Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Shubham Final File

Caricato da

Jasvir Singh0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

36 visualizzazioni68 pagine6 month training file

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento6 month training file

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

36 visualizzazioni68 pagineShubham Final File

Caricato da

Jasvir Singh6 month training file

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 68

TRAINING REPORT

Submitted to the Department of Mechanical engineering of

B.G.I.E.T SANGRUR

Providing the Details of Six Months Training

At

YERIK INTERNATIONAL(LUDHIANA)

Submitted To: Submitted By:

Er. Gurmeet Singh Cheema Shubham Garg

100111128504

DEPARTMENT OF MECHANICAL ENGINEERING

BHAI GURDAS INSTITUTE OF ENGINEERING &

TECHNOLOGY

(SANGRUR)

Jan-June (2014)

`

Page | 3

ACKNOWLEDGEMENT

I would like to thank the entire yerik international who has provided me this

six months training. I am thankful to the HRD officer of training centre who

organized my training schedule and also the DGMs and AGMs of various shop

departments who have provided me the various knowledge about their respective

shops.

I also thanks to the workers of their respective departments, who were always

ready to clarify our doubts and helped us to increase our knowledge by illustrating us

to the finer points.

I wish to express my deep gratitude to all the concerned persons, whose co-

operation and co-ordination have given me the success to complete my training in

organization.

I hope that my report will reflect our technical knowledge and innovativeness

`

Page | 4

PREFACE

Industrial training is part and parcel of every technical course and gives a face or form

to all the theoretical knowledge we gain in our classroom. We get to have a virtual

experience of the processes, methods, objects and phenomenon which used to be just

an imaginary picture in our minds. It also gives an exposure to the environment of the

industries and workshops which are virtual components of our professional life. We

too were provided with this opportunity this summer.

We are thankful to our college administration that handed this invaluable

chance to us and at the same time we pay our regards to the administration of HMT

Pinjore (Machine Tools Division) that proved to be a great supporting force for the

fulfillment of the purpose. The officials and the workers of the firm provided us with

the best of their attention and share ample of knowledge of their concerned field with

us.

`

Page | 5

ABSTRACT

Industrial Training plays very much significant role in the course of engineering. It

provides the student during the engineering course a boost to enhance his technical

skills, abilities and creativity. Industrial training backens up the theoretical knowledge

by practical knowledge gained during the course. As is widely said, ounce of

practical is better than the tons of theory. In fact, both these two things are

incomplete without each other. In this report, I have tried my level best to present the

work undertaken by me during my training period in liquid, concise and precise

manner. Engineering means optimum utilization of resources for the achievement of

the desired objectives. Projects and some suggestions given by me in this report under

the guidance of my Industrial Tutor, Mr. Dinesh Rana MR. is a step forward towards

the definition of engineering.

`

Page | 6

TABLE OF CONTENTS

Chapters Contents Page No.

1. Introduction 8

2. Raw Material Procurement 14

3. Manufacturing Infrastructure 16

3.1. Bar Drawing Facility 17

3.2. Forging Facility 19

3.3. Heat Treatment 20

3.4. Machine Shop (forged

components)

21

3.5. Machine Shop (Drawn

Components)

22

3.6. Surface Treatment 24

3.7. Tool Room 25

4. Components Manufactured 26

4.1. Spring Pin 29

4.2. U-bolt 32

4.3. Over running clutch 36

4.4. Top link pipe 37

4.5. Eye bolt 38

4.6. Top link pin 39

5. Hot Forging Shop 40

6. Cold Forging Shop 42

7. Heat Treatment 44

7.1. Annealing 45

7.2. Hardening 46

7.3. Tempering 47

7.4. Induction Hardening 51

8. Non-Ferrous Bush Shop 54

9. Surface Treatment

10.1. Zinc-Plating Shop 59

`

Page | 7

10.2. Phosphating Shop 60

11. Projects

11.1. Project 1 62

`

Page | 8

C CH HA AP PT TE ER R1 1: :

I IN NT TR RO OD DU UC CT TI IO ON N

1.1 COMPANY PROFILE

The word, YERIK, is the synonym of Gods own creation. This is the feeling behind

all the actions and activities undertaken at YERIK INTERNATIONAL.

YERIK, which is a venture into Steel Industry, has its roots in the companies which

are the trend setters, the pioneers, the leaders, catering to your needs of Agriculture

Machinery, Steel Forgings and other allied Engineering Products for the last 18 years.

The cultures of industrial giants, Resource International & Excell Exports (in which

Mr. M.K. Chopra was a partner) and Preet Forgings Pvt. Ltd., have seeped into the

paraphernalia of YERIK by virtue of the substantial involvement of its proprietor, Mr.

M.K. Chopra into the working and trendsetting activities of these companies, with

him being the mind and soul of the group.

His experience of the world market and scrupulous and conscientious dealing with his

customers since 1990 has finally materialized in the form of YERIK

INTERNATIONAL.

Tanav Chopra who is elder son of Mr. M.K. Chopra, after completing his Masters in

Business Administration (from university of WALES) has joined Yerik. He is

assisting his father in sales & management. Tanav is also a diploma holder in Tools &

Die making.

The group goes global with YERIK, taking care of the Agriculture machinery,

Engineering goods & Hand tool markets of US, Europe, Australia, South Africa,

Middle East & Asia Pacific.

The overall working of the group is governed by Mr. Mohinder Chopra, with the help

of the trust worthy and Mr. Yash Pal Trehan (Vice President-Technical) along with a

`

Page | 9

vast team of over 800 dedicated Workers and Engineers (some have been trained in

Italy), who give their 100% every second, to the company and its growth.

Beside business activities YERIK group is involved in sports activities. Mr. M.K.

Chopra is President of Ludhiana Badminton Academy which is providing free

coaching to children from the age group of 6-13 years. Academy is also providing

scholarship to needy & poor kids.

1.2 PRODUCT RANGE

1. Forged Top links & Parts

.

Fig. no. 1.2 (a)

2. Pto Adaptors

Fig. no. 1.2 (b)

3. Draw Bars & Stay Straps

`

Page | 10

Fig. no. 1.2 (c)

4. Weldons

Fig. no. 1.2 (d)

5. Forged Top Links & Parts

Fig.no- 1.2(e)

6. Stabilizers

Fig. no.-1.2(f)

7. Pins

`

Page | 11

Fig. no.-1.2(g)

8. Hitch balls

Fig. no. -1.2(h)

9. Tine bushes

Fig. no. 1.2 (i)

10. Weather caps

`

Page | 12

Fig. no. 1.2 (j)

11. Levelling boxes

Fig. no. 1.2 (k)

12. Small parts

`

Page | 13

Fig. no. 1.2 (l)

pin

`

Page | 14

CHAPTER 2:

RAW MATERIAL PROCUREMENT

The raw material is in form of long cylindrical rods. The raw material is different

types of nuts & bolts. The colour codification for different for different materials are

as follows:

Material

Colour Code

Mild Steel /C-30 No colour

6T/EN-8K White

EN-8D Black

CK-45 Brown

SAE-1541 Yellow

SAE-4140 Sky Blue

SAE-8620 Pink

EN-353 Green

41 Cr 4 Navy Blue

H.D.S. 9% W White, Red

H.C.H. Cr Yellow, Red

O.H.N.S. Yellow, Navy Blue

H.S.S. 16:4:1 (TCV) White, Yellow

H.S.S. 6:5:2 White, Navy Blue

EN-24 Yellow, Green

EN-31 Sky-Blue, Navy Blue

EN-36 Yellow, Black

H.D.S. 5% Cr Sky Blue, Red

EN-45 White, Green

42 Cr Mo2 Smoke Grey

SAE 15B41 Orange

`

Page | 15

2.1 RAW MATERIAL SUPPLY

As per the quality policy of every industry the raw material for a manufacturing must

be of excellent quality as per the requirement. These materials are passed through a

metallurgy laboratory for inspection and testing as per requirements. There are

various Indian industries for fulfilling the raw material requirement of the industry.

Some of the majors industries which supply the raw material to are listed as follow:-

1. Garg Industries, Dhandari

2. O.K. Industries Pvt. Ltd.Dhandari

3. Prem Auto Ltd.

4. Surinder Engineering Works

When the raw material is once unloaded in the industry, then the yellow tag is

given to it. Yellow tag is used to show that the material is going under inspection and

testing in the metallurgy laboratory. After the inspection and testing if it is found that

material has a quality and properties as per industrial requirements, then green tag is

given to it and if it fails as per the requirements, then red tag is given to it.

`

Page | 16

CHAPTER 3:

MANUFACTURING INFRA-STRUCTURE

BAR DRAWING FACILITY

COLD FORGING FACILITY

HOT FORGING FACILITY

HEAT TREATMENT FACILITY

Carburising

Hardening

Tempering

Annealing

INDUCTION HARDENING

MACHINING FACILITY

SURFACE TREATMENT

Phosphating

Auto black

Zinc Electro-plating

Painting

TOOL ROOM

FERROUS & NON FERROUS BUSH SHOP

`

Page | 17

3 3. .1 1 M MANUFACTURING F FACILITIES

The strength and expertise in the development and manufacture of Components due to

our In-house facilities has explored new horizons to provide a vast range

of components. Almost all the operations are carried out under One-roof.:-

3.1 Bar Drawing Facility

Step Turning Acid Pickling Bar Drawing

Bar Straightening Power Press Band Saw

Fig: 3.1 Processes in Bar Drawing

In a rod or bar drawing, the product must remain straight. In the Bar Drawing Section

the following steps are followed:-

1. Step turning

2. Pickling

`

Page | 18

3. Drawing

4. Straightening

5. Cutting

6. Facing & chamfering

There are the following machines in the bar drawing section:-

1. Step turning machines 3

2. Pickings tanks 8

3. Chain draw benches 5

4. Straightening machines 5

5. Cutting machine

Shearing presses 7

Band saws 3

6. Facing & chamfering

Single end chamfering 5

Both end chamfering 3

`

Page | 19

3 3. .2 2 F FO OR RG GI IN NG G F FA AC CI IL LI IT TY Y

Fig. 3.2 Forging Process

Facilities:

Friction Screw & Power Press

Centre Lathes

Drilling

SPMs.

Dia Reduction

Cold Heading Double Stroke &

Single Stroke

`

Page | 20

3 3. .3 3 H HE EA AT T T TR RE EA AT TM ME EN NT T

(Carburizing, Hardening, Tampering, Annealing )

Fig. 3.3 Induction hardening & Muffle Furnaces

Facilities:

Oil Fired Salt Bath Furnace

Oil Quenching

Water Quenching

Air Circulated Furnace

Electric Muffle Furnace

Electric Salt Bath Furnace

Tempering Plant Air Circulated

Electric Pre-Heating

Annealing

Induction Hardening

`

Page | 21

3 3. .4 4 M MA AC CH HI IN NE E S SH HO OP P

(Forged Components)

Fig. 3.4 Machining Process

Facilities:

Production Lathes

Milling

Threading, Thread Rolling

Polishing

Drilling

Rotary Milling

Tapping

`

Page | 22

3 3. .5 5 M MA AC CH HI IN NE E S SH HO OP P

(Drawn Components)

Fig. 3.5 Drawn Components

Facilities:

Grinding

Bore Grinding

Tool Grinder

Slot Making

Drilling

Automatic Cutting

Tapping

Spl. Purpose Coping

Facing

Milling

Nut Forming

`

Page | 23

Bar End Turning

Thread Rolling

U-Bolt Bending

Bar Turning

Production Lathes

Copy Turning

Bar Drawing

Wire Drawing

Bar Straightening

Circular Metal Cutting

Descaling & Re-Coiling

Coil Opening

`

Page | 24

3 3. .6 6 S SU UR RF FA AC CE E T TR RE EA AT TM ME EN NT T

Fig.3.6 Painting & Electroplating Process

Facilities:

Zinc Plating Plant

Auto Blackening Plant

Phosphating Plant,

Shot Blasting M/c

Paint Booth

`

Page | 25

3 3. .7 7 T TO OO OL L R RO OO OM M

Fig. 3.7 Tool Room

Facilities:

Grinding

Tool & Cutter Grinder

Milling

Shaping

Drilling

Planner

Slotting

Pedestral Grinding

Electric Drill

Tap Resharpening

Surface Plate

`

Page | 26

CHAPTER 4:

COMPONENTS MANUFACTURED

For all the components produced, the procedure, before going to machine

shop, is same; which is as follows:

Annealing: The raw material is first of all annealed to refine its grain structure.

Step turning: The first operation is step turning. The long round bar is loaded onto

a platform & is fed to a lathe machine in which a fixture is there to support the tools.

The tooling arrangement is such that four tools are set in circular arrangement. The

rod is sent to the tools which rotate & reduce the diameter of the bar up to a certain

length.

Acid pickling: This operation is done in order to remove any kind of surface

defects on the surface of long round bars. The bars of different diameter are put in

sulphuric acid (commercial grade). The quantity of sulphuric acid required for

different rods of U-bolts is as follows:

Bar thickness Sulphuric acid

(commercial Grade)

11-16 mm 10.0 ltr.

18-20 mm 12.0 ltr.

21-23 mm 15.0 ltr.

24-32 mm 17.5 ltr.

33-45 mm 20.0 ltr.

`

Page | 27

The time period for different rods to be acid pickled is 6-8 hours depending on the

diameter.

Cold bar drawing: Then the acid treated bar is sent to the bar- drawing machine.

The reduced end of the bar is put in the die of required diameter. The end is gripped

by a lock. Then the lock is pulled by a very large force which is applied by a big chain

powered by a heavy motor. Thus the bar gets reduced in diameter but is elongated.

Bar cutting: The elongated bar is then cut by using a power- press. The required

length is once set & an obstacle is fixed at that length. Each time the bar strikes that

obstacle the press is actuated and the bar is cut. But this method is conventional one.

The production is not so high in this case, because at a time only one piece can be cut

& also the quality of cut is not good. So a much advanced method is used, which is

automatic power hacksaw. 8-10 bars are loaded on the machine at a time & hacksaw

is started. Due to automation the hacksaw each time cuts equal length & quality of cut

is also good.

Bar straightening: The bar when elongated gets bent & has to be straightened

before machining. So it is sent to the bar straightening machine. The bars are sent into

the machine in whish two skew rollers are there. These rollers are set to rotate and bar

is passed through them. These rollers straighten the bar.

`

Page | 28

Fig. 4 Plant 1

List of the product manufactured in plant:

SPRING PIN

U-BOLT

OVER RUNNING CLUTCH

TOP LINK PIPE

EYE BOLT

TOP LINK PIN

`

Page | 29

4 4. .1 1 S SP PR RI IN NG G P PI IN N

Fig. 4.1 Spring Pin

This section deals in manufacturing of various types of pins. This section has total 31

machines.

1. Special purpose facing machine

4

2. Horizontal drilling machine

5

3. Vertical drilling machine

2

4. Horizontal milling machine

3

5. Vertical drilling machine

4

6. Horizontal milling machine (single spindle)

5

7. Tapping machine (horizontal)

1

8. Tapping machine (vertical)

3

9. Grooving machine (SPM)

2

`

Page | 30

10. Pneumatic press

1

11. Magna flux crack detection machine

1

The Various Operation performed in manufacturing Spring Pin are

given as.

S. No. Process Description.

1. Step turning.

2. Pickling.

3. Bar Drawing.

4. Straightening.

5. Peel off.

6. a) Auto cutting, Tap hole, Counter sinking & chamfering.

b) Raw grinding.

7. a) Manual cutting.

b) Side facing.

c) Raw grinding.

d) Tap hole drilling.

e) Counter sinking.

f) Chamfering.

8. Stamping .

9. Grease hole drilling.

`

Page | 31

10. Cotter slot .

11. Grease slot .

12. Cross hole drill.

13. De burring of cross hole.

14. Tapping .

15. Oil flow test .

16. Visual inspection.

17. Induction hardening.

18. Inspection hardener.

19. Outer dia grinding.

Important Points :-

.

1. Material used:- C K 45.

2. Application :- it is used to hold the leaf spring with bracket, it is

mainly used in heavy automobiles

.

`

Page | 32

4 4. .2 2 U U B BO OL LT T

Fig. 4.2 U-Bolts

This section deals with the manufacturing of u bolts. These section has a total

of 29 machines.

1. SPM facing

4

2. SPM turning

5

3. Hydraulic press (vertical)

3

4. Hydraulic press (horizontal)

1

5. Profile threading machine

3

6. Center less grinder

1

`

Page | 33

7. Hot bending machine

2

8. Cold bending machine

2

9. Grinding machine

1

10. Air compressor

1

11. SPM for nut assembly

1

12. Stamping machine

2

13. Heater

3

`

Page | 34

The various operations performed in manufacturing U bolts are

given below:-

Sr. No. Process Description.

1. Step turning.

2. Pickling.

3. Bar drawing.

4. Straightening.

5. Blank cutting.

6. End facing.

7. Roll dia turning.

8. Roll dia grinding.

9. Stamping.

10. Thread rolling.

11. Center forging.

12. U forming.

13. Heat treatment.

a) Hardening .

b) Tempering.

14. Surface treatment.

a) Zinc plating .

b) Phosphating.

c) Painting .

`

Page | 35

d) Hydrogen de embrittlement ( heated air circulated

furnace).

15. Final inspection.

16. Nut assembly.

17. Packing.

Important Points :-

1. Material used :- M.S., C-45, EN 8K.

2. Daily production :- 2500pcs (local ), 1500pcs(export).

3. Application :- Clamping the leaf spring with axle.

`

Page | 36

4 4. .3 3 O OV VE ER R R RU UN NN NI IN NG G C CL LU UT TC CH H

Fig. 4.3 Over Running Clutch

The various operations performed in manufacturing over running

clutch are given below:-

S.NO. PROCESS DESCRIPTION

1. Forging

2. Rough Machining

3. CNC Machining 1

st

4. Broaching

5. Machining on male part

6. Press Fitting

7. MIG Welding

8. CNC Machining 2

nd

`

Page | 37

9. Slotting

10. Drilling

11. Finishing

12. Zinc Plating

4 4. .4 4 T TO OP P L LI IN NK K P PI IP PE E

Fig. 4.4 Top Link Pipe

The various operations performed in manufacturing TOP LINK

PIPE are given below:-

S.NO. PROCESS DESCRIPTION

1. Cutting

2. Reducing

3. Boring

4. Threading

`

Page | 38

5. Drilling

6. Buffing

7. Plating

4 4. .5 5 E EY YE E B BO OL LT T

Fig. 4.5 Eye Bolt

The various operations performed in manufacturing EYE BOLT are given

below:-

S.NO. PROCESS DESCRIPTION

1. FORGING

2. CNC MACHINING- 1st

3 3. . C CN NC C M MA AC CH HI IN NI IN NG G 2 2N ND D

4 4. . T TH HR RE EA AD DI IN NG G

5 5. . B BR RI IG GH HT T Z ZI IN NC C P PL LA AT TI IN NG G

`

Page | 39

4 4. .6 6 T TO OP P L LI IN NK K P PI IN N

Fig. 4.6 top Link Pin

The various operations performed in manufacturing Top link Pin

are given below:-

S S. .N NO O. . P PR RO OC CE ES SS S D DE ES SC CR RI IP PT TI IO ON N

1. Cutting

2. Machining

3. Drilling

4. Grinding

5. Zinc Plating

`

Page | 40

CHAPTER 5

H HO OT T F FO OR RG GI IN NG G S SH HO OP P

In this shop the hot forging is done on the specimen (Rod) by the forging press having

pully mechanism to make the parts.

The detail of hot forging shop

1. Part Name : Clevises

Material : Mild Steel

Machine : Hot Forging Machine

2. IInd machine of hot forging power press to make forged lashing bracket for D-

ring.

Part Name : Forged Lashing Bracket for D-ring

Material : Mild Steel

Machine : Hot forging machine

3. IIIrd forging press machine is the make forged lashing rings.

Part Name : Forged Lashing Rings

Material : Mild Steel

Machine : Hot Forging Power Press

`

Page | 41

4. IV machine is to make fringes by hot forging press

Part Name : Fringes

Material : Mild Steel

Machine : Hot forging press.

`

Page | 42

CHAPTER 6

C CO OL LD D F FO OR RG GI IN NG G S SH HO OP P

Various machines in the card forging shop as below:-

1. Trimming machine

2. Cold heading machine

3. Trimming cum reducing machine

4. Cold heading machine (Single stage)

5. Power press

6. Power Press

7. SPM for facing

8. SPM for facing

9. Power press

10. Power Press

11. Power Press

12. Motor Stamping machine

13. Tool Grinding

14. Tool Grinder

15. Tool Grinder

16. Power Press

17. Centre lathe for coiling

18. Centre Lathe

19. Thread rolling machine

20. Vertical drilling machine

`

Page | 43

21. Vertical drilling machine

22. Vertical drilling machine

23. Vertical drilling machine

24. SPM for facing

25. Thread rolling machine

26. SPM for roll dia turning

27. SPM for roll dia turning

28. SPM for Stud Facing

29. SPM for Stud Facing

30. Caustic Soda Drum

31. Saw Dust Drum

32. Fire Brick Cutter

33. Trimming machine

34. Header (Single stage)

`

Page | 44

CHAPTER 7

H HE EA AT T T TR RE EA AT TM ME EN NT T

Heat treatment is an important operation in the manufacturing process of many

machine parts and tools. Only by heat treatment is it possible to impart the high

mechanical properties to steel required for the normal operation of modern machinery

and tools.

Heat treatment of various items is done in this section. Heat treatment is

defined as an operation of heating and cooling of metal in the solid state to induce

certain desired properties of steel by changing the size and shape of the grain of which

it is composed or by changing its micro-constituents. It is generally employed for the

following purpose:-.

1. To improve machinability.

2. To change or refine grain size.

3. To relieve the stress of the metal induced during hot and cold working.

4. To increase resistance to wear, heat and corrosion.

5. To produce a hard surface on a ductile interior.

The heat treatment processes used here are:-

1. ANNEALING

`

Page | 45

2. HARDENING

3. TEMPERING

7 7. .1 1 A AN NN NE EA AL LI IN NG G

Fig. 7.1 Annealing Furnace

Annealing is one of the most important widely- used

operations in the heat treatment of the steel . The purpose of annealing is to

obtain softness, improve machinability, increase or restore ductility and

toughness relive internal stresses, refine grain size and to prepare steel for

subsequent heat treatment. Slow cooling is required in annealing to enable the

austenite to decompose at low degree of super cooling so as to form

pearlite+ferrite structure in hypoeutectoid steel.

`

Page | 46

7 7. .2 2 H HA AR RD DE EN NI IN NG G

Fig. 7.2 Induction Hardening

Hardening is heat treatment process in which steel is heated to a temperature

above the critical point, held at this temperature and then quenched in water ,oil ,or

molten salt baths. Hardened steel is in a stressed condition and is very brittle so that it

cannot be employed for practical purpose after hardening steel must be tempered to

reduce the brittleness relive the internal stress caused by hardening and to obtain

predetermined mech. Properties. Hardening temperature& time depends upon

chemical composition and resence of carbon contents. The more carbon and alloying

admixtures in a steel and the more intricate and large the part being hardened the

slower it should heated to avoid stresses due to temperature difference between the

internal and external layer of metal , warping , and even cracking.

`

Page | 47

7 7. .3 3 T TE EM MP PE ER RI IN NG G

Fig. 7.3 Muffle Furnace

Tempering leads to the decomposition martensite

into a ferrite-cementite mixture and strongly affects all properties of steel. At low

tempering temperature the hardness changes only to a small extent and the true tensile

strength and bending strength are increased. A further increase in tempering

temperature reduce the hardness true tensile strength, propotional limit and yield point

while the relative elongation and reduction of area are increased. The cooling rate

after tempering has a great effect on the residual stresses. The slower an article is

cooled, the less the residual stresses will be. The properties of steel after hardening

followed by tempering are always higher than that of annealed steel.

The various heat treatment processes being given to various categories of jobs involve

the following procedure.

`

Page | 48

1. The given pieces of jobs are tied together with an ordinary piece of wire just for

the purpose of holding the group of pieces so that they could be properly dipped in

the tank.

2. Now the various are suspended in the preheated tank for the preheating purpose.

Temperature involves is about 400 degree celcius. The pre heater consist of three

electrode and a thermocouple for detecting the temperature of the bath. Panel

consisting of regularity temp. Controls the whole process.

3. After preheating the pieces are now ready for any further heat treatment process.

Now for hardening purpose the material are again suspended in hardening furnace

whose temperature about 830 to 880 degree Celcius. The bath consists of salt

neutral in character and melts to liquid form under heating. The soaking time

consist of for 9mm.thick object are 15 min. then for quenching the materials are

dipped in oil tank till the material gets cooled to room temp. The quenching media

consist of various type depending upon the material composites and properties, for

e.g. :- for mild steel they use water and for hot die steel they use air as a medium

for cooling purpose.

4. Tempering is carried out in order to remove brittleness of the material .Tempering

consist of heating it about 555 to 720 degree celcius, range differ for different

material

`

Page | 49

5. . The soaking time is about 20 min.

6. Then the piece is clean with the help of caustic soda and hydrochloric acid. They

use caustic soda to remove grease, oil etc.

7. Next the surface finished process of phosphating \ auto black \ zinc plating is

carried out.

8. The thickness of coating is about 10 microns. Special care has to be made for the

U-bolt increases after heat treatment process .The gap has to be reduced manually

by means of hammer.

PROCEDURES FOR HEAT TREATMAENT

1. TITLE:-Procedure for control of heat treatment process.

PURPOSE:-To ensure that the process is carried out under controlled conditions by

qualified operators to ensure that specific requirements are met.

SCOPE:-This process covers all the items requiring heat treatment.

`

Page | 50

RESPONSIBILITY:-Section in charge is responsible for implementation to this

procedure. H.O.D works and plant in charge are overall responsible for

implementation of this procedure.

2. TITLE:-Procedure for material storage and material handling at shop floor.

PURPOSE:-To ensure proper handling, damage free movement and proper storage of

material during process.

SCOPE:-It covers all the activities related to the material handling and storage for all

the material being processed at shop floor.

RESPONSIBILITY:-All section in charge and plant in charges are responsible for

effective implementation of this procedure in respective areas H.O.D works is overall

responsible.

SR. NO. MATERIAL HARDENING /

NORMALIZING

TEMPERING

1. EN-8D/C-45 830-860 550-660

2. EN-15/SAE-1541 840-870 550-660

`

Page | 51

3. EN-18/14Cr4 850-880 550-700

4. EN-14/SAE-4140 850-880 550-720

5. EN-45 870-930 400-550

6. EN-353/SAE-8620 780-820 150-200

7.4 I IN ND DU UC CT TI IO ON N H HA AR RD DE EN NI IN NG G

Fig. 7.4 Induction Hardening

Surface hardening is a selective heat treatment in which the surface layer of a metal

are hardened to a certain depth while a relatively soft core is maintained.

`

Page | 52

TYPES OF INDUCTION HARDENING

A. Hardening with high frequency induction heating

B. Harding with electrical contact resistance heating

C. Hardening with electrolytic heating

D. Oxyacetylene flame hardening.

The principle purpose of surface hardening is to increase the hardness and wear

resistance of the surface of metal articles. At the same time, the reliability in operation

of a machine component is increased, as well as its fatigue limit.

At YERIK INTERNATIONAL a high frequency current about 200 Hz is

passed through a cooper inductor block, which acts as a primary coil of transformer,

the block is placed around but does not touch the surface to be hardened. The heating

effect is due to the induction eddy current and hysteresis loss in the surface material

.The heated jobs are then quenched immediately by spray of water delivered through

numerous of small holes in the block. A depth case of approximately 3mm. is

obtained in about 5 sec.

`

Page | 53

ADVANTAGES OF INDUCTION HARDENING

1. It enables the time requirement for heat treatment to be sharply reduced ,thereby

increasing the labor productivity.

2. Article may be heated with practically no scaling so that the metal allowance for

subsequent machining may be reduced.

3. Deformation due to heat treatment is considerably reduced.

`

Page | 54

CHAPTER 8

N NO ON N F FE ER RR RO OU US S B BU US SH H S SH HO OP P

Fig. 8.1 Aluminium Bronze Bushes

Cell-1

1. SPM Lathe

2. SPM Lathe

3. SPM Lathe

4. SPM Lathe

5. Grinding machine

6. Grinding Machine

`

Page | 55

Cell-2

1. SPM Lathe

2. SPM Lathe

3. SPM Lathe

4. SPM Lathe

5. Grooving machine

Cell No.-3

1. SPM Lathe

2. SPM Lathe

3. SPM Lathe

4. SPM Lathe

Cell No. 4

1. Drilling machine

2. SPM Lathe

3. SPM Lathe

4. SPM Lathe

5. SPM Lathe

6. Facing Machine

7. Grooving Machine

`

Page | 56

8. Reaming machine

PROCESS FOR MAKING NON FEROUS BUSH SHOP

1. Make core from the core sand for the bush

2. Then place the core in the die

3. Pour the molten brass in the die

4. After cooling of the bush the runner and riser are break with the help of

hammer.

5. The milling operation is done on the bush.

There are different-2 sizes of bush of different diameter and different length.

These are machine and in the machining section. There are four cell- Cell No. 1,

2,314 for making bush of different sizes.

i) Spring Bush

ii) Bell Crank Bush Big

iii) Bush for King Pin.

The machining operation done on spring bush in Cell No.1

Cell No. 1

Operations Machines

1. Internal diameter SPM Lathe

turning (rough)

`

Page | 57

2. Internal Diameter SPM lathe

turning final

3. Outer Diameter Turning SPM lathe

facing, chamfering and

inner diameter chamfer

4. 2

nd

side facing SPM lathe

5. Grinding Grinding Machine

6. Packing Manually

SPRING BUSH

Operations

1. Internal Diameter turning rough

2. Internal Diameter tuning final

3. Outer diameters turning

4. 2

nd

side facing

5. Oil grooving

Cell No.3

Bell Crank Bush Big

1. Internal Diameter turning rough

2. Internal Diameter reaming

3. Outer Diameter turning

4. Facing

`

Page | 58

5. Grinding

Cell No. 4

Bush for king Pin

1. Internal diameter turning rough

2. Internal diameter turning final

3. Outer diameter turning final

4. Side facing

5. Grinding

6. Oil grooving

7. Stamping

`

Page | 59

CHAPTER 9

SURFACE TREATMENT

9 9. .1 1 Z ZI IN NC C P PL LA AT TI IN NG G S SH HO OP P

Fig.10.1 Electroplating Barrel

The products are transferred from machine shop to zinc plating shop for zinc

plating. The procedure for zinc plating is as under

1. Caustic is done to removed the Grease on the products

2. Wash in the cold water tank

3. H.C.L. tank

4. Electrolysis Electrolysis i.e. Zinc-plating is done in tank in which there are

two zinc plates and the one barrel which is reveled by the gear and the products are to

which zinc planting is done are placed in it. After that they are take off from the tank

and wash, them check with Gauge for the correct quality ( Salt in the tank like boric

acid etc.) There are small 2 holes in the barrel for go salt solution in the barrel for zinc

platting.

In this way the zinc plating is done.

`

Page | 60

9 9. .2 2 P PH HO OS SP PH HA AT TI IN NG G S SH HO OP P

After the heat treatment is done, nut, bolt are phosphating or auto black. There

are number of tanks in which dilute solution for auto black

or for phosphating. We discuss below the process how the phosphating

is done.

PROCEDURE OR STEPS FOR BLACK PHOSPHATING

1. Degreasing So that Grease on the product should be removed

2. Cold water

3. Cold water

4. Acid pickling (HCL acid)

5. Cold water

6. Cold water

7. Cold water

8. Blackening by black Fast (BF 100)

9. Cold water

10. Oil coat (OC 20)

11. Oil coat (OC 20)

`

Page | 61

PROCEDURE OR STEPS FOR GREY PHOSPHATING

1. Degreasing So that Grease on the product should be removed

2. Cold water

3. Cold water

4. Acid pickling (HCL acid)

5. Cold water

6. Cold water

7. Cold water

8. Blackening by grey Fast (BF 99)

9. Cold water

10. Oil coat (OC 20)

11. Oil coat (OC 20)

`

Page | 62

PROJECT -1 :-

Aim of the Project

To reduce set up time in formation of stud using cold forging and hence improve the

production.

Research methodology

1. To study the whole cycle of stud formation using cold forging

2. Analyse the whole process

3. Suggest ways to improve the whole cycle and increase the efficiency of machine.

INTRODUCTION

Cold forging Cold forging deforms metal while it is below its recrystallization point.

Cold forging is generally preferred when the metal is already a soft metal, like

aluminum. This process is usually less expensive than hot forging and the end product

requires little, if any, finishing work. Sometimes, when aluminum is cold forged into

a desired shape, it is heat treated to strengthen the piece. This is called "tempering.

The Cold Forging Process

Despite the word "cold," cold forging actually occurs at or near room temperature.

The most common metals in cold forging applications are usually standard or carbon

alloy steels. One of the most common types of cold forging is a process called

impression-die forging, where the metal is placed into a die that is attached to an

anvil. The metal is then hit by a descending hammer and forced into the die.

`

Page | 63

Depending on the product, the hammer may actually be dropped on the metal

numerous times in a very rapid sequence.

Cold Forging Considerations We choose cold forging over hot forging for a

number of reasonssince cold forged parts require very little or no finishing work,

that step of the fabrication process is often dispensable, which saves money. Cold

forging is also less susceptible to contamination problems, and the final component

features a better overall surface finish. Other benefits of cold forging include:

Easier to impart directional properties

Improved interchangeability

Improved reproducibility

Increased dimensional control

Handles high stress and high die loads

Produces net shape or near-net shape parts

Some possible disadvantages include:

Easier to impart directional properties

Improved interchangeability

Improved reproducibility

Increased dimensional control

Handles high stress and high die loads

Produces net shape or near-net shape parts

`

Page | 64

The metal surfaces must beclean and free of scale before forging occurs

The metal is less ductile

Residual stress may occur

Heavier and more powerful equipment is needed

Stronger tooling is required

INTRODUCTION TO PROJECT SET UP TIME Setup Time is defined as the

time to change from the last item of the previous order to the first good item of the

next order. It is also known as changeover time. IN GENERAL TERMS it is The

time between the last good part off the current run and the first good part off the next

run.

IT INCLUDES

1 Preparation. 30%

2 Removing and

mounting.

5%

3 Measurements,

calibration and

settings.

15%

4 Trail runs and

adjustments.

50%

The present set up includes formation of stud using cold forging on single header

machine .This machine works on a simple principle in which the rotational force of a

motor is transformed into a translational force vector. Therefore the energy in a

`

Page | 65

mechanical press comes from the motor. Mechanical presses are generally faster than

hydraulic or screw presses. Unlike some presses, in a mechanical press, the

application of force varies in both speed and magnitude throughout the distance of the

stroke. When performing a manufacturing operation using a mechanical press, the

correct range of the stroke is essential.These types of presses are commonly used in

forging manufacture, and sheet metal working. A mechanical press is often a good

choice for impact extrusion, since a fast, quickly repeatable application of force over a

limited distance is what is needed for that type of manufacturing operation. The

eccentric press uses a motor to drive an eccentric shaft, rotating in a connecting rod.

The connecting rod moves a ram in a slider joint one dimensionally. The eccentric

shaft itself is round, therefore it may completely rotate within the connecting rod. The

center of the drive is not the center of the overall shaft. As the motor rotates, the

center of the drive remains stable but the overall center of the shaft changes. This

causes the shaft to change position, providing motion.

The rotation of shaft causes the header to move forward which has a die fixed in its

mouth .

`

Page | 66

Raw material is loaded onto a platform and it is automatically feeded into the slot

where die is fixed in the base of machine. The system is controlled by a cam

mechanism which drives its 114

power from the shaft itself with the help of bevel gears. When the ingot is placed into

the mouth the header strikes and the metal piece is forged with the help of the die. In

the slot side a ejector pin is provided which ejects the work piece once it is forged.

This ejector is operated with the help of cam which derives its

power from main shaft. The system is such that in 2 strokes of header only 1 single

piece is formed. This is done so because sometimes the work piece gets stuck in the

header so that can deform the whole work piece and can harm the machine itself. The

cam system is also adjusted according to that.

`

Page | 67

With the current set up around 17 pieces are manufactured per minute. The main

problem arising with this set up is that the production rate is too low. So to increase

the production rate following remedies are provided. 116

REMEDIES

PROPOSAL 1

First solution to this problem is to provide an ejector pin on the inner side of the

header that can strike the work piece that gets struck into the header if any. This

ejector pin will work wiyh the help of a cam operated system driving power from the

machine itself . This proposal if implemented precautiously after taking due

`

Page | 68

limitations into consideration can increase the production to about 35 work pieces in a

minute.

PROPOSAL 2 "SMED" (Single Minute Exchange of Dies)

Setup includes preparation, replacement, location and adjustment activities.It is easy

to experience a reduction of set-up time from hours to minutes by following a simple

process called "SMED" which means "Single Minute Exchange of Dies." This process

was developed in Japan by Shigeo Shingo during the 1950's. Firstly we should

determine which activities are internal and external. External elements of work can be

completed while the machine is still running e.g. get the next tool, get all your clamps,

get lifting equipment in place, put equipment away, etc. Internal elements of work can

only be done while the machine is stopped e.g. change the tool, adjust the machine

depth, sharpen a tool (which requires the machine to be stopped), etc. Incredible

reductions is total setup time have been realized simply by making internal activities

external activities. The following four-step approach may be used to reduce setup

time:

EXAMPLE FIGURE

1. Classify each setup step as either Internal or External. Internal steps are those done

while the process is inactive. External steps are done while the process is operating.

2. Convert Internal steps to External steps. We want to reduce the time the process is

non-operational, so we need to reduce the time associated with the Internal steps. The

quickest way to do this is to do as many of these steps as we can while the process is

operational. For example, if we can collect the money from the customer as their

burgers are being cooked, then the total cycle time is reduced.

`

Page | 69

3. Reduce time for remaining Internal steps. There are some Internal steps that cannot

be donewhile the process is operational. We now want to concentrate on reducing the

time required to complete those steps that require the process to be delayed. For

example, since the burgers cannot be cooked until we know what the customer wants

to order, we will try to reduce the time it takes to place the customer order.

4. Eliminate adjustments. Adjustments, as discussed in the Analyze stage, can be

reduced through effective process control. Designed Experiments may be used to

understand the causes of process variation that precede the adjustment. As you can see

from the diagram once you can define an internal or external element, you can

separate them. This will allow us to complete all external elements for the next set-up

while the machine is still running the current parts. When the current run is finished,

everything required for changeover to the next part is available and ready.

CONCLUSION :-

This proposal if implemented precautiously after taking due limitations into

consideration can increase the production to about 35 work pieces in a minute.

Potrebbero piacerti anche

- Lmescience 2 SemDocumento39 pagineLmescience 2 SemJasvir SinghNessuna valutazione finora

- Seminar On Solar Power GenerationDocumento17 pagineSeminar On Solar Power GenerationJasvir Singh100% (2)

- Energy Conversion 15Documento34 pagineEnergy Conversion 15Bala MuruganNessuna valutazione finora

- Main WeldingDocumento44 pagineMain WeldingJasvir SinghNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Global Environment and Operations StrategyDocumento73 pagineThe Global Environment and Operations StrategyJoy LuNessuna valutazione finora

- oscarUK05 07Documento4 pagineoscarUK05 07nikolatnNessuna valutazione finora

- AR-82 Painting MetalworkDocumento5 pagineAR-82 Painting MetalworkAmal ChinthakaNessuna valutazione finora

- 26.strengthening of Structural Elements by Ordinary Reinforcement (New One)Documento49 pagine26.strengthening of Structural Elements by Ordinary Reinforcement (New One)deepesh3191Nessuna valutazione finora

- Line History SheetDocumento4 pagineLine History SheetBethel NdifonNessuna valutazione finora

- A 738 MX30 Cinza 3279 EnglishDocumento2 pagineA 738 MX30 Cinza 3279 EnglishThiago TorresNessuna valutazione finora

- Remalox HD 35 Optimum Impact and Wear ProtectionDocumento2 pagineRemalox HD 35 Optimum Impact and Wear ProtectionCamilo MesaRNessuna valutazione finora

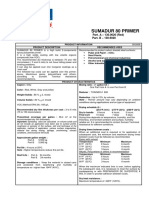

- 130.0020 - Sumadur 80 PrimerDocumento2 pagine130.0020 - Sumadur 80 Primerhelioxavier2Nessuna valutazione finora

- Through Weld Renewal - 03Documento40 pagineThrough Weld Renewal - 03Vijay KanugantiNessuna valutazione finora

- Cleaning and Passivation of Stainless Steel Using CitrisurfDocumento3 pagineCleaning and Passivation of Stainless Steel Using CitrisurfChitu IulianNessuna valutazione finora

- Logistics Lifecycle Within The Product LifecycleDocumento4 pagineLogistics Lifecycle Within The Product LifecycleTuan NguyenNessuna valutazione finora

- Frontier School Division Job Safety Analysis for Milling Machine OperationsDocumento5 pagineFrontier School Division Job Safety Analysis for Milling Machine OperationsAshok SureshNessuna valutazione finora

- GSK Quality in Supply Chain & After SalesDocumento15 pagineGSK Quality in Supply Chain & After SalesReal Will SelfNessuna valutazione finora

- Tata Consulting Engineers Limited Minimum Inspection Requirements For Butterfly ValvesDocumento2 pagineTata Consulting Engineers Limited Minimum Inspection Requirements For Butterfly Valveser_sanjaypatelNessuna valutazione finora

- Cost of Goods Manufactured Formula Excel TemplateDocumento5 pagineCost of Goods Manufactured Formula Excel TemplatePrecious UmingaNessuna valutazione finora

- Physical Distribution Chapter 7Documento63 paginePhysical Distribution Chapter 7Yeshambel EwunetuNessuna valutazione finora

- Simufact - Professional Forming SimulationDocumento12 pagineSimufact - Professional Forming SimulationMrLanternNessuna valutazione finora

- Chemical Pulping ProcessDocumento19 pagineChemical Pulping ProcessSyahmi HarizNessuna valutazione finora

- 4T03 Site Handover Meeting Minutes v4-0Documento11 pagine4T03 Site Handover Meeting Minutes v4-0engsam777Nessuna valutazione finora

- Quality Control - Wikipedia, The Free EncyclopediaDocumento3 pagineQuality Control - Wikipedia, The Free EncyclopediaBaguma Grace GariyoNessuna valutazione finora

- Microstructure Exp. 1: Metals and CompositesDocumento29 pagineMicrostructure Exp. 1: Metals and CompositesR-wah LarounetteNessuna valutazione finora

- Metel Drilling - Irwin PDFDocumento20 pagineMetel Drilling - Irwin PDFArun SasiNessuna valutazione finora

- Pert7Documento14 paginePert7Ardi Pribadi100% (1)

- US Steel Corporation Case Analysis in Strategic ManagementDocumento7 pagineUS Steel Corporation Case Analysis in Strategic ManagementraymundsagumNessuna valutazione finora

- Chapter 14 RevisedDocumento18 pagineChapter 14 RevisedLim Cia ChienNessuna valutazione finora

- Mca GoldDocumento1.604 pagineMca GoldBramh NarayanNessuna valutazione finora

- Dye Penetrant TestDocumento14 pagineDye Penetrant TestSaif FaridiNessuna valutazione finora

- Monarch CPI oil water separatorsDocumento2 pagineMonarch CPI oil water separatorskumarvns111Nessuna valutazione finora

- LNG WeldingDocumento12 pagineLNG Weldingrodofgod100% (1)

- Pool Plaster and Concrete Product GuideDocumento42 paginePool Plaster and Concrete Product GuideMuhammad Farhan PutraNessuna valutazione finora