Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Articol - 01 - 550 - Carozzi, Colombi Et Al - The Use of GFRP Grids For Structural

Caricato da

bigggredTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Articol - 01 - 550 - Carozzi, Colombi Et Al - The Use of GFRP Grids For Structural

Caricato da

bigggredCopyright:

Formati disponibili

Page 1 of 8

THE USE OF GFRP GRIDS FOR STRUCTURAL REHABILITATION OF

MASONRY ELEMENTS

Francesca Giulia CAROZZI

Research Assistant

Politecnico di Milano

P.zza L. da Vinci, 32 20133 Milan (Italy)

carozzi@stru.polimi.it

Pierluigi COLOMBI

Associate Professor

Politecnico di Milano

P.zza L. da Vinci, 32 20133 Milan (Italy)

colombi@stru.polimi.it

Christian DI FEO

Research Assistant

Politecnico di Milano

P.zza L. da Vinci, 32 20133 Milan (Italy)

difeo@stru.polimi.it

Antonino MONTALBANO

Technical Service

Sika Italia s.p.a.

Via Einaudi, 6 20068 Peschiera Borromeo (MI) (Italy)

montalbano.antonino@it.sika.com

Carlo POGGI

Full Professor

Politecnico di Milano

P.zza L. da Vinci, 32 20133 Milan (Italy)

poggi@stru.polimi.it

Abstract

This paper illustrates the use of FRP materials to reinforce existing masonry buildings,

including buildings of historical and architectural value. In this work an innovative technique

(glass fibres reinforced plastic grid applied by cement or lime based mortars) to improve the

structural behaviour of masonry elements is analyzed. This paper illustrates the preliminary

results of an ongoing experimental research project at the LPM of the Politecnico di Milano.

The work is divided in 3 parts. In the first one the reinforcing technique is illustrated and the

mechanical properties of the GFRP grid and cement or lime based mortars are evaluated. In

the second one the debonding strength of the reinforcing system is investigated. Finally, in the

third one, the proposed reinforcing technique is compared to a standard system which makes

use of CFRP wraps and epoxy resin. In the conclusions the advantages and disadvantages of

the reinforcing system are discussed.

Keywords: masonry, GFRP grid, experimental technique, debonding of external

reinforcement, cement and lime mortars

Page 2 of 8

1. Introduction

This paper illustrates the use of glass fiber reinforced polymer (GFRP) grid combined with

cement or lime based mortar to reinforce masonry buildings with historical and architectural

value. Comparing to steel, timber or concrete historical structures, masonry structures poses

different problems since the designer should take into account the complexity of the structure

geometry, the variety of used materials and the changes that building have experienced over

the time. Design of strengthening system should include solutions which are compatible with

existing materials, reversible and with minimum impact on the building historical value.

This work is motivated by the back analysis of buildings damaged during 2009 earthquake in

LAquila (Italy) which has shown the necessity to reinforce both structural and non structural

elements such as partition walls. Since the reinforcing system should be compatible with

materials from both the physical and chemical point of view and also reversible or at least

removable, this research investigates the possibility of usage of GFRP grid applied to the

substrate by cement or lime mortars.

Several experimental researches have been carried out in the past on masonry elements

strengthened by steel, GFRP and CFRP grid in combination with mortars or epoxy resin.

Capozucca [1], Briccoli Bati et al. [2], Faella et al. [3] has investigated the problem of

debonding of the reinforcement system from the substrate from both experimental and

analytical point of view. On the other hand, seismic retrofitting of masonry wall by FRP grid

reinforced mortars was also investigated in the literature. Tomazevic et al. [4], El Gawady et

al. [5] and Papanicolau et al. [6] performed dynamic tests on reinforced masonry panel with

FRP grids or wrap embedded in a mortar layer. Several authors [7] analysed durability and

compatibility between historical masonries and different FRP reinforcing systems,

investigating the effects of aggressive environmental conditions.

An experimental program was recently started at the LPM of the Politecnico di Milano on the

reinforcement of masonry structures by GFRP grid with an SBR coating (SikaWrap

-350G

Grid) applied to masonry elements by a cementitious (Sika

MonoTop-722 Mur) or a lime

based mortars (Sika

R-I-Z). In particular the use of a lime base mortar was investigated in

order to fulfil the compatibility requirement as stated before.

The mechanical properties of the reinforcement components were first investigated and in

particular the tensile strength of the GFRP grid in the warp and the weft directions and the

compressive and flexural strength of the mortars were experimentally evaluated. Also the

properties of fresh mortars were measured but they are out of the scope of present work.

In order to investigate the debonding strength of the reinforcing systems, double shear lap

pull-push tests were performed on a reinforcement strips bonded to the opposite side of a

single brick. Different types of clay brick were investigated, i.e. historical and modern bricks,

in order to evaluate the influence of surface roughness on the debonding load.. A custom

testing rig were designed and realized to perform the debonding tests.

For comparison purposes, a reinforcement system realized by CFRP wrap and epoxy resin

(SikaDur

-330) was investigated. The CFRP wrap consisted of one layer of 300 g/m

2

unidirectional textile bonded to the masonry elements by thixotropic epoxy resin (SikaDur

-

330).

2. The experimental program

In the following preliminary results of an ongoing experimental program at the LPM of the

Politecnico di Milano are presented. The program consists of 3 phases. In the first one the

mechanical properties of the components of the reinforcing systems (FRP materials and

mortars) were evaluated. In the second one the debonding strength of the reinforcing system

were measured by double shear lap tests. Finally, in the third one the effectiveness of

mechanical devices to improve the debonding strength (GFRP or CFRP chords) will be

Page 3 of 8

investigated. This last phase is out of the scope of the present work and it will not be

documented in the following.

2.1 Characterization of the reinforcement components

The first phase of the experimental program included the characterization of the

reinforcement components, i.e. the GFRP grid (SikaWrap

-350G Grid) and the cementitious

(Sika

MonoTop-722 Mur) and the lime based (Sika

R-I-Z) mortar (see Figure 1).

a) b)

Figure 1. Characterization of the reinforcement components: a) strips of GFRP grid and b) bending test

of a mortar specimen

2.1.1 GFRP grid

Tensile tests were performed on single roving in the warp and weft direction (5 specimens in

each direction). Tensile test was also performed on a grid strip of width 5cm, again in the

warp and roving directions (5 specimens in each direction). Tests were carried out using an

Instron 2kN and an MTS 250kN machines. In order to avoid local damage of the specimens

during the tensile tests, special fibreglass tabs were used (see Figure 1). The experimental

results are summarized in Table 1.

Table 1. Characterization of GFRP grid

Test type

Mean failure

load [kN]

Roving in the warp direction 1,11

Roving in the weft direction 1,03

Grid strip of width 5cm (3 rovings in the warp direction) 3,36

Grid strip of width 5cm (4 rovings in the weft direction) 4,24

2.1.2 Cement and lime based mortar

Two types of mortars were considered, i.e. a cementitious and a lime based mortar. In both

cases, the mechanical properties were investigated and in particular the compressive and

flexural strength were determined (see Table 2). In particular 6 specimens were tested for

both cementitious and lime based mortar. Also the properties of fresh mortar were measured

but they are out of the scope of the present work and it will be not documented in the

following.

Page 4 of 8

Table 2. Characterization of compressive and flexural strength

Test type

Mean compression

strength [N/mm

2

]

Mean flexural strength

[N/mm

2

]

Cementitious mortar

Sika

MonoTop 722 Mur

27,13 8,38

Lime based mortar

Sika

R-I-Z

2,75 1,03

2.2 Characterization of the reinforcement systems: debonding strength

Experimental tests were performed on pull-push double lap joints realized by GFRP grid

bonded to the two sides of a single brick. The specimens included two types of clay bricks,

i.e. historical and modern bricks and two types of mortars, i.e. a cementitious and a lime

based mortar. For comparison purposes, a reinforcement system realized by CFRP wraps and

epoxy resin (SikaDur

-330) was also investigated. Different bond lengths (5, 10 and 15cm)

and reinforcing widths (3cm to 8cm) were also considered in order to investigate the effect of

these parameters on the debonding strength. An MTS250 testing machine was used and a

special test rig was designed and realized to perform the double shear lap debonding test (see

Figure 2). Tests layout are summarized in Table 3.

a) b)

Figure 2. Double shear lap debonding test: a) test rig and b) specimen at failure

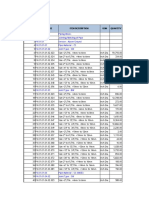

Table 3. Layout of the sxperimental tests

Brick type Reinf. type

Resin/mortar

type

Bond length

[cm]

Reinf. width

[cm]

Modern brick GFRP grid Cem. mortar 5 - 10 - 15 5

Historical brick GFRP grid Lime mortar 10 - 15 5

Modern brick GFRP grid Lime mortar 10 - 15 5

Modern brick CFRP wrap Epoxy resin

5

10

15

3 - 6

3 - 4 - 5 - 6 - 8

4 - 6

Page 5 of 8

2.2.1 GFRP grid and cementitious mortar

Test results are reported in Table 4 while the load-displacement graphs for different bond

length are shown in Figure 3a. The bond length has a clear influence on the failure load and

failure mode. As illustrated in Figure 3b the failure load increases with the bond length while

shorter reinforcements (5cm and 10cm) showed grid slippage before the tensile failure of the

GFRP grid. On the other hand for longer reinforcements the failure mode was tensile failure

of the GFRP grid without grid slippage (see Figure 4). In any case debonding of the

reinforcement from the substrate was never achieved. The optimum bond seems to be 15cm

with a mean failure load of 4.06kN.

Table 4. Tests results of the system with GFRP grid and cementitious mortar

Test N Bond length

[cm]

Failure load

[kN]

Mean failure

load [kN]

Failure mode

Ce 5 - 1 5 0,90

1,06

Slippage of the

GFRP grid

Ce 5 - 2 5 0,93

Ce 5 - 3 5 1,08

Ce 5 - 4 5 1,34

Ce 5 - 5 5 1,03

Ce 10 - 1 10 2,37

2,63

Slippage and then

tensile failure of

the GFRP grid

Ce 10 - 2 10 2,63

Ce 10 - 3 10 2,75

Ce 10 - 4 10 2,57

Ce 10 - 5 10 2,81

Ce 15 - 1 15 3,79

4,06

Tensile failure of

the GFRP grid

Ce 15 - 2 15 4,47

Ce 15 - 3 15 3,78

Ce 15 - 4 15 3,17

Ce 15 - 5 15 4,50

Ce 15 - 6 15 3,95

Ce 15 - 7 15 4,78

a) b)

Figure 3. Tests results of the system with GRFP grid and cementitious mortar: a) load-displacement

graph and b) bond length effect

Page 6 of 8

a) b)

Figure 4. Debonding failure mode of the system with GRFP grid and cementitious mortar: a) bond length

5cm and b) bond length 15cm

2.2.2 GFRP grid and lime based mortar

Tests results are reported in Table 5. Tests were mainly performed (see Table 3) with

historical clay brick (6 specimens) and, for comparison purposes, additional tests (2

specimens) were performed by modern clay brick.

Table 5. Tests results of the system with GFRP grid and lime based mortar

Test N

Bond length

[cm]

Failure load

[kN]

Mean failure

load [kN]

Failure mode

Ca 10 - 1 H 10 1,91

1.50

Debonding of the

reinforcement

from the substrate

Ca 10 - 2 H 10 0,36

Ca 10 - 3 H 10 2,25

Ca 10 4M 10 1,04 1.04

Ca 15 1H

15 1,38

1.73

Failure of the

mortar layer

Ca 15 2H

15 2,66

Ca 15 3H 15 1,16

Ca 15 5M 15 0,5 0.5

Note: H indicated historical brick and M modern brick

a) b)

Figure 5. Tests results for GRFP grid and lime based mortar: a) load-displacement graph and b) failure

mode (bond length 10cm)

Page 7 of 8

The load-displacement graph is reported in Figure 5a. The relevant graph clearly illustrate the

effect of the brick type on the failure load. Historical bricks with irregular surface showed in

fact a greater failure load compared to modern bricks with a smooth surface (see Table 5).

The failure mode (see Figure 5b) was debonding of the reinforcement from the substrate

together with, for greater bond length, tensile failure of the mortar layer. Also in this case the

optimum value of the bond length seems to be 15cm but the relevant failure load is equal to

1,73kN which corresponds to 45% of the failure load of the reinforcing system with

cementitious mortar.

2.2.3 CFRP wrap and epoxy resin

For comparison purposed, tests were performed with reference to a reinforcing system

realized by CFRP wrap and epoxy resin in according to CNR DT200/2004 [8]. Tests included

specimens with different bond length and reinforcement width in order to evaluate the

influence of these parameters on the debonding strength. Failure mode in all cases was

reinforcement delamination from the substrate with a thin brick layer attached to the

reinforcement. Test results are reported in Table 6 while the load-displacement graphs are

illustrated in Figure 6. In particular Figure 6a illustrates the effect of reinforcement width for

a bond length equal to 10cm while Figure 6b illustrates the effect of bond length for a

reinforcement width of 6cm. The optimum bond length and reinforcement width seems to be

equal to 10cm and 6cm, respectively (see Table 6). The relevant failure load is equal to

28.11kN which much greater than the failure load of the reinforcing system with cementitious

or lime based mortar.

Table 6. Tests results on system with CFRP wrap and epoxy resin

Reinf. width [cm]

Bond length [cm]

3 4 5 6 8

5 10,11kN - - 21,26kN -

10 15,32kN 12,95kN 21,04kN 28,11kN 22,49kN

15 - 9,37kN - 26,23kN -

a) b)

Figure 6. Tests results for CFRP wrap and epoxy resin: a) load-displacement graph for different

reinforcement width and b) load-displacement curve for different bond length.

Page 8 of 8

3. Discussion and conclusions

Results of the experimental tests showed that different reinforcement configurations clearly

exhibit different failure modes and different debonding forces.

Reinforcing system based on cementitious mortar showed failure modes associated to GFRP

grid slippage and/or tensile failure.

Since the lime based mortar has low mechanical characteristics the failure mode of the

relevant reinforcing system was associated to debonding of the reinforcement from the

substrate and failure of the mortar.

Failure mode of specimens with epoxy resin and CFRP wrap was in all cases reinforcement

delamination with a thin brick layer attached to the reinforcement.

Testing of strengthening system with epoxy resin and CFRP wrap has shown better

performances compared to reinforcing systems with cementitious or lime based mortar.

Anyway these reinforcing system doses not fulfill the requirements of compatibility and

reversibility with historical masonry structures.

4. Acknowledgements

The financial support to the first author from Regione Lombardia and Sika Italia s.p.a. and to

the third author from the Reluis project is gratefully acknowledged.

5. References

[1] CAPOZUCCA, R., Experimental FRP/SRP-historic masonry delamination,

Composite Structures, Vol. 92, 2010, pp. 891-903.

[2] BRICCOLI BATI, S., ROVERO, L., TONIETTI, U. Strengthening masonry arches

with composites materials, Journal of Composites for Construction, Vol. 11(1), 2007,

pp. 33-41.

[3] FAELLA, C., MARTINELLI, E., NIGRO E., PACIELLO, S., Shear capacity of

masonry walls externally strengthened by a cement-based composite material: an

experimental campaign, Construction and Building Materials, Vol. 24, 2010, pp. 84-93.

[4] TOMAZEVIC, M., WEISS, P., Displacement capacity of masonry buildings as a basis

for the assessment of behavior factor: an experimental study, Bulletin of Earthquake

Engineering, Vol. 8, 2010, pp. 1267-1294.

[5] EL GAWADY, M. A., LESTRUZZI, P., BADOUX, M., Aseismic retrofitting of

unreinforced masonry walls using FRP, Composites: part B, Vol. 37, 2006, pp. 148-

162.

[6] PAPANICOLAU C., G., TRIANTAFILLOU, T., C, PAPATHANASIOU, M,

KYRIAKOS, K., Textile reinforced mortars (TRM) versus FRP as strengthening

materials of URM walls: out-of. plane cyclic loading, Vol. 41, 2008, pp. 143-157.

[7] VALLUZZI, M.R., GARBIN, E., PANIZZA, M., BINDA, L., TEDESCHI, C.,

Moisture and Temperature Influence on FRP Masonry Bonding, XII DBMC, April

2011

[8] CNR DT 200/2004, Guide for the design and construction of externally bonded FRP

systems for strengthening existing structures materials, RC and PC structures,

masonry structures, Italian National Research Council, 2004. Available from

http://www.cnr.it/Englishversion/CNR/Activities/RegulationCertification.html

Potrebbero piacerti anche

- CMHC Canadian Wood Frame House Construction PDFDocumento335 pagineCMHC Canadian Wood Frame House Construction PDFindianteenv100% (5)

- Bill of Materials SuarezDocumento7 pagineBill of Materials SuarezRonald MilanaNessuna valutazione finora

- The Hollow Core Floor Design and ApplicationsDocumento236 pagineThe Hollow Core Floor Design and ApplicationsShrushanth KsNessuna valutazione finora

- Checklist For Boomi Pooja: Project: Doc. No.: QA/CL-EXC/01 Client: Project LocationDocumento28 pagineChecklist For Boomi Pooja: Project: Doc. No.: QA/CL-EXC/01 Client: Project LocationThang Tran VietNessuna valutazione finora

- Business PlanDocumento60 pagineBusiness PlanRhuss SalazarNessuna valutazione finora

- Structural Behaviour of Composite Sandwich PanelsDocumento16 pagineStructural Behaviour of Composite Sandwich PanelsvasfidNessuna valutazione finora

- Brick Masonry DesignDocumento34 pagineBrick Masonry DesignWan Rids0% (1)

- Strengthening of Reinforced Concrete Columns Using FRP-Akash Krupeshkumar ChauhanDocumento6 pagineStrengthening of Reinforced Concrete Columns Using FRP-Akash Krupeshkumar ChauhanAkash ChauhanNessuna valutazione finora

- IS 13920 2016 Amendments PDFDocumento14 pagineIS 13920 2016 Amendments PDFYOGESH CHAUHANNessuna valutazione finora

- Drain Design Limit StateDocumento8 pagineDrain Design Limit Stateafifa kausarNessuna valutazione finora

- Joint Design 2 (2001) - Nails, Staples & ScrewsDocumento16 pagineJoint Design 2 (2001) - Nails, Staples & Screwssteveh49100% (1)

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- 371r 98Documento36 pagine371r 98Mirkiñho Gutiérrez Quiroz100% (1)

- Elastic, Plastic and Yield Design of Reinforced StructuresDa EverandElastic, Plastic and Yield Design of Reinforced StructuresNessuna valutazione finora

- The Rehabilitation of The Deficient RC Exterior Beam-Column Joints Using Cement Based CompositesDocumento8 pagineThe Rehabilitation of The Deficient RC Exterior Beam-Column Joints Using Cement Based CompositesVinod RevankarNessuna valutazione finora

- Mechanical Behaviour of Brick Masonry ArDocumento10 pagineMechanical Behaviour of Brick Masonry ArHussain AbbasNessuna valutazione finora

- IET BICET 2014 El-Gamal Et Al-FinalDocumento6 pagineIET BICET 2014 El-Gamal Et Al-FinalmfhfhfNessuna valutazione finora

- Study On Flexural Behaviour of Ferrocement Slabs Reinforced With PVC-coated Weld MeshDocumento8 pagineStudy On Flexural Behaviour of Ferrocement Slabs Reinforced With PVC-coated Weld MeshIJERDNessuna valutazione finora

- Comparative study of strengthening circular concrete columns with softFRPDocumento7 pagineComparative study of strengthening circular concrete columns with softFRPmasud0768Nessuna valutazione finora

- Study On FlexuralDocumento8 pagineStudy On FlexuralRafael CuaNessuna valutazione finora

- 3 PDFDocumento14 pagine3 PDFsakeriraq81Nessuna valutazione finora

- Ijri Cce 02 004Documento7 pagineIjri Cce 02 004ijripublishersNessuna valutazione finora

- Studying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsDocumento11 pagineStudying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsAarohiShirkeNessuna valutazione finora

- Ubead Marzouk LyeDocumento6 pagineUbead Marzouk LyeAmmar A. AliNessuna valutazione finora

- Ferrocement Column BehaviourDocumento4 pagineFerrocement Column BehaviourPushpakaran PillaiNessuna valutazione finora

- Carbon Fibre Reinforced RodsDocumento7 pagineCarbon Fibre Reinforced RodsKiran KoshyNessuna valutazione finora

- Structural Glass Fiber Reinforced Concrete for Slabs on GroundDocumento7 pagineStructural Glass Fiber Reinforced Concrete for Slabs on GroundJayanth RaviNessuna valutazione finora

- Department of Civil Engineering, KJCOEMRDocumento26 pagineDepartment of Civil Engineering, KJCOEMRSwapnil ShindeNessuna valutazione finora

- Effectiveness of A Masonry Strengthening Technique Made With A GFRP-mesh-reinforced Mortar CoatingDocumento10 pagineEffectiveness of A Masonry Strengthening Technique Made With A GFRP-mesh-reinforced Mortar Coatingc_passerino6572Nessuna valutazione finora

- 4APM Islam Et Al 2011 CFRPDocumento5 pagine4APM Islam Et Al 2011 CFRPMashfiqul IslamNessuna valutazione finora

- Fiber Reinforced Plymer Load Transfer Devices in Jointed Concrete PavementsDocumento15 pagineFiber Reinforced Plymer Load Transfer Devices in Jointed Concrete PavementsKannan S100% (1)

- Performance of Ferrocement Panels in Different EnvironmentsDocumento8 paginePerformance of Ferrocement Panels in Different EnvironmentsSulaiman Mohsin AbdulAzizNessuna valutazione finora

- Engineering Journal Behaviour of R.C Beam and Glass Fiber Reinforced Polymer Composite Beam For Shear StrengthDocumento9 pagineEngineering Journal Behaviour of R.C Beam and Glass Fiber Reinforced Polymer Composite Beam For Shear StrengthEngineering JournalNessuna valutazione finora

- The Effect of Shrinkage Cracks On The Load Bearing Capacity of Steel-Fibre-Reinforced Roller-Compacted - Concrete PavementsDocumento27 pagineThe Effect of Shrinkage Cracks On The Load Bearing Capacity of Steel-Fibre-Reinforced Roller-Compacted - Concrete PavementsLouis KiwaNessuna valutazione finora

- 3EXPERIMENTALVERIFICATIONOFTHENEWMODELS1Documento13 pagine3EXPERIMENTALVERIFICATIONOFTHENEWMODELS1djarir yahiaouiNessuna valutazione finora

- Optimum Mix Design of Steel-Fibre-Reinforced Concrete PlatesDocumento2 pagineOptimum Mix Design of Steel-Fibre-Reinforced Concrete PlatesSANGEETHA SNessuna valutazione finora

- Mech. Test of Concrete With Aggregates HauledDocumento13 pagineMech. Test of Concrete With Aggregates HauledMichael Parohinog GregasNessuna valutazione finora

- Experimental Study of Flexure and Impact On Ferrocement SlabsDocumento5 pagineExperimental Study of Flexure and Impact On Ferrocement Slabsadwaid paloliNessuna valutazione finora

- Enhancing Flexural Performance of GFRC Square Foundation Footings Through Uniaxial Geogrid ReinforcementDocumento8 pagineEnhancing Flexural Performance of GFRC Square Foundation Footings Through Uniaxial Geogrid ReinforcementPoonam KilaniyaNessuna valutazione finora

- 7th Int'l Conf on Civil Eng Strengthen thin concrete with hempDocumento7 pagine7th Int'l Conf on Civil Eng Strengthen thin concrete with hempKenan KajosevicNessuna valutazione finora

- Repair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperDocumento9 pagineRepair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperD Raul CfNessuna valutazione finora

- Script MCE181005Documento3 pagineScript MCE181005Tariq MahmoodNessuna valutazione finora

- Ferro CementDocumento13 pagineFerro CementPagal PaglaNessuna valutazione finora

- CRCPDocumento4 pagineCRCPKhaled AldossariNessuna valutazione finora

- Poles DeignDocumento24 paginePoles DeignIbrahim TalaatNessuna valutazione finora

- Discussion on Bonding Performance between FRP Bars and ConcreteDocumento5 pagineDiscussion on Bonding Performance between FRP Bars and ConcreteEng-Alma AhmadNessuna valutazione finora

- Experimental Evaluation of FRP-to-concrete Bond Strength in EBROG Technique For Strengthening Concrete MembersDocumento8 pagineExperimental Evaluation of FRP-to-concrete Bond Strength in EBROG Technique For Strengthening Concrete MembersHuda AlrikabiNessuna valutazione finora

- Engineering Structures: SciencedirectDocumento11 pagineEngineering Structures: SciencedirectHussein ElsanadedyNessuna valutazione finora

- Strengthening and Repair of RC Beams With Fiber Reinforced Concrete-Giovanni Martinola-2010Documento9 pagineStrengthening and Repair of RC Beams With Fiber Reinforced Concrete-Giovanni Martinola-2010sardarumersialNessuna valutazione finora

- Aire CCC 113 PDFDocumento6 pagineAire CCC 113 PDFLaur HaxhiuNessuna valutazione finora

- A Study On Properties of Concrete With The Use of Jute FiberDocumento22 pagineA Study On Properties of Concrete With The Use of Jute Fibergaur_shashikant4432Nessuna valutazione finora

- Strength and Durability Properties of Geopolymer ConcreteDocumento8 pagineStrength and Durability Properties of Geopolymer ConcretetiprajNessuna valutazione finora

- Finite Element Modeling of Reinforced Concrete Beams Strengthened With FRP Laminates: A ReviewDocumento8 pagineFinite Element Modeling of Reinforced Concrete Beams Strengthened With FRP Laminates: A ReviewAfia.S.HameedNessuna valutazione finora

- GFRP Beams Behavior StudyDocumento8 pagineGFRP Beams Behavior StudySabin RautNessuna valutazione finora

- Experimental Study On Strengthening of RC Slab Using GFRP Sheets IJERTCONV6IS06028Documento3 pagineExperimental Study On Strengthening of RC Slab Using GFRP Sheets IJERTCONV6IS06028AminNessuna valutazione finora

- Retrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysDocumento12 pagineRetrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysSudha JNessuna valutazione finora

- Strengthening of Beams Using Glass Fiber Reinforced Polymer (GFRP) LaminateDocumento9 pagineStrengthening of Beams Using Glass Fiber Reinforced Polymer (GFRP) LaminateRatnakarVarunNessuna valutazione finora

- Concrete-Reinforcement Bond Strength FactorsDocumento6 pagineConcrete-Reinforcement Bond Strength FactorsRazanNessuna valutazione finora

- Effect of Combined Environmental Cycles On The Bond of FRP Sheets To Concrete (2001) - Paper PDFDocumento6 pagineEffect of Combined Environmental Cycles On The Bond of FRP Sheets To Concrete (2001) - Paper PDFJulio Humberto Díaz RondánNessuna valutazione finora

- Ferrocement Water Tank Experimental InvestigationDocumento6 pagineFerrocement Water Tank Experimental InvestigationMuthu KuttyNessuna valutazione finora

- Experimental Study of Maintenance and Treatment of R.C.C. Building by Fiber Reinforced PlasticDocumento4 pagineExperimental Study of Maintenance and Treatment of R.C.C. Building by Fiber Reinforced PlasticEditor IJTSRDNessuna valutazione finora

- Development and Experimental Study of Bond Between FRP Rebar and ConcreteDocumento6 pagineDevelopment and Experimental Study of Bond Between FRP Rebar and ConcreteApplied Science and Engineering Journal for Advanced ResearchNessuna valutazione finora

- IJETR041352Documento8 pagineIJETR041352erpublicationNessuna valutazione finora

- Mechanical and Bond Properties of New Generation CFRP Reinforcing BarsDocumento23 pagineMechanical and Bond Properties of New Generation CFRP Reinforcing BarsAhmed AjelNessuna valutazione finora

- Regain in Strength of Reinforced Concrete Columns-Akash ChauhanDocumento6 pagineRegain in Strength of Reinforced Concrete Columns-Akash ChauhanAkash ChauhanNessuna valutazione finora

- Effect of Lathe Waste Review 1Documento22 pagineEffect of Lathe Waste Review 1dreamboy87Nessuna valutazione finora

- Ext_Abst_SHDocumento16 pagineExt_Abst_SHTiago GassmanNessuna valutazione finora

- Acma Layout Format ICBE0915Documento10 pagineAcma Layout Format ICBE0915Holly WestNessuna valutazione finora

- A Study On The Shrinkage Control of Fiber Reinforced Concrete PavementDocumento8 pagineA Study On The Shrinkage Control of Fiber Reinforced Concrete PavementShahid Lima KhanNessuna valutazione finora

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessDa EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNessuna valutazione finora

- Tevi RotundeDocumento8 pagineTevi RotundebigggredNessuna valutazione finora

- Tevi RotundeDocumento8 pagineTevi RotundebigggredNessuna valutazione finora

- Wood-Frame Construction in Past EarthquakesDocumento7 pagineWood-Frame Construction in Past EarthquakesbigggredNessuna valutazione finora

- Performance of Wood-Frame Construction in EarthquakesDocumento8 paginePerformance of Wood-Frame Construction in EarthquakesbigggredNessuna valutazione finora

- Studiu Consolidare Fibre de CarbonDocumento144 pagineStudiu Consolidare Fibre de CarbonbigggredNessuna valutazione finora

- Manual AlarmaPCS200 EI08Documento38 pagineManual AlarmaPCS200 EI08bigggredNessuna valutazione finora

- Manual Proiectare Ancoraje ArmaturiDocumento27 pagineManual Proiectare Ancoraje ArmaturibigggredNessuna valutazione finora

- Roof Truss Facts MitekDocumento10 pagineRoof Truss Facts MitekbigggredNessuna valutazione finora

- Abaqus Bond Pull Out SimulationDocumento23 pagineAbaqus Bond Pull Out Simulation429e10d421Nessuna valutazione finora

- PipingDocumento57 paginePipingIshwar AltNessuna valutazione finora

- OrionDocumento60 pagineOrionbasum matNessuna valutazione finora

- Pulley DIDocumento4 paginePulley DIDen Yogi HardiyantoNessuna valutazione finora

- Mechanical Properties of Materials NotesDocumento28 pagineMechanical Properties of Materials NotesMat MatttNessuna valutazione finora

- Airo WaterDocumento27 pagineAiro WaterAhana SahaNessuna valutazione finora

- Design of Retaining Walls: Retaining Wall - Retains Earth - When Level DifferenceDocumento17 pagineDesign of Retaining Walls: Retaining Wall - Retains Earth - When Level DifferencebiniamNessuna valutazione finora

- Short Resume of Khairul AlamDocumento1 paginaShort Resume of Khairul AlamKhandaker Khairul Alam100% (1)

- Concrete Using Saw DustDocumento5 pagineConcrete Using Saw DustUmange RanasingheNessuna valutazione finora

- Temporary Facility (Bunk House)Documento4 pagineTemporary Facility (Bunk House)Noel MarceloNessuna valutazione finora

- Ar. Architectual Patterns PDFDocumento18 pagineAr. Architectual Patterns PDFedrisNessuna valutazione finora

- Cementitious Fairing Coat for Concrete Surface RepairDocumento2 pagineCementitious Fairing Coat for Concrete Surface Repairm.aliNessuna valutazione finora

- Adequa UralitaDocumento11 pagineAdequa UralitaDurban Chamber of Commerce and IndustryNessuna valutazione finora

- Cast Walls and Slab at The Same Time With Tunnel Forms - tcm45-341116Documento3 pagineCast Walls and Slab at The Same Time With Tunnel Forms - tcm45-341116akbar102Nessuna valutazione finora

- AssessmentDocumento4 pagineAssessmentMARIFA ROSERONessuna valutazione finora

- Fosfiber PPF High Performance Micro Polypropylene FibreDocumento2 pagineFosfiber PPF High Performance Micro Polypropylene FibreTori Small100% (1)

- Guentner Cooler Storage Rooms Info enDocumento4 pagineGuentner Cooler Storage Rooms Info enAnonymous 5moojwNessuna valutazione finora

- Energimac PHOENIXDocumento4 pagineEnergimac PHOENIXdlight0Nessuna valutazione finora

- Sound InsulationDocumento33 pagineSound InsulationMukulNessuna valutazione finora

- Ks Series Vertical Cad Details KSMR KSMMR Ksaz KSMW KSSL NaDocumento72 pagineKs Series Vertical Cad Details KSMR KSMMR Ksaz KSMW KSSL NaTaurai ChiwanzaNessuna valutazione finora

- Item 1003Documento6 pagineItem 1003Ester MarianNessuna valutazione finora

- Structural Drawings For KisimayoDocumento7 pagineStructural Drawings For KisimayoSamson Mide FolorunshoNessuna valutazione finora