Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Loading of Power Transformers

Caricato da

ajaymann0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

83 visualizzazioni3 pagineThis document discusses how utilities can reduce costs by loading power transformers beyond their nameplate ratings without affecting reliability. It presents a methodology from an IEEE guide for determining allowable transformer loading levels based on hot-spot temperature limits. Calculations are provided showing how different loading scenarios above nameplate ratings can increase peak load capacity while minimizing life loss over time. The analysis finds that planned and emergency overloads can allow up to 27% and 70% higher peak loads respectively while maintaining transformer life expectancy.

Descrizione originale:

Power Trasnformer

Titolo originale

Loading of power transformers

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document discusses how utilities can reduce costs by loading power transformers beyond their nameplate ratings without affecting reliability. It presents a methodology from an IEEE guide for determining allowable transformer loading levels based on hot-spot temperature limits. Calculations are provided showing how different loading scenarios above nameplate ratings can increase peak load capacity while minimizing life loss over time. The analysis finds that planned and emergency overloads can allow up to 27% and 70% higher peak loads respectively while maintaining transformer life expectancy.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

83 visualizzazioni3 pagineLoading of Power Transformers

Caricato da

ajaymannThis document discusses how utilities can reduce costs by loading power transformers beyond their nameplate ratings without affecting reliability. It presents a methodology from an IEEE guide for determining allowable transformer loading levels based on hot-spot temperature limits. Calculations are provided showing how different loading scenarios above nameplate ratings can increase peak load capacity while minimizing life loss over time. The analysis finds that planned and emergency overloads can allow up to 27% and 70% higher peak loads respectively while maintaining transformer life expectancy.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Loading of Power Transformers:

Reducing Costs Without Affecting Reliability

4

Burns &McDonnell

By Bill Strongman, P.E., and

KiahHarris, P.E.

Introduction

In the past, normal utility practice has

been to load power transformers to no

more than the nameplate rating (e.g.

OA/FOA/FOA) for normal peak opera-

tion, and to some limit above nameplate

for emergency operation. The IEEE

Guide for Loading Mineral-Oil-Immersed

Transformers (Std C57.91-1995) suggests

that transformers can be loaded beyond

nameplate rating during peak hours of

operation, provided they are loaded

below nameplate rating during non-

peak times. This assumes a willingness

to accept an accelerated loss of life for a

short duration given that the trans-

former life will be extended during low

load hours.

In today's competitive environment,

utilities need to review ways to reduce

costs without affecting reliability. By

using the methodology presented in the

Guide to determine allowable trans-

former loading, the utility can defer

transformer upgrades and thus reduce

overall costs while keeping reliability

the same. The intent of this article is to

provide a discussion and example of

how the Guide might be applied to utili-

ty substation transformers.

Explanationof Theory

Transformer nameplate rating is based

on life expectancy, which in turn is

based on insulation loss of life.

Deterioration of insulation is a time

function of temperature. The expected

life of a 65 C rise transformer is based

on a continuous hot-spot temperature of

110 C. That is, for each hour that the

transformer is operated at a hot-spot

temperature of 110 C, the life is reduced

by 1 hour. The IEEE Guide assumes a

normal life of 180,000 hours.

The Guide provides a methodology for

determining acceptable loading levels

beyond the 110 C hot-spot limit. The

underlying concept is that the additional

aging for hot-spot temperatures above

110 C is offset during periods when hot-

spot temperatures are much lower. The

Guide discusses the concepts of Normal

Life Expectancy Loading, Planned

Loading Beyond Nameplate Rating,

Long-time Emergency Loading, and

Short-time Emergency Loading, which

are defined as follows:

Normal Life Expectancy Loading

(NLE): Normal life expectancy

occurs when a transformer is operat-

ed at 110 C continuously. The Guide

recommends allowing the hot-spot

temperature to reach 120 C for a

short period during the day, provid-

ed the transformer will be operated

for longer periods below 110 C.

Planned Loading Beyond Nameplate

(PLBN): Where transformers do not

carry steady continuous loads, which

is the more typical utility operation,

loading can be such that the hot-spot

temperature can rise to 120-130 C.

This operating scenario is intended

for planned repetitive loads.

Long-time Emergency Loading

(LTE): In situations where a trans-

former is expected to carry emer-

gency loads, the hot-spot tempera-

ture can rise to 120-140 C. This is not

a normal operating condition and is

expected to cover a prolonged out-

age (from several hours to several

months) to some system element

(single contingency outage).

Expectation is that these types of

events will occur only two or three

times over the life of the transformer.

Short-time Emergency Loading

(STE): For highly unlikely conditions

(second and third contingencies) the

hot-spot temperature can be allowed

to go as high as 180 C. This would

be expected to occur for a short peri-

od (two to three hours) and only

once or twice over the life of the

transformer.

Other factors that must be taken into

account when applying the above

loading levels, especially for Short-

time Emergency Loading, include:

Evolution of free gas due to heating

of winding and lead conductors may

reduce dielectric strength.

Operating at high temperatures will

cause reduced mechanical strength

of both conductor and structural

insulation; however, this is normally

more of a concern during transient

over-current conditions.

Thermal expansion of conductors,

insulation or structural parts at high

temperatures may result in perma-

nent deformation that could con-

tribute to mechanical or dielectric

failure.

Pressure build-up in bushings could

result in leaking gaskets, loss of oil,

and ultimately dielectric failure.

Abuild-up of oil decomposition

products at the contact point can

increase resistance in the contacts of

tap changers.

Auxiliary equipment internal to the

transformer may also be subject to

risk.

Top oil temperatures above 105 C

can cause oil expansion that might

be greater than the holding capacity

of the tank, which can result in

Daily Load Pattern

0.00

0.20

0.40

0.60

0.80

1.00

1.20

Hour

Figure1

5

TechBriefs

operation of the pressure relief

device and subsequent loss of oil.

Rating of connected equipment may

limit the ability to load the trans-

former beyond nameplate.

Determinationof AllowableLoads

The Guide provides a calculation of the

"Aging Acceleration Factor," which can

be interpreted as the number of hours

the insulation ages for one hour at a

given hot-spot temperature. The hot-

spot temperature rise is a function of the

transformer heating characteristics such

as top-oil temperature rise above ambi-

ent and hot-spot rise above top-oil tem-

perature. These temperature rises are

added to the ambient to determine the

final hot-spot temperature.

As a transformer is loaded, the hot-spot

temperature increases. The intent is to

load the transformer as high as possible

without exceeding the allowed hot-spot

temperature. The following presents an

example of how the calculations in the

Guide might be used to determine the

allowable load on an hourly basis for the

various loading levels above. For the

purpose of this article, the allowed hot-

spot temperatures for each load level

are:

Hot-spot Temp

NLE 120 C

PLBN 130 C

LTE 140 C

STE 180 C

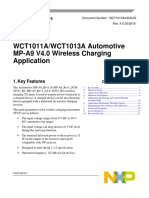

The resulting loading levels for given

hot-spot temperatures are a function of

both load patterns for the substations

and the transformer characteristics. The

load patterns were taken as typical sum-

mer loads for a utility in the Midwest, as

shown in Figure 1. The transformer

characteristics were assumed to be:

Top-oil rise over ambient at rated

load: 35 C

Hottest-spot rise over top-oil temper-

ature, at rated load: 45 C

Ratio of load loss at rated load to no-

load loss: 6.5

Oil thermal time constant at rated

load: 1.25

Exponent of loss function vs. top-oil

rise: 1.0

Exponent of load squared vs. wind-

ing gradient: 1.0

These values are taken from the 1981

IEEE Guide to Loading Mineral-Oil-

Immersed Power Transformers (C57.92-

1981) as being reasonable assumptions

where actual data is not available.

For this example, the nameplate rating

of the transformer is 6250 kVAand the

ambient temperature is assumed to be

40 C.

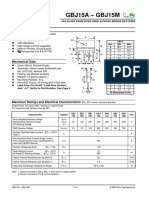

Table 1 presents the load, temperature

and Age Acceleration Factors for one

day assuming the transformer is to be

loaded at Planned Loading Beyond

Nameplate. The table shows the main

components of the calculations. There

are intermediate steps in the calculations

to arrive at the final hot-spot tempera-

ture. The reader is directed to the Guide

for these steps. The peak allowable load

is found by setting the maximum

allowed hot-spot temperature at 130 C

and using the "Goal Seek" function in

Excel to find the maximum peak one-

hour load.

PLBN Load and Loss of Life

0%

20%

40%

60%

80%

100%

120%

140%

Hour

0

1

2

3

4

5

6

7

8

Load Loss of Life

L

o

a

d

%

N

a

m

e

p

la

t

e

L

o

s

s

o

f

L

if

e

(

H

r

s

/

H

r

)

13579

1

1

1

3

1

5

1

7

1

9

2

1

2

3

Figure2

Again, the intent is to load transformers

beyond the nameplate ratings without

adversely reducing the life of the trans-

former. The aging is shown in the last

two columns. As can be seen, the accu-

mulated aging of the transformer over a

24-hour period for this scenario is about

43 hours. The loads and age acceleration

factor from Table 1 are presented graphi-

cally in Figure 2.

The loading and loss of life for the other

three loading levels were also calculated.

The following are the results of the

analyses:

Allowed Hot-Spot Temperatures

NLE PLBN LTE STE

120 C 130 C 140 C 180 C

Peak Allowable Loading

117% 127% 135% 170%

Loss of Life Over Peak Hour

2.5 hrs. 7 hrs. 17 hrs. 424 hrs.

Loss of Life Over Day

18 hrs. 48 hrs. 96 hrs. 480 hrs.

On an annual basis, the loss of life for a

transformer is considerably lower than

shown above. This is due to two factors

1) the ambient temperatures are much

lower for the majority of the year and 2)

loads are much lower than the peak for

the majority of the year. Aging can be as

low as 0.1 hours over a 24-hour period.

For example, the accumulated aging

was calculated to be 0.116 hours for a 24-

hour period assuming an ambient of 20

C and a load of 100% of nameplate.

The above analysis is based on assumed

transformer heating characteristics. It

should be noted that the hot-spot tem-

perature, and subsequently the loss of

life, is sensitive to the input assumptions

used for the transformers. A1 C

decrease in the top-oil rise over ambient,

or the hot-spot rise over top oil results in

a 1% increase in the allowable loading.

The values used in this study are consid-

ered to be conservative.

6

Burns &McDonnell

KiahHarrisi s a pr i nci pal i n t he

management ser vi ces gr oup. He

has over 25 year s ex per i ence i n

t he pl anni ng, desi gn and const r uc-

t i on of el ect r i cal engi neer i ng

pl ant s, t r ansmi ssi on and subst at i on

f aci l i t i es, and syst em di spat ch cen-

t er s. He has a bachel or s degr ee

and mast er s degr ee i n el ect r i cal

engi neer i ng f r om t he Uni ver si t y of

Mi ssour i .

Bill Strongmani s a seni or

pl anni ng engi neer i n Bur ns &

McDonnel l s management ser vi c-

es gr oup. He has over 25 year s

ex per i ence i n t he el ect r i c ut i l i t y

i ndust r y, r angi ng f r om gener a-

t i on pl anni ng t o di st r i but i on

desi gn. He has a bachel or s

degr ee i n el ect r i cal engi neer i ng

and a mast er s degr ee i n busi -

ness admi ni st r at i on, bot h f r om

t he Uni ver si t y of Al ber t a.

Benefits

There are three benefits that need to be

considered. First, for substations with

single transformers, the loading for

expected system peaks can go to 125%

of the nameplate rating. This could

delay transformer change-out by five or

six years. Second, where substations are

strongly interconnected through the dis-

tribution system, the load from an out-

aged transformer can be transferred to

the remaining transformer(s) provided

the loading on any of the remaining

transformers does not exceed 135% of

nameplate. Finally, where there are two

transformers operated in parallel in the

same substation, the loading on the

remaining transformer for an outage to

the other transformer can go to 160%,

provided the loading is only for two to

three hours.

Conclusions &Discussion

Utilities can take advantage of the ability

of transformers to safely handle over-

peak conditions to reduce installation

costs and maintain system reliability.

Utilities should consider loading trans-

formers to the PLBN levels (in the order

of 115-125%) for distribution substations

that have one transformer. For distribu-

tion substations that have two trans-

formers, the STE rating of 160% could be

used for short duration loading situa-

tions. For substations where loads can

be moved to other substations, the LTE

rating of 135% could be used.

It is very important that, in considering

the above loading levels, the utility

obtain data on the transformer. The

transformer temperature characteristics

are especially important in the calcula-

tions, and thus the utility should search

its records or check with the manufac-

turer to determine the characteristics.

Also, especially for older units, the utili-

ty should check with its maintenance

group to determine if there are any

problems that would preclude a unit

from being loaded above nameplate.

Table1

Load, Temperature, AgeAccelerationFactors

HOUR KVA PU TopOil Hot Spot Hot Spot Age Accumulated

Load Load Delta Delta Temperature Acceleration AAF

C C C Factor (hrs) (hrs)

100 5549 0.89

200 5356 0.86 47.09 7.81 94.90 0.20 0.20

300 5264 0.84 46.06 7.60 93.66 0.17 0.38

400 5001 0.80 43.53 7.00 90.53 0.12 0.50

500 4913 0.79 42.55 6.80 89.35 0.11 0.61

600 4918 0.79 42.30 6.81 89.12 0.10 0.71

700 5114 0.82 43.75 7.26 91.01 0.13 0.84

800 5595 0.90 47.87 8.38 96.25 0.23 1.07

900 5812 0.93 49.80 8.90 98.70 0.30 1.38

1000 6501 1.04 56.87 10.65 107.52 0.77 2.15

1100 6970 1.12 62.16 11.91 114.06 1.51 3.66

1200 7201 1.15 65.00 12.54 117.55 2.13 5.79

1300 7396 1.18 67.56 13.09 120.65 2.89 8.68

1400 6779 1.08 60.38 11.39 111.77 1.20 9.87

1500 6844 1.10 61.29 11.56 112.85 1.34 11.21

1600 7495 1.20 69.38 13.37 122.76 3.53 14.74

1700 7833 1.25 74.07 14.35 128.42 6.03 20.77

1800 7909 1.27 75.43 14.57 130.00 6.98 27.76

1900 7724 1.24 73.35 14.03 127.38 5.47 33.23

2000 7286 1.17 68.08 12.78 120.87 2.95 36.18

2100 7287 1.17 68.30 12.78 121.08 3.01 39.18

2200 6928 1.11 64.15 11.79 115.94 1.82 41.00

2300 6714 1.07 61.74 11.22 112.95 1.35 42.35

2400 6320 1.01 57.34 10.18 107.53 0.78 43.13

Potrebbero piacerti anche

- Advanced Temperature Measurement and Control, Second EditionDa EverandAdvanced Temperature Measurement and Control, Second EditionNessuna valutazione finora

- Dynamic Loading of Power TransformersDocumento24 pagineDynamic Loading of Power TransformersGustavo AguayoNessuna valutazione finora

- Life Cycle Management of Power Transformers Using Transformer Protection RelayDocumento7 pagineLife Cycle Management of Power Transformers Using Transformer Protection RelaycuamiNessuna valutazione finora

- Transformer Ratings and Transformer LifeDocumento6 pagineTransformer Ratings and Transformer LifeidfiNessuna valutazione finora

- Power Transformers: Overview Factors On Assessing Insulation LifeDocumento8 paginePower Transformers: Overview Factors On Assessing Insulation LifeДенис ЛяпуновNessuna valutazione finora

- Effects of Overloading of Oil Immerse XformerDocumento4 pagineEffects of Overloading of Oil Immerse Xformerjck07Nessuna valutazione finora

- Thermal Overload Protection 2Documento5 pagineThermal Overload Protection 2Anonymous DKv8vpNessuna valutazione finora

- Power TransformersDocumento18 paginePower Transformers2011kumarNessuna valutazione finora

- Ieee C57.92-1981Documento65 pagineIeee C57.92-1981yebri100% (1)

- 97 MIPSYCON Power Transformer Life Cycle Cost ReductionDocumento11 pagine97 MIPSYCON Power Transformer Life Cycle Cost ReductioncalripkenNessuna valutazione finora

- Cold Load Pick-Up - Theory and Industry PracticesDocumento30 pagineCold Load Pick-Up - Theory and Industry PracticesamirrezafeyziNessuna valutazione finora

- Transformer Life ManagementDocumento20 pagineTransformer Life ManagementwiyatnoNessuna valutazione finora

- Chapter 7 Overload Capacity of Power TransformersDocumento10 pagineChapter 7 Overload Capacity of Power Transformerstenk_man100% (1)

- Dissolved Gas Analysis of A Thermally Overloaded Oil-Immersed Current TransformerDocumento8 pagineDissolved Gas Analysis of A Thermally Overloaded Oil-Immersed Current Transformerfcof1232374Nessuna valutazione finora

- Power Transformer Loading Studies Considering Over ExcitationDocumento7 paginePower Transformer Loading Studies Considering Over ExcitationHelloNessuna valutazione finora

- Evaluation of Transformer Loading Above Nameplate RatingDocumento13 pagineEvaluation of Transformer Loading Above Nameplate RatingMuhammad Ali Masood CheemaNessuna valutazione finora

- Techniques For Estimation of Hot Spot Temperatures in TransformersDocumento4 pagineTechniques For Estimation of Hot Spot Temperatures in TransformersSatheesh Kumar NatarajanNessuna valutazione finora

- PWR TransformersDocumento11 paginePWR TransformersManas PandaNessuna valutazione finora

- Sanjay Kar Chowdhury Cbip 2006Documento7 pagineSanjay Kar Chowdhury Cbip 2006Gunadevan ChandrasekaranNessuna valutazione finora

- Transformer Refurbishment Policy at Rte Conditioned by The Residual Lifetime AssessmentDocumento10 pagineTransformer Refurbishment Policy at Rte Conditioned by The Residual Lifetime AssessmentPit SamprasNessuna valutazione finora

- Condition Monitoring PaperDocumento10 pagineCondition Monitoring Papersubhamay sarkarNessuna valutazione finora

- 22A105CDocumento12 pagine22A105CDuram_Han_2546Nessuna valutazione finora

- Thermal Overload Protection of Power TransformersDocumento33 pagineThermal Overload Protection of Power TransformersmentongNessuna valutazione finora

- Thermal Modelling For Dynamic Transformer Rating in Low Carbon Distribution Network OperationDocumento6 pagineThermal Modelling For Dynamic Transformer Rating in Low Carbon Distribution Network Operationbpd21Nessuna valutazione finora

- Assessment of Power Transformer Cooler With Femlab: Abstract-The Significance of Overload in Power System HasDocumento7 pagineAssessment of Power Transformer Cooler With Femlab: Abstract-The Significance of Overload in Power System HasConstantin DorinelNessuna valutazione finora

- An Investigation On The Effects of Environmental Factors in Transformer'S Insulation LifeDocumento8 pagineAn Investigation On The Effects of Environmental Factors in Transformer'S Insulation LifeRa muNessuna valutazione finora

- Ampacity Tables and Correction Factors - Okonite Electrical Wire & CableDocumento3 pagineAmpacity Tables and Correction Factors - Okonite Electrical Wire & Cabledk4monjureNessuna valutazione finora

- Forecasting The Nature of Power Transformer Insulation Oil Using Chemical Properties of Dissolved GasesDocumento10 pagineForecasting The Nature of Power Transformer Insulation Oil Using Chemical Properties of Dissolved GasesMurali KrishnaNessuna valutazione finora

- Luwendran MoodleyDocumento7 pagineLuwendran MoodleyDante FilhoNessuna valutazione finora

- Combined Cycle Power Plant OperationDocumento21 pagineCombined Cycle Power Plant OperationEgit Bobyarta100% (5)

- Loading Power Transformers Beyond Nameplate RatingsDocumento23 pagineLoading Power Transformers Beyond Nameplate RatingsHamayoun MurtazaNessuna valutazione finora

- 15 Combined Cycle Power Plant OperationDocumento21 pagine15 Combined Cycle Power Plant OperationParmeshwar Nath Tripathi100% (3)

- Battery Management GuideDocumento10 pagineBattery Management GuideR.S. Kumaraswamy100% (1)

- Uprating and Expanding Existing SubstationsDocumento29 pagineUprating and Expanding Existing SubstationsEgbodor PeterNessuna valutazione finora

- 058467Documento18 pagine058467Marco Bertoldi100% (1)

- Understanding UPS Overload CapabilitiesDocumento19 pagineUnderstanding UPS Overload Capabilitiestllmal002Nessuna valutazione finora

- Electrical 2 - Group B - TempDocumento6 pagineElectrical 2 - Group B - TempMohamed LabibNessuna valutazione finora

- Assessment of Overload Capability of Power Transformers by Online MonitoringDocumento12 pagineAssessment of Overload Capability of Power Transformers by Online MonitoringДенис ЛяпуновNessuna valutazione finora

- Guide For Loading Mineral-Oil-Immersed Overhead A N D Pad-Mounted T Ri Utiontran OrmersDocumento26 pagineGuide For Loading Mineral-Oil-Immersed Overhead A N D Pad-Mounted T Ri Utiontran OrmersEdna LópezNessuna valutazione finora

- Short Time Over Load of Transformer PDFDocumento107 pagineShort Time Over Load of Transformer PDFIrfan AliNessuna valutazione finora

- Effects of Environmental Factors in Transformer's Insulation Life PDFDocumento10 pagineEffects of Environmental Factors in Transformer's Insulation Life PDFBoris EugeneNessuna valutazione finora

- Powergen Europe 2014, Cologne: Gas Turbine Short and Long Term Operation and Failure MechanismsDocumento13 paginePowergen Europe 2014, Cologne: Gas Turbine Short and Long Term Operation and Failure MechanismsKR PANessuna valutazione finora

- IEEMA Article On Over Current ProtectionDocumento5 pagineIEEMA Article On Over Current ProtectionHari Krishna.MNessuna valutazione finora

- Power Transformer Condition Monitoring and Remanent Life AssessmentDocumento5 paginePower Transformer Condition Monitoring and Remanent Life AssessmentAmarinder DhimanNessuna valutazione finora

- Selecting Distribution-Transformer Size: Member AieeDocumento6 pagineSelecting Distribution-Transformer Size: Member AieeMikhaelRodriguezNessuna valutazione finora

- Ieee STD C57 100-1995Documento4 pagineIeee STD C57 100-1995José Enrique García VillarrealNessuna valutazione finora

- Dissolved Gas Analysis of Transformer: Cellulose Insulation Carbon OxidesDocumento2 pagineDissolved Gas Analysis of Transformer: Cellulose Insulation Carbon OxidesheroNessuna valutazione finora

- Temperature Correction Factors - Power Grid IndiaDocumento6 pagineTemperature Correction Factors - Power Grid IndiaAMIT BISWASNessuna valutazione finora

- Battery Life ExpentancyDocumento4 pagineBattery Life ExpentancySAMEERNessuna valutazione finora

- Name Abhijit Dilip MahaleDocumento3 pagineName Abhijit Dilip Mahale0004Prathamesh TayadeNessuna valutazione finora

- Maximizing Heat-Transfer Fluid LongevityDocumento8 pagineMaximizing Heat-Transfer Fluid LongevityDefenceDogNessuna valutazione finora

- Technological Development - Health Monitoring - Maximizing Efficiency - Advance Communication System - Regulatory and Environmental IssuesDocumento37 pagineTechnological Development - Health Monitoring - Maximizing Efficiency - Advance Communication System - Regulatory and Environmental IssuesAnonymous pKsr5vNessuna valutazione finora

- IEEE C57.91-1981-Transformer Loading PDFDocumento65 pagineIEEE C57.91-1981-Transformer Loading PDFAvijnan Mitra50% (2)

- Malfunction Detection of The Cooling System in Air-Forced Power Transformers Using Online Thermal MonitoringDocumento11 pagineMalfunction Detection of The Cooling System in Air-Forced Power Transformers Using Online Thermal MonitoringДенис ЛяпуновNessuna valutazione finora

- Turbine MaintainanceDocumento9 pagineTurbine Maintainanceer_sanjaypatel100% (2)

- Blast Furnace Technical, Operational and Economical AssistanceDocumento11 pagineBlast Furnace Technical, Operational and Economical Assistancedontspamme9299Nessuna valutazione finora

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDa EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideValutazione: 4 su 5 stelle4/5 (8)

- Tendernotice 1Documento3 pagineTendernotice 1ajaymannNessuna valutazione finora

- Level - 3 - Ais Manual 33kv Type 22 08 2014 PDFDocumento44 pagineLevel - 3 - Ais Manual 33kv Type 22 08 2014 PDFajaymannNessuna valutazione finora

- 12 5 16 MVA Power Transformer Data Sheet PDFDocumento5 pagine12 5 16 MVA Power Transformer Data Sheet PDFajaymannNessuna valutazione finora

- Minilec Catalouge PDFDocumento64 pagineMinilec Catalouge PDFajaymannNessuna valutazione finora

- NGR Guide PDFDocumento4 pagineNGR Guide PDFajaymannNessuna valutazione finora

- 11 KV VCBDocumento3 pagine11 KV VCBajaymannNessuna valutazione finora

- TManual Chapter 01 PDFDocumento22 pagineTManual Chapter 01 PDFJay Rameshbhai ParikhNessuna valutazione finora

- Electrical Machines IDocumento16 pagineElectrical Machines Isuryaprakash001Nessuna valutazione finora

- 07-Upm Celp Lightning Protection System For BuildingsDocumento62 pagine07-Upm Celp Lightning Protection System For BuildingsajaymannNessuna valutazione finora

- GDN 180 PDFDocumento33 pagineGDN 180 PDFb_913664038Nessuna valutazione finora

- Short Circuit Calculations in 60 SecondsDocumento5 pagineShort Circuit Calculations in 60 Secondscoolcreative100% (3)

- Technical Data Sheet "Infinity 3100": 10 15 20 kVA 3Ph - 1PhDocumento7 pagineTechnical Data Sheet "Infinity 3100": 10 15 20 kVA 3Ph - 1PhFlorin MNessuna valutazione finora

- CM2283 MCT EnvAcelDocumento4 pagineCM2283 MCT EnvAcelAdrián MolineroNessuna valutazione finora

- NHD C12864LZ FSW FBW 3V3Documento13 pagineNHD C12864LZ FSW FBW 3V3christjjonesNessuna valutazione finora

- Radar Systems: TEST - 01Documento8 pagineRadar Systems: TEST - 01mounikaNessuna valutazione finora

- Convention Paper: Simulation of An Analog Circuit of A Wah Pedal: A Port-Hamiltonian ApproachDocumento9 pagineConvention Paper: Simulation of An Analog Circuit of A Wah Pedal: A Port-Hamiltonian ApproachMafeCastro1998Nessuna valutazione finora

- TMA EricssonDocumento29 pagineTMA Ericssonthe_kamalkrish50% (2)

- Small Switch Mode Power Supplies Modification Secrets PDFDocumento41 pagineSmall Switch Mode Power Supplies Modification Secrets PDFpedram92% (12)

- Ho1-Ele-007 - e - Electrical Cable ScheduleDocumento9 pagineHo1-Ele-007 - e - Electrical Cable SchedulePrasadNessuna valutazione finora

- LAB Experiement 2Documento5 pagineLAB Experiement 2lillyNessuna valutazione finora

- Cambridge International General Certificate of Secondary EducationDocumento16 pagineCambridge International General Certificate of Secondary EducationSeanNessuna valutazione finora

- Service Manual: NSX-T99 NSX-T99EDocumento21 pagineService Manual: NSX-T99 NSX-T99EGlaucia MachadoNessuna valutazione finora

- GBJ15M Diode Cau Chinh Luu PDFDocumento4 pagineGBJ15M Diode Cau Chinh Luu PDFHưng HQNessuna valutazione finora

- Transformer XII Physics Investigatory ProjectDocumento12 pagineTransformer XII Physics Investigatory ProjectRudraksh SinhaNessuna valutazione finora

- Vlsi WiresDocumento23 pagineVlsi WiresTalha Syed NaqviNessuna valutazione finora

- LED Booklet Master File DefDocumento46 pagineLED Booklet Master File DefFlorin NourescuNessuna valutazione finora

- DMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLDocumento8 pagineDMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLemil_88Nessuna valutazione finora

- Southern Cable CatalogDocumento62 pagineSouthern Cable Catalogahish_8955% (20)

- UT5Documento15 pagineUT5Jignesh ShahNessuna valutazione finora

- 01xa Automotive MP-A9 V4.0 Wireless ChargingDocumento52 pagine01xa Automotive MP-A9 V4.0 Wireless ChargingAlamNessuna valutazione finora

- GSM Site Survey RulesDocumento41 pagineGSM Site Survey Rulestanujsatle60% (5)

- Rishabh Shunt Datasheet (Updated) PDFDocumento7 pagineRishabh Shunt Datasheet (Updated) PDFVijay PandaNessuna valutazione finora

- Basic Steps in PLC ProgrammingDocumento4 pagineBasic Steps in PLC ProgrammingNenad IlicNessuna valutazione finora

- Date Sheet-Terminal Exams - Fall 20-1Documento6 pagineDate Sheet-Terminal Exams - Fall 20-1Muhammad Zaeem AkmalNessuna valutazione finora

- Esh 12-710W Esh 12-710W: Esc 100-12 Esc 150-12 FR Esc 100-12Documento2 pagineEsh 12-710W Esh 12-710W: Esc 100-12 Esc 150-12 FR Esc 100-12muhammadNessuna valutazione finora

- PCB Designing Fundamentals: Compiled By: Hiren Patel (ET Dept.)Documento42 paginePCB Designing Fundamentals: Compiled By: Hiren Patel (ET Dept.)Chintaan PatelNessuna valutazione finora

- (NB24-T554-01D) Specsheet 01152010Documento2 pagine(NB24-T554-01D) Specsheet 01152010nextekpowerNessuna valutazione finora

- Automatic Fire Alarm and Fire Controlling SystemDocumento22 pagineAutomatic Fire Alarm and Fire Controlling SystemHaymanot LegesseNessuna valutazione finora

- 01457264Documento26 pagine01457264ナス サンNessuna valutazione finora

- Substrate Integrated Waveguide (SIW) Techniques: The State-of-the-Art Developments and Future TrendsDocumento23 pagineSubstrate Integrated Waveguide (SIW) Techniques: The State-of-the-Art Developments and Future TrendsclanonNessuna valutazione finora

- Current MirrorDocumento13 pagineCurrent Mirrorakshaykamath123Nessuna valutazione finora