 pagineTypes of sealants and their applicationsAn-an ChanNessuna valutazione finora

- Friction Coefficient Hdpe Slip MembraneDocumento4 pagineFriction Coefficient Hdpe Slip MembraneBogdanBNessuna valutazione finora

- Granular Equivalence (G.E.) Values For Various MaterialsDocumento1 paginaGranular Equivalence (G.E.) Values For Various Materialsجميل عبد الله الحماطيNessuna valutazione finora

- (New) Required Balance Stock Up To 31-12-2018 As Per This FormatDocumento50 pagine(New) Required Balance Stock Up To 31-12-2018 As Per This FormatNasim AkhtarNessuna valutazione finora

- M.Sc. Steel - 4 Composite Steel-Concrete DesignDocumento56 pagineM.Sc. Steel - 4 Composite Steel-Concrete DesignAbdullahNessuna valutazione finora

- NMS Extracted TablesDocumento2.275 pagineNMS Extracted Tablestqxbj6srvmNessuna valutazione finora

- JUB Home UK Brochure 18Documento16 pagineJUB Home UK Brochure 18Bojan BjelajacNessuna valutazione finora

- Waterproof Cement-Based Coating: ThorosealDocumento1 paginaWaterproof Cement-Based Coating: Thorosealcolleen berganciaNessuna valutazione finora

- Concrete Column Schedule: CC1 CC2 CC3 CC4 CC5 CC6 CC7 CC8 CC9 CC10 CC11 CC12 CC13Documento1 paginaConcrete Column Schedule: CC1 CC2 CC3 CC4 CC5 CC6 CC7 CC8 CC9 CC10 CC11 CC12 CC13Rolly Marc G. SoteloNessuna valutazione finora

- Rockfall Protection DesignDocumento5 pagineRockfall Protection DesignPrakash Singh RawalNessuna valutazione finora