Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SPO Compact Flange Designer's Manual

Caricato da

Baskar KannaiahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SPO Compact Flange Designer's Manual

Caricato da

Baskar KannaiahCopyright:

Formati disponibili

SPOCompactFlangeDesigner'sManual

DESIGNERSMANUAL

VectorInternationalDoc.No.A10601,Rev.3

SPOCompactFlangeDesigner'sManual

Contents

SECTION1:

GENERALDESCRIPTIONOFTHESPOCOMPACTFLANGE

SECTION2:

INSTALLATIONANDASSEMBLYPROCEDURE

SECTION3:

FLANGEDIMENSIONS

SECTION4:

SEALRING/GROOVEDIMENSIONS

SECTION5:

WEIGHTSEACHFLANGE

SECTION6:

LENGTHOFSTUDBOLTS

SECTION7:

BOLTWEIGHTS

SECTION8:

ASSEMBLYWEIGHTS

SECTION9:

COMPARISON

SECTION10:

PRESSURETEMPERATURERATINGS

SPOCompactFlangeDesigner'sManual

SPOCompactFlange:Designer'sManual

Revisedissue

21.06.05

TBJ

SL

InternalReview

20.06.05

TBJ

Revisedissue

12.11.03

TBJ

SL

SL

InternalReview

28.08.03

TBJ

SL

Revisedissue(Doc.no.B26/96)

30.11.00

MHA

BO

SL

InternalReview

30.05.97

FK

InternalReview

23.01.97

FK

GLa

REV.

REASONFORISSUE

ISSUEDATE

PREPARED

CHECKED

DocumentTitle

SPOCompactFlangeDesigner's

Manual

Doc.No.

SPO

A10601

Page

FK/TBJ

Noofpages

11

29

APPROVAL

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|2

Section1:

GeneralDescriptionofthe

SPOCompactFlange

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|3

Contents

0. HOWTOSELECTFLANGES.................................................................................................5

FLANGERATINGSANDCAPACITIES.........................................................................................5

1. INTRODUCTION................................................................................................................6

1.1

1.2

1.3

1.4

1.5

1.6

SCOPE..................................................................................................................................6

BACKGROUND.......................................................................................................................6

MAINFEATURES.....................................................................................................................6

APPLICATION.........................................................................................................................7

NORSOKL005...................................................................................................................7

SERVICES..............................................................................................................................7

2. REFERENCES8

3. ABBREVIATIONS...............................................................................................................9

4. SPOCOMPACTFLANGE...................................................................................................10

4.1

4.2

4.3

4.4

HOWITWORKS!..................................................................................................................10

SEALRINGANDGROOVE........................................................................................................10

SWIVELFLANGES..................................................................................................................11

INTEGRALFLANGES...............................................................................................................11

5. COMPACTFLANGETECHNOLOGY...................................................................................12

5.1 CONNECTORSTRENGTH.........................................................................................................12

5.2 SEALINGINTEGRITY...............................................................................................................12

5.3 FATIGUESTRENGTH...............................................................................................................12

5.4 FIRESAFETY.........................................................................................................................12

5.5 CORROSION........................................................................................................................13

5.6 EROSION............................................................................................................................13

5.7 MAINTENANCEANDINSPECTION.............................................................................................13

5.8 WATERLOCKING..................................................................................................................13

5.9 SPOCOMPACTFLANGETHEOBVIOUSCHOICE..................................................................13

5.9.1 Enhancedsealingreliability......................................................................................13

5.9.2 Reducedspaceandweight.......................................................................................13

5.9.3 IXsealring................................................................................................................13

5.9.4 Easierandquickermakeupandinstallation...........................................................14

5.9.5 Lowerlifecyclecosts................................................................................................14

6. TRANSPORTATION,STORAGE,HANDLINGANDFABRICATION........................................15

6.1

6.2

6.3

6.4

TRANSPORTATIONANDSTORAGE.............................................................................................15

HANDLING..........................................................................................................................15

WELDINGOFFLANGESTOPIPEENDSOREQUIPMENT...................................................................15

SURFACEPREPARATIONANDCOATING......................................................................................15

7. EXTERNALLOADING.......................................................................................................16

7.1

AXIALLOADSANDBENDINGMOMENT.......................................................................................16

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|4

7.2

7.3

TORSIONANDSHEAR.............................................................................................................16

THERMALSHOCK..................................................................................................................16

8. SPOCOMPACTFLANGEAPPLICATIONDATA...................................................................17

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

MATERIALS.........................................................................................................................17

PRESSURECLASSESANDSIZES..................................................................................................18

FLANGETYPESANDDESIGNATIONS...........................................................................................18

SEALRINGDESIGNATION........................................................................................................19

FLANGEDIMENSIONSANDWEIGHTS.........................................................................................19

BOLTLENGTHSANDWEIGHTS..................................................................................................20

MAINDIMENSIONSANDWEIGHTSINCLUDINGASSEMBLYWEIGHTS.................................................20

WELDNECKDIMENSIONS.......................................................................................................20

LOADCAPACITY....................................................................................................................20

9. INFORMATIONTOBESUPPLIEDBYPURCHASER.............................................................21

10. AVAILABILITY...............................................................................................................21

11. SERVICES 21

AppendixA):Figures

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|5

0. HOWTOSELECTFLANGES

FLANGERATINGSANDCAPACITIES

VectorInternationalcandeterminethecapacityofSPOCompactFlangesaccordingtoa

numberofstandardssuchasASMEVIII,Div.2,Appendix4;EN134453andASMEB31.3.

Thetablesandinteractionequationsincludedinthisbookareforassistanceinflangeselection

andareapproximateinnaturetendingtotheconservativeside.Thesetablesareaccordingto

NORSOKL005(basedonASMEVIII,Div.2)andalsocomplywithASME31.3,andapplytoweld

neckflangesonly.

FinalverificationofthecapacityoftheselectedflangesshouldbeperformedbyVector

Internationalonreceivingtheorder.Relevantloadcombinationsshouldbespecified.

ThepressureratingsarebasedonthecapacitiesaccordingtoASME/ANSIandincorporatethe

sameallowanceforundeterminedpipeworkforcesasANSIB16.5(itemD1.2).

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|6

1. INTRODUCTION

1.1

Scope

TheSPOCompactFlangestandardarecircularflangesforpipes,valves,fittings,pressure

vesselsandaccessories.ThisDesignersManualcoversthefullperformancedataapplicableto

theSPOCompactFlange,includingthefollowingmainitems:

Flangedescriptionandmainfeatures

Handling,storage,transportationandfabrication

Flangedimensionaldataandweighttables

Flangepressure/temperatureandexternalloadcapacities

Selectionguidelines

Order/quotationprocedure

Installationandmaintenance

Thisdataisapplicabletoweldneck,blind,swivelandintegralflangeinadditiontolineblanks

inClassdesignations:Class150,300,600,900,1500,2500,and4500Intermediateandnominal

sizesfromNPStoNPS48(DN15toDN1200).NotethatClass2500and4500Intermediate

flangeshavearangefromNPStoNPS24(DN15toDN600).Itisapplicabletoforgedflanges

ofstandardsupplyalthoughplatescanbeusedforblindflangesandbarstockmaterialsfor

smallersizes.Flangesintegralwithassociatedequipment(bothcastandforged)arecoveredby

thisusermanual.Dataarealsoprovidedfortheflangebolting,sealringsandcomparisonwith

conventionalconnectors.

1.2

Background

TheSPOCompactFlangeisaflangedconnectordevelopedbyVectorInternationalAS.

SPOCompactFlangesareforpipes,valves,fittings,pressurevesselsandaccessories.TheSPO

CompactFlangewasfirstusedforareliefwellriserin19871988andsubsequentlyfor

productionrisersandexportrisers.Sincethen,SPOCompactFlangeshavebeenusedfora

numberofdemandingapplicationssuchastitaniumdrillingrisers,flexiblerisers,heat

exchangers,processplants,nuclearreactorsandsubseainstallations.VectorInternationalhas

developedastandardrangeofcompactflanges.Thesestandardizedflangeshavebeen

engineeredwithgoodcapacitytoaccommodateexternalloads,valveneckconfigurationsand

standardmakeuptools.

1.3

Mainfeatures

TheSPOCompactFlangesprovideanalternativetoconventionalflangesofferingthe

advantageofbeingsmallerandlighterandhavingsuperiorsealingandloadcarryingcapability.

Theyprovideacostefficientandtechnicallysuperiormethodofconnectingpipeworkand

associatedequipment.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|7

1.4

Application

TheSPOCompactFlangehasbeenusedinmanyapplicationsthroughoutavarietyofdifferent

industries.Thefollowingisapartiallistofexistingandpotentialserviceapplications:

Oilandgasproductionpipelines,flowlines,risers,injectionsystems,manifolds,well

heads,separators,processmodules.

Petrochemicalrefiningandprocessing.

OEMvalves,fittings,vesselclosures,heattransferequipment,separatorsandpumps.

Nuclearplant.

Over30.000SPOCompactFlanges(2002)fromsizes60arenowinoperation.Thereisno

recordedleakageduringservicesincethefirstflangewasinstalledin1989tothepresentday.

1.5

NORSOKL005

TheNORSOKstandardL005chapter5ProductStandardisbasedontheSPOCompactFlange.

AllnominaldimensionsofflangesinL005areidenticalwiththeSPOCompactFlange.Hence

theSPOCompactFlangemeetsallrequirementsintheNORSOKstandard.

1.6

Services

Anyclarificationrequiredshouldbeaddressedto:

VectorInternationalAS

P.O.Box2176

NO3003Drammen

Norway

Phone:

Telefax:

Email:

(+47)32209300

(+47)32810464

SPO@vectorint.com

Normalofficehoursarefrom08.00hrs.to15.30hrsfromMondaytoFriday.Ifindoubtplease

consultVectorInternational.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|8

2. REFERENCES

Standardsandspecificationsadoptedbyreferencesinthismanualare:

ANSIB1.1

Unifiedinchscrewthreads.

ASME/ANSIB18.2.2 Squareandhexnuts(inchseries).

ANSIB36.10M

Weldedandseamlesswroughtsteelpipe.

ASMEB16.5

Pipeflangesandflangedfittings.

ASMEB16.10

Facetofaceandendtoenddimensionsofvalves.

ASMEB16.34

Valvesflanged,threaded,andweldingend.

ASMEB16.47

Largediametersteelflanges.

ASMEB31.3

ProcessPiping.

ASMESectionVIII

RulesforconstructionofpressurevesselsDiv.2

AlternativerulesAppendix6and4.

ISO27681

Generaltolerances.Part1:Tolerancesforlinearandangular

dimensionswithoutindividualtoleranceindications.

ISO4200

Plainendsteeltubes,weldedandseamless.Generaltables

ofdimensionsperunitlength.

ISO9001:2000

QualitySystem.Requirements.

EN134453

UnfiredpressurevesselsPart3:Design

NORSOKL005

Compactflangedconnections

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|9

3. ABBREVIATIONS

ASME

ASTM

BL

Class

DN

IF

ISO

IX

NPS

PB

PN

PS

RI

RT

SB

SC

SR

SW

WN

AmericanSocietyforMechanicalEngineers

AmericanSocietyforTestingandMaterials

Blindflange

ANSIpressureclass(psi)

Nominalsizeofpipe(metricunits)

Integralflangeaspartofsomeotherequipmentorcomponent

InternationalStandardizationOrganization

Sealringdesignation

Nominalpipesize(inch)

Paddleblank

Nominalpressure,seeabove(bar)

Paddlespacer

Rigidinterfacefacewithstuddedbolts

Roomtemperature

Spectacleblind

Swivelcollarforwelding

Swivelring

Swivelflangewhichincludesswivelcollarandswivelring

Weldneckflange

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|10

4. SPOCOMPACTFLANGE

TheSPOCompactFlangesystemcomprisesflanges,sealsandbolting(Figure1)andreplaces

conventionalANSI,API,BS,DIN,MSSandUNIflangesbutatreducedweight,overall

dimensionsandcostsinadditiontoincreasedsealingreliability.

4.1

Howitworks!

Acompleteweldneckconnectorassemblyconsistsoftwoweldneckflanges,asealringanda

setofstudboltswithheavyhexnuts.ThisisshowninFigure1.Alternativelyitmayconsistof

oneweldneckflangeandaswivelflangeorablind,etc.Theprincipalfeatureoftheflangeis

theflangefacegeometryandprovisionofadoublemetalseal.Thisdoublemetalsealisa

primaryfeatureoftheconnection.Theredundantdoublesealisasafetyfeaturemakingthis

connectionanorderofmagnitudesaferthanatypicalsinglesealsystem.

Theflangefaceincludesaslightlyconvexbevelwiththehighestpoint,calledtheheel,adjacent

totheboreandasmallouterwedgearoundtheouterdiameteroftheflange.TheSPO

CompactFlangeweldneckconnectorismadeupbytightening/tensioningtheflangebolting

whichpullsthetwoconnectorhalves(weldnecks)together.Axialforcesareexertedonthe

taperofthemetalsealringandtranslatedintoaradialsealingforce.Furthermorewith

increasedpreloadisthebevelclosedandfacetofacecontactisachievedattheouterwedge

whilemostoftheboltpreloadistransferredascompressiveforcesbetweentheflangefacesat

theheel,seeFigure1.ThearrowsinFigure1indicatetheappliedforces/pressureandthe

contactforcesaftermakeupandduringnormaloperation.Asealiscreatedbyapplicationof

thissealseatingstressattheflangeheel.Throughoutthecompleterangeofnormaloperating

loadsacontactstressinexcessoftheoperationalpressureismaintainedattheheelseal

location.Theflangealsoremainsincontactalongitsoutercircumferenceattheflangefaces.

Finallythereisanelasticsealringwhichiscompressedradially.Thesealringforceisprovided

bytheelasticstoredenergyinthestressedsealring.Anyaccidentalheelleakagewillgivea

internalpressureactingonthesealringinsideintensifyingthesealingaction.

ThemaindesignfeaturesaresummarisedinFigure2.Thebackfaceoftheflangeinthemade

uppositionisparalleltotheflangefaceinordertopreventbendingoftheboltsinthe

assembledcondition.

4.2

Sealringandgroove

Thereisonlyonesealringsizeforeachpipesizeregardlessofflangepressurerating,pipe

scheduleandmaterial.Itisnonloadcarryinginordertoensureagainstloadinducedseal

damageandpromotecouplingstability.Whentheflangesarepulledtogetherduringassembly,

theringisassistingthefinalalignmentofthejoint.Overtensioningofboltswillnotdamage

thesealring.

Theringwithstandrepeatedinstallationsinthesamegroove.Thesealringsarefrequently

reuseduptotentimes,i.e.contactforceswillnotcauseanyplasticdeformationofneitherring

norgroovewhicharedetrimentalforthesealingperformance.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|11

4.3

Swivelflanges

Inordertosolvetheproblemofboltholealignmentduringsubseapipeinstallation,Vector

Internationalhavedevelopedaswivelflange.Thisconnectorfeaturestwopiececonstruction

consistingofaswivelringwhichswivels(360rotation)aroundtheswivelcollar,seeFigure3,

whichallowsforeasyalignmentoftheflangeboltholes.

Inadditiontosubseapipeconnections,theseflangesarealsowellsuitedformaking

connectionstoOEMequipmentsuchasvalves,compressors,pressurevesselsandpumps.

Swivelflangeseliminatethetimeconsumingpracticeoftwoholing,aprocedurecommonly

usedtoassureflangetoflangeboltholealignmentbetweentwoopposingpiecesof

equipment.

TheswivelringcanasanoptionbeextendedasindicatedbythedashedlineinFigure3,ifitis

requiredtoclosetheflangedconnection.Inordertosavecost,carbonsteelswivelringsmay

beusedincombinationwithmoreexoticmaterialsintheswivelcollars(notforsubsea).

4.4

Integralflanges

TheintegralflangesfulfillstheminimumwallthicknessrequirementsgiveninASME/ANSI

B16.34.Thenutcanalwaysbetightenedbyasocketspannerensuringthatavalvetovalve

interfacemakeupwithSPOCompactFlangealwaysispossible.Themaindimensionsofthe

standardSPOCompactFlangesareallwithintheenvelopeofstandardASMEB16.5andASME

B16.47flanges.Dimensionsforendflangesarereadilyavailabletoensurecompletepiping

systemcompatibility.Majorvalvemanufacturescoveringthefollowingvalvetypes:ball,gate,

check,globe,choke,plugandbutterflyvalveshaveconfirmedthattheycanuseaSPO

CompactFlangeontheirvalves.

TheintegralflangemaximumneckouterdiameteristabulatedinSection3:Flangedimensions.

However,thiscanbereducedtostandardpipeODasindicatedbytheletterAinFigure3.

LargerneckODcanalsobeused,however,accessforthemakeuptoolshouldbechecked.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|12

5. COMPACTFLANGETECHNOLOGY

TheSPOCompactFlangedesignhasbeendevelopedthroughveryextensivetestingand

analysis.Inadditionthestandardrangeofcompactflangeshavebeenthoroughlyassessedto

ensureapplicabilityinallconventionaluses,easyhandlingandsimpleinstallationwith

conventionaltools.

5.1

Connectorstrength

ExtensivefullscaletestshavebeenperformedatDnV.Thesetestshaveincludedcombined

internalpressure,axialtensionandmomentloadingtofailureaswellasstressanalysisand

fatigue.DnVhasalsoperformedtraditionalbursttestsaswellaspressuretestswithnitrogen

andfiretests.TestsandevaluationshavealsobeenperformedbyBritishGasandConoco.

Thisveryextensivetestinghasbeenparalleledbyveryextensivefiniteelementanalysis

coveringallrelevantconsiderationssuchasultimatestrength,loadcyclingandshakedown,

stressanalysis,contactsealperformance,sealringperformanceandbolttensioning.This

analysishasbeencorrelatedwiththetestresultstogiveanextremelythorough

documentationofthecompactflangeconnectorsresponseandcapacity.Fewconnectorshave

beenasthoroughlydocumentedastheSPOCompactFlange.

5.2

Sealingintegrity

TheSPOCompactFlangefeaturestwometalsealsinseries,whicharebasedoncompletely

differentdesigns.Theflexibleringisprestresseddiametricallyandindependentofprestress

aftertheflangeshavebeenmated.Thesecondsealisprovidedbythehighseatingstress

createdbytheprestressattheheelwhentheflangesareinitiallymated.Asaconsequence

theirfailuremodeshaveverylittlecorrelation.Thisprovidesahighdegreeofredundancyand

averyhighdegreeofreliabilityagainstleakage.Similarreliabilitylevelscanonlybeachieved

withweldedconnections.Theperformanceofthesesealshasbeenverifiedintests.Testshave

alsoincludedmakeup,breakoutandinterchangeabilitytestsin15cyclesverifyingthatseal

ringscanbereused.

5.3

Fatiguestrength

TheSPOCompactFlangeswillnormallyhavefatiguestrengthexceedingthatoftheadjoining

girthweldedpipesection.Inconventionalflangeconnectionstheboltswillbeextremely

susceptibletofatiguedamage.TheprestressednonseparatingdesignoftheSPOCompact

Flangesachievesverysmallstressrangesintheboltswellbelowthefatiguelimitforabase

material.Thestressconcentrationintheoptimizedflangefilletislowandthestress

concentrationduetotheflangegeometryatthegirthweldlocationisnegligible.

5.4

Firesafety

FiretestinghasbeenperformedforSPOCompactFlangesbyDnV.DnVconsiderAPI6FB,Part2

(1992)tobeinadequateresultinginexistingpipeconnectionsnotbeingfiresafe.SPOCompact

Flangesweremorerigorouslytested,e.g.whereAPIrequire1burnerDnVused4burnerswith

thesametemperature,holdperiodsandpressure/momentsasrequiredbyAPI.Theresults

weresuccessfulandconclusive.TheSPOCompactFlangehasahighcapacityinfireexposure.

Thetestdatacanbeusedtoevaluaterelevantfireexposure.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|13

5.5

Corrosion

Theconnectoraccommodatesinternalcorrosionallowanceswithoutaffectingthesealing

performance.TheIXsealringisnotexposedtointernalorexternalmediaandnocorrosion

appearbetweensealringandgroove.Corrosiontestandserviceexperiencesshowsthat

sealingsurfaces,flangefaces,sealringsandclampedpartsofboltsarefreefromcorrosion.No

weldoverlayshouldthereforeberequiredforcarbonsteelforaggressivemedia,i.e.well

stream,producedwater,waterinjectionorfirewatersystems.

5.6

Erosion

Thecompactflangeisofstreamlinetypedesignwithnosignificantcreviceordiscontinuityin

thebore.Theflangeiscorrespondinglyresistanttoerosiondamage.

5.7

Maintenanceandinspection

Thedirectflangefacetoflangefacecontactwithloadtransferbetweensolidflangefaces

eliminatestheriskofreducedboltprestressduetotimeorloaddependentsealorgasket

deformations,flangewarpingoverloadorotherphenomena.Boltretighteningisnotrequired.

Thesealsandclamppartsoftheboltsarelocatedinaprotecteddryenvironment.

Furthermore,thesealringisnotexposedtoloadfluctuations,frettingmotionsorotherseal

degradingeffects.Sealandboltreplacementisthereforenotexpectedtoberequired.

Inspectionwithrespecttoexternalcorrosionshouldbeasforconventionalflanges.

5.8

Waterlocking

Underwatertestingandsubseainstallationshavedocumentedthatwaterlockingdoesnot

occurwiththeSPOCompactFlange.

5.9

SPOCompactFlangeTHEOBVIOUSCHOICE

ThestandardSPOCompactFlangeshasthefollowingmaintechnicalandcommercialbenefits

comparedtoconventionalconnectors:

5.9.1 Enhancedsealingreliability

ConventionalflangedconnectorsaccordingtoBS,DIN,ANSIandAPIstandardstypicallyhavea

lowreliabilityagainstleakagecomparedtogirthweldedpipes.SPOCompactFlangeshave

beenacceptedandusedforpipingandriserswheregirthweldedpipestraditionallyhavebeen

used.

5.9.2 Reducedspaceandweight

SPOCompactFlangesofferasignificantweightandspacesavingoverconventionalflanged

connectors,seeattachedtables.Typicalweightsavingis6575%.TheSPOCompactFlange

diameterisalwayssmallerthenclamptypeconnectors,whenclampdimensionsare

considered.Thesmallerdiameterpermitsmorecloselypackedpiperuns,smalleropeningsfor

pipeaccess,easierreelingandeasiertrenchingorburial.

5.9.3 IXsealring

TheIXsealringwillwithstandrepeatedinstallationsduetoitselasticsealcharacteristics.The

standardserieshasonlyonegrooveandIXsealringperpipesize,independentofpressure

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|14

class.Thisreducesthenumberofsealringtypestoaminimum.Conventionalflangesand

clamptypeconnectorsnecessitatestockingdifferentsealringstocoverforboththepipe

scheduleandpressureratingoftheconnectorwithinagivenpipesize.

5.9.4 Easierandquickermakeupandinstallation

TheSPOCompactFlangesreducedweightandsizealloweasierhandlingandassembly.The

controlledflangerotation(facetofacecontact)preventsflangeabusebyovertensioningof

thebolts.Closingoftheoutergapisanindicationofthatcorrectpreloadhasbeenachieved.

Reducedconnectorsizeleavesmoreroomfortheoperatorandthetooling,andthesmaller

diameterboltingallowslighterweighttoolingtobeused.Experienceshowscorrespondingly

shortermakeuptimeforSPOCompactFlangesthanforconventionalflanges,atypicalvalueis

50%less.

5.9.5 Lowerlifecyclecosts

Capitalcost

1. Reducedinitialcost.

2. Lowerhandling,installationandtransportationcostsduetoreducedweightand

dimensions.

3. Reducedweightandcostforloadcarryingstructures,i.e.mainsteelintopsidedeck

structure.

Operatingcost

1. Maintenancefreeconnections(noboltrelaxation,nocreviceorstresscorrosion,noseal

replacement).

2. Periodicmaintenanceofinstalledequipment(e.g.valves,separators)atreducedcostasseal

ringscanbereusedandmanhoursformakeupandbreakoutislowerandhencesystem

downtimetimeisshorter.

Costofdeferredproduction

Systemdowntimecostduetoflangefailureisnegligibleduetothesuperiorsealing

performance.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|15

6. TRANSPORTATION,STORAGE,HANDLINGANDFABRICATION

6.1

Transportationandstorage

Whenflangesareshippedtheyarepackedwithflangefaceprotectors.Thisprotectionshallbe

maintainedinplaceinordertoavoidscratches,indentations,etc.thatwillbedetrimentalto

thesealingintegrityoftheflange.Uponreceivaltheprotectionshouldbeinspected.Ifithas

beendamageditshouldberemovedandtheflangefaceinspectedfordamagetothesealing

faces,i.e.theheel,wedgeandgrooveouterdiameterface.Anyminordamageshouldbemade

goodinaccordancewiththerepairproceduresinthisdocument.Adamageflangeface

protectorshouldbereplacedimmediately.Transportationandstorageshouldbeperformed

onpalletswiththeflangefaceup.

Theflangefacemustnotbepainted,asthiswillimpairthesealingperformanceoftheflange.

Topreventcorrosiontheflangefaceshouldbecoatedwithgreaseduringstorageand

transportation.Preservationsontheflangefaces,whicharedifficulttoremove,shouldnotbe

used.I.e.mechanicalmeansofremovalshallnotbeusedonflangesealingfaces.

Flanges,sealringsandbolts,regardlessofmaterialtype,shouldbestoredindoororunder

coveruntilintendeduse.Thesealringsandboltsshouldbestoredinoriginalpackinguntilfinal

installation.

6.2

Handling

Whenliftingandhandlingcompactflangescareshouldbetakentoavoiddamagetoseal

surfaces.Slingsshouldpreferablynotbearontosealsurfacesorweldpreparationssuchaswill

occurifthreadedthroughtheboltholes.Softslingscanbeusedforliftingsingleflanges,and

wires,chainsandsimilarhardandangularcomponentsshouldbeavoided.Boltordowels

throughtheboltholesaresuitableforlifting.Ifspecified,threadedholesforliftingeyescanbe

providedonthesidefaceofflanges.Liftingofprefabricatedpipespoolsintheflangebolt

holes,flangeliftingpoints,etc.shouldnotbedone.

6.3

Weldingofflangestopipeendsorequipment

Thestandardweldneckflangeisprovidedwithastandardweldbevelpreparationforwelding,

e.g.ASME/ANSIB16.5.Thecompactflangesmaybeweldedtopipingandothercomponent

equipmentbyestablishedweldingprocedures.Initialfitupandalignmenttolerancesusedin

thefabricationofconventionalANSIflangesarealsoacceptablefortheSPOCompactFlange.

Duringwelding,careshouldbetakentoprotectthesealingfacesfromanydamage,i.e.,

scratchingandweldsplatter.Protecttheflangefaceagainstoxidationduringwelding,post

weldheattreatmentandotherheatingoftheflanges.

6.4

Surfacepreparationandcoating

Theflangefacesmustbeprotectedduringgritblastingandcleaningoperationstoprevent

contaminationofthesurface.Theflangefacesmustalsobeprotectedduringsuchprocessesas

painting,waxingandthermalsprayingofmetalliccoating.Particularcareshouldbetakento

checkthatthesealingsurfacesarecompletelyclean.Paintsandcoatingsontherearfaceof

theflangeinthenutbearingareasandbearingareasforswivelflangesshouldberemoved.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|16

7. EXTERNALLOADING

7.1

Axialloadsandbendingmoment

Connectorsoperatingwithintheirclassceilingpressuresforstandardmaterialhaveresidual

capacitytoaccommodateexternalloadssuchasaxialandbendingmomentloads.

Conventionalflangeconnectorssubjecttobendingtendtoseparate.Thisresultinareduction

ofthegasketseatingloadsonconventionalsealsandmayresultinleakage.TheSPOCompact

Flangeconnectoriscapableofwithstandhigherbendingloadsthanconventionalflanges

beforeleakagestarts.AstheIXsealringispressureenergisedthereisaneedtomaintaina

constantsealelementcompressiveforceandthis,coupledwiththemechanicaladvantageof

thewedgingactionoftheflangemakeup,meanstheconnectionisrelativelyinsensitiveto

separationforces.

Becausetheflangefacecontactareaislargerthanthecrosssectionoftheadjoiningpipe

compressiveaxialloadsincombinationwiththecompressiveloadsformthebendingmoment

havenoeffectontheconnectorcapacity.Onlyaxialforcesandtensionloadsfromthebending

momentneedstobeconsidered.

7.2

Torsionandshear

Torsionmomentsandshearloadsareinitiallyresistedbyfrictionforcesbetweentheflange

faces.Shouldthetorsionmomentorshearloadbeofsufficientmagnitudesuchthatslippage

occur,thesealintegrityoftheunitisnotadverselyaffected.Thisfeatureprovidesasaferelief

forexcessivetorsionandshearloadsnotalwayseasilypredicted.

7.3

Thermalshock

Forveryseverethermalchock(i.e.quenching),theIXsealringwillnotbedirectlyaffectedand

thesealingreliablyisnotadverselyaffected.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|17

8. SPOCompactFlangeAPPLICATIONDATA

8.1

Materials

Flangesareavailablefromstandardforgingorcastingwithsealringsincompatiblehigh

strengthforgedmaterials.ThesealringsarenormallycoatedwithPTFE.Standardbolting

materialsareA193B7andA320L7/L43.Inchstudboltsthreadedatbothendsorfulllength

maybeused.Heavyhexnuts(ANSIB18.2.2)shallbeused.Threadsshallbecoarseseries,Class

2A(ANSIB1.1),andnutsshallbecoarseseries,Class2B.Nominaldiameters1in.andsmaller

shallcoarsethreadseries(UNC);nominaldiameters11/8in.andlargershallbeofthe8thread

series(8UN).

Table8.1listssomecommonmaterials.E.g.combinecarbonsteelflangewithcarbonsealring

andstainlesssteelflangewithstainlesssealring.Sealringsintitaniumarealsoavailable.

Boltingforallflange

SPOCompactFlange

IXsealring

andsealringmaterial

combinations

A105

Carbo A350 LF2

nsteel A694 F52

CS360(F52)

examp A694 F60

A193

B7

les

A694 F65

A193

B16

AISI

4130(Lowalloy)

A320

L7

Stainle A182 F316

A320

L43

ss

A182 F44(6Mo)

A182 F51(Duplex)

steel

A182 F49

A564 630(174PH)

examp A182 F51(Duplex)

les

A182 F53(SuperDuplex)

Table8.1:CommonmaterialsforSPOCompactFlangeapplications

Flangematerial Servicetemperature

Carbonsteel

Stainlesssteel

Stainlesssteel

Stainlesssteel

SS/Nickelalloy/

CSwithinlay

All

50Cto+250C

50Cto+250C

100Cto+250C

200Cto+150C

200Cto+250C

>+250C

Table8.2:Colourcodingofsealrings

Min. yield = 270 MPa

Sealringmaterial

CS360

22CrDuplex

17/4PH

AusteniticSS1

Nickelalloy(Inco625,

718,A286etc.)

Suitable

SealringPTFEcolour

Blue

Yellow

Orange

Red

Black

Nottobecoated

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|18

8.2

Pressureclassesandsizes

ThepresentrangeofpressureclassesincludesthefollowingClassdesignation(ANSI)Class150,

300,600,900,1500,2500and4500Intermediate.Thepressurerating(ANSI)forthepressure

Classesare,ASMEB16.5andASMEB16.34:

Class

Nominal

ASMEpressureratingceiling

Pressureclass

abbreviation

pressure

valuesatRT

psig

barg

Class

150

CL150

PN

20

290

20,0

Class

300

CL300

PN

50

750

51,7

Class

600

CL600

PN

110

1500

103,4

Class

900

CL900

PN

150

2250

155,2

Class

1500

CL1500

PN

260

3750

258,6

Class

2500

CL2500

PN

420

6250

431,0

Class

4500INT

CL4500I

NA

520,0

Table8.3:Pressureclassoverview

Therangeofnominalpipesize(NPS)is

1122345681012141618202224

262830323436384042444648

Class2500and4500Iareonlyavailableupto24.

8.3

Flangetypesanddesignations

Figure3andFigure4showsomeflangetypeswiththerelevantdesignations.Thetypesof

flangesaregivenintable6.1.

Type

Description

abbreviation

WN

Weldneckflange

BL

Blindflange

SC

Swivelcollarforwelding

SR

Swivelring

SW

Swivelflangewhichincludesswivelcollarandswivelring

IF

Integralflangeaspartofsomeotherequipmentorcomponent

RI

Rigidinterfaceaspartofsomeotherequipmentorcomponent

withstuddedbolts

PB

Paddleblank

PS

Paddlespacer

SB

Spectacleblank

Table8.4:Typesofflanges

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|19

Theflangesandcollarshavethefollowingstandarddesignation:

Nominalflangesizetheappropriatenumber,

VectorInternationalstandardidentificationSPOCF

FlangetypeabbreviationaccordingtoTable8.4

PressureclassdesignationabbreviationaccordingtoTable8.3,CL

FacingtypethegroovenumberfortheIXsealring(theNPSnumber),IX

Pipeschedule/thickness,Sch/Wt

Materialdesignation,

Examples

Example1

DesignationofweldneckflangeinClass600withIXgroove,nominalsizeNPS10with

pipeschedule40SandmaterialA182F51(duplex):

10SPOCFWNCL600IX10Sch.40SA182F51

Example2

DesignationofblindflangeinClass900withIXgroove,nominalsizeNPS20and

materialA350LF2:

20SPOCFBLCL900IX20A350LF2

Example3

DesignationofweldneckflangeinClass4500IwithIXgroove,nominalsizeNPS8with

pipewallthicknessequalto30.0mmandmaterialA182F51(duplex):

8SPOCFWNCL4500IIX8Wt.30.0A182F51

8.4

Sealringdesignation

ThefigureinSection4:SealRing/GroovedimensionsillustratesIXgroovefacingsandtheIX

sealring.TheIXsealringisdesignatedasfollows:

VectorInternationalidentificationmarkSPOCF

TypeIX

Size(nominalpipesize),e.g.10

Materialdesignation,e.g.A182F51.

Example:SPOCFIX10A182F51

8.5

Flangedimensionsandweights

SeeSection3:FlangedimensionsandSection5:WeightsEachFlange.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|20

8.6

Boltlengthsandweights

SeeSection6:LengthofStudboltsandSection7:BoltWeights.

8.7

Maindimensionsandweightsincludingassemblyweights

SeeSection8:AssemblyWeightsandSection9:Comparison.

8.8

Weldneckdimensions

Theminimumoutsidediameteroftheweldneckofweldneckorswivelcollarflangeisequalto

thenominaloutsidediameterofthepipe.Themaximumboreisequaltothespecifiednominal

bore.Thisassuresthattheminimumweldneckthicknessisthespecifiednominalvalue.

8.9

Loadcapacity

Section10:PressureTemperatureRatingspresentsvaluesgivenforstandardweldneck

flangesfortemperaturesupto250C.Thegivenratingsarebasedonusingboltswithstrength

equaltoASTMA193B7andpretensionedto75%ofyieldasspecifiedinSection2:Installation

andassemblyprocedure.

Thegivenratingsrepresentaflangeutilisationof0.5forinternalpressure.Theadditional

externalloadcapacitycanbecalculatedusingthemethoddescribedinAppendixDofNORSOK

L005.Forswivelflanges,theexternalloadcapacityisavailablefromVectorInternationalupon

request.

VectorInternationalcansupplyexternalloadcapacitydiagramswiththeflangesfortheaset

ofspecifieddesigndata;flangenominalsizeandpressureclass,borediameter,pipeouter

diameterifnonstandard,designpressureandtemperatureandflangematerialspecification.

BlindflangesandspacerblindswillhavepressureratingstomeetB16.5.Hencetheblindscan

beusedforhydrostaticpressuretestsupto1.5xlistedpressureratinginB16.5forthe

appropriateblindflangematerial.

Fortemperaturesabove250C,VectorInternationalwillsupplythepressureratingsand

externalloadcapacities.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|21

9. Informationtobesuppliedbypurchaser

Inadditiontothestandarddesignationdetailedinchapter8,thefollowingadditional

informationshouldbesuppliedbythepurchaserintheinquiryand/ororder,where

appropriate:

Outsidediameterforweldneck/pipe,ifdifferentformthosespecifiedinthisstandard.

Boreatflangefaceandneck(weldneck)iftaperedboretobemachined,seefigure3.

Weldendpreparationifdifferentfromthosespecifiedinthisstandard.

Materialcertificaterequirements.

Boltingmaterialandpreloadmethod(torque/hydraulictension)whenboltsareordered

withtheflanges.

10.AVAILABILITY

SPOCompactFlangesaremanufacturedbyVectorInternationalASandunderlicensebyother

manufactures.

11.SERVICES

VectorInternationaldesignandmanufactureanextensiverangeofadhocSPOCompact

Flangedesigns,manyoutsidethestandardrange.SmallerandlighterSPOCompactFlanges

affordsubstantialcostsavingswherehighalloyedandexoticmaterialsareinvolved.Should

sizingberequired,thefollowinginformationshouldbesupplied:

Designpressure,temperatureandexternalloadsforactualloadconditions

Pipe/flangematerials

Pipeorpressurevesselcode

Pipeboreandoutsidediameter

Boltingmaterial

Additionrequirements,e.g.corrosionallowance

Quantitiesandschedule

Ourteamofengineersandtechniciansisavailabletoassistclientswithintegratedteamwork,

design,specialflangedesigns,sitesupervisionandassemblyoftheSPOCompactFlange.For

specialcasesVectorInternationalwillbehappytoassistwithmoredetailedanalysisincluding

nonlinearfiniteelementanalysis.

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|22

AppendixA:Figures

Figure1:HowSPOCompactFlangeworks(exaggeratedbevelangle)

23

Figure2:SPOCompactFlangestandardfeatures........................................................................24

Figure3:Flangetypesassemblies.............................................................................................25

Figure4:Flangetypes(contd)lineblanks................................................................................26

Figure5:Weldendsofweldneckflangesandswivelcollars......................................................27

Figure6:Studlength....................................................................................................................28

Figure7:ComparisonSPOCompactflangevsANSIflange..........................................................29

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|23

Figure1:HowSPOCompactFlangeworks(exaggeratedbevelangle)

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|24

Figure2:SPOCompactFlangestandardfeatures

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|25

Figure3:Flangetypesassemblies

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|26

Figure4:Flangetypes(contd)lineblanks

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|27

Figure5:Weldendsofweldneckflangesandswivelcollars

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|28

Figure6:Studlength

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|29

ANSI

Highhydrostaticforce

Largemomentarm

Reducedstiffness

Reducedsealingreliability

Loadtransferthroughgasket

SPOCompactFlange

Smallhydrostaticforce

Smallmomentarm

Increasedstiffness

Increasedsealingreliability

Loadtransferthroughflangefaces

Figure7:ComparisonSPOCompactflangevsANSIflange.

6CL2500WN(relativetoscale)

SPOCompactFlangeDesigner'sManualDoc.no.:A10601Rev.no.:3Page|30

Section2:

Installationandassemblyprocedure

Section3:

Flangedimensions

Section4:

SealRing/Groovedimensions

Section5:

WeightsEachFlange

Section6:

LengthofStudbolts

Section7:

BoltWeights

Section8:

AssemblyWeights

Section9:

Comparison

Section10:

PressureTemperatureRatings

Potrebbero piacerti anche

- SPO Compact Flange Technical v02 2012Documento40 pagineSPO Compact Flange Technical v02 2012Bueno8100% (2)

- SPO Compact Flange Designer's ManualDocumento137 pagineSPO Compact Flange Designer's ManualZarra Fakt100% (1)

- Quality Requirements For Line Pipe: JanuaryDocumento14 pagineQuality Requirements For Line Pipe: JanuaryJose Anisio Silva100% (1)

- Nondestructive Evaluation: Buried Pipe NDE Reference Guide: Electric Power Research InstituteDocumento226 pagineNondestructive Evaluation: Buried Pipe NDE Reference Guide: Electric Power Research InstituteMo GhaziNessuna valutazione finora

- L&T Gate Globe Check Valves API 602Documento12 pagineL&T Gate Globe Check Valves API 602Shankey JAlan100% (1)

- ANSI-B16.47 Ser B Blind and Welding Neck FlangesDocumento7 pagineANSI-B16.47 Ser B Blind and Welding Neck FlangesRicelles Silveira MartinsNessuna valutazione finora

- Evaluation of Flanged Connections Due To Piping L.oaoDocumento9 pagineEvaluation of Flanged Connections Due To Piping L.oaoSJNessuna valutazione finora

- Stress Concentration Roark-Ch06Documento42 pagineStress Concentration Roark-Ch06marisNessuna valutazione finora

- Flange Leakage 6Documento2 pagineFlange Leakage 6hamid sobirinNessuna valutazione finora

- AIVDocumento5 pagineAIVgusloh100% (1)

- Dimensions For Fabricated Steel Water Pipe Fittings: AWWA StandardDocumento32 pagineDimensions For Fabricated Steel Water Pipe Fittings: AWWA StandardNelson MejiaNessuna valutazione finora

- Seipp 2014Documento5 pagineSeipp 2014Andres VallebellaNessuna valutazione finora

- Nozzle StressDocumento25 pagineNozzle StressvamsiNessuna valutazione finora

- Pipe Wall Thickness, Hoop Stress and Sustain Stress QuestionDocumento10 paginePipe Wall Thickness, Hoop Stress and Sustain Stress QuestionSharun SureshNessuna valutazione finora

- Wall thickness calculation for 36-inch gas pipelineDocumento1 paginaWall thickness calculation for 36-inch gas pipelinetitir bagchiNessuna valutazione finora

- FEA On ThermowellDocumento4 pagineFEA On Thermowellvaisakp777Nessuna valutazione finora

- Flow Induced Vibration Choke ValvesDocumento8 pagineFlow Induced Vibration Choke Valvesharmeeksingh01Nessuna valutazione finora

- Design of Compact Flange JointsDocumento15 pagineDesign of Compact Flange JointsAkhil JoseNessuna valutazione finora

- Review of Design Guideline For Small Diameter BranchDocumento24 pagineReview of Design Guideline For Small Diameter Branchmihai37Nessuna valutazione finora

- Pipe Work Damper Sept 02Documento7 paginePipe Work Damper Sept 02Manel MontesinosNessuna valutazione finora

- Increase Allowable Stress CodeDocumento9 pagineIncrease Allowable Stress Codewenny_tpdNessuna valutazione finora

- Vibration Control of Piping SystemsDocumento6 pagineVibration Control of Piping SystemsJinho JungNessuna valutazione finora

- 1981 OTC 4067 PalmerDocumento8 pagine1981 OTC 4067 PalmerVeena S VNessuna valutazione finora

- Barutzki PDFDocumento9 pagineBarutzki PDFesutjiadiNessuna valutazione finora

- Guidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework pdf - Google 搜索 PDFDocumento2 pagineGuidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework pdf - Google 搜索 PDFjasonwu11150% (2)

- Nozzle Stiffness and Stress Computation Using A Parametrically Controlled Finite Element Modeling ApproachDocumento4 pagineNozzle Stiffness and Stress Computation Using A Parametrically Controlled Finite Element Modeling ApproachkysucoNessuna valutazione finora

- Din en Iso 16135Documento26 pagineDin en Iso 16135Ahmed HassanNessuna valutazione finora

- Recent Developments in Piping Vibration Screening LimitsDocumento15 pagineRecent Developments in Piping Vibration Screening Limitstgpg7fk758Nessuna valutazione finora

- PVP2008-Hinnant and PaulinDocumento50 paginePVP2008-Hinnant and PaulinFeliper65Nessuna valutazione finora

- Assessment of Flaws in Pipe Girth WeldsDocumento17 pagineAssessment of Flaws in Pipe Girth Weldssherviny100% (1)

- 10.1.1.144.9002 SW FatigueDocumento13 pagine10.1.1.144.9002 SW Fatigueb_wooNessuna valutazione finora

- Review of Fatigue Strength Assessment ofDocumento18 pagineReview of Fatigue Strength Assessment ofNrl SyafiniNessuna valutazione finora

- Effect of Welding Parameters on PE Weld QualityDocumento22 pagineEffect of Welding Parameters on PE Weld Qualityvipul anandNessuna valutazione finora

- Leak Before Break Fracture Mechanics ThesisDocumento251 pagineLeak Before Break Fracture Mechanics ThesisMohamed Elwi MitwallyNessuna valutazione finora

- Api 5L1 - 2002Documento15 pagineApi 5L1 - 2002GentelmanOnlyNessuna valutazione finora

- Acoustically Induced Vibration Mitigations in Compressor Piping SystemsDocumento10 pagineAcoustically Induced Vibration Mitigations in Compressor Piping SystemsaerosanthNessuna valutazione finora

- Flange Leakage PDFDocumento48 pagineFlange Leakage PDFGaurav TripathiNessuna valutazione finora

- Taller3 Modeling Concepts in Buried Pipe AnalysisDocumento29 pagineTaller3 Modeling Concepts in Buried Pipe AnalysisFSAAVEDRAF100% (1)

- Buried Pipeline Lowering in Trench Stress AnalysisDocumento9 pagineBuried Pipeline Lowering in Trench Stress AnalysisGhanshyam ShuklaNessuna valutazione finora

- EN1591 Flange DesignDocumento9 pagineEN1591 Flange DesignmadodandembeNessuna valutazione finora

- Fracture Initiation, Propagation, and Arrest in PipelinesDocumento30 pagineFracture Initiation, Propagation, and Arrest in PipelinesCarlos NievesNessuna valutazione finora

- Autopipe TutorialDocumento198 pagineAutopipe TutorialMuhammad Nashir100% (1)

- RP f101 - 2010 10 PDFDocumento42 pagineRP f101 - 2010 10 PDFVo Trong ThaiNessuna valutazione finora

- Improvement of IEC 60534-8-3 Standard Fo PDFDocumento12 pagineImprovement of IEC 60534-8-3 Standard Fo PDFDenon EvonNessuna valutazione finora

- Pipelines Stress Analysis Report MechatronicsDocumento10 paginePipelines Stress Analysis Report MechatronicsJuan Carlos RiveraNessuna valutazione finora

- JIP - Field Segmented Fittings - Phase 2 Report - FINAL - 12-06-11 - tcm153-484341Documento127 pagineJIP - Field Segmented Fittings - Phase 2 Report - FINAL - 12-06-11 - tcm153-484341quiron2010Nessuna valutazione finora

- Stress indices for piping with trunnion attachmentsDocumento10 pagineStress indices for piping with trunnion attachmentsfileseekerNessuna valutazione finora

- Flange Leakage Evaluation Based On NC 3658 PDFDocumento3 pagineFlange Leakage Evaluation Based On NC 3658 PDFkaruna346Nessuna valutazione finora

- PVP2017-66086 Trunnion ElbowsDocumento9 paginePVP2017-66086 Trunnion ElbowsshaffetiNessuna valutazione finora

- API Specification 15HR: High-Pressure Fiberglass Line PipeDocumento1 paginaAPI Specification 15HR: High-Pressure Fiberglass Line Pipefajar7777Nessuna valutazione finora

- Itt Grinnell Pipe Hanger Design & Engineering 2008Documento80 pagineItt Grinnell Pipe Hanger Design & Engineering 2008ITT GRINNELLNessuna valutazione finora

- Piping Vibrations ConferenceDocumento12 paginePiping Vibrations ConferenceGustavo Espinosa MartinezNessuna valutazione finora

- Asme Sem1Documento60 pagineAsme Sem1zahoorNessuna valutazione finora

- 3600 - Hi-Lo Pilot SwitchDocumento10 pagine3600 - Hi-Lo Pilot Switchsumesh19778933Nessuna valutazione finora

- BS 5351 - 1986Documento31 pagineBS 5351 - 1986anmoljassal100% (1)

- BS 5160Documento29 pagineBS 5160surangaNessuna valutazione finora

- Operation and Maintenance Manual-Floating Ball Valves-2011Documento9 pagineOperation and Maintenance Manual-Floating Ball Valves-2011engineeringikptNessuna valutazione finora

- Visual guide to JIS fittings dimensions and specificationsDocumento8 pagineVisual guide to JIS fittings dimensions and specificationsSis Woyo100% (1)

- Functional Specification Pressure GaugeDocumento9 pagineFunctional Specification Pressure GaugeSurendra ReddyNessuna valutazione finora

- Inventory Usage SampleDocumento27 pagineInventory Usage SampleAnonymous lt2LFZHNessuna valutazione finora

- Tri P10Documento10 pagineTri P10isaac2408Nessuna valutazione finora

- ButterflyDocumento24 pagineButterflyVinodh VinoNessuna valutazione finora

- I2SL Fan Codes Standards 2013 Fan Codes StandardsDocumento32 pagineI2SL Fan Codes Standards 2013 Fan Codes StandardsBaskar KannaiahNessuna valutazione finora

- Chemical Feed Systems Basic Design Berschauer 060712Documento9 pagineChemical Feed Systems Basic Design Berschauer 060712Baskar KannaiahNessuna valutazione finora

- Experienced Based Rules of Chemical EngineeringDocumento33 pagineExperienced Based Rules of Chemical Engineeringintania66Nessuna valutazione finora

- Channels 0. Channels and Pipes With Frictional and Singular Pressure DropDocumento111 pagineChannels 0. Channels and Pipes With Frictional and Singular Pressure DropBaskar KannaiahNessuna valutazione finora

- NCPWB-TR-Steel Pipe Fitting DataDocumento285 pagineNCPWB-TR-Steel Pipe Fitting DataBaskar KannaiahNessuna valutazione finora

- Air Receivers Volume CalculationDocumento98 pagineAir Receivers Volume CalculationBaskar Kannaiah100% (1)

- Tri P10Documento10 pagineTri P10isaac2408Nessuna valutazione finora

- 01 - Fluid FlowDocumento80 pagine01 - Fluid FlowEmir KarNessuna valutazione finora

- Drainge&Waste WaterDocumento43 pagineDrainge&Waste WatermohdnazirNessuna valutazione finora

- 06 CompressorsDocumento16 pagine06 CompressorsmunatsiNessuna valutazione finora

- Chapter 4: Absorbers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocumento11 pagineChapter 4: Absorbers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallBaskar KannaiahNessuna valutazione finora

- Multiport Diffuser Design and AnalysisDocumento27 pagineMultiport Diffuser Design and Analysisjoapme100% (1)

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A PumpDocumento11 pagineCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pumpthanh_79Nessuna valutazione finora

- Fo Filling & Transfer SystDocumento1 paginaFo Filling & Transfer SystBaskar KannaiahNessuna valutazione finora

- Pump Energy Efficiency Calculation ToolDocumento8 paginePump Energy Efficiency Calculation ToolSoma NathanNessuna valutazione finora

- Bunkering Procedures No 13Documento2 pagineBunkering Procedures No 13Baskar KannaiahNessuna valutazione finora

- Crude Oil Transfer ProDocumento3 pagineCrude Oil Transfer ProBaskar KannaiahNessuna valutazione finora

- Equipment Data & P&id 1-10Documento10 pagineEquipment Data & P&id 1-10Baskar KannaiahNessuna valutazione finora

- Installation, Operation, and Maintenance Manual: Non-Welded Grease Duct SystemsDocumento20 pagineInstallation, Operation, and Maintenance Manual: Non-Welded Grease Duct SystemsBaskar KannaiahNessuna valutazione finora

- Stern TubeDocumento6 pagineStern TubeBaskar KannaiahNessuna valutazione finora

- Bilge SystemDocumento1 paginaBilge SystemBaskar KannaiahNessuna valutazione finora

- Pump Curve CalcDocumento6 paginePump Curve CalcBaskar KannaiahNessuna valutazione finora

- Pressure drop calculation for vapor pipelineDocumento5 paginePressure drop calculation for vapor pipelineBaskar KannaiahNessuna valutazione finora

- EnerMech Cranes & Lifting ExpertiseDocumento4 pagineEnerMech Cranes & Lifting ExpertiseBaskar KannaiahNessuna valutazione finora

- Heat Balance DiagramDocumento10 pagineHeat Balance DiagramJitendra Bhatia100% (3)

- SealingDocumento6 pagineSealingBaskar KannaiahNessuna valutazione finora

- Load CalculationDocumento5 pagineLoad CalculationBaskar Kannaiah100% (1)

- ASTM A106 Pipe Specifications - American Piping ProductsDocumento7 pagineASTM A106 Pipe Specifications - American Piping ProductsJonnah Faye MojaresNessuna valutazione finora

- Introduction To Hook-Up & CommissioningDocumento25 pagineIntroduction To Hook-Up & CommissioningHazwan Jamhuri100% (4)

- (Process Industry Practices) Design of ASME B31.3Documento24 pagine(Process Industry Practices) Design of ASME B31.3aguiarv88100% (1)

- Data Sheets-T220425-499Documento9 pagineData Sheets-T220425-499pedro torresNessuna valutazione finora

- LG Room Air Conditioner Service ManualDocumento72 pagineLG Room Air Conditioner Service Manualcaovadio88100% (1)

- Tobee® Warman SP SPR Vertical Slurry PumpsDocumento8 pagineTobee® Warman SP SPR Vertical Slurry PumpsDonna ZhangNessuna valutazione finora

- Water Heater Gi 0631 LDocumento14 pagineWater Heater Gi 0631 LSopyan PermanaNessuna valutazione finora

- SS 272-2012 - PreviewDocumento10 pagineSS 272-2012 - PreviewNhat NguyenNessuna valutazione finora

- Stator CW SOP-2Documento12 pagineStator CW SOP-2SonratNessuna valutazione finora

- Ameet Sir Working 28.10.2017Documento71 pagineAmeet Sir Working 28.10.2017saurabhNessuna valutazione finora

- Operating Manual For Vispac Seal System: P M U PDocumento25 pagineOperating Manual For Vispac Seal System: P M U PAgustantoNessuna valutazione finora

- II Pipeline Design Codes and Standards-MSGDocumento74 pagineII Pipeline Design Codes and Standards-MSGSanjay Kumar100% (3)

- Rules For The Classification of Naval Ships: Part C - Machinery, Systems and Fire ProtectionDocumento444 pagineRules For The Classification of Naval Ships: Part C - Machinery, Systems and Fire Protectionguichen wangNessuna valutazione finora

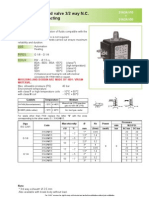

- Solenoid valve 3/2 way N.C. direct acting featuresDocumento2 pagineSolenoid valve 3/2 way N.C. direct acting featuresJoseph A. LoeNessuna valutazione finora

- Hydraulic Ram Pump Manual (ITDG) PDFDocumento55 pagineHydraulic Ram Pump Manual (ITDG) PDFDugao Aya-os100% (2)

- Wellhead Tubewire FeedthruDocumento1 paginaWellhead Tubewire FeedthruDaniel ChiriacNessuna valutazione finora

- TransTech Diseño PlantaDocumento24 pagineTransTech Diseño PlantaAndres PercyNessuna valutazione finora

- Mid Mock Board - June 16, 2019 - Practical Problem - QuestionnaireDocumento15 pagineMid Mock Board - June 16, 2019 - Practical Problem - QuestionnaireReyfel Desca0% (1)

- Glycol Dehydration Unit English LetterDocumento4 pagineGlycol Dehydration Unit English LetterRaulCamachoNessuna valutazione finora

- 1.0 ObjectiveDocumento7 pagine1.0 Objectivehengjhoe constructNessuna valutazione finora

- Prakarsa-Iliadi - Slickline - Rigless Application 20180307Documento90 paginePrakarsa-Iliadi - Slickline - Rigless Application 20180307AsfanNessuna valutazione finora

- BOOK District Heating Handbook PDFDocumento77 pagineBOOK District Heating Handbook PDFTony LewisNessuna valutazione finora

- Flexitallic Gaskets Design - CriteriaDocumento63 pagineFlexitallic Gaskets Design - CriteriabigbirdoncrackNessuna valutazione finora

- MSS SP-117 2011Documento12 pagineMSS SP-117 2011ISRAEL PORTILLO100% (2)

- VSTECH Mechanical Project IdeasDocumento2 pagineVSTECH Mechanical Project IdeasSandeep MagapuNessuna valutazione finora

- Doyle, Lawrence E. - Elshennawy, Ahmad K. - Schrader, George F - Manufacturing Processes & Materials-Society of Manufacturing Engineers (2000)Documento865 pagineDoyle, Lawrence E. - Elshennawy, Ahmad K. - Schrader, George F - Manufacturing Processes & Materials-Society of Manufacturing Engineers (2000)Anibal Daza100% (1)

- Autoclave Subsea Ball ValvesDocumento20 pagineAutoclave Subsea Ball Valvesvp989Nessuna valutazione finora

- Norsok M 630Documento160 pagineNorsok M 630Alex KuvoricNessuna valutazione finora

- Equation - Single - Phase - Gas - Pipeline - Flow - PreviewDocumento17 pagineEquation - Single - Phase - Gas - Pipeline - Flow - PreviewmrezzaNessuna valutazione finora

- Engelsmann Vibration Sieves: Universal, Economic, Compact ScreeningDocumento16 pagineEngelsmann Vibration Sieves: Universal, Economic, Compact ScreeningBagi84Nessuna valutazione finora