Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

OILCO Swivel Joint Catalog No508 PDF

Caricato da

hamr010 valutazioniIl 0% ha trovato utile questo documento (0 voti)

244 visualizzazioni36 pagineOILCO Corporation designs, engineers, and manufactures a wide range of standard and specialty equipment. Every component is made of the finest materials and machined to precision tolerances. Swivel joints are manufactured in eight styles, available in cast, manufactured and jacketed versions.

Descrizione originale:

Titolo originale

OILCO Swivel Joint Catalog No508.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoOILCO Corporation designs, engineers, and manufactures a wide range of standard and specialty equipment. Every component is made of the finest materials and machined to precision tolerances. Swivel joints are manufactured in eight styles, available in cast, manufactured and jacketed versions.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

244 visualizzazioni36 pagineOILCO Swivel Joint Catalog No508 PDF

Caricato da

hamr01OILCO Corporation designs, engineers, and manufactures a wide range of standard and specialty equipment. Every component is made of the finest materials and machined to precision tolerances. Swivel joints are manufactured in eight styles, available in cast, manufactured and jacketed versions.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 36

PO Box 226 Monmouth Junction, NJ 08852 USA

Phone: 732-329-4666 Fax: 732-329-9422

Email: sales@oilco-usa.com

www.oilco-usa.com

L

L

o

o

a

a

d

d

i

i

n

n

g

g

Arm Catalog

2008

Catalog No. 508

S

S

w

w

i

i

v

v

e

e

l

l

J

J

o

o

i

i

n

n

t

t

C

C

a

a

t

t

a

a

l

l

o

o

g

g

PO Box 226 Monmouth Junction, NJ 08852 USA

Phone: 732-329-4666 Fax: 732-329-9422

Email: sales@oilco-usa.com

www.oilco-usa.com

Quality For Over 70 Years

In 1935, the OILCO Corporation, through one of its divisions, introduced the first completely packaged loading

assembly to the petroleum industry. This spirit of innovation, and commitment to quality and leadership which are the

hallmarks of our philosophy, keep OILCO brand products at the forefront of the liquid handling industry today.

OILCO Corporation designs, engineers, and manufactures a wide range of standard and specialty equipment. Every

component is made of the finest materials and machined to precision tolerances. CNC and advanced milling

operations ensure proper dimensional accuracy. Castings are tested three times throughout the manufacturing

process to ensure absolute accuracy.

Loading arms and swivel joints are most often associated with the petroleum and petrochemical industries. The

fact is, however, that these sturdy and versatile devices are used for liquid handling in a multitude of industries;

metal manufacturing, marine loading and unloading, and general contracting. The following is a brief review of the

major components of liquid handling systems, and how they have helped industries flourish.

S Sw wi iv ve el l J Jo oi in nt ts s

Essential components in the liquid handling systems, swivel joints are a fixture in American industry. These

unassuming but precisely engineered devices give loading arms usually rigid the flexibility needed to meet

necessary handling requirements.

OILCO swivel joints are manufactured in eight styles, available in cast, manufactured and jacketed, with

flanged, threaded, or welded ends. All are adaptable to piping, tubing, and hoses. And all can be modified to meet

requirements for inlets, outlets, counterbalancing, and connections. They are also available in a variety of metal

alloys, seal compounds, and finishes.

Low Torque Type: Recently introduced by OILCO with the only documented research curve, these units

reduce torque by up to 65% as compared to conventional swivel joints

Split Flange Design: Introduced by OILCO in the late 80s, these units allow for packing seal replacement

without removal of ball bearings

TimkenRoller Bearing Type: Guaranteed for life, removable seal design

Roller Bearing Type: the most traditional swivel joint, long lasting, low cost

Q Qu ua al li it ty y

Every OILCO product must pass a battery of tests to assure you of the highest reliability and performance and to live

up to the OILCO name. This includes all trade standards, domestic and international shipping regulations, and all ISO

9001-2000 compliances. Castings are tested for operational and surface defects. Machined parts are scrutinized for

tightness under pressure. Special manufacturing processes such as flame hardening are used to ensure long term

product performance. After every OILCO swivel joint is assembled, it is tested again to ensure that swivels perform

under maximum pressure or vacuum.

T

T

a

a

b

b

l

l

e

e

o

o

f

f

C

C

o

o

n

n

t

t

e

e

n

n

t

t

s

s

Product Overview 1

Swivel J oint Configurations 2

OILCO Numbering System 2

80 Series O Ring Swivel J oints 3

880 Series O Ring Swivel J oints 3

90 Series V Ring Swivel J oints 4

857 Removable Seal Swivel J oint 4

Split Flange Swivel J oints 5

2000 Roller Bearing Series Swivel J oints 5

Low Torque (LT) 90 Series 6

Stainless Steel Insert Series (SSI) 7

Special Application Swivel J oints 7

Steam J acketed Swivel J oints 8

14, 16 & 18 Swivel J oints 9

Counterbalance Swivel J oints 10

80 Series Threaded Connections 11

80 Series Flanged Connections 13

880 Series Threaded Connections 15

880 Series TTMA Connections 17

90 Series Threaded Connections 19

90 Series Flanged Connections 21

2000 Series Threaded 23

2000 Series Flanged 25

Steam J acketed Flanged 27

Swivel J oint Data Sheet Questionnaire 29

Chemical Resistance Chart 31

O O- -R Ri in ng g & & V V- -R Ri in ng g D De es si ig gn n

The standard OILCO O-ring is a single point pressure seal design.

Contained within opposing grooves, the compression along the

sealing surfaces promotes a positive adherence while maintaining

rotation and keeping friction loss to its minimum. Buna-N is

standard, but Viton, Teflon, Nitrile, Kalrez, Chemrez, EPDM

and EPR are available options, depending on the product and

customer requirements.

The OILCO V-ring is a triple seal configuration, spring energized,

and self-adjusting for normal wear. A Teflonspring adapter and

equally spaced compression springs forces the interlocking three

seals to flare and constantly maintain an optimal positive seal.

Buna-N is standard, but Viton, Teflon, Nitrile, Kalrez,

Chemrez, EPDM and EPR are available options, depending on

the product and customer requirements.

B Ba al ll l B Be ea ar ri in ng g & &

T Ti im mk ke en n R Ro ol ll le er r B Be ea ar ri in ng g

OILCO utilizes various ball bearing and dimensional

specifications to offer the highest moment load to swivel joint

ratio in the industry. OILCO begins the swivel joint line with a

graduated ball bearing design in the dual, flame hardened

raceways. Ball bearings are available in either chrome or

stainless steel.

For extreme load carrying capacity, OILCO offers a swivel

joint line incorporating the tapered Timkenroller bearing.

Virtually friction free movement, the roller bearings offer

superior durability and permanent alignment with simple seal

replacement and easy internal maintenance.

S Sw wi iv ve el l J Jo oi in nt t O Op pt ti io on ns s & &

S Sp pe ec ci ia al l P Pr ro oj je ec ct t A Ap pp pl li ic ca at ti io on ns s

OILCO offers the industry both the most swivel joint design

options and the most extensive level of secondary options.

Available on most series, OILCO can manufacture customer

specific applications in less time than anyone else. Such

options include:

Low Torque

Epoxy Coating

Stainless Steel Inserts

Customized Additions or Design

Regardless of the complexity of the project, OILCO can design

and manufacture the right swivel every time.

Page 1

OILCO manufactures the traditional eight configurations of swivel joint design. Each can be modified

accordingly, and both the inlet and outlet connections can be tailored to suit the specific job requirements.

Style 10

3 Planes of Rotation

Style 20

1 Plane of Rotation

Style 30

1 Plane of Rotation

Style 40

1 Plane of Rotation

Style 50

2 Planes of Rotation

Style 60

2 Planes of Rotation

Style 70

2 Planes of Rotation

Style 80

3 Planes of Rotation

Connection end and material descriptions

F - 150#RF ANSI flanges

NF - TTMA tank truck flanges

O - NPT threads

S - Carbon steel

SS - Stainless steel

A - Aluminum

M - Modified

(*no indication note is female NPT threads)

Seal Compounds:

V Viton

T Teflon

EPR EPR

EPDM EPDM

K - Kalrez

C - Chemrez

(*no indication is Buna-N)

Special Extension Notes:

LT - Low Torque design

P - Sealed for submerged

service

H - Handle

(*epoxy paint, modifications,

etc. also noted here)

Seal compound type

Final extensions beyond seal indicate

special application or treatment

Identifies the connection ends and materials used for

construction

Indicates nominal pipe

size of unit

Illustrates series style, the final digit

noting the overall configuration

8 8 9 92 2- -F FS S- -T T- -L LT T

Page 2

M Mo od de el l 8 80 0 S Se er ri ie es s S Sw wi iv ve el l J Jo oi in nt t

The OILCO 80 Series is a heavy duty, leak proof construction and low

maintenance joint. Flow restrictions and product turbulence are held to a

minimum. And for submerged applications, the 80 Series is excellent

when utilized as a submerged service unit.

It is a ball bearing, single point seal design with a felt dust seal backup that allows for an endless number of

applications. The 80 Series is available in carbon steel, stainless steel T-316, and aluminum. Sizes range from

1 1/2" to 6" in all materials. All styles are available in flanged, threaded, and butt-weld ends. Packing seal

material is Buna-N (standard) but Viton, Teflon, Nitrile, Kalrez, Chemrez, EPDM and EPR are available.

The 80 Series swivel joint is a leak proof, low maintenance design. It has widely spaced ball races allowing for

better alignment and longer packing life. Flow restriction and internal turbulence are held to a minimum with a

smooth bore design. The single point seal will operate under both a vacuum and a pressure environment. And

the felt dust seal prevents all foreign matter from entering the swivel chamber.

There is also a vast range of optional lubrication media that allows the 80

Series to competitively operate in a multitude of environments. It can be packed

and sealed for use as a submerged service unit. It can be cleaned and treated

for use in oxygen transfer. And it can even be greased and prepared for use in

the commercial food industry. This makes the OILCO 80 Series swivel joint an

indispensable element in todays industrial arena.

M Mo od de el l 8 88 80 0 S Se er ri ie es s S Sw wi iv ve el l J Jo oi in nt t

Designed to be a light weight, sturdy, entry model swivel joint, the cast

aluminum 880 Series includes all the traditional industry requirements in

an affordable unit.

Standardized features include full rotation along the swivel plane, wide

ball race spacing for increased load carrying capacity, and precision

milled pressure seal and dust seal surfaces. A single o ring design with

available compounds of Buna-N (standard), Viton, Teflon, Nitrile,

Kalrez, Chemrez, EPDM and EPR are available. This allows for

multiple use applications. The 880 Series can be plugged for submerged

operating conditions.

The 880 Series is available from 2 to 4 sizes, with either threaded or flanged connections. Optional coatings

are available upon request, or swivel joints can be left with a natural cast finish.

A primary loading arm component, the 880 Series swivel joints offer the versatility of the OILCO line at a

competitive price. With proper installation and maintenance, these swivel joint can be in the field for years with

problem free service. Repair kits are readily available for all sealing compounds.

Page 3

M Mo od de el l 9 90 0 S Se er ri ie es s S Sw wi iv ve el l J Jo oi in nt t

The 90 Series swivel joint is designed with a three "V" ring seal

configuration that is spring loaded and self adjusting for normal wear.

The incorporation of these "V" rings maintains a constant optimal

pressure, securing a reliable seal long after conventional single rings or

compression seals may be compromised.

The 90 Series is available in carbon steel, stainless steel T-316, and

aluminum. Sizes range from 1 1/2" to 12" in all materials. All styles are

available in flanged, threaded, butt-weld ends, or even socket ends.

Packing seal material is Buna-N (standard) but Viton, Teflon, Nitrile,

Kalrez, Chemrez, EPDM and EPR are available.

OILCO has also developed a secondary manufacturing process

specifically for the 90 Series swivel joints, creating the "low torque" (LT)

version. These extensively treated swivels reduce the amount of torque

up to 65% as compared with conventional swivels. Friction in the sealing

and ball race surfaces are dramatically reduced, therefore providing a

swivel joint that can be used in damage critical environment.

Most commercial concerns, through over 50 years of field research and testing have been addressed by the

OILCO 90 Series. These improvements are a standard and have been incorporated into the line without changing

any of the external dimensions, insuring market consistency. By far, this swivel joint covers the widest range of

production and safety considerations in the market today.

Page 4

M Mo od de el l 8 85 57 7 R Re em mo ov va ab bl le e S Se ea al l

This popular riser swivel joint is precision engineered and built of the

finest materials to give long life, trouble free service under the most

extreme conditions. It is the most commonly utilized swivel joint for

unsupported bottom loading assemblies. The 857 Series comes

standard with Timkenroller bearings that afford a friction free

movement in the horizontal plane. The sealing surface is maintained

by a CNC milled collar unit that features a double "O" ring design over

a polished sleeve, which can be replaced within 15 minutes while

never having to dismantle the loading arm assembly.

The Model 857 riser swivel joint is constructed of machine milled

carbon steel. The sealing chamber is protected by a high density

plastic shield. Packing seal material is Buna-N (standard) but Viton,

Teflon, Nitrile, Kalrez, Chemrez, EPDM and EPR are available.

Standard configuration is a style 20 with 150#raised faced, flanged

ends. It is offered in 4 size.

S Sp pl li it t F Fl la an ng ge e S Sw wi iv ve el l J Jo oi in nt ts s

A modified version of the OILCO 80 Series swivel joint line, the 1400 and 1900 Split Flange Series adopts all the

traditional criteria of the O ring swivel and offers it in a removable seal version. It is a ball bearing, single point

seal design with a dust seal backup that allows for an endless number of applications. The split flange series is

available in carbon steel, stainless steel T-316, and aluminum, with various seal configurations. Sizes range from 1

1/2" to 6" in all materials, and up to 18 in carbon steel and stainless steel. All styles are available in flanged,

threaded, and butt-weld ends.

The 1400 and 1900 Series have widely spaced ball races allowing for better

alignment and longer packing life. The single point seal will operate under both a

vacuum and a pressure environment. Packing seal material is Buna-N (standard)

but Viton, Teflon, Nitrile, Kalrez, Chemrez, EPDM and EPR are available.

And the felt dust seal prevents all foreign matter from entering the swivel

chamber. The split design of the body cavity allows for easy in-field service

without having to remove the ball bearings. This greatly reduces the risk of

operator and maintenance error, while constantly assuring proper alignment as

determined by the factory. Further, the pressure seal has been positioned in

such a manner that replacement time is considerably reduced.

Like the 80 Series, the Split Flange Series can be lubricated in various manners enhancing the versatility of

application. It can be packed and sealed for use as a submerged service unit. It can be cleaned and treated for

use in oxygen transfer. And it can even be greased and prepared for use in the commercial food industry

2 20 00 00 0 S Se er ri ie es s w wi it th h T Ti im mk ke en n

R Ro ol ll le er r B Be ea ar ri in ng gs s

The OILCO 2000 Series offers the best load carrying capacity in the industry. Unequalled in durability and overall

moment ratings, combined with virtually friction free movement and minimal seal wear, there is simply no other

swivel joint that measures up to its performance level.

Timkenroller bearings are proven stronger than any other

conventional bearings. And put inside the precision CNC milled

2000 Series swivel joint spool, permanent alignment is assured.

Such is the confidence in the manufacturing of the 2000 Series,

the bearings are guaranteed by OILCO for the life of the joint.

Only subject to proper installation, operation and regularly

scheduled maintenance.

The OILCO 2000 Series is offered in carbon steel, stainless steel

T-316 and aluminum. Packing seal material is Buna-N (standard)

but Viton, Teflon, Nitrile, Kalrez, Chemrez, EPDM and EPR

are available. The 2000 Series has a wide range of availability

2 through 12. And all styles are available in threaded, flanged,

and butt weld connections.

Page 5

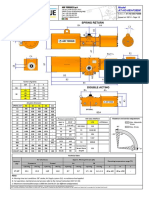

L Lo ow w T To or rq qu ue e S Se er ri ie es s L LT T

The application of the low torque option for the 90

Series swivel joint is for the entire nominal size

range. Following the CNC milling stage, the spool

sleeve is polished on a lathe and turned to an extra

smooth surface. The body portion receives a

specifically tailored honing. And the swivel joint

utilizes a specific low friction graphite lubricant. This

process is also not limited to carbon steel units, but

can be applied to both aluminum and stainless steel

assemblies as well. Illustrated below is the torque

curve for these swivel joints. The averages are

taken from working conditions, in 75F ambient

temperatures, and are +5 in/lb as indicated. Units

are rated with standard seals.

The Low Torque ("LT") model swivel joint is a specifically conditioned 90 Series swivel joint that reduces torque

up to 65% more than any other conventional joint. The low torque option is a secondary procedure applied

during the manufacturing process, prior to welding procedures. Uses of the LT Series are where chinking of

hoses or unnecessary wear are of crucial concern. The low torque swivel can be broken with a minimal amount

of manual pressure, assisting in ease of use for the operator. The 90 Series Low Torque is vital to sensitive

operations.

Page 6

S St ta ai in nl le es ss s S St te ee el l I In ns se er rt ts s

In order to continually find better ways in serving the industry, OILCO has

developed a special hybrid swivel joint in order to meet several working

concerns and cost efficiency issues. The development of the stainless steel

inserts for use in the 90 Series swivels has increased the life expectancy of

the standard carbon steel units, while not forcing the consumer to rely

solely on the markedly higher priced full stainless steel T-316 version.

Inspired by the needs of the iron and steel mills, OILCO sought to

understand the complex chemical problems for pumping vast quantities of

on site water through the lids of the melting pots. Due to the intense

chemical treatment of the water, standard steel joints were suffering with

extensive pitting and corrosion of the sealing surface. While traditional

wisdom would warrant the use of stainless steel, the problem still arose,

albeit in a slower timeline. However, the use of upgraded stainless steel

(especially in the larger 10" and 12" sizes) became a huge cost

consideration for the plant engineers.

By isolating the critical areas of the sealing service, OILCO managed to develop a

process that mates the benefits of stainless steel, while keeping the cost of the unit

down to a more manageable level. The result was the stainless steel insert swivel

joint. These swivels are dimensionally identical to their carbon steel and stainless

steel counterparts, but utilize the necessary aspects of each material to prolong the

seal life and seal area integrity.

S Sp pe ec ci ia al l A Ap pp pl li ic ca at ti io on n S Sw wi iv ve el ls s

OILCO Liquid Handling Systems has a tradition of outfitting even the most

complex and demanding application with the absolute right swivel joint.

Regardless of 80 Series, 90 Series, split flange, or even steam jacketed,

OILCO has tirelessly worked to fulfill engineering specifications and

customer needs. This unique ability to customize an already diverse swivel

joint line is what truly marks the innovative side of OILCO and its product

capabilities.

Ranging from special mounting circumstances, to epoxy coating, to modified

handling and insertion, OILCO has the ability to manufacture any swivel joint

necessary to fulfill project requirements. It is through the ability to restructure

the manufacturing and assembly process, that OILCO can continually alter

the project to suit tedious requirements or otherwise rare engineering

conditions.

OILCO Liquid Handling Systems leads the industry in hands on adaptability.

Regardless of core differences in unit design, simple exterior coating, dated

reproduction work, or complex "one-off" innovations, OILCO has the tradition

and desire to satisfy those needs.

Page 7

S St te ea am m J Ja ac ck ke et te ed d S Sw wi iv ve el l J Jo oi in nt ts s

OILCO Liquid Handling Systems has an extensive history in the development of steam jacketed

equipment for custom applications. Beginning in 1981 in collaboration with DuPont, OILCO was able

to benchmark the most complete jacketing design and conform to all operating expectations. Drawing

on these decades of experience, almost any loading or unloading configuration can be made to serve as

a steam jacketed assembly. Internal product lines can handle 500 psi while the steam chambers can

work up to a range of 150 psi. The swivel joint packing seals are able to withstand temperatures of up to

600 F. All internal elbows are long radius and standard weight, allowing the assembly to be piggable

when required. The incorporated joints are adaptable to suction or pressure lines with standard packing

seals. Research, design, and adaptability are all keys features for both the individual components and

complete units required to service any given project.

Constructed of a lighter gauge material on the exterior of the

unit, a standard jacket will allow steam to circulate evenly in

order to preclude binding of the product. The external jacketing

of OILCO's swivel joints not only covers the elbow, but also the

entire ball race swivel area, providing positive rotation at all

times. Every swivel joint and associated assembly is

manufactured with long radius elbows to allow the application to

be piggable. These steam jacketed swivel are used for such

viscous materials as petroleum products, asphalt, tars, heavy

oil, liquid sulphur, chemicals, and food products. Steam jacketed

swivels are available in sizes ranging from 2" to 10" and are

constructed from carbon steel, stainless steel, or aluminum.

Packing seal material is Buna-N (standard) but Viton, Teflon,

Nitrile, Kalrez, Chemrez, EPDM and EPR are available.

Steam jacketed swivel joints and loading assemblies are necessary where the

product being transferred has an increased tendency to stiffen due to cooler

ambient temperatures. By circulating a high pressure steam around the primary

unit, flow rates will remain constant and the chance of a stall or clog is

significantly reduced. Also, by heating the transfer zone, either a loading arm or

swivel joint, the area within the assembly is kept clear of obstructions.

Steam jacketing also aids service in colder climates where the tendency for

swivels to "freeze" or lock is commonplace. By pumping hot steam through the

surrounding chambers, the raceways and sealing surfaces are properly

maintained and easier to operate. The secondary effect of this is increased life of

the swivel and packing seals by reducing the amount of friction.

Page 8

Standard Dimensions

Size A B

in. mm in. mm in. mm

14 356 21 533 24 607

16 406 23.5 597 24 607

18 457 25 635 25 635

Page 9

O Ov ve er rs si iz ze ed d & & H He ea av vy y D Du ut ty y

1 14 4 , , 1 16 6 & & 1 18 8 S Sw wi iv ve el l J Jo oi in nt ts s

Based on industry feedback, and the consistent shift to higher

volume transfers, OILCO Liquid Handling Systems has

concentrated some of its focus on reliable and simple maintenance

swivels joints. By expanding the already well known 1400 and

1900 Split Flange Series, OILCO increased the overall dimensions

of the units to accommodate many of the mainstream pipeline

sizes.

These swivels have widely spaced ball races allowing for better

alignment and higher moment load. The single point seal will

operate under both a vacuum and a pressure environment.

Packing seal material is Buna-N (standard) but Viton, Teflon,

Nitrile, Kalrez, Chemrez, EPDM and EPR are available. Felt

and O-ring dust seals prevent all foreign matter from entering the

ball chamber and a secondary rubber seal prevents debris from

contacting the main pressure seal. The split design of the body

cavity allows for easy in-field service without having to remove the

ball bearings. This greatly reduces the risk of operator and

maintenance error, while constantly assuring proper alignment as

determined by the factory.

The large size Split Flange Series is offered in both

carbon steel and stainless steel T-316. The ball

chambers are CNC milled and then polished to

specific tolerances to ensure load carrying capacity

and rotation throughout the operational life of the

swivel joint. Dual grease fittings are installed

directly over the ball retainers screws in order to

best direct lubricate and protect the raceways. And

to further combat corrosion based on atmospheric

conditions, the customer can add the option of

stainless steel ball bearings.

For larger transfer requirements, the OILCO Split

Flange Series offers the range to handle some of

the heaviest commercial pipelines and installations

in the industry.

Page 10

T To or rs si io on n S Sp pr ri in ng g C Co ou un nt te er rb ba al la an nc ce ed d

S Sw wi iv ve el l J Jo oi in nt ts s

OILCO Liquid Handling Systems manufactures each of the major

configurations of swivel joints in conjunction with the torsion spring

counterbalance. Each unit (i.e. the single spring Model 641, the

double spring Model 640, and the double-double spring Model 645) is

available for mounting on every style 50 or style 70 swivel joint. Every

swivel joint configuration is also available with any number of inlet and

outlet combinations; male threaded, flanged, or female half coupling. OILCO

can design the counterbalance swivel joint units to be piggable (as seen to the

right in the steam jacketed model), welded construction, or engineered to

required specifications by the customer to meet project needs. The versatility

in the OILCO torsion spring and its mounting swivel is undeniable.

Upfeed Counterbalance Swivel Joints

1 15 50 0# # R Ra ai i s se ed d F Fa ac ce e

C Co on nn ne ec ct t i i o on n

R Ri i g gh ht t H Ha an nd d P Pl l a an n

6 64 40 0/ /6 64 45 5 M Mo ou un nt t i i n ng g

F Fe em ma al l e e N NP PT T C Co on nn ne ec ct t i i o on n

L Le ef f t t H Ha an nd d P Pl l a an n

6 64 41 1 M Mo ou un nt t i i n ng g

T TT TM MA A F Fl l a an ng ge ed d

C Co on nn ne ec ct t i i o on n

R Ri i g gh ht t H Ha an nd d P Pl l a an n

6 64 40 0/ /6 64 45 5 M Mo ou un nt t i i n ng g

M Ma al l e e N NP PT T C Co on nn ne ec ct t i i o on n

L Le ef f t t H Ha an nd d P Pl l a an n

6 64 40 0/ /6 64 45 5 M Mo ou un nt t i i n ng g

Downfeed Counterbalance Swivel Joints

M Ma al l e e N NP PT T C Co on nn ne ec ct t i i o on n

L Le ef f t t H Ha an nd d P Pl l a an n

6 64 40 0/ /6 64 45 5 M Mo ou un nt t i i n ng g

F Fe em ma al l e e N NP PT T C Co on nn ne ec ct t i i o on n

R Ri i g gh ht t H Ha an nd d P Pl l a an n

6 64 40 0/ /6 64 45 5 M Mo ou un nt t i i n ng g

F Fe em ma al l e e N NP PT T C Co on nn ne ec ct t i i o on n

R Ri i g gh ht t H Ha an nd d P Pl l a an n

6 64 41 1 M Mo ou un nt t i i n ng g

T TT TM MA A F Fl l a an ng ge ed d

C Co on nn ne ec ct t i i o on n

R Ri i g gh ht t H Ha an nd d P Pl l a an n

6 64 40 0/ /6 64 45 5 M Mo ou un nt t i i n ng g

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 7 5/8 9 1/8 10 5/16 15 1/4

Size 2 3 4 6

A 6 5/8 7 5/8 8 11 1/8

B 4 5 6 8 3/4

Size 2 3 4 6

A 7 5/8 10 5/8 10 5/16 15 1/4

B 3 4 1/2 5 11/16 7 7/8

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 3 4 1/2 5 11/16 7 7/8

8 81 1- -S S

S St ty yl le e 1 10 0

8 82 2- -S S

S St ty yl le e 2 20 0

8 83 3- -S S

S St ty yl le e 3 30 0

8 84 4- -S S

S St ty yl le e 4 40 0

Page 11

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 3 4 1/2 5 11/16 7 7/8

C 7 5/8 9 1/8 10 5/16 15 1/4

Size 2 3 4 6

A 7 5/8 9 1/8 10 5/16 15 1/4

B 4 5 6 15 1/4

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 3 4 1/2 5 11/16 7 7/8

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 7 5/8 9 1/8 10 5/16 15 1/4

C 3 4 1/2 5 11/16 7 7/8

8 85 5- -S S

S St ty yl le e 5 50 0

8 86 6- -S S

S St ty yl le e 6 60 0

8 87 7- -S S

S St ty yl le e 7 70 0

8 88 8- -S S

S St ty yl le e 8 80 0

Page 12

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 9 1/8 10 3/8 11 5/8 16 7/8

Size 2 3 4 6

A 9 5/8 10 1/8 10 5/8 14 3/8

B 6 7 1/2 9 11

Size 2 3 4 6

A 9 1/8 10 3/8 11 5/8 16 7/8

B 4 1/2 5 3/4 7 9 1/2

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 4 1/2 5 3/4 7 9 1/2

8 81 1- -F F

S St ty yl le e 1 10 0

8 82 2- -F F

S St ty yl le e 2 20 0

8 83 3- -F F

S St ty yl le e 3 30 0

8 84 4- -F F

S St ty yl le e 4 40 0

Page 13

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 4 1/2 5 3/4 7 9 1/2

C 9 1/8 10 3/8 11 5/8 16 7/8

Size 2 3 4 6

A 9 1/8 10 3/8 4 16 7/8

B 6 7 1/2 9 11

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 4 1/2 5 3/4 7 9 1/2

Size 2 3 4 6

A 8 5/8 10 5/8 12 5/8 19 3/8

B 9 1/8 10 3/8 11 5/8 16 7/8

C 4 1/2 5 3/4 7 9 1/2

Page 14

8 85 5- -F F

S St ty yl le e 5 50 0

8 86 6- -F F

S St ty yl le e 6 60 0

8 87 7- -F F

S St ty yl le e 7 70 0

8 88 8- -F F

S St ty yl le e 8 80 0

Size 2 3 4

A 5 9/16 5 15/16 7 5/8

Size 2 3 4

A 6 11/16 8 1/4 10 5/8

B 6 3/16 7 1/16 9 1/8

Size 2 3 4

A 6 3/16 7 1/16 9 1/8

B 2 7/8 3 7/8 3 3/4

Size 2 3 4

A 6 11/16 8 1/4 10 5/8

B 2 7/8 3 7/8 9 1/8

8 88 81 1- -A A

S St ty yl le e 1 10 0

8 88 82 2- -A A

S St ty yl le e 2 20 0

8 88 83 3- -A A

S St ty yl le e 3 30 0

8 88 84 4- -A A

S St ty yl le e 4 40 0

Page 15

Size 2 3 4

A 6 11/16 8 1/4 10 5/8

B 2 7/8 3 7/8 7 1/16

C 6 3/16 7 1/16 9 1/8

Size 2 3 4

A 6 3/16 7 1/16 9 1/8

Size 2 3 4

A 6 11/16 8 1/4 10 5/8

B 2 7/8 3 7/8 4 3/4

C 6 3/16 7 1/16 9 1/8

Size 2 3 4

A 6 11/16 8 1/4 10 5/8

B 2 7/8 3 7/8 4 3/4

8 88 85 5- -A A

S St ty yl le e 5 50 0

8 88 86 6- -A A

S St ty yl le e 6 60 0

8 88 87 7- -A A

S St ty yl le e 7 70 0

8 88 88 8- -A A

S St ty yl le e 8 80 0

Page 16

Size 2 3 4

A n/a 8 1/4 10 5/8

B n/a 8 1/16 10 1/8

Size 2 3 4

A n/a 6 5/16 8 5/8

Size 2 3 4

A n/a 8 1/16 10 1/8

B n/a 4 7/8 5 3/4

Size 2 3 4

A n/a 8 1/4 105/8

B n/a 4 7/8 5 3/4

8 88 81 1- -A AN NF F

S St ty yl le e 1 10 0

8 88 82 2- -A AN NF F

S St ty yl le e 2 20 0

8 88 83 3- -A AN NF F

S St ty yl le e 3 30 0

8 88 84 4- -A AN NF F

S St ty yl le e 4 40 0

Page 17

Size 2 3 4

A n/a 8 1/4 10 5/8

B n/a 4 7/8 5 3/4

C n/a 11 15/16 14 7/8

Size 2 3 4

A n/a 8 1/16 10 1/8

Size 2 3 4

A n/a 8 1/4 10 5/8

B n/a 4 7/8 5 3/4

Size 2 3 4

A n/a 8 10 5/8

B n/a 4 7/8 5 3/4

C n/a 8 1/16 10 1/8

8 88 85 5- -A AN NF F

S St ty yl le e 5 50 0

8 88 86 6- -A AN NF F

S St ty yl le e 6 60 0

8 88 87 7- -A AN NF F

S St ty yl le e 7 70 0

8 88 88 8- -A AN NF F

S St ty yl le e 8 80 0

Page 18

Size 2 3 4 6 8

A 8 7/8 11 1/8 14 3/4 20 3/8 24 3/4

B 7 7/8 9 5/8 12 7/16 16 1/4 18 7/8

Size 2 3 4 6 8

A 6 7/8 8 1/8 9 3/8 12 1/8 13

B 4 5 6 9 1/4 11

Size 2 3 4 6 8

A 7 1/8 9 5/8 12 7/16 16 1/4 18 7/8

B 3 4 1/2 5 11/16 7 7/8 10 1/8

Size 2 3 4 6 8

A 8 7/8 11 1/8 14 3/4 20 3/8 24 3/4

B 3 4 1/2 5 11/16 7 7/8 10 1/8

C 6 9 11 3/8 15 3/4 20 1/4

9 91 1- -S S

S St ty yl le e 1 10 0

9 92 2- -S S

S St ty yl le e 2 20 0

9 94 4- -S S

S St ty yl le e 4 40 0

Page 19

9 93 3- -S S

S St ty yl le e 3 30 0

9 97 7- -S S

S St ty yl le e 7 70 0

9 98 8- -S S

S St ty yl le e 8 80 0

Size 2 3 4 6 8

A 8 7/8 11 1/8 14 3/4 20 3/8 24 3/4

B 3 4 1/2 5 11/16 7 7/8 10 1/8

C 7 7/8 9 5/8 12 7/16 16 1/4 18 7/8

Size 2 3 4 6 8

A 7 7/8 9 5/8 12 7/16 16 1/4 18 7/8

B 4 5 6 9 1/4 11

Size 2 3 4 6 8

A 8 7/8 11 1/8 14 3/4 20 3/8 24 3/4

B 3 4 1/2 5 11/16 7 7/8 10 1/8

Size 2 3 4 6 8

A 8 7/8 11 1/8 14 3/4 20 3/8 24 3/4

B 7 7/8 9 5/8 12 7/16 16 1/4 18 7/8

C 3 4 1/2 5 11/16 7 7/8 10 1/8

9 95 5- -S S

S St ty yl le e 5 50 0

9 96 6- -S S

S St ty yl le e 6 60 0

Page 20

Size 2 3 4 6 8 10 12

A 8 11 1/8 14 3/4 20 3/8 24 3/4 31 1/16 37 1/2

B 9 3/8 10 7/8 13 3/4 17 7/8 20 3/4 25 1/16 30

Size 2 3 4 6 8 10 12

A 9 7/8 10 5/8 12 3/4 15 3/8 16 3/4 19 1/16 22 1/2

B 6 7 1/2 9 11 13 1/2 16 19

Size 2 3 4 6 8 10 12

A 9 3/8 10 7/8 13 3/4 17 7/8 20 3/4 25 1/16 30

B 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

Size 2 3 4 6 8 10 12

A 8 7/8 11 1/8 14 3/4 20 3/8 24 31 1/16 37 1/2

B 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

C 9 11 1/2 14 19 24 28 33

9 91 1- -F F

S St ty yl le e 1 10 0

9 92 2- -F F

S St ty yl le e 2 20 0

Page 21

9 93 3- -F F

S St ty yl le e 3 30 0

9 94 4- -F F

S St ty yl le e 4 40 0

Size 2 3 4 6 8 10 12

A 8 7/8 11 1/8 14 3/4 20 3/8 24 3/4 31 1/16 37 1/2

B 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

C 9 3/8 10 7/8 13 3/4 17 7/8 20 3/4 25 1/16 30

Size 2 3 4 6 8 10 12

A 9 3/8 10 7/8 13 3/4 17 7/8 20 3/4 25 1/16 30

B 6 7 1/2 9 11 13 1/2 16 19

Size 2 3 4 6 8 10 12

A 8 7/8 11 1/8 14 3/4 20 3/8 24 3/4 31 1/16 37 1/2

B 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

Size 2 3 4 6 8 10 12

A 8 7/8 11 1/8 14 3/4 20 3/8 24 3/4 31 1/16 37 1/2

B 9 3/8 10 7/8 13 3/4 17 7/8 20 3/4 25 1/16 30

C 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

9 95 5- -F F

S St ty yl le e 5 50 0

9 96 6- -F F

S St ty yl le e 6 60 0

9 97 7- -F F

S St ty yl le e 7 70 0

9 98 8- -F F

S St ty yl le e 8 80 0

Page 22

Size 2 3 4 6

A 9 3/4 12 1/2 15 1/8 21

B 8 3/4 11 13 3/16 17

Size 2 3 4 6

A 7 3/4 9 1/2 10 7/8 13

B 5 1/2 7 7/8 9 11

Size 2 3 4 6

A 3 4 1/2 5 11/16 8

B 8 3/4 11 13 3/16 17

Size 2 3 4 6

A 3 4 1/2 5 11/16 8

B 9 3/4 12 1/2 15 1/8 21

2 20 01 10 0- -S S

S St ty yl le e 1 10 0

2 20 02 20 0- -S S

S St ty yl le e 2 20 0

2 20 03 30 0- -S S

S St ty yl le e 3 30 0

2 20 04 40 0- -S S

S St ty yl le e 4 40 0

Page 23

Size 2 3 4 6

A 3 4 1/2 5 11/16 8

B 9 3/4 12 1/2 15 1/8 21

C 8 3/4 11 13 3/16 17

Size 2 3 4 6

A 8 3/4 11 13 3/16 17

B 5 1/2 8 9 11

Size 2 3 4 6

A 3 4 1/2 5 11/16 8

B 9 3/4 12 1/2 15 1/8 21

Size 2 3 4 6

A 3 4 1/2 5 11/16 8

B 9 3/4 12 1/2 15 1/8 21

C 8 3/4 11 13 3/16 17

2 20 05 50 0- -S S

S St ty yl le e 5 50 0

2 20 06 60 0- -S S

S St ty yl le e 6 60 0

2 20 07 70 0- -S S

S St ty yl le e 7 70 0

2 20 08 80 0- -S S

S St ty yl le e 8 80 0

Page 24

Size 2 3 4 6 8 10 12

A 9 3/4 12 1/2 15 1/8 21 26 1/4 31 1/2 36 3/4

B 10 1/4 12 1/4 14 1/8 18 1/2 22 1/4 25 1/2 29 1/4

Size 2 3 4 6 8 10 12

A 10 3/4 12 13 1/8 16 18 1/4 19 1/2 21 3/4

B 6 7 1/2 9 11 13 1/2 16 19

C 5 3/4 6 1/2 7 1/8 9 10 1/4 11 1/2 12 3/4

Size 2 3 4 6 8 10 12

A 10 1/4 12 1/4 14 1/8 18 1/2 22 1/4 25 1/2 29 1/4

B 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

Size 2 3 4 6 8 10 12

A 9 3/4 12 1/2 15 1/8 21 26 1/4 31 1/2 36 3/4

B 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

2 20 01 10 0- -F F

S St ty yl le e 1 10 0

2 20 02 20 0- -F F

S St ty yl le e 2 20 0

2 20 03 30 0- -F F

S St ty yl le e 3 30 0

2 20 04 40 0- -F F

S St ty yl le e 4 40 0

Page 25

Size 2 3 4 6 8 10 12

A 9 3/4 12 1/2 15 1/8 21 26 1/4 31 1/2 36 3/4

B 10 1/4 12 1/4 14 1/8 18 1/2 22 1/4 25 1/2 29 1/4

C 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

Size 2 3 4 6 8 10 12

A 10 1/4 12 1/4 14 1/8 18 1/2 22 1/4 25 1/2 29 1/4

B 6 7 1/2 9 11 13 1/2 16 19

Size 2 3 4 6 8 10 12

A 9 3/4 12 1/2 15 1/8 21 26 1/4 31 1/2 36 3/4

B 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

Size 2 3 4 6 8 10 12

A 9 3/4 12 1/2 15 1/8 21 26 1/4 31 1/2 36 3/4

B 10 1/4 12 1/4 14 1/8 18 1/2 22 1/4 25 1/2 29 1/4

C 4 1/2 5 3/4 7 9 1/2 12 14 16 1/2

2 20 05 50 0- -F F

S St ty yl le e 5 50 0

2 20 06 60 0- -F F

S St ty yl le e 6 60 0

2 20 07 70 0- -F F

S St ty yl le e 7 70 0

Page 26

2 20 08 80 0- -F F

S St ty yl le e 8 80 0

Size 2 3 4 6 8 10

A 10 7/8 14 1/8 18 3/4 26 3/8 32 3/4 41 1/16

B 10 3/8 12 3/8 15 3/4 20 7/8 24 3/4 30 1/16

Size 2 3 4 6 8 10

A 10 3/8 11 1/8 13 1/4 16 3/8 17 3/4 20 1/16

Size 2 3 4 6 8 10

A 10 3/8 12 3/8 15 3/4 20 7/8 24 3/4 30 1/16

B 6 7 3/4 9 1/2 13 1/2 16 1/2 20

Size 2 3 4 6 8 10

A 10 7/8 14 1/8 18 3/4 26 3/8 32 3/4 41 1/16

B 6 7 3/4 9 1/2 13 1/2 16 1/2 20

9 91 1- -F FS SJ J

S St ty yl le e 1 10 0

9 92 2- -F FS SJ J

S St ty yl le e 2 20 0

9 93 3- -F FS SJ J

S St ty yl le e 3 30 0

9 94 4- -F FS SJ J

S St ty yl le e 4 40 0

Page 27

Size 2 3 4 6 8 10

A 107/8 14 1/8 18 3/4 26 3/8 32 3/4 41 1/16

B 6 7 3/4 9 1/2 13 1/2 16 1/2 20

C 10 3/8 12 3/8 15 3/4 207/8 24 3/4 301/16

Size 2 3 4 6 8 10

A 103/8 12 3/8 15 3/4 20 7/8 24 3/4 201/16

Size 2 3 4 6 8 10

A 107/8 14 1/8 18 3/4 26 3/4 32 3/4 41 1/16

B 6 7 3/4 9 1/2 13 1/2 16 1/2 20

Size 2 3 4 6 8 10

A 107/8 14 1/8 18 3/4 26 3/8 32 3/4 41 1/16

B 6 7 3/4 9 1/2 13 1/2 16 1/2 20

C 10 3/8 12 3/8 15 3/4 207/8 24 3/4 30 1/16

9 95 5- -F FS SJ J

S St ty yl le e 5 50 0

9 96 6- -F FS SJ J

S St ty yl le e 6 60 0

9 97 7- -F FS SJ J

S St ty yl le e 7 70 0

9 98 8- -F FS SJ J

S St ty yl le e 8 80 0

Page 28

1. What will the product be used for?

2. What size line is being used? Inches / mm

3. Preferred material of construction?

4. Preferred seal material?

5. Minimum operating temperature? F / C

6. Maximum operating temperature? F / C

7. Type of configuration:

Three swivels with straight

end connections at both

ends (3 planes)

Style 10

Single swivel with straight

connections (1 plane)

Style 20

single swivel with 90 degree

elbow at end (1 plane)

Style 30

single swivel with 90 degree

elbows at both ends

(1 plane)

Style 40

two swivels with 90 degree

angles (2 plane)

Style 50

Page 29

two swivels at 90 degree

angle (2 plane)

Style 60

two swivels with elbows at

each end connection

(2 plane)

Style 70

three swivels with additional

elbow (3 plane)

Style 80

8. Connections type:

Butt weld end connections Both Ends One End

150 #raised face weld neck connections Both Ends One End

150 #raided face slip on connections Both Ends One End

Threaded half coupling connections Both Ends One End

TTMA flanged connections Both Ends One End

Special Please specify requirements

Both Ends One End

9. Is the item use for submerged service? Yes No

10. Is the item required to be steam jacketed? Yes No

11. Are there any testing procedures required Yes No

beyond standard hydrostatic pressure tests?

Please Specify:

12. Is there specific documentation required? Yes No

Please Specify:

13. Other requirements:

Page 30

Fluid Metal Seal Material

Key:

A =Excellent

B =Good

C =Fair / Poor

D =Not Recommended

Blank =Insufficient Data

A

l

u

m

i

n

u

m

C

a

r

b

o

n

S

t

e

e

l

S

t

a

i

n

l

e

s

s

S

t

e

e

l

B

u

n

a

-

N

V

i

t

o

n

E

P

R

R

u

b

b

e

r

B

u

t

y

l

T

e

f

l

o

n

Chloroform, dry D B A D B D D A

Chromic Acid 50% D C C C B D D A

Citric Acid B D A B A A A A

Copper Acetate D C A B D A A A

Copper Cyanide D A A B B A

Copper Nitrite D D B A A B B A

Copper Sulfate C D B A A A C A

Cresote B B A A A D D A

Cresote Oil B B B C A D D A

Cresylic Acid C C B D B D D A

Cyclohexane A A A A A D D A

DDT B D B B A D D A

Detergents, synthetic B B B A C A

Dichloroethyl Ether (Chlorex) B B B D C C C A

Dowtherm A B A D A D A

Ethane A C B A A D D A

Ethanol Amine A B A B D B B A

Ethers A A A D C C C A

Ethyl Acetate A B B D D B B A

Ethyl Cellulose A C A B D B B A

Ethyl Chloride, dry B B A B B B B B

Ethyl Chloride, wet D D B B B B B A

Ethylene Chloride C A D B D D A

Ethylene Diamine C B A A D A A A

Ethylene Dichloride D B A D B C C A

Ethylene Glycol A B B A A A A A

Ethylene Oxide B B B D C C C A

Fatty Acids B D A B A C C A

Ferric Chloride D D D C B C C A

Ferric Sulfate D D B A A B B A

Formaldehyde, cold (Formalin) A A A B D B B A

Formaldehyde, hot (Formalin) B D C B D B B A

Formic Acid, cold B D B C C B B A

Formic Acid, hot D D B C C B B A

Freon Gas, dry B B A B B D D A

Freon 11, MF, 112, BF, 12, 13 B A B B D D A

Freon 21 B A D D D D A

Freon 22 A A D D B B A

Freon 113, TF B A B C D D A

Fuel Oil A B A A A D D A

Furfural A A A D D B B A

Gas, Manufactured B B B A A C A

Gas, Natural B B A A A C A

Gas, Odorizers A B B B A A

Gasoline, Aviation A A A C A D D A

Gasoline, Leaded A A A B A D D A

Gasoline, Sour A B A B A D D A

Gasoline, Unleaded A A A B A D D A

Gelatin A D A A A A A

Glucose A B A A A A A A

Glue A A B A A B A

Glycerine (Glycerol) A C A A A A A A

Herbicides See specific chemical listing

Hexane A B B A A D A

Hydraulic Oil, Petroleum Base A A A A A D D A

Hydrocyanic Acid A D A B A A A A

Hydrogen Gas, cold A B A B A A A A

Hydrogen Gas, hot C B B B A A A

Hydrogen Peroxide, Concentrate A D B D A C C A

Hydrogen Peroxide, Dilute A D B B A B A

Hydrogen Sulfide, Dry A B A C D A A A

Hydrogen Sulfide, Wet B C B D D A A A

Hypo (Sodium Thiosulfate) B D A A A B A

Isobutyl Acetate B B A B D B B A

Isobutyl Alcohol B B A D B A A A

Fluid Metal Seal Material

Key:

A =Excellent

B =Good

C =Fair / Poor

D =Not Recommended

Blank =Insufficient Data

A

l

u

m

i

n

u

m

C

a

r

b

o

n

S

t

e

e

l

S

t

a

i

n

l

e

s

s

S

t

e

e

l

B

u

n

a

-

N

V

i

t

o

n

E

P

R

R

u

b

b

e

r

B

u

t

y

l

T

e

f

l

o

n

Acetate Solvents A A A D D D D A

Acetic Acid, aerated B D A C C B A

Acetic Acid, Air Free B D B C D B A

Acetic Acid, crude C C B D D B B A

Acetic Acid, glacial A D A B D B B A

Acetic Acid, pure B D B D D B B A

Acetic Acid, 10% B C B D D B B A

Acetic Acid, 80% B C B D D C A

Acetic Acid Vapors B D D D C D A

Acetone A A A D D A A A

Acetylene A A A B A A A A

Acrylonite B B A D C D D A

Alcohol, Amyl A B A B B A A A

Alcohol, Butyl A B A A A B B A

Alcohol, Ethyl B B A B B A A A

Alcohol, Isopropyl B B B B A A A A

Alcohol, Methyl B C A B D B B A

Alcohol, Propyl A B A B A A A A

Aluminum Chloride C C B A A A A A

Aluminum Flouride C D C A A A A A

Aluminum Potassium Sulfate D B B B B A

Aluminum Sulfate C D B A A A A

Ammonia, Anhydrous Liquid B A A B D A A A

Ammonia, Aqueous B A A B B B B A

Ammonia, Gas, hot B A C D B B A

Ammonia Solutions B B A B D A A A

Ammonium Chloride C C B B A A A A

Ammonium Hydroxide 28% C B B B C B B A

Ammonium Hydroxide, concentrate C C B D C B B A

Ammonium Nitrate B D A A B A A A

Ammonium Phosphate C D B A A A A A

Ammonium Phosphate, Di-basic B D B A D A A A

Ammonium Sulfate C C B A D A A A

Aniline C C B D C B B A

Asphalt Liquid C B A C A D D A

Barium Chloride D C B A A A A A

Barium Hydroxide D C B A A A A

Barium Sulfide D C B A A A A A

Benzene (Benzol) B B B D B D D A

Benzine See Petroleum Ether

Borax (Sodium Borate) C C A B A A A A

Boric Acid B D B B A B A

Butadiene B B A C B D D A

Butane A B B B B D D D

Butyl Acetate B B B D D B B A

Butyl Stearate B B B A D D A

Butylcellosolve A A A D D B B A

Butylene A A A C B D D A

Calcium Acetate C A B D A A A

Calcium Bisulfite C D B A A D D A

Calcium Chloride C C B A A A B A

Calcium Hydroxide D C B A A A A A

Calcium Nitrate C B A B B B B A

Carbonic Acid A D A D B B B A

Carbonic Acid (Phenol) A D B D B C C A

Carbon Dioxide Dry A A A A B B B A

Carbon Disulphide A B A A A D D A

Carbon Tetrachloride, dry B B A B A D D A

Carbon Tetrachloride, Wet D D B C B D D A

Caustic Potash D D B B B B A

Caustic Soda D B A C B B B A

Cellosolve B B B D D B B A

Cellulose Acetate B B D D B B A

Chlorine Gas, dry C B B D B B C A

Chlorobromomethane B A D A C C A

Page 31

Fluid Metal Seal Material

Key:

A =Excellent

B =Good

C =Fair / Poor

D =Not Recommended

Blank =Insufficient Data

A

l

u

m

i

n

u

m

C

a

r

b

o

n

S

t

e

e

l

S

t

a

i

n

l

e

s

s

S

t

e

e

l

B

u

n

a

-

N

V

i

t

o

n

E

P

R

R

u

b

b

e

r

B

u

t

y

l

T

e

f

l

o

n

Propionic Acid 20% B D B A A A

Propylene A A A D A D D A

Propylene Diamine B B A D D D D A

Propylene Dichloride C B B D B D D A

Propylene Glycol A B B A A B B A

Propylene Oxide B B B D D B B A

Resins & Rosins A C A C A A

Rubber or Latex Emulsions A B A A A

Shellac bleached & orange A A A A C B A

Silicone Fluids B B B B B A

Soap Solutions (Stearates) C A A A A A A A

Sodium Aluminate D C B A A A A A

Sodium Bicarboate C C B A A A A A

Sodium Bisulfate 10% D D A A A A A A

Sodium Borate B C B A A A A A

Sodium Carbonate (Soda Ash) D B A A A A A A

Sodium Chloride D C B A A B B A

Sodium Chronate D B A A A A A A

Sodium Cyanide D C B A D A A A

Sodium Hydroxide 20% Cold D A A B B A A A

Sodium Hydroxide 20% Hot D B A B C B B A

Sodium Hydroxide 50% Cold D A A B C A A A

Sodium Hydroxide 50% Hot D B A B C B B A

Sodium Hydroxide70% Cold D C A B C A A A

Sodium Hydroxide 70% Hot D C B C C B B A

Sodium Metaphosphate D D A A B B B A

Sodium Nitrate A B A B D A A A

Sodium Peroxide C C A B A A A A

Sodium Phosphate D C A B A A A A

Sodium Phosphate Di-basic D C B A A A A A

Sodium Phosphate Tri-basic B B A A A A A A

Sodium Silicate D B B A A A A A

Sodium Sulfate B B A A A A A A

Sodium Sulfide C C B A A A A A

Sodium Thiosulfate B C A B A A A A

Stearic Acid A C B A A B B A

Stoddards Solvent A A A A A D D A

Styrene A A A D B D D A

Sulfate, Liquors C C B C B B B A

Sulfuric Acid 0 to 77% D D B D A C C A

Sulfuric Acid 100% D C A D B D D A

Sulfurous Acid C D B C A C C A

Tall Oil C B B B A D D A

Tar & Tar Oils B B A B A D D A

Tartaric Acid B D A B A C C A

Toluol (Toluene) (Methyl Benzene) A A A D B D D A

Trichlorethylene A B B C B D D A

Varnish A C A C B D D A

Vinyl Chloride D A D B C C A A

Water, Distilled A D A A C A A A

Water, Fresh A C A A C A A A

Water, Sea C D A A C A A A

Xylene (Zylol), Dry A B A D B D D A

Fluid Metal Seal Material

Key:

A =Excellent

B =Good

C =Fair / Poor

D =Not Recommended

Blank =Insufficient Data

A

l

u

m

i

n

u

m

C

a

r

b

o

n

S

t

e

e

l

S

t

a

i

n

l

e

s

s

S

t

e

e

l

B

u

n

a

-

N

V

i

t

o

n

E

P

R

R

u

b

b

e

r

B

u

t

y

l

T

e

f

l

o

n

Iso-Butane A A A A D D D A

Iso-Butanol A B A A B B B A

Iso-Propanol B B B B A A A A

Iso-Propylamine A B A A A A A

Isopropyl Acetate A B B D B B B A

J et Fuels, P-4, P-5 and P-6 A A A B A D D A

Kerosene A B A A A D D A

Lacquer (and solvent) A C A D D D D A

Lactic Acid, concentrated hot C D B D B D D A

Lactic Acid Dilute, cold A D A B A B B A

Lactic Acid Dilute, hot B D A C D C C A

Lime Sulphur Solutions C B A D A A A A

LPG A B A A A D D A

Magnesium Chloride D C B A A A A

Magnesium Hydroxide D B A B A B A

Magnesium Sulfate D B A A A B B A

Mercury B A A A A A A A

Methane A B B A A D D A

Methanol B C A B D B B A

Methyl Cellosolve A B A C D B A

Methyl Chloride D B A D B D D A

Methyl Ethyl Keytone A A A D D A A A

Methyl Isobutyle Ketone A A A D D A A A

Mineral Oils A B A A A D D A

Naptha A B B B A D D A

Napthalene B B B D A D A

Napthenic Acid B B A C A D D A

Natural Gas, Sour B B A A A D A

Nickel Chloride D D B A A B B A

Nickel Sulfate D D B A A A A A

Nitric Acid 30% D D A C B B B A

Nitric Acid 80% B D B D C D D A

Nitric Acid 100% B D A D C D D A

Nitrobenzene B B A D C D C A

Nitrogen A A A A A A A A

Nitrogen Fertilizer Solutions B A B A B B A

N. Octane A A A B A D D A

Octyl Alcohol B B A B B B B A

Oils, Petroleum Refined A A A A A D D A

Oils, Petroleum Sour A B A B A D D A

Oils, Water Mixture A B A A A D D A

Oleic Acid B C B C B D D A

Oleum B B B D B D D A

Oxalic Acid C D B C A B B A

Palmitric Acid B C B B A D D A

Perchlorethylene, dry B B A C A D D A

Pesticides See specific chemical listing

Petroleum Ether (Naptha) A A A A A D D A

Phenol A D A D B D A

Phosphoric Acid 10% D D B B B B B A

Phosphoric Acid 50% D D B C B B B A

Phosphoric Acid 80% D B A C B B B A

Phosphoric Acid 85% D C B D B B B A

Phthalic Anhydride B C B C A C C A

Picric Acid C D B C B B B A

Potassium Acetate Solutions D B A B D A B A

Potassium Carbonate D B B A A B A

Potassium Chloride D C B A A A A A

Potassium Cynate Solutions B D A B B A

Potassium Cyanide D B B A A A A A

Potassium Hydroxide, Dilute Cold D A A B D A A A

Potassium Hydroxide, Dilute Hot D B A B D A A A

Potassium Nitrite A B B A A A A A

Potassium Sulfate A B A A A A A A

Producer Gas B B B A A D D A

All ratings are based on media at room temperature

unless otherwise specified. This chart is a guide. Please

be advised that in any given case many factors such as

solution, concentration, temperature, degree of agitation

and presence of impurities influence the rate of corrosion.

The information contained herein is general in nature and

while drawn from sources deemed to be reliable and

presumed accurate, is not guaranteed in any way by

OILCO. Any application requires the use of qualified

experts and subject to limitations normally present.

Page 32

PO Box 226 Monmouth Junction, NJ 08852 USA

Phone: 732-329-4666 Fax: 732-329-9422

Email: sales@oilco-usa.com

www.oilco-usa.com

Serving the Industry Since 1935

T

T

h

h

e

e

S

S

w

w

i

i

v

v

e

e

l

l

J

J

o

o

i

i

n

n

t

t

P

P

e

e

o

o

p

p

l

l

e

e

.

.

c

c

o

o

m

m

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Pro CervoDocumento38 paginePro CervoPacoNessuna valutazione finora

- Storage Tank Design: Email:moemen - Hussein@alexu - Edu.egDocumento58 pagineStorage Tank Design: Email:moemen - Hussein@alexu - Edu.egahmadhatakeNessuna valutazione finora

- Koos Air EliminatorDocumento1 paginaKoos Air Eliminatorhamr01Nessuna valutazione finora

- TECHNICAL INFORMATION FTL8x PDFDocumento32 pagineTECHNICAL INFORMATION FTL8x PDFhamr01Nessuna valutazione finora

- FCX3 Trunnion Ball ValvesDocumento32 pagineFCX3 Trunnion Ball Valveshamr01Nessuna valutazione finora

- SET X Y DA Center of Gravity: ISO 5211 Interface Pressure ConnectionDocumento2 pagineSET X Y DA Center of Gravity: ISO 5211 Interface Pressure Connectionhamr01Nessuna valutazione finora

- Inter Graph TANK Users PDFDocumento143 pagineInter Graph TANK Users PDFhamr01Nessuna valutazione finora

- SCI Carbon Forged Fittings PDFDocumento18 pagineSCI Carbon Forged Fittings PDFhamr01Nessuna valutazione finora

- Red Book # 9105-4 Pontoon Floating Roof General InformationDocumento7 pagineRed Book # 9105-4 Pontoon Floating Roof General Informationhamr01100% (1)

- Swivel Joints General Info DE Lo Res PDFDocumento2 pagineSwivel Joints General Info DE Lo Res PDFhamr01Nessuna valutazione finora

- Tank Roof Design - ConstructabilityDocumento4 pagineTank Roof Design - Constructabilityjvillarro7Nessuna valutazione finora

- External Floating Roof Tank CalcutationsDocumento6 pagineExternal Floating Roof Tank Calcutationshamr01100% (1)

- Korir Et Al. (2014) The Fortification of Tea With Sweeteners and Milk and Its Effect On in Vitro PDFDocumento9 pagineKorir Et Al. (2014) The Fortification of Tea With Sweeteners and Milk and Its Effect On in Vitro PDFYvonne TongNessuna valutazione finora

- Alcohols - Reasoning QnsDocumento5 pagineAlcohols - Reasoning Qnstanishka0307Nessuna valutazione finora

- Ch5. ST - Lecture4 FunctionDocumento50 pagineCh5. ST - Lecture4 Functionsultan khabeebNessuna valutazione finora

- Polypropylene - Chemistry and Production ProcessesDocumento45 paginePolypropylene - Chemistry and Production Processeschiuchan888Nessuna valutazione finora

- Comparison of Hydrogen Specification in National Standards For ChinaDocumento5 pagineComparison of Hydrogen Specification in National Standards For Chinabarun1977Nessuna valutazione finora

- Tobacco Mosaic Virus (TMV) : B.Sc. I Botany Unit - I Lecture - 3Documento5 pagineTobacco Mosaic Virus (TMV) : B.Sc. I Botany Unit - I Lecture - 3vineetvishal73100% (1)

- 8.color Cosmetics-IDocumento24 pagine8.color Cosmetics-Ikamasuke hegdeNessuna valutazione finora

- Mechster 5310P: Commitment To Quality and ConsistencyDocumento1 paginaMechster 5310P: Commitment To Quality and ConsistencyreinpolyNessuna valutazione finora

- NutraHacker Complete SASDocumento9 pagineNutraHacker Complete SASJustin KellyNessuna valutazione finora

- Overview Challenges in The Production of BiodieselDocumento9 pagineOverview Challenges in The Production of BiodieselHugo SantanaNessuna valutazione finora

- Mycosphere 5 Dulayetal.2015Documento9 pagineMycosphere 5 Dulayetal.2015egemNessuna valutazione finora

- 302 Epoxy Ester Floor Paint TDSDocumento2 pagine302 Epoxy Ester Floor Paint TDSraja qammar100% (1)

- Product Line FlottecDocumento0 pagineProduct Line Flottecrichard gutierrezNessuna valutazione finora

- Microbiology An Introduction 11th Edition Tortora Test Bank DownloadDocumento987 pagineMicrobiology An Introduction 11th Edition Tortora Test Bank DownloadMarge Norton0% (1)

- Processes For Modifying RosinDocumento5 pagineProcesses For Modifying RosinBatuhan ElçinNessuna valutazione finora

- 713 00095 01 Essential Chemistries For Industrial Water Treatment EmeaiDocumento8 pagine713 00095 01 Essential Chemistries For Industrial Water Treatment EmeaimnasiroleslamiNessuna valutazione finora

- 15th Group ElementsDocumento36 pagine15th Group ElementsReyanNessuna valutazione finora

- Alcohols-Phenols and EthersDocumento16 pagineAlcohols-Phenols and EthersTr Mazhar PunjabiNessuna valutazione finora

- Expansion Joint Waterstops, Internal:, Black, LECOTRIL DIN 18541Documento2 pagineExpansion Joint Waterstops, Internal:, Black, LECOTRIL DIN 18541Dilhara WickramaarachchiNessuna valutazione finora

- Anatomy and Physiology Midterm Exam 2011-12Documento3 pagineAnatomy and Physiology Midterm Exam 2011-12cstavrop18100% (2)

- Product InformationDocumento3 pagineProduct Informationvanhung68Nessuna valutazione finora

- CH1801 C5 Plasmid IsolationDocumento7 pagineCH1801 C5 Plasmid IsolationTanisha ChowdharyNessuna valutazione finora

- 4.1.1 Protic Vs Aprotic SolventDocumento36 pagine4.1.1 Protic Vs Aprotic SolventDawit BirhanuNessuna valutazione finora

- Plastic Degradation by Microorganism: MethodologyDocumento1 paginaPlastic Degradation by Microorganism: MethodologyPurvi SoniNessuna valutazione finora

- MCQ On Manufacturing of CompositesDocumento4 pagineMCQ On Manufacturing of CompositesAnilKumar43% (7)

- Ethylene Plant Contaminants: A Database and Interactive ToolDocumento23 pagineEthylene Plant Contaminants: A Database and Interactive ToolEmmanuel LecrenayNessuna valutazione finora

- Fundamentals of Refining Products and PropertiesDocumento46 pagineFundamentals of Refining Products and Propertiesmujeebtalib100% (1)

- Fischer Speier EsteriterificationDocumento32 pagineFischer Speier EsteriterificationAl AkilNessuna valutazione finora

- Essential Oils ChemistryDocumento27 pagineEssential Oils ChemistryTaleem CityNessuna valutazione finora

- Detox Diets For Toxin Elimination and Weight Management: A Critical Review of The EvidenceDocumento12 pagineDetox Diets For Toxin Elimination and Weight Management: A Critical Review of The Evidence94bbbd37dfNessuna valutazione finora