Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Casting QQQQQQQQQQ

Caricato da

Jared HartDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Casting QQQQQQQQQQ

Caricato da

Jared HartCopyright:

Formati disponibili

Q ti t 2014 Questionset2014

PleasecheckanswerfrommyPPT y

M t lC ti MetalCasting

B SKM d l BySKMondal

IES2001

The main purpose of chaplets is

(a) To ensure directional solidification

(b) To provide efficient venting

(c) For aligning the mold boxes

(d) T h (d) To support the cores

IES1996

Which of the following methods are used for

bt i i di ti l lidifi ti f i d i obtaining directional solidification for riser design

1. Suitable placement of chills 1. Suitable placement of chills

2. Suitable placement of chaplets

3. Employing padding

Select the correct answer.

( ) d (b) d ( ) d (d) d (a) 1 and 2 (b) 1 and 3 (c) 2 and 3 (d) 1, 2 and 3

IES2007

Which one of the following is the correct

t t t? statement?

Gate is provided in moulds to

(a) Feed the casting at a constant rate

(b) Give passage to gases ( ) p g g

(c) Compensate for shrinkage

(d) Avoid cavities (d) Avoid cavities

GATE2009

MatchtheitemsinColumnIandColumnII MatchtheitemsinColumnIandColumnII.

ColumnIColumnII

PMetallicChills1 Supportforthecore P.MetallicChills1.Supportforthecore

Q.MetallicChaplets2.Reservoirofthemoltenmetal

R Riser3 Controlcoolingofcritical R.Riser3.Controlcoolingofcritical

sections

S ExothermicPadding4 Progressivesolidification S.ExothermicPadding4.Progressivesolidification

(a) P1,Q3,R2,S4 (b) P1,Q4,R2,S3

(c) P 3 Q 4 R 2 S 1 (d) P 4 Q 1 R 2 S 3 (c) P3,Q4,R2,S1 (d) P4,Q1,R2,S3

GATE1992

Inagreensandmouldingprocess,uniform

rammingleadsto

(a) Lesschanceofgasporosity

(b) Uniformflowofmoltenmetalintothemould (b) Uniformflowofmoltenmetalintothemould

cavity

(c) Greaterdimensionalstabilityofthecasting (c) Greaterdimensionalstabilityofthecasting

(d) Lesssandexpansiontypeofcastingdefect

GATE2011

Green sand mould indicates that Green sand mould indicates that

(a) polymeric mould has been cured

(b) mould has been totally dried

(c) mould is green in colour ( ) g

(d) mould contains moisture

IES1995

Which one of the following materials will require

the largest size of riser for the same size of casting? the largest size of riser for the same size of casting?

(a) Aluminium ( )

(b) Cast iron

(c) Steel

(d) Copper.

For 2014 (IES, GATE & PSUs) Page 1 of 17

GATE1999

Which of the following materials requires the

l t h i k ll hil ki largest shrinkage allowance, while making a

pattern for casting?

( ) l (a) Aluminium

(b) Brass

(c) Cast Iron

(d) Plain Carbon Steel (d) Plain Carbon Steel

IES1999

I lidifi ti f t l d i ti In solidification of metal during casting,

compensation for solid contraction is p

(a) Provided by the oversize pattern

(b) Achieved by properly placed risers

(c) Obtained by promoting directional

lidifi i solidification

(d) Made by providing chills (d) Made by providing chills

ISRO2007

Shrinkage allowance is made by

( ) dd l d l d (a) Adding to external and internal dimensions

(b) Subtracting from external and internal

dimensions

(c) Subtracting from external dimensions and ( ) g

adding to internal dimensions

(d) Adding to external dimensions and subtracting (d) Adding to external dimensions and subtracting

from internal dimensions

GATE2001

Shrinkage allowance on pattern is provided to

compensate for shrinkage when p g

(a) The temperature of liquid metal drops from

pouring to freezing temperature pouring to freezing temperature

(b) The metal changes from liquid to solid state at

freezing temperature freezing temperature

(c) The temperature of solid phase drops from

f i freezing to room temperature

(d) The temperature of metal drops from pouring

to room temperature

GATE2004

Gray cast iron blocks 200 x 100 x 10 mm are to be

t i d ld Sh i k ll f cast in sand moulds. Shrinkage allowance for

pattern making is 1%. The ratio of the volume of

tt t th t f th ti ill b pattern to that of the casting will be

(a) 0.97 (b) 0.99 (c) 1.01 (d) 1.03

GATE2008

While cooling, a cubical casting of side 40 mm

undergoes 3%, 4% and 5% volume shrinkage

during the liquid state, phase transition and solid

state respectively The volume of metal state, respectively. The volume of metal

compensated from the riser is

(a) 2% (b) 7% (c) 8% (d) 9%

GATE2011

A cubic casting of 50 mm side undergoes volumetric A cubic casting of 50 mm side undergoes volumetric

solidification shrinkage and volumetric solid

contraction of 4% and 6% respectively No riser is contraction of 4% and 6% respectively. No riser is

used. Assume uniform cooling in all directions. The

side of the cube after solidification and contraction is side of the cube after solidification and contraction is

(a) 48.32 mm

(b) 49.90 mm

(c) 49.94 mm 49 94

(d) 49.96 mm

IAS1995

A i (A) A i d l i il Assertion (A): A pattern is made exactly similar to

the part to be cast.

R (R) P i d k h ld Reason (R): Pattern is used to make the mould

cavity for pouring in molten for casting.

( ) B h A d R i di id ll d R i h (a) Both A and R are individually true and R is the

correct explanation of A

(b) B h A d R i di id ll b R i h (b) Both A and R are individually true but R is not the

correct explanation of A

( ) A i b R i f l (c) A is true but R is false

(d) A is false but R is true

IAS2003

M h Li I (M i l b ) i h Li II Match List I (Material to be cast) with List II

(Shrinkage Allowance in mm/m) and select the

correct answer using the codes given belowthe lists: correct answer using the codes given belowthe lists:

ListI ListII

(MaterialtoCast)(ShrinkageAllowanceinmm/m) (MaterialtoCast)(ShrinkageAllowanceinmm/m)

(A) Greycastiron 1. 7 10

(B) Brass 2 15 (B) Brass 2. 15

(C) Steel 3. 20

(D) Zinc 4 24 (D) Zinc 4. 24

Codes:A B C D A B C D

(a) 1 2 3 4 (b) 3 4 1 2 (a) 1 2 3 4 (b) 3 4 1 2

(c) 1 4 3 2 (d) 3 2 1 4 For 2014 (IES, GATE & PSUs) Page 2 of 17

IES1994

Which of the following materials can be used for

making patterns? making patterns?

1. Aluminium 2. Wax 3. Mercury 4. Lead 3 y 4

Select the correct answer using the codes given below:

Codes:

(a) 1,3 and 4 (b) 2,3 and 4 (c) 1, 2 and 4 (d) 1, 2 and 3

GATE2000

Disposablepatternsaremadeof

(a) Wood

(b) Rubber

(c) Metal

(d) P l (d) Polystyrene

IES2008

The pattern adopted for those castings where there

ti hi h t t ll k d are some portions which are structurally weak and

are likely to break by the force of ramming are

ll d called:

(a) Loose piece pattern

(b) Follow board pattern

(c) Skelton pattern ( ) p

(d) Single piece pattern

GATE2012(PI) ( )

In sand casting, fluidity of the molten metal

i ith increases with

(A) increase in degree of superheat

(B) decrease in pouring rate

(C) increase in thermal conductivity of the mould ( ) y

(D) increase in sand grain size

ISRO2011

Fluidity in casting (CI) operation is greatly

i fl d b influenced by

a) Melting temperature of molten metal a) Melting temperature of molten metal

b) Pouring temperature of molten metal b) Pouring temperature of molten metal

c) Finish of the mould )

d) Carbon content of molten metal

Calculatethepermeabilitynumberofsandifittakes1min

25stopass2000cm

3

ofairatapressureof5g/cm

2

through

thestandardsample.

2

5.0 /

1min25 1 417min

p g cm

T s

=

= = 1min25 1.417min

501.28

70.75

5 1 417

T s

R

= =

= =

5 1.417

IES2007

Whatispermeability?Permeabilityismoreimportant

inthebasicprocessofsandcastingthanporosity.Give

i t t f thi f t oneimportantreasonforthisfeature.

[2marks] [2marks]

IES2002

Assertion (A): In CO casting process the mould or Assertion (A): In CO

2

casting process, the mould or

core attains maximumstrength.

Reason (R): The optimum gassing time of CO Reason (R): The optimum gassing time of CO

2

through the mould or core forms Silica Gel which

imparts sufficient strength to the mould or core imparts sufficient strength to the mould or core.

(a) Both A and R are individually true and R is the

correct explanation of A correct explanation of A

(b) Both A and R are individually true but R is not the

correct explanation of A correct explanation of A

(c) A is true but R is false

(d) A i f l b t R i t (d) A is false but R is true

GATE 2008 (PI) GATE 2008(PI)

In sand casting of a hollow part of lead, a cylindrical core g p , y

of diameter 120 mm and height 180 mm is placed inside

the mould cavity. The densities of core material and lead

are 1600 kg/m

3

and 11 300 kg/m

3

respecti el The net are 1600 kg/m

3

and 11,300 kg/m

3

respectively. The net

force (in N) that tends to lift the core during pouring of ( ) g p g

molten metal will be

(a) 19.7 (b) 64.5 (c) 193.7 (d) 257.6

For 2014 (IES, GATE & PSUs) Page 3 of 17

IES2008

Small amount of carbonaceous material sprinkled

on the inner surface of mould cavity is called

(a) Backing sand

( ) (b) Facing sand

(c) Green sand (c) Green sand

(d) Dry sand (d) Dry sand

IES2002

In the grain size determination using standard

charts, the relation between the given size charts, the relation between the given size

number n and the average number of grains 'N'

per square inch at a magnification of 100 X is

( ) N

n

(a) N = 2

n

(b) N = 2

nl

(b) N 2

(c) N = 2

n + 1

(d) N = 2

n

+ 1

IES2011

In light metal casting runner should be so designed In light metal casting, runner should be so designed

that:

It id i ti 1. It avoids aspiration

2. It avoids turbulence

3. The path of runner is reduced in area so that

unequal volume of flow through each gate q g g

takes place

(a) 1 and 2 only (b) 1 and 3 only (a) 1 and 2 only (b) 1 and 3 only

(c) 2 and 3 only (d) 1, 2 and 3

G 20 0 ( ) GATE 2010(PI)

D i h filli f i d ld i b During the filling process of a given sand mould cavity by

molten metal through a horizontal runner of circular cross

section the frictional head loss of the molten metal in the

runner will increase with the runner will increase with the

(a) increase in runner diameter

(b) decrease in internal surface roughness of runner

(c) decrease in length of runner

(d) increase in average velocity of molten metal (d) increase in average velocity of molten metal

IES 2011 IES2011

Match List I with List II and select the correct answer using

the code given below the lists : the code given below the lists :

ListI ListII

A.Topgate 1.Heavyandlargecastings

B.Bottomgate 2.Mostwidelyusedandeconomical g y

C.Partinggate 3.Turbulence

C d

D.Stepgate 4.Unfavourable temperaturegradient

Codes

A B C D A B C D

( ) (b) (a) 3 4 2 1 (b) 1 4 2 3

(c) 3 2 4 1 (d) 1 2 4 3

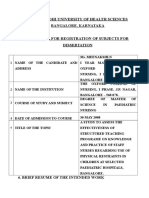

IES1998

A sand casting mould A sand casting mould

assembly is shown in

the above figure. The the above figure. The

elements marked A

and B are respectively and B are respectively

(a) Sprue and riser

(b) I t d i (b) Ingate and riser

(c) Drag and runner

(d) Riser and runner

GATE2002

The primary purpose of a sprue in a casting

mould is to ou d s to

(a)Feed the casting at a rate consistent with the rate

of solidification of solidification

(b)Act as a reservoir for molten metal

( ) d l l f h i b i h (c)Feed molten metal from the pouring basin to the

gate

(d)Help feed the casting until all solidification takes

place

IES 1998 IES1998

Whichofthefollowingaretherequirementsofanideal Whichofthefollowingaretherequirementsofanideal

gatingsystem?

1 Themoltenmetalshouldenterthemouldcavitywithas 1. Themoltenmetalshouldenterthemouldcavitywithas

highavelocityaspossible.

2 Itshouldfacilitatecompletefillingofthemouldcavity 2. Itshouldfacilitatecompletefillingofthemouldcavity.

3. Itshouldbeabletopreventtheabsorptionofairorgases

fromthesurroundingsonthemoltenmetalwhile fromthesurroundingsonthemoltenmetalwhile

flowingthroughit.

Selectthecorrectanswerusingthecodesgivenbelow: Selectthecorrectanswerusingthecodesgivenbelow:

(a)1,2and3 (b)1and2 (c)2and3 (d)1and3

IES2009

C id th f ll i t t t Considerthefollowingstatements:

1.Theactualentrypointthroughwhichthemolten

metalentersthemouldcavityiscalledingate.

2.Bottomgateincaseofamouldcreatesunfavourable g

temperaturegradient.

3.Sprueincaseofamouldismadetaperedtoavoidair 3.Sprueincaseofamouldismadetaperedtoavoidair

inclusion.

Whichoftheabovestatementsis/arecorrect? Whichoftheabovestatementsis/arecorrect?

(a)1only (b)1and2 (c)2and3 (d)1and3

For 2014 (IES, GATE & PSUs) Page 4 of 17

GATE2001

The height of the downsprue is 175 mm and its

ti l t th b i

2

Th crosssectional area at the base is 200 mm

2

. The

crosssectional area of the horizontal runner is

l

2

A i l i di t th also 200 mm

2

. Assuming no losses, indicate the

correct choice for the time (in seconds) required to

fill a mould ca it of olume 0

6

mm

3

(Use g 0 fill a mould cavity of volume 10

6

mm

3

. (Use g = 10

m/s

2

).

( ) (b) ( ) (d) (a)2.67 (b)8.45 (c)26.72 (d)84.50

GATE 2007 GATE2007

A 200 mm long down sprue has an area of cross g p

section of 650 mm

2

where the pouring basin meets the

down sprue (i.e. at the beginning of the down sprue). p ( g g p )

A constant head of molten metal is maintained by the

pouring basin. The Molten metal flow rate is 6.5 10

5

p g 5

mm

3

/s. Considering the end of down sprue to be open

to atmosphere and an acceleration due to gravity of p g y

10

4

mm/s

2

, the area of the down sprue in mm

2

at its end

(avoiding aspiration effect) should be ( g p )

(a)650.0 (b)350.0 (c)290.7 (d)190.0

Contd

IES2003

A ti ti f i d t d i th ti A gating ratio of 1: 2: 4 is used to design the gating

system for magnesium alloy casting. This gating ratio

refers to the cross section areas of the various gating refers to the cross section areas of the various gating

elements as given below:

1 Down sprue 2 Runner bar 3 Ingates 1. Down sprue 2. Runner bar 3. Ingates

The correct sequence of the above elements in the

ratio 1: 2: 4 is ratio 1: 2: 4 is

(a) 1, 2 and 3

(b) d (b) 1,3 and 2

(c) 2, 3 and 1

(d) 3, 1 an 2

IES2005

The gating ratio 2: 8: 1 for copper in gating system

d i f t th ti f f design refers to the ratio of areas of:

(a) Sprue: Runner: Ingate

(b) Runner: Ingate: Sprue

(c) Runner: Sprue: Ingate ( ) p g

(d) Ingate: Runner: Sprue

GATE2010

Inagatingsystem,theratio1:2:4represents

(a) Sprue basearea:runnerarea:ingate area

(b) Pouringbasinarea:ingate area:runnerarea

(c) Sprue basearea:ingate area:castingarea

(d) R i i (d) Runnerarea:ingate area:castingarea

IAS1999

A i (A) Th f fl f l h h Assertion (A): The rate of flow of metal through sprue

is NOT a function of the crosssectional areas of

sprue runner and gate sprue, runner and gate.

Reason (R): If respective crosssectional areas of

sprue, runner and gate are in the ratio of 1: 2: 2, the p , g ,

system is known as unpressurised gating system.

(a) Both A and R are individually true and R is the correct y

explanation of A

(b) Both A and R are individually true but R is not the

l i f A correct explanation of A

(c) A is true but R is false

(d) f l b (d) A is false but R is true

IES 1994 IES1994

Assertion (A): In a mould, a riser is designed and placed Assertion (A): In a mould, a riser is designed and placed

so that the riser will solidify after the casting has solidified.

Reason (R): A riser is a reservoir of molten metal which Reason (R): A riser is a reservoir of molten metal which

will supply molten metal where a shrinkage cavity would

have occurred.

(a) Both A and R are individually true and R is the correct

explanation of A p

(b) Both A and R are individually true but R is not the

correct explanation of A p

(c) A is true but R is false

(d) A is false but R is true (d) A is false but R is true

IES2011

The relationship between total freezing time t The relationship between total freezing time t,

volume of the casting V and its surface area A,

according to Chvorinovs rule is : g

( )

V

a t k

A

=

( )

A

A

b t k

V

=

2

( )

V

A

c t k

V

=

2

( )

V

V

d t k

A

=

Where K is a constant

A

For 2014 (IES, GATE & PSUs) Page 5 of 17

IES1998

A spherical drop of molten metal of radius 2 mm

was found to solidify in 10 seconds. A similar drop

of radius 4 mmwould solidify in of radius 4 mmwould solidify in

(a) 14.14 seconds

(b) 20 seconds

(c) 28.30 seconds

(d) 40 seconds

GATE 2013 GATE2013

A b h d ti lidifi i i Th A cube shaped casting solidifies in 5 min. The

solidification time in min for a cube of the same

material, which is 8 times heavier than the original

casting, will be

( ) (b) ( ) (d) (a) 10 (b) 20 (c) 24 (d) 40

GATE2003

With a solidification factor of 0.97 x 10

6

s/m

2

, the

solidification time (in seconds) for a spherical

casting of 200 mmdiameter is

( ) (b) 8 ( ) (d) (a) 539 (b) 1078 (c) 4311 (d) 3233

IES2006

According to Chvorinov's equation, the

lidifi ti ti f ti i ti l t solidification time of a casting is proportional to:

(a) v

2

(a) v

(b) v

(c) 1/v

(d) 1/v

2

Where, v = volume of casting

GATE 2010(PI)

S lidifi ti ti f t lli ll ti i Solidification time of a metallic alloy casting is

(a) Directly proportional to its surface area (a) Directly proportional to its surface area

(b) Directly proportional to the specific heat of the y p p p

cast material

(c) Directly proportional to the thermal diffusivity of

h l l the molten metal

(d)Inversely proportional to the pouring (d)Inversely proportional to the pouring

temperature.

GATE2007

Volume of a cube of side 'l' and volume of a sphere of

radius r are equal. Both the cube and the sphere are solid

d f t i l Th b i t Th ti f th and of same material. They are being cast. The ratio of the

solidification time of the cube to the same of the sphere is: p

( ) ( ) ( ) ( )

3 6 2 2 3 2 4

4 r 4 r 4 r 4 r

a b c d

6 l 6 l 6 l 6 l

6 l 6 l 6 l 6 l

GATE2011(PI) ( )

In a sand casting process, a sphere and a cylinder

of equal volumes are separately cast from the same of equal volumes are separately cast from the same

molten metal under identical conditions. The

height and diameter of the cylinder are equal. The e g t a d d a ete o t e cy de a e equa . e

ratio of the solidification time of the sphere to that

of the cylinder is

(a) 1.14

(b) 0.87 ( ) 7

(c) 1.31

(d) 0 76 (d) 0.76

GATE2009(PI)

l d l d f d d h h l d l d A solid cylinder of diameter D and height equal to D, and a solid

cube of side L are being sand cast by using the same material.

Assuming there is no superheat in both the cases, the ratio of

solidification time of the cylinder to the solidification time of the

cube is

(a) (L/D)

2

(a) (L/D)

2

(b) (2L/D)

2

(c) (2D/L)

2

(d) (D/L)

2

(d) (D/L)

For 2014 (IES, GATE & PSUs) Page 6 of 17

IES 2012 IES 2012

Th ti f f f l f it l f Theratioofsurfaceareaofvolumeforaunitvolumeof

riserisminimumincaseof

(a)Cylindricalriser

(b)Sphericalriser

(c)Hemisphericalriser

(d)Cuboidsriser

IES 2011 Conventional IES2011Conventional

A round casting is 20 mm in diameter and 50 mm in

length. Another casting of the same metal is elliptical in

i i h j i i i f d cross section, with a major to minor axis ratio of 2, and

has the same length and crosssectional area as the has the same length and cross sectional area as the

round casting. Both pieces are cast under the same

conditions. What is the difference in the solidification

i f h i ? [ M k ] times of the two castings ? [10 Marks]

( ) ( )( )

Areaof ellipse

Ci f 3 3 3

ab

b b b

=

( ) ( )( )

( )

2 2

Circumference 3 3 3

2 / 2 (approx.)

a b a b a b

a b

= + + +

= +

ConventionalQuestionESE2003

Compare the solidification time of two optimum side Compare the solidification time of two optimum side

risers of the same volume with one has cylindrical shape

and other is parallopiped. [30 Marks]

ConventionalQuestionIES2008 Q

Calculate the size of a cylindrical riser (height and diameter

equal) necessary to feed a steel slab casting of dimensions

30 x 30 x 6 cm with a side riser casting poured horizontally 30 x 30 x 6 cm with a side riser, casting poured horizontally

into the mould.

[Use Modulus Method]

[ 0 Marks] [10 Marks]

Conventional QuestionIES2007 Q

Calculate the size of a cylindrical riser (height and

) diameter equal) necessary to feed a steel slab

casting of dimensions 25 x 25 x 5 cm with a side casting of dimensions 25 x 25 x 5 cm with a side

riser, casting poured horizontally into the mould.

[Use Caines Method]

[ For steel a = 0.10, b = 0.03 and c = 1.00 ]

IES1995

Directional solidification in castings can be

improved by using

(a) Chills and chaplets

( ) (b) Chills and padding

(c) Chaplets and padding (c) Chaplets and padding

(d) Chills, chaplets and padding. (d) Chills, chaplets and padding.

GATE1998,2007

Chills are used in moulds to

(a) Achieve directional solidification

(b) Reduce the possibility of blowholes

(c) Reduce freezing time

(d) S h l fl f d i l (d) Smoothen metal flow for reducing splatter.

IAS1994

Chillsareusedincastingmouldsto

(a) Achievedirectionalsolidification

(b) Reducepossibilityofblowholes

(c) Reducethefreezingtime (c) Reducethefreezingtime

(d) Increasethesmoothnessofcastsurface

IES1997

( ) l b l d h bl l Assertion (A): Steel can be melted in hot blast cupola.

Reason (R): In hot blast cupola, the flue gases are used to

preheat the air blast to the cupola so that the temperature in

the furnace is considerably higher than that in a

i l l conventional cupola.

(a) Both A and R are individually true and R is the correct

l i f A explanation of A

(b) Both A and R are individually true but R is not the

l i f A correct explanation of A

(c) A is true but R is false

(d) A is false but R is true

For 2014 (IES, GATE & PSUs) Page 7 of 17

IES 2012 IES 2012

Statement (I): Cupola furnace is not employed for ( ) C p p y

melting steel in foundry

Statement (II): The temperatures generated within a ( ) p g

cupola are not adequate for melting Steel

(a) Both Statement (I) and Statement (II) are ( ) ( ) ( )

individually true and Statement (II) is the correct

explanation of Statement (I)

(b) Both Statement (I) and Statement (II) are

individually true but Statement (II) is not the correct

explanation of Statement (I)

(c) Statement (I) is true but Statement (II) is false

(d) Statement (I) is false but Statement (II) is true

GATE1996

Light impurities in the molten metal are prevented

f hi th ld it b idi from reaching the mould cavity by providing a

(a) Strainer

(b) Button well

(c) Skim bob ( )

(d) All of the above

GATE2005

A mould has a downsprue whose length is 20 cm

d th ti l t th b f th and the cross sectional area at the base of the

downsprue is 1cm

2

. The downsprue feeds a

h i t l l di i t th ld it f horizontal runner leading into the mould cavity of

volume 1000 cm

3

. The time required to fill the

mould ca it ill be mould cavity will be

(a)4.05 s (b)5.05 s (c)6.05 s (d)7.25 s

GATE2012(PI)

A mould having dimensions 100 mm 90 mm 20 mm is filled A mould having dimensions 100 mm 90 mm 20 mm is filled

with molten metal through a gate as shown in the figure. For

height h and crosssectional area A, the mould filling time is t

1

. g g

1

The height is now quadrupled and the crosssectional area is

halved. The corresponding filling time is t

2

. The ratio t

2

/t

1

is

1

( )

2

a

2

( )1

( )

b

( ) 2

( )2

c

d

GATE 2006 GATE2006

In a sand casting operation, the total liquid head is

i i d h h i i l h ld maintained constant such that it is equal to the mould

height. The time taken to fill the mould with a top gate

i If h ld i fill d i h b is t

A.

If the same mould is filled with a bottom gate,

then the time taken is t

B

. Ignore the time required to

fill h d f i i l ff A fill the runner and frictional effects. Assume

atmospheric pressure at the top molten metal surfaces.

Th l i b d i The relation between t

A

and t

B

is

(A) 2

(B) 2

B A

t t =

(B) 2

(C)

B A

A

B

t t

t

t

=

= ( )

2

(D) 2 2

B

B A

t t =

GATE 2007 (PI) Li k d S 1 GATE 2007(PI)LinkedS1

In a sand casting process, a sprue of 10 mm base In a sand casting process, a sprue of 10 mm base

diameter and 250 mm height leads to a runner

which fills a cubical mould cavity of 100 mm size which fills a cubical mould cavity of 100 mm size

The volume flowrate (in mm

3

/s) is

(a) 0.8 x 10

5

(b) 1.1 x 10

5

(c) 1 7 x 10

5

(d) 2 3 x 10

5

(c) 1.7 x 10

5

(d) 2.3 x 10

5

GATE 2007 (PI) Li k d S 2 GATE 2007(PI)LinkedS2

In a sand casting process, a sprue of 10 mm base In a sand casting process, a sprue of 10 mm base

diameter and 250 mm height leads to a runner

which fills a cubical mould cavity of 100 mm size which fills a cubical mould cavity of 100 mm size

The mould filling time (in seconds) is

(a) 2.8 (b) 5.78

(c) 7 54 (d) 8 41 (c) 7.54 (d) 8.41

IES2009

2marks

IAS2011Main

Sketch a mould for two hollow components to be

cast. On the diagram, indicate runner, gate, riser,

core, cope, sprue, pouring basin, sprue well, drag,

parting line parting line.

[10Marks] [ ]

For 2014 (IES, GATE & PSUs) Page 8 of 17

GATE2004

Misrun is a casting defect which occurs due to

(a) Very high pouring temperature of the metal

(b) Insufficient fluidity of the molten metal

(c) Absorption of gases by the liquid metal

(d) I li f h ld fl k (d) Improper alignment of the mould flasks

GATE2009

Two streams of liquid metal which are not hot

h t f l lt i t ti d f t enough to fuse properly result into a casting defect

known as

(a) Cold shut

(b) Swell

(c) Sand wash

(d) Scab

ld h f MoldShift

The mold shift defect occurs when cope and drag

ldi b h t b l li d or molding boxes have not been properly aligned.

IES2001

Scabisa

(a) Sandcastingdefect

(b) Machiningdefect

(c) Weldingdefect

(d) F i d f (d) Forgingdefect

IAS2004

MatchList I(CastingDefects)withList II(Explanation)andselectthecorrect MatchListI(CastingDefects)withListII(Explanation)andselectthecorrect

answerusingthecodesgivenbelowthelists:

ListI ListII

(CastingDefects) (Explanation) (CastingDefects) (Explanation)

A.Metallicprojections 1.Consistofroundedorroughinternalorexposedcavities

includingblowholesandpinholes

B.Cavities 2.Formedduringmelting,solidificationandmoulding.

C.Inclusions 3.Includessinglefolds,laps,scarsadheringsandlayersand

oxidescale

D.Discontinuities 4.Includecracks,coldorhottearingandcoldshuts

Consistoffins flashormassi eprojectionsandrough 5.Consistoffins,flashormassiveprojectionsandrough

surfaces

Codes:A B C D A B C D

(a) 1 5 3 2 (b) 1 5 2 4 (a) 1 5 3 2 (b) 1 5 2 4

(c) 5 1 2 4 (d) 5 1 3 2

GATE2003

Hardnessofgreensandmouldincreaseswith

(a) Increaseinmoisturecontentbeyond6percent y p

(b) Increaseinpermeability

(c) Decreaseinpermeability (c) Decreaseinpermeability

(d) Increaseinbothmoisturecontentand

bilit permeability

IES1998

A i (A) S iff i b h b Assertion(A):Stiffeningmembers,suchaswebs

andribs,usedonacastingshouldbeliberally

provided provided.

Reason(R):Theywillprovideadditionalstrength

toacastmember toacastmember.

(a) BothAandRareindividuallytrueandRisthe

correctexplanationofA correctexplanationofA

(b) BothAandRareindividuallytruebutRisnot the

correctexplanationofA correctexplanationofA

(c) AistruebutRisfalse

(d) Ai f l b tRi t (d) AisfalsebutRistrue

IES2005

In gating system design, which one of the

following is the correct sequence in which choke

area, pouring time, pouring basin and sprue sizes

are calculated?

(a) Chokearea Pouringtime Pouringbasin Sprue

(b) Pouringbasin Sprue Chokearea Pouringtime (b) ou g bas Sp ue C o e a ea ou g t e

(c) Chokearea Sprue Pouringbasin Pouringtime

(d) P i b i P i ti Ch k S (d) Pouringbasin Pouringtime Chokearea Sprue

IES1997

Ifthemeltingratioofacupolais10:1,thenthe

cokerequirementforonetonmeltwillbe

(a) 0.1ton

(b) 10tons (b) 10tons

(c) 1ton

(d) t (d) 11tons

For 2014 (IES, GATE & PSUs) Page 9 of 17

IES2009

Inwhichoneofthefollowingfurnacesmostofthe

nonferrousalloysaremelted?

(a) Reverberatory furnace

(b) Inductionfurnace (b) Inductionfurnace

(c) Cruciblefurnace

(d) P tf (d) Potfurnace

IAS2001

Whichofthefollowingpatternmaterialsareused

inPrecisionCasting?

1. PlasterofParis

2. Plastics 2. Plastics

3. AnodizedAluminium Alloy

F M 4. FrozenMercury

Selectthecorrectanswerusingthecodesgivenbelow:

(a)1and2(b) 2and4(c)3and4(d)1and3

IAS2004

Whichoneofthefollowinggatingsystemsisbest

suitedtoobtaindirectionalsolidification?

(a) Topgrating

(b) Partlinegrating (b) Part linegrating

(c) Bottomgrating

(d) St d ti (d) Steppedgrating

IES2011

In the designation of Aluminium casting A514 0 In the designation of Aluminium casting A514.0

indicates :

( ) Al i i it (a) Aluminium purity

(b) Aluminiumcontent

(c) Percentage of alloy element

(d) Magnesium Content (d) Magnesium Content

A (d) Ans. (d)

SpecialCasting SpecialCasting

BySKMondal BySKMondal

IES 2010 IES2010

Considerthefollowingadvantagesofshell Considerthefollowingadvantagesofshell

mouldcasting:

Cl di i lt l 1.Closedimensionaltolerance.

2.Goodsurfacefinish.

3.Lowcost.

E i 4.Easier.

Whichofthesearecorrect?

(a)1,2and3only (b)2,3and4only

( ) ( ) (c)1,2and4only (d)1,2,3and4

IES1996

Consider the following ingredients used in

moulding:

1. Dry silica sand

2.Clay 2.Clay

3.Phenol formaldehyde

S di ili t 4.Sodium silicate

Those used for shell mould casting include

(a) 1, 2 and 4 (b) 2, 3 and 4

(c) 1and 3 (d) 1, 2, 3 and 4 ( ) 3 ( ) , , 3 4

IES2005

I h ll ldi h th h llthi k Inshellmoulding,howcantheshellthickness

beaccuratelymaintained?

( ) (a)Bycontrollingthetimeduringwhichthepattern

isincontactwithmould

(b)Bycontrollingthetimeduringwhichthepattern

isheated

(c)Bymaintainingthetemperatureofthepatternin

therangeof175

o

C 380

o

C therangeof175 C 380 C

(d)Bythetypeofbinderused

For 2014 (IES, GATE & PSUs) Page 10 of 17

IES2006

Shellmouldingcanbeusedfor:

(a) Producingmillingcutters g g

(b) Makinggoldornaments

(c) Producingheavyandthickwalledcasting (c) Producingheavyandthickwalledcasting

(d) Producingthincasting

IES2007

Which of the following are employed in shell

ldi ? moulding?

1. Resin binder 2. Metal pattern 3. Heating coils

Select the correct answer using the code given

below:

(a) 1 and 2 only (b) 1 and 3 only

(c) 2 and 3 only (d) 1 2 and 3 (c) 2 and 3 only (d) 1, 2 and 3

IAS2007

The mould in shell moulding process is made up

f hi h f th f ll i ? of which of the following?

(a) Gypsum + setting agents (a) Gypsum + setting agents

(b) Green sand + clayy

(c) Sodium silicate + dried sand

(d) Dried silica + phenolic resin

IAS1999

M t h Li t I (M ldi P ) ith Li t II (Bi di Match List I (Moulding Process) with List II (Binding

Agent) and select the correct answer using the codes

given belowthe lists: g

List I List II

A. Green sand 1. Silicate

B. Core sand 2. Organic

C. Shell moulding 3. Clay

D CO Pl f P i D. CO2 process 4. Plaster of Paris

5. Plastic

Codes:A B C D A B C D Codes:A B C D A B C D

(a) 3 2 5 1 (b) 3 2 4 1

(c) 2 3 5 4 (d) 2 3 4 5 (c) 2 3 5 4 (d) 2 3 4 5

IES2009

2marks

IES2011

The proper sequence of investment casting steps is : The proper sequence of investment casting steps is :

(a) Slurry coating pattern melt outShakeout Stucco

ti coating

(b) Stucco coating Slurry coating Shakeout Pattern

melt out

(c) Slurry coating Stucco coating Pattern melt out y g g

Shakeout

(d) Stucco coating Shakeout Slurry coating Pattern (d) Stucco coating Shakeout Slurry coating Pattern

melt out

GATE2006

An expendable pattern is used in

( ) l h (a) Slush casting

(b) Squeeze casting

(c) Centrifugal casting

(d) Investment casting (d) Investment casting

GATE2011(PI)

Which of the following casting processes uses

expendable pattern and expendable mould?

(a) Shell mould casting

( ) (b) Investment casting

(c) Pressure die casting (c) Pressure die casting

(d) Centrifugal casting (d) Centrifugal casting

ISRO2010

Investment casting is used for

(a) Shapes which are made by difficulty using complex

tt i d ti patterns in sand casting

(b) Mass production p

(c) Shapes which are very complex and intricate and

can't be cast by any other method

(d) There is nothing like investment casting (d) There is nothing like investment casting

For 2014 (IES, GATE & PSUs) Page 11 of 17

IES1992

Themostpreferredprocessforcastinggasturbine

bladesis:

(a) Diemoulding

(b) Shellmoulding (b) Shellmoulding

(c) Investmentmoulding

(d) S d ti (d) Sandcasting

20 0 JWM2010

Considerthefollowingmaterials: g

1.Wax

2 Wood 2.Wood

3.Plastic

Whichofthesematerialscanbeusedaspatternin

investmentcastingprocess?

(a)1,2and3 (b)1and2only

(c)2and3only (d)1and3only (c)2and3only (d)1and3only

IES 2010 IES2010

Assertion (A): The investment casting is used for ( ) g

precision parts such as turbine plates, sewing

machines etc.

Reason (R): The investment castings have a good

surface finish and are exact reproductions of the surface finish and are exact reproductions of the

master pattern.

(a) Both A and R are individually true and R is the (a) Both A and R are individually true and R is the

correct explanation of A

(b) B th A d R i di id ll t b t R i NOT th (b) Both A and R are individually true but R is NOT the

correct explanation of A

(c) A is true but R is false

(d) A is false but R is true

IES 2007 IES2007

Consider the following statements in respect of

investment castings:

1. The pattern or patterns is/are not joined to a stalk or

sprue also of wax to forma tree of patterns.

2.The prepared moulds are placed in an oven and heated

gently to dry off the invest and melt out the bulk of wax.

3.The moulds are usually poured by placing the moulds in

a vacuum chamber. Which of the statements given above

are correct?

(a) 1 and 2 only (b) 1 and 3 only

(c)2 and 3 only (d) 1, 2 and 3 3 y 3

IES2006

Which of the following materials are used for

making patterns in investment casting method?

1. Wax 2. Rubber 3. Wood 4. Plastic

Select the correct answer using the codes given below: Select the correct answer using the codes given below:

(a) Only 1 and 3 (b) Only 2 and 3

( ) O l d (d) O l d (c) Only 1, 2 and 4 (d) Only 2, 3 and 4

IAS1996

Light and intricate parts with close dimensional

tolerances of the order of 0.005 mm are

produced by

(a) Investment castingg

(b) Die casting

(c) Centrifugal casting (c) Centrifugal casting

(d) Shell mould casting

IES 2013 IES2013

Statement (I): Mould walls of a permanent mould are

kept thick kept thick.

Statement (II): The thicker mould walls retain

i h i i fl f l l maximum heat increasing flowof molten metal.

(a) Both Statement (I) and Statement (II) are individually

true and Statement (II) is the correct explanation of

Statement (I)

(b) Both Statement (I) and Statement (II) are individually

true but Statement (II) is not the correct explanation of ( ) p

Statement (I)

(c) Statement (I) is true but Statement (II) is false (c) Statement (I) is true but Statement (II) is false

(d) Statement (I) is false but Statement (II) is true

IES2011

Consider the following advantages of die casting over Consider the following advantages of die casting over

sand casting :

1 Rapidity of the process 1. Rapidity of the process

2. Smooth surface

3 Strong dense metal structure 3. Strong dense metal structure

Which of these advantages are correct ?

( ) d (a) 1, 2 and 3

(b) 1 and 2 only

(c) 2 and 3 only

(d) 1 and 3 only 3 y

IES2009

Which of the following are the most suitable

materials for die casting?

(a) Zinc and its alloys

(b) Copper and its alloys (b) Copper and its alloys

(c) Aluminiumand its alloys

(d) L d d it ll (d) Lead and its alloys

For 2014 (IES, GATE & PSUs) Page 12 of 17

20 0 JWM2010

Assertion (A) : In die casting method, small ( ) g ,

thickness can be filled with liquid metal.

Reason (R) : The air in die cavity trapped inside the Reason (R) : The air in die cavity trapped inside the

casting causes problems.

(a) BothAandRareindividuallytrueandRisthe (a) BothAandRareindividuallytrueandRisthe

correctexplanationofA

(b) B hA dR i di id ll b Ri h (b) BothAandRareindividuallytruebutRisnot the

correctexplanationofA

(c) AistruebutRisfalse

(d) AisfalsebutRistrue ( )

IES2005

Which one of the following processes produces a

casting when pressure forces the molten metal

into the mould cavity?

(a) Shell moulding (b) Investment casting g g

(c) Die casting (d) Continuous casting

IES2006

In which of the following are metal moulds used?

(a) Greensand mould

(b) Dry sand mould

(c) Die casting process (c) Die casting process

(d) Loam moulding

IES1995

A i (A) A l i i ll i h % ili i Assertion (A): An aluminium alloy with 11 % silicon is

used for making engine pistons by die casting

technique technique.

Reason (R): Aluminium has low density and addition

of silicon improves its fluidity and therefore its p y

castability.

(a) Both A and R are individually true and R is the correct y

explanation of A

(b) Both A and R are individually true but R is not the

l i f A correct explanation of A

(c) A is true but R is false

(d) f l b (d) A is false but R is true

IES1995

MatchListIwithListIIandselectthecorrectanswertakingthehelp MatchListIwithListIIandselectthecorrectanswertakingthehelp

ofcodesgivenbelowthelists:

ListI ListII

(Products) (Processofmanufacture) (Products) (Processofmanufacture)

A. Automobilepistoninaluminiumalloy 1.Pressurediecasting

B. Enginecrankshaftinspheroidal

hi i G i di i graphiteiron 2.Gravitydiecasting

C. Carburettor housinginaluminiumalloy 3.Sandcasting

D. Casttitaniumblades 4.Precisioninvestment

i casting

5.Shellmoulding

Code: A B C D A B C D

(a) 2 3 1 5 (b) 3 2 1 5

(c) 2 1 3 4 (d) 4 1 2 3

IAS2007

Considerthefollowingstatements:

1. Zincdiecastingshavelowstrength. g g

2. Inthediecastingprocess,verythinsectionsor

complexshapescanbeobtainedeasily. complexshapescanbeobtainedeasily.

Whichofthestatementsgivenaboveis/arecorrect?

( ) l (a) 1only

(b) 2only

(c) Both1and2

(d) Neither1nor2 ( )

IAS1996

A i (A) Di i i ld d f d Assertion (A): Die casting yields a product of good

accuracy and finish.

R (R) L l i ll d i di Reason (R): Low melting alloys used in die

casting.

( ) B h A d R i di id ll d R i h (a) Both A and R are individually true and R is the

correct explanation of A

(b) B h A d R i di id ll b R i h (b) Both A and R are individually true but R is not the

correct explanation of A

( ) A i b R i f l (c) A is true but R is false

(d) A is false but R is true

IES2011

Consider the following statements : Consider the following statements :

1. Hot chamber machine is used for casting zinc, tin and

th l lti ll other low melting alloys.

2. Cold chamber machine is used for die casting of

ferrous alloys

3. Rapid cooling rate in die casting produces high 3 p g g p g

strength and quality in many alloys.

Which of these statements are correct? Which of these statements are correct?

(a) 1, 2 and 3 (b) 1 and 2 only

( ) d l (d) d l (c) 2 and 3 only (d) 1 and 3 only

GATE2007

Which of the following engineering materials is

th t it bl did t f h t h b di the most suitable candidate for hot chamber die

casting?

( ) b l (a) Lowcarbon steel

(b) Titanium

(c) Copper

(d) Tin (d) Tin

For 2014 (IES, GATE & PSUs) Page 13 of 17

IES1995

A i (A) Al i i ll i h Assertion (A): Aluminium alloys are cast in hot

chamber die casting machine.

Reason (R): Aluminium alloys require high melting Reason (R): Aluminium alloys require high melting

when compared to zinc alloys.

(a) Both A and R are individually true and R is the correct (a) Both A and R are individually true and R is the correct

explanation of A

(b) Both A and R are individually true but R is not the (b) Both A and R are individually true but R is not the

correct explanation of A

(c) A is true but R is false ( )

(d) A is false but R is true

GATE2009(PI) ( )

Hot chamber die casting process is NOT suited for

(a) Lead and its alloy

(b) Zinc and its alloy

( ) Ti d it ll (c) Tin and its alloy

(d) Aluminumand its alloy ( ) y

GATE2002

In centrifugal casting, the impurities are

( ) f l d b d (a) Uniformly distributed

(b) Forced towards the outer surface

(c) Trapped near the mean radius of the casting

(d) Collected at the centre of the casting (d) Collected at the centre of the casting

GATE1993

Centrifugally cast products have

(a) Large grain structure with high porosity g g g p y

(b) Fine grain structure with high density

(c) Fine grain structure with lowdensity (c) Fine grain structure with lowdensity

(d) Segregation of slug towards the outer skin of the

ti casting

GATE2008(PI) ( )

In hollow cylindrical parts, made by centrifugal casting,

the density of the part is

( ) i h i (a) maximum at the outer region

(b) maximum at the inner region (b) maximum at the inner region

(c) maximum at the midpoint between outer and inner ( ) p

surfaces

(d) uniform throughout

IES2008

Which of the following casting processes does not Which of the following casting processes does not

/do not require central core for producing pipe?

1 Sand casting process 1. Sand casting process

2. Die casting process

3 Centrifugal casting process 3. Centrifugal casting process

Select the correct answer using the code given below:

( ) d (a) 1 and 2

(b) 2 only

(c) 2 and 3

(d) 3 only 3 y

IES2009

Which one of the following casting processes is

b t it d t k bi i h ll best suited to make bigger size hollow

symmetrical pipes? y p p

(a) Die casting

(b) Investment casting

(c) Shell moulding

(d) Centrifugal casting

IES2007

Which one of the following is the correct

statement?

In a centrifugal casting method

(a) No core is used (a) No core is used

(b) Core may be made of any metal

( ) C i d f d (c) Core is made of sand

(d) Core is made of ferrous metal

IES1998

Poormachinability ofcentrifugallycastironpipe

isdueto

(a) Chilling

(b) Segregation (b) Segregation

(c) Densestructure

(d) Hi h ld t ti d (d) Highmouldrotationspeed

For 2014 (IES, GATE & PSUs) Page 14 of 17

IES2009

Which of the following are the most likely

characteristics in centrifugal casting?

(a) Fine grain size and high porosity

(b) Coarse grain size and high porosity (b) Coarse grain size and high porosity

(c) Fine grain size and high density

(d) C i i d hi h d it (d) Coarse grain size and high density

IES2007

MatchListIwithListIIandselectthecorrectanswerusingthecodegiven MatchListIwithListIIandselectthecorrectanswerusingthecodegiven

belowtheLists:

ListI ListII

(CastingProcess) (Principle) (CastingProcess) (Principle)

A. Diecasting 1.Themetalsolidifiesinarotatingmould

B. Investmentcasting 2.Thepatternclusterisrepeatedlydipped

intoaceramicslurryanddustedwith

f refractory

C. Shellmoulding 3.Moltenmetalisforcedbypressureinto

ametallicmould

D Centrifugalcasting 4 Aftercooling theinvestisremoved D. Centrifugalcasting 4.Aftercooling,theinvestisremoved

fromthe Castingbypressurejettingor

vibratorycleaning

Code: A B C D A B C D

(a) 2 1 3 4 (b) 3 4 2 1

(c) 2 4 3 1 (c) 3 1 2 4

IES2000

M t hLi tI(P ) ithLi tII(P d t / t i l ) MatchListI(Process)withListII(Products/materials)

andselectthecorrectanswerusingthecodesgiven

belowtheLists:

ListI ListII

A. Diecasting 1.Phenolformaldehyde

B. Shellmolding 2.C.I.pipes

C. CO

2

molding 3.Nonferrousalloys

D C if l i S di ili D. Centrifugalcasting 4.Sodiumsilicate

Codes:A B C D A B C D

(a) 1 3 4 2 (b) 3 1 4 2 (a) 1 3 4 2 (b) 3 1 4 2

(c) 3 1 2 4 (d) 1 3 2 4

IAS2004

MatchListI(NameoftheProcess)withListII(Advantage)andselectthecorrect

answerusingthecodesgivenbelowthelists:

List I List II ListI ListII

(NameoftheProcess) (Advantage)

A. SandCasting 1.Largecylindricalpartswithgoodquality

B C i ld ti E ll tdi i l d f B. Ceramicmoldcasting 2.Excellentdimensionalaccuracyandsurface

finish

C. Diecasting 3.Intricateshapesandclosetoleranceparts

D C if l i Al li d h if li i D. Centrifugalcasting 4.Almostanymetaliscastandthereifnolimitto

size,shapeandweight

5.Gooddimensionalaccuracy,finishandlow

porosity

Codes:A B C D A B C D

(a) 2 3 5 1 (b) 4 1 2 3

(c) 2 1 5 3 (d) 4 3 2 1

IAS2003

A i (A) S i if l i i Assertion (A): Semicentrifugal casting process is

similar to true centrifugal casting except that the

central core is used in it to form inner surface central core is used in it to form inner surface.

Reason (R): In semicentrifugal casting process the

axis of spin is always vertical p y

(a) Both A and R are individually true and R is the correct

explanation of A p

(b) Both A and R are individually true but R is not the

correct explanation of A

(c) A is true but R is false

(d) A is false but R is true

IES2013

Statement (I): In semi centrifugal casting a particular

shape of the casting is produced by mould, core and the p g p y

centrifugal force of molten metal.

Statement (II): The centrifugal force aids to proper Statement (II): The centrifugal force aids to proper

feeding to produce the casting free from porosity.

(a) Both Statement (I) and Statement (II) are individually (a) Both Statement (I) and Statement (II) are individually

true and Statement (II) is the correct explanation of

Statement (I) Statement (I)

(b) Both Statement (I) and Statement (II) are individually

t b t St t t (II) i t th t l ti f true but Statement (II) is not the correct explanation of

Statement (I)

( ) ( ) b ( ) f l (c) Statement (I) is true but Statement (II) is false

(d) Statement (I) is false but Statement (II) is true

IES2000

M t hLi tI(T f ti ) ithLi tII(W ki i i l ) MatchListI(Typeofcasting)withListII(Workingprinciples)

andselectthecorrectanswerusingthecodesgivenbelowthe

Lists:

Li tI Li tII ListI ListII

A. Diecasting 1.Moltenmetalisforcedintothedie

underpressure

B. Centrifugalcasting 2.Axisofrotationdoesnotcoincidewith

axisofmould

C. Centrifuging 3.Metalsolidifieswhenmouldisrotating g g 3 g

D. Continuouscasting 4.Continuouslypouringmoltenmetal

intomould

Codes: A B C D A B C D Codes: A B C D A B C D

(a) 1 3 2 4 (b) 4 3 2 1

(c) 1 2 3 4 (d) 4 2 3 1

IAS2004

Which of the following are produced by slush

casting?

(a) Hollowcastings with thick walls

(b) Hollowcastings with thin walls (b) Hollowcastings with thin walls

(c) Thin castings

(d) Thi k ti (d) Thick castings

IES2011

The method of casting for producing ornamental pieces The method of casting for producing ornamental pieces

are:

( ) Sl h d it ti (a) Slush and gravity casting

(b) Pressed and slush casting

(c) Gravity and semi permanent mould casting

(d) Semi permanent mould and pressed casting (d) Semi permanent mould and pressed casting

For 2014 (IES, GATE & PSUs) Page 15 of 17

IES 2012 IES 2012

The process of making hollow castings of noncircular The process of making hollow castings of non circular

shape and desired thickness by permanent mould

without the use of cores is known as without the use of cores is known as

(a) Die casting (b) Slush casting

( ) P d ti (d) C t if l ti (c) Pressed casting (d) Centrifugal casting

IAS2002

M t hLi tI(C ti P ) ithLi tII MatchListI(CastingProcess)withListII

(Applications)andselectthecorrectanswerusingthe

codesgivenbelowtheLists: g

ListI ListII

(CastingProcess) (Applications)

A. Centrifugalcasting 1. Carburetor

B. Squeezecasting 2. Pipes

C Di C i Wh l f C. DieCasting 3. Wheelsfor

automobiles

4 Gearhousings 4. Gearhousings

Codes:A B C A B C

(a) 2 3 1 (b) 4 1 3 (a) 2 3 1 (b) 4 1 3

(c) 2 1 3 (d) 4 3 1

IES2009 IES2009

2marks

IES1996

Whichofthefollowingpairsarecorrectlymatched?

1. Pitmoulding ..................Forlargejobs. g g j

2. Investmentmoulding ...Lostwaxprocess.

3 Plastermoulding Mouldpreparedin 3. PlastermouldingMouldpreparedin

gypsum.

( ) d (b) d (a) 1,2and3 (b) 1and2

(c) 1and3 (d) 2and3

IES1997

Which one of the following pairs is not correctly

matched?

(a) Aluminiumalloy piston Pressure die casting

(b) Jewellery.. Lost wax process (b) Jewellery.. Lost wax process

(c) Large pipes ..Centrifugal casting

(d) L b ll L ldi (d) Large bells Loam moulding

GATE1998

Li tI Li tII ListI ListII

(A) Sandcasting (1) Symmetricaland

circularshapesonly circularshapesonly

(B) Plastermouldcasting (2) Partshavehardened

skinsandsoftinterior

(C) Shellmouldcasting (3) Minimumpost

castingprocessing

(D) Investmentcasting (4) Partshaveatendency (D) Investmentcasting (4) Partshaveatendency

towarp

(5) Partshavesoftskin (5)

andhardinterior

(6) Suitableonlyfornon

f t l ferrousmetals

GATE1992

M h h f ll i ldi / i i h Matchthefollowingmoulding/castingprocesseswith

theproduct:

Moulding/Castingprocesses Product Moulding/Castingprocesses Product

(A) Slushcasting (P)Turbineblade

(B) Shellmoulding (Q)Machinetoolbed (B) Shellmoulding (Q)Machinetoolbed

(C) Drysandmoulding (R)Cylinderblock

(D) C t if l ti (S)H ll ti (D) Centrifugalcasting (S)Hollowcastings

likelampshades

(T)Rainwaterpipe (T)Rainwaterpipe

(U)Castironshoe

brake brake

GATE1996

ListI ListII

(A) Rivetsforaircraftbody 1. Forging y g g

(B) Carburettor body 2. Coldheading

(C) Crankshafts 3 Aluminiumbased (C) Crankshafts 3. Aluminiumbased

alloy

(D) N il P di ti (D) Nails 4. Pressurediecasting

5. Investmentcasting

IES2003

M t hLi tI(P d t ) ithLi tII(C ti P ) d l t MatchListI(Products)withListII(CastingProcess)andselect

thecorrectanswerusingthecodesgivenbelowtheLists:

ListI ListII

(Products) (CastingProcess)

A. Hollowstatues 1. CentrifugalCasting

B Dentures 2 InvestmentCasting B. Dentures 2. InvestmentCasting

C. Aluminiumalloypistons 3. SlushCasting

D. Rockerarms 4. ShellMoulding

G i Di C i 5. GravityDieCasting

Codes: A B C D A B C D

(a) 3 2 4 5 (b) 1 3 4 5 ( ) 3 4 5 ( ) 3 4 5

(c) 1 2 3 4 (d) 3 2 5 4

For 2014 (IES, GATE & PSUs) Page 16 of 17

IES1993

M h h i fLi I(E i ) i h h i MatchtheitemsofListI(Equipment)withtheitems

ofListII(Process)andselectthecorrectanswerusing

thegivencodes thegivencodes.

ListI(Equipment) ListII(Process)

P HotChamberMachine 1 Cleaning P HotChamberMachine 1. Cleaning

Q Muller 2. Coremaking

R DielectricBaker 3 Diecasting R DielectricBaker 3. Diecasting

S SandBlaster 4. Annealing

5 Sandmixing 5. Sandmixing

(a) P2,Q1,R4,S5 (b) P4,Q2,R3,S5

(c) P 4 Q 5 R 1 S 2 (d) P 3 Q 5 R 2 S 1 (c) P4,Q5,R1,S2 (d) P3,Q5,R2,S1

IAS2004

M hLi I(N f h C i P ) i hLi II(P D fi i i ) d l MatchListI(NameoftheCastingProcess)withListII(ProcessDefinition)andselect

thecorrectanswerusingthecodesgivenbelowthelists:

ListI ListII

(NameoftheCastin Process) (ProcessDefinition) (NameoftheCastingProcess) (ProcessDefinition)

A. Diecasting 1.Thisprocessinvolvesuseofamouldmadeof

Driedsilicasandandphenolic resinmixture

B El t l ti I thi lt t li f db B. Electroslag casting 2.Inthisprocess,moltenmetalisforcedby

Pressureintoametalmould

C. Centrifugalcasting 3.Thisprocessemploysaconsumableelectrode

D P i i i Thi i l i ld hil h D. Precisioncasting 4.Thisprocessinvolvesrotatingamouldwhilethe

metalsolidifies

5.Thisprocessproducesverysmooth,highly

Accuratecastingsfrombothferrousandnon

ferrousalloys

Codes:A B C D A B C D

(a) 5 4 1 2 (b) 2 3 4 5

(c) 5 3 4 2 (d) 2 4 1 5

GATE 2007 (PI) GATE 2007(PI)

Match the lists

Group1 Group2

P.SandCasting 1.Turbineblades

QCentrifugalCasting 2 ICEnginePistons Q.CentrifugalCasting 2.ICEnginePistons

R.InvestmentCasting 3.Largebells

S.DieCasting 4.Pulleys

(a) P 4, Q 1, R 3, S 2 (b) P 2, Q 4, R 3, S 1

(c) P 3, Q 4, R 1, S 2 (d) P 3, Q 2, R 1, S 4 ( ) 3, Q 4, , ( ) 3, Q , , 4

Q.No Option

Q.No Option

ConventionalCastingProcessCh21

Q.No Option

1 A

2 A

p

13 C

14 D 2 A

3 C

14 D

15 D

4 A

5 D

16 B

17 B

6 A

7 D

18 B

19 D

8 C

9 B

20 A

21 A 9 B

10 D

11 A

21 A

11 A

12 B

SpecialCastingProcessCh22

Q.No Option

Q.No Option

1 D

2 C

11 A

12 A

3 C

4 B

12 A

13 D

14 A

5 C

6 A

14 A

15 A

6 A

7 D

16 B

17 A

8 C

9 B

10 D

For 2014 (IES, GATE & PSUs) Page 17 of 17

Potrebbero piacerti anche

- L A R G e - S C A L e M e T H A M P H e T A M I N e M A N U F A C T U R eDocumento21 pagineL A R G e - S C A L e M e T H A M P H e T A M I N e M A N U F A C T U R eDaria Schka100% (1)

- Manual of GardeningDocumento812 pagineManual of GardeningPrakash PatelNessuna valutazione finora

- Manufacturing Technology - MCQDocumento74 pagineManufacturing Technology - MCQjpbhimani100% (1)

- KPC Drilling Rig AcceptanceDocumento3 pagineKPC Drilling Rig Acceptanceislam atifNessuna valutazione finora

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDa EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNessuna valutazione finora

- Amem201 Group1 Multiple Choice Q&A Amem201Documento4 pagineAmem201 Group1 Multiple Choice Q&A Amem201Aero NaveenNessuna valutazione finora

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- List of Government Circuit Bungalow Nuwara EliyaDocumento4 pagineList of Government Circuit Bungalow Nuwara EliyaAsitha Kulasekera78% (9)

- Metal Cas MCQDocumento25 pagineMetal Cas MCQKanhaiyaPrasadNessuna valutazione finora

- Inked CultureDocumento90 pagineInked Culturemar phisNessuna valutazione finora

- Manufacturing ProcessesDocumento54 pagineManufacturing ProcessesDunRainvilleAllonarSumagang100% (1)

- Question BankDocumento13 pagineQuestion BankAkshay Kumar100% (1)

- 220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsDocumento34 pagine220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsJVMNessuna valutazione finora

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeDa EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNessuna valutazione finora

- EscheatmentDocumento58 pagineEscheatmentlaarigao100% (2)

- Energy Optimization of A Large Central Plant Chilled Water SystemDocumento24 pagineEnergy Optimization of A Large Central Plant Chilled Water Systemmuoi2002Nessuna valutazione finora

- Production Question Set 2 2Documento70 pagineProduction Question Set 2 2KBSMANIT89% (19)

- MCQ-Metal Forming ProcessDocumento16 pagineMCQ-Metal Forming ProcessKunal Wagh67% (9)

- Industrial Chemistry of Oxides for Emerging ApplicationsDa EverandIndustrial Chemistry of Oxides for Emerging ApplicationsNessuna valutazione finora

- Metal Casting MCQDocumento21 pagineMetal Casting MCQVetsa Sairohit100% (5)

- Civil Engineering Objective Questions With AnswersDocumento8 pagineCivil Engineering Objective Questions With AnswersBiplab Banerjee71% (7)

- Casting, Welding, Machine Tools, Material SCDocumento240 pagineCasting, Welding, Machine Tools, Material SCPrabhat YadavNessuna valutazione finora

- Casting Question Set-2014Documento17 pagineCasting Question Set-2014Naman GuptaNessuna valutazione finora

- Sand CastingDocumento81 pagineSand CastingAshok PradhanNessuna valutazione finora

- Sand CastingDocumento81 pagineSand Castingkumarrohit91100% (2)

- Special Casting Fig Q A For StudentsDocumento60 pagineSpecial Casting Fig Q A For StudentsRavinder Antil75% (4)

- CASTINGQDocumento15 pagineCASTINGQAshok PradhanNessuna valutazione finora

- Forging Fig Q A AnalysisDocumento12 pagineForging Fig Q A AnalysisKBSMANITNessuna valutazione finora

- 3.2 Special Casting Q&A For StudentsDocumento9 pagine3.2 Special Casting Q&A For Studentsnikhilbatham100% (1)

- 55 MCQ of CastingDocumento8 pagine55 MCQ of CastingVivek Bajpai100% (1)

- Metal CastingDocumento8 pagineMetal CastingYash DesaaiNessuna valutazione finora

- Deewane: Ies & Gate: Test 06Documento33 pagineDeewane: Ies & Gate: Test 06Mayank SaxenaNessuna valutazione finora

- Powder Metallurgy Fig Q A For StudentsDocumento6 paginePowder Metallurgy Fig Q A For StudentsRavinder Antil100% (2)

- Extrusion Fig Q A AnalysisDocumento13 pagineExtrusion Fig Q A AnalysisRavinder AntilNessuna valutazione finora

- ManufacturingDocumento17 pagineManufacturingPadmaNessuna valutazione finora

- Casting-Welding Paper Solutions PDFDocumento9 pagineCasting-Welding Paper Solutions PDFNitesh MalavNessuna valutazione finora

- Moulding and Pattern NotesDocumento28 pagineMoulding and Pattern Notesprabhu100% (1)

- EC 2014 SolvedDocumento5 pagineEC 2014 SolvedPeeka Prabhakara RaoNessuna valutazione finora

- Sand Mould Casting Multiple Choice QuestionsDocumento9 pagineSand Mould Casting Multiple Choice QuestionsAyoub Mohamed100% (1)

- IES 2000 - II With Solution - EditedDocumento20 pagineIES 2000 - II With Solution - EditedHarshal ThakreNessuna valutazione finora

- Production Question Set 2013 by S K MondalDocumento63 pagineProduction Question Set 2013 by S K MondalKBSMANIT60% (5)

- Solution For Assignment 2Documento3 pagineSolution For Assignment 2akshaythakkar_219925Nessuna valutazione finora

- Question Set New 2013 2Documento65 pagineQuestion Set New 2013 2Arun P DayalNessuna valutazione finora

- A65BDocumento3 pagineA65BSiva Kumar SNessuna valutazione finora

- Metal Forming ME GATE 2020 Previous Year With Ans KeyDocumento9 pagineMetal Forming ME GATE 2020 Previous Year With Ans Keyhyper meshNessuna valutazione finora

- TYPE A - Real Time Quiz End Semester Examination - ME331Documento7 pagineTYPE A - Real Time Quiz End Semester Examination - ME331Selvi RNessuna valutazione finora

- Production 2014 Question SetDocumento79 pagineProduction 2014 Question SetKrishna GopalNessuna valutazione finora

- Paper 2 June 2013Documento5 paginePaper 2 June 2013Ignite TutorialNessuna valutazione finora

- Casting & Welding Theory & Questions Altogethre 2013Documento66 pagineCasting & Welding Theory & Questions Altogethre 2013Stark029Nessuna valutazione finora

- Casting ME GATE 2020 Previous Year With Ans KeyDocumento10 pagineCasting ME GATE 2020 Previous Year With Ans Keyhyper meshNessuna valutazione finora

- Ies 1997 - II ScanDocumento21 pagineIes 1997 - II ScanK.v.SinghNessuna valutazione finora

- Question Set New 2014Documento77 pagineQuestion Set New 2014monu991100% (1)

- Metal Forming PI GATE 2020 Previous Year With Ans KeyDocumento7 pagineMetal Forming PI GATE 2020 Previous Year With Ans Keyhyper meshNessuna valutazione finora

- Mody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyDocumento2 pagineMody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyAtul GaurNessuna valutazione finora

- Me QSDocumento8 pagineMe QSSaket MishraNessuna valutazione finora

- Teachers and Students Aids - Jss 3 Basic Technology QuestionsDocumento3 pagineTeachers and Students Aids - Jss 3 Basic Technology Questionschelaw RichardNessuna valutazione finora

- Question Set 2014Documento79 pagineQuestion Set 2014harshal2000Nessuna valutazione finora

- Production Question and Answer All 2012Documento149 pagineProduction Question and Answer All 2012AnshulJainNessuna valutazione finora

- Production Q A 2013 S K Mondal Mobile VersionDocumento557 pagineProduction Q A 2013 S K Mondal Mobile VersionKBSMANIT67% (3)

- Ies 2002 - II ScanDocumento32 pagineIes 2002 - II ScanK.v.SinghNessuna valutazione finora

- Production Question and Answer Set 1Documento79 pagineProduction Question and Answer Set 1KBSMANIT94% (16)

- Sheet Metal Operation Figures and Q A For StudentsDocumento15 pagineSheet Metal Operation Figures and Q A For StudentsRavinder Antil75% (4)

- Challenges in Corrosion: Costs, Causes, Consequences, and ControlDa EverandChallenges in Corrosion: Costs, Causes, Consequences, and ControlNessuna valutazione finora

- Advances in Ceramic Armor XIDa EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNessuna valutazione finora

- Advances in Ceramic Armor, Bioceramics, and Porous MaterialsDa EverandAdvances in Ceramic Armor, Bioceramics, and Porous MaterialsJerry C. LaSalviaNessuna valutazione finora

- He 3 Basic Types of Descriptive Research MethodsDocumento2 pagineHe 3 Basic Types of Descriptive Research MethodsRahul SarinNessuna valutazione finora

- Geography - Development (Rural - Urban Settlement)Documento32 pagineGeography - Development (Rural - Urban Settlement)jasmine le rouxNessuna valutazione finora

- 21 05 20 Montgomery AssocDocumento1 pagina21 05 20 Montgomery AssocmbamgmNessuna valutazione finora

- Blood DonationDocumento19 pagineBlood DonationsuruthiNessuna valutazione finora

- 2015 12 17 - Parenting in America - FINALDocumento105 pagine2015 12 17 - Parenting in America - FINALKeaneNessuna valutazione finora

- Coarse DispersionsDocumento35 pagineCoarse Dispersionsraju narayana padala0% (1)

- BR Interlock Pallet Racking System 2009 enDocumento8 pagineBR Interlock Pallet Racking System 2009 enMalik Rehan SyedNessuna valutazione finora

- Safety AuditDocumento9 pagineSafety AuditRobena Nagum BagasNessuna valutazione finora

- What Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Documento5 pagineWhat Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Rica machells DaydaNessuna valutazione finora

- Datasheet MEC MPS200 v1 2018Documento4 pagineDatasheet MEC MPS200 v1 2018Cepi Sindang KamulanNessuna valutazione finora

- Hmo Details November 2022 1Documento6 pagineHmo Details November 2022 1Saad BelloNessuna valutazione finora

- Chapter FourDocumento9 pagineChapter FourSayp dNessuna valutazione finora

- Onuaguluchi1996 1Documento10 pagineOnuaguluchi1996 1IkaSugihartatikNessuna valutazione finora

- 4 StartUp GuideDocumento2 pagine4 StartUp GuideSamuel RomeroNessuna valutazione finora

- Series RL: Standards General DataDocumento4 pagineSeries RL: Standards General DataBalamurugan SankaravelNessuna valutazione finora

- Rajivgandhi University of Health Sciences Bangalore, KarnatakaDocumento19 pagineRajivgandhi University of Health Sciences Bangalore, KarnatakaHUSSAINA BANONessuna valutazione finora

- Ecological Imbalance in IndiaDocumento4 pagineEcological Imbalance in IndiaabhywaNessuna valutazione finora

- Mdx-40a Use en R1 PDFDocumento100 pagineMdx-40a Use en R1 PDFMarcos BustamanteNessuna valutazione finora

- 2020 Q2 CushWake Jakarta IndustrialDocumento2 pagine2020 Q2 CushWake Jakarta IndustrialCookiesNessuna valutazione finora

- Pyq of KTGDocumento8 paginePyq of KTG18A Kashish PatelNessuna valutazione finora

- Endothermic Gas Production Overview: Tmosphere Ngineering OmpanyDocumento6 pagineEndothermic Gas Production Overview: Tmosphere Ngineering OmpanyJhon ChitNessuna valutazione finora

- Social Style InventoryDocumento12 pagineSocial Style InventoryMaheshwari JaniNessuna valutazione finora