Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LSCM Group 2 Scientific Glass Case Analysis

Caricato da

Cesar CuchoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LSCM Group 2 Scientific Glass Case Analysis

Caricato da

Cesar CuchoCopyright:

Formati disponibili

Scientific Glass, Inc.

:

Inventory Management

Batch: PGCBM-21, 2012

Gro! "o.: 2

Corse: #ogistics an$ S!!ly Chain Management

Professor%s "ame: &r. ' ( S )i*ayaraghavan

St$y Center: Bangalore + Cnningham ,oa$

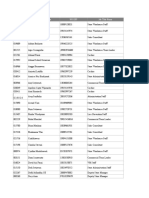

SMS I& "ame

110-21 Sa*ith PP

1102./ ,a*eev "air

110-0/ "avin 1eg$e

110200 Praveen Ma$i!ati

110-0/ Sree$evi 3rishnamrthy

110420 ,ama5rishnan Parthasarathy

Contents

Contents...................................................................................................................................... 2

Introduction.................................................................................................................................. 3

Critical Issues faced by the Company.......................................................................................... 3

Addressing the Critical Issues...................................................................................................... 3

Changing Warehousing Functions............................................................................................ 4

Evaluating the ptions.......................................................................................................... 4

Implementing !roposed !olicy Changes".................................................................................#

$ecommendations................................................................................................................... %

Creative ptions.......................................................................................................................... %

$estructuring rder&Fulfillment 'teps......................................................................................%

$edesigning the (ransportation ptions..................................................................................)

!lan ahead............................................................................................................................... *

Economies of 'cale................................................................................................................ +,

Appendi-.................................................................................................................................... +,

$eferences................................................................................................................................ +,

Intro$ction

Scientific Glass, Inc. (SG) established in 1992 is a midsize player in specialized glassware

industry pr!iding specialized labratry and research facilities. SG is a fast grwing

rganizatin with annual sales f "#$ millin fr the year ending 2%%9. &he cmpanies e'isting

mar(et regins include )rth *merica, +urpe, *sia ,acific and -est f the .rld. &he

industry that SG perates frecasts a rbust annual sales grwth f /0120. SG faces frmidable

large e3uipment pr!iders alng with lw1end cmpetitrs which act has impediment t the

cmpany4s grwth.

SG manufactures mre than /%%% different standardized prducts ranging frm less than "/ t

mre than "/%% and the cmpany decided t establish its direct sales frce alng gegraphical

lines with eight territries in 5S and 6anada. SG als attempted t impr!e its fill rate and

custmer respnse time by adding warehuses apart frm their largest warehuse ne't t its

manufacturing plant in .altham, 7assachussets and ,heni', *rizna. &he cmpany by the end

f 2%%#, brught nline si' ther leased warehuses strategically situated in &rnt, Seattle,

8en!er, 8allas, *tlanta, and 6hicag.

Critical Isses face$ 6y the Com!any

&he cmpany4s cmpensatin prgram t achie!e 990 custmer fill rate made mst f

the warehuse managers t (eep higher in!entry le!els than re3uired. &he plicy f

990 fill rate is a pint t be cnsidered while 920 being the industry standard.

7re!er, the cmpany4s in!entry cntrl plicies t nt t e'ceed $% days supply are

als regularly !ilated. *ll these aspects are affecting the cmpanies plan fr

internatinal e'pansins and cmpany4s target debt t capital ratis are increased t 9%0.

* centralized in!entry mnitring and recrding system at .altham warehuse was nt

enugh t capture the inaccuracies caused by damaged, lst, and stlen gds, human

errrs led t the mismatch between the cmputer generated recrd and the actual

in!entry. Salespeple regularly as(ed warehuse managers t perfrm manual in!entry

chec(s but the time re3uired t trac( it dwn, and the time and cst f the inter1

warehuse transfer, absrbed much f the prfit frm the sale.

($$ressing the Critical Isses

&he ab!e1mentined issues can be addressed in tw ma:r ways. ;irst t restructure the

lgistics and supply chain by changing the number f warehuses functins and secndly by

implementing the prpsed plicy changes.

Changing 7arehosing 8nctions

&he in!entry issues can be handled by changing warehusing functins and the ptins gi!en in

the case are<

Centrali9ing the 7arehosing 8nction< In this ptin, the cmpany can maintain a

centralized warehuse near the manufacturing site near .altham and ser!e the custmer

rders frm all the regins.

':o centrali9e$ 7arehoses< .ith tw warehuses ptin, SG can thin( f pling the

rder frm east and west separately by adding ne warehuse in west in additin t the

current warehuse in .altham, which is lcated in east. &he demands in the central part

can be pled frm these tw warehuses independently.

Maintaining the crrent eight 7arehoses< .ith this ptin f eight warehuses, each

warehuse will be respnding t the demand in its regin independent f all the ther

warehuses.

;tsorcing the 7arehosing fnctions< In this ptin, SG can utsurce the

distributin functin t Glbal =gistics (G=), wh pr!ides deli!ery ser!ices that

included centralized warehusing in *tlanta.

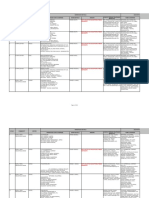

Evaluating the Options

>ased n the data pr!ided in +'hibit / ? 2 the transprtatin csts, a!erage in!entry

le!els and the fill rate fr the prpsed ptins were as fllws<

.(he detailed calculations for the above evaluations are available in the embedded e-cel

in Appendix/.

'rans!ortation Costs

Transportation with 8 Warehouses 2%,0.2%24,)

Transportation with 2 Warehouses 2#3,.344,42

Transportation with 1 Warehouses 2#+0.2*+)*4

Transportation with Outsourcing 2301.681047*

@The outsourcing transportation cost includes shipping from Waltham to Atlanta.

(verage Inventory #evels

Total Overstock in 8 Warehouses #4%.)#*3*+3

Total Overstock in 2 Warehouses 24#.,*4**,*

Total Overstock in 1 Warehouses +03.2##3+4

or Outsourcing !o "# $anage% &nventor'

8ill ,ate

Owne% Warehouse Outsourcing

(rlen)e'e

r #ri**in

(rlen)e'e

r #ri**in

,.*4%#2+)0

0

,.*#32,023

*

0.+602+068

3

0.+6416,82

1

($$itional Costs an$ Benefits

"1% 7illin can be a!ided frm .arehuse maintenance e'penses if the warehusing

peratins are utsurced t Glbal =gistics.

Im!lementing Pro!ose$ Policy Changes:

1. Greater enfrcement by the warehuse managers f maintaining nly sufficient in!entries in

the warehuses t meet the cmpany4s target fill rate f 990.

7erits<

o &argeting 990 fill rate will help the cmpany t a!id 1%0 underage cst and %.$0

!erage csts.

o -einfrce mar(et leadership by e'ceeding the mar(et standard f 920 fill rate.

o Impr!e custmer satisfactin by reducing the unfilled rders.

-is(s<

o 7aintaining a higher le!el f in!entries will lead t the !erage csts during

demand fluctuatins.

2. 8iscntinuatin f the practice f allwing sales peple t maintain trun( stc(.

7erits<

o +fficient in!entry management.

-is(s<

o 8iscntinuatin f trun( stc( will disable the cmpany frm shrt ntice deli!eries.

o 8emti!ating the sales managers by undermining their ability t maintain hard1wn

custmer accunts.

/. 6reatin f daily reprts and wee(ly summaries n in!entry m!ements fr e!ery

warehuse

7erits<

o .ith the usage f latest in!entry management I& systems, daily reprts and wee(ly

reprts can be easily generated withut any manual inter!entins. &his will als help

the cmpany in reducing the bac(rder.

o 7aintaining reprts and summaries in e!ery warehuse will reduce the time and cst

f inter1warehuse transfer.

-is(s<

o *dditinal respnsibility fr the warehuse managers t (eep the reprts and

summaries, hwe!er this can be mitigated by the use f I& systems.

9. ,eridic physical audits and cntrl prcedures fr all warehuse stc(s.

7erits<

o 8emand and supply f the in!entries acrss the warehuses can be easily mnitred

and mismatch between cmputer recrds at the centralized warehuse and actual

in!entry can be a!ided.

-is(s<

o .ithut ha!ing efficient warehuse prcesses li(e the ab!e steps, the physical audits

alne will nt lead t any impr!ements in the lng run, as the errr will gradually

creep int the system.

o *dditinal respnsibility fr the warehuse managers.

,ecommen$ations

>ased n ur e!aluatin f this case the utsurcing seems t be the mst efficient ptins due

the fllwing parameters<

=west in!entry cst

)egligible warehusing peratin e'penses.

) SG managed In!entry

>etter fill rate at lwer cst

Insurance cst brne by the Glbal =gistics

In additin, by utsurcing warehusing, in!entry management and rder fulfillment, SG4s

senir managers wuld be able t fcus n increasing sales, understanding emerging custmer

needs, and de!elping the ne't generatin f the firm4s prducts.

Gi!en the lw tuch utsurcing mdel, SG shuld be able t e'pand easily in ther mar(ets by

replicating the business mdel.

.ith all rder1fulfillment and in!entry1cntrl, Glbal =gistics persnnel wuld administer

functins, and utsurcing seems t be the cst effecti!e ptin, SG need nt g fr the

implementin f the prpsed plicy changes.

Creative ;!tions

,estrctring ;r$er-8lfillment Ste!s

SG can thin( f shipping the in!entries t the custmer directly frm ther warehuses in case

f insufficient in!entry at the riginal warehuse and thereby the cmpany can a!id the

transfer price between the warehuses. *s highlighted in the belw flwchart.

Redesigning the Transportation Options

In the e!ent SG chses t run all eight reginal warehuses acrss )rth *merica, they can

thin( f redesigning the transprtatin ptin by intrducing 7il( -un transprtatin and

8istributin 6enters.

Plan ahea$

SG4s current mar(et f their annual sale is split between )rth *merica (9%0), +urpe (/%0),

*sia ,acific regin (2%0) and -est f the .rld (1%0) and therefre the fcus primarily has

been n )rth *merica with e'isting relatinship with distributrs in +urpe and *sia.

6mpany shuld re!iew its strategy in de!elping mar(ets especially in *sia ,acific and =atin

*merica gi!en the relati!e saturatin f )rth *merican and +urpean mar(ets. SG shuld

e'plre the pssibility f establishing their wn sales ffices and increase their dedicated

representatin in these de!elping mar(ets, smething which the distributrs will nt be able t

ffer due t their !ested interests. *ls gi!en the fact that utsurcing their in!entry and

distributin management seems a !iable ptin, the cmpany shuld access this ptin in the

!erseas mar(ets t reduce their csts.

Economies of Scale

SG is e'periencing an increase in lw1end cmpetitin and standardizatin in 3uality f

labratries prducts, the cmpany by utsurcing its nn1cre acti!ities can cncentrate n its

main functins and fcus n understanding the mar(et re3uirements and needs f its custmers.

*s the cmpany is stri!ing t achie!e 990 fill rate, which will pr!ide the cmpany a

cmpetiti!e ad!antage and the cst efficiencies achie!ed can be rein!ested t grw the

ecnmies f scale that acts as barriers fr their cmpetitrs.

(!!en$i<

SG Calculations. xls

,eferences

Scientific Glass Inc. A 6ase Study

Supply 6hain 7anagement1 Strategy, ,lanning and Bperatin (9th +ditin) by Sunil 6hpra,

,eter 7eindl ? 8.C Dalra

6urse 7aterial and ,resentatin slides by 8r. & * S Ci:ayaragha!an

Potrebbero piacerti anche

- Case Study of Scientific GlassDocumento6 pagineCase Study of Scientific GlassT/ROXNessuna valutazione finora

- Sap Ewm Configuration GuideDocumento11 pagineSap Ewm Configuration Guidev jay35% (17)

- CMI CaseDocumento4 pagineCMI CaseSaurabh BoseNessuna valutazione finora

- The US Current Account DeficitDocumento5 pagineThe US Current Account DeficitturbolunaticsNessuna valutazione finora

- Report Case Study 3Documento7 pagineReport Case Study 3bruxa87Nessuna valutazione finora

- Scientific Glass ExcelDocumento13 pagineScientific Glass ExcelSakshi ShardaNessuna valutazione finora

- Leitax Case Analysis: Digital Camera MarketDocumento9 pagineLeitax Case Analysis: Digital Camera MarketAshfaq Shaikh50% (2)

- Case Study On Scientific Glass Inc Inventory ManagementDocumento45 pagineCase Study On Scientific Glass Inc Inventory ManagementMuhammad Ali SheikhNessuna valutazione finora

- Scientific Glass Inc - Inventory ManagementDocumento11 pagineScientific Glass Inc - Inventory ManagementdathanNessuna valutazione finora

- USTDocumento4 pagineUSTJames JeffersonNessuna valutazione finora

- Verna Industrial EstateDocumento2 pagineVerna Industrial Estatesushant adivirekarNessuna valutazione finora

- Scientific GlassDocumento9 pagineScientific GlassLajwanti M JethwaniNessuna valutazione finora

- LSCM Group 2 Scientific Glass Case AnalysisDocumento10 pagineLSCM Group 2 Scientific Glass Case AnalysisCesar CuchoNessuna valutazione finora

- WM Transfer Order and Inventory DocumentsDocumento16 pagineWM Transfer Order and Inventory Documentsssvinu007100% (1)

- Scientific Glass IncDocumento17 pagineScientific Glass IncSakshi Sharda100% (1)

- Manage inventory with centralized warehousesDocumento21 pagineManage inventory with centralized warehousesbonilopez150% (2)

- Warehousing in Gurgaon 'Documento30 pagineWarehousing in Gurgaon 'RakeshKumar SharmaNessuna valutazione finora

- Warehouse Handling Proposal (Traknus - HMU) - Final 2.1 v.4Documento23 pagineWarehouse Handling Proposal (Traknus - HMU) - Final 2.1 v.4Abi UmiNessuna valutazione finora

- Scientific Glass inventory problems and solutionsDocumento4 pagineScientific Glass inventory problems and solutionssarakhan0622Nessuna valutazione finora

- Sealed Air's Strategy to Tackle Falling Market ShareDocumento8 pagineSealed Air's Strategy to Tackle Falling Market ShareJaganathan AbhinavNessuna valutazione finora

- Sonoco ProductsDocumento20 pagineSonoco ProductsJuli Gupta100% (1)

- New Balance Case StudyDocumento3 pagineNew Balance Case StudyDimas AdityaNessuna valutazione finora

- Scientific Glass Inventory ReportDocumento2 pagineScientific Glass Inventory Reportleo fricke50% (2)

- Curled Metal Inc: Submitted To Prof Gururaj Kidiyoor Group I1Documento9 pagineCurled Metal Inc: Submitted To Prof Gururaj Kidiyoor Group I1paminderNessuna valutazione finora

- Foldrite Furniture Company: CASE StudyDocumento4 pagineFoldrite Furniture Company: CASE StudyJapkirat Oberai0% (1)

- Planning To Meet A Surge in DemandDocumento19 paginePlanning To Meet A Surge in DemandAbhi0% (1)

- Barilla SpaDocumento11 pagineBarilla Spavariapratik100% (1)

- Boston Creamery Case AnalysisDocumento19 pagineBoston Creamery Case AnalysisAkshay Agarwal50% (2)

- Foldrite Furniture CaseDocumento7 pagineFoldrite Furniture CaseJoe Joy0% (2)

- Plaza, THE Logistic S Park of Zaragoz ADocumento10 paginePlaza, THE Logistic S Park of Zaragoz ARahulTiwariNessuna valutazione finora

- Financial Analysis and Inventory Management of Laboratory Equipment CompanyDocumento29 pagineFinancial Analysis and Inventory Management of Laboratory Equipment CompanyShirsendu Bikash DasNessuna valutazione finora

- Balancing Process Capacity - .Com - Microsoft.word - Openxmlformats.wordprocessingmlDocumento2 pagineBalancing Process Capacity - .Com - Microsoft.word - Openxmlformats.wordprocessingmlswarnima biswariNessuna valutazione finora

- LSCM Group 2 Scientific Glass Case AnalysisDocumento9 pagineLSCM Group 2 Scientific Glass Case Analysisshahbaaz syedNessuna valutazione finora

- Scientific Glass Inc FinalDocumento21 pagineScientific Glass Inc FinalSakshi ShardaNessuna valutazione finora

- LSCM Group 2 Scientific Glass Case AnalysisDocumento10 pagineLSCM Group 2 Scientific Glass Case AnalysisArshpreet SinghNessuna valutazione finora

- Fuyao Glass - SummarizationDocumento2 pagineFuyao Glass - SummarizationLucas AalbersNessuna valutazione finora

- Sports Obermeyer's Sourcing StrategyDocumento12 pagineSports Obermeyer's Sourcing Strategyharsh0322Nessuna valutazione finora

- Risk Management FoldRite Furniture AssignmentDocumento8 pagineRisk Management FoldRite Furniture AssignmentAbhra Debroy100% (1)

- Barilla Spa Case DraftDocumento30 pagineBarilla Spa Case DraftHrishikesh MahapatraNessuna valutazione finora

- 2017 Spring Case Study Questions SCM 479 NewDocumento4 pagine2017 Spring Case Study Questions SCM 479 NewSaddam AwanNessuna valutazione finora

- Intel Pentium Chip Flaw AccountingDocumento1 paginaIntel Pentium Chip Flaw AccountingShaheen MalikNessuna valutazione finora

- Frito Lay LogisticsDocumento8 pagineFrito Lay LogisticsAmber LiuNessuna valutazione finora

- Diagnose The Underlying Cause of The Difficulties That The JITD Program Was Created To Solve. What Are The Benefits and Drawbacks of This Program?Documento2 pagineDiagnose The Underlying Cause of The Difficulties That The JITD Program Was Created To Solve. What Are The Benefits and Drawbacks of This Program?SARTHAK NAVALAKHA100% (1)

- Netscape Initial Public OfferingDocumento1 paginaNetscape Initial Public Offeringaruncec2001Nessuna valutazione finora

- Foldrite Furniture Co.: Planning To Meet A Surge in DemandDocumento7 pagineFoldrite Furniture Co.: Planning To Meet A Surge in DemandAshish Verma0% (1)

- Plaza, The Logistics Park of ZaragozaDocumento11 paginePlaza, The Logistics Park of ZaragozaRahulTiwariNessuna valutazione finora

- Forecasting Case - XlxsDocumento8 pagineForecasting Case - Xlxsmayank.dce123Nessuna valutazione finora

- New Balance Case StudyDocumento4 pagineNew Balance Case StudyTejashviNessuna valutazione finora

- Barilla - CaseDocumento14 pagineBarilla - CaseSevana YadegarianNessuna valutazione finora

- Printicomm's acquisition of DigitechDocumento7 paginePrinticomm's acquisition of DigitechAK0% (1)

- Dore Dore CaseDocumento5 pagineDore Dore CaseDIshant KulwalNessuna valutazione finora

- Ortho 500 Sales StrategyDocumento4 pagineOrtho 500 Sales StrategyAparna SinghNessuna valutazione finora

- Case-Sports ObermeyerDocumento56 pagineCase-Sports ObermeyerSiddharth MehtaNessuna valutazione finora

- Otisline Case StudyDocumento2 pagineOtisline Case Studynkumar_324Nessuna valutazione finora

- Curled Metal CaseDocumento5 pagineCurled Metal CaseGuo YuNessuna valutazione finora

- Category CaptaincyDocumento9 pagineCategory CaptaincycmoreblrNessuna valutazione finora

- Barilla and The JITD SystemDocumento7 pagineBarilla and The JITD Systemdave6288% (16)

- WellfleetDocumento3 pagineWellfleetAziez Daniel AkmalNessuna valutazione finora

- Barilla's Spa Case Study (Group-04)Documento18 pagineBarilla's Spa Case Study (Group-04)lokesh_chaudhary_1Nessuna valutazione finora

- Amore Case Group 33Documento3 pagineAmore Case Group 33TatineniRohitNessuna valutazione finora

- Case Analysis On Merloni Elettrodomestici SpaDocumento6 pagineCase Analysis On Merloni Elettrodomestici SpaKrishna Raj ShailNessuna valutazione finora

- Creativity at GunDocumento4 pagineCreativity at GunGuntashsingh AnandNessuna valutazione finora

- Lucent's Supply Chain Changes in AsiaDocumento9 pagineLucent's Supply Chain Changes in AsiaAndy VibgyorNessuna valutazione finora

- Case QuestionsDocumento7 pagineCase QuestionsAbbey LiNessuna valutazione finora

- Godrej Consumer Products Limited - SDM 2 - B5 - 2013Documento9 pagineGodrej Consumer Products Limited - SDM 2 - B5 - 2013Priyesh TripathiNessuna valutazione finora

- Introduction to Management Accounting ConceptsDocumento73 pagineIntroduction to Management Accounting Conceptssweet haniaNessuna valutazione finora

- W. W. Grainger, Inc., Is A Leading Supplier of Maintenance, Repair, and Operating (MRO) Products To Businesses and Institutions in The UnitedDocumento3 pagineW. W. Grainger, Inc., Is A Leading Supplier of Maintenance, Repair, and Operating (MRO) Products To Businesses and Institutions in The UnitedJalaj GuptaNessuna valutazione finora

- C 7WY0 WH 02 201 LAY000 0 Lay General Construction Areas @work PDFDocumento1 paginaC 7WY0 WH 02 201 LAY000 0 Lay General Construction Areas @work PDFDidier LZNessuna valutazione finora

- Registered WH 20191224.pdf (24-Dec-2019)Documento150 pagineRegistered WH 20191224.pdf (24-Dec-2019)Aditya Sharma100% (1)

- ABLE Contract - Fiberhome Project (Attachment)Documento3 pagineABLE Contract - Fiberhome Project (Attachment)Ferris FerrisNessuna valutazione finora

- Warehouse 1 Warehouse 2 Warehouse 3: Plant Capacity Plant 1 80 Plant 2 60 Plant 3 100 Plant 4 120Documento11 pagineWarehouse 1 Warehouse 2 Warehouse 3: Plant Capacity Plant 1 80 Plant 2 60 Plant 3 100 Plant 4 120SatheeskumarNessuna valutazione finora

- Warehouse List 15.03.2018 Web UpdationDocumento224 pagineWarehouse List 15.03.2018 Web UpdationJEETENDRA KUMAR0% (1)

- SGS Audit Progress Report As On 17 Sept 2013Documento3 pagineSGS Audit Progress Report As On 17 Sept 2013Investors of NSELNessuna valutazione finora

- FEbruray 2019 Final Time Expired List Updated As On 11.03.2019Documento210 pagineFEbruray 2019 Final Time Expired List Updated As On 11.03.2019Peyush MehtoNessuna valutazione finora

- Registered WH ListDocumento129 pagineRegistered WH ListGIRISH JOSHINessuna valutazione finora

- Location inventory trackingDocumento116 pagineLocation inventory trackingManish SinhaNessuna valutazione finora

- Zoominfo Lead GenerationDocumento225 pagineZoominfo Lead GenerationDilawer HussainNessuna valutazione finora

- Q1 2018 Store Pesanggrahan Sales ResultsDocumento30 pagineQ1 2018 Store Pesanggrahan Sales ResultsTanal HrdNessuna valutazione finora

- Stock 29-03-2023Documento12 pagineStock 29-03-2023Abdullah MohammadNessuna valutazione finora

- Combined Loading Details For ChennaiDocumento5 pagineCombined Loading Details For Chennaigrinspan2001Nessuna valutazione finora

- List of Participants for Improving Organizational Communication Effectiveness TrainingDocumento1 paginaList of Participants for Improving Organizational Communication Effectiveness TrainingRifqy septafaniNessuna valutazione finora

- 1432553745404-Private Container Operators PDF Apr.Documento1 pagina1432553745404-Private Container Operators PDF Apr.Jigisha VasaNessuna valutazione finora

- Pvt. Hired Godown Table - WBSWCDocumento8 paginePvt. Hired Godown Table - WBSWCAvijitSinharoyNessuna valutazione finora

- Used Return Count SheetDocumento8 pagineUsed Return Count SheetFirdaus HamzahNessuna valutazione finora

- Hiring Dehiring of GodownDocumento12 pagineHiring Dehiring of GodownAkshay MishraNessuna valutazione finora

- Data No BPJS TK Karyawan KhiDocumento8 pagineData No BPJS TK Karyawan KhiHafiizh NurrahmanNessuna valutazione finora

- Carrera 2D#92-61 Jose Luis MartinezDocumento3 pagineCarrera 2D#92-61 Jose Luis Martinezjose luis martinez martinezNessuna valutazione finora

- Government of India Registration Certificate (AmendedDocumento5 pagineGovernment of India Registration Certificate (AmendedManish DaveNessuna valutazione finora

- Line ItemsDocumento6 pagineLine ItemsFrancis DedumoNessuna valutazione finora

- Internal Stock Transfers Monitoring SystemDocumento49 pagineInternal Stock Transfers Monitoring SystemMark Lester GatuzNessuna valutazione finora